Page 1

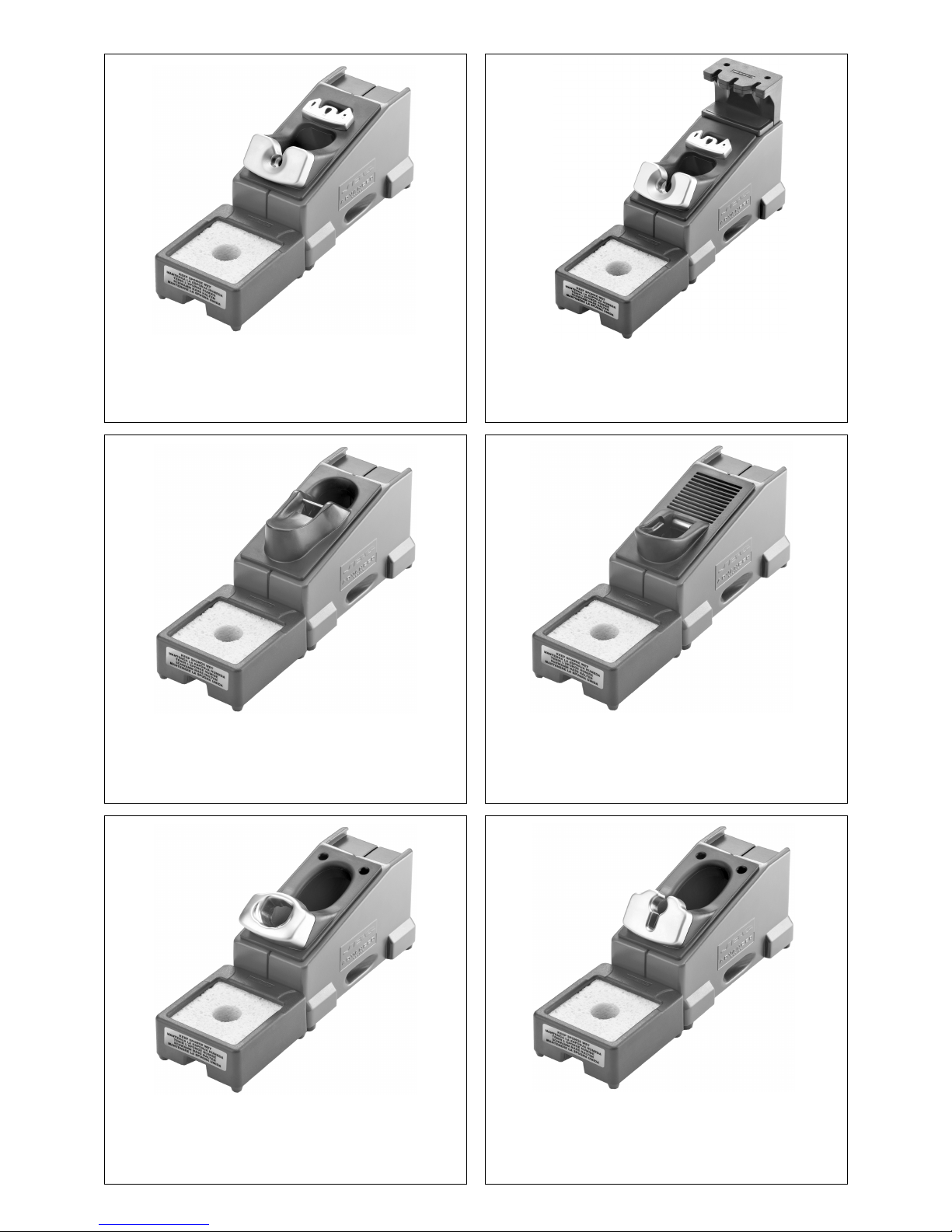

STANDS

Reference Guide

Index Page

English 1

Español 7

Page 2

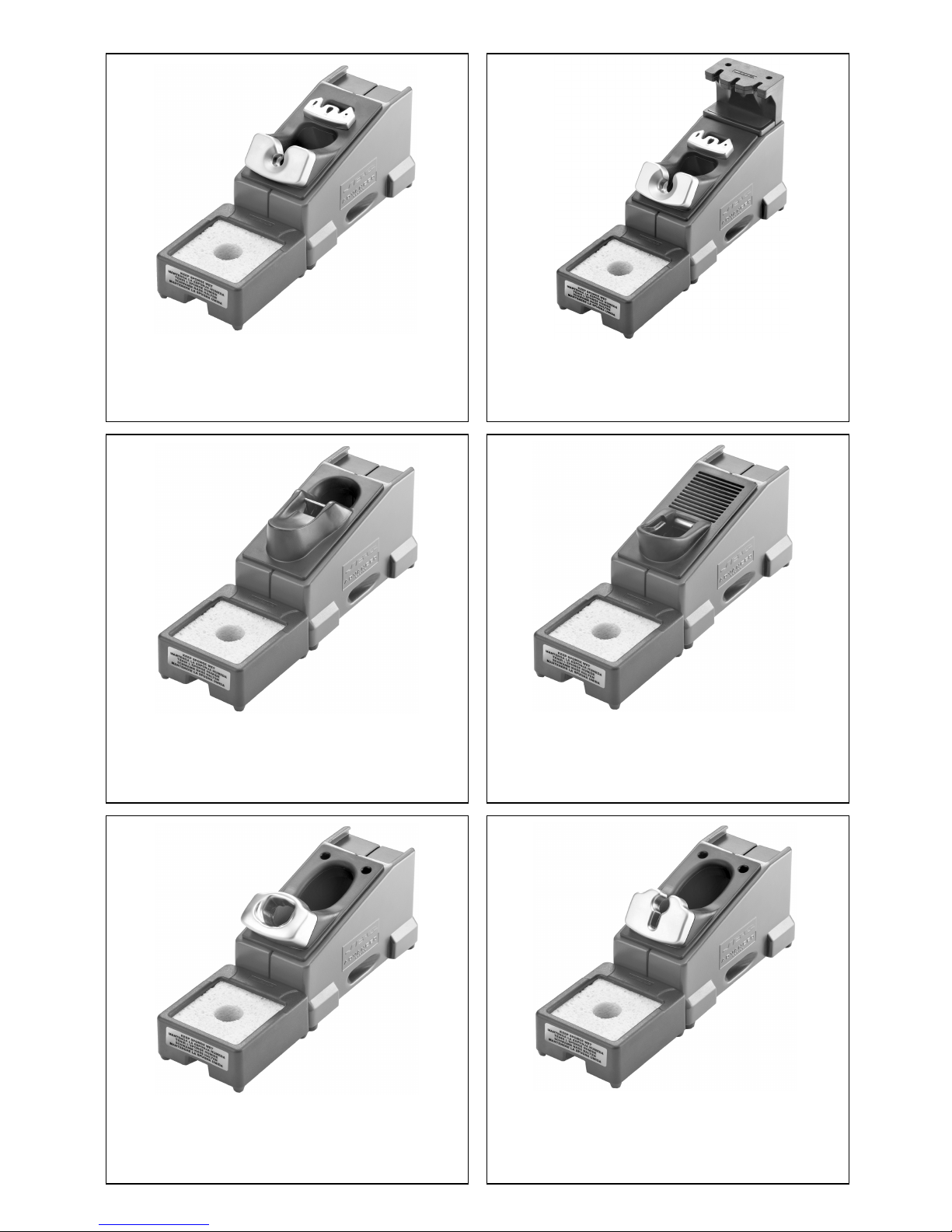

Adaptable to:

2210 soldering handpiece.

This stand can be connected to the following

JBC stations: DI 3000, DI 2860, DD 5700,

DM 6700 and AM 6850.

AD 8211

0788211

Adaptable to: PA 4200 hot tweezers.

This stand can be connected to the following

JBC stations: DI 3000, DI 2860, DD 5700,

DM 6700 and AM 6850.

PA 8121

0788121

STANDS

Adaptable to:

2245 soldering handpiece.

This stand can be connected to the following

JBC stations: DI 3000, DI 2860, DD 5700,

DM 6700 and AM 6850.

AD 8241

0788241

Adaptable to: PA 1200 micro hot tweezers.

This stand can be connected to the following

JBC stations: DI 3000, DI 2860, DD 5700,

DM 6700 and AM 6850.

PA 8111

0788111

Adaptable to:

AP 1300 solder feed iron.

This stand can be connected to the following

JBC stations: DI 3000, DI 2860, DD 5700,

DM 6700 and AM 6850.

AP 8131

0788131

Adaptable to: 2510 soldering iron.

This stand is valid to the following JBC

station: AL 2500.

AL 8251

0788251

1

ENGLISH

Page 3

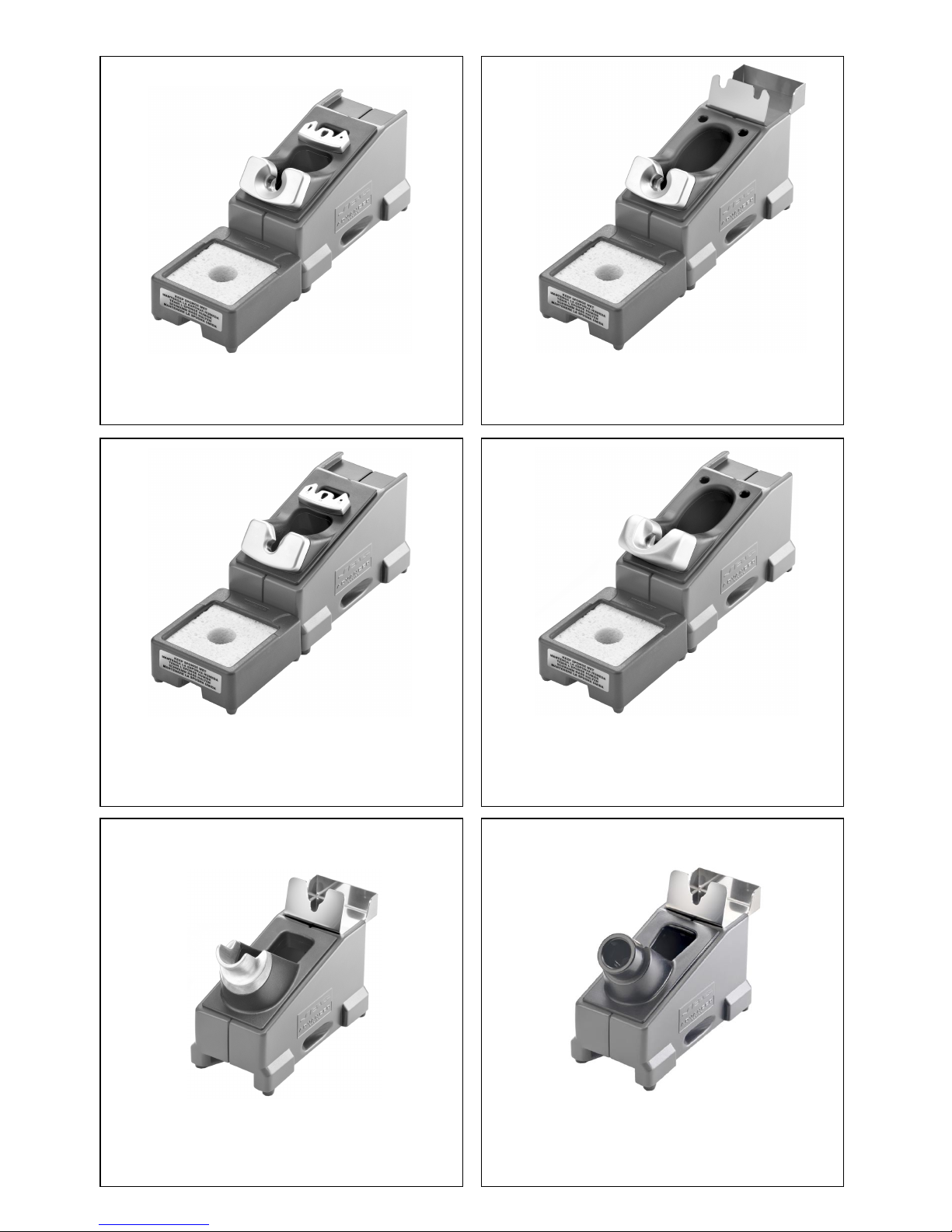

Adaptable to: 2245 soldering handpiece.

This stand is valid to the following JBC

station: HD 4700.

HD 8471

0788471

Adaptable to:

DR 5650 desoldering iron.

This stand can be connected to the following

JBC stations: DI 2860, DD 5700, DM 6700

and AM 6850.

DR 8501

0788501

RANGE

Adaptable to:

DR 3600 micro desoldering

iron. This stand can be connected to the

following JBC stations: DI 2860, DD 5700,

DM 6700 and AM 6850.

DR 8361

0788361

TE 8601

0788601

Adaptable to:

TE 5400 heater.

This stand is valid to the following JBC

station: TE 5400.

JT 8801

0788801

Adaptable to:

JT 7800 heater.

This stand is valid to the following JBC

station: JT 7750 and AM 6850.

Adaptable to:

2245 nitrogen handpiece.

This stand is valid to the following JBC

station: MN 9016.

MN 8861

0788861

2

ENGLISH

Page 4

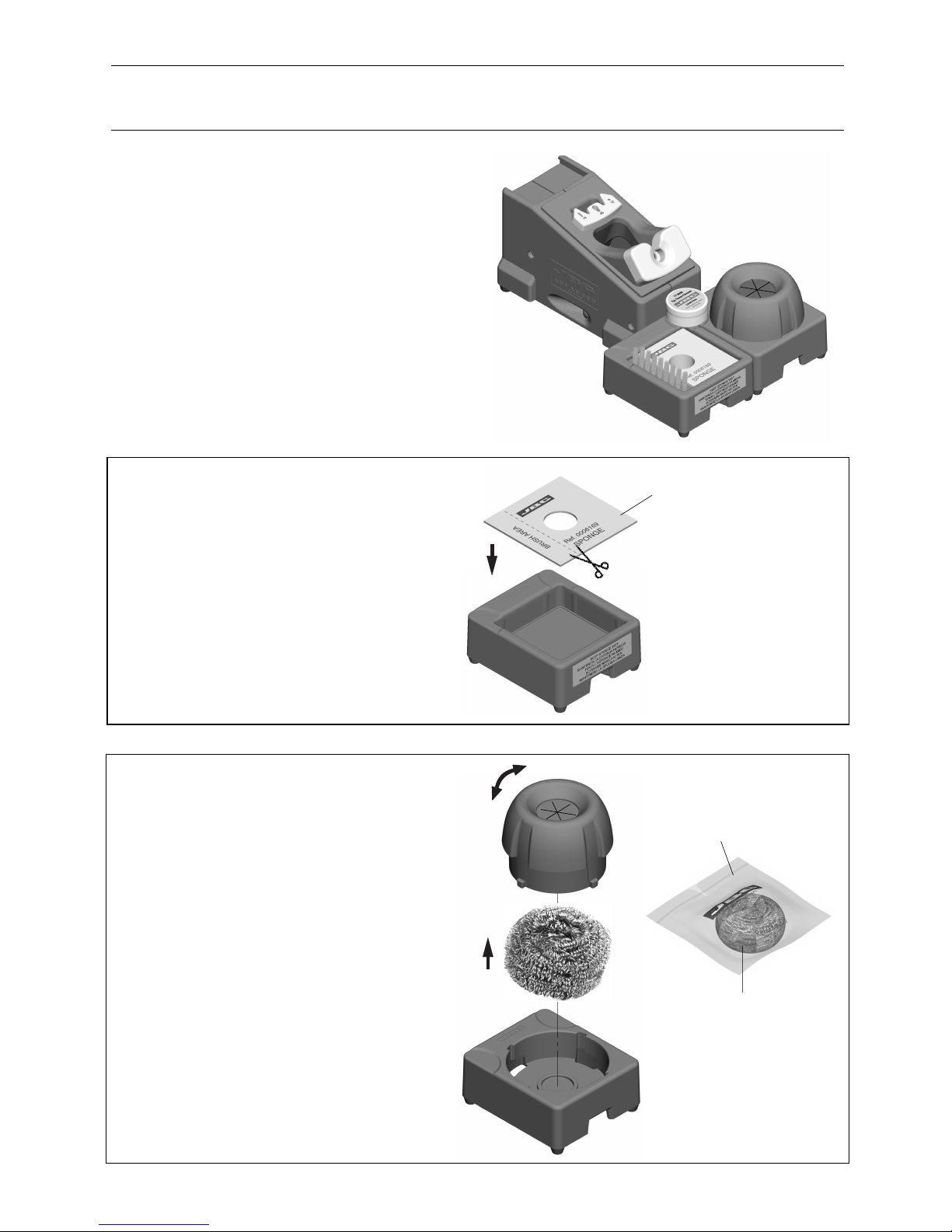

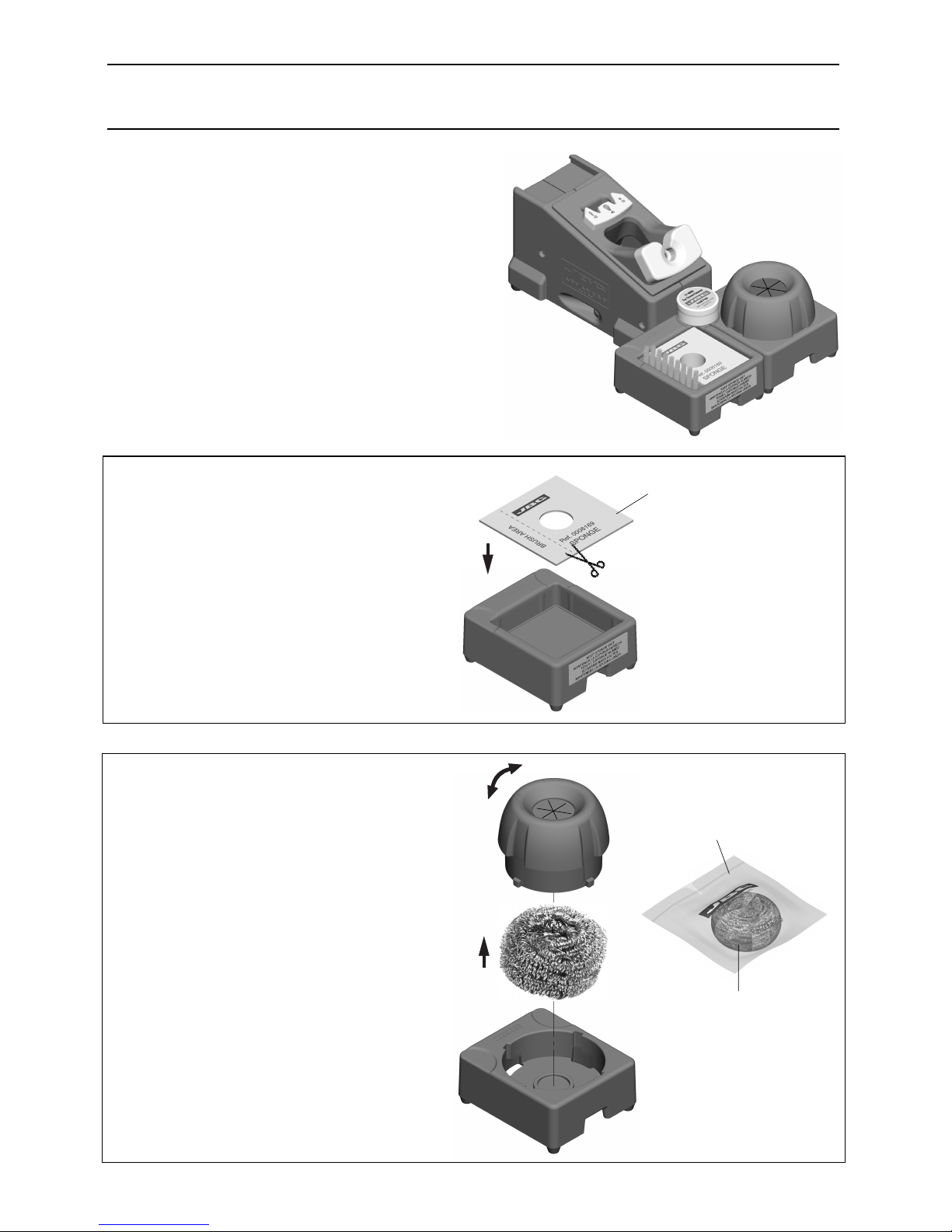

JBC Tip cleaning Range

With the increasingly demanding

conditions in which soldering tips are

being used, it is essential to apply the right

cleaning method. Leadfree solder alloys

have changed the (hand)soldering

process in recent years. In order to deal

with the incresed oxidation, product of the

often increased soldering temperature, the

higher flux content and the higher

activated flux chemistries, JBC introduces

its new range of tip cleaning tools:

1 - SPONGE STAND ACCESSORY

Ref. 0007080

The standard from the leaded era.

Mechanically smooth but criticised for the

thermal shock that the tip suffers every

time it is being cleaned. When cleaned

and replaced frequently and always in

combination with demineralised water that

is to keep the sponge moist not soaked,

it is a valid cleaning method in both leaded

and leadfree processes.

2 - BRASS WOOL CLEANING ACCESSORY

Ref. 0006760

This cleaning method has the advantage

that there is no water involved so the tip

does not suffer a thermal shock. It is

very effective in eliminating oxide layers

that build up on the tip, especially at

high temperatures. It wil not remove all

the solder from the tip so it prevents

the tip from oxidizing between cleaning

and re-wetting. It needs to be used

gently and a particle blocker (not to be

used above 400 ºC, 750 ºF) should be

in place in order to prevent little brass

pieces, that enevitably break off the

pad, from polluting the process.

Cut to use with metal

brush ref.: 0006217

Release the brass

cleaning wool from

the bag and place it

inside the stand.

Brass cleaning wool

ref.: 0006205

TIP CLEANING RANGE

Sponge

ref.: 0006169

3

ENGLISH

Page 5

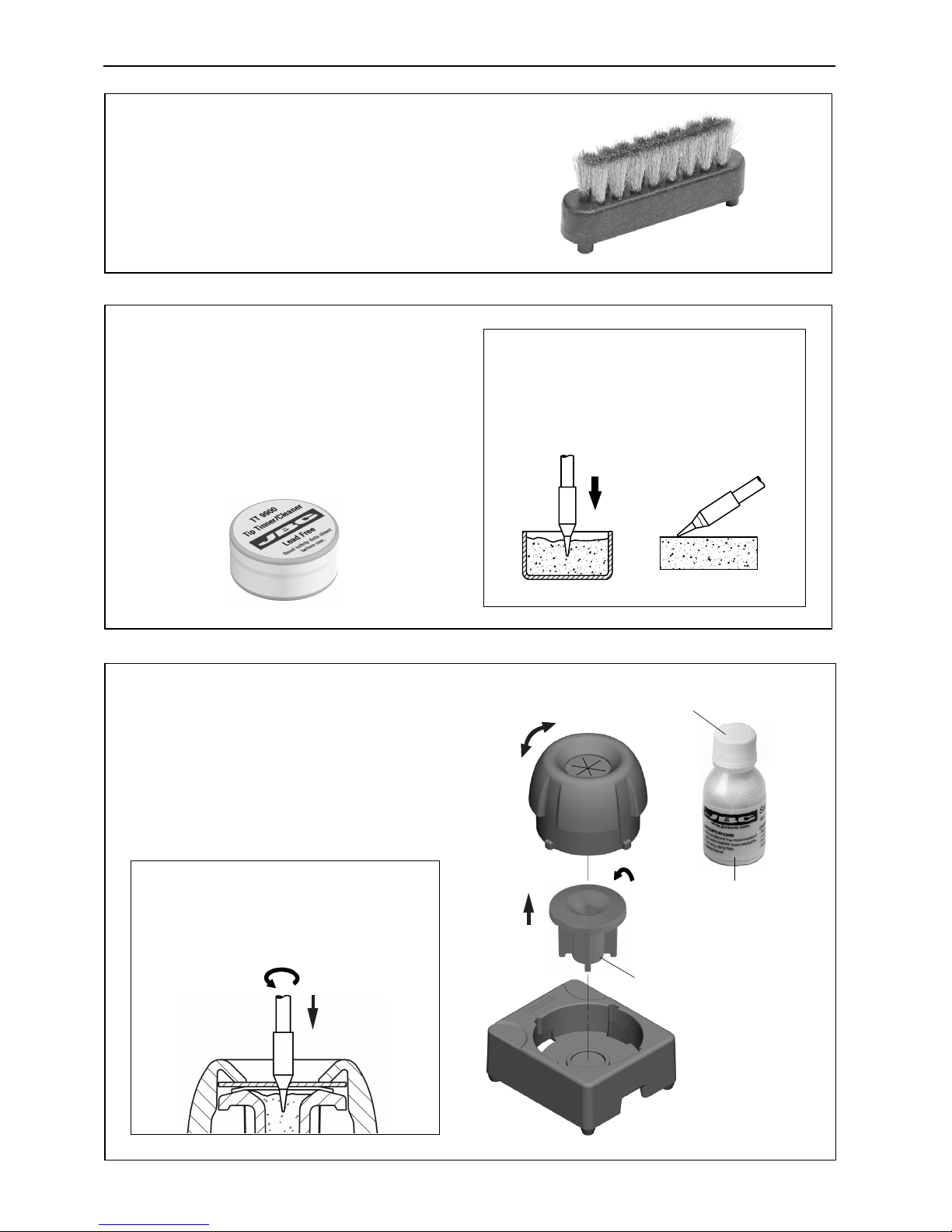

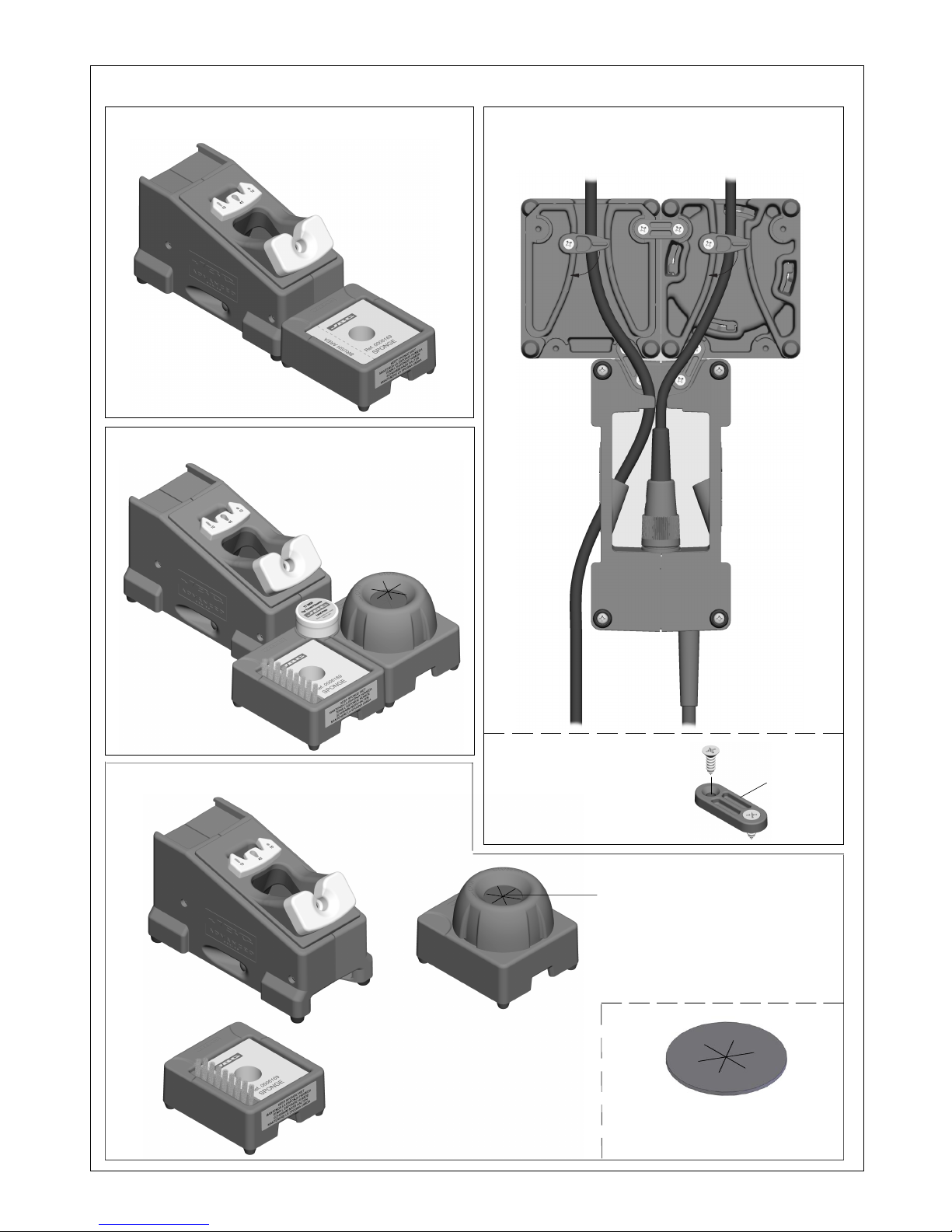

3 - METAL BRUSH

Ref. 0006217

4 - TIP TINNER / CLEANER

Ref. 9900000

2. Pull the tip out and let it dry.

3. Clean the grade with a wet sponge.

1. Introduce the soldering tip in the

paste.

A long proven method of chemically

cleaning and retinning at the same time.

It should be used when the above

methods fail and a very active cleaning

method is needed.

The metal brush differs from the cleaning

wool in that it is a little bit more agressive

on the tip. It therefore cleans the tip very

well but it should be used gently.

5 - SAND CLEANING ACCESSORY

Ref. 0006780

JBC's sand cleaning method reconditions

even the most oxidised tips and makes

them wettable again. This method is

advisable when all else fails.

Sand bottle (30 c.c.)

ref.: 0006211

Deposit

2. Pull the tip out.

1. Enter the soldering tip inside

the sand and turn it around.

Fill in the deposit

with sand and place

it inside the stand.

(see position).

4

ENGLISH

Page 6

The cleaning accessories can be combined at the user's convenience:

33

33

3 - Cleaning accessories used separately.

Membrane

Clip

Ref.0006584

Pass the cables of the tool under the stands.

Joining cleaning accessories to the

stand.

22

22

2 - Different accessories combined.

11

11

1 - With sponge only.

5

ENGLISH

To join the stand you only

need to screw the parts

under the fixing clip.

Membrane not to be used

above 400 ºC (750 ºF).

Page 7

It is possible to extend the stand cable by means

of an accessory called “stand cable extension”,

Ref. 0781286. By doing so, the user can have

the control unit further away from the tools and

off his/her work table.

For the aspiration tube of the desoldering iron, a

silicone tube extension kit, Ref. 0781287, has

also been manufactured.

For both kits, the length of the cable is 1.5 m.

Stand cable extension

Ref. 0781286

Lenght: 1.5 m

Silicone tube

extension kit

Ref. 0781287

Lenght: 1.5 m

6

ENGLISH

Page 8

Para el

Lápiz 2210.

Este soporte puede conectarse a las

siguientes estaciones JBC: DI 3000,

DI 2860, DD 5700, DM 6700 y AM 6850.

AD 8211

0788211

Para la pinza PA 4200.

Este soporte puede conectarse a las

siguientes estaciones JBC: DI 3000,

DI 2860, DD 5700, DM 6700 y AM 6850.

PA 8121

0788121

SOPORTES

Para el

Lápiz 2245.

Este soporte puede conectarse a las

siguientes estaciones JBC: DI 3000,

DI 2860, DD 5700, DM 6700 y AM 6850.

AD 8241

0788241

Para la pinza PA 1200.

Este soporte puede conectarse a las

siguientes estaciones JBC: DI 3000,

DI 2860, DD 5700, DM 6700 y AM 6850.

PA 8111

0788111

Para el soldador con aportación estaño

AP 1300. Este soporte puede conectarse a

las siguientes estaciones JBC: DI 3000,

DI 2860, DD 5700, DM 6700 and AM 6850.

AP 8131

0788131

Adaptable to: 2510 soldering iron.

Este soporte puede conectarse a las

siguientes estaciones JBC: AL 2500.

AL 8251

0788251

7

ESPAÑOL

Page 9

ESPAÑOL

Para el Lápiz 2245.

Este soporte puede conectarse a las

siguientes estaciones JBC: HD 4700.

HD 8471

0788471

Para el desoldador

DR 5650.

Este soporte puede conectarse a las

siguientes estaciones JBC: DI 2860,

DD 5700, DM 6700 and AM 6850.

DR 8501

0788501

RANGO

Para el microdesoldador

DR 3600.

Este soporte puede conectarse a las

siguientes estaciones JBC: DI 2860,

DD 5700, DM 6700 and AM 6850.

DR 8361

0788361

TE 8601

0788601

Para el calefactor

TE 5400 heater.

Este soporte puede conectarse a las

siguientes estaciones JBC: TE 5400.

JT 8801

0788801

Para el calefactor

JT 7800.

Este soporte puede conectarse a las

siguientes estaciones JBC: JT 7750 and

AM 6850.

Para el Lápiz de nitrógeno

2245.

Este soporte puede conectarse a las

siguientes estaciones JBC: MN 9016.

MN 8861

0788861

8

Page 10

Herramientas de limpieza JBC

Con el incremento de las cada vez más

exigentes condiciones en la que los soldadores

están siendo usados, se hace imprescindible

aplicar el método correcto de limpieza. Las

aleaciones de la soldadura sin plomo han

cambiado el proceso de la soldadura (manual)

en los últimos años. Con el fin de reducir el

aumento de oxidación, causado por el frecuente

aumento de la temperatura, el alto contenido

del flux y componentes químicos en el proceso

de la soldadura sin plomo. JBC presenta su

nueva gama de productos de limpieza.

1 - ACCESSORIO SOPORTE ESPONJA

Ref. 0007080

El estándar desde la era del plomo.

Esponja suave pero criticada por el

choque térmico que la punta sufre todas

las veces que se limpia. Limpiar y

reemplazar frecuentemente la esponja y

combinar con agua desmineralizada para

mantenerla húmeda y no empapada.

2 - ACCESORIO SOPORTE ESPONJA

METÁLICA

Ref. 0006760

Este sistema de limpieza tiene la ventaja

de que no hay agua implicada, así que

la punta no sufre choque térmico. Es

efectivo en eliminar las capas de óxido

que se forman en la punta,

especialmente a altas temperaturas. No

elimina todo el estaño de la punta de

modo que se evita su oxidación entre la

limpieza y el restañado. Debe ser

utilizada con cuidado y su sistema

bloqueador (no utilizarse por encima de

los 400ºC) evita que pasen piezas de

la misma esponja que polucionaría el

proceso.

Cortar para usar cepillo

metálico ref.: 0006217

Sacar la esponja

metálica de la bolsa

y ubicarla en el

interior del soporte.

Esponja metálica

ref.: 0006205

HERRAMIENTAS DE LIMPIEZA

Esponja

ref.: 0006169

9

ESPAÑOL

Page 11

3 - CEPILLO METÁLICO

Ref. 0006217

4 - TIP CLEANER / TINNER

Ref. 9900000

2. Quite la punta y déjela secar.

3. Limpie el grado con una esponja

húmeda.

1. Introduzca la punta soldadora en la

pasta.

Es un sistema químico de limpieza y

restañado de la punta al mismo tiempo.

Debe ser usado cuando los métodos

anteriores fallan y se requiere un sistema

muy activo de limpieza.

Se diferencia de la esponja metálica en

que es un poco més agresivo. Por lo que

limpia la punta muy bien.

Reacondiciona incluso las puntas más

oxidadas y las hace utilizables otra vez.

Este método esta aconsejado cuando los

demás fallan.

Frasco de arena (30 c.c.)

ref.: 0006211

Depósito

2. Quite la punta.

1. Entre la punta soldadora en

la arena y gírela.

Llenar de arena el

depósito y ubicarlo en

el interior del soporte

(observar posición)

10

ESPAÑOL

5 - ACCESORIO DE ARENA

LIMPIADORA

Ref. 0006780

Page 12

Los accesorios de limpieza pueden combinarse según les convenga a los usuarios:

33

33

3 - Accesorios de limpieza separados.

Membrana

Clip

Ref.0006584

Pasar los cables de las herramientas por

debajo de los soportes.

Soportes de limpieza unidos.

22

22

2 - Diferentes accesorios combinados.

11

11

1 - Solo con la esponja.

11

ESPAÑOL

Para unir los soportes

solo necesita unir las

partes por debajo con

el clip de sujeción.

No usar la membrana por

encima de 400 ºC (750 ºF).

Page 13

ESPAÑOL

Existe como accesorio un kit alargo cable

soportes Ref. 0781286 que permite alargar la

longitud del cable soporte. De esta manera el

usuario puede tener la unidad de control más

alejada de las herramientas y fuera de su mesa

de trabajo.

Para el tubo de aspiración del desoldador

también se ha creado un kit alargo tubo silicona

Ref. 0781287.

En los dos kits la longitud del cable es de 1,5m.

Kit alargo cable soportes

Ref. 0781286

Longitud: 1,5 m

Kit alargo tubo

silicona

Ref. 0781287

Longitud: 1,5 m

12

Page 14

Page 15

WARRANTY ENGLISH

The JBC 2 years warranty, guarantees

this equipment against all manufacturing

defects, covering the replacement of

defective parts and all necessary labour.

Warranty does not cover product wear

due to use or mis-use.

In order for the warranty to be valid,

equipment must be returned, postage

paid, to the dealer where it was

purchased enclosing this, fully filled in,

sheet.

GARANTIA ESPAÑOL

JBC garantiza este aparato durante 2

años, contra todo defecto de fabricación,

cubriendo la reparación con sustitución

de las piezas defectuosas e incluyendo

la mano de obra necesaria.

Quedan excluidas de esta garantía las

averías provocadas por mal uso del

aparato y desgaste por uso.

Es indispensable para acogerse a esta

garantía el envio del aparato al

distribuidor donde se adquirió, a portes

pagados, adjuntando esta hoja

debidamente cumplimentada.

GARANTIE FRANÇAIS

JBC garantit cet appareil 2 ans contre

tout défaut de fabrication. Cela comprend

la réparation, le remplacement des

pièces défectueuses et la main d'oeuvre

nécessaire.

La garantie ne couvre pas l’usure liée à

l’utilisation et à la mauvaise utilisation du

matériel.

Pour bénéficier de cette garantie il est

indispensable d'envoyer l'appareil chez

le distributeur où il a été acquis, en ports

payés, en joignant cette fiche dûment

remplie.

✂

Page 16

0006710-0508

GARANTIE DEUTSCH

Für das vorliegende Gerät übernimmt

JBC eine Garantie von 2 Jahren, für alle

Fabrikationsfehler. Diese Garantie

schliesst die Reparatur bzw. den Ersatz

der defekten Teile sowie die

entsprechenden Arbeitskosten ein.

Ausgeschlossen von dieser

Garantieleistung sind durch

unsachgemässen Gebrauch

hervorgerufene Betriebsstörungen und

normale Gebrauchsabnützungen.

Zur Inanspruchnahme dieser Garantie

muss das Gerät portofrei an den

Vertriebshändler geschickt werden, bei

dem es gekauft wurde. Fügen Sie dieses

vollständig ausgefüllte Blatt bei.

GARANZIA ITALIANO

La JBC garantisce quest'apparato 2

anni contro ogni difetto di fabbricazione,

e copre la riparazione e la sostituzione

dei pezzi difettosi, includendo la mano

d'opera necessaria.

Sono escluse da questa garanzia le

avarie provocate da cattivo uso

dell'apparato e logorio da utilizzo.

Per usufruire di questa garanzia, è

indispensabile inviare, in porto franco,

l'apparato al distributore presso il quale

è stato acquistato, unitamente a questo

foglio debitamente compilato.

DATE OF PURCHASE

FECHA DE COMPRA

DATE D'ACHAT

KAUFDATUM

DATA DI ACQUISTO

STAMP OF DEALER

SELLO DEL DISTRIBUIDOR

CACHET DU DISTRIBUTEUR

STEMPEL DES HÄNDLERS

TIMBRO DEL DISTRIBUTORE

SERIAL Nº

✂

MANUFACTURED BY

JBC Industrias, S.A.

Ramón y Cajal, 3 - 08750 MOLINS DE REI

BARCELONA - SPAIN

Tel.: +34 93 325 32 00 - Fax: +34 93 680 49 70

http://www.jbctools.com e-mail:info@jbctools.com

Loading...

Loading...