Jaypro Sports FBGP-720 User Manual

4

3

2

1

FBGP-720

FOOTBALL GOAL

SPECIFICATIONS

23'-4''

Ø2 3/8'' x 3/8'' wall

B B

ALUMINUM UPRIGHTS

INSIDE

HIGH SCHOOL REF

18'-6''

INSIDE

COLLEGE REF

20'

UPRIGHTS

REV

DC

A

30'

OVERALL

HEIGHT

FAX:

800.444.1779 (SALES)

860.440.0628 (ENG.)

CHKD BY

SHEET

1 1

OF

BTS

Ø4 1/2'' x 23' 4'' High School

GOOSENECK Ø5 9/16 x .258 WALL

GALVANIZED STEEL

78 in OFFSET

A A

54 in

36 in

SIDE VIEW

T:\Aftermarket\Football\Drawings\FGBP-720\SPECIFICATIONS\PAGE ONE.idw

REV: A 7/14/2010

4

Ø4 1/2'' X 18' 6'' College

GALVANIZED STEEL CROSSBAR

PLAYING

SURFACE

FBGP-720 HIGH SCHOOL WHITE

FBGP-720YW HIGH SCHOOL YELLOW

FBGP-720C COLLEGE WHITE

FBGP-720XCYW COLLEGE YELLOW

3

FRONT VIEW

2

10 '

TO CROSSBAR

PHONE:

800.243.0533 (TOLL FREE)

860.447.3001 (LO CAL)

JAYPRO SPORTS, LLC, 976 HARTFORD TURNPIKE, WATERFORD, CT 06385 USA

DESCRIPTION

FBGP-720 SPECIFICATIONS

PART NUMBER

FBGP-720

SIZE

SCALE

B

N/A

THIS DRAWING IS THE SOLE PROPERTY O F JAYPRO SPORTS INC. AND MAY

NOT BE REPRODUCED WITHOUT WRITTEN PERMISSION OR CONSENT

DATE

www.jaypro.com

DWN BY

7/10/2006

1

FBGP-720 SERIES

OFFICIAL 6’ OFFSET FOOTBALL GOAL POST

- PERMANENT AND SEMI-PERMANENT INSTALLATIONS -

LIST OF MATERIALS

ITEM NO. PART NO. DESCRIPTION QTY.

1 HS5119 Bolt-HX HD ½”-13x5” 8

2 HS5066 Bolt-HX HD ½”-13x7 ¾” 4

3 HN268 ½”-13 LOCK NUT 12

4 HW2044 ½” FLAT WASHER 12

5 HS1616 Bolt-3/8”-16x2 ¾” 8

6 HN1230 3/8”-16 LOCK NUT 8

7 HW2047 3/8” FLAT WASHER 8

8 SR167 ½-13 x 8 in THREADED ROD 1

9 HN5038 ½-13 FLANGE NUT 2

IMPORTANT

1) The location of the gooseneck with respect to the field is critical. By rule, the

front of the crossbar should be even with the field side (inside) edge of the end

line such that the crossbars measure 360 ft apart, inside to inside. The distance

from the end line to centerline of the bottom upright (gooseneck) is approximately

78” for the FBGP-720 series. See Figure 1

2) The footing depth is dependant on the type of installation, permanent or semipermanent. For permanent installations see Figure 3. For a semi-permanent using

a standard ground sleeve (Part No. FBSLV6) see Figure 4, and for a semipermanent with height adjuster see Figure 5. Materials for the semi-permanent

with height adjuster installation (Part No. FBGPGS-6) include the ground sleeve,

height adjuster and hardware.

3) Concrete should be a minimum 4000-psi mix.

4) The crossbar should be level and at a height of 10 ft above ground level. The

uprights should be plumb in both directions, front to back and side to side.

Adjust goal components as necessary. Note that a certain amount of deflection in

the crossbar is to be expected due to the weight of the end fittings and uprights on

each end.

T:\Aftermarket\Football\Drawings\FGBP-720\DOCUMENTATION\FBGP-720 Installs.doc

REV D 4/10

1

SLEEVE AND GOOSENECK INSTALLATION

1) Excavate the footing hole to the appropriate dimensions shown. See Figure 1 and

2 for locating the footing and height of the gooseneck. Use Figure 3 for

dimensions required for permanent installations. Use Figure 4 for semipermanent installations with a standard ground sleeve (FBSLV6) and Figure 5 for

semi-permanent installations with sleeve and height adjuster option (FBGPGS-6).

2) Once hole is excavated re-check depths to assure the correct crossbar height (10’

0”) will be achieved. Note: Due to the weight of the crossbar and uprights the

gooseneck will deflect downward approximately 1” to 1-1/2”.

3) Create a 6” base by using a concrete block or pouring a level pad 6” in the bottom

of the hole. Allow 48 hours to cure. Once the 6” pad has cured, center your

lower upright (gooseneck) in the hole; making sure the upright is perpendicular

and square to the playing field. Adequately support the gooseneck to prevent any

movement and allow to cure for a full 48 hrs.

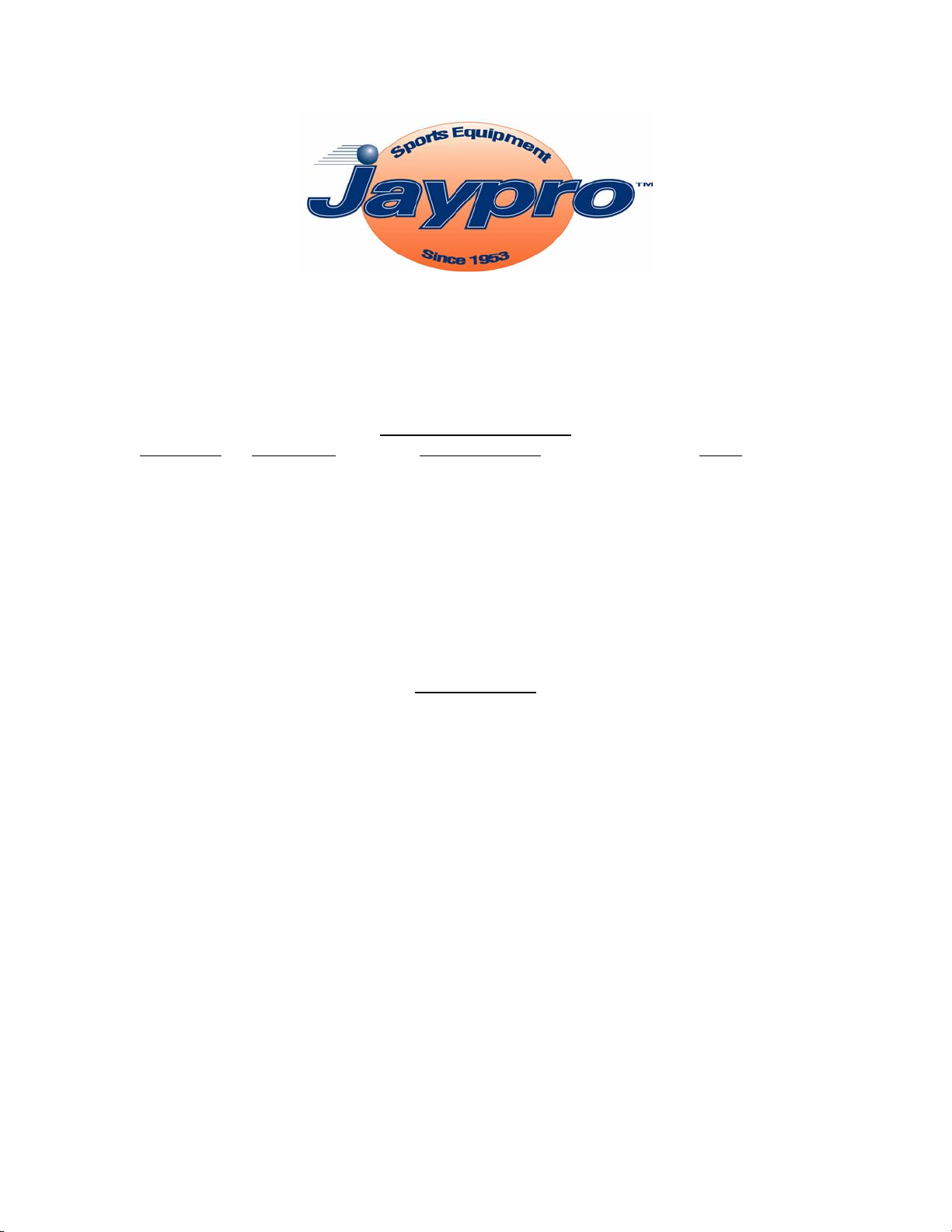

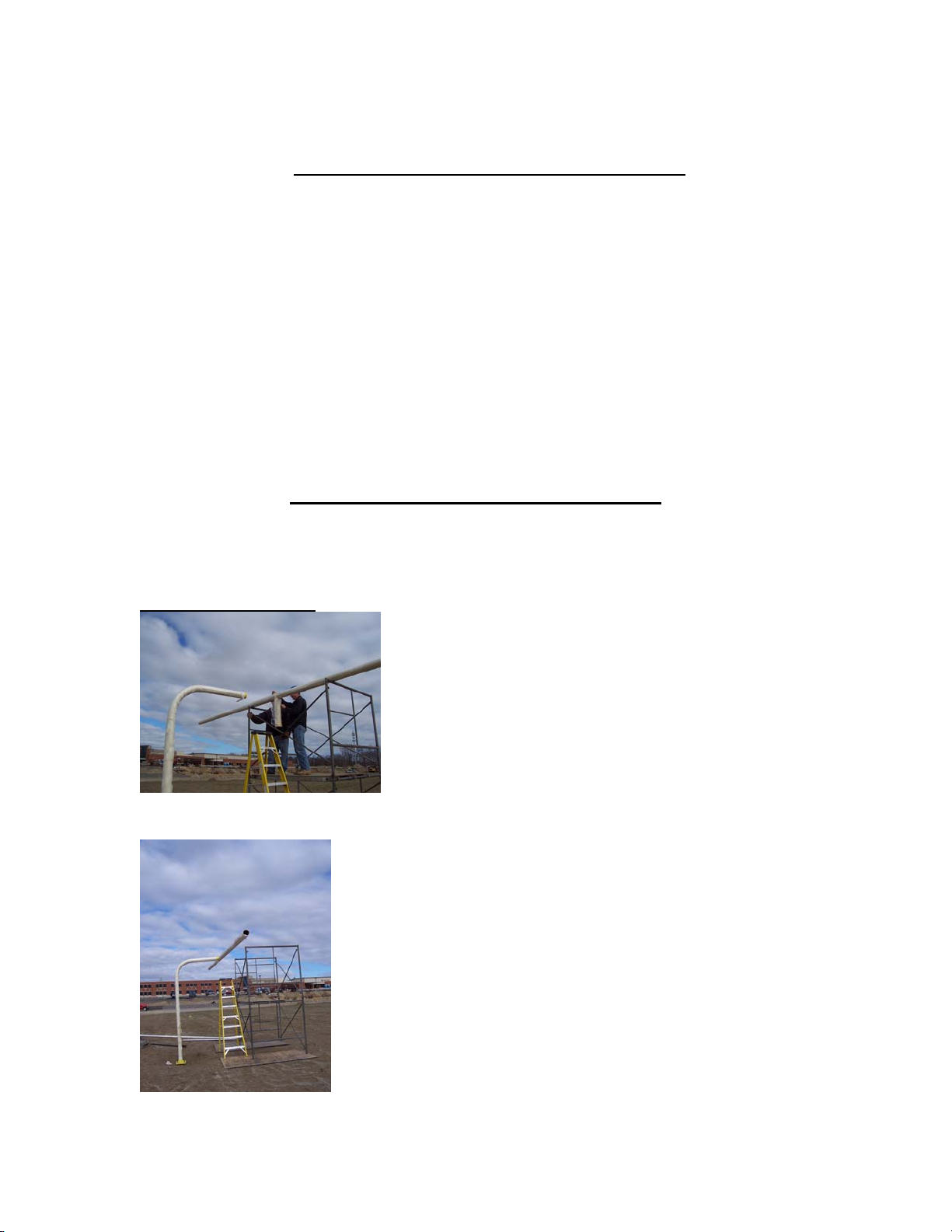

Cross-bar and Upright Installation

Once the footing is complete and the concrete has set for 48 hours, next install the

crossbar.

Crossbar Installation:

Use 10’ scaffolding and a ladder, have two people on

the scaffolding to lift and move the crossbar. Now with a third person on the ladder

guide the insert into the gooseneck.

Insert crossbar into gooseneck. Set crossbar depth so the front

edge of the crossbar is inline with the inside edge (field side) of the end line. Once the

T:\Aftermarket\Football\Drawings\FGBP-720\DOCUMENTATION\FBGP-720 Installs.doc

REV D 4/10

2

crossbar is level, mark (by using a center punch) and drill the holes through the

gooseneck. Start with a 3/16” bit, then a 3/8” bit and finally a ½” bit.

Mark and Drill Crossbar:

Once the holes are drilled, use the ½” bolts with two flat washers and thin lock nut. Use

a Silicon sealant used on each side of the bolt to prevent corrosion.

Tightening ½” bolts between crossbar and gooseneck:

T:\Aftermarket\Football\Drawings\FGBP-720\DOCUMENTATION\FBGP-720 Installs.doc

REV D 4/10

3