Jaypro Sports FBGP-700C User Manual

4

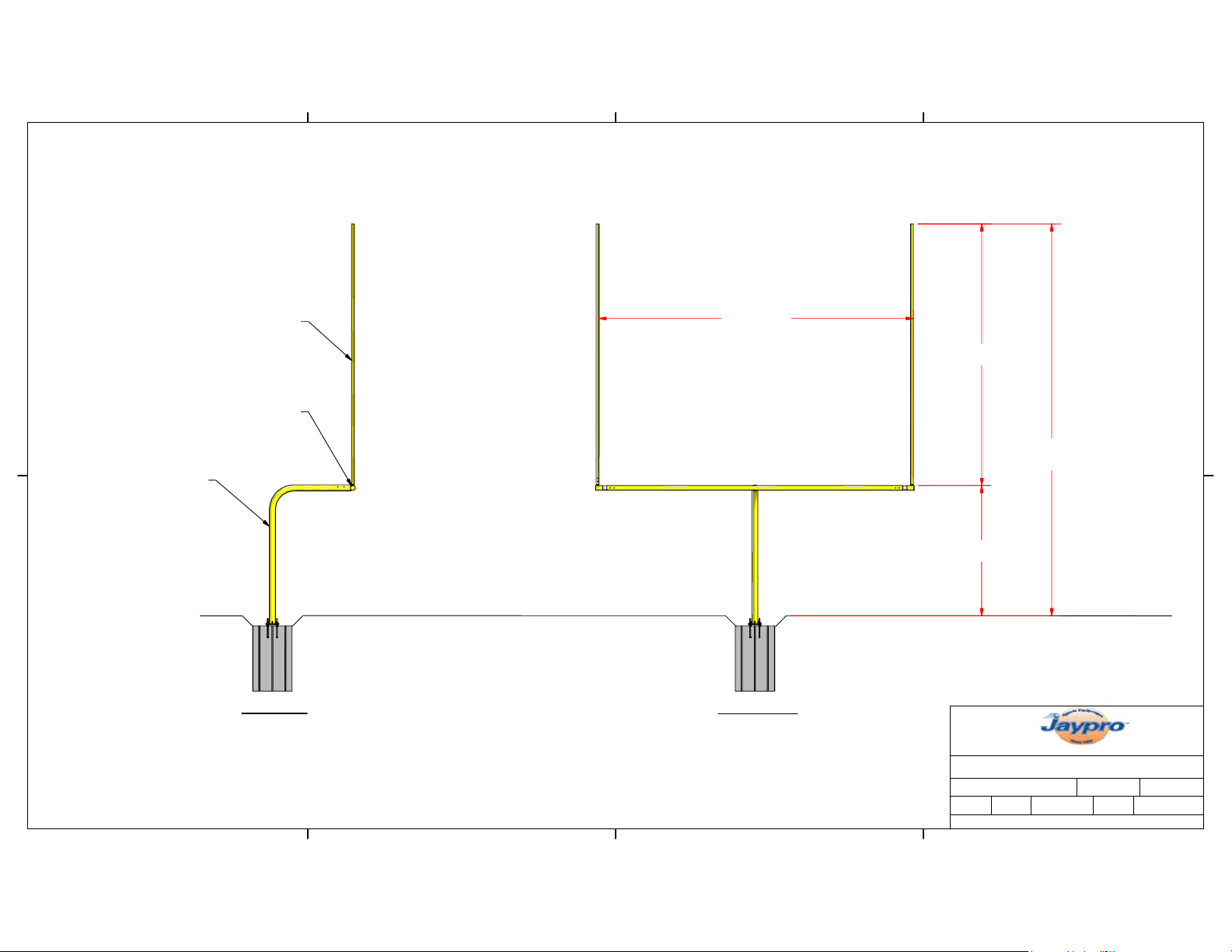

FBGP-700

FOOTBALL GOAL

SPECIFICATIONS

3

2

1

B B

n2 3/8" x 3/8" wall

ALUMINUM UPRIGHTS

n4 1/2" x 23'-4" High School

n4 1/2" x 18'-6" College

23'-4"

INSIDE

HIGH SCHOOL

(REF)

18'-6"

INSIDE

COLLEGE

(REF)

20'-0"

UPRIGHTS

GALVANIZED STEEL CROSSBAR

30'-0"

OVERALL

GALVANIZED STEEL

GOOSENECK

10'

TO CROSSBAR

HEIGHT

GROUND LEVEL

A A

SIDE VIEW

FBGP-700 HIGH SCHOOL WHITE

FBGP-700YW HIGH SCHOOL YELLOW

FBGP-700C COLLEGE WHITE

FBGP-700CYW COLLEGE YELLOW

4

3

FRONT VIEW

2

PHONE:

800.243.0533 (TOLL FREE)

860.447.3001 (LO CAL)

JAYPRO SPORTS, LLC, 976 HARTFORD TURNPIKE, WATERFORD, CT 06385 USA

DESCRIPTION

FBGP-700 SPECIFICATIONS

PART NUMBER

FBGP-700

SIZE

SCALE

B

N/A

THIS DRAWING IS THE SOLE PROPERT Y OF JAYPRO SPORTS INC. AND MAY

NOT BE REPRODUCED WITHOUT WRITTEN PERMISSION OR CONSENT

DATE

www.jaypro.com

DWN BY

7/11/2006

1

REV

DC

800.444.1779 (SALES)

860.440.0628 (ENG.)

CHKD BY

SHEET

-

1 1

FAX:

BTS

OF

FBGP-700 SERIES

OFFICIAL 6’ OFFSET FOOTBALL GOAL POST

-WITH LEVELING PLATE-

LIST OF MATERIALS

ITEM NO. PART NO. DESCRIPTION QTY.

1 HS5119 Bolt-HX HD ½”-13x5” 8

2 HS5066 Bolt-HX HD ½”-13x7 ¾” 4

3 HN268 ½”-13 LOCK NUT 12

4 HW2044 ½” FLAT WASHER 12

5 HS1616 Bolt-3/8”-16x2 ¾” 8

6 HN1230 3/8”-16 LOCK NUT 8

7 HW2047 3/8” FLAT WASHER 8

8 AF65 Top upright cap 4

9 FBGP601 ANCHOR ROD 8

10 HN5017 LOCK NUT 7/8”-9 8

11 HW5003 STANDARD FLAT WASHER 7/8” 16

12 HN5020 HEX NUT 7/8”-9 16

13 FBGP602 LEVELING PLATE 2

IMPORTANT

1) The location of the gooseneck with respect to the field is critical. By rule, the

front of the crossbar should be even with the field side (inside) edge of the end

line such that the crossbars measure 360 ft apart, inside to inside. The distance

from the end line to centerline of the bottom upright (gooseneck) is approximately

78” for the FBGP-700 series. See Figure 1

2) The footing depth is 5’-8”. Concrete should be a minimum 4000 psi mix. For

installation see Figure 2.

3) The crossbar should be level and at a height of 10 ft above ground level. The

uprights should be plumb in both directions, front to back and side to side.

Adjust goal components as necessary. Note that a certain amount of deflection in

the crossbar is to be expected due to the weight of the end fittings and uprights on

each end.

4) It is strongly recommended that a Protective Post Pad be placed around the

gooseneck when the goals are in use.

T:\Aftermarket\Football\Drawings\FBGP-700\DOCUMENTATION\FBGP-700Installs.doc

REVISION D 7/10

1

FOOTING INSTALLATION

1) Excavate the footing hole to the appropriate dimensions as shown in Figure 1 and

2 for locating the footing. Pour the footing, using minimum 4,000 psi mix, to

within 8’’ from ground level.

2) Assemble anchor rod to leveling plate by installing 7/8”-9 hex nut onto anchor

rod and engaging 7” of thread. Slip anchor rod thru holes in leveling plate

orienting the anchor rod as shown. Install second 7/8”-9 hex nut onto anchor rod

and tighten down so that the leveling plate is now held securely between the two

nuts. Place into concrete, level and square.

3) Let the foundation cure for a minimum of 48 hours.

GOOSENECK INSTALLATION

1) Once the footing is complete and the concrete has set for 48 hours, rig the

gooseneck onto the anchor bolts, as shown in Figure 2.

2) Adjust the height and plum the gooseneck. Secure all hardware. Note: Due to

the weight of the crossbar and uprights the gooseneck will deflect downward

1’’ to 1 ½’’.

3) All 7/8’’ –9 nuts and bolts should be coated with heavy grease. Each stud

should be protected by placing heavy poly film over greased studs and

wrapping with tape.

CROSSBAR AND UPRIGHT INSTALLATION

Crossbar Installation:

Use 10’ scaffolding and a ladder, have two people

on the scaffolding to lift and move the crossbar. Now with a third person on the ladder

guide the insert into the gooseneck.

T:\Aftermarket\Football\Drawings\FBGP-700\DOCUMENTATION\FBGP-700Installs.doc

REVISION D 7/10

2

Insert crossbar into gooseneck. Set crossbar depth so the front edge of the crossbar is

inline with the inside edge (field side) of the end line. Once the crossbar is level, mark

(by using a center punch) and drill the holes through the gooseneck. Start with a 3/16”

bit, then a 3/8” bit and finally a ½” bit.

Mark and Drill Crossbar:

Once the holes are drilled, use the ½” bolts with two flat washers and thin lock nut.

Silicon is used on each side of the bolt to prevent corrosion.

T:\Aftermarket\Football\Drawings\FBGP-700\DOCUMENTATION\FBGP-700Installs.doc

REVISION D 7/10

3

Loading...

Loading...