Page 1

MÁQUINA DUPLICADORA CAPRI

MANUAL DE INSTRUCCIONES

KEY CUTTING MACHINE CAPRI

INSTRUCTION MANUAL

MACHINE DUPLICATRICE CAPRI

NOTICE D’UTILISATION

DUPLIZIERMASCHINE CAPRI

BEDIENUNGSANLEITUNG

NØGLEMASKINE CAPRI

BRUGSANVISNING

MÁQUINA DUPLICADORA CAPRI

MANUAL DE INSTRUÇÕES

CAPRI

Page 2

ENGLISH

CAPRI

INSTRUCTION MANUAL

KEY CUTTING MACHINE

Page 3

ENGLISH

1.- PRESENTATION AND GENERAL ASPECTS

1.1 GENERAL POINTS

1.2 TRANSPORT AND PACKING

1.3 IDENTIFICATION LABEL

2. - CHARACTERISTICS OF THE MACHINE

2.1 FAMILIES OF KEYS

2.2 ACCESSORIES

2.3 TOOL STORE

2.4 ELECTRIC CIRCUIT

2.5 TECHNICAL DATA

2.6 MAIN ELEMENTS OF THE MACHINE

2.7 COMPONENTS AND FUNCTIONAL PARTS

2.7.1 CHANGING THE CUTTER AND TRACER POINT (21)

2.7.2 BLOCKING THE SLIDE AT THE END OF THE “Y” AXIS TRAVEL

2.7.3 CLAMP (6)

2.7.4 TRACER POINT SPRING MECHANISM (11)

2.7.5 SPRING MECHANISM AND BLOCKING THE SLIDE ON THE “X” AXIS (5 AND 4)

2.7.6 SUPPORT LEVER FOR TUBULAR KEYS

2.7.7 CUTTER SPEED (17)

2.7.8 KEYPAD-DISPLAY (1)

2.7.9 VERTICAL ADJUSTMENT OF THE TRACER POINT (15)

2.7.10 CONTROL OF CUTTING FORCE

3.- CUTTING

3.1 CUTTING PROCESS

3.2 KEY CUTTING

3.2.1 KA-2, KA-3 AND KA-4 KEYS.

3.2.2 KE-1 KEY.

3.2.3 SEA-1 KEY.

3.2.4 OP-WH.P AND OP-WY.P KEYS

3.2.5 ME-3.P AND ME-4.P KEYS

3.2.6 TUBULAR KEYS

3.2.7 FIC-2 AND FIC-3 KEYS

3.2.8 WIN-1D, WIN-2D, WIN-3D AND WIN-4D KEYS.

3.2.9 JIS-4.P KEY

3.2.10 FO-6.P KEY

3.2.11 MCM-10 KEY.

3.2.12 TE-T60 AND TE-T80 KEYS

4.- MAINTENANCE

4.1 REPLACING THE CLAMP JAWS

4.2 ADJUSTING THE JAWS

4.2.1 NORMAL ADJUSTMENT

4.2.2 PRECISION ADJUSTMENT

4.3 REPLACING THE FUSES

4.4 TIGHTENING AND REPLACING THE BELT

4.5 REPLACING THE MOTOR

4.6 REPLACING THE KEYPAD-DISPLAY

4.7 REPLACING THE ELECTRONIC CONTROL CARD

4.8 REPLACING THE POWER CARD AND CIRCUIT BREAKER

5.- SAFETY

6.- WASTE DISPOSAL

6.1 PACKING

6.2 SWARF

6.3 MACHINE

7.- KEY-CUTTER-TRACER POINT-ANGLE CUT-ADAPTOR TABLE

8.- EXPLODED VIEW

Page 4

ENGLISH

1.- PRESENTATION AND GENERAL ASPECTS

1.1 GENERAL POINTS

The CAPRI key cutting machine has been designed on the basis of safety standards

currently in force in the EU.

The safety of the personnel involved in handling this type of machines can only be

achieved with a well designed worker safety programme, like the implementation of

a maintenance programme and following recommended advice as well as compliance

with the safety standards included in this manual.

Although the machine is not difficult to install, it is best not to try to install, adjust or

use it without having first read this manual.

The machine leaves our factory ready for use and only requires calibration operations

for the tools that are going to be used.

1.2 TRANSPORT AND PACKING

The machine comes in a robust cardboard box protected with packing foam with the

following dimensions:

Width = 520 mm; Height = 650 mm; Depth = 575 mm

Weight of machine plus packing = 30 Kg.

When you unpack the machine, check carefully to see if it has suffered any damage

during transportation.

If you find any problems, please inform the carrier immediately and do not do anything

with the machine until the carrier’s agent has carried out an inspection.

To move the machine from one place to another, get hold of the machine by the base,

and not by any other part.

1.3 IDENTIFICATION LABEL

The CAPRI key cutting machine has an identification label, giving the machine’s serial or

registration number, the manufacturer’s name

and address, the CE mark and year of manufacture.

2. - CHARACTERISTICS OF THE MACHINE

The CAPRI machine is a highly robust and precision key cutting machine, which stands

out for having a clamp that enables many different types of keys to be clamped, without

the need for any adaptors.

It incorporates a novel force control system, which increases cutting precision.

2.1 FAMILIES OF KEYS

The CAPRI machine cuts the following types of keys, among others:

- Dimple keys

- Wave keys

- Tubular keys

- FIC-2 and FIC-3 keys

- WIN-1D, WIN-2D, WIN-3D and WIN-4D keys

- JIS-4.P keys

- FO-6.P keys

2.2 ACCESSORIES

The machine is supplied with a number of accessories for its use and maintenance. All

these accessories can be housed in the machine’s tool store.

- 2 fuses (housed in the bottom of the tool store)

- Set of Allen keys (5, 3 and 2.5)

- 1 special 1.5 short-arm Allen key

- 2 tip-stop strips

- 2 jaw adjustment rods.

- 2 adaptors for CHI-1T tubular key

- Cutters: F-1 and F-13

- Tracer points: T-1 and T-13.

2.3 TOOL STORE

The machine has a tool store, which is fitted to the top of the machine. It can be removed and laid directly on a table (in this way providing extra space on top of the machine,

which can be used for keeping keys, accessories, etc…).

2.4 ELECTRIC CIRCUIT

The main components of the electric and electronic circuits are as follows:

Socket.

Connection plate.

3-position switch.

Transformer.

Motor.

Keypad-display.

Control card.

Cutter.

Tracer point.

Clamp.

Lighting LED.

Force sensor.

See Figure 2

2.5 TECHNICAL DATA

Motor: Single phase 400 W. ,230 V - 50 Hz (Optional: Single phase 400W, 110V – 60Hz)

Cutter: HSS (Optional: Hard metal)

Cutter speed: 6,000 and 11,000 r.p.m.

Clamps: Two clamping faces and 0 / 45 º tilting

Displacement: On three axes with precision roller guides.

Effective stroke: X axis = 71 mm; Y axis = 62 mm; Z axis = 40 mm

Lighting: LED

Dimensions: Width = 430 mm, Depth = 385 mm and Height = 485 mm

Weight: 25 Kg

2.6 MAIN ELEMENTS OF THE MACHINE

1.- Keypad-display

2.- Clamp-holder slide (X – Y axes)

3.- Slide activation lever, x – y axes

4.- Knob to block clamp-holder slide, x axis

5.- Slide spring mechanism activation wheel, x-axis

6.- Clamp

7.- Lever to block clamp rotation

8.- Clamp knob

9.- Head (Z axis)

10.- Lever to activate and block head, z axis

11.- Tracer point spring mechanism knob

12.- Tool-holder

13.- Cutter

14.- Tracer point

15.- Tracer point height adjustment wheel

16.- Main switch

17.- Motor speed selector (2 speeds)

18.- Lighting LEDs

19.- Swarf protector

20.- Tool store

21.- Cutter blocking button

See Figure 3

2.7 COMPONENTS AND FUNCTIONAL PARTS

2.7.1 CHANGING THE CUTTER AND TRACER POINT (21)

To release the cutter, you have to press the cutter blocking button and at the same time

rotate the tool-holder by hand.

After removing the cutter to be replaced, insert the new cutter and secure it in the toolholder, making sure that its end butts up against the inside of the tool-holder.

The tracer point is replaced in the same way as the cutter. The only difference to bear in

mind is that the rotation of the tracer point is always blocked internally.

2.7.2 BLOCKING THE SLIDE AT THE END OF THE “Y” AXIS TRAVEL

In order to prevent the slide from moving in the “Y” direction, whilst the key cutting

machine is holding the keys in the clamp, the slide has been equipped with momentary

blocking in that direction.

To active this blocking, just move the slide as far as it will go in the direction towards

to the key cutting machine.

To deactivate the blocking, just move the slide forward, exercising a little force.

2.7.3 CLAMP (6)

The features of the clamp on the CAPRI key cutting machine are superior to those of any

normal machine on the market, as it has two separate clamping faces. In addition, the

clamps can be blocked in any rotation position between 45º 0º -45º.

2.7.4 TRACER POINT SPRING MECHANISM (11)

The tracer point can be used in two different ways, depending on the work you are

going to do:

Page 5

ENGLISH

- Tracer point with spring mechanism. The tracer point spring mechanism is

only used for cutting dimple keys.

- Tracer point blocked. The blocked tracer point is used to carry out cutting

operations with the slide forward. In general, for cutting wave keys.

To activate or deactivate the tracer point spring mechanism, you just have to turn the

tracer point spring mechanism knob 180º (half turn).

When the tracer point spring mechanism is activated, the tracer point tip is located

slightly below its adjustment position in relation to the cutter. This tracer point position

enables you to insert it gently into the hole in the original key, before the cutter starts

cutting the key to be copied. This avoids any vibrations and sudden movements of the

slide.

To find out the status of the tracer point at any time (with spring mechanism or blocked),

there is an indicator on the machine’s keypad-display which provides this information. If

the light is on, the spring mechanism is activated. On the other hand, if the light is off,

the tracer point is blocked.

2.7.5 SPRING MECHANISM AND BLOCKING OF THE SLIDE ON THE

“X” AXIS (5 AND 4)

We recommend that you use the spring mechanism for the slide on the “X” axis to carry

out lateral cutting of wave keys.

We recommend you use the blocking of the slide on the “X” axis for cutting or dimpling

in a straight line.

2.7.6 SUPPORT LEVER FOR TUBULAR KEYS

The CAPRI key cutting machine has a fold-away lever on its top-left side which helps to

make cutting tubular keys, wave keys, etc. more comfortable, as it serves as a support

point for the hand activating the slide travel lever.

2.7.7 CUTTER SPEED (17)

The machine has a speed selector on its right side, which enables you to select the

cutter rotation speed. In general terms, you can say that the rotation speed depends

on the cutter material:

- Position I: To work with an HSS cutter (6,000 rpm)

- Position II: To work with a HARD METAL cutter (11,000 rpm)

- Position O: Cutter at rest.

2.7.8 KEYPAD-DISPLAY (1)

ON-OFF button

Press it for the keypad-display functions to go into ACTIVE mode. A green light will

appear next to the button.

Press it again for the keypad-display to go into STAND-BY mode. A red light will appear

next to the button.

Lighting button

Press it to switch on the lighting diodes (if they are off) or switch them off if they are on.

This button operates independently of the status of the “ON-OFF” button.

SPRING MECHANISM indicator

If the blue light is on, this means that the tracer point is in SPRING MECHANISM ACTIVATED mode.

If the blue light is off, this means that the tracer point is BLOCKED (spring mechanism

deactivated).

MODE button

This button is for activating-deactivating operation of the tracer point vertical adjustment system.

TRACER POINT ADJUSTMENT indicators.

The light on the left comes on when the tracer point is touching the key.

The light on the right comes on when the cutter is touching the key.

FORCE visual indicator.

Indicates the ideal force to be applied during cutting.

NOTE: In addition to the visual indicator, the force control system also has an audible

indicator that emits a sound when you have achieved the ideal cutting force. This audible indicator can be activated-deactivated by pressing the MODE and ON-OFF buttons

at the same time.

2.7.9 VERTICAL ADJUSTMENT OF THE TRACER POINT (15)

Each time the cutter-tracer point is changed, the tracer point has to be vertically adjusted.

In order to be able to use the tracer point electronic vertical adjustment system, the

keypad-display must be active (when it is active, a green light appears next to the

ON-OFF button).

When the keypad-display is active, you can activate-deactivate the tracer point electronic vertical adjustment system by pressing the MODE button.

To vertically adjust the tracer point, proceed as follows:

• Secure the cutter and tracer point in their corresponding tool-holders. Make sure

that they have been secured, inserted upwards as far as they go.

• Secure two similar keys in the machine clamps.

• Release the tracer point spring mechanism (tracer point blocked).

• Lower the head, until the cutter and the tracer point rest on the keys in the

clamps. Then, one of the following three situations will occur:

LEFT BLUE LIGHT. If only the blue light on the left comes on, this means that

the tracer point is touching the key, but the cutter is not. Therefore, you have to

turn the cutter adjustment wheel to the left, until both adjustment lights some on.

RIGHT BLUE LIGHT. If only the blue light on the right comes on, this means that

the cutter is touching the key, but the tracer point is not. Therefore, you have to

turn the tracer point adjustment wheel to the right, until both adjustment lights

come on.

LEFT AND RIGHT BLUE LIGHTS. This means that both the cutter and tracer

point are touching their respective keys. This means that the height of the tracer

point has been adjusted.

IMPORTANT NOTE: When adjusting the height of the tracer point, you need to bear

in mind the type of key you are going to cut. If it is a WAVE key, very little force needs

to be applied to the head activation lever (on the visual force indicator no light should

come on). On the other hand, if it is a DIMPLE key, the blue adjustment lights have to

come on, and the force indicator should indicate the ideal cutting force for dimple keys

(to achieve this, you have to apply a slight force on the head activation lever).

2.7.10 CONTROL OF CUTTING FORCE

The CAPRI machine has a revolutionary cutting force control system. This is a patented

system, which when you are cutting DIMPLE keys, indicates the ideal force to exercise

on the head activation lever. It has two indicators for this purpose:

Visual indicator. The ideal cutting force is achieved when the line of lights reaches the white arrow.

Audible indicator. When the line of lights reaches the white arrow, the machine

emits a sound. This audible indicator can be activated-deactivated by pressing the

MODE and ON-OFF buttons at the same time.

This cutting force control system enables you to cut DIMPLE keys with great precision.

You will cut the holes in the key with exactly the same force with which you have

adjusted the height of the tracer point. In this way, you obtain maximum precision in

cutting DIMPLE keys.

3.- CUTTING

3.1 CUTTING PROCESS

• Switch on the machine using the main switch located on the back right-hand side

of the machine.

• To improve visibility in the work area, activate the lighting by turning on the switch

located on the keypad-display.

• With the help of the table provided in this manual, select the cutter and tracer

point necessary to cut the key.

• Change the cutter and tracer point.

• Momentarily block the slide at the end of the “Y” axis travel.

• Secure the original key in the left side of the clamp, and the key to be cut in the

right side. When securing the keys, bear in mind the following details:

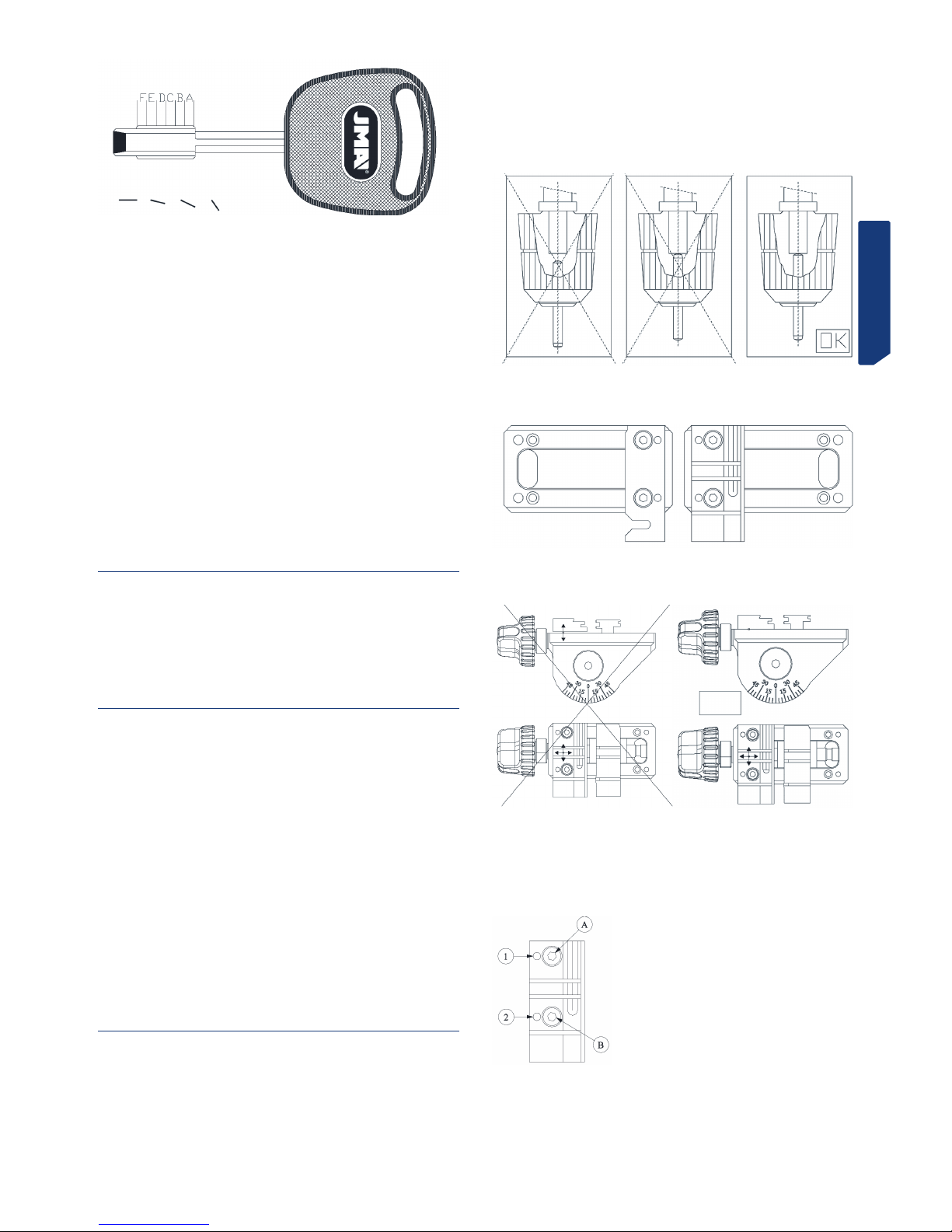

- KEY STOP. It may be a key which is stopped from being inserted further by its

shoulders (Fig. 4.A), or a key stopped by its tip (Fig. 4.B).

- ADAPTOR. For some very specific types of key, it may be necessary to use an

adaptor.

Page 6

ENGLISH

- ANGLE CUT. Some keys have angle cut dimples, for which it is necessary to

rotate the clamp.

• Carry out the vertical adjustment of the tracer point.

• Activate the systems which simplify the cutting work:

TRACER POINT: Activate or deactivate the tracer point spring mechanism,

depending on the type of key being cut.

SLIDE: Based on the model of key, it may be a good idea to activate the slide

spring mechanism, or block the slide in the “X” direction.

SUPPORT: Depending on the type of key, it may be a good idea to use the support

lever for tubular keys.

• Start rotating the cutter, having first selected one of the two speeds available.

• Proceed to cut the key. If it is a dimple key, use the help of the cutting force

control system.

3.2 CUTTING KEYS

3.2.1 KA-2, KA-3 AND KA-4 KEYS.

• Different pairs of cutters and tracer points are used depending on the key to be cut.

See table.

• The key is secured in the clamp when its shoulders stop it from being inserted any

further.

• Depending on the model of key to be cut, it is necessary to rotate the clamps based

on the angle required. See table.

• It is necessary to activate the tracer point spring mechanism.

• Use the cutting force control system to increase cutting precision.

• NOTE: The dimples cut on the KA-3 key must always be on the lowest part of the

clamp.

• NOTE: The dimples cut on the KA-2 key must always be on the highest part of the

clamp.

See Fig. 5

3.2.2 KE-1 KEY.

• Use cutter-tracer point pair: F-1 / P-1.

• The key is secured in the clamp when its shoulders stop it from being inserted any

further, but in this case it is inserted from the back.

• It is necessary to position the clamps at an angle of 5º.

• It is necessary to activate the tracer point spring mechanism.

• Use the cutting force control system to increase cutting precision.

• NOTE: The dimples cut on the KE-1 key must always be on the highest part of the

clamp.

• NOTE: You have to use the relevant adaptor to cut the lateral dimples.

See Fig. 6

3.2.3 SEA-1 KEY.

• Use cutter-tracer point pair: F-3 / P-3.

• The key is secured in the clamp when its shoulders stop it from being inserted any

further.

• It is necessary to block the tracer point (deactivate the spring mechanism).

• NOTE: After vertically adjusting the tracer point, you need to slightly lower the

tracer point, by turning the adjustment wheel 5 points to the right. Then you have to

insert the tracer point in the channel of the bit and block the machine head. Next slightly

raise the tracer point so that it does not drag the key.

• NOTE: Enter through the middle of the channels without touching the sides, and on

the second pass enter from the right side and exit from the left, without exercising any

pressure (just gently supporting the tracer point).

• NOTE: To cut the lateral dimples, use the cutter-tracer point combination: F-1 /

P-1. Insert until shoulders stop the key from going in any further. Activate the tracer

point spring mechanism and use the cutting force control system.

See Fig. 7

3.2.4 OP-WH.P AND OP-WY.P KEYS

• Use cutter-tracer point pair: F-11 / P-11.

• The key is secured in the clamp when its tip stops it from being inserted any further.

• It is necessary to block the tracer point (deactivate the spring mechanism).

• NOTE: After vertically adjusting the tracer point, you need to slightly lower the

tracer point, by turning the adjustment wheel 5 points to the right. Then you have to

insert the tracer point in the channel of the bit and block the machine head. Next slightly

raise the tracer point so that it does not drag the key.

• NOTE: We recommend using the slide spring mechanism system.

• NOTE: We recommend you do a roughing pass and then another finishing pass

following the whole profile of the pattern of the key. Machine in a downward direction

(from the tip of the key to the head).

See Fig. 8

3.2.5 ME-3.P AND ME-4.P KEYS

• Use cutter-tracer point pair: F-11 / P-11.

• Secure the key in the clamp using the AD-MM2 adaptor.

- Position the adaptor on the clamp, so that it is stopped by the tip.

- Insert the key into the adaptor.

- As you secure the adaptor in the clamp, the key is secured in the adaptor.

• It is necessary to block the tracer point (deactivate the spring mechanism).

• NOTE: After vertically adjusting the tracer point, you need to slightly lower the

tracer point, by turning the adjustment wheel 5 points to the right. Then you have to

insert the tracer point in the channel of the bit and block the machine head. Next slightly

raise the tracer point so that it does not drag the key.

• NOTE: We recommend using the slide spring mechanism system.

See Fig. 9

3.2.6 TUBULAR KEYS

• Use cutter-tracer point pair: F-8 / P-8.

• Secure the key in the clamp “V”.

• It is necessary to activate the tracer point spring mechanism.

• The cutting operation is more comfortable if you rest the hand activating the slide

activation lever on the support lever for tubular keys.

See Fig. 10

3.2.7 FIC-2 AND FIC-3 KEYS

• Use cutter-tracer point pair: F-11 / P-11.

• Secure the key in the clamp, resting it against the bottom and pushing it towards

the front face of the clamp.

• It is necessary to block the tracer point (deactivate the spring mechanism).

• Block the machine head at a height at which the cutter passes over the clamp but

without brushing against it.

• Cut the two top sides.

• Turn the keys taking care to remove any burrs to ensure correct positioning and

clamping of the key, and cut the other two sides of the key.

See Fig. 11

3.2.8 WIN-1D, WIN-2D, WIN-3D AND WIN-4D KEYS.

• Use cutter-tracer point pair: F-15 / P-15.

• Secure two key blanks in the clamp, and use them to vertically adjust the tracer

point.

• Clamp the original key with the teeth facing upwards (as shown in the drawing).

• It is necessary to block the tracer point (deactivate the spring mechanism).

• Insert the tracer point precisely in one of the dimples, and block the machine head

at that height.

• Start cutting.

See Fig. 12

3.2.9 JIS-4.P KEY

• Use cutter-tracer point pair: F-11 / P-11.

• Secure the key in the clamp using the AD-MJ adaptor.

-Position the adaptor on the clamp, so that it is stopped by the tip.

-Insert the key into the adaptor, until its shoulders are stopped by the plate that

rotates. In this position, clamp the key in the adaptor.

• It is necessary to block the tracer point (deactivate the spring mechanism).

See Fig. 13

3.2.10 FO-6.P KEY

• Use cutter-tracer point pair: F-22 / P-22.

• Secure the key in the clamp, using the relevant adaptor.

- Position and secure the adaptors on the clamp.

- When positioning the key, make sure that it is really flat, so that the two cuts

are the same.

• It is necessary to block the tracer point (deactivate the spring mechanism).

• Insert the tracer point if the groove of a letter. Block the machine head and raise

the tracer point slightly so that it does not knock against the adaptor.

• Start cutting.

See Fig. 14

Reading the code on the original key

• The original key has 6 cutting positions, which are defined by the letters: A, B, C, D, E

and F, as shown in the figure below.

• In each of the key’s positions, there are 4 different possible combinations (defined by

numbers), which we are going to indicate and number:

Page 7

ENGLISH

1 2 3 4

• Height no. 1, indicates that it should not be cut. Position no. 2 indicates there is a

small notch in the key and when it is slightly deeper this is position no. 3. Height no. 4

is the deepest notch in the key.

• You then take the key and mark the combinations of each of the 6 positions, as

shown below, by way of example:

POSITION A B C D E F

COMBINATION 3 4 1 2 4 2

NOTE: The series of combination numbers is the key code.

3.2.11 MCM-10 KEY.

• Special positioning in the clamp. See figure.

See Fig.15

3.2.12 TE-T60 AND TE-T80 KEYS

• Special positioning in the clamp. The TE-T60 is clamped as shown in the drawing.

• The TE-T80 key has the peculiarity that to machine the left side it is clamped like

the TE-T60 and to machine the right side the key has to be clamped by the back part of

the clamp (like with the MCM-10 key).

See Fig. 16

4.- MAINTENANCE

When carrying out any maintenance work, it is necessary to meet the following requirements:

1. Never carry out any maintenance work with the machine switched on.

2. Unplug the machine.

3. Strictly adhere to the indications in this manual.

4. Only use original spare parts.

4.1 REPLACING THE CLAMP JAWS

The CAPRI machine’s clamp has three pairs of jaws (left fixed jaw, right fixed jaw and

moving jaw). If any of them become damaged, you can replace them with new jaws,

separately.

To replace the left fixed jaw (A) or the right fixed jaw (B), you just have to undo the two

screws securing them, and remove them by pulling them upwards. Reverse the process

to fit the new jaws.

To replace the moving jaw (C), you need to follow the steps below:

1) With the help of a cutter or something similar, remove the clamp knob’s black

plastic cover.

2) Whilst locking the locknut with a size 14 spanner, insert a no. 5 Allen key into the

hole revealed in the clamp knob, and unscrew it.

3) Tilt the clamp 45º, and manually turning the spindle, remove it from one of the

sides. Once the spindle has been removed, the moving jaw is released and you can

remove it.

4) To fit the new moving jaw, simply reverse the process.

IMPORTANT NOTE: When you replace the left fixed jaw or the right fixed jaw, you

always have to adjust the pair of jaws that has been replaced. On the other hand, if you

replace the moving jaw, it is not necessary to carry out any adjustment on the jaws.

See Fig. 17

4.2 ADJUSTING THE JAWS

Whenever you replace the left fixed jaw or the right fixed jaw, you have to adjust the

pair of jaws that has been replaced. On the other hand, the replacement of the moving

jaw does not require any adjustment to the jaws.

There are two different ways of adjusting the jaws:

NORMAL adjustment

PRECISION adjustment

4.2.1 NORMAL ADJUSTMENT

This is a quick, simple adjustment, which will give you an acceptable adjustment

enabling you to cut keys with a certain amount of precision.

To carry out this adjustment, follow these steps:

1) Secure the two adjustment rods in their relevant tool-holders, inserting then as far

as they will go into the tool-holder, with the tapered part of the adjustment rods on the

outside.

2) The left fixed jaw on the right-hand side of the clamp and the right fixed jaw on the

left-hand side of the clamp cannot be adjusted, as they are held in position by means

of pins. So you have to fit them, by guiding them with their pins and then securing them

with their corresponding screws.

3) Therefore, knowing that in each pair of jaws there is one with a fixed position, you

have to adjust the other jaw in relation to the one with the fixed position.

4) Insert the screws for the jaw to be adjusted, but do not tighten them. So that the

jaw can be moved by hand, but cannot lift up from the surface it is resting on.

5) Adjust the jaw:

5.1) Insert the tracer point adjustment rod into hole no. 1 in the jaw.

5.2) Make the cutter adjustment rod coincide with hole no. 1 in the other jaw.

5.3) Raise the head and carry out the same operation, with hole no. 2 in the jaws.

5.4) Repeat this operation as many times as necessary until the adjustment rods

enter smoothly without the need for any force, in both hole no. 1 and hole

no. 2.

5.5) With the two adjustment rods inserted in holes no. 1, block the head, and

slightly tighten screw B.

5.6) With the two adjustment rods inserted in holes no. 2, block the head and

slightly tighten screw A.

5.7) Repeat the above operation, but fully tightening screws A and B.

5.8) Once you have completed the adjustment process, with the help of the special

short-arm 1.5 Allen key, tighten the two setscrews located between the clamp

knob and the jaw you have adjusted. This will ensure that the jaw you have adjusted is tightly secured.

Page 8

ENGLISH

4.2.2 PRECISION ADJUSTMENT

This adjustment requires a certain amount of skill, and ensures that the replaced jaws

are very precisely adjusted.

To carry out this adjustment, follow these steps:

1) The left fixed jaw on the right-hand side of the clamp and the right fixed jaw on the

left-hand side of the clamp cannot be adjusted, as they are held in position by means

of pins. So you have to fit them, by guiding them with their pins and then securing them

with their corresponding screws.

2) Therefore, knowing that in each pair of jaws there is one with a fixed position, you

have to adjust the other jaw in relation to the one with the fixed position.

3) Insert the screws for the jaw to be adjusted, but do not tighten them. So that the

jaw can be moved by hand, but cannot lift up from the surface it is resting on.

4) With the help of the special short-arm 1.5 Allen key, unscrew the two jaw adjustment setscrews about 1 turn (these are the two setscrews located between the

clamp knob and jaw you are going to adjust).

5) Then, insert any cutter-tracer point pair in their corresponding tool-holders, but

the wrong way around (with the cutting tips inside the tool-holder). Lower the machine

head, and block it at a height at which the tools can touch the sides of the jaws.

6) Activate the tracer point electronic vertical adjustment system.

7) Rest the end of the jaw that is clamped (the one with the fixed position) against

the side of the tool. Manually, move the jaw to be adjusted in the direction of the clamp

knob, and maintaining pressure on the jaw in that direction, move it forward until it also

touches the side of its corresponding tool. In this position, tighten the screws securing

the jaw a little. You will know when the tools are touching their corresponding jaws,

because the tracer point electronic vertical adjustment system’s lights will come on.

8) Then, separate the moving jaw from the jaw to be adjusted, turning the clamp knob

to do so.

9) Position the tool in alignment with one of the screws securing the jaw, and in this

position rest the tool against the jaw that is clamped (the one with the fixed position).

Then, keeping at all times a slight pressure between the tool and the jaw that is clamped (the one with the fixed position), very slowly tighten the setscrew aligned with the

tool and the jaw screw. The moment will come when the second light on the tracer point

electronic vertical adjustment system will come on. When this happens, stop tightening

the setscrew.

10) Position the tool in alignment with the other screw securing the jaw, and carry out

the same operation again.

11) Check again that the jaws are adjusted in those two positions (in front of the

clamping screws), and if necessary, slightly adjust the position of the jaw tightly very

slightly the corresponding setscrew.

12) You have now completed the adjustment. Now you have to fully tighten the two

screws securing the jaw.

13) Finally, tighten the two jaw adjustment setscrews a little. This will ensure that the

jaw you have adjusted is tightly secured.

4.3 REPLACING THE FUSES

If the machine does not start when you activate the on-off switches, you need to check

the fuses. You can do this in the following way:

1) Switch of the machine using the main switch and unplug it.

2) Remove the fuse-holder which is under the main switch.

3) Use a tester to check if a fuse has blown and, if so, replace it with one of the same

type and value.

4.4 TIGHTENING AND REPLACING THE BELT

To check the tightness of the belt or to replace it, follow these steps:

1) Switch off the machine using the main switch, and unplug it.

2) Undo the 4 screws (5) securing the head guard and remove it. The screws are on

the right side, the left side, on the top and at the back. To remove the head guard it is

necessary first of all to push the cutter locking button right in as far as it will go (E).

3) Loosen but do not undo the 4 screws (6) securing the motor.

4) Loosen but do not undo the 2 locknut nuts (7).

Tightening: When you turn the two tightening screws (8), the motor moves towards

the back of the machine. When you see that the belt is tight enough, tighten up the two

locknut nuts (7) again, and the screws (6) securing the motor.

Replacement: Loosen but do not undo the 2 screws tightening the belt (8). Remove the

damaged belt and replace it with a new one. When you turn the two tightening screws

(8), the motor moves towards the back of the machine. When you see that the belt is

tight enough, tighten up the two locknut nuts (7) again, and the screws (6) securing

the motor.

5) Put the head guard back and secure it in place.

See Fig. 18

4.5 REPLACING THE MOTOR

You can carry out this operation in the following way:

1) Switch off the machine using the main switch and unplug it.

2) Undo the 4 screws (5) securing the head guard and remove it. The screws are on

the right side, the left side, on the top and at the back. To remove the head guard it is

necessary first of all to push the cutter locking button right in as far as it will go (E).

3) Undo the 6 screws (9) securing the motor guard (F) and remove it.

4) Remove the belt (G).

5) Disconnect the power cables going to the motor.

6) Undo the 4 screws (6) securing the motor.

7) Remove the motor.

8) Access the bottom of the motor with a flat screwdriver, block the motor shaft and

manually turn the pulley (H) until it comes out (it is left-threaded).

9) Undo the 4 screws (10) securing the motor support plate and remove it.

10) To fit the new motor, reverse the procedure above.

See Fig. 19

4.6 REPLACING THE KEYBOARD-DISPLAY

You can carry out this operation in the following way:

1) Switch off the machine using the main switch, and unplug it.

2) Undo the 4 screws (5) securing the head guard and remove it. The screws are on

the right side, the left side, on the top and at the back. To remove the head guard it is

necessary first of all to push the cutter locking button right in as far as it will go (E).

3) Disconnect the flat cable connecting the keypad-display (K) to the electronic control card.

4) Release the old keypad-display (K) from the head guard and remove it.

5) To fit the new keypad-display, reverse the procedure above.

See Fig. 20

Page 9

ENGLISH

4.7 REPLACING THE ELECTRONIC CONTROL CARD

You can carry out this operation in the following way:

1) Switch off the machine using the main switch and unplug it.

2) Undo the 4 screws (5) securing the head guard and remove it. The screws are on

the right side, the left side, on the top and at the back. To remove the head guard it is

necessary first of all to push the cutter locking button right in as far as it will go (E).

3) Disconnect the electronic control card’s main connector (L)

4) Disconnect the flat cable connecting the keypad-display (K) to the electronic control card

5) Undo the 3 screws (11) securing the electronic control card (L) to the head guard

and remove it.

6) To fit a new electronic control card, reverse the procedure above.

See Fig. 21

4.8 REPLACING THE POWER CARD AND CIRCUIT

BREAKER

You can carry out this operation in the following way:

1) Switch off the machine using the main switch and unplug it.

2) Unscrew the machine’s 4 feet (P) and remove them.

3) Undo the 5 screws (12) the lower protection plate and remove it.

4) Disconnect all the cables from the card you want to replace, noting down beforehand the position of each cable.

5) To release the power card (M) or the circuit breaker (N), just press on the lugs on

each of the 4 pins holding it, and pull the card up.

6) To fit the new power card or circuit breaker, just reverse the procedure above.

See Fig. 22

5.- SAFETY

For your safety, we recommend that you follow these guidelines:

• Do not try and start or operate the machine until all the safety aspects, installation

instructions, operators’ guide and maintenance procedures have been complied with

and understood.

• Always disconnect the mains electricity supply, before carrying out any cleaning or

maintenance work.

• Always keep the machine and the area around it clean.

• Work with dry hands.

• Use protective goggles, even if the machine is fitted with guards.

• Make sure that the machine has an earth connection.

We recommend that you work with the machine at a height at which you feel comfortable:

• It is best to work whilst sat in a chair. Adjust the height of the chair so that your

eyes are at the height of the highest part of the machine.

• If you work standing up, depending on your height, it is advisable to place something between the table and the machine to raise the machine so that your eyes are

level with the highest part of the machine.

6.- WASTE DISPOSAL

Waste is understood to be any substance or object from human activities or natural

cycles, that is no longer being used or not intended for any further use.

6.1 PACKING

• As the packing the CAPRI comes in is made of cardboard, it can be recycled as

packing.

• As waste, it is comparable to solid urban waste and, therefore, can only be disposed in special containers for cardboard.

• The elements protecting the machine inside the cardboard box are made of polymeric material comparable to solid urban waste and, therefore, can only be disposed of

in the normal installations for waste disposal.

6.2 SWARF

• The waste from the key cutting process is classified as special waste, but is comparable to solid urban waste, like for example a metal scouring pad.

• This waste shall be disposed of as classified by the laws currently in force in the

EU, by taking it to special installations for waste disposal.

6.3 MACHINE

• Before demolishing the machine it is necessary to put it out of action first, cutting

off the electricity supply and separating the plastic parts from the metal parts.

• After carrying out this operation, all the waste can be disposed of in compliance

with the laws in force in the country in which the machine was used.

7.- KEY-CUTTER-TRACER POINT-ANGLE CUTADAPTOR TABLE

To be able to do the work properly, the machine has a series of accessories:

See final list.

8.- EXPLODED VIEW

See Fig. 23

Page 10

2

3 4.A

4.B

Page 11

5

6

7

9 10

8

Page 12

11

14

16 17

15

12

13

Page 13

18

20 21

22

19

Page 14

23

Page 15

REFERENCIA

REFERENCE

REFERENCE

ARTIKELNUMMER

REFERENCE

REFERÊNCIA

MARCA

MANUFACTURER

MARQUE

HERSTELLER

MÆRKE

MARCA

FRESA

CUTTER

FRAISE

FRÄSER

FRÆSER

FRESA

PALPADOR

TRACER POINT

PALPEUR

TASTER

FØLER

APALPADOR

INCLINACION

ANGLE

INCLINAISON

NEIGUNG

HÆLDNINGS-VINKEL

INCLINAÇÃO

ADAPTADOR

ADAPTOR

ADAPTATEUR

ADAPTER

ADAPTER

ADAPTADOR

ABC-6 ABC F-5 P-5

ABC-7 ABC F-5 P-5

ABL-1 ABLOY F-11 P-11 AD-ABL

ABL-2 ABLOY F-11 P-11 AD-ABL

ABL-3 ABLOY F-11 P-11 AD-ABL

ABL-4 ABLOY F-11 P-11 AD-ABL

ABU-16 ABUS F-1 P-1

ABU-34 ABUS F-1 P-1 AD-CI

ABU-61 ABUS F-1 P-1 AD-CI

ABU-63 ABUS F-1 P-1 AD-CI

ABU-66 ABUS F-1 P-1 AD-CI

AGA-12 AGA F-13 P-13

AGA-25 AGA F-13 P-13

AGA-29 AGA F-5 P-5

AGA-38 AGA F-1 P-1

AGA-39 AGA F-1 P-1

AGA-42 AGA F-1 P-1

AGA-43 AGA F-1 P-1

AGA-44 AGA F-1 P-1

AGA-48 AGA F-1 P-1

AGA-49 AGA F-1 P-1

AGA-50 AGA F-1 P-1

AGB-2 AGB F-1 P-1

AGB-4 AGB F-1 P-1

AGB-5 AGB F-1 P-1

AMG-8D AMIG F-5 P-5

AMG-9D AMIG F-5 P-5

AMG-10 AMIG F-5 P-5

AMG-10D AMIG F-5 P-5

AP-1D APEX F-13 P-13

AP-1D CVC F-5 P-5

AP-1D SIB F-14 P-14

AP-3D APEX F-13 P-13

AP-4D APEX F-13 P-13

AP-5D APEX F-19 P-19

AX-2.P AXA F-11 P-11

AZ- 7 AZBE F-15 P-15

AZ- 8D AZBE F-5 P-5

AZ- 9 AZBE F-13 P-13

AZ-12 AZBE F-13 P-13

AZ-14 AZBE F-13 P-13

AZ-29 AZBE F-13 P-13

AZ-32 AZBE F-13 P-13

BAI-8D BASI F-5 P-5

BAI-9D BASI F-5 P-5

BAG-1 BAGEM F-1 P-1

BEY-1D BEY F-13 P-13

BEY-2D BEY F-19 P-19

BKY-1 BORKEY F-1 P-1

BKY-2 BORKEY F-1 P-1

BM-1.P BMW F-1 P-1

BM-4 BMW F-11 P-11 AD-MJ

BM-5.P BMW F-11 P-11 AD-MJ

BM-6.P BMW F-11 P-11

BRAS-1 BRAS F-13 P-13

BUL-1 BULAT F-1 P-1

BRI-16 BRICARD F-1 P-1

BRI-25 BRICARD F-1 P-1 AD-CI

BRI-26 BRICARD F-1 P-1 AD-CI

BRI-27 BRICARD F-1 P-1 AD-CI

BRI-28 BRICARD F-1 P-1 AD-CI

BRI-29 BRICARD F-1 P-1 AD-CI

BRI-30 BRICARD F-1 P-1 AD-CI

BRI-31 BRICARD F-1 P-1 AD-CI

BRI-33 BRICARD F-1 P-1 AD-CI

BUL-1 BULAT F-1 P-1

BYP-1D BYP F-19 P-19

CAY-2 CAYS F-1 P-1

CE-114 CES F-32 P-32

CES WSM CES F-32 P-32

CHU-10 CHUBB F-1 P-1

CI-14 CISA F-1 P-1

CI-17 CISA F-1 P-1

Page 16

CI-21 CISA F-1 P-1 AD-CI

CI-25 CISA F-1 P-1 AD-CI

CI-26 CISA F-1 P-1 AD-CI

CI-30 CISA F-1 P-1 AD-CI

CI-31 CISA F-1 P-1 AD-CI

CI-32 CISA F-1 P-1 AD-CI

CI-33 CISA F-1 P-1 AD-CI

CI-35 CISA F-1 P-1 AD-CI

CI-48 CISA F-1 P-1 AD-CI

CI-56 CISA F-1 P-1 AD-CI

CI-57 CISA F-1 P-1 AD-CI

CI-59 CISA F-1 P-1

CI-60 CISA F-1 P-1 AD-CI

CIT-1P CITROEN F_11 P-11

COR-37 IFAM F-19 P-19

COR-77 CORBIN F-5 P-5

CVL-9D CVL F-13 P-13

DAF-2 DAF F-13 P-13

DAF-3D DAF F-13 P-13

DAF-4D DAF F-13 P-13

DEK-3 DEKABA F-1 P-1

DEK-4 DEKABA F-1 P-1

DEK-8 DEKABA F-1 P-1

DLC-1 DELCA F-1 P-1

DLC-2 DELCA F-1 P-1

DLC-3 DELCA F-1 P-1

DO-3 DOMUS F-1 P-1

DO-4 DOMUS F-1 P-1

DOM-17I DOM F-1 P-1

DOM-22 DOM F-1 P-1

DOM-30 DOM F-1 P-1

DOM-31 DOM F-1 P-1

DOM-32 DOM F-1 P-1

DOM-33 DOM F-1 P-1 AD-STS

DOM-34 DOM F-1 P-1 AD-STS

DOM-39 DOM F-1 P-1

DOM-39

(agujero rasgado)

(elongated hole)

(trou oblong)

(Langloch)

aflange hul

(orificio rasgado)

DOM F-1 / F-23 P-23

DOM-43 DOM F-1 P-1

DOM-56D DOM F-1 P-1

DOM-63D DOM F-1 P-1

DOM-B1 DOM F-1 P-1

DO-3 DOMUS F-1 P-1

DO-4 DOMUS F-1 P-1

DR-1 DIERRE F-11 P-11

ELZ-10 ELZETT F-5 P-5

EZ-DS10 EZCURRA F-1 P-1

EZ-DS10 EZCURRA F-16 P-16

EZ-DS10E EZCURRA F-1 P-1

EZ-DS10E EZCURRA F-16 P-16

EZ-DS15 EZCURRA F-1 P-1

EZ-DS15 EZCURRA F-16 P-16

EZ-DS15R EZCURRA F-1 P-1

EZ-DS15R EZCURRA F-16 P-16

FAV-2 BYP F-5 P-5

FAC-19 FAC F-1 P-1

FAC-23 FAC F-1 P-1

FAY-1D FAYN F-5 P-5

FIC-18 FICHET F-18 P-18 FIC18-DAKAR

FI-16.P TRW-SIPEA F-33 P-33

FO-6.P FORD F-22 P-22 AD-FO

FO-24P FORD F-11 P-11

FTH-7 FTH F-5 P-5

FTH-16 FTH F-19 P-19

FTH-23 FTH F-5 P-5

FTH-24 FTH F-5 P-5

FTH-25 FTH F-5 P-5

FTH-26D FTH F-5 P-5

FTH-29 FTH F-5 P-5

FTH-30 FTH F-5 P-5

GDA-1.P GERDA F-1 P-1

GIOB-3.P LANCIA F-6 P-6

HTE-50 HTEC F-5 P-5

HOND-17.P HONDA F-11 P-11

Page 17

HU-2.P HUF F-11 P-11

HU-HAA.P AUDI F-11 P-11 AD-AUDI

HU-DH.P VOLVO F-11 P-11

HU-DN.P VOLVO F-11 P-11

IF-2 IFAM F-1 P-1

IF-4 IFAM F-1 P-1

IF-6 IFAM F-19 P-19

IR-1.P IR F-1 P-1

INCE-1E INCECA F-18 P-18ª

INCE-2E INCECA F-18 P-18ª

IS-6D ISEO F-1 P-1

IS-10.P ISEO F-1 P-1

IS-14D ISEO F-1 P-1

ITO-2D ITO F-1 P-1

JAR-1E JARDI F-14 P-14 AD-JAR1E

JIS-4.P JIS F-11 P-11 AD-JIS

KA-1 KABA (8) F-1 P-1

KA-2 KABA (20) F-5 P-5

KA-2 KABA (20) F-43 P-43 45º

KA-3 KAB( emini) F-1 P-1 15º

KA-4 KABA (Cuattro) F-1 P-1 15º

KA-4 KABA Nueva F-1 P-26 45º

KA-5 ** KABA F-5 P-5

KA-6 KABA F-1 P-1

KA-7 KABA F-1 P-1

KA-8 KABA F-1 P-1

KA-10 KABA F-1 P-1

KA-11 KABA F-1 P-1

KAE-1 KALE F-1 P-1

KAE-2 KALE F-1 P-1

KAE-4 KALE F-1 P-1

KAE-10D KALE F-1 P-1

KAE-11D KALE F-1 P-1

KAE-12D KALE F-13 P-13

KE-1 KESO F-1 P-1 5º

KE-2 KESO F-1 P-1

KE-3 KESO (2000) F-5 P-5

KE-4 KESO(2000) F-1 P-1

JAU-1.P TIBBE F-1 P-1

JAU-2.P TIBBE F-1 P-1

LAP- 4 LAPERCHE F-13 P-13

LAP- 8D LAPERCHE F-13 P-13

LAP-10D LAPERCHE F-13 P-13

LAP-11D LAPERCHE F-13 P-13

LAP-13.P LAPERCHE F-13 P-13

LAP-17.P LAPERCHE F-13 P-13

LAP-20.P LAPERCHE F-13 P-13

LAP-21.P LAPERCHE F-13 P-13

LAP-22.P LAPERCHE F-13 P-13

LAP-23.P LAPERCHE F-13 P-13

LIN-13 LINCE F-12B P-12B

LIN-13 LINCE F-5 P-5

LIN-19D LINCE F-5 P-5

LIN-21D LINCE F-1 P-1

MAS-15P MASTER F-6 P-6

MASL-1 MASTER LOCK F-1 P-1

MAZ-12.P1 MAZDA F-1 P-1

MCM- 4SS MCM F-1 P-1

MCM- 4SS MCM F-B P-B

MCM- 4SS MCM F-C P-C

MCM-10 MCM F-13 P-13

MCM-16 MCM F-1 P-1

MCM-21D MCM F-1 P-1

MCM-27 MCM F-13 P-13

ME-2.P MERCEDES F-11 P-11 AD-MJ

ME-3.P MERCEDES F-11 P-11 AD-MJ

ME-4.P MERCEDES F-11 P-11 AD-MM

ME-5.P MERCEDES F-11 P-11 AD-MM

ME-6.P MERCEDES F-11 P-11 AD-MM

ME-7.P MERCEDES F-11 P-11 AD-MM

ME-8.P MERCEDES F-11 P-11 AD-MM

ME-10.P MERCEDES F-11 P-11 AD-MM

ME-11.P MERCEDES F-11 P-11 AD-MM

ME-12.P MERCEDES F-11 P-11 AD-MM

MLM-4 MLM F-1 P-1

MSM-1 MSM F-19 P-19

MULT-2.P MULTLOCK F-12A P-12A

MULT-2.P MULTLOCK F-12B P-12B

MULT-3.P MULTLOCK F-12A P-12A

Page 18

MULT-3.P MULTLOCK F-12B P-12B

MULT-4.P MULTLOCK F-12A P-12A

MULT-4.P MULTLOCK F-12B P-12B

MULT-5.P MULTLOCK F-12A P-12A

MULT-5.P MULTLOCK F-12B P-12B

MUL-T10.P MULTLOCK F-12A P-12A

MUL-T10.P MULTLOCK F-12B P-12B

NE-40.P VOLVO F-11 P-11

NE-41.P VOLVO F-11 P-11

NE-51P2 PEUGEOT F-11 P-11

OJ-Q OJMAR F-5 P-5

OMC-3 OMEC F-1 P-1

OMC-4 OMEC F-1 P-1

OP-11C1 OPEL F-11 P-11

OP-WH.P OPEL F-11 P-11

OP-WHC OPEL F-11 P-11

OP-WY.P OPEL F-11 P-11

PFA-13D (lateral) PFAFFENHAIN F-34 P-34

PFA-14D (lateral) PFAFFENHAIN F-34 P-34

PFA-15D (lateral) PFAFFENHAIN F-34 P-34

PFA-16D (lateral) PFAFFENHAIN F-34 P-34

PEN-2 PENZMASH F-1 P-1

PEU-1C1 VALEO/PEUGEOT F-11 P-11

PEU-2C1 VALEO/PEUGEOT F-11 P-11

PIC-8D PICARD F-1 P-1

PTN-1D POTENT F-19 P-19

PTN-2D POTENT F-19 P-19

ROSE-1 ROSSETTI F-1 P-1

SAA-1.P SAAB F-11 P-11

SCR-1 SECURITAL F-1 P-1

SEA-1 SEA F-3 P-3 Canal

SEA-1 SEA F-1 P-1 Lateral

SEA-2 SEA F-3 P-3 Canal

SEA-2 SEA F-1 P-1 Lateral

SEC-1 SECUREMME F-19 P-19

SEC-2 SECUREMME F-19 P-19

SEC-3 SECUREMME F-19 P-19

SER-3D SERRALLER F-1 P-1

SIP-4P4 TRW-SIPEA F-11 P-11

SIP4-P3 TRW-SIPEA F-11 P-11

SPI-1 SPIDER F-1 P-1

SPI-1D SPIDER F-1 P-1

STS-35 STS F-1 P-1

STS-36 STS F-1 P-1

STS-37 STS F-1 P-1

STS-38 STS F-1 P-1

STS-X5 STS F-5 P-5

STS-X6 STS F-5 P-5

SUB-2.P SUBARU F-11 P-11

T-10 Plus STS-TESA F5 P-5

T-10 STS – TESA F-13 P-13

T-10 2005 TESA F-1 P-1

TE-T11 TESA F-5 P-5

T-14 STS F-5 P-5

TE-T12PLUS TESA F-5 P-5

TE-T60 TESA F-5 P-5

TE-T61 TESA F-5 P-5

TE-T62 TESA F-5 P-5

TE-T80 TESA F-5 P-5

TE-T80SC TESA F-5 P-5

TE-T82 TESA F-5 P-5

TEC-2 TECSESA F-5 P-5

TIT-6 TITAN F-1 P-1

TOV-2 TOVER F-1 P-1

TOV-4 TOVER F-1 P-1

TOV-5 (2f25) TOVER F-1 P-1

TOV-5 (2f25) TOVER F-6 P-6

TOV-6 TOVER F-1 P-1

TOV-7 TOVER F-1 P-1

TOYO-18.P TOYOTA F-11 P-11

TOYO-30.P1 TOYOTA F-11 P-11

TRO-1 TARONI F-1 P-1

TRO-1D TARONI F-1 P-1

TV-3 IX – STS –TESA F-1 P-1

TV-5 IX – STS –TESA F-1 P-1

TV-8 IX – STS –TESA F-1 P-1

TV-9 IX – STS – TESA F-1 P-1

TX-1 SH-2 SH-3 F-19 P-19

UCEM-5D UCEM F-14 P-14

Page 19

UCEM-5I UCEM F-14 P-14

UCEM-8D.P UCEM F-13 P-13

UCEM-13D UCEM F-13 P-13

UCEM-17D UCEM F-13 P-13

URB-3D URBIS F-1 P-1

URB-4D URBIS F-1 P-1

VA-11 VACHETTE F-43 P-43 30º

VA-15 VACHETTE F-21 P-21

VA-25 VACHETTE F-21 P-21 19º

VA-26 VACHETTE F-21 P-21 19º

VA-27 VACHETTE F-21 P-21 19º

VA-28 VACHETTE F-21 P-21 19º

VA-56 VACHETTE F-21 P-21 19º

VA-58 VACHETTE F-21 P-21 19º

VA-70 VACHETTE F-1 P-1

CIT-1.P VALEO F-11 P-11

PEU-1.P VALEO F-11 P-11

TKY-2 T-KEY F-1 P-1

URB-3D URBIS F-1 P-1

URB-4D URBIS F-1 P-1

VI-14 VIRO F-13 P-13

WIL-22 WILKA F-1 P-1

WIN-1D WINKHAUS F-15 P-15

WIN-1I WINKHAUS F-15 P-15

WIN-2D WINKHAUS F-15 P-15

WIN-3D WINKHAUS F-15 P-15

WIN-4D WINKHAUS F-15 P-15

X-5 STS – TESA F-5 P-5 AD-STS

X-6 STS – TESA F-5 P-5 AD-STS

YA-23 YALE F-11 P-11 AD-JIS

YA-81 YALE F-1 P-1

YAR-1 YARDENI F-13 P-13

YAR-2 YARDENI F-13 P-13

YAR-3 YARDENI F-13 P-13

ZA-10 ZADI F-1 P-1

ZA-14P ZADI F-33 P-33

Con la mordaza universal (llaves tipo Fichet)

With the universal clamp (Fichet type keys)

Avec l’étau universel (clés type Fichet)

Mit der universellen Spannvorrichtung (Schlüssel vom Typ Fichet)

Med universal kæben (nøgler af Fichet typen)

Com o grampo universal (chaves tipo Fichet)

FIC-2 FICHET F-11 P-11

FIC-3 FICHET F-11 P-11

FIC-4 FICHET F-11 P-11

Con la mordaza universal (llaves tubulares)

With the universal clamp (tubular keys)

Avec l’étau universel (clés tubulaires)

Mit der universellen Spannvorrichtung (röhrenförmige Schlüssel)

Med universal kæben (rørnøgler)

Com o grampo universal (chaves tubulares)

TUBULAR CHICAGO Y OTRAS F-8 P-8

( El duplicado de este tipo de llaves deberá realizarse a bajas revoluciones).

(This type of key should be cut at low revolutions).

(La reproduction de ce type de clés doit être réalisée à basses révolutions).

(Das Kopieren dieses Schlüsseltyps muss mit niedriger Drehzahl ausgeführt werden).

(Kopiering af denne nøgle type bør udføres med et lavt omdrejningstal)

(A duplicação deste tipo de chaves deve realizar-se a baixas rotações).

** Calzar la llave con una galga 0.3 mm. Apretar la llave en la mordaza con ayuda de la chapa de tope punta.

** Pack the key with a 0.3 mm gauge. Tighten the key in the clamp with the help of the tip stop plate.

** Chausser la clé avec une jauge de 0.3 mm. Serrer la clé dans l’étau à l’aide de la plaquette de butée en pointe.

** Untelegen Sie den Schlüssel mit einer Lehre 0.3 mm. Spannen Sie den Schlüssel in der Spannvorrichtung mit Hilfe des spitzen Anschlagblechs ein.

** Nøglen bør fyldes efter med en afstand på 0.3 mm. Spænd nøglen fast på kæben ved hjælp af spidstappen.

** Colocar uma bitola de 0,3 mm na chave. Apertar a chave no grampo com a ajuda da chapa de pressão de ponta.

Page 20

Page 21

Page 22

www.jma.es

Member Of Altuna Group

JMA HEADQUARTERS

ALEJANDRO ALTUNA, S.A.

Tel +34 943 79 30 00

Fax +34 943 79 72 43

Bidekurtzeta, 6

P.O.Box - Apdo. 70

20500 Arrasate - Mondragón

Gipuzkoa – SPAIN

www.jma.es

ventas@jma.es

JMA ARGENTINA

JMA ARGENTINA S.A.

Tel +54-3461 462 422

Fax +54 3461 462 607

Av. Central Acero Argentino Oeste 678

Parque industrial COMIRSA

2900 San Nicolas (Prov. Buenos Aires)

www.jma-argentina.com

info@jma-argentina.com

JMA FRANCE

JMA FRANCE

Tel +33 01 39 22 42 10

Fax +33 01 39 22 42 11

Technoparc

13, rue Edouard Jeanneret

F- 78306 Poissy Cedex

www.jmafrance.fr

service.commercial@jmafrance.fr

JMA INDIA

JMA KEYS INDIA PVT. LTD

Tel +91 124 427 5482

Fax +91 0124 428 5451

H-239 Soshant Shopping Arcade

Sunshant Lok-1, Block B

122002 Gurgaon

Haryana

www.jmakeys.in

info@jmakeys.in

JMA MAROC

JMA MAROC S.A.R.L.

Tel +212 520 150 535

Fax +212 520 150 536

El Oulfa

Casablanca

Marruecos

www.jma.ma

jma@jma.ma

JMA MEXICO

LLAVES ALTUNA DE MEXICO S.A de C.V

Tel +52-33-3777-1600

Fax +52-33-3777-1690

Av. Aviación No. 5520

Col. San Juan de Ocotán

C.P. 45019 Zapopan, Jalisco

www.jma.com.mx

ventas@jma.com.mx

JMA POLSKA

JMA POLSKA Sp. z.o.o.

Tel +48 42 635 12 80

Fax +48 42 635 12 85

91- 342 Lodz ul. Zb

ą

szynska 3

www.jmapolska.pl

biuro@jmapolska.pl

JMA PORTUGAL

ALTUNA PORTUGAL

COMERCIO DE CHAVES UNIPESSOAL, LDA.

Tel +35 121 994 7470

Fax +35 121 994 7471

Urbanizaçâo dos Areeiros, Lote 67 C/v

2695-733 Sâo Joao da Talha

www.jmaportugal.com

geral@jmaportugal.com

JMA UK

SKS LTD

Tel +44 144 229 1400

Fax +44 144 286 3683

Unit 2, Canalside

Northbridge Road

Berkhamsted

Herts HP4 1EG

www.skskeys.co.uk

sales@skskeys.co.uk

JMA USA

ALTUNA GROUP USA INC.

Tel +1 817.385.0515

Fax +1 817.385.4850

1513 Greenview Drive

75050 Grand Prairie, Texas

www.jmausa.com

info@jmausa.com

Loading...

Loading...