Page 1

07610-003-08-60 A

July 2, 2005

Dishmachine Component

Maintenance Instructions

Drain Solenoid

Replacment

Conserver XL

Conserver XL2

Conserver XL2-CML

Conserver XL2-CMR

Page 2

3. Once the cover is removed, the solenoid and wiring are

www.jacksonmsc.com

The dishmachines of the Conserver XL series come

equipped with a solenoid and associated components that lift the

drain stopper during the operating cycle. This provides for efficient

and automatic draining of the machine prior to the rinse cycle. The

main component of this system is the drain solenoid itself. As with

any other electrical component, there may come a time when this

part fails and needs to be replaced.

The instructions provided here are for maintenance personnel only. Unauthorized persons should not attempt any of the

steps contained in these instructions.

Warning: many of the instructions and steps within

this document require the use of tools. Only authotized per sonnel should ever perform any maintenance procedure on

the dishmachine!

PREPARATION

1. Power must be secured to the unit at the service breaker. Tag or lock out the service breaker to prevent accidental or

unauthorized energizing of the machine.

2. Ensure that the unit is completely drained prior to

beginning this maintenance action.

TOOLS REQUIRED

The following tools will be needed to perform this mainte-

nance evolution:

1. Phillipshead screwdriver

2. Needle nose pliers

3. Wire cutters

4. 3/8” nut driver

STEPS (Conserver XL)

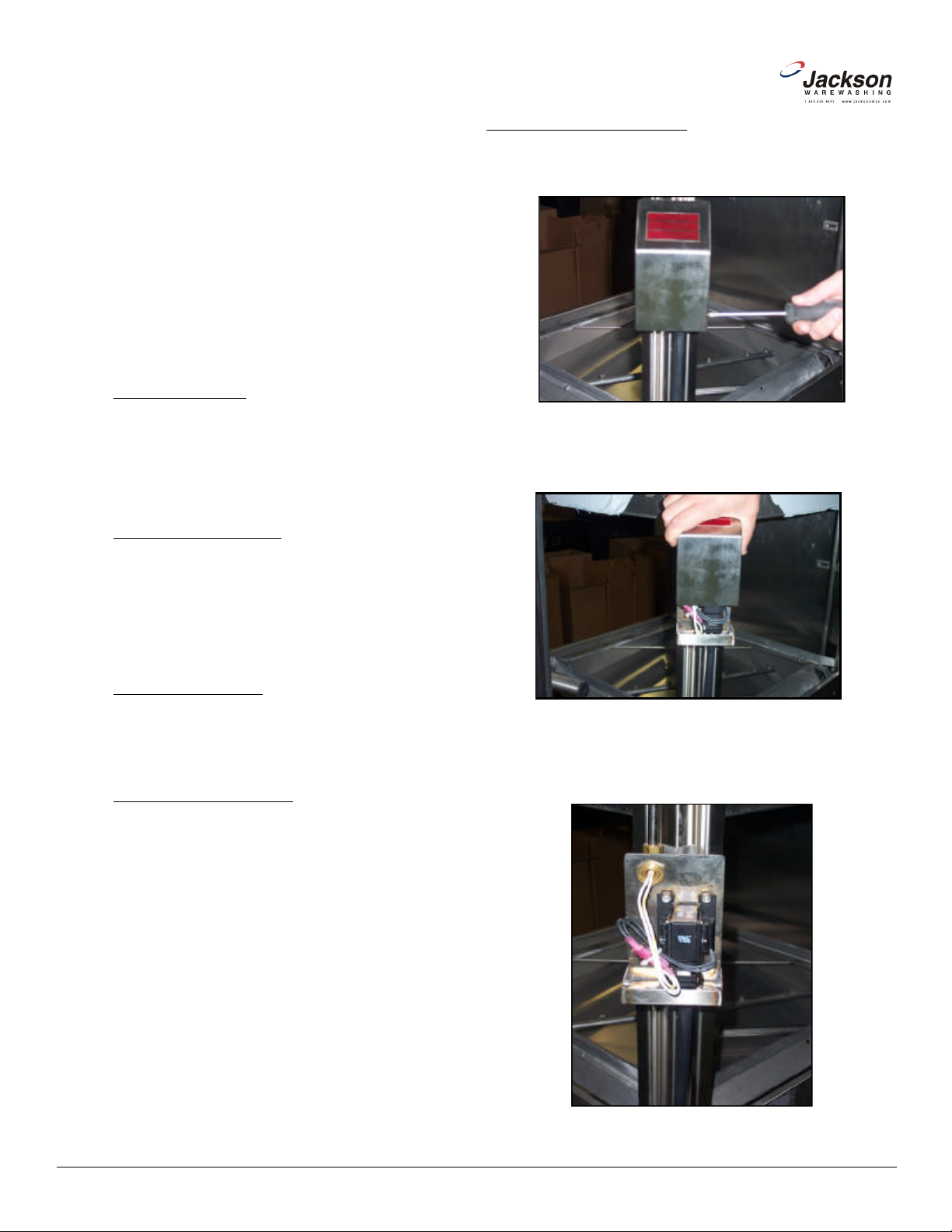

1. Remove the four screws holding the cover on (Consever XL).

Removing screws for solenoid cover (Conserver XL)

2. Remove the cover by gripping firmly and sliding up.

TIME REQUIRED

It is estimated that it will take (1) person thirty minutes to

perform this task, not including all of the items indicated in the section entitled “PREPARATION”.

IMPORTANT NOTES

1. Read these instructions thoroughly before attempting

this maintenance action. Become familiar with the parts and what

actions need to be taken. This will save time in the long run!

Removing solenoid cover (Conserver XL)

exposed.

Exposed solenoid and wires (Conserver XL)

2

Conserver XL/XL2 Drain Slolenoid Replacement Instructions

Revision A (07/02/2005)

Page 3

4. Using the needle nose pliers, take the bent parts of the cotter pin

8. Gently separate the wires at the terminals. This will electrically

9. Now use the nut driver to remove the (4) locknuts used to mount

11. You may dispose of the drain solenoid. Do not return it to

Jackson unless specifically requested to do so by the Technical

Service Department or a Technical Service Representative. You

12. Before installing your new solenoid, verify that the the voltage

ratings marked on the component correspond to the voltage of the

unit. You can verify the unit’s voltage by referring to the machine

and bend them back so that the pin is relatively straight.

Adjusting the cotter pin (Conserver XL) Separating the wires (Conserver XL)

5. With the pin straightened, pull it out from the opposite side. This

will disconnect the drain link from the solenoid.

www.jacksonmsc.com

disconnect the drain solenoid from the dishmachine.

the solenoid to the dishmachine.

Removing the cotter pin (Conserver XL) Removing the locknut (Conserver XL)

6. Using the wire cutters, remove the tie-wraps that are holding the

wires.

Cutting the tie-wraps (Conserver XL)

7. Note: It is very important that you do not cut or break the insulation on the wires. These wires will carry line voltage and any sort

of breakage can cause dmagae to the unit or harm to personnel. If

you do cut or break the wire(s), the wiring must be repaired in

accordance with national, state and local electrical codes.

10. Remove the old drain solenoid.

Removing the drain solenoid (Conserver XL)

should now retrieve your service kit.

Conserver XL/XL2 Drain Slolenoid Replacement Instructions

Revision A (07/02/2005)

3

Page 4

www.jacksonmsc.com

data plate located on the right side of the tub.

13. Verify that the new solenoid’s slide does not bind and moves

freely before installing it. If it does not, contact Jackson Technical

Service.

Verifying the free movement of the solenoid (Conserver XL)

14. Attach the new drain solenoid to the machine using the (4) locknuts.

15. Reconect the wires to solenoid. Refer to the machine schemat ic if you have any questions regarding the wiring of the solenoid. It

can be found on the inside of the control box cover. If you machine

does not have a schematic, please contact Jackson Technical

Service.

16. Tie-wrap the wires so that they will be out of the way when the

cover is placed back on.

Drain solenoid cover location (Conserver XL2)

Removing the locknut (Conserver XL2)

17. Using the cotter pin, re-attach the drain link. Ensure that after

putting the pin through that you pull back the ends to secure it in

place.

18. Slide the cover back on taking care not to pinch or smash any

wires.

19. Secure the cover using the (4) screws.

20. Proceed to the section entitled “AFTER MAINTENANCE

ACTIONS”.

STEPS (Conserver XL2 Models)

1. Note: These instructions apply to all of the Conserver XL2 mod els, including the Conserver XL2-CML and Conserver XL2-CMR.

2. Locate the cover for the drain solenoid. It is located underneath

the tub on the sump. Using the nutdriver, remove the locknut holding the cover in place. With the locknut removed, push back on the

cover and it should come right off. Do not attempt to pry the cover

off as this could cause damage to the cover, the stud or the wiring

for the drain solenoid.

Removing the cover (Conserver XL2)

The drain solenoid exposed (Conserver XL2)

4

Conserver XL/XL2 Drain Slolenoid Replacement Instructions

Revision A (07/02/2005)

Page 5

3. Once the cover is removed, the drain solenoid and its wiring will

7. Gently separate the wires at the terminals. This will electrically

8. Now use the nut driver to remove the (4) locknuts used to mount

10. You may dispose of the drain solenoid. Do not return it to

Jackson unless specifically requested to do so by the Technical

Service Department or a Technical Service Representative. You

11. Before installing your new solenoid, verify that the the voltage

ratings marked on the component correspond to the voltage of the

unit. You can verify the unit’s voltage by referring to the machine

12. Verify that the new solenoid’s slide does not bind and moves

freely before installing it. If it does not, contact Jackson Technical

-

14. Reconect the wires to solenoid. Refer to the machine schemat

-

ic if you have any questions regarding the wiring of the solenoid. It

can be found on the inside of the control box cover. If you machine

does not have a schematic, please contact Jackson Technical

be exposed.

4. Using the wire cutters, remove the tie-wraps that are holding the

wires.

www.jacksonmsc.com

disconnect the drain solenoid from the dishmachine.

the solenoid to the dishmachine.

Cutting the tie-wraps (Conserver XL2)

5. Note: It is very important that you do not cut or break the insulation on the wires. These wires will carry line voltage and any sort

of breakage can cause dmagae to the unit or harm to personnel. If

you do cut or break the wire(s), the wiring must be repaired in

accordance with national, state and local electrical codes.

6. Using the needle nose pliers, take the bent parts of the cotter pin

and bend them back so that the pin is relatively straight. With the

pin straightened, pull it out from the opposite side. This will disconnect the drain link from the solenoid.

Removing the cotter pin (Conserver XL2)

Removing the locknuts (Conserver XL2)

9. Remove the old drain solenoid.

should now retrieve your service kit.

data plate located on the right side of the tub.

Service.

Separating the wires (Conserver XL2)

Conserver XL/XL2 Drain Slolenoid Replacement Instructions

Revision A (07/02/2005)

Verifying the free movement of the solenoid (Conserver XL)

13. Attach the new drain solenoid to the machine using the (4) lock

nuts.

Service.

5

Page 6

www.jacksonmsc.com

15. Tie-wrap the wires so that they will be out of the way when the

cover is placed back on.

16. Using the cotter pin, re-attach the drain link. Ensure that after

putting the pin through that you pull back the ends to secure it in

place.

17. Slide the cover back on taking care not to pinch or smash any

wires.

18. Secure the cover using the (4) screws.

19. Proceed to the section entitled “AFTER MAINTENANCE

ACTIONS”.

AFTER MAINTENANCE ACTIONS

1. Reconnect the incoming water (if disconnected) and

turn on. Then restore power to the unit. Run the unit for at least 10

cyles to ensure that the drain solenoid is working properly. If any

problems arise you can contact Jackson Technical Service.

SPECIAL NOTES

1. Work performed on Jackson dishmachines by unauthorized or unqualified personnel may void the warranty. Before beginning this or any other maintenance evolution on a unit under warranty, you should contact a certified Jackson technician or Jackson

Technical Service. You can find a list of qualified service agencies

in the back of you unit’s installation manual.

SPECIAL PARTS

Drain Solenoid Replacment Kitt:

For 110 volt machines order 6401-003-08-58

For 230 volt machines order 6401-003-08-59

CONTACT INFORMATION

Jackson MSC Inc. provides technical support for all of the

dishmachines detailed in this manual. We strongly recommend that

you refer to this manual before making a call to our technical sup port staff. Please have this manual with you when you call so that

our staff can refer you, if necessary, to the proper page. Technical

support is available from 8:00 a.m. to 5:00 p.m. (EST), Monday

through Friday. Technical support is not available on holidays.

Contact technical support toll free at 1-888-800-5672. Please

remember that technical support is available for service personnel

only.

6

Conserver XL/XL2 Drain Slolenoid Replacement Instructions

Revision A (07/02/2005)

Loading...

Loading...