Page 1

WHIRL WIZARD

RECIRCULATING SOAK SINK

CONVERSION

INSTALLATION/OPERATIONINSTALLATION/OPERATION

& SERVICE MANUAL& SERVICE MANUAL

Visit Jackson on the Internet at:

www.jacksonmsc.com

July 20, 2000 P/N 7610-011-70-65

Page 2

MANUFACTURERS WARRANTY

ONE YEAR LIMITED PARTS & LABOR WARRANTY

ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM DEFECTS IN

MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION FOR A PERIOD OF (1) ONE YEAR FROM THE DATE OF

PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM THE DATE OF SHIPMENT FROM THE FACTORY.

Jackson MSC agrees under this warranty to repair or replace , at its discretion, any original part which fails under normal use due to

faulty material or workmanship during the warranty period, providing the equipment has been unaltered, and has been properly installed,

maintained and operated in accordance with the applicable factory instruction manual furnished with the machine and the failure is

reported to the authorized service agency within the warranty period. This includes the use of factory specified genuine replacement

parts, purchased directly from a Jackson authorized parts distributor or service agency. Use of generic replacement parts may create

a hazard and void warranty certification.

The labor to repair or replace such failed part will be paid by Jackson MSC, within the continental United States, Hawaii and Canada,

during the warranty period provided a Jackson MSC authorized service agency, or those having prior authorization from the factory, performs the service. Any repair work by persons other than a Jackson MSC authorized service agency is the sole responsibility of the

customer. Labor coverage is limited to regular hourly rates, overtime premiums and emergency service charges will not be paid by

Jackson MSC.

Accessory components not installed by the factory carry a (1) one year parts warranty only. Accessory components such as table limit

switches, pressure regulators, pre rinse units, etc. that are shipped with the unit and installed at the site are included. Labor to repair

or replace these components is not covered by Jackson MSC.

This warranty is void if failure is a direct result from shipping, handling, fire, water, accident, misuse, acts of god, attempted repair by

unauthorized persons, improper installation, if serial number has been removed or altered, or if unit is used for purpose other than it

was originally intended.

TRAVEL LIMITATIONS

Jackson MSC limits warranty travel time to (2) two hours and mileage to (100) one hundred miles. Jackson MSC will not pay for travel

time and mileage that exceeds this, or any fees such as those for air or boat travel without prior authorization.

WARRANTY REGISTRATION CARD

The warranty registration card supplied with the machine must be returned to Jackson MSC within 30 days to validate the warranty.

REPLACEMENT PARTS WARRANTY

Jackson replacement parts are warranted for a period of 90 days from the date of installation or 180 days from the date of shipment

from the factory, which ever occurs first.

PRODUCT CHANGES AND UPDATES

Jackson MSC reserves the right to make changes in design and specification of any equipment as engineering or necessity requires.

THIS IS THE ENTIRE AND ONLY WARRANTY OF JACKSON MSC. JACKSON’S LIABILITY ON ANY CLAIM OF ANY KIND, INCLUD -

ING NEGLIGENCE, WITH RESPECT TO THE GOODS OR SERVICES COVERED HEREUNDER, SHALL IN NO CASE EXCEED THE

PRICE OF THE GOODS OR SERVICES OR PART THEREOF WHICH GIVES RISE TO THE CLAIM.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING FOR FITNESS OR MERCHANTABILITY, THAT ARE NOT

SET FORTH HEREIN, OR THAT EXTEND BEYOND THE DURATION HEREOF. UNDER NO CIRCUMSTANCES WILL JACKSON

MSC BE LIABLE FOR ANY LOSS OR DAMAGE, DIRECT OR CONSEQUENTIAL, OR FOR THE DAMAGES IN THE NATURE OF

PENALTIES, ARISING OUT OF THE USE OR INABILITY TO USE ANY OF ITS PRODUCTS.

ITEMS NOT COVERED

This warranty does not cover cleaning or deliming of the unit or any component such as, but not limited to, wash arms, rinse arms or

strainers at anytime. Nor does it cover adjustments such as, but not limited to, timer cams, thermostats or doors, beyond 30 days from

the date of installation. In addition, the warranty will only cover the replacement of wear items such as curtains, drain balls, door guides

or gaskets during the first 30 days after installation. Also not covered are conditions caused by the use of incorrect (non-Commercial)

grade detergents, incorrect water temperature or pressure or hard water conditions.

Page 3

TABLE OF CONTENTS

Section Title Page

I General Section

Specifications 1

Detail of the Data Plate 2

General Notes 3

II Installation Instructions 4

III Installation Assembly 5

IV Operation Instructions/Changing Directions 6

V Parts and Drawings

Main Assembly 7

Ordering Replacement Wire 8

Conduit and Fittings 9

Ordering Replacement Fasteners 10

VI Jackson Maintenance and Repair Centers 12

VII 115 Volt, 60 Hz, 1 Phase Schematic 19

VIII Important Information Data Sheet 20

Page 4

SPECIFICATIONS OF THE WHIRL WIZARD

This unit can be adapted to most standard three compartment sink to provide recirculated water to assist in the removal of soil from

ware. The entire unit will fit within the frame work of standard sinks, so no additional floor space is required.

A one (1) horsepower motor and pump continually recirculates warm detergent laden water through a unique agitator mounted in the

drain hole in the sink. The water exits through vanes located on the agitator causing a vortex in the water in the sink. This constant

action, in conjunction with a low sudsing detergent, loosens food soil. A built-in thermostatically controlled heating system maintains

water temperature between 110 and 120 degrees Farenheit.

The unit includes the following:

1. One (1) horsepower pump motor with built-in thermal overload protection.

2. Pump fitted with internal cutting blades.

3. Built-in thermostatically controlled heating system.

4. Illuminated power ON/OFF switch.

5. Heavy duty grounded power cord.

6. 304 stainless steel construction.

ELECTRICAL REQUIREMENTS:

MODEL VOLTS HZ PHASE TOTAL AMPS

WW-1 115 60 3 16.1

1

Page 5

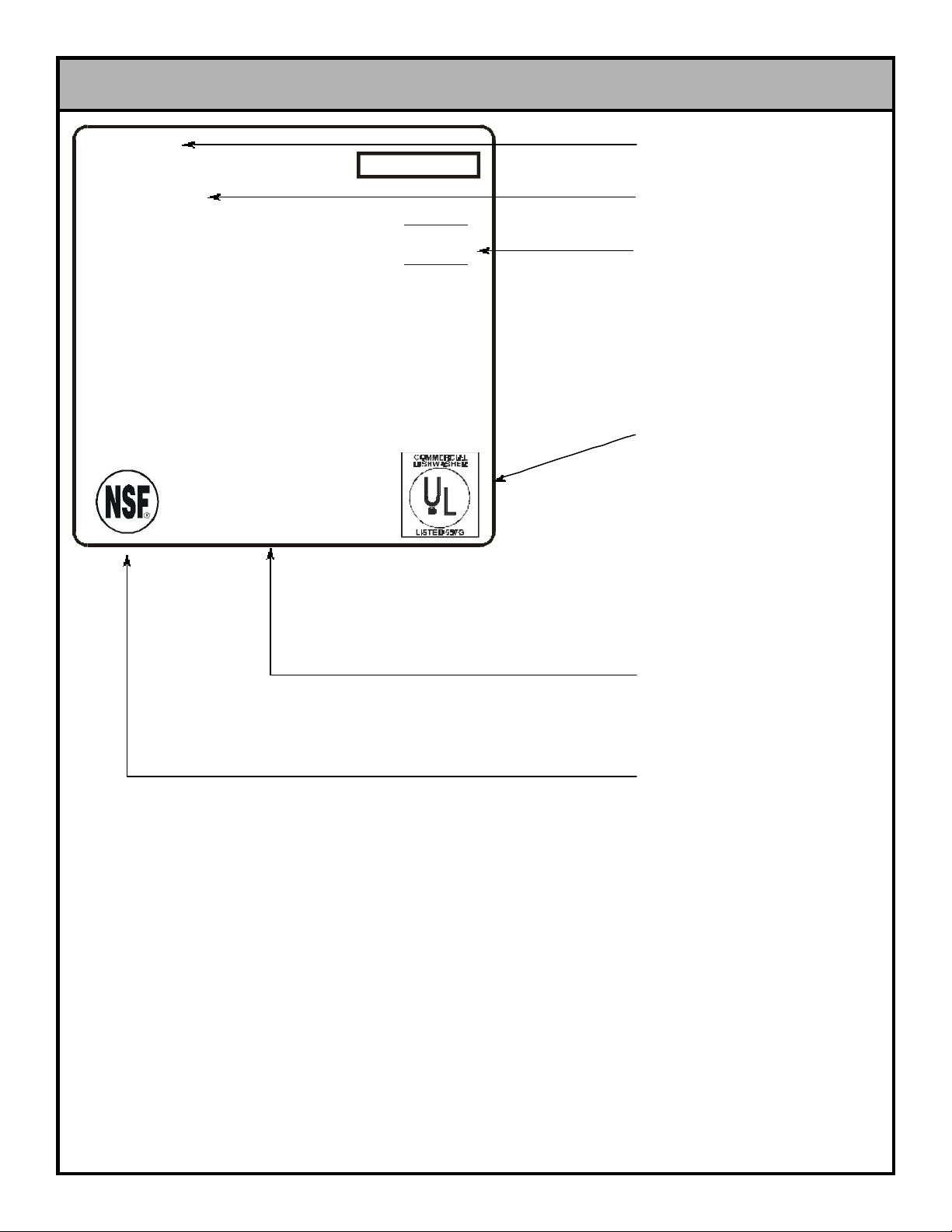

DETAIL OF THE WHIRL WIZARD DATA PLATE

SERIAL NO.:

MODEL:

WASH MOTOR:

HEATER:

TOTAL LOAD

CONNECT TO A MINIMUM 20 AMP SUPPLY - CIRCUIT

PROTECTED WITH A 20 AMP NONTIME - DELAY FUSE

OR OVERCURRENT PROTECTOR

60Hz 1 PH 2 WIRE

1 HP

.4 KW

115 VOLT

13.3 AMPS

2.8 AMPS

16.1 AMPS

MANUFACTURER’S

LOGO

MODEL DESIGNATION

(I.E. “WHIRL WIZARD”)

AMPERAGE LOAD

INFORMATION

UL LOGO (SEE NOTE #1)

MANUFACTURERS

ADDRESS INFORMATION

NSF LOGO (SEE NOTE #2)

The data plate is located on the unit cover. Under no circumstance should the data plate be removed from the unit. The data plate is

essential in identifying the particular characteristics of your machine and is of great benefit to installers, operators, and maintenance

personnel. Do not use the above data plate to represent your machine. The data plate above is a generic representation used only

to show you where to locate information.

2

Page 6

GENERAL NOTES SECTION

Before connecting, operating, or adjusting any of the dishmachines covered in this manual, please carefully read through the entire

manual to familiarize yourself with the machine and its proper operation. This manual contains important operating, safety, and maintenance information concerning your dishmachine. You must follow the instructions and guidelines provided in this manual to ensure

that your warranty remains in effect.

FOR SERVICE PERSONNEL: Jackson MSC Inc. provides technical support for all of the dishmachines detailed in this manual. We

strongly recommend that you refer to this manual before making a call to our technical support staff. Please have this manual with you

when you call so that our staff can refer you, if necessary, to the proper page. Technical support is avaliable from 8:00 a.m. to 5:00 p.m.

(EST), Monday through Friday. Technical support is not available on holidays. Contact technical support toll-free at 1-888-800-5672.

Please remember that technical support is available for service personnel only. Non-service personnel should refer to the list of provided service agencies in this manual for local service support.

NOTES CONCERNING THE DATA PLATES:

This area of the data plate denotes the minimum parameters that must be met in order for your dishmachine to operate at the designed

level of efficiency. Not meeting the required parameters can result in substandard performance of the dishmachine. Do not refer to the

data plate example in this manual for the parameters of your machine; instead, refer to the data plate affixed to the machine. Not every

machine operates the same way. If you are unsure of whether or not you are meeting the required minimum parameters, contact your

nearest Jackson authorized service agency.

NOTE 1: The UL logo on the data plate indicates that this machine is Listed by Underwriters Laboratories Inc. Representative samples

of this product have been evaluated by UL and meet applicable UL Standards and requirements. For more information concerning the

UL logo and UL standards in general, you may visit them on the internet at www.ul.com.

NOTE 2: The NSF logo on the data plate indicates that this machine has been listed under NSF Standard 2 as having met the requirements of that standard. All of Jackson’s NSF-approved machines are listed on the NSF website at www.nsf.org.

3

Page 7

INSTALLATION INSTRUCTIONS

VISUAL INSPECTION: Before installing the unit, check the container and machine for damage. A damaged container is an indicator that the machine may have been hadled roughly during shipping. If there is damage to both the container and the machine, do

not throw away the container. The machine has been inspected at

the factory and is expected to arrive to you in new, undamaged

condition. However, rough handling by carriers or others may

have resulted in damage occuring to the machine. If such a situation does occur, do not return the unit to Jackson. Instead contact

both the dealer you purchased the unit through and the carrier.

Ask the carrier to send a representative out to inspect the damage

and make a report of it. You normally have 48 hours to contact a

carrier to report damages, but this varies based on locale. The

best advice is to contact your carrier and dealer as soon as damage is discovered.

UNPACKING THE MACHINE: Once the machine has been

removed from the container, ensure that there are no obvious

missing parts. This may not be apparent at first glance. If you discover that a part is missing, contact Jackson MSC Inc. immediately.

LEVEL THE MACHINE:

1. Position the Whirl Wizard under the sink drainboard.

2. Adjust left to right and front to back.

3. Align inlet and outlet tubes with plumbing from main flow chamber (item 2).

4. To adjust the height, loosen the allen screws in each leg socket connector.

5. Slide leg out to desired height. The drain connection on the

machine should be at the same level as the sink drain connection.

6. Tighten the allen head screws in each leg socket connector.

7. Fine adjustments in height can be made by turning the bullet

foot in each leg.

INSTALLING THE MACHINE:

1. Locate the sink at the highest end of the drain slope.

7. Tighten the screws in item 6 until the assembly is held in place.

Care must be taken to position screws where they are accessible

and will not be covered by the hose barb when assembled into the

main flow chamber.

8. In the bottom of the main flow chamber (item 2), install the 11/2” NPT close nipple (item 10).

9. The 1-1/2” NPT tee (item 9) is screwed onto the 1-1/2” nipple

(item 10).

10. From the tee (item 9) to the drain, install the following items:

1-1/2” close nipple (item 10) and 1-1/2” ball valve (item 11). Make

sure the handle of the ball valve (item 11) is easily accessible by

the operator.

11. On the sink side of the tee (item 9) install a 1-1/2” NPT hose

barb (item 12).

12. On the inlet side of the main flow chamber (item 2) install a 1”

NPT hose barb (item 8).

13. With different styles and types of sinks, the directional manifold (item 1) may require modification. The directional tubing may

need to be bent to conform to the bottom of the sink or reduced in

length. Since it is fabricated from thin wall stainless steel, a hacksaw can be used to cut the tubing.

HOSE CONNECTIONS:

1. Position the 1-1/2” ID intake line hose (item 13) with the Whirl

Wizard as xlose to the sink as possible, mark and cut to the length

required.

2. Repeat with the 1” ID discharge line hose (item 14).

3. Connect the intake and discharge line hoses with hose clamps

(item 15) to their respective connections.

NOTE: ENSURE THAT THE HOSE CLAMPS ARE TIGHT

BEFORE OPERATING THE UNIT.

CAUTION: IF DIRECT FLOOR DRAIN IS UNDER OR NEAR

MACHINE, MAKE CERTAIN THAT ADEQUATE PROTECTION IS

PROVIDED TO PREVENT WATER SPLATTER FROM DAMAG ING THE UNIT.

2. Disconnect the existing drain plumbing from the sink.

3. Remove the crumb cup.

4. Clean off old plumber’s putty from the sink. Add fresh putty to

the sink flange.

5. Position the main flow chamber (item 2) through the bottom of

the sink. From the bottom, slip the rubber washer (item 3), fiber

washer (item 4), back-up flange (item 5) and mounting flange

(item 6) on the main flow chamber.

6. Once in position, mount the jam spring (item 7) on to the main

flow chamber. This will hold items 3 through 5 in place.

ELECTRICAL POWER CONNECTION:

1. The Whirl Wizard requires a dedicated 20 amp, 115 volt single

phase circuit.

2. A 20 amp NEMA 5-20R receptacle is required for the NEMA 520P cord set and plug shipped with the machine.

CAUTION: A NEMA 5-20R RECEPTACLE IS REQUIRED. IF

NOT AVAILABLE A QUALIFIED ELECTRICIAN SHOULD

INSTALL THE CORRECT RECEPTACLE.

4

Page 8

INSTALLATION ASSEMBLY

1542" Hose Clamp

4730-011-83-17

1

2

8

3

4

5

6

11 12

910

14

15

7

13

ITEM QTY DESCRIPTION MFG No.

1 1 Directional Manifold 5700-031-70-49

2 1 Main Flow Chamber 5700-031-83-05

3 1 Rubber Washer, 3-1/2" Diameter 5330-011-70-87

4 1 Fiber Washer, 3-1/2" Diameter 5330-011-70-48

5 1 Flange, Back-Up 5340-011-83-13

6 1 Mounting Flange 5340-011-83-14

7 1 Spring, Jam 5340-011-83-04

8 1 Hose Barb, 1" NPT to 1" Hose PVC 4730-011-70-36

9 1 Tee, 1-1/2" FNPT, Stainless Steel 4730-011-70-39

10 2 Nipple, Close, 1-1/2" NPT, Stainless Steel 4730-011-70-86

11 1 Ball Valve Assembly 5700-011-70-40

Ball Valve Only 4820-111-71-46

Handle Only 5700-021-70-45

12 1 Hose Barb, 1-1/2" NPT x 1-1/2" PVC 4730-011-70-38

13 1 Hose, 1-1/2" ID x 2'-0" Long 5700-021-69-20

14 1 Hose, 1" ID x 2'-0" Long 5700-021-69-19

5

Page 9

OPERATION INSTRUCTIONS

OPERATION:

1. Install the directional manifold (item 1) into the main flow chamber (item 2).

2. Fill the sink with hot water.

3. Add the proper chemicals (non-foaming detergent) for soaking pots, pans and utensils.

4. Pre-scrap pots, pans and utensils of all large loose soil.

NOTE: THE WHIRL WIZARD POT SINK IS NOT A GARBAGE DISPOSAL! IT IS INTENDED TO SOFTEN SOIL WHICH IS DIFFICULT

TO REMOVE. BAKED-ON SOIL MAY STILL REQUIRE ADDITIONAL EFFORT TO REMOVE.

5. With the power switch in the ON position, place the soiled pots, pans and utensils into the sink.

NOTES: PLACEMENT OF POTS AND PANS SHOULD BE DONE IN A MANNER THAT NOTHING WILL OBSTRUCT THE MAIN

FLOW OF WATER.

6. Allow pots, pans and utensils to soak for 15 to 20 minutes to soften and loosen soil.

CLEANING INSTRUCTIONS:

1. Turn the power switch to the OFF position.

2. Turn the ball valve to the open position and drain the sink.

3. When the sink is empty, remove the directional manifold (rotate counter-clockwise) and clean.

4. Re-install the directional manifold into the main flow chamber.

CHANGING DIRECTION OF MACHINE INSTALLATION:

1. Remove the cover from the Whirl Wizard.

2. Remove the power switch from the side and insert into the pre-punched hole in the opposite end of the unit.

3. To extend the wiring, cut the tie wraps. There is sufficient length to allow the power switch to be relocated.

4. Re-install the cover.

6

Page 10

19

201Decal, Whirl Wizard Logo, Right (Not Shown)

9905-021-70-59

18

17

MAIN ASSEMBLY

1

2

3

15

5

4 16

6

8, 9 7 14

12 10

ITEM QTY DESCRIPTION MFG No.

1 1 Cover Assembly 5700-021-70-31

2 1 Box Bottom 5700-031-67-89

3 2 Screw, 10-32 x 1/2" Long, Truss Head 5305-011-39-36

4 4 Leg Assembly with Bullet Foot 5700-021-67-93

5 4 Bullet Foot 5340-108-01-03

6 1 Pump and Motor Assembly 6105-021-69-18

7 1 Chopper Assembly 5700-021-70-32

8 4 Locknut, 1/4"-20 with Nylon Insert 5310-374-01-00

9 4 Flat Washer, 1/4" 5311-174-01-00

10 1 Inlet Plumbing 5700-031-68-31

11 1 "J" Tube, Outlet 5700-021-68-60

12 1 Suction Connector Tube 5700-011-70-33

13 1 Discharge Connector Tube 5700-011-70-34

14 4 Hose Clamp, 2" 4730-719-01-37

15 1 Heater, Flexible, 120 Volts, 400 Watts 4540-021-70-21

16 1 Contactor, Motor 5945-109-05-69

17 1 Power Switch 5930-011-82-72

18 1 Power Cord 6145-011-70-28

19 1 Decal Whirl Wizard Logo, Left 9905-021-70-64

7

Page 11

ORDERING REPLACEMENT WIRE

ORDERING REPLACEMENT WIRE FOR YOUR DISHMACHINE

Jackson dishmachines have several color and gauges of wire used in them and it may become necessary to replace these wires.

Wire may be ordered from Jackson MSC Inc., but please note that it is only available in feet. Ensure that you order the correct color

and guage.

BLACK WIRE:

RED WIRE:

6 Gauge 6145-002-15-91

8 Gauge 6145-104-43-00

10 Gauge 6145-104-16-00

12 Gauge 6145-112-01-00

14 Gauge 6145-104-09-00

18 Gauge 6145-104-01-97

18 Gauge with Orange Stripes 6145-011-35-66

18 Gauge with White Stripes 6145-011-35-65

18 Gauge with Yellow Stripes 6145-011-35-64

BLUE WIRE:

6 Gauge 6145-002-15-92

8 Gauge 6145-104-45-00

10 Gauge 6145-104-08-00

14 Gauge 6145-104-05-00

18 Gauge 6145-104-37-00

18 Gauge with Black Stripes 6145-011-59-56

18 Gauge with Blue Stripes 6145-011-81-74

18 Gauge with White Stripes 6145-011-81-73

18 Gauge with Yellow Stripes 6145-011-81-75

20 Gauge 6145-104-02-97

6 Gauge 6145-002-15-93

8 Gauge 6145-104-44-00

10 Gauge 6145-104-42-00

14 Gauge 6145-104-04-00

18 Gauge 6145-104-35-00

18 Gauge with Black Stripes 6145-011-46-35

18 Gauge with Red Stripes 6145-011-46-37

18 Gauge with White Stripes 6145-011-46-36

18 Gauge with Yellow Stripes 6145-011-46-38

20 Gauge 6145-104-06-97

20 Gauge with Black Stripes 6145-104-17-97

20 Gauge with White Stripes 6145-104-13-97

GREEN WIRE:

8 Gauge 6145-002-15-94

14 Gauge 6145-104-03-00

18 Gauge 6145-104-32-00

18 Gauge with Yellow Stripes 6145-001-44-96

20 Gauge 6145-104-05-97

20 Gauge with Black Stripes 6145-011-59-57

20 Gauge with Yellow Stripes 6145-104-11-97

GREY WIRE:

18 Gauge 6145-104-36-00

18 Gauge with Black Stripes 6145-011-81-71

18 Gauge with Blue Stripes 6145-011-81-72

18 Gauge with Red Stripes 6145-011-46-41

18 Gauge with White Stripes 6145-011-35-60

18 Gauge with Yellow Stripes 6145-011-46-42

20 Gauge 6145-104-03-97

WHITE WIRE:

10 Gauge 6145-104-19-00

14 Gauge 6145-104-10-00

18 Gauge 6145-104-39-00

18 Gauge with Black Stripes 6145-011-35-70

18 Gauge with Blue Stripes 6145-011-46-40

18 Gauge with Green Stripes 6145-011-35-69

18 Gauge with Grey Stripes 6145-002-20-18

18 Gauge with Red Stripes 6145-011-35-67

18 Gauge with Yellow Stripes 6145-011-35-68

20 Gauge 6145-104-04-97

20 Gauge with Orange & Yellow Stripes 6145-104-16-97

20 Gauge with Yellow Stripes 6145-104-15-97

YELLOW WIRE:

18 Gauge 6145-104-33-00

18 Gauge with Black Stripes 6145-011-81-68

18 Gauge with Blue Stripes 6145-011-81-70

18 Gauge with Red Stripes 6145-011-81-69

20 Gauge 6145-104-07-97

8

Page 12

ORDERING REPLACEMENT WIRE (CONTINUED)/CONDUIT & FITTINGS

MISCELLANEOUS WIRE:

Brown (18 Gauge) 6145-104-20-00

Brown (20 Gauge) 6145-104-08-97

Orange (18 Gauge) 6145-104-34-00

Orange with Black Stripes (18 Gauge) 6145-011-35-62

Orange with Blue Stripes (18 Gauge) 6145-011-46-39

Orange with White Stripes (18 Gauge) 6145-011-35-63

Orange with Yellow Stripes (18 Gauge) 6145-011-35-61

Orange (20 Gauge) 6145-104-10-97

Pink (18 Gauge) 6145-011-82-69

Purple (18 Gauge) 6145-104-31-00

Violet (20 Gauge) 6145-104-09-97

Plug, GFI 6145-001-97-90

Cable, 16 Gauge, 3 Wire Romex 6145-001-98-29

Cord, Hubble Plug MC 6145-011-47-23

Cord, S-J 6145-011-49-02

Cord, Power 6145-011-70-28

Cord, 115V Power 6145-309-02-00

Cord, 125V Power, 96 “ Long 6145-309-04-00

CONDUIT AND RELATED FITTINGS

Jackson dishmachines come with a wide variety of conduit and fittings for use in routing the wires of the machine. The list below

provides for most of stock of such items. When ordering, remember that Jackson does not offer pre-cut sections of conduit for your

machine, instead it is sold by the foot. Please take into account in slack that will be necessary once installing the new conduit to

ensure that it fits correctly. It is recommended that you order at least 6” more conduit than you require to ensure that you have

enough for trimming.

CONDUIT:

Conduit, 1/2”, Liquidtite 5975-101-25-00

Conduit, 1/2”, Non-Metallic 5975-111-46-57

Conduit, 1/2”, PVC 5975-105-04-00

Conduit, 1/2”, Sealtite 5975-105-01-00

Conduit, 1/2”, Xtraflex 5975-105-06-44

Conduit, 3/8”, Liquidtite 5975-105-02-00

Conduit, 3/4”, Cole-Flex 5975-105-05-00

Conduit, 3/4”, Liquidtite 5975-105-03-00

Conduit, 3/4”, Non-Metallic 5975-011-47-71

Conduit, 3/4” Xtraflex 5975-105-07-44

Conduit, 1”, Carlon 5975-011-68-42

CONDUIT FITTINGS:

Elbow, Cole-Flex, 1/2”, 90 Degree 5975-205-40-00

Elbow, Xtraflex, 1/2”, 90 Degree 5975-205-44-44

Elbow, Xtraflex, 3/4”, 90 Degree 5975-205-45-44

Fitting, 1/2” Straight 5975-011-45-13

Fitting, 1/2”, Straight, Zinc Plated 5975-111-89-89

Fitting, 1/2”, 45 Degree 5975-011-45-23

Fitting, 1/2”, 45 Degree, Zinc Plated 5975-111-89-86

Fitting, 1/2”, 90 Degree 5975-011-45-14

Fitting, 1/2”, 90 Degree, Zinc Plated 5975-111-89-88

Fitting, 3/4”, Straight 5975-011-47-72

Fitting, 3/4”, 45 Degree 5975-011-47-74

Fitting, 3/4”, 90 Degree 5975-011-47-73

Fitting, 1”, Straight 5975-011-70-75

Fitting, 1”, 90 Degree 5975-011-68-43

Fitting, Cole-Flex, 1/2” Straight 5975-205-03-00

Fitting, Cole-Flex, 3/4” Straight 5975-205-41-00

Fitting, Cole-Flex, 3/4”, 90 Degree 5975-204-42-00

Fitting, Liquidtite, .231 ID/.394 OD 5975-011-49-03

Fitting, Liquidtite, .25 ID/.546 OD 5975-011-65-51

Fitting, Liquidtite, .27 ID/.48 OD 5975-011-59-50

Fitting, Liquidtite, 1/2”, 90 Degree 5975-111-01-00

Fitting, Liquidtite, 3/8”, Straight 5975-205-03-82

Fitting, Liquidtite, 3/8”, 90 Degree 5975-205-02-82

Fitting, Liquidtite, 3/4”, Straight 5975-205-15-02

Fitting, Liquidtite, 3/4”, 45 Degree 5975-205-01-82

Fitting, Liquidtite, 3/4”, 90 Degree 5975-205-07-82

Fitting, Xtraflex, 1/2”, Straight 5975-205-47-44

Fitting, Xtraflex, 3/4”, Straight 5975-205-46-44

Nut, 1-1/4” 5975-011-42-54

9

Page 13

ORDERING REPLACEMENT FASTENERS

Dishmachines come with a variety of fasteners used to hold them together. On the following pages will be comprehensive list of all

of the fasteners you may order. Jackson reserves the right to require minimum quantities to be ordered.

SCREWS:

Screw, 1/4”-20 x 1/4”, Set 5305-002-10-14

Screw, 1/4”-20 x 1/2”, Phillips Truss Head 5305-174-03-00

Screw, 1/4”-20 x 1/2”, Set Screw 5305-011-71-51

Screw, 1/4”-20 x 1/2”, Slotted Truss Head 5305-002-22-81

Screw, 1/4”-20 x 1/2”, Thumb 5305-011-38-62

Screw, 1/4”-20 x 1/2”, with Rubber Washer 5305-974-01-00

Screw, 1/4”-20 x 5/8”, 80 Deg CSink 5305-002-20-30

Screw, 1/4”-20 x 5/8”, Hex Head 5305-274-24-00

Screw, 1/4”-20 x 5/8”, Phillips Truss Head 5305-174-04-00

Screw, 1/4”-20 x 1-1/8”, Hex Head 5305-274-21-00

Screw, 1/4”-20 x 1-1/4”, Flat Head 5305-174-19-00

Screw, 1/4”-20 x 1-3/8”, Hex Head 5305-274-19-00

Screw, 1/4”-20 x 1-1/2”, Flat Head 5305-174-11-00

Screw, 1/4”-20 x 1-1/2”, Hex Head 5305-274-23-00

Screw, 1/4”-20 x 1-1/2”, Phillips Head 5305-011-44-50

Screw, 1/4”-20 x 1-1/2”, Slotted Truss Hd 5305-002-22-82

Screw, 1/4”-20 x 1-3/4”, Hex Head 5305-274-10-00

Screw, 1/4”-20 x 3-3/4”, Hex Head 5305-011-93-68

Screw, 5/16”-18 x 1/2”, Hex Head 5306-011-88-67

Screw, 5/16”-18 x 1-1/4”, Flat Head 5305-011-83-49

Screw, 3/8”-16 x 1”, Socket Head 5305-356-04-00

Screw, 3/8”-16 x 1-1/4”, Hex Head Plated 5305-256-04-00

Screw, 3/8”-16 x 2”, Cap 5305-011-74-98

Screw, 4-40 x 1/4”, Phillips Pan Head 5305-011-36-92

Screw, 4-40 x 3/8”, Phillips Truss Head 5305-011-59-70

Screw, 4-40 x 1/2” Phillips Pan Head 5305-011-38-19

Screw, 4-40 x 5/8” Phillips Truss Head 5305-011-49-70

Screw, 4-40 x 3/4”, Phillips Pan Head 5305-011-59-64

Screw, 4-40 x 1”, Slotted Pan Head 5305-179-01-00

Screw, 6-32 x 1/4”, Flat Head 5305-171-01-00

Screw, 6-32 x 1/4”, Round Head 5305-151-02-00

Screw, 6-32 x 1/2”, Phillips Head 5305-171-15-00

Screw, 6-32 x 1/2”, Phillips Truss Head 5305-011-39-34

Screw, 6-32 x 3/8”, Phillips Head 5305-171-02-00

Screw, 6-32 x 3/8”, Phillips Round Head 5305-171-07-00

Screw, 6-32 x 5/8”, Phillips Round Head 5305-011-39-85

Screw, 6-32 x 3/4”, Round Head 5305-171-03-00

Screw, 6-32 x 3/4”, Phillips Pan Head 5305-011-37-05

Screw, 6-32 x 7/8”, Phillips Round Head 5305-171-10-00

Screw, 8-32 x 1/4”, Phillips Pan Head 5305-172-09-00

Screw, 8-32 x 1/4”, Slotted Round Head 5305-172-01-00

Screw, 8-32 x 3/8”, Phillips Flat Head 5305-776-03-00

Screw, 8-32 x 3/8”, Phillips Flat Head 5305-011-37-07

Screw, 8-32 x 3/8”, Round Head 5305-172-02-00

Screw, 8-32 x 1/2”, Hex Head 5305-002-02-87

Screw, 8-32 x 1/2”, Phillips Flat Head 5305-011-37-06

Screw, 8-32 x 3/4”, Phillips Round Head 5305-172-06-00

Screw, 10-24 x 3/8”, Flat Head Undercut 5305-773-02-00

Screw, 10-24 x 3/8”, Phillips Truss Head 5305-173-03-00

Screw, 10-24 x 1/2”, Phillips Truss Head 5305-173-18-00

Screw, 10-24 x 1/2”, Set 5305-473-02-00

Screw, 10-24 x 5/8”, Hex Head 5305-011-40-89

Screw, 10-24 x 3/4”, Hex Head 5305-273-05-00

Screw, 10-24 x 2-1/4”, Hex Head 5305-011-38-10

Screw, 10-32 x 1/4”, Round Head 5305-173-01-00

Screw, 10-32 x 3/8”, Phillips Pan Head 5305-173-26-00

Screw, 10-32 x 3/8”, Phillips Truss Head 5305-173-12-00

Screw, 10-32 x 3/8”, Round Head, Slotted 5305-173-02-00

Screw, 10-32 x 1/2”, Phillips Flat Head 5305-011-44-51

Screw, 10-32 x 1/2”, Phillips Pan Head 5305-011-44-52

Screw, 10-32 x 1/2”, Phillips Truss Head 5305-011-39-36

Screw, 10-32 x 1/2”, Self Tapping 5305-011-62-69

Screw, 10-32 x 1/2”, Slotted Truss 5305-173-04-00

Screw, 10-32 x 5/8”, Fillister Head 5305-973-02-00

Screw, 10-32 x 3/4”, Shoulder, .25 Shoulder 5305-011-86-65

Screw, 10-32 x 3/4”, Phillips Truss Head 5305-011-62-17

Screw, 10-32 x 3/4”, Phillips Truss Head 5305-011-49-33

Screw, 10-32 x 7/8”, Fillister Head 5305-973-04-00

Screw, 10-32 x 7/8”, Hex Head 5305-279-01-00

Screw, 10-32 x 1”, Phillips Pan Head 5305-002-19-42

Screw, 10-32 x 1-1/8” Fillister Head 5305-973-03-00

Screw, 10-32 x 1-1/4”, Phillips Truss Head 5305-011-66-03

Screw, 10-32 x 1-1/4”, Socket Head 5305-356-16-00

Screw, 10-32 x 1-1/2”, Fillister Head 5305-973-01-00

Screw, 10-32 x 1-3/4”, Phillips Pan Head 5305-011-62-67

Screw, 10-32 x 1-3/4”, Self Tapping 5305-011-59-92

BOLTS:

Bolt, 1/4”-20 x 3/8”, Hex Head 5305-274-20-00

Bolt, 1/4”-20 x 1/2”, Hex Head 5305-274-02-00

Bolt, 1/4”-20 x 3/4”, Hex Head 5305-274-04-00

Bolt, 1/4”-20 x 7/8”, Hex Head 5305-274-05-00

Bolt, 1/4”-20 x 1”, Hex Head 5305-254-06-00

Bolt, 1/4”-20 x 1-1/4”, Hex Head 5305-274-22-00

Bolt, 1/4”-20 x 2”, Hex Head 5306-011-84-72

Bolt, 1/4”-20 x 2-1/4”, Hex Head 5305-011-30-50

Bolt, 1/4”-20 x 2-1/2”, Hex Head 5306-011-83-52

Bolt, 1/4”-20 x 2-3/4”, Hex Head 5306-011-46-62

Bolt, 1/4”-20 x 3-1/4”, Hex Head 5306-002-05-55

Bolt, 5/16”-18 x 5/8”, Hex Head 5305-275-09-00

Bolt, 5/16”-18 x 3/4”, Hex Head 5305-275-04-00

Bolt, 5/16”-18 x 1” , Hex Head 5305-275-06-00

Bolt, 5/16”-18 x 1-1/4”, Hex Head 5305-275-10-00

Bolt, 3/8”-16 x 3/4”, Hex Head 5306-011-71-60

Bolt, 3/8”-16 x 7/8”, Hex Head 5306-011-36-95

Bolt, 3/8”-16 x 1”, Hex Head 5305-276-03-00

Bolt, 3/8”-16 x 1”, Hex Head, Plated 5305-256-03-00

Bolt, 3/8”-16 x 1-1/4”, Hex Head 5305-276-10-00

Bolt, 3/8”-16 x 1-3/4”, Hex Head 5306-011-36-94

Bolt, 3/8”-16 x 2-1/4”, Hex Head 5306-011-95-12

Bolt, 3/8”-16 x 2-3/4”, U-Bolt 5306-011-51-34

Bolt, 3/8”-16 x 4”, Hex Head 5306-956-02-00

Bolt, 1/2”-13 x 1-3/4” 5305-011-71-94

Bolt, 10-24 x 3/8”, Hex Head 5306-011-63-29

Bolt, 10-32 x 3/8” 5306-011-62-45

10

Page 14

ORDERING REPLACEMENT FASTENERS (CONTINUED)

LOCKWASHERS:

Lockwasher, 1/4”, Split 5311-274-01-00

Lockwasher, 3/8”, Split 5311-276-01-00

Lockwasher, 3/8”, Split 5311-256-01-00

Lockwasher, 5/8” 5311-278-02-00

Lockwasher, 5/16”, Split 5311-275-01-00

Lockwasher, 5/16”, Split, Cad Plated 5311-255-01-00

Lockwasher, #4, External Tooth 5311-011-59-70

Lockwasher, #6 External Tooth 5311-271-02-00

Lockwasher, #8 5311-272-02-00

Lockwasher, #8, External Tooth 5311-272-01-00

Lockwasher, #8, Internal Tooth 5311-272-03-00

Lockwasher, #10, External Tooth 5311-273-02-00

Lockwasher, #10, Internal Tooth 5311-273-03-00

Lockwasher, #10, Split 5311-273-01-00

FLAT WASHERS:

Washer, Flat, Brass, 3/32” ID 5311-129-08-00

Washer, Flat, Brass, 1/4” ID 5311-129-09-00

Washer, 1/4” ID x 3/4” OD 5311-011-76-30

Washer, Flat, 5/16” ID 5311-175-01-00

Washer, Flat, Brass, 5/16”, Cadplated 5311-156-01-00

Washer, Flat, S/S, 3/8” ID 5311-176-01-00

Washer, 3/8” ID x 9/16” OD 5311-011-71-49

Washer, 1/2” ID x 1” OD x 1/8” Thick 5311-011-71-48

Washer, 1/2” ID x 1-5/16” OD, Cadplated 5311-157-01-00

Washer, Nylon, .51” ID x .76” OD 5311-011-62-65

Washer, Flat, S/S, 11/16 “ ID x 1/2” OD 5311-178-01-00

Washer, 7/8” ID x 1-1/2” OD 5311-011-35-37

Washer, Flat, 1/4” ID 5311-174-01-00

Washer, Flat, #10 5311-173-02-00

LOCKNUTS:

Locknut, 1/4”-20 with Nylon, High Profile 5310-374-01-00

Locknut, 1/4”-20 with Nylon, Low Profile 5310-374-02-00

Locknut, 5/16”-24 with Nylon, High Profile 5310-375-01-00

Locknut, 5/16”-24 with Nylon, Low Profile 5310-374-03-00

Locknut, 3/8”-16, with Nylon, High Profile 5310-011-72-55

Locknut, 3/8”-16, with Nylon, Low Profile 5310-376-02-00

Locknut, 4-40, with Nylon 5310-279-06-00

Locknut, 6-32, with Nylon 5310-373-03-00

Locknut, 10-24, with Nylon 5310-373-01-00

Locknut, 10-32, with Nylon 5310-373-02-00

HEX NUTS:

Nut, Hex, 1/4”-20 5310-274-01-00

Nut, Hex, 1/4”-20, Cad Plated 5310-254-01-00

Nut, Hex, 5/16”-18 5310-275-01-00

Nut, Hex, 5/16”-18, Cad Plated 5310-255-01-00

Nut, Hex, 3/8”-16 5310-276-02-00

Nut, Hex, 3/8”-16, Cad Plated 5310-256-02-00

Nut, Hex, 1/2”-13 5310-011-72-58

Nut, Hex, 6-32 5310-271-01-00

Nut, Hex, 8-32 5310-272-01-00

Nut, Hex, 10-24 5310-273-02-00

Nut, Hex, 10-32 5310-273-01-00

MISCELLANEOUS NUTS:

Nut, 1/4”-20, Acorn 5310-174-01-00

Nut, 1/4”-20, Hex, Serrated 5310-011-66-49

Nut, 1/4”-20, Wing, Nylon 5310-994-01-00

Nut, 5/16”-18, Keps 5310-955-01-00

Nut, 5/8”-18, Brass 5310-228-01-11

Nut, 6-32, Keps 5310-002-24-29

Nut, 10-24, Hex Cap 5310-173-01-00

Nut, 10-24, Wing, Nylon 5310-993-01-00

11

Page 15

JACKSON MAINTENANCE & REPAIR CENTERS (USA)

ALABAMA

Jones-McLeod Appliance

1616 7th Avenue North

Birmingham, AL 35203

(205) 251-0159

(800) 821-1150

(205) 322-1440 fax

Jones-McLeod Appliance

854 Lakeside Drive

Mobile, AL 36693

(334) 666-7278

(800) 237-9859

(334) 661-0223 fax

ALASKA

Restaurant Appliance Service

7219 Roosevelt Way NE

Seattle, WA 98115

(206) 524-8200

(800) 433-9390

(206) 525-2890 fax

ARIZONA

GCS Service, Inc. #78

5052 South 40th Street

Phoenix, AZ 85040

(602) 474-4510

(800) 510-3497

(602) 470- 4511 fax

Authorized Commercial

Food Equipment Service

4832 South 35th St.

Phoenix, AZ 85040

(602) 234-2443

(800) 824-8875

(602) 232-5862 fax

ARKANSAS

Bromely Parts & Service

10th & Ringo

P.O. Box 1688

Little Rock, AR 72202

(501) 374-0281

(800) 482-9269

(501) 374-8352 fax

Commercial Parts & Service

3717 Cherry Road

Memphis, TN 38118

(901) 366-4587

(800) 262-9155

(901) 366-4588 fax

CALIFORNIA

P & D Appliance

4220-C Roseville Road

North Highlands, CA 95660

(916) 974-2772

(800) 824-7219

(916) 974-2774

CALIFORNIA (cont)

P & D Appliance

100 South Linden Avenue

S. San Francisco, CA 94080

(650) 635-1900

(800) 424-1414

(650) 635-1919 fax

Barkers Food

Machinery Equipment

5367 Second Street

Irwindale, CA 91706

(626) 960-9390

(800) 258-6999

(626) 337-4541 fax

GCS Service, Inc. #24

1100 East Pico Blvd

Los Angeles, CA 90021

(213) 683-2090

(800) 327-1433

(213) 683-2099 fax

GCS Service, Inc. #24

650 S. Grand Avenue

Suite 111

Santa Ana, CA 92705

(714) 542-1798

(800) 540-0719

(714) 542-4787 fax

GCS Service, Inc. #52

360 Littlefield

S. San Francisco, CA 94080

(650) 635-0720

(800) 969-4427

(650) 871-4019 fax

GCS Service, Inc. # 84

9030 Kenamar Drive

Suite 313

San Diego, CA 92121

(858) 549-8411

(800) 422-7278

(858) 549-2323 fax

COLORADO

GCS Service, Inc. #60

4251 S. Natches Ct.

Unit C

Sheridan, Co 80110

(303) 371-9054

(800) 972-5314

Metro Appliance Service

1640 South Broadway

Denver, CO 80210

(303) 778-1126

(800) 525-3532

(303) 778-0268 fax

CONNECTICUT

GCS Service, Inc. #06

302 Murphy Road

Hartford, CT 06114

(860) 549-5575

(800) 423-1562

(860) 527-6355 fax

DELAWARE

Food Service Equipment

2101 Parkway South

Broomall, PA 19008

(610) 356-6900

(610) 356-2038 fax

GCS Service, Inc. #44

817 N. Third Street

P.O. Box 3564

Philadelphia, PA 19123

(215) 925-6217

(800) 441-9115

(215) 925-6208 fax

Elmer Schultz Service

36 Belmont Ave.

Wilmington, DE 19804

(302) 655-8900

(800) 225-0599

(302) 656-3673 fax

EMR Service Division

106 Willamsport Circle

Salisbury, MD 21804

(410) 543-8197

(410) 543-4038 fax

FLORIDA

GCS Service, Inc. #15

3373 N. W. 168th Street

Miami, FL 33056

(305) 621-6666

(800) 766-8966

(305) 621-6656 fax

Commercial Appliance Service

8416 Laurel Fair Circle

Building 6, Suite 114

Tampa, FL 33610

(813) 663-0313

(800) 282-4718

(813) 663-0212 fax

GCS Service, Inc. #14

3902 Corporex Park Drive

Suite 350

Tampa, FL 33619

(813) 626-6044

(800) 282-3008

(813) 621-1174

12

Page 16

JACKSON MAINTENANCE & REPAIR CENTERS (USA)

FLORIDA (cont)

GCS Service, Inc. # 13

4305 Vineland Road

Suite G-12

Orlando, FL 32811

(407) 841-2551

(800) 338-7322

(407) 423-8425 fax

Jones-McLeod Appliance

854 Lakeside Drive

Mobile, AL 36693

(334) 666-7278

(800) 237-9859

(334) 661-0223 fax

GEORGIA

GCS Service, Inc. #16

3127Presidential Dr.

Atlanta, GA 30340

(770) 452-7322

(300) 334-3599

(770) 452-7473 fax

Southeastern

Restaurant Service

2200 Norcross Pkwy,

Suite 210

Norcross, GA 30071

(770) 446-6177

(800) 235-6516

(770) 446-3157 fax

Whaley Foodservice Repairs

109-A Owens Industrial Drive

Savannah, GA 31405

(912) 447-0827

(888) 765-0036

(912) 447-0826 fax

HAWAII

Food Equipment Parts &

Service Co.

300 Puuhale Road

Honolulu, HI 96819

(808) 847-4871

(808) 842-1560 fax

IDAHO

Ron’s Service

703 E. 44th Street, Suite 10

Garden City, ID 83714

(208) 375-4073

(208) 375-4402 fax

Restaurant Appliance Service

7219 Roosevelt Way Ne

Seattle, WA 98115

(206) 524-8200

(800) 433-9390

(206) 525-2890 fax

ILLINOIS

INDIANA

IOWA

KANSAS

GCS Service Inc. #12

696 Larch Avenue

Elmhurst, IL 60126

(630) 941-7800

(800) 942-9689

(630) 941-6048 fax

Cone’s Repair Service

2408 40th Avenue

Moline, IL 61265

(309) 797-5323

(800) 716-7070

(309) 797-3631 fax

Eichenauer Services, Inc.

130 S. Oakland Street

Decatur, IL 62522

(217) 429-4229

(800) 252-5892

(217) 429-0226 fax

GCS Service, Inc. #80

9722 Reavis Park Drive

St. Louis, MO 63123

(314) 638-7444

(800) 284-4427

(314) 638-0135 fax

Commercial Parts and Service

5310 E. 25th Street

Indianapolis, IN 46218

(317) 545-9655

(800) 727-8710

(317) 549-6286 fax

Goodwin-Tucker Group

3509 Delaware Avenue

Des Moines, IA 50313

(515) 262-9308

(800) 372-6066

(515) 262-2936 fax

Cone’s Repair Service

1056 27th Ave. SW

Cedar Rapids, IA 52404

(319) 365-3325

(800) 747-3326

(319) 365-0885 fax

GCS Service Inc. #82

6107 Connecticut

Kansas City, MO 64120

(816) 920-5999

(800) 229-6477

(816) 920-7387 fax

KENTUCKY

Certified Service Center

Ramco Business Park

4283 Produce Road

Louisville, Ky 40218

(502) 964-7007

(800) 637-6350

(502) 964-7202 fax

Commercial Parts & Service

4204 South Brook Street

Louisville, KY 40214

(502) 367-1788

(800) 752-6160

(502) 367-0400 fax

Certified Service Center

1051 Goodwin Drive

Lexington, KY 40505

(606) 254-8854

(800) 432-9269

(606) 231-7781 fax

Commercial Parts & Service

1002 Nandino Blvd.

Lexington, KY 40511

(606) 255-0746

(800) 432-9260

(606) 255-0748 fax

LOUISIANA

Bana Parts, Inc.

1501 Kueble Street

Harahan, LA 70123

(504) 734-0076

(800) 325-7543

(504) 734-8456 fax

Bana Parts, Inc.

4028 Greenwood Road

Shreveport, LA 71109

(318) 631-6550

(800) 832-6550

(318) 636-5675 fax

MAINE

GCS Service, Inc. #09

180 Second Street

Chelsea, MA 02150

(617) 889-9393

(800) 225-1155

(617) 889-1222 fax

Massachusetts Restaurant

Supply

34 South Street

Somerville, MA 02143

(617) 868-1930

(800) 338-6737

(617) 868-5331 fax

13

Page 17

JACKSON MAINTENANCE & REPAIR CENTERS (USA)

MARYLAND

GCS Service, Inc. #07

2660 Pittman Drive

Silver Spring, MD 20910

(301) 585-7550 (DC)

(410) 792-0388 (Balt)

(800) 638-7278

(301) 495-4410 fax

EMR Service Division

700 East 25th Street

Baltimore, MD 21218

(410) 467-8080

(800) 879-4994

(410) 467-4191 fax

EMR Service Division

106 Willamsport Circle

Salisbury, MD 21804

(410) 543-8197

(888) 687-8080

(410) 548-4038 fax

EMR Service Division

2626 Pittman Drive

Silver Spring, MD 20910

(301) 588-8080

(800) 348-2365

(301) 588-6985 fax

MASSACHUSETTS

GCS Service, Inc. #09

180 Second Street

Chelsea, MA 02150

(617) 889-9393

(800) 225-1155

(617) 889-1222 fax

MICHIGAN

GCS Service, Inc. #20

31829 West Eight Mile Road

Livonia, MI 48152

(248) 426-9500

(800) 772-2936

(248) 426-7555 fax

GCS Service, Inc. #21

3516 Roger B Chaffe SE

Grand Rapids, MI 49548

(248) 426-9500

(800) 772-2936

(248) 426-7555 fax

Jackson Service

3980 Benstein Road

Commerce Township, MI 48382

(248) 363-4159

(800) 332-4053

(248) 363-5448 fax

MINNESOTA

GCS/Metro Service, Inc.

2857 Louisiana Avenue N.

Minneapolis, MN 55427

(612) 546-4221

(800) 345-4221

(612) 546-4286 fax

MISSISSIPPI

Commercial Parts & Service

5755 Gallant Drive

Jackson, MS 39206

(601) 956-7800

(800) 274-5954

(601) 956-1200 fax

MISSOURI (cont)

Kammerlin Parts & Service

2728 Locust Street

St. Louis, MO 63103

(314) 535-2222

(314) 535-6205 fax

MONTANA

Restaurant Appliance Service

7219 Roosevelt Way NE

Seattle, WA 98115

(206) 524-8200

(800) 433-9390

(206) 525-2890 fax

NEBRASKA

Goodwin-Tucker Group

815 N. 19th Street

Omaha, NE 68102

(402) 345-7400

(800) 228-0342

(402) 346-6145 fax

NEVADA

GCS Service, Inc. #77

3585 East Patrick Lane

Suite 1000

Las Vegas, NV 89102

(702) 450-3495

(800) 500-9060

(702) 450-3491 fax

Burney’s Commercial Service

4480 Aldevaran Avenue

Las Vegas, NV 89103

(702) 736-0006

(702) 798-7531 fax

Massachusetts Restaurant

Supply

34 South Street

Somerville, MA 02143

(617) 868-1930

(800) 338-6737

(617) 868-5331 fax

Ace Service Co.

95 Hampton Avenue

Needham, MA 02494

(781) 449-4220

(800) 225-4510 MA & NH

(781) 444-4789 fax

GCS Service, Inc. #06

302 Murphy Road

Hartford, CT 06114

(860) 549-5575

(800) 723-1562

(860) 527-6355 fax

Commercial Parts & Service

3717 Cherry Road

Memphis, TN 38118

(901) 366-4587

(800) 262-9155

(901) 366-4588 fax

MISSOURI

GCS Service, Inc. #82

6107 Connecticut

Kansas City, MO 64120

(816) 920-5999

(800) 229-6477

(816)920-7387 fax

GCS Service, Inc. # 80

9722 Reavis Park Drive

St. Louis, MO 63123

(314) 638-7444

(800) 284-4427

(314) 638-0135 fax

NEW HAMPSHIRE

GCS Service, Inc. #09

180 Second Street

Chelsea, MA 02150

(617) 889-9393

(800) 225-1155

(617) 889-1222 fax

Massachusetts Restaurant

Supply

34 South Street

Somerville, MA 02143

(617) 868-1930

(800) 338-6737

(617) 868-5331 fax

Ace Service Co.

95 Hampton Avenue

Needham, MA 02494

(781) 449-4220

(800) 225-4510 MA & NH

(781) 444-4789 fax

14

Page 18

JACKSON MAINTENANCE & REPAIR CENTERS (USA)

NEW JERSEY

Jackson Faspray Service

155 Sargeant Avenue

Clifton, NJ 07013

(973) 471-8000

(800) 356-6740

(973) 471-1289 fax

GCS Service, Inc. #44

817 N. Third Street

Philadelphia, PA 19123

(215) 925-6217

(800) 441-9115

(215) 925-6208 fax

GCS Service, Inc. #02

1 Madison ST., Bldg. F

E. Rutherford, NJ 07073

(973) 614-0003

(800) 399-8294

(973) 614-0320 fax

Food Service Equipment

2101 Parkway South

Broomall, PA 19123

(610) 356-6900

(610) 356-2038 fax

NEW MEXICO

Stove Parts Supply Co.

2120 Solana Street

Ft. Worth, TX 76117

(817) 831-0381

(800) 433-1804

(817) 834-7754 fax

NEW YORK

GCS Service, Inc. #01

932 Grand Street

Brooklyn, NY 11211

(718) 486-5220

(800) 969-4271

(718) 486-6772 fax

Duffy’s Equipment Service

3138 Oneida Street

Sauquiot, NY 13456

(315) 737-9401

(800) 443-8339

(315) 737-7132 fax

B.E.S.T., Inc.

3003 Genesee Street

Buffalo, NY 14225

(716) 893-6464

(800) 338-5011

(716) 893-6466 fax

NEW YORK (cont)

Appliance Installation &

Service Corp.

1336 Main Street

Buffalo, NY 14209

(716) 884-7425

(800) 722-1252

(716) 884-0410 fax

Northern Parts & Service

21 Northern Avenue

Plattsburgh, NY 12903

(518) 563-3200

(800) 634-5005

(800) 782-5424 fax

Jackson Faspray Service

155 Sargeant Avenue

Clifton, NJ 07013

(973) 471-8000

(800) 356-6740

(973) 471-1289 fax

NORTH CAROLINA

Whaley Foodservice Repairs

8334-K Arrowridge Blvd.

Charlotte, NC 28273

(704) 529-6242

(704) 529-1558 fax

Whaley Foodservice Repairs

203-D Creek Ridge Road

Greensboro, NC 27406

(336) 333-2333

(336) 333-2533 fax

Whaley Foodservice Repairs

335-105 Sherwee Drive

Raleigh, NC 27603

(919) 779-2266

(919) 779-2224 fax

Whaley Foodservice Repairs

6418-101 Amsterdam Way

Wilmington, NC 28405

(910) 791-0000

(910) 791-6662 fax

NORTH DAKOTA

GCS/Metro Service Inc.

2857 Louisiana Avenue N.

Minneapolis,MN 55427

(612) 546-4221

(800) 345-4221

(612) 546-4286 fax

OHIO

Certified Service Center

890 Redna Terrace

Cincinnati, OH 45215

(513) 772- 6600

(800) 543-2060

(513) 612-6600 fax

OHIO (cont)

Commercial Parts &

Service of Columbus

1150 West Mound Street

Columbus, OH 43223

(614) 221-0057

(800) 837-8327

(614) 221-3622 fax

GCS Service, Inc.

2830 Johnstown Rd.

Columbus, OH 43219

(614) 476-3225

(800) 282-5406

(614) 476-1196 fax

Electrical Appliance

Repair Service

5805 Valley Belt Road

Cleveland, OH 44131

(216) 459-8700

(800) 621-8259

(216) 459-8707 fax

OKLAHOMA

Krueger Inc.

100 NE 24th Street

Oklahoma City, OK 73105

(405) 528-8883

(800) 522-8069

(405) 528-5405 fax

Hagar Restaurant Equipment

1229 W. Main Street

Oklahoma City, OK 73106

(405) 235-2184

(800) 445-1791

(405) 236-5592 fax

OREGON

Ron’s Service

16364 SW 72nd Ave.

Portland, OR 97224

(503) 624-0890

(800) 851-4118

(503) 684-6107 fax

PENNSYLVANIA

GCS Service, Inc. #44

817 N. Third Street

P.O. Box 3564

Philadelphia, PA 19123

(215) 925-6217

(800) 441-9115

(215) 925-6208 fax

Elmer Schultz Service

540 North 3rd Street

Philadelphia, PA 19123

(215) 627-5400

(215) 627-5408 fax

15

Page 19

JACKSON MAINTENANCE & REPAIR CENTERS (USA)

PENNSYLVANIA (cont)

Food Service Equipment

2101 Parkway South

Broomall, PA 19008

(610) 356-6900

(610) 356-2038

A.I.S. Commercial Parts &

Service

1816 West 26th Street

Erie, PA 16508

(814) 456-3732

(800) 332-3732

(814) 452-4843 fax

GCS Service, Inc. #44

4400 Lewis Road, Suite E

Harrisburg, PA 17111

(717) 564-3282

(800) 367-3225

(717) 564-9286 fax

K & D Parts & Service

1833-41 N. Cameron Street

Harrisburg, PA 17103

(717) 236-9039

(800) 932-0503

(717) 238-4367 fax

AFS-Authorized Factory

Service, Co.

940 FIrst Avenue

Coraopolis, PA 15108

(412) 262-2330

(800) 222-8767

(412) 262-2245 fax

GCS Service, Inc. #48

210 Vista park Drive

Pittsburgh, PA 15205

(412) 787-1970

(800) 738-1221

(412) 787-5005 fax

RHODE ISLAND

GCS Service, Inc. #90

1002 Waterman Ave.

E. Providence, RI 02914

(401) 434-6803

(800) 462-6012

(401) 438-9400 fax

SOUTH CAROLINA

Whaley Foodservice Repairs

I-26 & US1

P.O. Box 4023

West Columbia, SC 29170

(803) 791-4420

(800) 877-2662

(803) 794-4630 fax

SOUTH CAROLINA (cont)

Whaley Foodservice Repairs

748 Congaree Road

Greenville, SC 29607

(864) 234-7011

(800) 494-2539

(864) 234-6662 fax

Whaley Foodservice Repairs

1406-C Commerce PI.

Myrtle Beach, SC 29577

(843) 626-1866

(843) 626-2632 fax

Whaley Foodservice Repairs

4740-A Franchise St.

N. Charleston, SC 29418

(843) 760-2110

(843) 760-2255 fax

SOUTH DAKOTA

Metro Commercial

Service, Inc.

2857 Louisiana Avenue N.

Minneapolis, MN 55427

(612) 546-4221

(800) 345-4221

(612) 546-4286 fax

TENNESSEE

Commercial Parts & Service

3717 Cherry Road

Memphis, TN 38118

(901) 366-4587

(800) 262-9155

(901) 366-4588 fax

Commercial Parts & Service

748 Fesslers Lane

Nashville, TN 37210

(615) 244-8050

(800) 831-7174

(615) 244-8885 fax

Commercial Appliance Service

919 8th Ave. South

Nashville, TN 37203

(615) 254-0906

(800) 476-0906

(615) 254-0919 fax

TEXAS

GCS Service, Inc. #90

2422 Arbuckle Court

Dallas, TX 75229

(972) 484-2954

(800) 422-5026

(972) 484-2531 fax

TEXAS (cont)

Stove Parts Supply Co.

2120 Solana Street

Ft. Worth, TX 76117

(817) 831-0381

(800) 433-1804

(817) 834-7754 fax

GCS Service, Inc. #88

8150 Westpark

Houston, TX 77063

(713) 785-9187

(800) 868-6957

(713) 785-3979 fax

Armstrong Repair Center

5750-A Royalton

Houston, TX 77081

(713) 666-7100

(800) 392-5325

(713) 661-0520 fax

Commercial Kitchen Repair

1377 N. Brasos

P.O. Box831128

San Antonio, TX 78207

(210) 735-2811

(800) 292-2120

(210) 735-7421 fax

UTAH

Lamonica’s Restaurant

Equipment Service

6182 S. Stratler Avenue

Murray, UT 84107

(801) 263-3221

(800) 527-2561

(801) 263-3229 fax

VERMONT

Authorized Appliance

Servicenter of Vermont

74 River Street

Rutland, VT 05701

(802) 775-5588

(800) 874-1080

(802) 775-9593 fax

Northern Parts & Service

4874 S. Catherine Street

Plattsburg, NY 12901

(518) 563-3200

(800) 634-5005

(800) 782-5424 fax

GCS Service, Inc. #09

180 Second Street

Chelsea, MA 02150

(617) 889-9393

(800) 225-1155

(617) 889-1222 fax

16

Page 20

JACKSON MAINTENANCE & REPAIR CENTERS (USA)

VIRGINIA

GCS Service, Inc. #18

5760 Northampton Blvd.

Suite 106

Virginia Beach, VA 23455

(757) 464-3500

(800) 476-4278

(757) 464-4106 fax

GCS Service, Inc. #07

2660 Pittman Drive

Silver Spring, MD 20910

(301) 585-7550 (DC)

(410) 792-0388 (Balt)

(800) 638-7278

(301) 495-4410 fax

GCS Service, inc. #18

2421 Grenoble Road

Richmond, VA 23294

(804) 672-1700

(800) 899-5949

(804) 672-2888 fax

Daubers, Inc.

7645 Dynatech Court

Springfield, VA 22153

(703) 866-3600

(800) 554-7788

(703) 866-4071 fax

WISCONSIN (cont)

Appliance Service Center, Inc.

786 Morris Ave.

Green Bay, WI 54304

(920) 496-9993

(800) 236-0871

(920) 496-9927 fax

WYOMING

Metro Appliance Service

1640 South Broadway

Denver, CO 80210

(303) 778-1126

(800)525-3532

(303) 778-0268 fax

WASHINGTON

Restaurant Appliance Service

7219 Roosevelt Way NE

Seattle, WA 98115

(206) 524-8200

(800) 433-9390

(206) 525-2890

WEST VIRGINIA

AFS-Authorized Factory

Service, Inc.

Rt.-1 Box 288

S. Charleston, WV 25312

(304) 344-8225

(800) 654-4606

(304) 344-8248 fax

WISCONSIN

Appliance Service Center, Inc.

2439 Atwood Avenue

Madison, WI 53704

(608) 246-3160

(800) 236-7440

(608) 246-2721 fax

Appliance Service Center, Inc.

6843 W. Belloit Road

West Allis, WI 53219

(414) 543-6460

(800) 236-6460

(414) 543-6480 fax

17

Page 21

JACKSON MAINTENANCE & REPAIR CENTERS (CANADA)

Kontac Industries

6504 South Broadway

Edmonton, AB T6B0E7

(780) 469-4869

(800) 661-2500

(780) 465-6937 fax

Key Food Equipment Services

#105-3728 North Fraser Way

Burnaby, BC V5J5G1

(604) 433-4484

(800) 665-2655

(604) 433-4684 fax

Choquette - CKS

2710 Lancaster Road

Unit 119

Ottawa, OT K1B4T7

(613) 739-8458

(800) 267-2515

(613) 739-3851 fax

Kontac Industries

6271-15 Dorman Road

Missisauga, OT L4V1H1

(905) 677-1580

(800) 661-2500

(905) 677-2863 fax

Choquette - CKS

8487 19th Avenue

Montreal, QU H1Z4J2

(514) 722-2000

(800) 361-7681(Quebec)

(514) 722-5050 fax

Service D’Equipment de

Cuisine Entretien

893 King O

Sherbroke, QU J1H1R9

(819) 821-2153

(819) 821-4015 fax

A.A. Dot (Service

d’Entretien)

15 St. Alphonse

Ste. Therese, QU J731G3

(450) 435-7736

(450) 435-5249 fax

Choquette - CKS

900 Pierre Bertrand

Suite 220

Vanier, QU G1M3k2

(418) 681-3944

(800) 463-5506

(418) 681-3385 fax

18

Page 22

WHIRL WIZARD

ELECTRICAL DIAGRAM

115 volt - 60 hertz - SINGLE PHASE

SEQUENCE OF OPERATION

1. After the sink is filled with water, power switch (S1) is placed in the “ON” position.

2. Motor contactor (R1) is energized.

3. Pump motor (M1) starts.

4. Heater element (H1) is energized.

5. Power light (E1) is energized.

NOTE: THE HEATER ELEMENT CONTAINS AN INTERNALLY-MOUNTED THERMOSTAT TO REGULATE THE TEMPERATURE OF

THE ELEMENT.

19

Loading...

Loading...