Page 1

TempStar®

Models

TempStar®

TempStar® HH

with optional Ventless

and Energy Recovery

Standard Features* Mandatory Specs

• Ventless: Does not require a hood

• Energy Recovery

• Internal condensing system

minimizes water vapor

• Sani-Sure ™ feature ensures proper

rinse water temperature

• Multi-cycle timer (Extra Heavy,

Heavy, Medium, Normal)

• Specially designed stainless steel

nozzles provide superior cleaning

action

• Auto-ll/auto-start

• Door switch

• Built-in pressure regulator and

door interlock are standard

• Delime/manual wash switch

• Hi-limit thermostat and low

water protection

• Uses standard 20” X 20”

(508 mm X 508 mm) racks

• Detergent/rinse additive signal

connection fuse box

• Self-draining stainless steel pump

• Built-in 70° F (38.9° C) rise booster

heater

• Field convertible from straight

through to corner and vice versa

Project

Item

Quantity

CSI Section 11400

Approval

Date

Specify:

Electric

Steam

Specify voltage _____________

Specify booster size _________

Options

480V Electrical

Single Phase

Drain Quench System

Scaltrol

Water Hammer Arrestor

Flanged Feet

False Panel

Steam Booster Heater

Security Package

Accessories

36-Compartment Rack

4-1/8” tall (105 mm)

5-5/8” tall (143 mm)

7” tall (178 mm)

Combination Rack

Peg Rack

TempStar®

with optional Ventless

and Energy Recovery

_

_

Specifications

TempStar uses 0.89 gallons (3 liters) of water

per rack; TempStar HH uses 1.36 gallons

(5 liters) of water per rack

TempStar (normal) cycle time - 87 seconds*

TempStar HH (normal) cycle time - 92 seconds*

TempStar - 39 racks per hour (normal cycle)*

TempStar HH - 37 racks per hour (normal cycle)*

Single point connections for all utilities

Cold water connection only*

Durable stainless steel construction

*Specs shown for TempStar / TempStar HH with optional Ventless and Energy Recovery

www.jacksonwws.com

TempStar - 17.25” (438 mm) door opening accepts

18” (457 mm) trays

TempStar HH - 20.75” wide x 27” high (527 mm x

686 mm) opening accommodates 18”x 16” (457

mm x 660 mm) sheet pans and 60-quart mixing

bowls

TempStar is eld phase convertible

TempStar ships fully assembled

TempStar® is ENERGY STAR® qualied.

TempStar® HH is not ENERGY STAR® qualied.

Page 2

TempStar®

TempStar®

with optional Ventless

and Energy Recovery

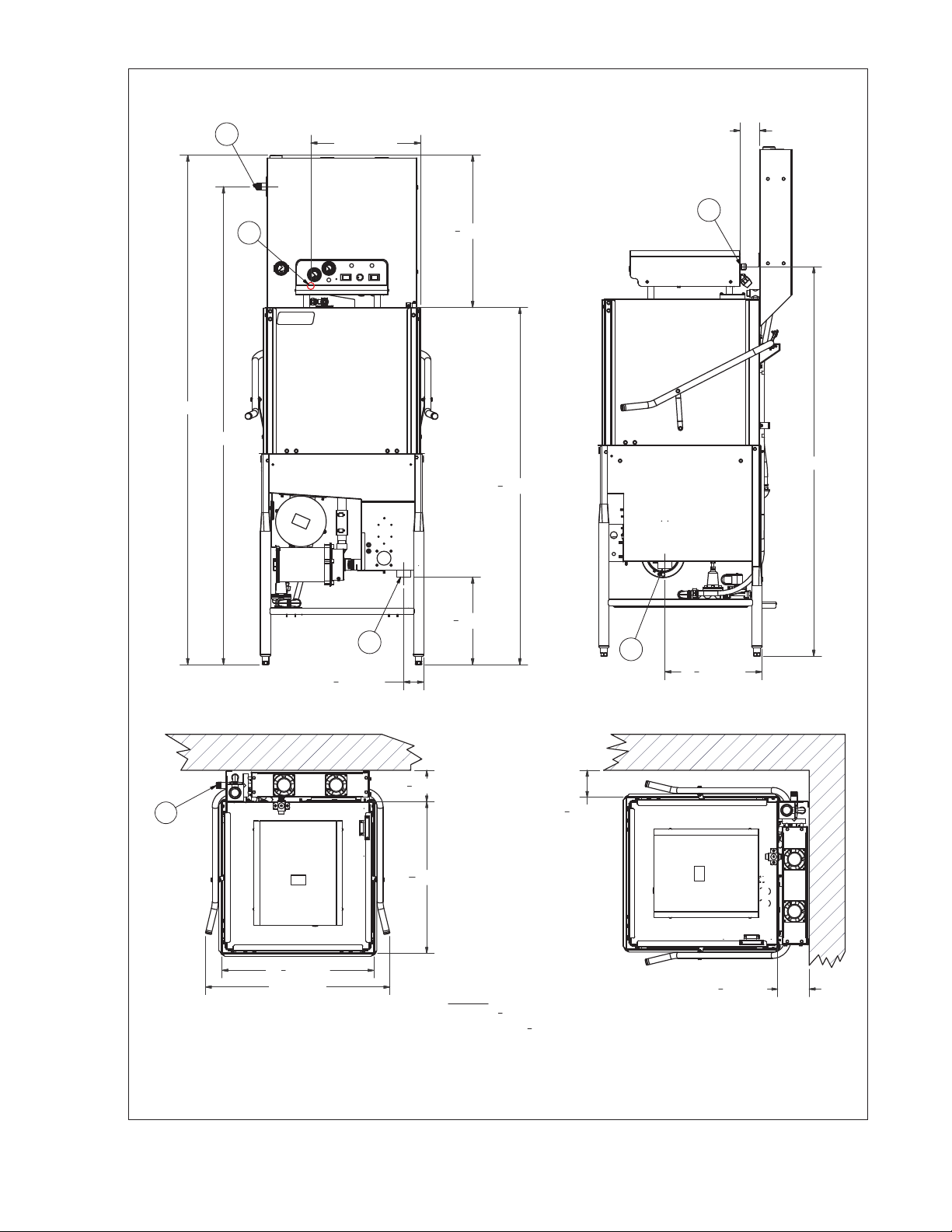

82 (2083mm)

77 (1956mm)

B

17 (432mm)

3 (79mm)

C

1

24

C

(616mm)

4

60 (1527mm)

3

57

(1468mm)

4

1

13

(337mm)

4

A

3

4

(120mm)

4

1

5

(134mm)

4

1

4

3

4 MIP

(114mm)

2

B

1

25

(641mm)

4

1

25

(641mm)

4

32 (813mm)

LEGEND

A) DRAIN 1

B) WATER INLET

C) ELECTRICAL CONNECTIONS

All vertical dimensions are ± 1/2" due to

adjustable bullet feet

1

2 IPS

A

1

15

(394mm)

2

1

5

(134mm)

4

www.jacksonwws.com

Page 3

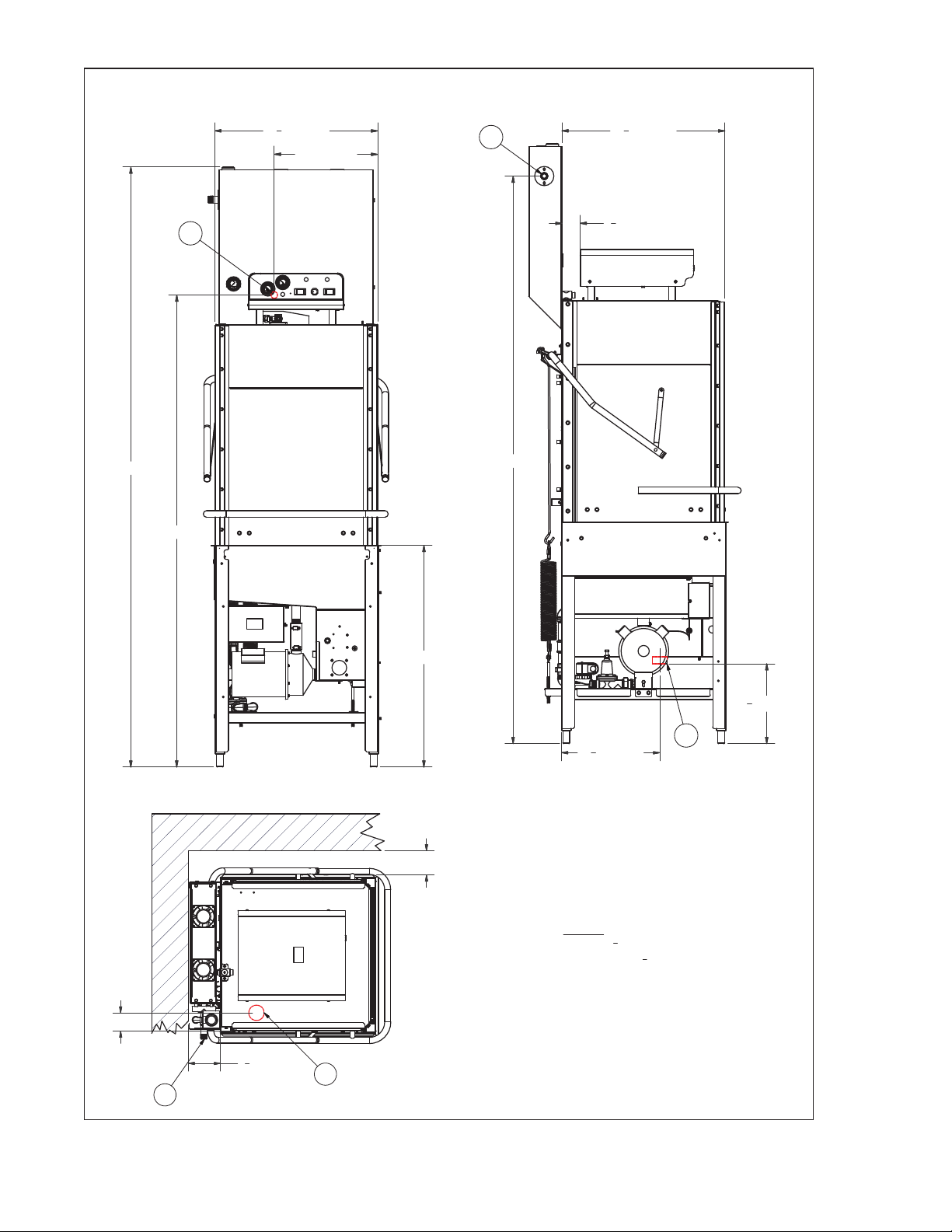

TempStar® HH

TempStar®

93 (2362mm)

73 (1856mm)

1

25

(637mm)

4

17 (432mm)

C

B

88 (2235mm)

25

3

2

(79mm)

4

1

(639mm)

4

with optional Ventless

and Energy Recovery

3 (76mm)

34 (861mm)

3

11

(298mm)

4

3

4 MIP

A

1

15

(387mm)

4

4 (101mm)

LEGEND

A) DRAIN 1

B) WATER INLET

C) ELECTRICAL CONNECTIONS

All vertical dimensions are ± 1/2" due to

adjustable bullet feet

1

5

(134mm)

4

A

B

1

2 IPS

www.jacksonwws.com

Page 4

TempStar®

3/4” (1.9 cm)

1 1/2” (3.81 cm) ROLL

MODEL NO.

with optional Ventless

and Energy Recovery

TempStar®*

TempStar® HH

MACHINE DIMENSIONS*

DIMENSION REQUIREMENTS

Wall Clearance (minimum)*

Clearance above Heat Exchanger (minimum)*

Standard Table Height

Inside Vertical Clearance - TempStar

Inside Vertical Clearance - TempStar HH

Machine Height with Door Open - TempStar

Machine Height with Door Open - TempStar HH

OPERATING CAPACITY*

Racks per Hour - TempStar

Racks per Hour - TempStar HH

OPERATING TEMPERATURES

Wash (minimum) 150° F (66° C)

Rinse (minimum)

TANK HEATER SPECIFICATIONS

Electric Wash Tank Heater

Electric Rinse Tank Heater - 70˚F (38.9˚C) Rise

WASH PUMP MOTOR

Wash Pump Motor - TempStar 1 hp

Wash Pump Motor - TempStar HH 2 hp

STEAM REQUIREMENTS

Steam Flow Pressure (PSIG)

Consumption @ 15 PSIG (Ibs/hr)

*Specs shown for TempStar / TempStar HH with optional Ventless and Energy Recovery

HOW TO SPECIFY:

HOW TO SPECIFY:

20 1/2”

(52.1 cm)

DRAIN

HEIGHT WIDTH DEPTH WEIGHT CLASS CUBE HEIGHT WIDTH DEPTH

82”

(2083 mm)

93”

(2362 mm)

25-1/4”

(641 mm)

25-1/4”

(641 mm)

30-1/2”

(775 mm)

30-1/2”

(775 mm)

HEIGHT

13-1/4”

(337 mm)

11-3/4”

(298 mm)

SHIPPING INFORMATION*

365 lbs

(166 kg)

435 lbs

(197 kg)

WATER REQUIREMENTS

Inlet Temperature*

Gallons per Hour*

Gallons per Rack

Waterline Size MIP (minimum)*

Drainline Size IPS (minimum)

Flow Pressure (PSI) Connection

Operating Flow Pressure (PSI)

Wash Tank Capacity

Booster Tank Capacity

APPROXIMATE LOAD AMPS

Power Supply

208V/60HZ/1PH

208V/60HZ/3PH

230V/60HZ/1PH

230V/60HZ/3PH

460V/60HZ/3PH

OPERATING CYCLE FOR TEMPSTAR*

Normal

Medium

Heavy

Extra Heavy

Normal Heavy Extra HeavyMedium

39 17 1124

37 17 1123

0” (0 mm)

6” (152 mm)

34” (864 mm)

17-1/4” (438 mm)

27” (686 mm)

76” (1933 mm)

86-3/4” (2202 mm)

180° F (82° C)

Volts

208V

230V

460V

208V

230V

460V

KW

4.1

5.0

5.0

10.5

12.9

12.9

TABLE DIMENSIONS

CONNECTION TO DISHMACHINE

92.5

92.5

70.63

cu. ft.

77.67

cu. ft.

(2184 mm)

(2108 mm)

Wash

40

100

160

280 13

86”

83”

Rinse

13

13

13

33”

(838 mm)

33”

(838 mm)

TempStar TempStar HH

40 - 90° F (4.4 - 32.2° C)

35 gal (133 L)

0.89 gal (3 L)

3/4”

1- 1/2”

40

10

8 gal (30 L)

3 gal (11 L)

TempStar

AMPS

75.8

46.3

83.6

50.7

24.1

Condensate

Dwell Total Cycle

4

4

4

4

(1092 mm)

(1245 mm)

50 gal (189 L)

1.36 gal (5 L)

3/4”

1- 1/2”

15 - 25

8 gal (30 L)

3 gal (11 L)

TempStar HH

AMPS

Removal

30

30

30

30 327

OPERATING CYCLE FOR TEMPSTAR HH*

Condensate

Dwell Total Cycle

Removal

2

30

2

30

2

30

30 330

2

15-20

45

Normal

Medium

Heavy

Extra Heavy

Wash

45

103

163

283 15

Rinse

15

15

15

AMBIENT HEAT LOAD (as tested on standard height model)

TempStar® with optional Ventless & Energy Recovery

TempStar® HH with optional Ventless & Energy Recovery

Latent Heat (BTU)

Sensible Heat (BTU)

5300

4500

43”

49”

40

87

55

96

61

28

87

147

207

92

150

210

Jackson WWS, Inc.

Shipping Address: 6209 North U.S. Highway 25E, Gray, KY 40734

www.jacksonwws.com

Mailing Address: P.O. Box 1060, Barbourville, KY 40906

Telephone: 888-800-5672 • Fax: 606-523-1799

Email: info@jacksonwws.com

07610-002-66-59B [10/28/16]

We reserve the right to change specications in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Loading...

Loading...