Page 1

SIDELOADER OPTION

for

RACK CONVEYOR

DISHMACHINES

INSTALLATION && OOPERATION

MANUAL

February 22, 2002 P/N 7610-002-56-30 (REV. A)

Visit Jackson on the Internet at:

www.jacksonmsc.com

Page 2

SECTION

DESCRIPTION PAGE

I. OPERATION INSTRUCTIONS 1

II. INSTALLATION DETAILS for LEFT TO RIGHT OPERATION 2

III. INSTALLATION DETAILS for RIGHT TO LEFT OPERATION 3

IV. DIMENSIONS 4

V. DRAWINGS

Tub Weldments (Left to Right) 5

Tub Weldments (Right to Left) 6

Loader Track Assembly (Left to Right) 7

Loader Track Assembly (Right to Left) 8

Pawl Bar Assembly (Left to Right) 9

Pawl Bar Assembly (Right to Left) 9

Pawl Bar Associated Parts 10

Miscellaneous Parts 12

Vent Cowl Options 13

VI. ELECTRICAL DIAGRAM 14

VI. JACKSON MAINTENANCE & REPAIR CENTERS 15

VII. IMPORTANT INFORMATION DATA SHEET 19

TABLE OF CONTENTS

i

Page 3

This accessory assists in the delivery of a full dish rack from the break down (scrapping) table to the dishmachine. It will convert the

direction of travel 90 degrees. Since the Sideloader is shipped mounted on the conveyor dishwasher there is no additional installation

required for this option. As it is operated mechanically by the dishwasher it does not require any plumbing or electrical connections.

This Sideloader does not require or add any additonal electrical or mechanical devices to the unit which could create operational or

maintenance problems. As designed the drive mechanism is powered by the conveyor drive motor on the dishmachine. An extension

on the pawl bar provides the drive to push the racks into the unit.

PREPARATION: Before proceeding with the start-up of the unit, verify that the Sideloader pan strainer is installed.

WARE PREPARATION: Proper preparation of ware will help ensure good results and less re-washes. If not done properly, ware may

not come out clean and the efficiency of the dishmachine will be reduced. It is important to remember that a dishmachine is not a

garbage disposal and that simply throwing unscrapped dishes into the machine simply defeats the purpose altogether of washing the

ware. Scraps should be removed from ware prior to being loaded into a rack. Pre-rinsing and pre-soaking are good ideas, especially

for silverware and casserole dishes. Place cups and glasses upside down in racks so that they do not hold water during the cycle. The

dishmachine is meant not only to clean, but to sanitize as well, to destroy all of the bacteria that could be harmful to human beings. In

order to do this, ware must be properly prepared prior to being placed in the machine.

WASHING A RACK OF WARE: Once a rack is fully loaded it shold be positioned against the front of the dish table. The rack should

then be moved into the sideloader until it activates the actuator swtich. Once the the machine is started, it should pull the rack through

the machine and push it out the unload end. Once a rack has started through, you may put another rack in.

OPERATIONAL INSPECTION: Based upon usage, the pan strainer may become clogged with soil and debris as the workday progresses. Operators should reguarly inspect the pan strainer to ensure it has not become clogged. If the strainer does become clogged,

it will reduce the washing capability of the machine. Instruct operators to clean out the pan strainer at regular intervals or as required

by work load.

SHUTDOWN AND CLEANING: At the end of the workday, remove the pan strainer and clean as required. Wipe out the inside of the

sideloader and then reinsert the strainer.

INSTALLATION & OPERATION INSTRUCTIONS

1

Page 4

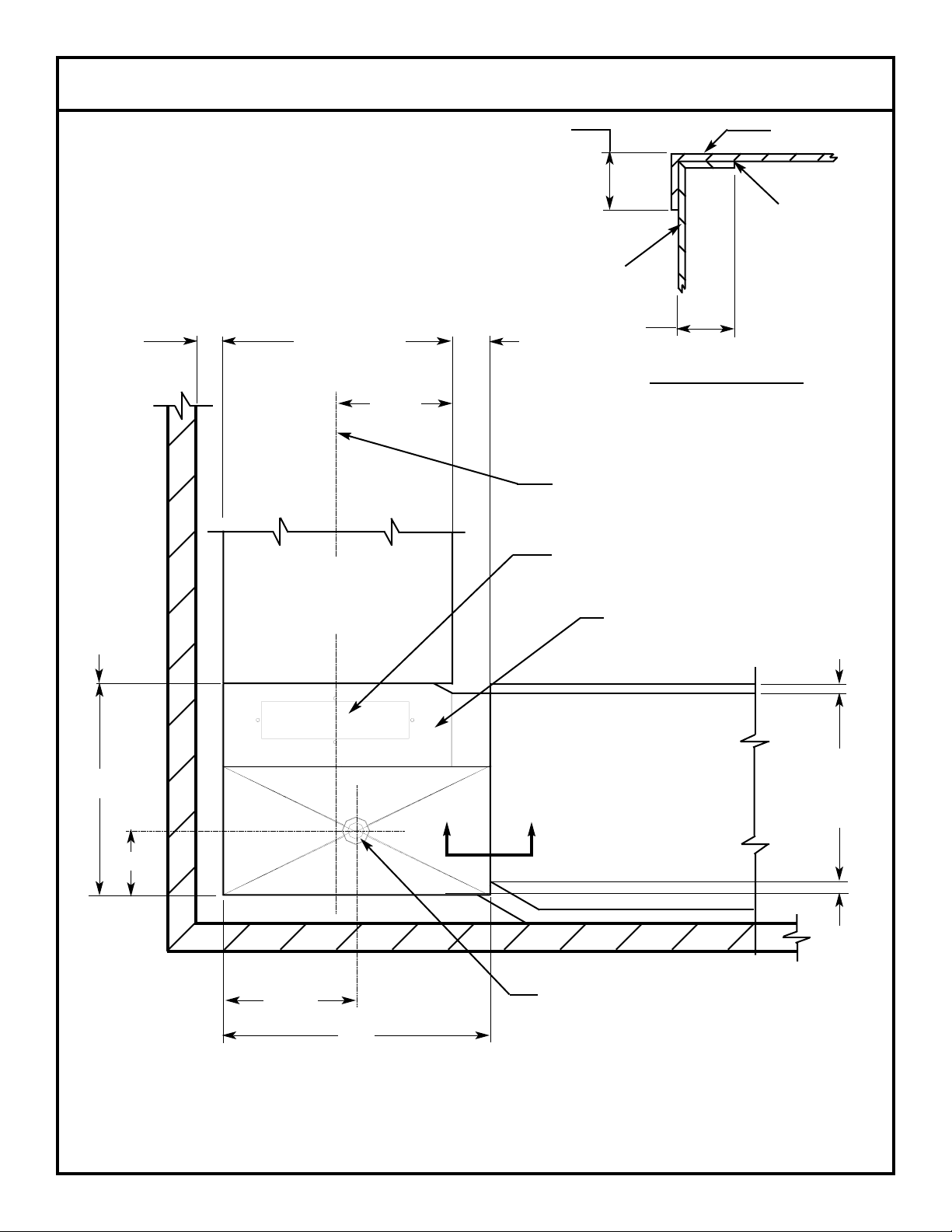

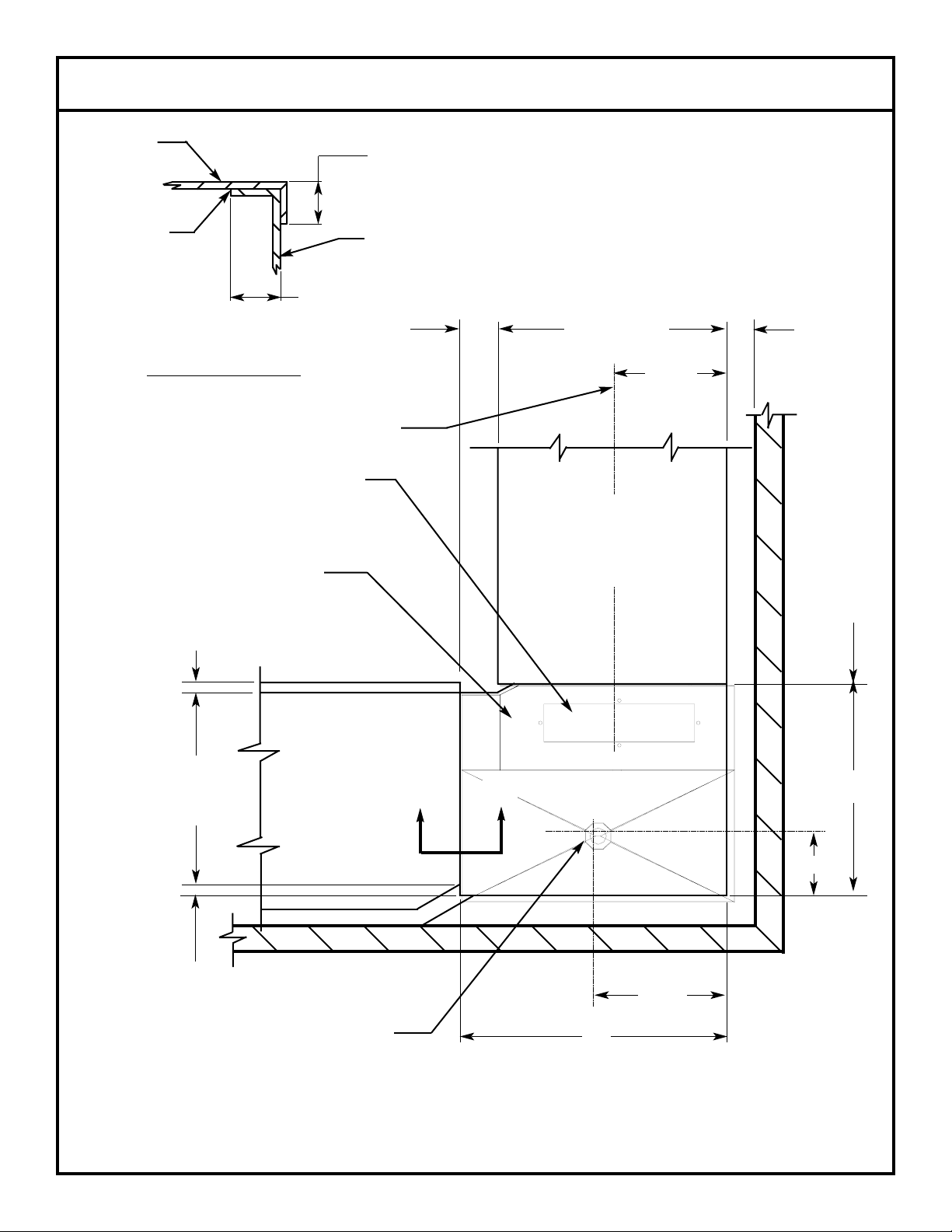

NOTE: ALL DIMENSIONS ARE TYPICAL.

INSTALLATION DETAILS for LEFT TO RIGHT OPERATION

2

23”

CONVEYOR

DISHWASHER

LENGTH

8”

4 1/2”

MINIMUM

25”

DISHWASHER

5”

12 1/2”

14 1/2”

29”

1 1/2” TABLE

ROLL

20 3/4”

OPENING

1”

A A

1/2”

MINIMUM

1/2”

DISHTABLE

USE SILICONE

BETWEEN

TABLE AND LIP

OF SIDELOADER TO

PREVENT

LEAKAGE.

WALL OF

SIDELOADER

SECTION “A-A”

CENTER-LINE

DISHMACHINE

SPLASH SHIELD

VENT CONNECTION

OPENING

1 1/2” DRAIN. CONNECTED

TODISHMACHINE DRAIN

LINE

CONVEYOR

DISHMACHINE

Page 5

NOTE: ALL DIMENSIONS ARE TYPICAL.

INSTALLATION DETAILS for RIGHT TO LEFT OPERATION

14 1/2”

29”

8”

23”

CONVEYOR

DISHMACHINE

LENGTH

4 1/2”

MINIMUM

12 1/2”

25”

DISHWASHER

5”

1 1/2” TABLE

ROLL

20 3/4”

OPENING

1”

1/2”

MINIMUM

DISHTABLE

1/2”

WALL OF

SIDELOADER

USE SILICONE

BETWEEN

TABLE AND LIP

OF SIDELOADER

TO PREVENT

LEAKAGE

SECTION “A-A”

CONVEYOR

DISHMACHINE

CENTER LINE

DISHMACHINE

VENT CONNECTION

OPENING

SPLASH

SHIELD

AA

1 1/2” DRAIN. CONNECTED TO

DISHMACHINE DRAIN LINE

3

Page 6

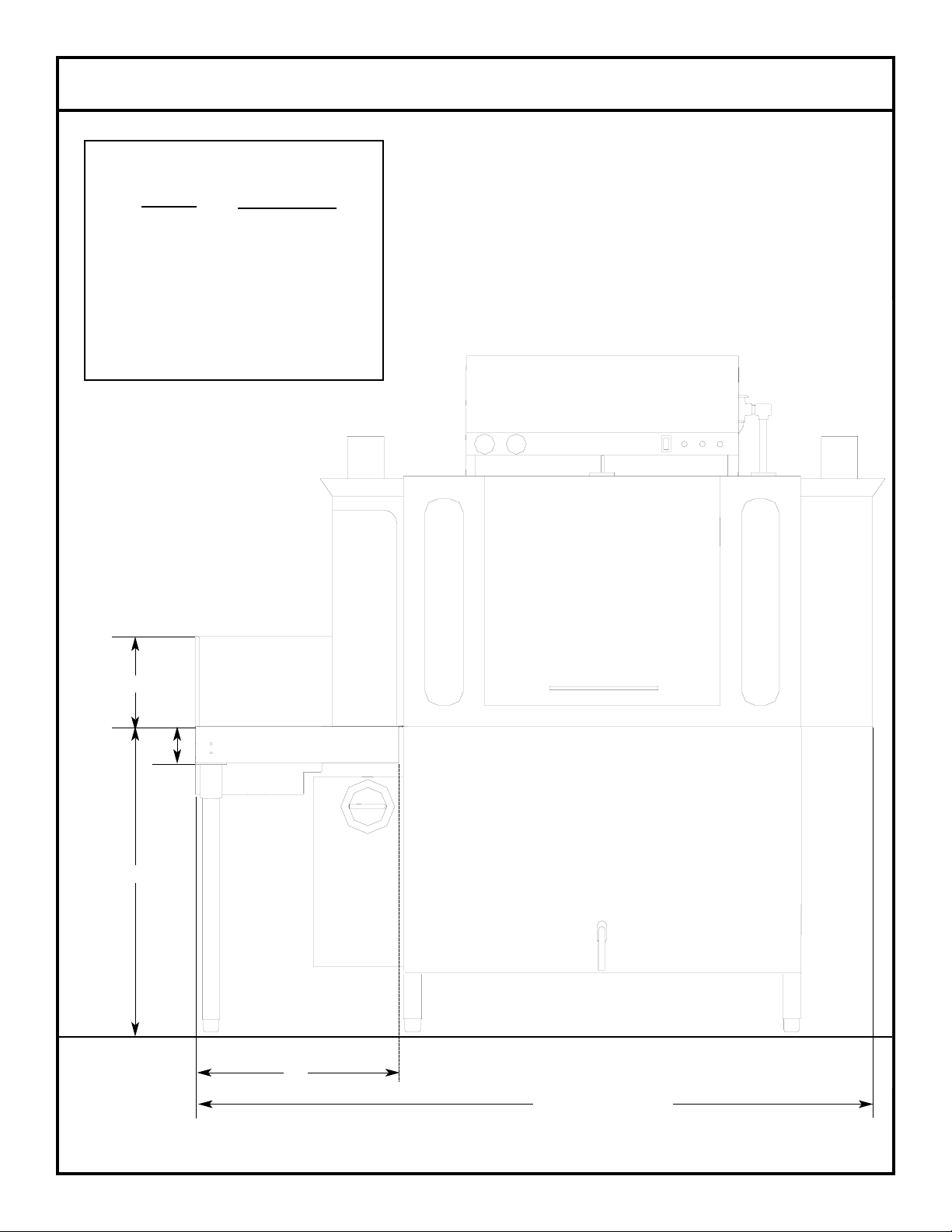

DIMENSIONS

4

Refer to chart above.

34”

23”

10”

4”

NOTE: ALL DIMENSIONS ARE TYPICAL.

MODEL

AJ-44

AJ-54

AJ-64

AJ-66

AJ-76

AJ-80

AJ-86

AJ-90

AJ-100

DIMENSIONS

75”

85”

95”

97”

107”

111”

117”

121”

131”

(Left to Right installation shown for reference.)

Page 7

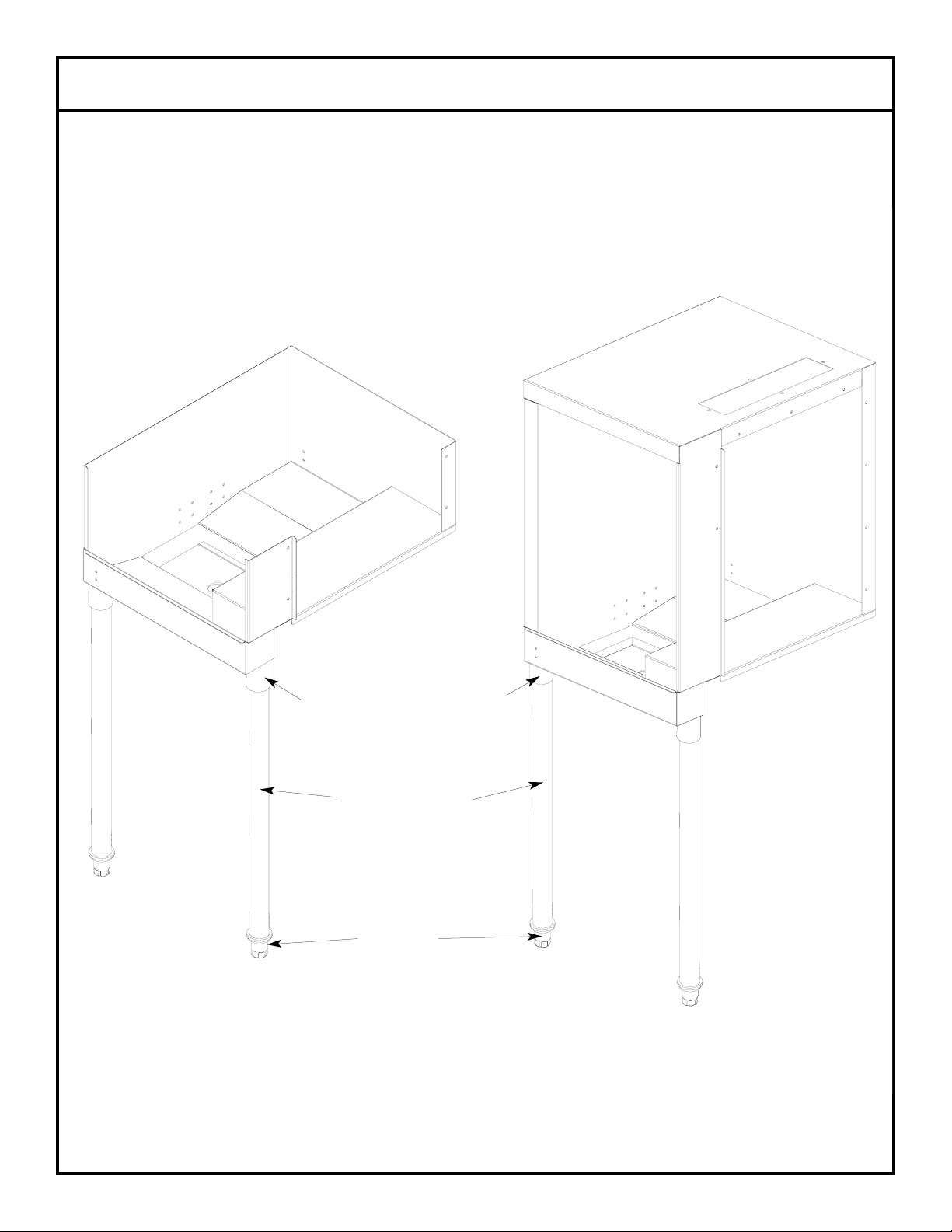

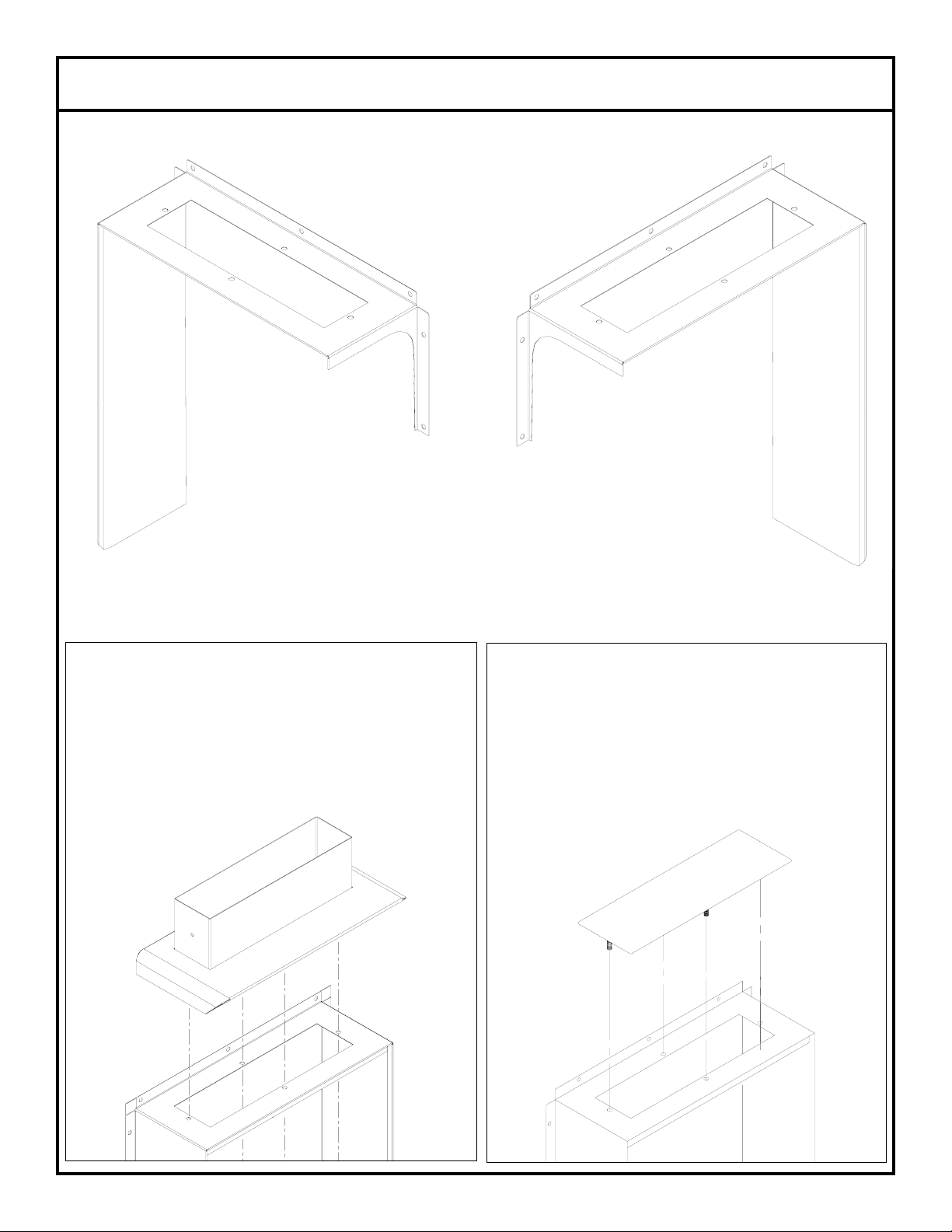

TUB WELDMENTS (LEFT TO RIGHT)

5

Leg Support Upright

5700-021-87-59

Bullet Feet

5340-108-01-03

Unhooded Tub Weldment

5700-041-92-85

Hooded Tub Weldment

5700-041-91-88

Leg Socket Component Weldment

5700-002-56-14

Associated Hardware:

Bolt, 1/4”-20 x 5/8” S.S. Hex Head 5305-274-24-00

Washer, 1/4”-20 I.D. 5311-174-01-00

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Page 8

TUB WELDMENTS (RIGHT TO LEFT)

6

Hooded Tub Weldment

5700-041-86-64

Unhooded Tub Weldment

5700-041-78-72

Leg Socket Component Weldment

5700-002-56-14

Leg Support Upright

5700-021-87-59

Bullet Feet

5340-108-01-03

Associated Hardware:

Bolt, 1/4”-20 x 5/8” S.S. Hex Head 5305-274-24-00

Washer, 1/4”-20 I.D. 5311-174-01-00

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Page 9

LOADER TRACK ASSEMBLY LEFT TO RIGHT

7

1 2 3 4 5 6 7

ITEM QTY DESCRIPTION Mfg. No.

1 1 Track Weldment 5700-031-78-98

1 Loader Actuator Assembly 5700-031-85-02

2 1 Loader Actuator Weldment 5700-021-85-05

3 1 End Cap 5700-011-60-92

4 1 Magnet 5930-111-69-25

5 2 Locknut, 1/4"-20 with Nylon Insert Low Profile 5310-374-01-00

6 2 Spacer 5700-011-71-44

7 2 Bolt, 1/4"-20 x 3/4" Long Hex H ead 5305-274-04-00

Associated Hardware:

Screw, 1/4”-20 x 1/2” S.S. 5305-274-02-00

Washer, 1/4”-20 I.D. 5311-174-01-00

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Page 10

LOADER TRACK ASSEMBLY RIGHT TO LEFT

8

ITEM QTY DESCRIPTION Mfg. No.

1 1 Track Weldment 5700-031-95-20

1 Loader Actuator Assembly 5700-021-75-67

2 1 Loader Actuator Weldment 5700-021-72-39

3 1 End Cap 5700-011-60-92

4 1 Magnet 5930-111-69-25

5 2 Locknut, 1/4"-20 with Nylon Insert Low Profile 5310-374-01-00

6 2 Spacer 5700-011-71-44

7 2 Bolt, 1/4"-20 x 3/4" Long Hex H ead 5305-274-04-00

7 6 5 4 3 2 1

Associated Hardware:

Screw, 1/4”-20 x 1/2” S.S. 5305-274-02-00

Washer, 1/4”-20 I.D. 5311-174-01-00

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Page 11

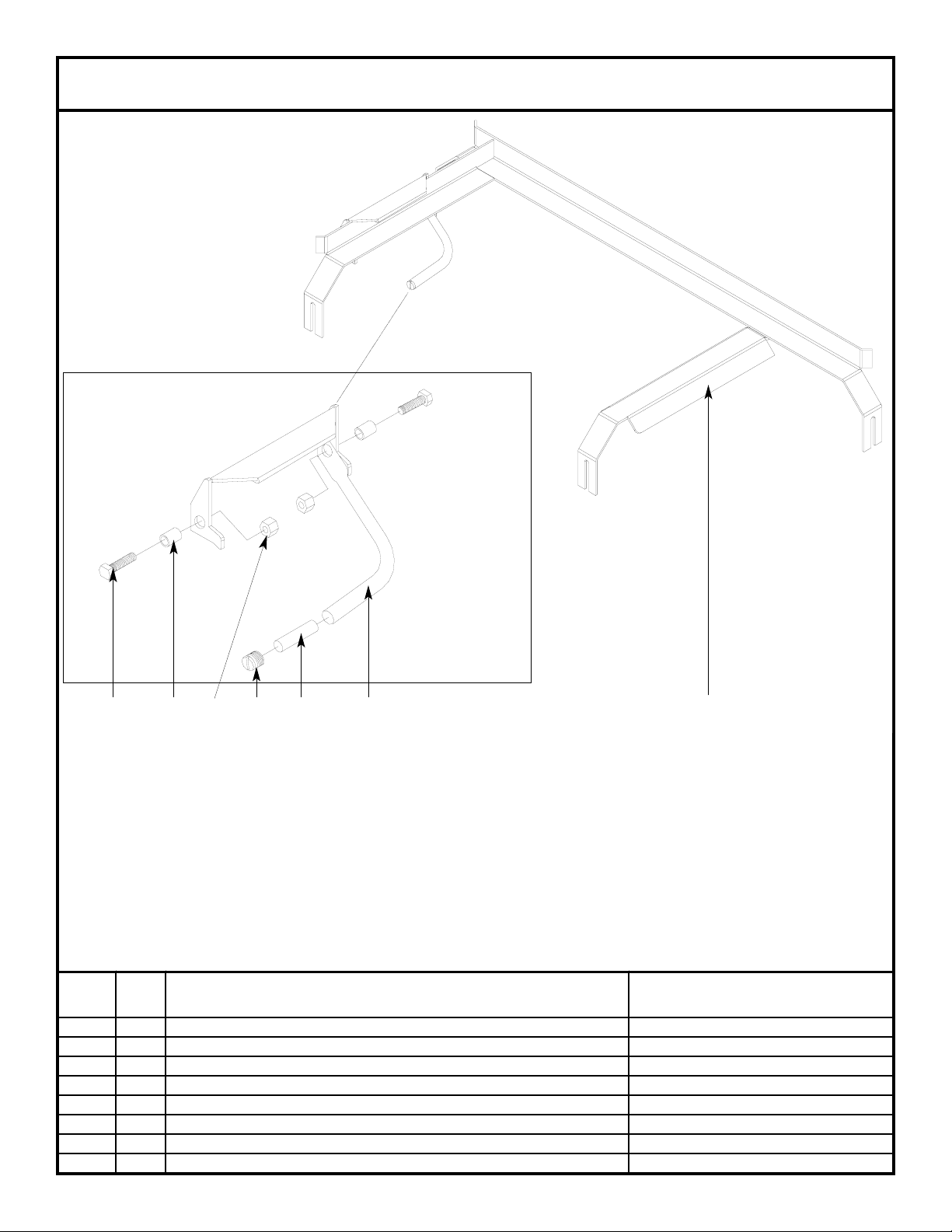

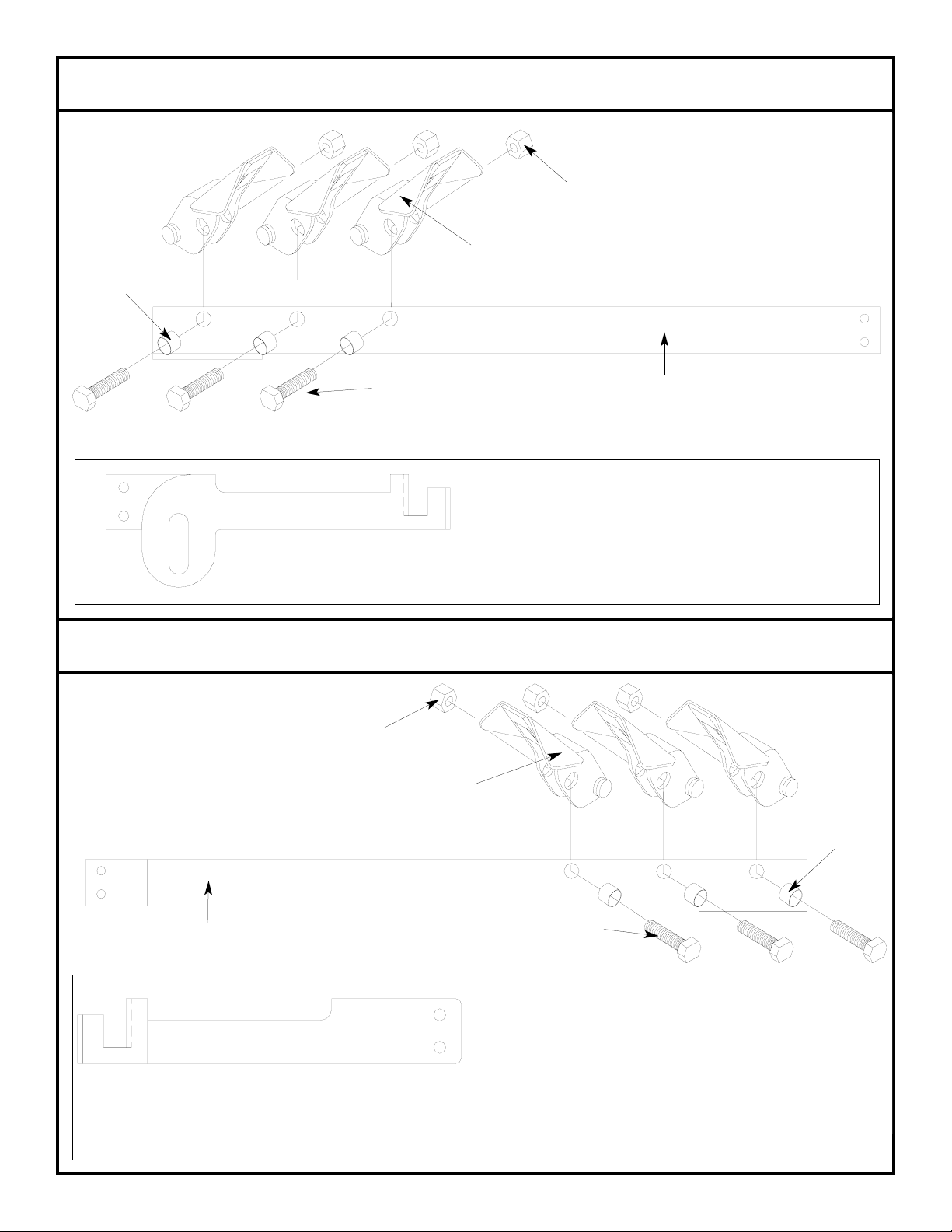

LEFT TO RIGHT PAWL BAR ASSEMBLY

RIGHT TO LEFT PAWL BAR ASSEMBLY

9

Complete Pawl Bar Assembly

5700-031-86-90

Pawl Dog Wing Weldment

5700-021-86-79

Locknut, 3/8”-16 w/Nylon Insert

5310-011-72-55

Bolt, 3/8” x 1 3/4”

5306-011-36-94

Pawl Bar Spacer

5700-011-71-45

Pawl Bar Weldment

5700-021-86-88

Locknut, 3/8”-16 w/Nylon Insert

5310-011-72-55

Complete Pawl Bar Assembly

5700-031-86-90

Pawl Dog Wing Weldment

5700-021-86-79

Bolt, 3/8” x 1 3/4”

5306-011-36-94

Pawl Bar Weldment

5700-021-86-88

Pawl Bar Spacer

5700-011-71-45

Pawl Bar Drive Linkage Weldment

5700-002-56-15

Associated Hardware:

Screw, 1/4”-20 x 1” S.S. HH Tap 5305-274-27-00

Locknut, 1/4”-20 S.S. Hex, w/Nylon Insert 5310-374-01-00

Pawl Bar Drive Linkage Weldment

5700-001-99-16

Associated Hardware:

Screw, 1/4”-20 x 1” S.S. HH Tap 5305-274-27-00

Locknut, 1/4”-20 S.S. Hex, w/Nylon Insert 5310-374-01-00

Page 12

PAWL BAR ASSOCIATED PARTS

10

Pawl Bar Roller Bracket

5700-031-77-94

Roller Shaft

5700-011-68-14

Bracket Rod Roller

5700-011-68-16

Associated Hardware:

Washer, 1/4”-20 I.D. 5311-174-01-00

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Page 13

PAWL BAR ASSOCIATED PARTS (CONTINUED)

11

Drive Gutter Gasket

5330-011-68-55

Pawl Bar Gutter Weldment

5700-021-66-86

Top Guide Block

5700-011-69-49

Bottom Guide Block

5700-011-69-50

Associated Hardware:

Washer, 1/4”-20 I.D. 5311-174-01-00

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Page 14

MISCELLANEOUS PARTS

12

Front Strainer Weldment

5700-021-85-10

Magnetic Reed Switch

5930-111-68-44

Reed Switch Cover Weldment

5700-011-46-51

Associated Hardware:

Screw, 8-32 x 3/4” 5305-011-72-66

Lockwasher, 8-32 External Tooth S.S. 5311-272-03-00

Page 15

VENT COWL OPTION

13

VENT SCOOP OPTION

Vent Scoop Assembly

5700-002-04-08

Associated Hardware:

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert

5310-374-01-00

STANDARD ASSEMBLY

Vent Cowl Cover

5700-011-74-67

Vent Cowl (Left to Right)

5700-031-79-19

Vent Cowl (Right to Left)

5700-031-79-20

Associated Components:

Top Vent Cowl Gasket 1 Per 5330-031-83-47

Side Vent Cowl Gasket 2 Per 5330-031-83-47

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert 5310-374-01-00

Associated Hardware:

Locknut, 1/4”-20 S.S. Hex w/Nylon Insert

5310-374-01-00

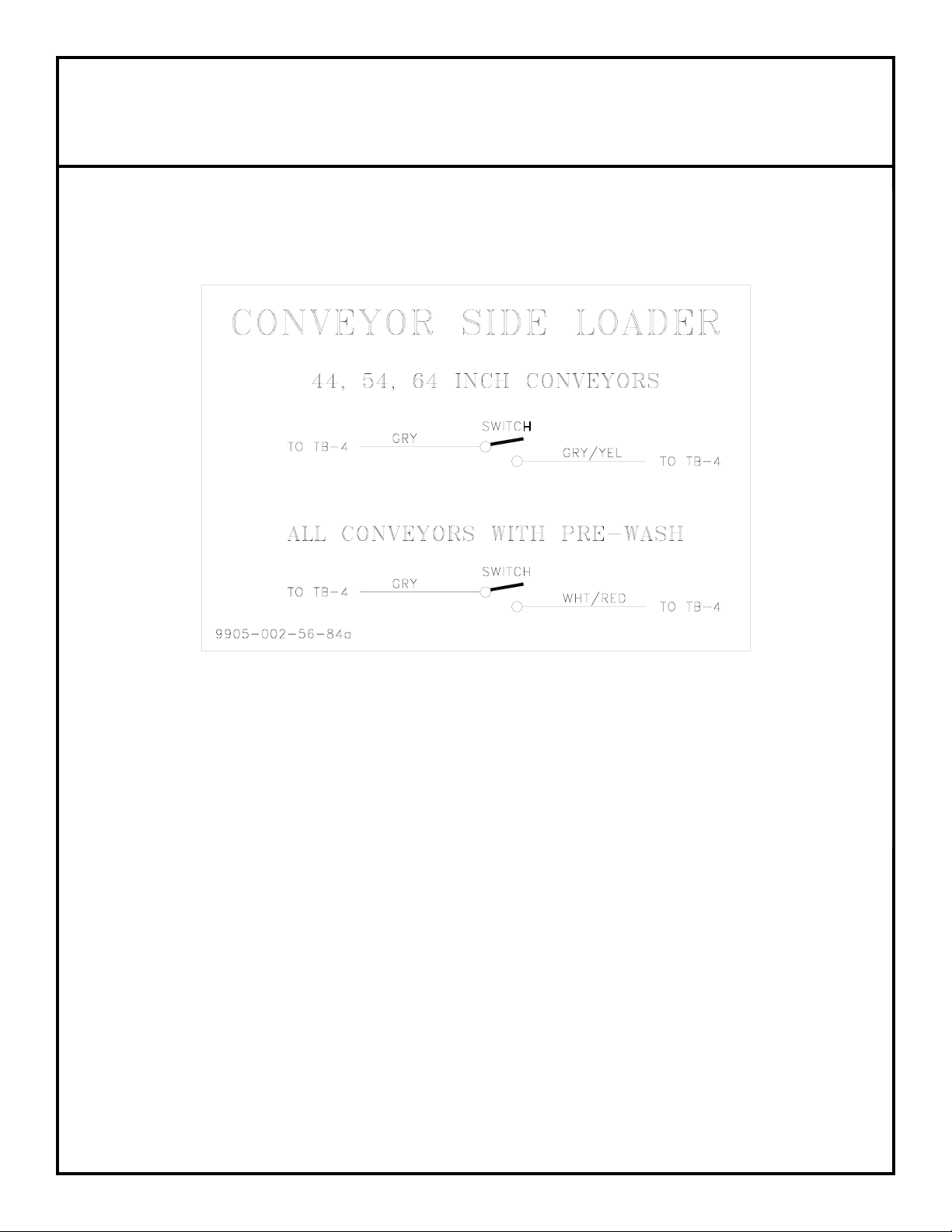

Page 16

SIDELOADER

ELECTRICAL DIAGRAM

208V - 230V - 60 HERTZ - SINGLE PHASE

14

Page 17

JACKSON MAINTENANCE & REPAIR CENTERS

ALABAMA

JONES-McLEOD

APPLIANCE SVC

1616 7TH AVE. NORTH

BIRMINGHAM, AL 35203

(205) 251-0159

800-821-1150

FAX: (205) 322-1440

service@jones-mcleod.com

JONES-McLEOD

APPLIANCE SVC

854 LAKESIDE DRIVE

MOBILE, AL 36693

(334) 666-7278

800-237-9859

FAX: (334) 661-0223

ALASKA

RESTAURANT APPLIANCE

SERVICE

7219 ROOSEVELT WAY NE

SEATTLE, WA 98115

(206) 524-8200

800-433-9390

FAX: (206) 525-2890

info@restappl.com

ARIZONA

AUTHORIZED COMMERCIAL

FOOD EQMT. SVC

4832 SOUTH 35TH STREET

PHOENIX, AZ 85040

(602) 234-2443

800-824-8875

FAX: (602) 232-5862

acsboss@aol.com

GCS SERVICE INC. #78

5052 SOUTH 40TH STREET

PHOENIX, AZ 85040

(602) 474-4510

800-510-3497

FAX: (602) 470-4511

phoenix@gcssvc.com

ARKANSAS

BROMLEY PARTS & SVC

10TH AND RINGO

P.O. BOX 1688

LITTLE ROCK, AR 72202

(501) 374-0281

(800) 482-9269

FAX: (501) 374-8352

brom@mindspring.com

COMMERCIAL PARTS & SVC.

3717 CHERRY ROAD

MEMPHIS, TN 38118

(901) 366-4587

800-262-9155

FAX: (901) 366-4588

CALIFORNIA

BARKERS FOOD MACHINERY

EQUIPMENT

5367 SECOND STREET

IRWINDALE, CA 91706

(626) 960-9390

800-258-6999

FAX: (626) 337-4541

bfms@jps.net

GCS SERVICE INC. #24

1100 EAST PICO BLVD.

LOS ANGELES, CA 90021

(213) 683-2090

800-327-1433

FAX: (213) 683-2099

los_angeles@gcssvc.com

GCS SERVICE INC. #24

650 S. GRAND AVE. STE 111

SANTA ANA, CA 92705

(714) 542-1798

800-540-0719

FAX: (714) 542-4787

santa_ana@gcssvc.com

GCS SERVICE INC. #52

360 LITTLEFIELD

S. SAN FRANCISCO, CA 94080

(650) 635-0720

800-969-4427

FAX: (650) 871-4019

san_francisco@gcssvc.com

GCS SERVICE INC. #84

9030 KENAMAR DR. STE 313

SAN DIEGO, CA 92121

(858) 549-8411

800-422-7278

FAX: (858) 549-2323

san_diego@gcssvc.com

P & D APPLIANCE SVC

100 SOUTH LINDEN AVE.

S. SAN FRANCISCO, CA 94080

(650) 635-1900

800-424-1414

FAX: (650) 635-1919

pndappl@aol.com

P & D APPLIANCE

4220-C ROSEVILLE ROAD

NORTH HIGHLANDS, CA 95660

(916) 974-2772

800-824-7219

FAX:(916) 974-2774

COLORADO

GCS SERVICE INC.

4251 S. NATCHES CT. #60#

UNIT C

SHERIDAN, CO 80110

(303) 371-9054

800-972-5314

FAX: (303) 371-4754

denver@gcssvc.com

METRO APPLIANCE SERVICE

1640 S BROADWAY

DENVER, CO 80210

(303) 778-1126

800-525-3532

FAX: (303) 778-0268

metroappls@aol.com

CONNECTICUT

GCS SERVICE INC. #06

302 MURPHY ROAD

HARTFORD, CT 06114

(860) 549-5575

800-423-1562

FAX: (860) 527-6355

hartford@gcssvc.com

DELAWARE

FOOD SERVICE EQMT.

2101 PARKWAY SOUTH

BROOMALL, PA 19008

(610) 356-6900

FAX: (610) 356-2038

dancerule@aol.com

GCS SERVICE INC. #44

817 N THIRD STREET

P.O. BOX 3564

PHILADELPHIA, PA 19123

(215)925-6217

800-441-9115

FAX: (215) 925-6208

philadelphia@gcssvc.com

ELMER SCHULTZ SERVICE

36 BELMONT AVE.

WILLMINGTON, DE 19804

(302) 655-8900

800-225-0599

FAX: (302) 656-3673

elmer2@erols.com

EMR SERVICE DIVISION

106 WILLIAMSPORT CIRCLE

SALISBURY, MD 21804

(410) 543-8197

FAX: (410) 548-4038

FLORIDA

COMMERCIAL APPLIANCE

SERVICE

8416 LAUREL FAIR CIRCLE

BLDG 6, SUITE 114

TAMPA, FL 33610

(813) 663-0313

800-282-4718

FAX: (813) 663-0212

commercialappliance@

worldnet.att.net

GCS SERVICE INC #15

3373 NW 168TH ST.

MIAMI, FL 33056

(305) 621-6666

800-766-8966

FAX: (305) 621-6656

miami@gcssvc.com

GCS SERVICE INC #13

4305 VINELAND RD STE G-12

ORLANDO, FL 32811

(407) 841-2551

800-338-7322

FAX: (407) 423-8425

orlando@gcssvc.com

GCS SERVICE INC #14

3902 CORPOREX PARK DR.

SUITE 350

TAMPA, FL 33619

(813) 626-6044

800-282-3008

FAX: (813) 621-1174

tampa@gcssvc.com

JONES-McLEOD

APPLIANCE SVC

854 LAKESIDE DRIVE

MOBILE, AL 36693

(334) 666-7278

800-237-9859

FAX: (334) 661-0223

service@jones-mcleod.com

GEORGIA

GCS SERVICE INC #16

3127 PRESIDENTIAL DR.

ATLANTA, GA 30340

(770) 452-7322

800-334-3599

FAX: (770) 452-7473

atlanta@gcssvc.com

SOUTHEASTERN

RESTAURANT SVC.

2200 NORCROSS PKWY.

SUITE 210

NORCROSS, GA 30071

(770) 446-6177

800-235-6516

FAX: (770) 446-3157

srsatl@aol.com

WHALEY FOODSERVICE

REPAIRS

109-A OWENS INDUSTRIAL

DRIVE

SAVANNAH, GA 31405

(912) 447-0827

888-765-0036

FAX: (912) 447-0826

HAWAII

FOOD EQMT. PARTS &

SERVICE CO.

300 PUUHALE RD.

HONOLULU, HI 96819

(808) 847-4871

FAX: (808) 842-1560

fepsco@hula.net

15

Page 18

JACKSON MAINTENANCE & REPAIR CENTERS

IDAHO:

RESTAURANT APPLIANCE SVC.

7219 ROOSEVELT WAY NE

SEATTLE, WA 98115

(206) 524-8200

800-433-9390

FAX: (206) 525-2890

info@restappl.com

RON'S SERVICE

703 E 44TH STREET STE 10

GARDEN CITY, ID 83714

(208) 375-4073

FAX: (208) 375-4402

ILLINOIS

CONES REPAIR SVC.

2408 40TH AVE.

MOLINE, IL 61265

(309) 797-5323

800-716-7070

FAX: (309)797-3631

jackb@cones.com

EICHENAUER SERVICES INC.

130 S OAKLAND ST.

DECATUR, IL 62522

(217) 429-4229

800-252-5892

FAX: (217) 429-0226

esi@esiquality.com

GCS SERVICE INC. #12

696 LARCH AVE.

ELMHURST, IL 60126

(630) 941-7800

800-942-9689

FAX: (630) 941-6048

chicago@gcsscv.com

GCS SERVICE INC. #80

9722 REAVIS PARK DR.

ST. LOUIS, MO 63123

(314) 683-7444

800-284-4427

FAX: (314) 638-0135

st_louis@gcssvc.com

INDIANA

COMMERCIAL PARTS & SVC.

5310 E 25TH STREET

INDIANAPOLIS, IN 46218

(317) 545-9655

800-727-8710

FAX: (317) 549-6286

peproane@aol.com

IOWA

GOODWIN-TUCKER GROUP

3509 DELAWARE AVENUE

DES MOINES, IA 50313

(515) 262-9308

800-372-6066

FAX: (515) 262-2936

goodwintuc@aol.com

CONES REPAIR SVC.

1056 27TH AVENUE SW

CEDAR RAPIDS, IA 52404

(319) 365-3325

800-747-3326

FAX: (319) 365-0885

KANSAS

GCS SERVICE INC. #82

6107 CONNECTICUT

KANSAS CITY, MO 64120

(816) 920-5999

800-229-6477

FAX: (816) 920-7387

kansas_city@gcssvc.com

KENTUCKY

CERTIFIED SERVICE CENTER

RAMCO BUSINESS PARK

4283 PRODUCE ROAD

LOUISVILLE, KY 40218

(502) 964-7007

800-637-6350

FAX: (502) 964-7202

droenigk@certifiedsc.com

CERTIFIED SERVICE CENTER

1051 GOODWIN DRIVE

LEXINGTON, KY 40505

(606) 254-8854

800-432-9269

FAX: (606) 231-7781

jadkins@certifiedsc.com

COMMERCIAL PARTS &

SERVICE

4204 SOUTH BROOK STREET

LOUISVILLE, KY 40214

(502) 367-1788

800-752-6160

FAX: (502) 367-0400

COMMERCIAL PARTS &

SERVICE

1002 NANDINO BLVD.

LEXINGTON, KY 40511

(606) 255-0746

800-432-9260

FAX: (606) 255-0748

LOUISIANA

BANA PARTS INC.

1501 KUEBLE STREET

HARAHAN, LA 70123

(504) 734-0076

800-325-7543

FAX: (504) 734-8456

BANA PARTS INC.

4028 GREENWOOD ROAD

SHREVEPORT, LA 71109

(318) 631-6550

800-832-6550

FAX: (318) 636-5675

MAINE

GCS SERVICE INC. #09

180 SECOND STREET

CHELSEA, MA 02150

(617) 889-9393

800-225-1155

FAX: (617) 889-1222

boston@gcssvc.com

MASSACHUSETTS

RESTAURANT SUPPLY

34 SOUTH STREET

SOMERVILLE, MA 02143

(617) 868-1930

800-338-6737

FAX: (617) 686-5331

MARYLAND:

EMR SERVICE DIVISION

700 EAST 25TH STREET

BALTIMORE, MD 21218

(410) 467-8080

800-879-4994

FAX: (410) 467-4191

baltparts@emrco.com

EMR SERVICE DIVISION

106 WILLIAMSPORT CIRCLE

SALISBURY, MD 21804

(410) 543-8197

888-687-8080

FAX: (410) 548-4038

baltparts@emrco.com

EMR SERVICE DIVISION

2626 PITTMAN DRIVE

SILVER SPRING, MD 20910

(301) 588-8080

800-348-2365

FAX: (301) 588-6985

baltparts@emrco.com

GCS SERVICE INC. #07

2660 PITTMAN DRIVE

SILVER SPRING, MD 20910

(301) 585-7550 (DC)

(410) 792-0338 (BALT)

(800) 638-7278

FAX: (301) 495-4410

dc_baltimore@gcssvc.com

MASSACHUSETTS

ACE SERVICE CO.

95 HAMPTON AVE.

NEEDHAM, MA 02494

(781) 449-4220

800-225-4510 MA & NH

FAX: (781) 444-4789

taceservice@aol.com

MASSACHUSETTS

RESTAURANT SUPPLY

34 SOUTH STREET

SOMERVILLE, MA 02143

(617) 868-1930

800-338-6737

FAX: (617) 868-5331

GCS SERVICE INC. #09

180 SECOND STREET

CHELSEA, MA 02150

(617) 889-9393

800-225-1155

FAX: (617) 889-1222

boston@gcssvc.com

GCS SERVICE INC. #06

302 MURPHY ROAD

HARTFORD, CT 06114

(860) 549-5575

800-723-1562

FAX: (860) 527-6355

hartford@gcssvc.com

MICHIGAN

GCS SERVICE INC. #20

31829 WEST EIGHT MILE RD.

LIVONIA, MI 48152

(248) 426-9500

800-772-2936

FAX: (248) 426-7555

detroit@gcssvc.com

JACKSON SERVICE COMPANY

3980 BENSTEIN RD.

COMMERCE TWSHP, MI 48382

(248) 363-4159

800-332-4053

FAX: (248) 363-5448

GCS SERVICE INC. #21

3516 ROGER B. CHAFFE SE

GRAND RAPIDS, MI 49548

(616) 241-0200

800-823-4866

FAX: (616) 241-0541

grand_rapids@gcssvc.com

MINNESOTA

GCS SERVICE INC.

2857 LOUISIANA AVENUE N.

MINNEAPOLIS, MN 55427

(612) 546-4221

800-345-4221

FAX: (612) 546-4286

minneapolis@gcssvc.com

MISSISSIPPI

COMMERCIAL PARTS & SVC.

5755 GALLANT DRIVE

JACKSON, MS 39206

(601) 956-7800

800-274-5954

FAX: (601) 956-1200

COMMERCIAL PARTS & SVC.

3717 CHERRY ROAD

MEMPHIS, TN 38118

(901) 366-4587

800-262-9155

FAX: (901) 366-4588

16

Page 19

JACKSON MAINTENANCE & REPAIR CENTERS

MISSOURI

GCS SERVICE INC. #82

6107 CONNECTICUT

KANSAS CITY, MO 64120

(816) 920-5999

800-229-6477

FAX: (816) 920-7387

kansas_city@gcssvc.com

GCS SERVICE INC. #80

9722 REAVIS PARK DR.

ST. LOUIS, MO 63123

(314) 638-7444

800-284-4427

FAX: (314) 638-0135

st_louis@gcssvc.com

KAMMERLIN PARTS & SVC.

2728 LOCUST STREET

ST. LOUIS, MO 63103

(314) 535-2222

FAX: (314) 535-6205

MONT

ANA:

RESTAURANT APPLIANCE SVC.

7219 ROOSEVELT WAY NE

SEATTLE, WA 98115

(206) 524-8200

800-433-9390

FAX: (206) 525-2890

info@restappl.com

NEBRASKA:

GOODWIN - TUCKER GROUP

815 N 19TH STREET

OMAHA, NE 68102

(402) 345-7400

800-228-0342

FAX: (402) 346-6145

goodwintuc@aol.com

NEVADA:

BURNEY'S COMMERCIAL

SERVICE

4480 ALDEBARAN AVE.

LAS VEGAS, NV 89103

(702) 736-0006

FAX: (702) 798-7531

GCS SERVICE INC. #77

3585 EAST PATRICK LANE

SUITE 1000

LAS VEGAS, NV 89102

(702) 450-3495

800-500-9060

FAX: (702) 450-3491

las_vegas@gcssvc.com

NEW HAMPSHIRE

GCS SERVICE INC. #09

180 SECOND STREET

CHELSEA, MA 02150

(617)889-9393

800-225-1155

FAX: (617) 889-1222

boston@gcssvc.com

ACE SERVICE CO.

95 HAMPTON AVE.

NEEDHAM, MA 02494

(781) 449-4220

800-225-4510 MA & NH

FAX: (781) 444-4789

taceservice@aol.com

MASSACHUSETTS RESTAURANT SUPPLY

34 SOUTH STREET

SOMERVILLE, MA 02143

(617) 868-1930

800-338-6737

FAX: (617) 868-5331

NEW JERSEY:

JACKSON FASPRAY SVC.

155 SARGEANT AVE.

CLIFTON, NJ 07013

(973) 471-8000

800-356-6740

FAX: (973) 471-1289

GCS SERVICE INC. #2

1 MADISON STREET

BUILDING F

EAST RUTHERFORD, NJ 07073

(973) 614-0003

800-399-8294

FAX: (973) 614-0230

east_rutherford@gcssvc.com

GCS SERVICE INC. #44

817 N THIRD STREET

PHILADELPHIA, PA 19123

(215) 925-6217

800-441-9115

FAX: (215) 925-6208

philadelphia@gcssvc.com

FOOD SERVICE EQMT.

2101 PARKWAY SOUTH

BROOMALL, PA 19008

(610) 356-6900

FAX: (610) 356-2038

dancerule@aol.com

NEW MEXICO:

STOVE PARTS SUPPLY CO.

2120 SOLANA STREET

FORT WORTH, TX 76117

(817) 831-0381

800-433-1804

FAX: (817) 834-7754

bua@stoveparts.com

NEW YORK

APPLIANCE INSTALLATION

AND SERVICE CORP.

1336 MAIN STREET

BUFFALO, NY 14209

(716) 884-7425

800-722-1252

FAX: (716) 884-0410

ais@worldnet.att.net

B.E.S.T. INC.

3003 GENESEE STREET

BUFFALO, NY 14225

(716) 893-6464

800-338-5011

FAX: (716) 893-6466

bestserv@aol.com

DUFFY'S EQUIPMENT SVC.

3138 ONEIDA STREET

SAUQUOIT, NY 13456

(315) 737-9401

800-443-8339

FAX: (315) 737-7132

duffyequip@aol.com

NORTHERN PARTS & SVC.

21 NORTHERN AVENUE

PLATTSBURGH, NY 12903

(518) 563-3200

800-634-5005

FAX: (800) 782-5424

info@northernparts.com

GCS SERVICE INC. #01

932 GRAND STREET

BROOKLYN, NY 11211

(718) 486-5220

800-969-4271

FAX: (718) 486-6772

new_york@gcssvc.com

JACKSON FASPRAY SVC.

155 SARGEANT AVE.

CLIFTON, NJ 07013

(973) 471-8000

800-356-6740

FAX: (973) 471-1289

jfs155@aol.com

NORTH CAROLINA

WHALEY FOODSERVICE

8334-K ARROWRIDGE BLVD

CHARLOTTE, NC 28273

(704) 529-6242

FAX: (704) 529-1558

info@whaleyfoodservice.com

WHALEY FOODSERVICE

REPAIRS

203-D CREEK RIDGE RD.

GREENSBORO, NC 27406

(336) 333-2333

FAX: (336) 333-2533

info@whaleyfoodservice.com

WHALEY FOODSERVICE

REPAIRS

335-105 SHERWEE DRIVE

RALEIGH, NC 27603

(919) 779-2266

FAX: (919) 779-2224

info@whaleyfoodservice.com

WHALEY FOODSERVICE

REPAIRS

6418-101 AMSTERDAM WAY

WILMINGTON, NC 28405

(910) 791-0000

FAX: (910) 791-6662

info@whaleyfoodservice.com

NORTH DAKOTA

METRO COMMERCIAL

SERVICE INC.

2857 LOUISIANA AVENUE N.

MINNEAPOLIS, MN 55427

(612) 546-4221

800-345-4221

FAX: (612) 546-4286

minneapolis@gcssvc.com

OHIO

CERTIFIED SERVICE CENTER

890 REDNA TERRACE

CINCINNATI, OH 45215

(513) 772-6600

800-543-2060

FAX: (513) 612-6600

sbarasch@certifiedsc.com

COMMERCIAL PARTS & SVC.

OF COLUMBUS

1150 WEST MOUND STREET

COLUMBUS, OH 43223

(614) 221-0057

800-837-8327

FAX: (614) 221-3622

GCS SERVICE INC.

2830 JOHNSTOWN ROAD

COLUMBUS, OH 43219

(614) 476-3225

800-282-5406

FAX: (614) 476-1196

columbus@gcssvc.com

ELECTRICAL APPLIANCE

REPAIR SVC.

5805 VALLEY BELT ROAD

CLEVELAND, OH 44131

(216) 459-8700

800-621-8259

FAX: (216) 459-8707

trears@aol.com

OKLAHOMA

HAGAR RESTAURANT EQMT.

1229 W MAIN STREET

OKLAHOMA CITY, OK 73106

(405) 235-2184

800-445-1791

FAX: (405) 236-5592

17

Page 20

JACKSON MAINTENANCE & REPAIR CENTERS

KRUEGER INC.

100 NE 24TH STREET

OKLAHOMA CITY, OK 73105

(405) 528-8883

800-522-8069

FAX: (405) 528-5405

kruegers@swbell.net

OREGON

RON'S SERVICE

16364 SW 72ND AVE

PORTLAND, OR 97224

(503) 624-0890

800-851-4118

FAX: (503) 684-6107

lrobinson@ronsservice.com

PENNSYLVANIA

A.I.S. COMMERCIAL PARTS &

SERVICE

1816 WEST 26TH STREET

ERIE, PA 16508

(814) 456-3732

800-332-3732

FAX: (814) 452-4843

aiserie@aol.com

AFS-AUTHORIZED FACTORY

SVC. INC.

940 FIRST AVE.

CORAOPOLIS, PA 15108

(412) 262-2330

800-222-8767

FAX: (412) 262-2245

ELMER SCHULTZ SVC.

540 NORTH 3RD STREET

PHILADELPHIA, PA 19123

(215) 627-5400

FAX: (215) 627-5408

elmer2@erols.com

FOOD SERVICE EQMT.

2101 PARKWAY SOUTH

BROOMALL, PA 19008

(610) 356-6900

FAX: (610) 356-2038

dancerule@aol.com

GCS SERVICE INC. #44

817 N THIRD STREET

P.O. BOX 3564

PHILADELPHIA, PA 19123

(215) 925-6217

800-441-9115

FAX: (215) 925-6208

philadelphia@gcssvc.com

GCS SERVICE INC. #44

4400 LEWIS ROAD

SUITE E

HARRISBURG, PA 17111

(717) 564-3282

800-367-3225

FAX: (717) 564-9286

harrisburg@gcssvc.com

GCS SERVICE INC. #48

210 VISTA PARK DRIVE

PITTSBURGH, PA 15205

(412) 787-1970

800-738-1221

FAX: (412) 787-5005

pittsburgh@gcssvc.com

K & D PARTS AND SERVICE

CO.

1833-41 N CAMERON STREET

HARRISBURG, PA 17103

(717) 236-9039

800-932-0503

FAX: (717) 238-4367

kdparts-service@paonline.com

RHODE ISLAND

GCS SERVICE INC. #09

1002 WATERMAN AVE.

EAST PROVIDENCE, RI 02914

(401) 434-6803

800-462-6012

FAX: (401) 438-9400

providence@gcssvc.com

SOUTH CAROLINA

WHALEY FOODSERVICE

REPAIRS

I 26&US1

P.O. BOX 4023

WEST COLUMBIA, SC 29170

(803) 791-4420

800-877-2662

FAX: (803) 794-4630

info@whaleyfoodservice.com

WHALEY FOODSERVICE

REPAIRS

748 CONGAREE ROAD

GREENVILLE, SC 29607

(864) 234-7011

800-494-2539

FAX: (864) 234-6662

info@whaleyfoodservice.com

WHALEY FOODSERVICE

REPAIRS

1406-C COMMERCE PL.

MYRTLE BEACH, SC 29577

(843) 626-1866

FAX: (843) 626-2632

info@whaleyfoodservice.com

WHALEY FOODSERVICE

REPAIRS

4740-A FRANCHISE STREET

N. CHARLESTON, SC 29418

(843) 760-2110

FAX: (843) 760-2255

info@whaleyfoodservice.com

SOUTH DAKOTA

GCS SERVICE INC.

2857 LOUISIANA AVENUE N.

MINNEAPOLIS, MN 55427

(612) 546-4221

800-345-4221

FAX: (612) 546-4286

minneapolis@gcssvc.com

TENNESSEE

COMMERCIAL PARTS & SVC.

3717 CHERRY ROAD

MEMPHIS, TN 38118

(901) 366-4587

800-262-9155

FAX: (901) 366-4588

COMMERCIAL PARTS & SVC.

748 FESSLERS LANE

NASHVILLE, TN 37210

(615) 244-8050

800-831-7174

FAX: (615) 244-8885

alesco1@aol.com

COMMERCIAL APPLIANCE

SVC.

919 8TH AVENUE SOUTH

NASHVILLE, TN 37203

(615) 254-0906

800-476-0906

FAX: (615) 254-0919

casnash@aol.com

TEXAS

ARMSTRONG REPAIR CENTER

5110 GLENMOUNT DRIVE

HOUSTON, TX 77081

(713) 666-7100

800-392-5325

FAX: (713) 661-0520

gm@armstrongrepair.com

COMMERCIAL KITCHEN

REPAIR CO.

1377 N BRAZOS

P.O BOX 831128

SAN ANTONIO, TX 78207

(210) 735-2811

800-292-2120

FAX: (210) 735-7421

brock@commercialkitchen.com

GCS SERVICE INC. #90

10850 SANDEN DRIVE

DALLAS, TX 75238-5325

(972) 484-2954

800-442-5026

FAX: (972) 484-2531

dallas@gcssvc.com

GCS SERVICE INC. #88

8150 WESTPARK

HOUSTON, TX 77063

(713)785-9187

800-868-6957

FAX: (713) 785-3979

houston@gcssvc.com

STOVE PARTS SUPPLY CO.

2120 SOLANA STREET

FORT WORTH, TX 76117

(817) 831-0381

800-433-1804

FAX: (817) 834-7754

bud@stoveparts.com

UTAH

LA MONICA'S RESTAURANT

EQMT. SVC.

6182 SOUTH STRATLER

AVENUE

MURRAY, UT 84107

(801) 263-3221

800-527-2561

FAX: (801) 263-3229

lamonica81@aol.com

VERMONT

AUTHORIZED APPLIANCE SERVICENTER OF VERMONT

74 RIVER STREET

RUTLAND, VT 05701

(802) 775-5588

800-874-1080

FAX: (802) 775-9593

suew

@authorizedapplianceofut.com

NORTHERN PARTS & SVC.

4874 S. CATHERINE STREET

PLATTSBURGH, NY 12901

(518) 563-3200

800-634-5005

FAX: (800) 782-5424

info@northernparts.com

GCS SERVICE INC. #09

180 SECOND STREET

CHELSEA, MA 02150

(617)889-9393

800-225-1155

FAX: (617) 889-1222

boston@gcssvc.com

VIRGINIA

DAUBERS, INC.

7645 DYNATECH COURT

SPINGFIELD, VA 22153

(703) 866-3600

800-554-7788

FAX: (703) 866-4071

daubers@aol.com

18

Page 21

JACKSON MAINTENANCE & REPAIR CENTERS

GCS SERVICE INC. #07

2660 PITTMAN DRIVE

SILVER SPRING, MD 20910

(301) 585-7550(DC)

(410) 792-0388(BALT)

800-638-7278

FAX: (301)495-4410

dc_baltimore@gcssvc.com

GCS SERVICE INC. #18

2421 GRENOBLE RD.

RICHMOND, VA 23294

(804) 672-1700

800-899-5949

FAX: (804) 672-2888

richmond@gcssvc.com

GCS SERVICE INC. #18

5760 NORTHAMPTON BLVD.

STE 106

VIRGINIA BEACH, VA 23455

(757) 464-3500

800-476-4278

FAX: (757) 464-4106

virginia_beach@gcssvc.com

WASHINGTON

GCS SERVICE INC.

6114 SIXTH AVENUE SOUTH

SEATTLE, WA 98108

(206) 763-0353

800-211-4274

FAX: (206) 763-5943

RESTAURANT APPLIANCE

SERVICE

7219 ROOSEVELT WAY, NE

SEATTLE, WA 98115

(206) 524-8200

800-433-9390

FAX: (206) 525-2890

info@restappl.com

WEST VIRGINIA

AFS-AUTHORIZED FACTORY

SVC INC.

RT.-1 BOX 288

S. CHARLESTON, WV 25312

(304) 344-8225

800-654-4606

FAX: (304) 344-8248

WISCONSIN

APPLIANCE SERVICE

CENTER, INC.

2439 ATWOOD AVE

MADISON, WI 53704

(608) 246-3160

800-236-7440

FAX: (608) 246-2721

ascmad@execpc.com

APPLIANCE SERVICE

CENTER, INC.

6843 W. BELOIT RD.

WEST ALLIS, WI 53219

(414) 543-6460

800-236-6460

FAX: (414) 543-6480

ascmil@execpc.com

APPLIANCE SERVICE CENTER

786 MORRIS AVE

GREEN BAY, WI 54304

(920) 496-9993

800-236-0871

FAX: (920) 496-9927

ascfox@execpc.com

WYOMING

METRO APPLIANCE SERVICE

1640 S BROADWAY

DENVER, CO 80210

(303) 778-1126

800-525-3532

FAX: (303) 778-0268

metroappls@aol.com

INTERNATIONAL

GLOBAL PARTS AND SUPPLY

7758 NW 72ND ST

MIAMI, FL 33166

(305) 885-6353

H.D. SHELDON AND CO

19 UNION SQUARE, WEST

NEW YORK, NY 10003

(212) 627-1759

(212) 924-6920

CANADA

THE GARLAND GROUP

1177 KAMATO ROAD

MISSISSAUGA, ONTARIO

L4W 1X4

(905) 206-8380

SALES

(905) 624-1419

FAX: (905) 624-1851

SERVICE

800-427-6668

FAX: 800-361-7745

18

Page 22

IMPORTANT INFORMATION DATA SHEET

19

Model:

Serial No.:

Installation Date:

Service Rep. Name:

Phone No.:

Notes:

Loading...

Loading...