Page 1

RackStar® 66

Models

RackStar 66

Standard Features

• Adjustable Rinse System

• Rainbow Rinse™ with arched

rinse arm design

• 19-3/4” (502 mm) clearance

• WISR® Cleaning System

• Double-wall insulated doors retain

heat, keeping wash water hot &

generating less heat in the dish

room

• Self-cleaning wash arms

• 22” pre-wash

• Fully automatic, including auto-ll

• Adjustable vent cowl collars

• Exclusive EnergyGuard™ controls

Project

Item

Quantity

CSI Section 11400

Approval

Date

• Self-draining stainless steel

wash pump

• Digital LED control panel

• Strike plate table limit switch

• Large front access for ease of

maintenance

• Stainless steel strainer pans

• Splash shields

• Stainless steel frame and legs

• Exhaust vent fan control

• 15kW wash tank heater

• Front dress panel

• Adjustable bullet feet

RackStar® 66

Mandatory Specs

Specify:

Electric

Steam

Specify Voltage______________

Specify Sanitizing Method:

High Temperature

Chemical Sanitizing

Specify Direction of Operation:

Left to Right

Right to Left

Options

Onboard Booster

40° F (22.2° C) Rise

70° F (38.9° C) Rise

Single Point Connection with

Onboard Booster

Steam Booster Heater

23” (584 mm) Unhooded Side Loader

30” (762 mm) Unhooded Side Loader

Flanged Feet

Prison Package

Specifications

Uses 0.35 gallons of water (1.32 liters) per rack in Econo Rinse mode

Uses 0.52 gallons of water (1.97 liters) per rack in Turbo Rinse mode

Cleans 223 racks per hour

22” (559 mm) pre-wash section has 3 upper and 1 lower

pre-wash arms

Durable stainless steel construction

(3 phase only)

Accessories

36-Compartment Rack

4-1/8” tall (104 mm)

5 - 5/8” tall (143 mm)

7” tall (178 mm)

Combination Rack

Peg Rack

Sheet Pan Rack

Drain Quench System

Scaltrol

Water Hammer Arrestor

www.jacksonwws.com

Page 2

RackStar® 66

Left to Right

4 1/8

[105 mm]

ADJUSTABLE FROM 73 1/2 - 76 "

76

"

[1867 - 1930 mm]

"

"

]

m

/4

m

1

0

4

7

3

8

[

"

]

m

8

/

m

7

4

4

2

1

[

16

[406 mm]

4

"

[1930 mm]

5

4

]

m

"

m

3

8

0

2

[

]

m

"

m

5

7

2

1

[

]

"

m

m

2

/

3

1

1

3

6

6

1

[

2

7 3/4

4 3/4

"

[121 mm]

4 " MIN

[102 mm]

]

m

"

m

6

6

1

0

4

[

1. Electrical Connection

(Provided on both sides of unit)

2. Pre-Wash Water Inlet

(1/2" NPT 180 °F)

3. Main Water Inlet

(1/2" NPT 180 °F)

4. Vent Connections

(Including Dampers)

5. Drain Connection

(1 1/2" NPT)

[197 mm]

"

24 "

[610 mm]

"

]

m

m

0

2

8

0

5

[

38 7/8

[988 mm]

3

"

]

"

m

8

m

/

1

4

8

5

3

1

[

]

"

m

4

m

/

1

3

6

5

9

7

2

[

28 7/16

[722 mm]

25 1/4

[642 mm]

4 3/4

[120 mm]

"

"

"

1

6 11/16

"

[169 mm]

"

]

6

m

1

/

5

m

1

1

1

1

8

3

[

66 "

[1676 mm]

86 "

[2184 mm]

2,3

"

]

m

2

/

m

1

0

8

4

6

7

1

[

"

]

]

m

m

"

8

m

/

m

3

0

3

9

0

6

1

5

6

6

5

1

1

[

[

1 3/4" using the machine’s adjustable feet.

www.jacksonwws.com

4" MIN

[102 mm]

5

18 5/16

[465 mm]

"

Page 3

RackStar® 66

5

[1

2

7

m

m

]

"

6

8

1

/

2

[

1

7

4

0

m

m

]

"

8

"

[

2

0

3

m

m

]

64 "

[1626 mm]

4 1/8

[105 mm]

"

4 1/8 "

[105 mm]

ADJUSTABLE FROM 51 1/2" TO 54"

[1308 mm TO 1372 mm]

21 1/4

[540 mm]

"

2

0

"

[

5

0

8

m

m

]

16 11/16

[424 mm]

"

51 11/16

[1313 mm]

"

4" MIN

[102 mm]

3

1

1

5

/

1

6

[

8

1

1

m

m

]

"

6

3

"

[

1

6

0

0

m

m

]

6

1

3

/

8

[

1

5

5

9

m

m

]

"

6 15/16

[176 mm]

"

Right to Left

4

"

]

4 1/8

"

8

"

]

m

m

3

0

2

[

m

m

5

7

2

1

[

]

m

"

m

2

/

3

1

1

3

6

6

1

[

4

]

"

m

4

m

/

1

0

7

4

8

3

[

ADJUSTABLE FROM 73 1/2 - 76 "

ADJUSTABLE FROM - 76 "

[1867 - 1930 mm]

[1867 - 1930 mm]

1

73

2

5

18 3/8

[466 mm]

[105 mm]

]

"

m

m

8

"

/

4

7

2

4

1

[

2,3

1

]

28 7/16

"

[722 mm]

25 1/4

"

[642 mm]

4 3/4

"

1

[120 mm]

6 11/16

[169 mm]

"

m

"

m

6

6

1

0

4

[

]

m

"

m

0

8

2

0

5

[

3

63 13/16

[1621 mm]

66 "

[1676 mm]

86 "

[2184 mm]

"

38 7/8

[987 mm]

2

"

7 13/16

[198 mm]

"

"

8

/

1

5

1

]

N

m

I

m

M

"

2

0

1

4

[

]

m

m

4

8

3

[

]

"

m

4

m

/

3

6

5

9

7

2

[

1. Electrical Connection

(Provided on both sides of unit)

2. Pre-Wash Water Inlet

(1/2" NPT 180 °F)

3. Main Water Inlet

(1/2" NPT 180 °F)

4. Vent Connections

(Including Dampers)

5. Drain Connection

(1 1/2" NPT)

1 3/4" using the machine’s adjustable feet.

4" MIN

[102 mm]

18 5/16

[465 mm]

"

5

www.jacksonwws.com

Page 4

RackStar® 66

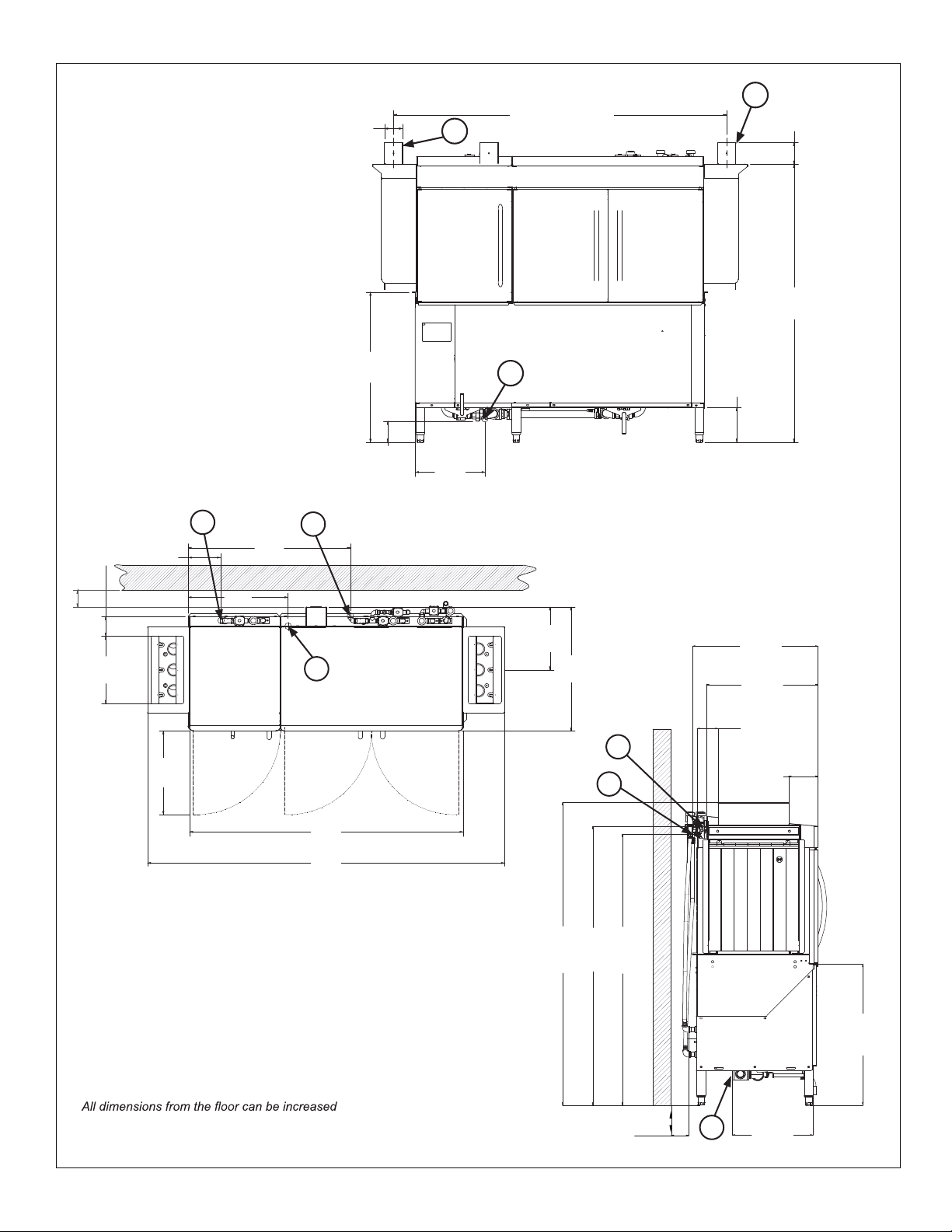

RECOMMENDED TABLE FABRICATION

TABLE CONNECTION

RACK RAIL

5/16" (8 mm)

1/4" (6 mm) TO

ABOVE DISHTABLE

RACK RAIL HEIGHT

TABLE

21.00" (533 mm)

MACHINE DIMENSIONS

MODEL NO.

RackStar 66

HEIGHT

64-1/2”

(1632 mm)

LENGTH

BETWEEN

DISHTABLES

66”

(1676 mm)

OPERATING CAPACITY

OPERATING TEMPERATURES

ELECTRICAL REQUIREMENTS*

BOOSTER HEATER ELECTRICAL REQUIREMENTS*

40° F (22.2° C) Minimum Rise 70° F (38.9° C ) Minimum Rise

kW AMPS kW AMPS

208V/60HZ/3PH

208V/60HZ/1PH

230V/60HZ/3PH

230V/60HZ/1PH

460V/60HZ/3PH

*Total amp draw for a single point connection with onboard booster heater (3 phase only) is calculated

by adding the amp load for the booster heater to the amp load for the machine.

HOW TO SPECIFY:

RackStar 66

12

12

12

Jackson WWS, Inc.

Shipping Address: 6209 North U.S. Highway 25E, Gray, KY 40734

3/4" (19 mm)

MAX TURNDOWN

ON TABLE

DEPTH WEIGHT CLASS CUBE HEIGHT WIDTH DEPTH

30”

(762 mm)

OPEN

50”

(1270 mm)

DEPTH

WITH DOORS

DRAIN

HEIGHT

(165 mm)

SHIPPING INFORMATION

6-1/2”

1,021 lbs

(463 kg)

USE SILICONE SEAL BETWEEN

TABLE & LIP OF DISHMACHINE

209

150

cu. ft.

DISHMACHINE TUB

89”

(2261 mm)

97”

(2464 mm)

WATER REQUIREMENTS

Chemical SanitizingHigh-Temperature

223223Racks per Hour

5,5755,575Dishes per Hour

8,0288,028Glasses per Hour

Chemical SanitizingHigh-Temperature

110 -120° F (43 -49° C)110 - 140° F (43 - 60° C)Pre-Wash

120° F (49° C)160° F (71° C)Wash (minimum)

120° F (49° C) 180° F (82° C)Rinse (minimum)

Approximate Total Load AMPS

SteamElectric Tank Heat

58.3

91.4

50.5

81.1

25.3460V/60HZ/3PH

9.7208V/60HZ/3PH

11.8208V/60HZ/1PH

9.5230V/60HZ/3PH

11.8230V/60HZ/1PH

4.8

Inlet Temperature (minimum)

With 40° F (22.2° C) Rise Booster Heater

With 70° F (38.9° C) Rise Booster Heater

Gallons per Hour (Econo Rinse / Turbo Rinse)

Gallons per Rack (Econo Rinse / Turbo Rinse)

Waterline Size IPS (minimum)

Drainline Size IPS (minimum)

Flow Pressure (PSI)

Flow Rate GPM (minimum)

Wash Tank Capacity

WASH PUMPS

Pre-Wash Pump Motor

CONVEYOR

Conveyor Motor

140° F (60° C)

110° F (43° C)

78 gal (295 L) / 116 gal (239.1 L)

0.35 gal (1.3 L) / 0.52 gal (1.97 L)

1/2”

1-1/2”

15

1.30 (4.9 LPM)

25 gal (95 L)

220 GPM (833 LPM)Pre-Wash Pump Capacity

270 GPM (1022 LPM)Wash Pump Capacity

6.07 FPM (1.85 MPM)Conveyor Speed (feet per minute)

VENTING REQUIREMENTS

Input End

33.3 17.2 47.7

57.7 17.2 82.7

27.7 18 41.5

47.9 18 71.912

13.8 18 20.712

STEAM COIL TANK HEAT (STEAM MODELS ONLY)

Steam Connection IPS

www.jacksonwws.com

Mailing Address: P.O. Box 1060, Barbourville, KY 40906

Telephone: 888-800-5672 • Fax: 606-523-1799

Email: info@jacksonwws.com

07610-004-36-87 [01/25/17]

We reserve the right to change specications in this bulletin without incurring any obligation for equipment previously or subsequently sold.

(1041 mm)

2 hp

3 hpWash Pump Motor

1/4 hp

200 CFM

200 CFMOutput End

400 CFMTotal CFM

3/4”

10-20Steam Flow Pressure (PSIG)

60Consumption @ 15 PSIG (lbs/hr)

41”

Loading...

Loading...