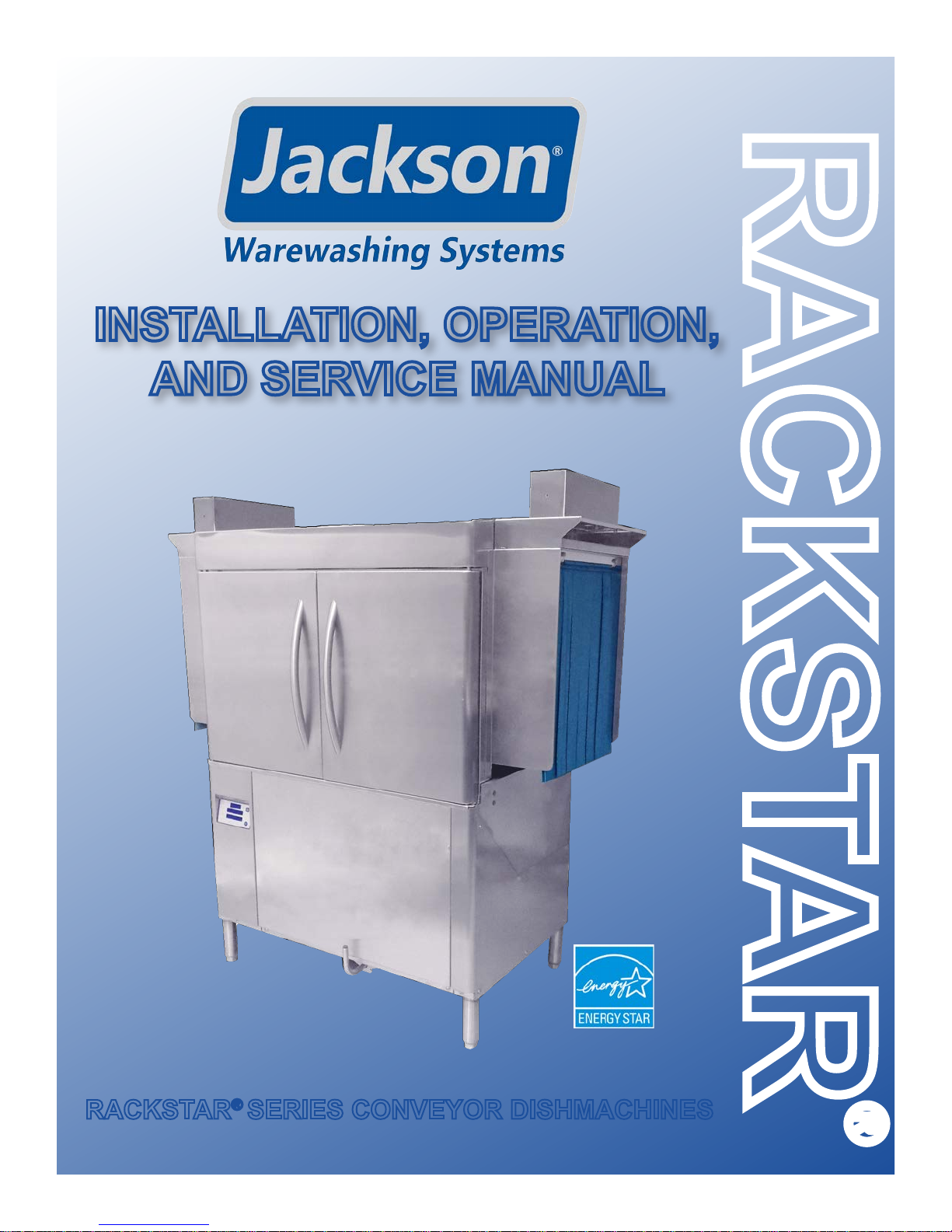

Page 1

INSTALLATION, OPERATION,

AND SERVICE MANUAL

RACKSTAR

RACKSTAR® SERIES CONVEYOR DISHMACHINES

RackStar® Manual • Rev B • 07610-004-33-05 • Issued: 9-21-2016 • Revised: 10-25-16

®

Page 2

Page 3

MANUFACTURER'S WARRANTY

ONE YEAR LIMITED PARTS AND LABOR WARRANTY

ALL NEW JACKSON DISHWASHERS ARE WARRANTED TO THE ORIGINAL PURCHASER TO BE FREE FROM DEFECTS IN

MATERIAL OR WORKMANSHIP, UNDER NORMAL USE AND OPERATION, FOR A PERIOD OF (1) ONE YEAR FROM DATE OF

PURCHASE, BUT IN NO EVENT TO EXCEED (18) EIGHTEEN MONTHS FROM DATE OF SHIPMENT FROM THE FACTOR Y.

Jackson WWS agrees under this warranty to repair or replace, at its discretion, any original part which fails under normal use

due to f aulty ma terial or workmanship during the warranty period, providing the equipment has been unaltered, and has been

properly installed, maintained, and operated in accordance with the applicable factory instruction manual and failure is reported

to an authorized service agency within the warranty period. This includes the use of factory-specied genuine replacement parts,

purchased directly from a Jackson-authorized parts distributor or service agency. Use of generic replacement parts may create a

hazard and void warranty certication.

The labor to repair or replace such failed part will be paid by Jackson WWS, within the continental United States, Hawaii, and Canada,

during the warranty period provided a Jackson WWS authorized service agency , or those having prior authorization from the factory,

performs the service. Any repair work by persons other than a Jackson WWS authorized service agency is the sole responsibility of

the customer. Labor coverage is limited to regular hourly rates; overtime premiums and emergency service charges will not be paid

by Jackson WWS.

Accessory components not installed by the factory carry a (1) one year parts warranty only . Accessory components such as table limit

switches, pre-rinse units, etc. that are shipped with the unit and installed at the site are included. Labor to repair or replace these

components is not covered by Jackson WWS.

This warranty is void if failure is a direct result from shipping, handling, re, water, accident, misuse, acts of God, attempted repair by

unauthorized persons, improper installation, if serial number has been removed or altered, or if unit is used for a purpose other than

originally intended.

TRAVEL LIMITATIONS

Jackson WWS limits warranty travel time to (2) two hours and mileage to (100) one-hundred miles. Jackson WWS will not pay for

travel time and mileage that exceeds this, or any additonal fees—such as those for air or boat travel—without prior authorization.

WARRANTY REGISTRATION

T o register your product, go to www.jacksonwws.com or call 1-888-800-5672. Failure to register your product will void the warranty.

REPLACEMENT PARTS WARRANTY

Jackson replacement parts are warranted for a period of (90) ninety days from date of installation or (180) one-hundred-eighty days

from the date of shipment from the factory, whichever occurs rst.

PRODUCT CHANGES AND UPDATES

Jackson WWS reserves the right to make changes in the design and specication of any equipment as engineering or necessity

requires.

THIS IS THE ENTIRE AND ONLY WARRANTY OF JACKSON WWS. JACKSON’S LIABILITY ON ANY CLAIM OF ANY KIND,

INCLUDING NEGLIGENCE, WITH RESPECT TO THE GOODS OR SERVICES COVERED HEREUNDER, SHALL IN NO CASE

EXCEED THE PRICE OF THE GOODS OR SERVICES OR PART THEREOF WHICH GIVES RISE TO THE CLAIM.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING FOR FITNESS OR MERCHANTABILITY, THAT ARE

NOT SET FORTH HEREIN, OR THAT EXTEND BEYOND THE DURATION HEREOF. UNDER NO CIRCUMSTANCES WILL

JACKSON WWS BE LIABLE FOR ANY LOSS OR DAMAGE, DIRECT OR CONSEQUENTIAL, OR FOR DAMAGES IN THE

NATURE OF PENALTIES, ARISING OUT OF THE USE OR INABILITY TO USE ANY OF ITS PRODUCTS.

ITEMS NOT COVERED

THIS WARRANTY DOES NOT COVER CLEANING OR DELIMING OF THE UNIT OR ANY COMPONENT SUCH AS, BUT NOT

LIMITED TO, WASH ARMS, RINSE ARMS, OR STRAINERS AT ANYTIME. NOR DOES IT COVER ADJUSTMENTS SUCH

AS, BUT NOT LIMITED TO, TIMER CAMS, THERMOSTATS, OR DOORS BEYOND (30) THIRTY DAYS FROM THE DATE OF

INSTALLATION. IN ADDITION, THE WARRANTY WILL ONLY COVER REPLACEMENT WEAR ITEMS SUCH AS CURTAINS,

DRAIN BALLS, DOOR GUIDES, OR GASKETS DURING THE FIRST (30) THIRTY DAYS AFTER INSTALLATION. ALSO,

NOT COVERED ARE CONDITIONS CAUSED BY THE USE OF INCORRECT (NON-COMMERICAL) GRADE DETERGENTS,

INCORRECT WATER TEMPERATURE OR PRESSURE, OR HARD WATER CONDITIONS.

Page 4

REVISION HISTOR Y

Revision

Letter

A 9-21-16 JH N/A Initial release of manual.

B 10-25-16 JH N/A

Revision

Date

Made by Applicable ECNs Details

Corrected delime instructions.

Corrected P/Ns for item #6 on pg. 42.

Updated pg. 13 to change the pressure regulator from standard to

optional.

Updated Miscellaneous Electrical Components page.

Added a Door Assemblies page.

Added a Frame Assembly page.

Added Display Fault Codes.

Page 5

ELECTRICALLY-HEATED MODELS:

®

®

44

66

RackStar

RackStar

NOMENCLATURE

Chemical-sanitizing rack conveyer machine.

STEAM-HEATED MODELS:

Steam-cleaning rack conveyer machine.

Model:

Serial No.:

Installation Date:

Service Rep. Name:

Phone Number:

RackStar

RackStar

®

44S

®

66S

Jackson WWS, Inc. provides

technical support for all of

the dishmachines detailed

in this manual. We strongly

recommend that you refer to

this manual before making a

call to our technical support

staff. Please have this manual

with you when you call so

that our staff can refer you, if

necessary, to the proper page.

Technical support is not available

on holidays.

Contact technical support toll

free at 1-888-800-5672.

Technical support is available

for service personnel only.

iii

Page 6

T ABLE OF CONTENTS

GUIDES

Symbols ......................................................................................................................................1

Abbreviations & Acronyms ..........................................................................................................1

SPECIFICATIONS

Machine Dimensions ..................................................................................................................2

Side-Loader Dimensions ............................................................................................................6

Steam Booster Heater Dimensions ............................................................................................7

Operating Parameters ................................................................................................................8

Electrical Requirements ............................................................................................................10

INSTALLATION

Installation Instructions ............................................................................................................. 13

External Device Wiring ............................................................................................................. 17

Curtain Installation Instructions................................................................................................. 18

Drain Quench Kit Instructions ................................................................................................... 19

Operating Instructions............................................................................................................... 21

Display Instructions................................................................................................................... 24

Delime Instructions ................................................................................................................... 25

MAINTENANCE

Preventative Maintenance ........................................................................................................ 26

TROUBLESHOOTING

Common Problems ................................................................................................................... 27

Display Programming ............................................................................................................... 29

Fault Codes .............................................................................................................................. 31

PARTS

Control Box Components.......................................................................................................... 33

Miscellaneous Electrical Components ...................................................................................... 34

Wash Heater & Heater Shroud Assemblies .............................................................................. 35

Pump Suction Assembly ...........................................................................................................36

Wash Heaters ...........................................................................................................................37

Plumbing Assemblies................................................................................................................ 38

Pre-Wash Tank Fill Assembly ...................................................................................................40

Wash Manifold & Arm Assembly ............................................................................................... 41

Pre-Wash Manifold & Arm Assembly ........................................................................................43

Page 7

PARTS

Rinse Assembly ........................................................................................................................ 45

Pawl Bar Assembly ...................................................................................................................47

Rack Paddle Assembly .............................................................................................................48

Drive Assembly ......................................................................................................................... 49

Ventilation Cowl ........................................................................................................................51

Ventilation Cowl for Unhooded Side-Loader .............................................................................52

Motor Overloads ....................................................................................................................... 53

Side-Loaders ............................................................................................................................ 54

Side-Loader Drive Linkage ....................................................................................................... 57

Steam Heating Coil Assembly ............................................................................................58

Booster Heater Option (Electric) ............................................................................................... 59

Frame Assembly ....................................................................................................................... 60

Door Assemblies ....................................................................................................................... 61

Miscellaneous Parts .............................................................................................................62

TABLE OF CONTENTS

SCHEMATICS

Booster Heater, 3-Phase ..........................................................................................................63

Booster Heater, 1-Phase, 12 kW ..............................................................................................64

Booster Heater, 1-Phase, 18 kW ..............................................................................................65

Steam Booster Heater .............................................................................................................. 66

RackStar 208/230 V, 50/60 Hz, 1-Phase .................................................................................. 67

RackStar 208/230 V, 50/60 Hz, 3-Phase .................................................................................. 68

RackStar 380/480 V, 50/60 Hz, 3-Phase .................................................................................. 69

RackStar Side-Loader .............................................................................................................. 70

ADDENDUM

Display Template ...................................................................................................................... 71

Page 8

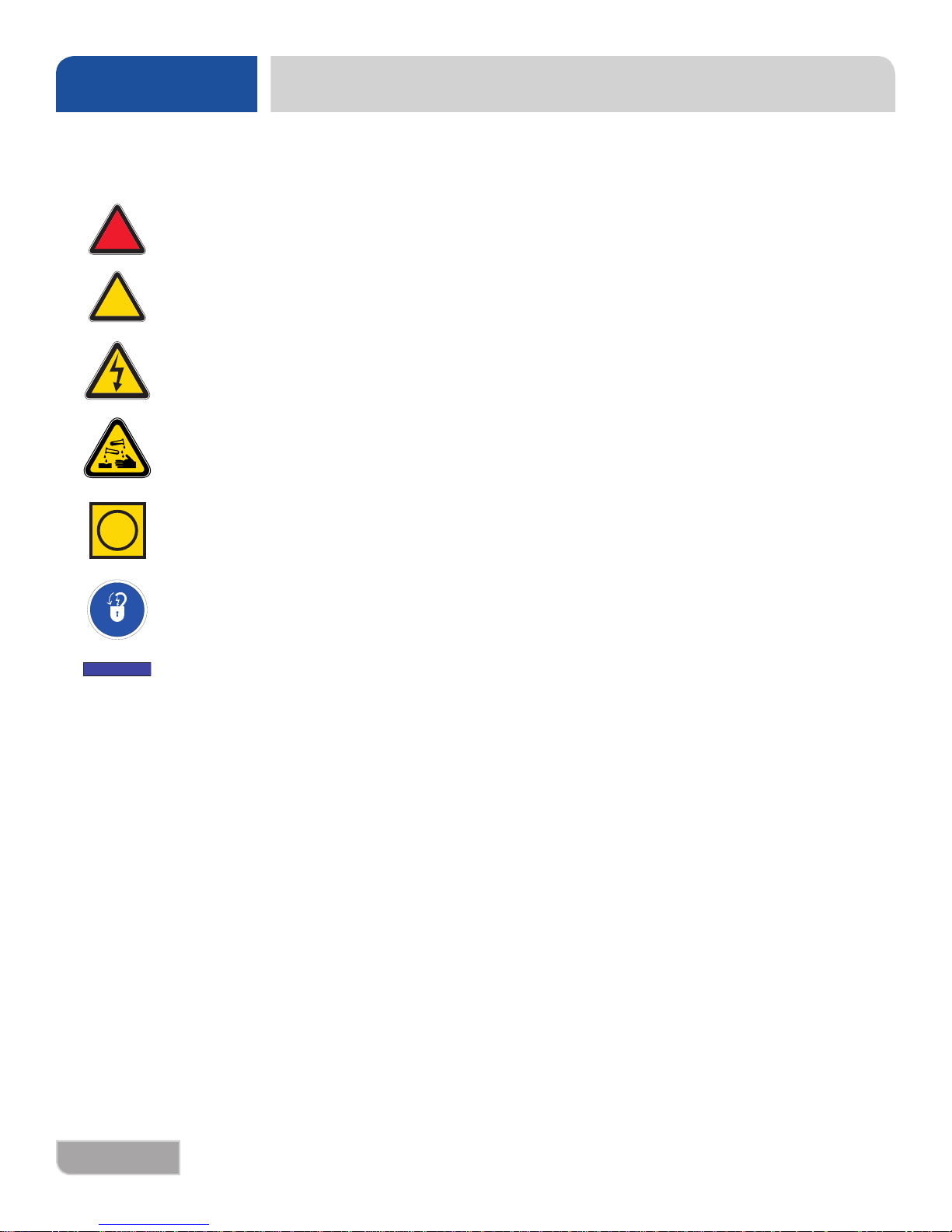

GUIDES

NOTICE

SYMBOLS

- risk of injury to personnel.

!

WARNING

- risk of damage to equipment.

!

CAUTION

- risk of electrical shock.

- caustic chemicals.

- reference data plate.

i

GUIDES

- lockout electrical power.

- important note.

ABBREVIA TIONS & ACRONYMS

ANSI - American National Standards Institute

CFM - Cubic Feet per Minute

GHT - Garden Hose Thread

GPM - Gallons per Minute

GPG - Grains per Gallon

HP - Horse Power

Hz - Hertz

ID - Inside Diameter

kW - Kilowatts

NFPA - National Fire Protection Association

NPT - National Pipe Thread

PSI - Pounds per Square Inch

V - Volts

1

07610-004-33-05-B

Page 9

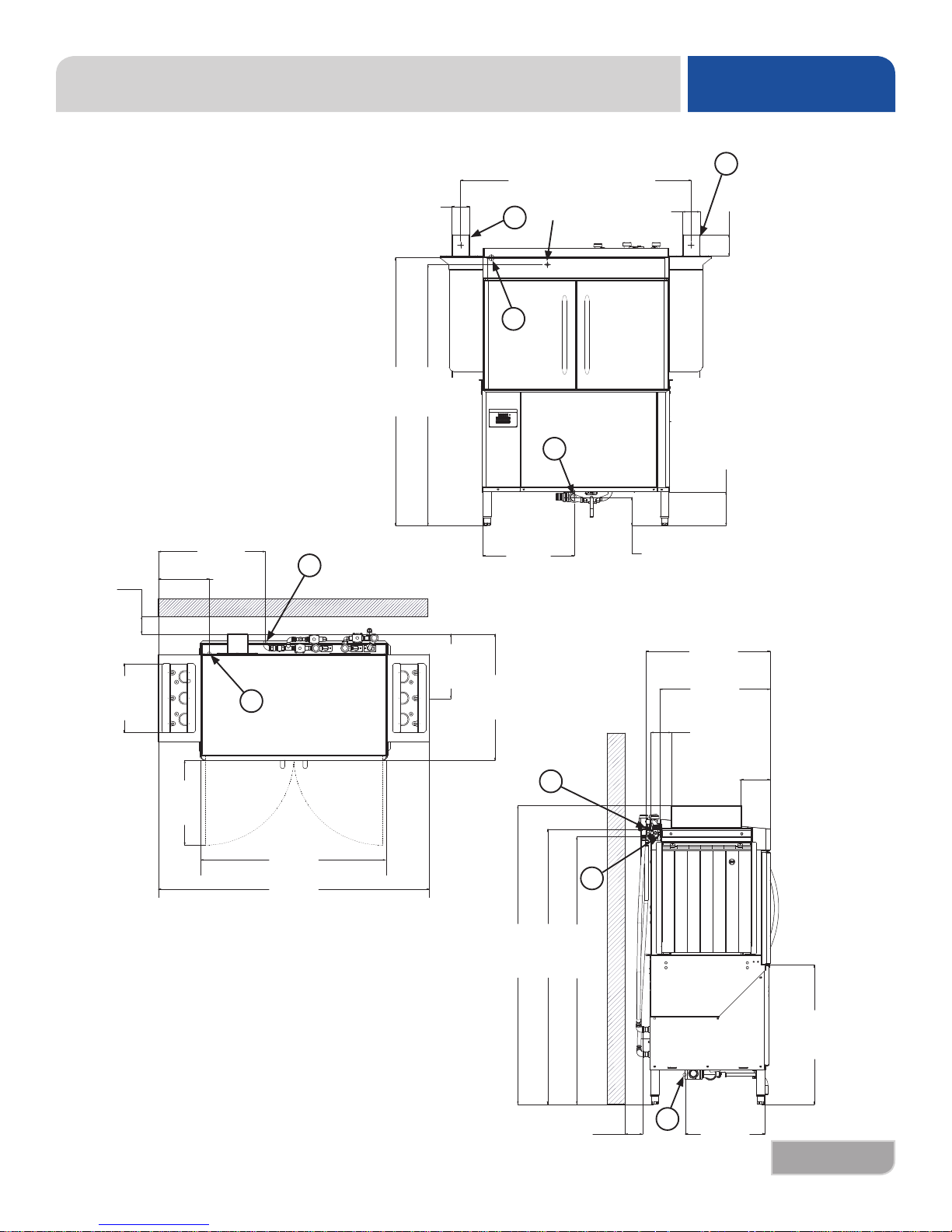

44" MACHINE DIMENSIONS

SPECIFICATIONS

1. Electrical Connection

(Provided on both sides of unit)

2. Water Inlet

(1/2" NPT 180 °F)

3. Drain Connection

(1 1/2" NPT)

4. Vent Connections

(Including Dampers)

All dimensions from the oor can be increased

1 3/4" using the machine’s adjustable feet.

25”

[635 mm]

12”

4" MIN

[101.6 mm]

[304.8 mm]

44" LEFT-TO-RIGHT

ADJUSTABLE FROM 51 1/2" TO 54"

[1308.1 mm TO 1371.6 mm]

4"

[101.6 mm]

2

4

4”

[101.6 mm]

1

]

]

m

m

m

m

“

4

1”

3

.2

.

6

6

0

9

0

4

6

5

1

[

[1

3

21"

2

[533.4 mm]

7"

[177.8 mm]

4

5”

[127.0 mm]

8”

[203.2 mm]

]

m

m

6”

4

1

.

6

0

[4

]

m

“

m

0

2

8

0

[5

1

[1117.6 mm]

[1625.6 mm]

1. Electrical Connection

(Provided on both sides of unit)

2. Water Inlet

(1/2" NPT 180 °F)

3. Drain Connection

(1 1/2" NPT)

4. Vent Connections

(Including Dampers)

3

28”

[711.2 mm]

25”

[635.0 mm]

5”

[127.0 mm]

7”

[177.8 mm]

18”

[457.2 mm]

]

m

m

2”

.8

3

2

1

[8

]

m

“

5

m

1

1

8

]

[3

m

m

0”

0

.

3

2

6

[7

1

44"

]

m

m

3”

.2

6

0

0

6

1

[

4" MIN

[101.6 mm]

2

]

m

m

4

1”

.

6

9

4

5

[1

64"

]

m

m

9”

.6

6

2

5

7

[1

07610-004-33-05-B

2

Page 10

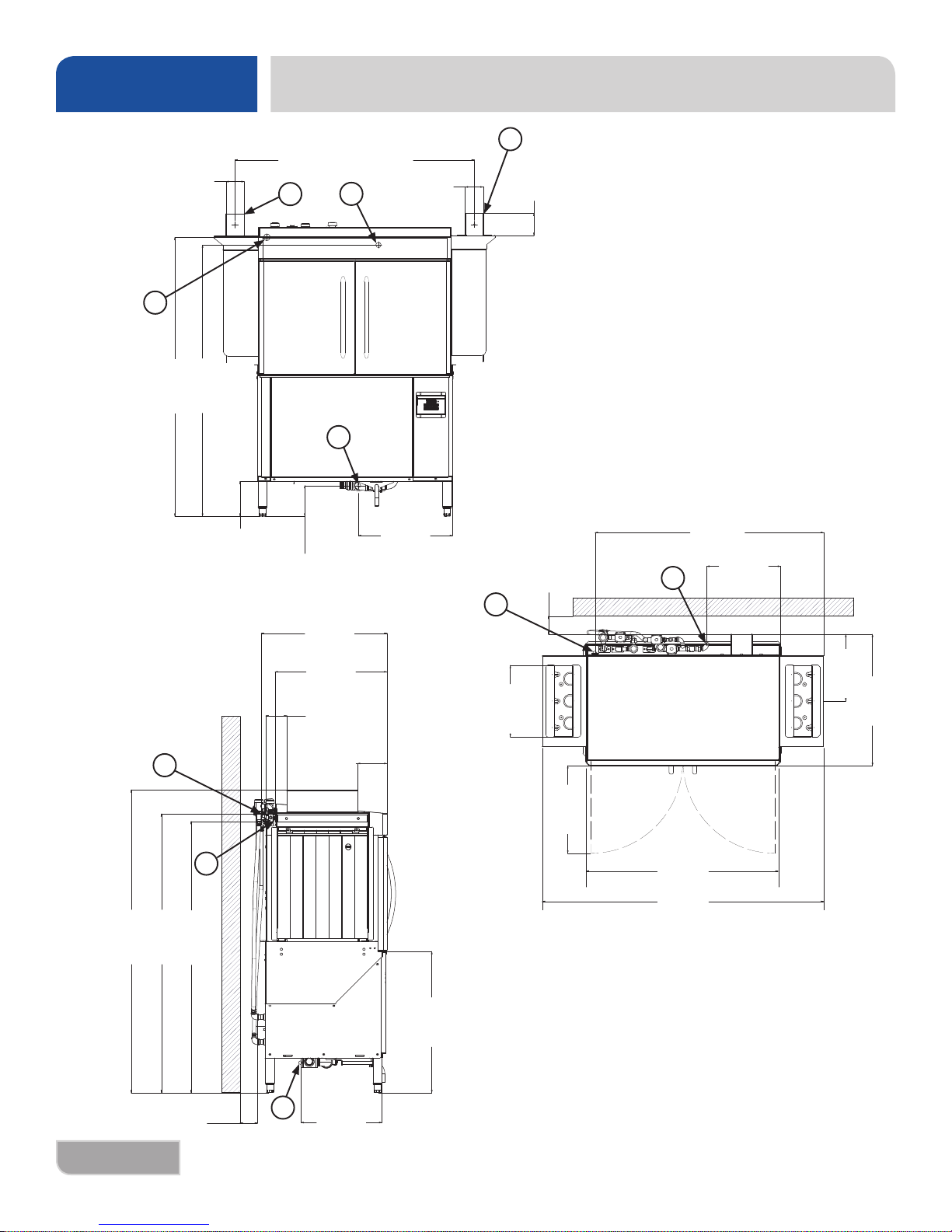

SPECIFICATIONS

44" MACHINE DIMENSIONS

44" RIGHT-TO-LEFT

4"

[101.6 mm]

1

]

m

m

3”

2

.

6

0

0

6

[1

ADJUSTABLE FROM 51 1/2" TO 54"

[1308.1 mm TO 1371.6 mm]

4

2

4"

[101.6 mm]

]

m

m

5”

0

.

7

2

[1

1. Electrical Connection

(Provided on both sides of unit)

2. Water Inlet

(1/2" NPT 180 °F)

3. Drain Connection

(1 1/2" NPT)

4. Vent Connections

(Including Dampers)

All dimensions from the oor can be increased

4

]

m

m

1”

4

.

6

9

4

5

[1

1 3/4" using the machine’s adjustable feet.

3

2

52”

[1320.8 mm]

[431.8 mm]

17”

]

m

m

8”

.2

3

0

2

[

7”

[177.8 mm]

21”

[533.4 mm]

4" MIN

[101.6 mm]

1

28”

[711.2 mm]

25”

[635.0 mm]

5”

[127.0 mm]

]

m

m

6”

4

1

.

6

0

[4

]

m

m

5”

1

.0

]

1

m

8

3

[

m

0”

.0

3

2

6

7

[

3

1

2

]

]

m

m

9”

.6

6

2

5

7

[1

]

m

m

m

m

3”

2

4

1”

.

.

6

6

0

9

0

4

6

5

[1

[1

7”

[177.8 mm]

]

m

m

0”

0

2

.

8

0

[5

44"

[1117.6 mm]

64"

[1625.6 mm]

1. Electrical Connection

]

m

m

2”

8

3

.

2

1

[8

(Provided on both sides of unit)

2. Water Inlet

(1/2" NPT 180 °F)

3. Drain Connection

(1 1/2" NPT)

4. Vent Connections

(Including Dampers)

4" MIN

[101.6 mm]

3

18”

[457.2 mm]

07610-004-33-05-B

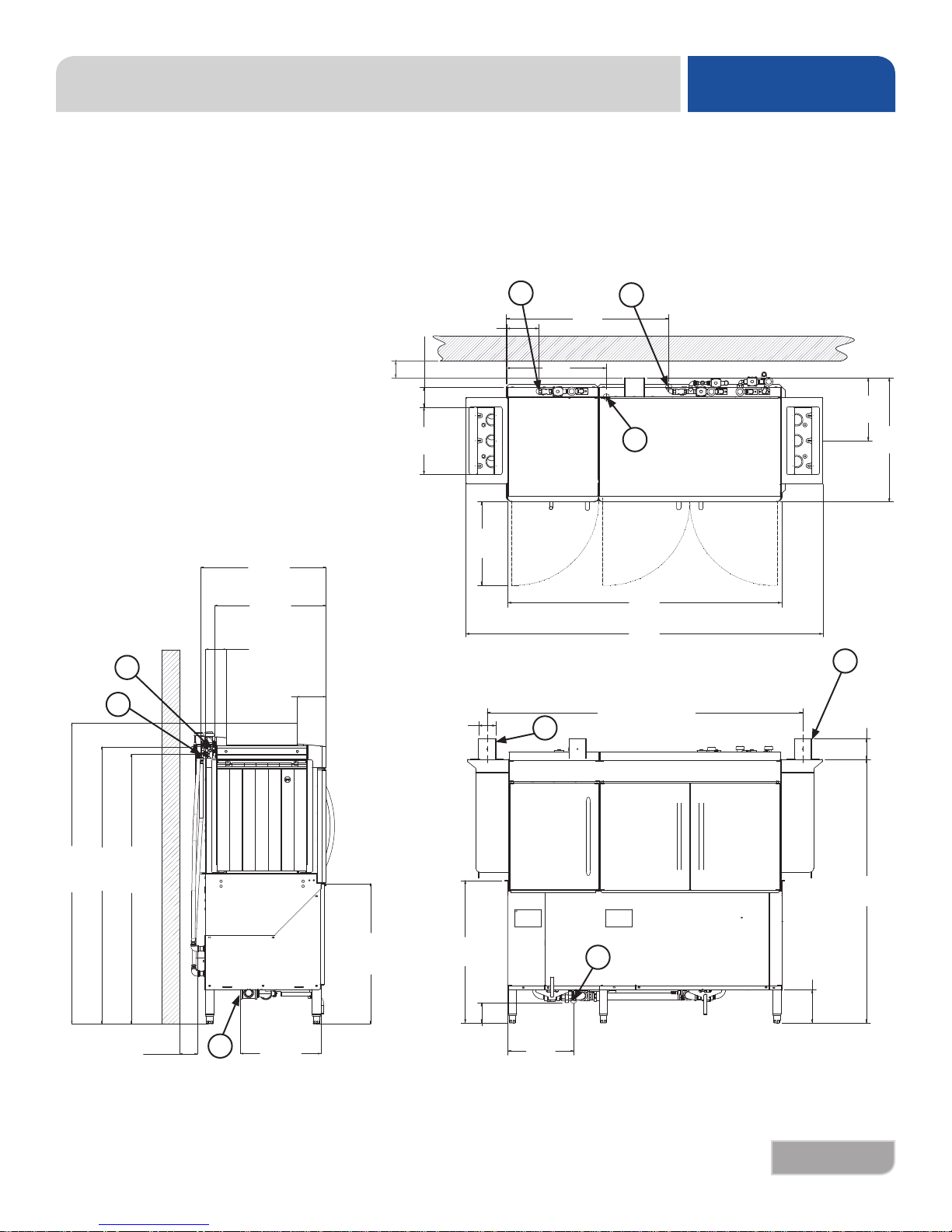

Page 11

>PP@

66" MACHINE DIMENSIONS

1. Electrical Connection

(Provided on both sides of unit)

2. Pre-Wash Water Inlet

(1/2" NPT 180 °F)

1. Electrical Connection

(Provided on both sides of unit)

3. Main Water Inlet

(1/2" NPT 180 °F)

2. 3UH:DVK:DWHU,QOHW

(1/2" NPT 180 °F)

4. Vent Connections

(Including Dampers)

3. Main Water Inlet

(1/2" NPT 180 °F)

5. Drain Connection

(1 1/2" NPT)

4. 9HQW&RQQHFWLRQV

(Including Dampers)

All dimensions from the oor can be increased

1 3/4" using the machine’s adjustable feet.

5. Drain Connection

(1 1/2" NPT)

$OOGLPHQVLRQVIURPWKHÀRRUFDQEHLQFUHDVHG

1 3/4" using the machine’s adjustable feet.

28 7/16

"

[722 mm]

25 1/4

"

[642 mm]

4 3/4

"

[120 mm]

1

6 11/16

"

2,3

[169 mm]

4 " MIN

[102 mm]

0,1

4 3/4

[121 mm]

>PP@

"

]

m

"

m

6

6

1

0

4

[

@

P

P

>

>PP@

SPECIFICATIONS

66" LEFT-TO-RIGHT

2

38 7/8

[610 mm]

>PP@

4

[988 mm]

24 "

>PP@

7 3/4

"

[197 mm]

2

>PP@

"

]

m

m

0

2

8

0

5

[

@

P

P

>

3

"

3

1

1

66 "

[1676 mm]

86 "

[2184 mm]

>PP@

ADJUSTABLE FROM 73 1/2 - 76 "

[1867 - 1930 mm]

>PP@

]

"

m

8

m

/

1

4

8

5

3

1

[

]

"

m

4

m

/

3

6

5

9

7

2

[

@

P

P

>

@

P

P

>

4

@

P

P

>

"

]

m

2

/

m

1

0

8

4

6

7

1

[

]

m

"

m

0

3

0

6

6

1

[

4" MIN

[102 mm]

"

]

m

8

/

m

3

9

1

5

6

5

1

[

5

18 5/16

[465 mm]

"

07610-004-33-05-B

@

P

P

>

"

]

6

m

1

/

5

m

1

1

1

1

8

3

[

@

P

P

>

@

P

P

>

>PP@

5

@

P

P

>

4

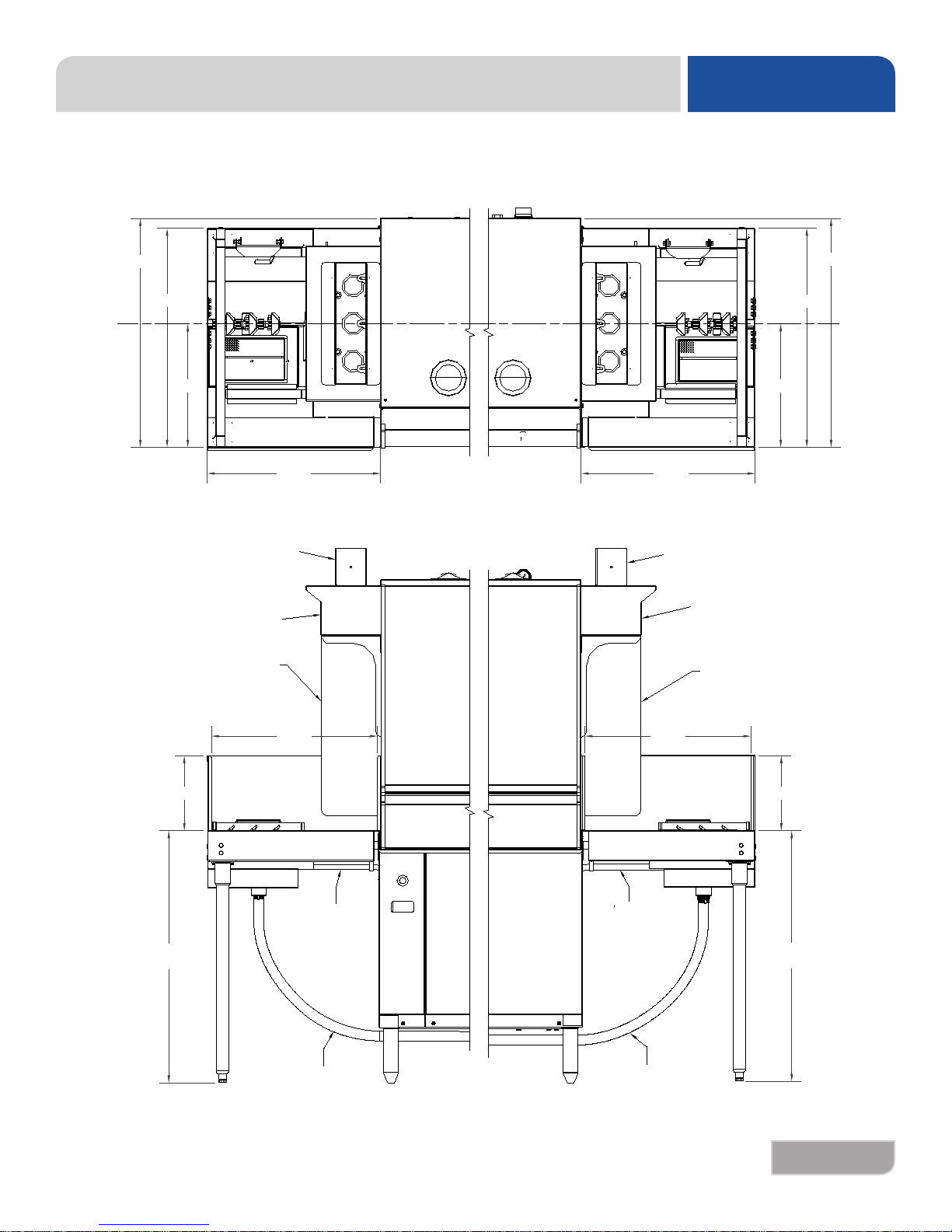

Page 12

SPECIFICATIONS

63 13/16

"

()

[2184 mm]

66" RIGHT-TO-LEFT

1. Electrical Connection

(Provided on both sides of unit)

2. Pre-Wash Water Inlet

(1/2" NPT 180 °F)

3. Main Water Inlet

2. 3UH:DVK:DWHU,QOHW

(1/2" NPT 180 °F)

(1/2" NPT 180 °F)

4. Vent Connections

3. Main Water Inlet

(Including Dampers)

(1/2" NPT 180 °F)

4. 9HQW&RQQHFWLRQV

5. Drain Connection

(Including Dampers)

(1 1/2" NPT)

5. Drain Connection

All dimensions from the oor can be increased

(1 1/2" NPT)

1 3/4" using the machine’s adjustable feet.

$OOGLPHQVLRQVIURPWKHÀRRUFDQEHLQFUHDVHG

1 3/4" using the machine’s adjustable feet.

28 7/16

"

[722 mm]

25 1/4

"

[642 mm]

4 3/4

"

1

2,3

[120 mm]

6 11/16

[169 mm]

"

"

6

1

"

6

1

66" MACHINE DIMENSIONS

1

1

]

m

m

6

0

4

[

]

m

m

6

0

4

[

]

m

"

m

0

8

2

0

5

[

]

m

"

m

0

8

2

0

5

[

4

3

63 13/16

[1621 mm]

3

[1621 mm]

66 "

[1676 mm]

86 "

86 "

[2184 mm]

ADJUSTABLE FROM 73 1/2 - 76 "

ADJUSTABLE FROM - 76 "

[1867 - 1930 mm]

[1867 - 1930 mm]

"

1

73

2

38 7/8

[987 mm]

38 7/8

[987 mm]

2

"

7 13/16

[198 mm]

"

2

"

7 13/16

[198 mm]

"

]

N

m

I

m

M

"

2

0

1

4

[

]

N

"

m

]

I

m

m

M

8

/

"

2

m

1

0

4

5

1

4

[

8

1

3

[

]

"

m

4

m

/

3

"

8

/

1

5

1

6

]

5

9

7

m

2

[

m

4

8

3

[

]

"

m

4

m

/

3

6

5

9

7

2

[

4

"

]

m

m

5

7

2

4 1/8

"

1

[105 mm]

[

"

]

m

2

/

m

1

0

8

4

6

7

1

[

]

m

"

m

0

3

0

6

6

1

[

4" MIN

[102 mm]

"

]

m

8

/

m

3

9

1

5

6

5

1

[

18 5/16

5

[465 mm]

"

5

]

m

"

m

2

/

3

1

1

3

6

6

1

[

]

"

"

]

m

6

4

m

m

/

1

/

1

0

m

5

7

4

8

1

3

[

1

1

1

8

3

[

5

18 3/8

[466 mm]

]

]

"

m

m

"

m

m

"

8

/

3

4

8

7

0

2

4

2

1

[

[

07610-004-33-05-B

Page 13

SIDE-LOADER DIMENSIONS

SPECIFICATIONS

30.32

29.00

16.35

ADJUSTABLE VENTILATION

DUCT ADAPTER

VENTILATION SCOOP

23" L-R UNHOODED

SIDE-LOADER

DIMENSION IS 30.00" FOR THE

30" UNHOODED SIDE-LOADER

23.00

23" R-L UNHOODED

SIDE-LOADER

DIMENSION IS 30.00" FOR THE

30" UNHOODED SIDE-LOADER

23.00

ADJUSTABLE VENTILATION

DUCT ADAPTER

VENTILATION SCOOP

30.32

29.00

16.35

VENTILATION COWL

WITH CUTOUT FOR

L-R UNITS

10.00

+1.00

34.00

-1.00

22.00

ELECTRICAL

CONDUIT

SIDE-LOADER

DRAIN HOSE

ELECTRICAL

CONDUIT

SIDE-LOADER

DRAIN HOSE

22.00

VENTILATION COWL

WITH CUTOUT FOR

R-L UNITS

10.00

34.00

+1.00

-1.00

07610-004-33-05-B

6

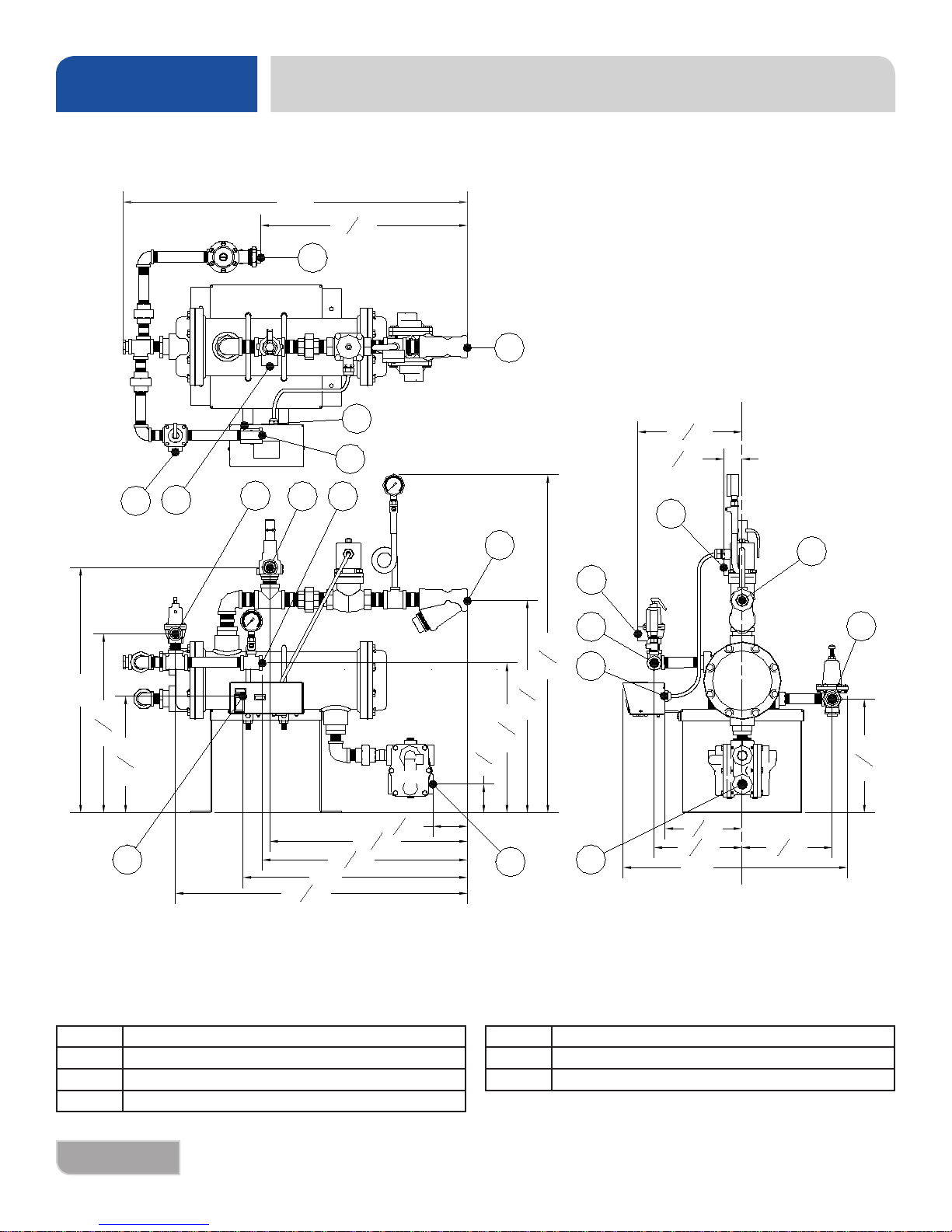

Page 14

SPECIFICATIONS

STEAM BOOSTER HEATER DIMENSIONS

33.69

1

20

in

4

W1

S

24 in

E

W2

PS

PW

in

2

1

17

in

8

3

11

E

PW

28

PS

5

22 in

in

8

W2

20

S

PW

W2

in

8

1

E

33

in

4

3

20

in

8

5

in

14

8

7

2

3

3

in

8

3

19

in

8

1

in

8

C

C

1

PS

10

3

1

8

in

4

1

7

5

8

22 in

in

8

S

W1

in

8

1

11

in

2

in

7

8

in

8

E MAIN ELECTRICAL CONNECTION (7/8" DIA HOLE)

W1 MAIN INLET WATER CONNECTION (3/4" NPT-F)

W2 WATER OUTLET CONNECTION (3/4" NPT-F)

PW WATER PRESSURE RELIEF OUTLET (3/4" NPT-F)

7

PS STEAM PRESSURE RELIEF OUTLET (1" NPT-F)

S STEAM SUPPLY TO BOOSTER (1" NPT-F)

C STEAM CONDENSATE CONNECTION (3/4" NPT-F)

07610-004-33-05-B

Page 15

OPERATING PARAMETERS

NOTICE

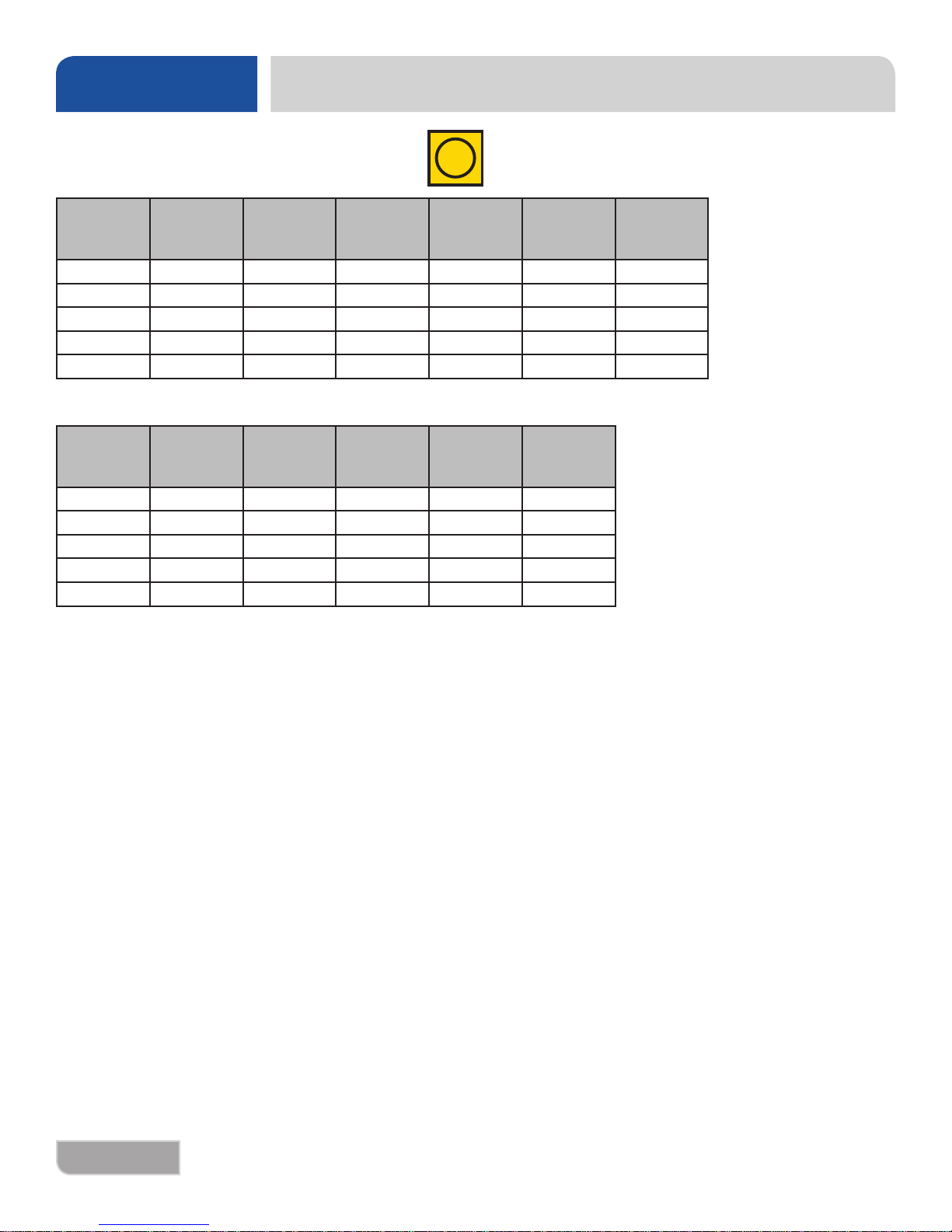

Model Designation: 44" 66" 44" STEAM 66" STEAM

Operating Capacity:

Racks per Hour 218 218 218 218

Dishes per Hour 3488 3488 3488 3488

Glasses per Hour 7848 7848 7848 7848

Tank Capacity (Gallons):

Wash Tank 35.6 35.6 35.6 35.6

Pre-Wash Tank N/A 15.8 N/A 15.8

Electrical Loads (as applicable):

Wash Motor HP 3.0 3.0 3.0 3.0

SPECIFICATIONS

Drive Motor HP 0.25 0.25 0.25 0.25

Pre-Wash Motor HP N/A 2.0 N/A 2.0

Wash Heater kW 15 15 N/A N/A

NOTE: Always refer to the machine data plate for specic electrical and water requirements.

The material provided on this page is for reference only and may change without notice.

i

07610-004-33-05-B

8

Page 16

SPECIFICATIONS

NOTICE

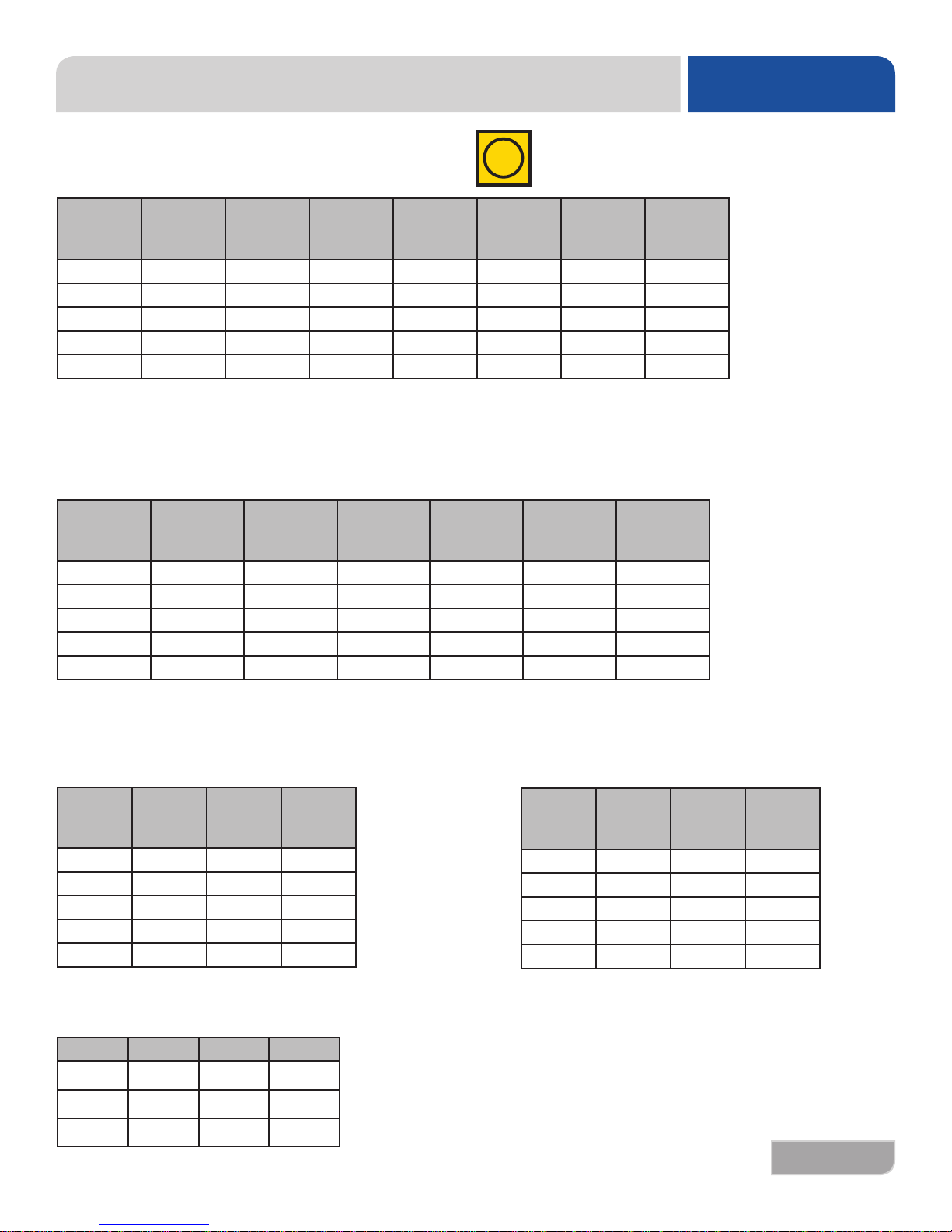

Model Designation: 44" 66" 44" STEAM 66" STEAM

HOT WATER SANITIZING

Water Temperatures (°F):

Pre-Wash Temperature (recommended) N/A 110-140 N/A 110-140

Minimum Wash Temperature 160 160 160 160

Incoming Rinse Temperature 180 180 180 180

Incoming Water Temperature

12 kW Booster 140 140 N/A N/A

18 kW Booster 110 110 N/A N/A

No Booster 180 180 180 180

CHEMICAL SANITIZING

Water Temperatures (°F):

OPERATING PARAMETERS

Pre-Wash Temperature (recommended) N/A 110-140 N/A 110-140

Minimum Wash Temperature 120 120 120 120

Minimum Rinse Temperature 120 120 120 120

Incoming Water Temperature

12 kW Booster 80 80 N/A N/A

18 kW Booster 50 50 N/A N/A

No Booster 120 120 120 120

Other Water Requirements:

Water Flow Pressure (PSI) 15 15 15 15

Flow Rate Minimum (GPM) 1.27 1.18 1.27 1.18

Water Line Size (NPT) 1/2" 1/2" 1/2" 1/2"

Drain Line Size (NPT) 1-1/2" 1-1/2" 1-1/2" 1-1/2"

Steam Requirements:

Steam Line for Wash Tank (NPT) N/A N/A 3/4" 3/4"

Steam Flow Pressure (PSI) N/A N/A 10-20 10-20

Consumption @ 15 PSI (lbs/hr) N/A N/A 60 60

NOTE: Always refer to the machine data plate for specic electrical and water requirements.

The material provided on this page is for reference only and may change without notice.

i

9

07610-004-33-05-B

Page 17

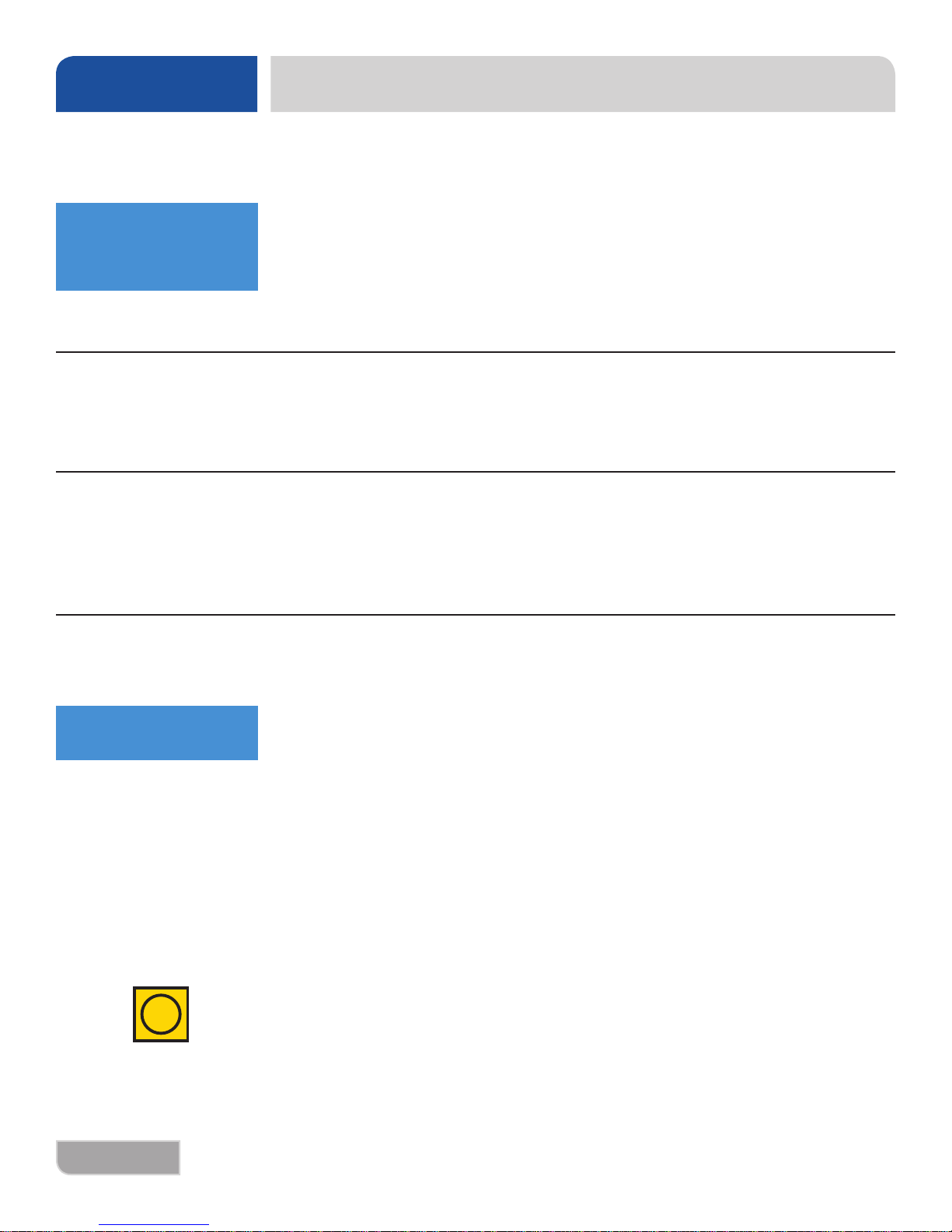

ELECTRICAL REQUIREMENTS

SPECIFICATIONS

i

All electrical ratings provided in this manual are for reference only. Always refer to the machine data plate to get the exact

electrical information for this machine. All electrical work performed on machines should be done in accordance

with applicable local, state, territorial, and national codes. Work should only be performed by qualied electricians and

authorized service agents. A list of authorized Service Agencies is located in the back of this manual.

Note that all electrical wiring used in the dishmachine must be rated, at a minimum, for 212 °F (100 °C), and that only

copper conductors must be used.

Where applicable, heating element amperage draws have been adjusted for the assumed input voltage. The manufacturer

assumes incoming voltages will be either 208, 230, or 460 Volts. Some of the heating elements used in our machines are

actually rated for other voltages, such as 240 or 480 Volts. Always verify the amperage draw of the machine in operation

when sizing circuit protection.

If the machine is equipped with the optional rinse heater, note the rinse heater has its own electrical connection and

therefore requires a separate service. Amperage loads for motors and heaters are called out on the machine data plate

for the installation/service technician.

The electrical congurations of the machines are as follows:

Available Electrical Characteristics:

• 208 V, 60 Hz, Single-phase

• 230 V, 60 Hz, Single-phase

• 208 V, 60 Hz, Three-phase

• 230 V, 60 Hz, Three-phase

• 460 V, 60 Hz, Three-phase

Available Wash Tank Heaters:

• 15 kW

Available Booster Tank Heaters:

• None (standard)

• 12 kW (40 °F rise in temperature)

• 18 kW (70 °F rise in temperature)

07610-004-33-05-B

10

Page 18

SPECIFICATIONS

ELECTRICAL REQUIREMENTS

i

44"

Wash

Volts Phase Hz

208 1 60 10.0 1.8 72.1 83.9

230 1 60 10.0 1.8 59.9 71.7

208 3 60 8.6 1.1 41.6 51.3

230 3 60 8.4 1.1 34.6 44.1

460 3 60 4.2 0.6 17.3 22.1

Motor

Amps

44" Steam

Wash

Volts Phase Hz

208 1 60 10.0 1.8 11.8

230 1 60 10.0 1.8 11.8

208 3 60 8.6 1.1 9.7

230 3 60 8.4 1.1 9.5

460 3 60 4.2 0.6 4.8

Motor

Amps

Drive

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

Total

Load

Total

Load

11

07610-004-33-05-B

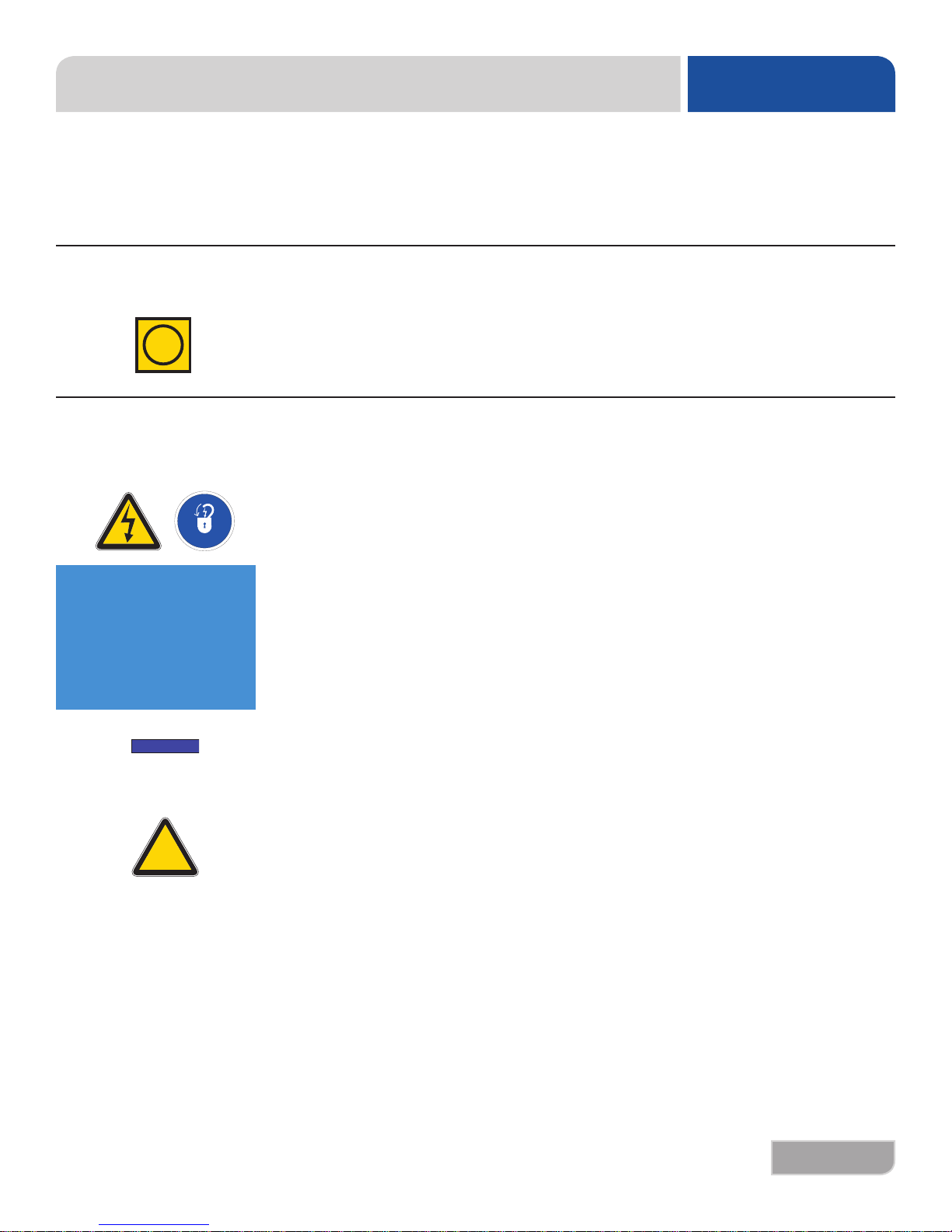

Page 19

ELECTRICAL REQUIREMENTS

i

66"

Pre-Wash

Volts Phase Hz

208 1 60 10.2 10.0 1.8 72.1 94.1

230 1 60 9.4 10.0 1.8 59.9 81.1

208 3 60 6.2 8.6 1.1 41.7 58.3

230 3 60 6.4 8.4 1.1 34.6 50.5

460 3 60 3.2 4.2 0.6 17.3 25.3

Motor

Amps

66" Steam

Pre-Wash

Volts Phase Hz

208 1 60 10.2 10.0 1.8 22.0

230 1 60 9.4 10.0 1.8 21.2

208 3 60 6.2 8.6 1.1 15.9

230 3 60 9.4 10.0 1.1 20.5

460 3 60 3.2 4.2 0.6 8.0

Motor

Amps

Wash

Motor

Amps

Wash

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

Drive

Motor

Amps

SPECIFICATIONS

Total

Load

Total

Load

40 °F Rise – 12 kW Booster

Rinse

Volts Phase Hz

208 1 60 57.7

230 1 60 47.9

208 3 60 33.3

230 3 60 27.7

460 3 60 13.8

Note: On the 208 V machines, the rinse heater is actually rated at 17.2 kW.

Heater

Amps

Blower/Dryer

Volts Phase Hz Amps

208 3 60 32.2

230 3 60 22.9

460 3 60 13.4

07610-004-33-05-B

70 °F Rise – 18 kW Booster

Rinse

Volts Phase Hz

208 1 60 82.7

230 1 60 71.9

208 3 60 47.7

230 3 60 41.5

460 3 60 20.7

Heater

Amps

12

Page 20

INSTALLATION

INSTRUCTIONS

VISUAL

INSPECTION

Do not throw away the

container if damage is

evident!

UNPACKING THE

MACHINE

LEVEL THE

DISHMACHINE

Before installing the unit, check the packaging and the machine for damage. Damaged

packaging might be an indication there is possible damage to the product. If there is

any type of damage to both the packaging and the unit, DO NOT THROW AWAY THE

PACKAGING. The dishmachine has been previously inspected at the factory and is

expected to arrive in new, undamaged condition. However, rough handling by carriers

or others might result in damage to the unit while it is in transit. If this occurs, DO NOT

RETURN THE UNIT TO THE MANUFACTURER. Instead, contact the carrier and ask them

to send a representative to the site to inspect the damage and request that an inspection

report be completed. Contact the carrier and dealer that sold you the unit within 48 hours

of receiving the machine in order to report possible freight damage.

The machine should be unboxed and removed from the pallet before installing. Remove

the wooden lift beams and their associated brackets after the unit has been positioned.

Open the front door and remove all materials from inside. Once unpacked, verify there are

no missing parts. If a part is missing, contact the manufacturer immediately.

The dishmachine is designed to operate while level. This is important to prevent any damage

to the machine during operation and to ensure the best possible results. The unit comes

equipped with adjustable bullet feet, which can be turned using a pair of pliers. Verify the

unit is level from front-to-back and side-to-side before making any electrical or plumbing

connections.

PLUMBING THE

DISHMACHINE

The plumber MUST ush

the incoming water line!

i

13

All plumbing connections must be made to adhere to local, state, territorial, and national

codes. The installing plumber is responsible for ensuring the incoming water lines are

ushed of debris before connecting to the machine. Note that chips and materials from

cutting processes can become lodged in the solenoid valves and prevent them from

opening or closing. Any valves that are found to be fouled or defective because of foreign

matter left in the water line and any subsequent water damage are not the responsibility of

the manufacturer.

Water hardness should be a maximum of 6 GPG. Hard water should be treated before

being used by the machine. Iron in the water line can cause staining. A lter designed

to remove iron from the water supply is highly recommended for supplies in excess of

0.1 ppm.

The manufacturer has an optional water pressure regulator to accommodate areas where

water pressure uctuates or is higher than the recommended pressure. The unit utilizes

a ow pressure of 15 PSI for the incoming water line. Do not confuse static pressure with

ow pressure. Static pressure occurs when there is no ow and the valves are closed.

Flow pressure occurs when water is running into the machine. The pressure regulator

should be adjusted to the proper ow pressure indicated on the data plate.

The water supply line must be 1/2" NPT minimum and must be able to provide water at the

minimum temperature indicated on the machine data plate.

A shut-off valve should be installed to allow isolating the dishmachine from the water

system in the event service is required. It is also suggested that a shock absorber (not

supplied with dishmachine) be installed on the incoming water line. This prevents water

hammer (hydraulic shock)—induced by the solenoid valve as it operates—from causing

damage to the equipment.

07610-004-33-05-B

Page 21

INSTRUCTIONS

NOTICE

INSTALLATION

CONNECTING

THE DRAIN LINE

STEAM LINE

CONNECTIONS

i

ELECTRICAL

POWER

CONNECTIONS

Disconnect electrical

power at the breaker or

disconnect switch and

tag-out in accordance

with procedures and

codes.

The drain for the unit is a gravity discharge drain. All piping to the machine drain must be

a minimum 1-1/2” NPT AND MUST NOT BE REDUCED. There must also be an air gap

between the machine drain line and the oor sink or drain. If a grease trap is required by

code, it should have a ow capacity of 5 GPM. 44" units have one drain connection point

and 66" units have two.

Some machines covered in this manual are designed to use low-pressure steam as a

source of heat for the wash tank. Those machines come with lines by which an outside

source of steam (e.g. steam booster) is connected. Connect all steam lines from the

booster to the machine in accordance with the booster manufacturer’s instructions. Ensure

that all applicable codes and regulations are adhered to. See the machine data plate for

information related to steam ow requirements.

All electrical connections are to be made in accordance with applicable portions of local,

state, territorial, and national codes.

This manual provides reference information regarding electrical requirements and loads,

but that information may change without notice. Always refer to the machine data plate for

voltage requirements, machine voltage, total amperage load, and serial number. If a data

plate has been damaged and cannot be read, contact the manufacturer.

The main power terminal blocks (for the dishmachine and for the rinse booster heater, if

applicable) are located at the top of the machine. Remove the top cover to access these

connections. Route incoming power lines within conduit that will connect via ttings to the

pre-punched holes in the back of the control box. Install power and ground wires to lugs as

indicated by the appropriate decals in the control box. Use copper conductors only . Use of

an anti-oxidation agent is permissible on the power connections. Tighten all connections.

Verify the incoming voltage matches the voltage indicated on the decal next to the

incoming power pre-punched hole.

07610-004-33-05-B

!

CAUTION

NOTE: The dishmachine has a separate power connection from the rinse booster heater

and the circuit protection requirements are different for each. Refer to the machine data

plate for information on minimum circuit protection.

CAUTION: Improperly connecting external devices can cause damage to the machine

and/or electrical infrastructure!

SEE PAGE 17 FOR A GUIDE ON WIRING EXTERNAL DEVICES (EXHAUST FAN,

CHEMICAL DISPENSERS, ETC.)

14

Page 22

INSTALLATION

NOTICE

INSTRUCTIONS

DISHMACHINE

VENTILATION

THERMOSTATS

CHEMICAL

FEEDER

EQUIPMENT

The dishmachine should be located with an adequate exhaust hood or ventilation system

with provisions for venting. This is essential to permit efcient removal of the condensation

exhaust. Ensure the exhaust system is acceptable in accordance with applicable codes

and standards.

NOTE: Any damage that is caused by steam and/or moisture due to improper

ventilation is NOT covered under the warranty .

Dishmachine ventilation requirements:

• Load End: 200 CFM

• Unload End: 200 CFM

The exhaust system must be sized to handle this volume for the dishmachine to operate

properly.

The thermostats on this unit have been set at the factory for the wash tank and should only

be adjusted by an authorized service agent.

This dishmachine DOES NOT COME WITH AN INTEGRAL CHEMICAL

SUPPLY/FEEDER SYSTEM. For the dishmachine to operate correctly, connect it to a

third-party chemical dispenser that meets the requirements of NSF Standard 29.

Contact a chemical supplier about connecting a dispenser to the dishmachine. Chemical

dispensers must be set for the type and concentration of chemicals being used.

Detergent usage and water hardness are two factors that contribute greatly to how

efciently the dishmachine will operate. Using the proper amount of detergent can be a

source of substantial savings. A qualied water treatment specialist can explain what is

needed to gain the maximum efciency from detergent.

The dishmachine can operate in either hot-water-sanitizing mode or chemical-sanitizing

mode. The mode of the machine is marked above the machine's data plate.

If the unit is operated in chemical-sanitizing mode, ensure an appropriate chlorine-based

sanitizer is used in the nal rinse line.

15

07610-004-33-05-B

Page 23

INSTRUCTIONS

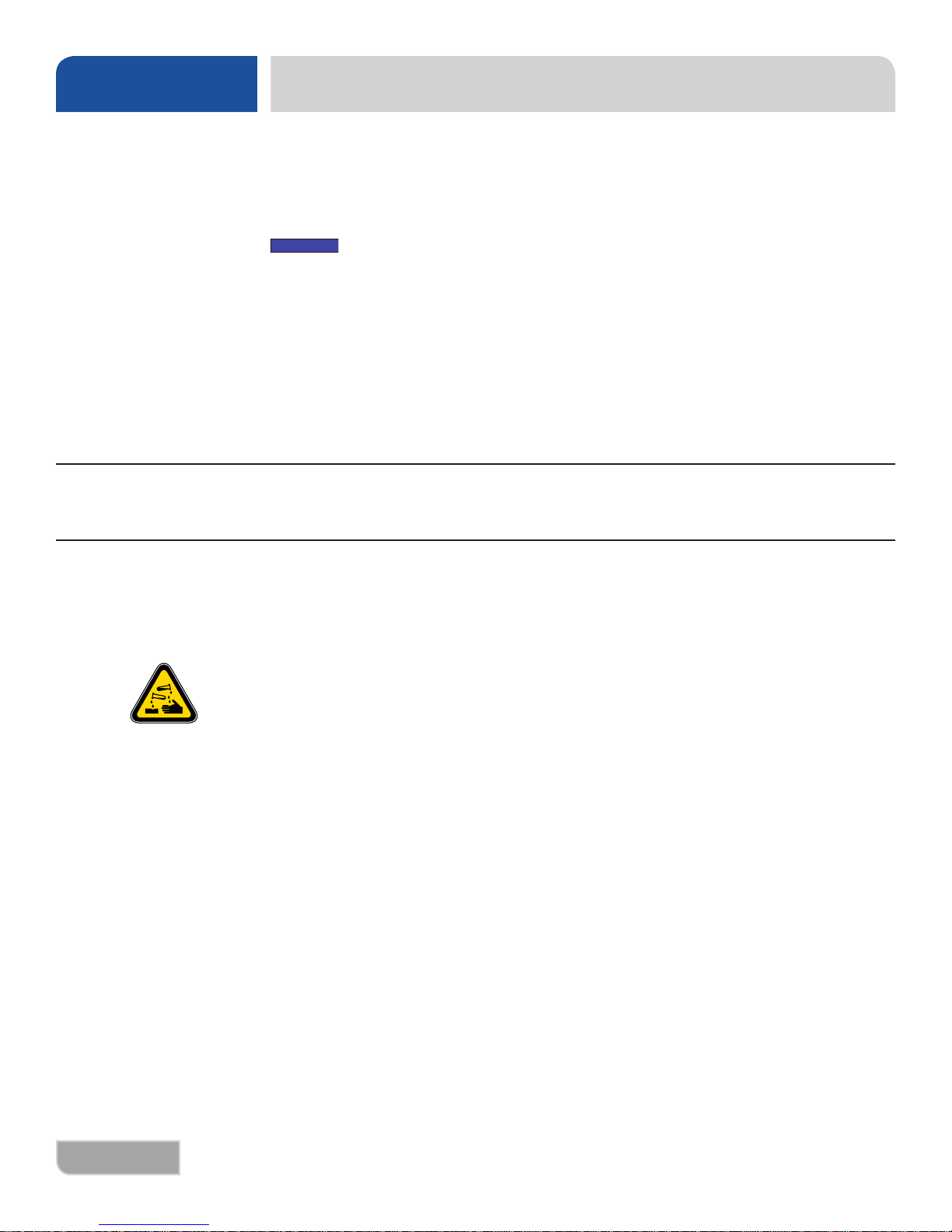

Bulkhead Opening for

Conductivity Probe

INSTALLATION

Adjustable Feet

Drain Connection

Main Electrical Opening

(provided on both sides of unit)

Incoming Water

07610-004-33-05-B

Booster Heater Electrical Opening

(provided on both sides of unit)

Detergent

Connection

Point

Drain Connection

16

Page 24

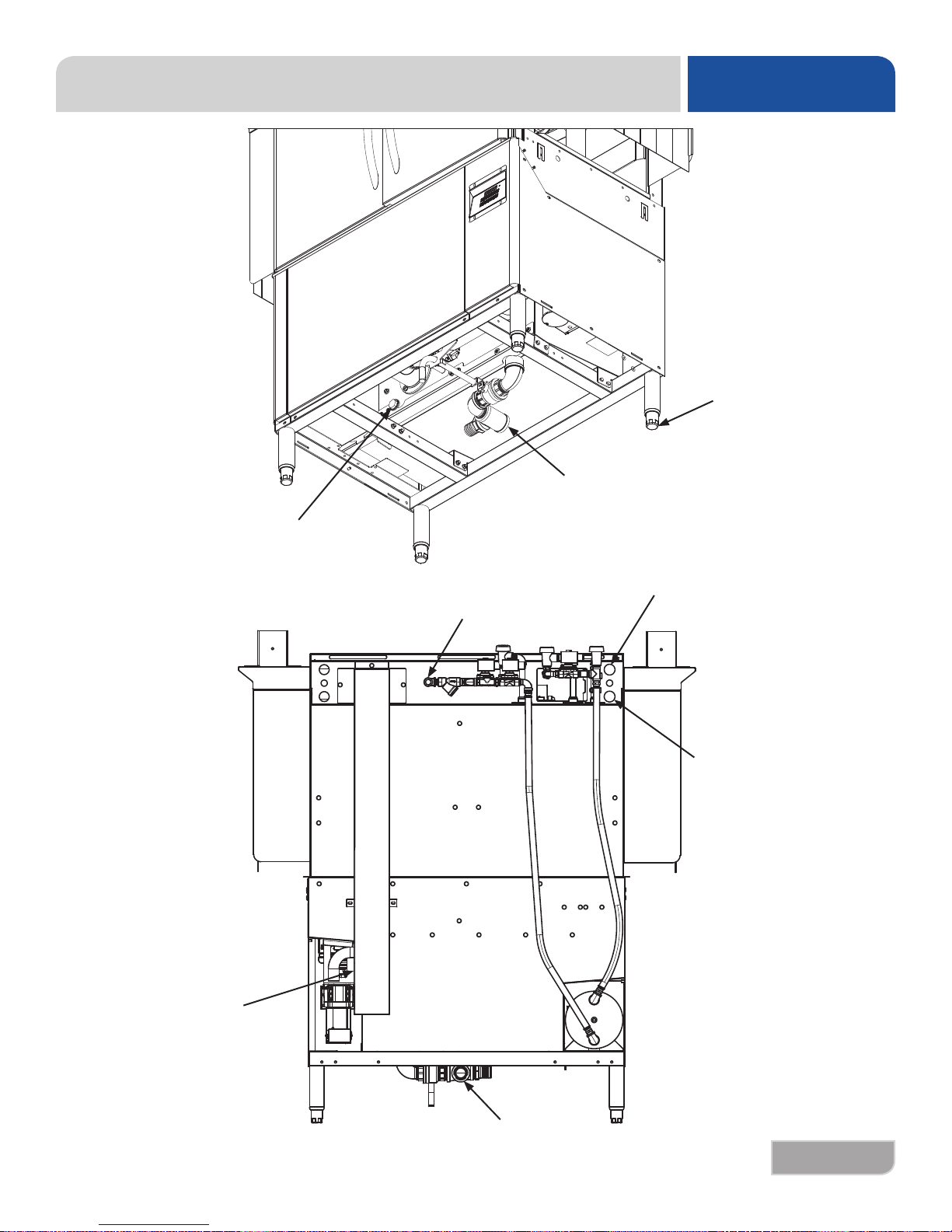

INSTALLATION

!

CAUTION

EXTERNAL DEVICE WIRING

Wiring Diagram

Exhaust Fan

Contactor

(customer provides)

Do NOT connect

primary load directly

to Terminal Board!

(EXTERNAL) EXT. RELAY

EXHAUST FAN

EXHAUST FAN

CONNECTION

CONNECTION

MAXIMUM LOAD

FAN LOAD ONTIMER OUTPUT

1 AMP, 240/120 VAC

5A, 1/4HP, 240VAC MAX

INPUT L1 OUTPUT TO

L1

L2

Dish Machine

Customer Connecons

TIMER

Terminal Board

WARNING: DISCONNECT POWER TO MACHINE BEFORE SERVICING

WARNING: DISCONNECT POWER TO MACHINE BEFORE SERVICING

CONSTANT VOLTAGE

CONSTANT VOLTAGE

CONNECTION

CONNECTION

LIVE WHEN MACHINE

LIVE WHEN MACHINE

POWER SWITCH IS ON

POWER SWITCH IS ON

FUSE: 3 AMP SLOW-ACTING

(3 AMP MAX.)

L1 OUT L2 OUT

L1

L2

RINSE AID DISPENSER

RINSE AID DISPENSER

CONNECTION

CONNECTION

LIVE WHEN RINSE

LIVE WHEN RINSE

VALVE IS OPEN

VALVE IS OPEN

FUSE: 3 AMP SLOW-ACTING

(3 AMP MAX.)

L1 OUT L2 OUT

L1

L2

LIVE WHEN WASH

PUMP MOTOR IS ON

FUSE: 3 AMP SLOW-ACTING

L1 OUT L2 OUT

Fuse Block

DETERGENT

DETERGENT

DISPENSER

DISPENSER

CONNECTION

CONNECTION

LIVE WHEN WASH

PUMP MOTOR IS ON

(3 AMP MAX.)

L1

L1

L2/N

L2

17

Chemical Supplies

Chemical Dispenser Tube Connection

Points to Rinse Injector:

P: Pressure Switch (1/4" NPT)

S: Sanitizer (1/8" NPT)

R: Rinse Aid (1/8" NPT)

07610-004-33-05-B

Page 25

CURTAIN INSTALLATION INSTRUCTIONS

The unit has decals marking the curtain locations inside the machine, starting at the load end and ending at the unload

end. The illustrations below indicate the size of the curtain to be placed on the curtain hooks

provided. If any curtain components are missing, these must be obtained and installed before operation.

DETERMINING CONVEYER DIRECTION: The dishmachine will be congured for either Left-to-Right or Right-to-Left

operation. Direction is from the load end to the unload end, as shown below.

INSTALLATION

44" Left-to-Right 44" Right-to-Left

XL S L L XL

Load

Unload

66" Left-to-Right

Pre-wash

XL S L S L L XL

Load

66" Right-to-Left

XL L L S L S XL

XL L L S XL

Unload

Unload

Pre-wash

Load

Unload

IMPORTANCE OF PROPER CURTAIN PLACEMENT: The curtains inside the dishmachine must be installed properly

for the machine to operate correctly. Curtains are used to control air currents inside the unit and assist in maintaining the heat

necessary to keep energy costs down. Note the approximate locations for each type of curtain in the above illustrations.

S = Short, L = Long, and XL = Extra Long. See the chart below for actual curtain lengths and part numbers. Note the

different part numbers for the curtain and curtain rod for the load end when a side-loader option is present.

Legend Length Part #

S 12" 08415-131-73-44

L 19" 08415-002-14-41

XL 24.25" 08415-002-47-37

Curtain Rod 20.50" 05700-003-77-52

07610-004-33-05-B

Side-Loader

Option

XL

(Load End Only)

Curtain Rod

(Load End Only)

Load

Part #

08415-003-84-88

05700-003-84-57

18

Page 26

INSTALLATION

• This kit should only be installed by qualified service personnel to reduce the risk of electric shock, serious injury, or

fire. A plumbing permit and the services of a licensed plumber and electrician might be required in some areas.

• Turn off the power supply and place the dishwasher disconnect (if applicable) in the off position. Lockout/tag-out to

prevent the power supply from being turned back on accidentally.

• Failure to install this kit within the guidelines might adversely affect safety, performance, component life, and warranty

coverage.

• Do NOT pull power for the Drain Quench Assembly from the machine! 120V facility power only!

DRAIN QUENCH KIT INSTRUCTIONS

!

WARNING

Tools Required

• Pipe Wrench

• Adjustable Wrench

• 5/16” Nut Driver

• 3/8” Nut Driver or Wrench

• Phillips Screwdriver

• Pipe Thread Sealant Tape or "Pipe Dope"

• Needle-nose Pliers

Instructions

1. Connect Drain Quench Assembly to the machine drain via 1.5” NPT street elbow (04730-206-32-00).

2. Orient assembly as shown below:

19

07610-004-33-05-B

Page 27

DRAIN QUENCH KIT INSTRUCTIONS

DRAIN QUENCH SYSTEM

3. Connect user-supplied 115V cord (from facility power) into solenoid box as shown below:

!

CAUTION

Power cannot

be taken from

the machine!

INSTALLATION

4. Connect cold water to inlet side of solenoid valve.

5. Secure all electrical (ensure connection is to 120V facility power) and plumbing connections.

6. Restore water and power to the machine and verify drain quench performance.

IF THERE ARE ANY ISSUES AFTER INSTALLATION, PLEASE CONTACT

TECHNICAL SERVICE AT 1-888-800-5672.

07610-004-33-05-B

20

Page 28

OPERATION

OPERATING INSTRUCTIONS

PREPARATION

i

Before operating the unit, verify the following:

• The strainers are installed.

• The drain valve is closed.

• The actuator switches move with relative freedom and do not bind.

21

POWER UP

• The curtains are installed correctly.

To place the unit in standby, press the START button on the display.

• The unit will automatically determine if there is proper water level in the wash tank. If

not, the unit will begin to ll until the appropriate level is reached.

• If the wash tank temperature is not at the minimum level for the mode of operation, the

wash heater will energize. Refer to the machine data plate for a better understanding of

the minimum temperatures needed to operate the unit correctly. It might take several

minutes for the wash tank to heat up, depending on the initial temperature of the water.

• If the machine is equipped with a rinse booster option, the booster will turn on when

the unit turns on.

• If the machine is heated with a steam booster, the steam booster must be turned on in

accordance with the manufacturer's instructions.

• Do not attempt to start the unit until:

1. The unit stops lling.

2. The unit has reached the appropriate wash tank temperature.

07610-004-33-05-B

Page 29

OPERATING INSTRUCTIONS

OPERATION

FIRST RACK

WARE

PREPARATION

W ASHING A

RACK OF WARE

The rst rack of ware that is placed in the unit will typically reduce the temperature of

the wash tank, and the rst rack might need to run through the unit again. This process

might be necessary any time the unit has not been operated for an extended period of

time, although this is dependent on the type of ware being used, its temperature, and the

ambient temperature of the kitchen area. To ensure proper operation, always observe the

temperatures of the wash and rinse when rst starting the unit.

Proper preparation of ware is essential for the smooth, efcient operation of this

dishmachine.

Any ware placed in the unit should have all solid food waste and scraps removed. Ware

should also be sprayed-down before entering the dishmachine.

Place cups and glasses upside-down in racks so they do not hold water during the cycle.

Presoak atware in warm water to assist in removing food. Load plates and saucers in the

same direction, with the food surface facing the unload end of the machine.

This dishmachine is designed to wash ware that is placed in a rack. Materials should not

be placed in the unit unless they are properly secured in a dish rack.

OPERATIONAL

INSPECTION

i

To start the cycle, gently push the rack into the unit on the load end. Once the wash

actuator has moved sufciently, the unit will automatically begin to convey the dish rack

through the unit. The entire cycle is automatic.

Operators should periodically review the following items while the

machine is operating. These items are important for operating the machine in an

efcient manner.

• Review wash and rinse temperatures and compare to the minimums on the data plate.

• Verify the pan strainers are not becoming clogged. Keeping these free of soil and

debris allows for much better ow of water through the machine and prevents any sort

of redeposit issues.

• Water pressure: The dishmachine is designed to run at a minimum of 15 PSI; if it is

any lower there will not be enough rinse water to properly remove detergent from the

ware.

• Wash and rinse arm nozzles should be free of debris. Open nozzles are essential to

the operation of the dishmachine.

07610-004-33-05-B

22

Page 30

OPERATION

OPERATING INSTRUCTIONS

SHUTDOWN

CLEANING

Do NOT clean the unit

with any type of metallic

scrubbing sponge!

To shut the unit down, press the START button on the front of the machine. To drain the

machine, move the drain valve to the drain position. If the machine is equipped with a

steam booster, shut it down in accordance with its manufacturer’s instructions.

Clean the unit at least once every 24 hours or at the end of the day. Cleaning assists in

maintaining the efcient operation of the unit by removing soil and debris that might other-

wise become trapped in nozzles or deposited onto ware.

• Curtains should be removed and scrubbed with mild detergent and a brush and

allowed to air-dry.

• Strainers should be removed and debris scooped out. Do not hit strainers to remove

debris; this can cause them to warp and not seat correctly. Rinsing the strainer under

water should remove the rest of any debris trapped in the part.

23

• Wash arms can be removed using a 7/16" driver. However, the dishmachine is

designed so that the wash arms are self-cleaning. Operators have the ability to ush the

arms by removing the plastic end-caps and running a rack through the unit. This should

only be done as a cleaning function with an empty rack and a tub that is lled with water.

• The internal chamber can be cleaned with a mild detergent and dishrag. The strainers

and pawl bar should be removed to provide as much room as possible.

• The outside of the unit should be cleaned with a standard countertop or general

cleaner. Do not attempt to clean inside any compartments, boxes, or chambers that are

secured with a cover. These normally contain live electrical components.

07610-004-33-05-B

Page 31

DISPLAY INSTRUCTIONS

OPERATION

RINSE MODES

CHECKING

CYCLE COUNT

GENERAL

Press the I Key for ECONO RINSE.

Press the II Key for TURBO RINSE.

While the unit is powered off, press and hold the Power Key. The total cycle count

will display for several seconds, followed by a normal .ON state.

1. When main power is rst connected to the unit, the digital display will sequence

through its LEDs to show all are functional.

2. The unit will then go into Standby Mode (blank display).

3. Press the Power Key.

4. The display will show “Heating” until the wash tank reaches operating

temperature.

Delime Key

125 F

Cycle Light

Power Key

HEATING

CYCLE 1

Rinse Options

5. The display will show “Ready” when the unit is ready to use.

180 F

READY

CYCLE 1

OPERATIONAL MESSAGES

DISPLAY CONDITION

"Check doors" One of the doors is not fully closed or one of the switches is not being triggered.

"Filling" The wash tank is lling with water.

"Heating" The unit is heating the water in the wash tank.

"Delime" The Delime Key has been pressed.

"Ready" The dishmachine is ready for operation.

"Wash Temp” A rack of dishes is progressing through the wash section.

Alternates “Wash Temp” & “Rinse Temp” A rack of dishes is progressing through the rinse section.

07610-004-33-05-B

24

Page 32

OPERATION

DELIME INSTRUCTIONS

DELIME

INSTRUCTIONS

To proceed with the delime operation, ll the dishmachine with the correct amount of delime

solution as recommended by the chemical supplier. The tank capacities of the machine can

be found in the Specications section of this manual.

After the chemicals are added, perform the following steps:

1. Press the DELIME button.

2. Disconnect or turn off chemical feeder pumps.

3. Close the doors.

4. Press the START button and run the machine for the length of time

recommended by the chemical supplier.

5. Press the START button to shut the unit off.

6. Wait ve minutes, then inspect the inside of the machine. If the machine is not

delimed, run again.

7. Once clean, drain and re-ll the machine and run two cycles to remove residual

deliming solution.

8. Drain and re-ll the machine.

9. The machine is ready to use.

This equipment is not recommended for use with deionized water or other

aggressive uids. Use of deionized water or other aggressive uids will result in

corrosion and failure of materials and components. Use of deionized water or other

aggressive uids will void the manufacturer’s warranty.

25

07610-004-33-05-B

Page 33

PREVENTATIVE MAINTENANCE

TROUBLESHOOTING

PREVENTATIVE

MAINTENANCE

i

Jackson highly recommends that any maintenance and repairs not specically discussed

in this manual be performed only by QUALIFIED SERVICE PERSONNEL. Performing

maintenance on your dishmachine may void your warranty, lead to larger problems, or

even cause harm to the operator. So if you have a question or concern, do not hesitate

to contact a QUALIFIED SERVICE AGENCY.

By following the operating and cleaning instructions in this manual, you should get the

most efcient results from your machine. As a reminder, here are some steps to take to

ensure that you are using the dishmachine the way it was designed to work:

1. Ensure that the water temperatures match those listed on the machine data plate.

There can be a variety of reasons why your water temperature could be too low.

2. Ensure that all strainers are clean and in place laying at before operating the machine.

When cleaning out strainers, do NOT beat them on waste cans. Wipe out strainers with

a rag and rinse under a faucet if necessary. Use a toothpick to dislodge any stubborn

debris.

3. Ensure that all wash and/or rinse arms are secure in the machine before operating.

4. Ensure that drains are closed/sealed before operating.

5. Remove as much soil from dishes by hand as possible before loading into racks.

6. Do not overll racks.

7. Ensure that glasses are placed upside-down in the rack.

8. Ensure that all chemicals being injected into machine have been veried as being at

the correct concentrations.

9. Clean the unit every 24 hours or at the end of every workday per the instructions in this

manual.

10. Follow all safety procedures, whether listed in this manual or put forth by local, state,

or national codes/regulations.

07610-004-33-05-B

26

Page 34

TROUBLESHOOTING

WARNING: Inspection, testing, and repair of electrical equipment should only be performed by a

qualied service technician. Many of the tests require that the unit have power to it and live electrical

!

WARNING

PROBLEM POSSIBLE CAUSE REMEDY

Dishmachine will not ll

after the door is closed.

Power “ON” light is

illuminated.

components be exposed. USE EXTREME CAUTION WHEN TESTING THE MACHINE.

1. Faulty rinse solenoid valve.

2. Faulty door switch.

1. Repair or replace valve as required.

2. Verify the wiring of the switch; if correct, replace switch.

COMMON PROBLEMS

Dishmachine will not ll

after the door is closed.

Power “ON” light is

NOT illuminated.

Dishmachine will not

run after the door is

closed. Power “ON”

light is illuminated and

the unit is lling.

Dishmachine runs

continuously in the wash

cycle.

Wash heater does not

work.

1. Service breaker tripped.

2. Machine not connected to

power source.

3. Faulty power source.

1. Wash motor faulty/damaged.

2. Wash motor contactor faulty.

1. Machine is in Delime mode.

1. Faulty heater element.

2. Faulty heater contactor.

1. Reset; if the breaker trips again, contact an electrician to

verify the amp draw of the machine.

2. Verify that the machine has been properly connected to

the power source.

3. Verify working power source.

1. Verify that the wash motor is getting power; if so, replace

the motor.

2. Check for continuity; if contacts are open, replace the

contactor.

1. Select an automatic cycle by choosing I, II, or III on the

controller display.

1. Check element for continuity; if open, replace the heater.

2. Replace the contactor.

1. Clogged or obstructed rinse

Dishmachine lls slowly

and/or the rinse is

weak.

arms.

2. Low incoming water pressure.

3. Y-strainer is clogged

27

1. Remove and clean the rinse arms.

2. Adjust the water pressure regulator to ensure that there

is 10 PSI ow.

3. Clean out the Y-strainer.

07610-004-33-05-B

Page 35

COMMON PROBLEMS

WARNING: Inspection, testing, and repair of electrical equipment should only be performed by a

qualied service technician. Many of the tests require that the unit have power to it and live electrical

!

WARNING

PROBLEM POSSIBLE CAUSE REMEDY

components be exposed. USE EXTREME CAUTION WHEN TESTING THE MACHINE.

TROUBLESHOOTING

No indication of

pressure.

Wash water is not

reaching required

temperature.

Doors will not close

completely.

Water leaks at the

wash pump.

1. Water turned off.

2. Transducer disconnected.

3. Pressure transducer defective.

1. Faulty wash heater.

2. Wash thermometer is defective.

1. Obstruction in door channel.

2. Machine not level.

1. Wash pump seal defective.

2. Petcock or pump drain (if

equipped) not shut/tight.

1. Turn water on.

2. Verify wiring.

3. Replace pressure transducer.

1. Check element for continuity; if open, replace the heater.

2. Replace thermometer.

1. Remove the obstruction.

2. Adjust the feet to level machine.

1. Replace the seal.

2. Close or tighten.

Will not rinse.

Dishes are not

coming clean.

07610-004-33-05-B

3. Loose hoses (hose clamps) on

the wash pump.

1. Defective rinse solenoid.

2. Faulty timer.

3. No water to the machine.

1. Machine temperatures are not up

to the minimum requirements.

2. No detergent/too much

detergent.

3. Tighten the hose clamps.

1. Repair or replace the rinse solenoid.

2. Replace timer.

3. Verify that there is water at 10 PSI connected to the

machine.

1. Verify that incoming water, rinse water, and wash

water match the required temperatures as listed on the

machine data plate.

2. Adjust detergent concentration as required for the

amount of water held by the machine.

28

Page 36

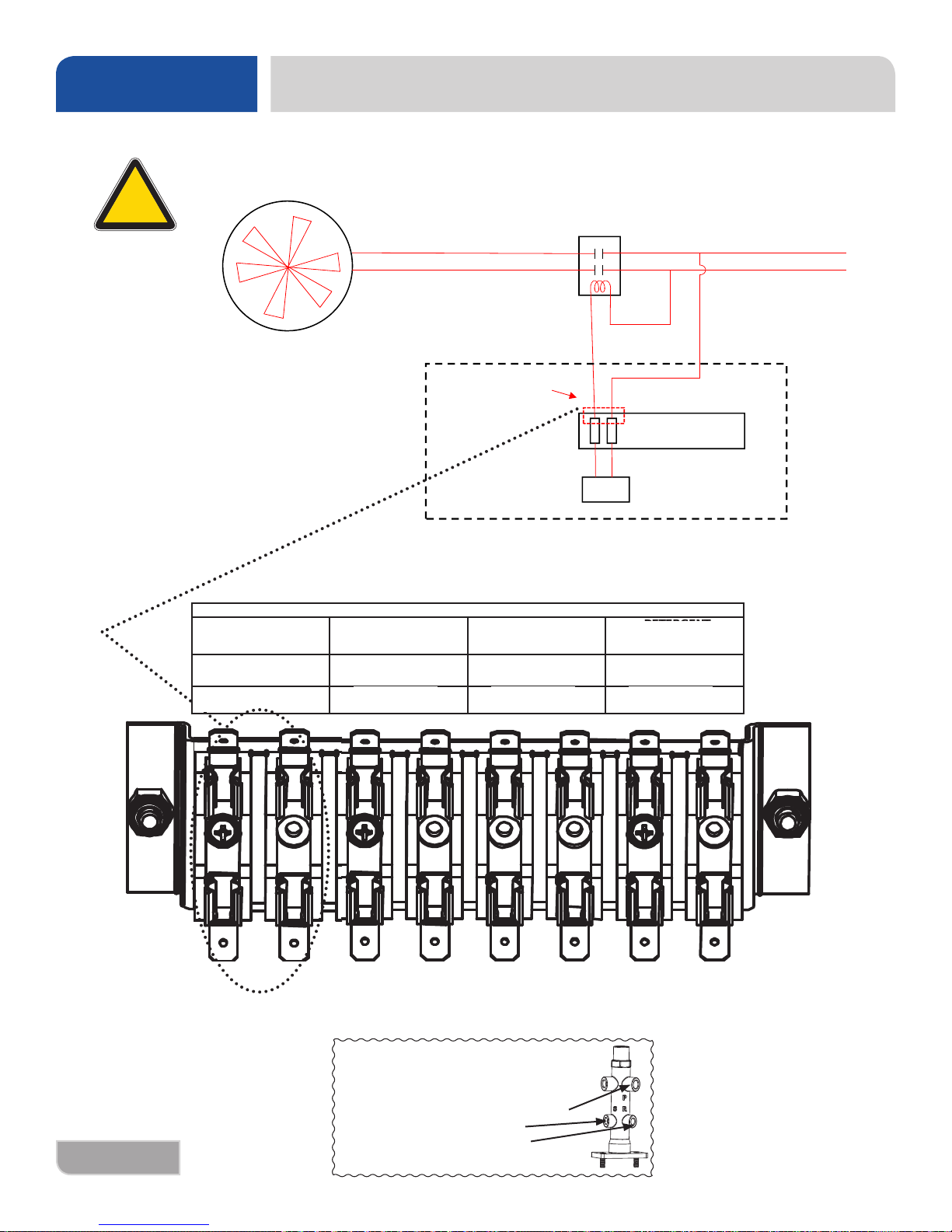

TROUBLESHOOTING

DISPLAY PROGRAMMING

PROGRAM

SELECTION MODE

To access Program Selection Mode, the unit should be on and preferably not in

operation (accessing this mode during operation will interrupt the process).

The programming Keys (Up-arrow, Down-arrow, and Select) are hidden on the

display and are shown below outlined with red dots.

1. Press and hold the I and II Keys until “Program” starts ashing (2 - 3 seconds).

PROGRAM

2. Press the Select Key.

3. Use the Up-arrow Key to change the program number to “6.”

PROGRAM

6

4. Press the Select Key.

5. “Program” will ash.

6. Press the Delime Key to exit.

READY

CYCLE 1

180 F

29

07610-004-33-05-B

Page 37

DISPLAY PROGRAMMING

TROUBLESHOOTING

SETUP MODE

To access Setup Mode, the unit should be on and preferably not in operation (ac-

cessing this mode during operation will interrupt the process).

1. Press and hold the Up-arrow and Down-arrow Keys until “Setup” starts ashing

(2 - 3 seconds).

SETUP

2. The display will then change to “Version” and show the rmware versions of the

IO module and UI board.

3. Use the Up-arrow Key to cycle through the categories (will be ashing).

• Language • Wash Offset

• Temperature Scale • Rinse Offset

• Wash Temperature • Boost Offset

• Boost Temperature • Spare Offset

LANGUAGE

4. Press the Select Key to choose the category you want to change.

• Regardless of the category, steps 5 - 7 remain the same.

5. Use the Up-arrow Key to change the options (will be ashing). Numerical

options are shown in the top window.

LANGUAGE

ENGLISH

6. Press the Select Key to accept the changes.

7. Press the Delime Key to exit.

07610-004-33-05-B

30

Page 38

TROUBLESHOOTING

DISPLAY SHOWS POSSIBLE CAUSES REMEDY

"F4 Service needed,"

"Check incoming

power"

1. Incoming power not properly connected.

2. L3 is missing (3-phase units only).

1. Low or no water pressure.

2. Faulty inlet valve or ll relay.

1. Check connections to heater.

2. Verify that L3 is present and connected properly.

1. Verify incoming water pressure is 8–12 PSI.

2. Verify that ll relay is supplying voltage to ll solenoid.

Replace faulty component.

FAULT CODES

“F6 Service needed,”

“No water in wash tank”

“F7 Service needed,”

“Check wash tank

thermostat”

“F8 No water in wash

tank,” “Check inlet

water and door”

F11 Service need-

ed –check wash tank

thermostat

F13 Communication

error. Check 6-pin

cable

3. Contactor to wash heater not turning off.

4. Faulty temperature input (T1) on IO

module.

5. Faulty temperature probe (T1).

6. Faulty oat switch allows heaters to operate with no water in tub.

1. Contactor to wash heater not turning off.

2. Faulty temperature input (P10) on IO

module.

3. Faulty temperature probe (T1).

1. Malfunction of ll solenoid or ll relay.

2. Door is open, which inhibits ll mode.

3. Faulty door switch.

1. Faulty temperature probe (T1). 1. Replace probe that connects to P10.

1. Loose connection in 6-pin cable between

display board and IO module.

2. Faulty 6-pin cable between display board

and IO module.

3. Faulty communication port on IO module or

display board.

3. Check for welded contacts. Verify that output from IO

module turns off when above the set temperature.

4. Substitute a 1.2 kΩ resistor for T1, and verify that wash

heater turns off. If not, replace IO module.

5. Verify that T1 resistance is correct with respect to temperature. (See Table 1.) If not, replace T1.

6. Replace oat switch.

1. Check for welded contacts. Verify that output from IO

module turns off when above the set temperature.

2. Substitute a 1.2 kΩ resistor for T1, and verify that wash

heater turns off. If not, replace IO module.

3. Verify that T1 resistance is correct with respect to temperature. (See Table 1.) If not, replace T1.

1. Replace faulty solenoid or ll relay.

2. Close door to activate door switch.

3. Replace or adjust door switch.

1. Fully disconnect 6-pin cable at each end, and reconnect

each end until a click is heard.

2. Inspect for broken wire or unseated terminal by gently

pulling on each wire at each end of the cable. Reseat any

loose terminals by inserting it fully into the housing using

long-nosed pliers. Replace cable if broken wire is found.

3. Temporarily substitute a veried good display board, and

check if F13 message recurs. If so, repeat substitution with

a good IO module.

31

07610-004-33-05-B

Page 39

FAULT CODES

TABLE 1: RESISTANCE-TO-TEMPERATURE VALUES

TROUBLESHOOTING

R (kΩ) °F

11.58 69.8

10.37 75.2

9.30 80.6

7.78 89.6

3.05 140.0

2.54 150.8

2.18 159.8

1.58 179.6

1.45 185.0

1.33 190.4

1.16 199.4

0.96 212.0

07610-004-33-05-B

32

Page 40

PARTS

1 2 3 4

CONTROL BOX COMPONENTS

12

ITEM QTY DESCRIPTION PART NUMBER

1 1 Terminal Block, 3-pole 05940-011-48-27

2 1 Fuse Holder 05920-011-72-89

3 2 Terminal Board 05940-002-78-97

4 1 PCB, Electronic Control 05945-004-47-81

5 4 Relay, KUP14AT5-120 P&B 3PO TP MO 05945-111-72-51

6 1 Timer, Universal Digital Multi-timer 05945-004-22-78

7 1 Overload 05945-111-68-40

8 2 Contactor, Wash Motor 05945-111-68-38

9 1 Overload 05945-111-68-39

10 1

11

Transformer, 208 V 05950-011-75-59

Transformer, 230/460 V 05950-011-68-35

10

56789

11 1 Contactor, CR353FE3AA1 3-pole 50A 05945-002-24-70

12 1 Fan 05999-004-30-62

33

07610-004-33-05-B

Page 41

MISCELLANEOUS ELECTRICAL COMPONENTS

1 2

3

PARTS

4

ITEM QTY DESCRIPTION PART NUMBER

1 4 Nut, Thumb, 6-32 Nylon 05310-002-83-12

2 1 Board, Populated Circuit 05945-004-36-33

3 4 Spacer, Display Board 05999-004-19-75

4 1 Panel with Display Membrane 05700-004-40-08

Thermistor Probe

06685-004-34-58

Temperature RTD

06680-002-16-80

Actuator Switch

05930-111-68-44

07610-004-33-05-B

Float Switch

06680-121-70-71

Float Switch Cover

06680-121-70-71

Probe Fitting, Brass

05310-924-02-05

34

Page 42

PARTS

WASH HEATER & HEATER SHROUD ASSEMBLIES

9

2

3

7

1

5

12

6

11

10

4

9

8

ITEM QTY DESCRIPTION PART NUMBER

1 1 Heater Shroud Weldment Lower 05700-003-74-21

2 1 Heater Shroud Weldment Upper 05700-003-74-24

3 1 Gasket, Suction Casting 05330-003-75-89

4 1 Gasket, Pump Suction 05330-003-75-87

5 1 Gasket, Heater 05330-200-02-70

6 1 Heater Box Rails 05700-003-74-72

7 1 Wash Pump Suction Weldment 05700-003-77-63

8 2 Washer, S/S 05311-174-01-00

9 9 Locknut, 1/4"-20 Hex w/Nylon Insert 05310-374-01-00

10 6 Nut, Hex 5/16"-18 S/S 05310-275-01-00

11 6 Lockwasher, 5/16" Split S/S 05311-375-01-00

12 1 Wash Heating Element, 15kW/18kW See Heater Chart

35

07610-004-33-05-B

Page 43

PUMP SUCTION ASSEMBLY

1

PARTS

4

Pump Suction Assembly

05700-003-83-98

RackStar

Pump Suction Assembly

3

ITEM QTY DESCRIPTION PART NUMBER

1 1 Gasket, Suction Casting 05330-003-75-89

2 1 Gasket, Pump Suction 05330-003-75-87

3 1 Pre-Wash Pump Suction Weldment 05700-003-82-27

®

66 Pre-wash

05700-004-34-24

2

4 1 Strainer, Pre-Wash Pump 05700-003-81-28

07610-004-33-05-B

36

Page 44

PARTS

WASH HEATERS

VOLTAGE PHASE KW PART NUMBER CONTACTOR

208 1 15 04540-121-68-45 05945-111-68-37

230 1 15 04540-121-68-46 05945-111-68-37

208 3 15 04540-121-68-45 05945-002-24-70

230 3 15 04540-121-68-46 05945-002-24-70

460 3 15 04540-121-68-47 05945-002-24-70

208 1 18 04540-121-79-30 05945-111-68-37

230 1 18 04540-121-79-31 05945-111-68-37

208 3 18 04540-121-79-30 05945-002-24-70

230 3 18 04540-121-79-31 05945-002-24-70

460 3 18 04540-121-79-32 05945-002-24-70

SERVICE NOTES: When replacing wash heaters, it is highly recommended to change the gasket as well. Once installed,

gaskets become compressed and are subject to extreme temperature changes. Replacing the gasket with the heater

might prevent future leaks.

The nuts used to secure the heater to the casting should be torqued to 16 in-lbs. After tightening, the unit should be allowed

to heat up and operate normally for approximately 30 minutes. Secure power to the machine and check the nuts once more

to verify they are torqued to 16 in-lbs.

37

07610-004-33-05-B

Page 45

PLUMBING ASSEMBLIES

PARTS

6

4 5

3

3

2

1

7

3

9

3

7

1

8

8

4

10

ITEM QTY DESCRIPTION PART NUMBER

1 3 Elbow, 90-Degree 1/2 Street Brass 04730-206-08-00

2 1 Vacuum Breaker 04820-003-06-13

3 5 Nipple, 1/2 Close Brass 04730-207-15-00

4 2 Solenoid Valve, 1/2 04810-003-71-55

5 1 Tee, 1/2 Brass 04730-211-27-00

6 1 Y-strainer 04730-217-01-10

7 2 Elbow, 1/2 NPT 04730-011-42-96

8 2 Adapter, 1/2 Fitting X Male 04730-011-59-53

9 1 Tee, 1/2 X 1/2 X 1/4 Female 04730-411-25-01

10 1 Tank Fill Injector Weldment 05700-003-76-84

1

07610-004-33-05-B

38

Page 46

PARTS

PLUMBING ASSEMBLIES

6

5

4

3

2

13

1

1

14

15

1

6

12

13

3

7

8

9

8

7

10

1112

ITEM QTY DESCRIPTION PART NUMBER

1 3 Plug, 1/8 Brass 04730-209-07-37

2 1 Elbow, 90-Degree 1/2 Street Brass 04730-206-08-00

3 2 Vacuum Breaker, 1/2" 04820-003-06-13

4 1 Injector, Turbo Rinse 05700-004-32-61

5 1 Elbow, 1/2 NPT Brass 04730-011-42-96

6 2 Nipple, 1/2 Brass 2 Long 04730-207-19-00

7 2 Adapter, 1/2 Fitting X Male 04730-011-59-53

8 2 Elbow, 1/2 04730-406-31-01

9 1 Union, 1/2 04730-412-05-01

10 1 Solenoid Valve, 1/2 04810-003-71-55

11 1 Fitting, Comp. 1/2 NPT X 1/4 05700-004-36-74

12 2 Tee, 1/2 Brass 04730-211-27-00

13 2 Nipple, 1/2 Close Brass 04730-207-15-00

14 1 Rinse Injector 05700-003-76-83

15 1 Plug, 1/4 Brass 04730-209-01-00

39

07610-004-33-05-B

Page 47

PRE-WASH TANK FILL ASSEMBLY

PARTS

5

4

3

2

1

10

6

7

8

9

ITEM QTY DESCRIPTION PART NUMBER

1 1 Y-strainer 04730-217-01-10

2 1 Nipple, 1/2" Close, Brass 04730-207-15-00

3 1 Valve, 1/2" 04810-003-71-55

4 2 Nipple, 1/2" Brass 2 Long 04730-207-19-00

5 1 Vacuum Breaker, 1/2" 04820-003-06-13

6 1 Elbow, 90-degree 1/2" Street Brass 04730-206-08-00

7 1 Wash Fill Injector 05700-003-77-56

8 1 Gasket, Rinse Manifold 05330-003-75-91

9 1 Tube, Tank Fill 05700-003-76-81

10 1 Elbow, 1/2" NPT 90 Brass 04730-011-42-96

07610-004-33-05-B

40

Page 48

1

2

4

5

4

6

7

13

8

9

14

14

10

11

11

10

12

14

13

3

PARTS

WASH MANIFOLD & ARM ASSEMBLY

Mechanical Pump Seal

05330-002-34-22

16

15

41

07610-004-33-05-B

Page 49

WASH MANIFOLD & ARM ASSEMBLY

ITEM QTY DESCRIPTION PART NUMBER

1 1 Pump & Motor Assembly See Table Below

2 1 Gasket, Pump Suction 05330-003-75-87

3 1 Gasket, Pump Discharge 05330-003-75-88

4 2 Hose Clamp, Range 2-9/16" to 3-1/2" 04730-003-15-40

5 1 Hose, Wash Pump Discharge 05700-003-77-62

PARTS

6 1

7 1 Casting, Wash Manifold 09515-003-71-50

8 1 Tube, Manifold Riser 05700-003-72-37

9 1 Wash Manifold Weldment, Upper 05700-003-73-66

10 1 Wash Arm Weldment, Top-right 05700-003-75-79

11 1 Wash Arm Weldment, Top-left 05700-003-75-80

12 12 Cap, Threaded 04730-603-12-00

13 3 O-Ring, Silicone, .103 Dia., 2-1/2" x 2-11/16" OD 05330-003-73-71

14 4 O-Ring, Silicone, .139 Dia., 2-1/4" ID x 2-1/2" OD 05330-003-73-72

15 1 Wash Arm Weldment, Bottom-right 05700-004-27-43

16 1 Wash Arm Weldment, Bottom-left 05700-004-27-42

PUMP & MOTOR ASSEMBLY PART NUMBER

Wash Pump, 3 HP, 208 V, 60 Hz, 3-Phase 06105-003-76-11

(L-R Machines) Lower Manifold

(R-L Machines) Lower Manifold

05700-004-27-39

05700-004-30-27

Wash Pump, 3 HP, 230 V, 60 Hz, 3-Phase 06105-003-76-11

Wash Pump, 3 HP, 460 V, 60 Hz, 3-Phase 06105-003-76-11

Wash Pump, 3 HP, 460 V, 60 Hz, 1-Phase 06105-003-76-13

Wash Pump, 3 HP, 230 V, 60 Hz, 1-Phase 06105-003-76-13

07610-004-33-05-B

42

Page 50

PARTS

PRE-WASH MANIFOLD & ARM ASSEMBLY

7

6

5

5

8

9

10

7

8

11

43

10

4

12

2

3

2

1

13

Mechanical Pump Seal

05330-002-34-22

07610-004-33-05-B

Page 51

PRE-WASH MANIFOLD & ARM ASSEMBLY

ITEM QTY DESCRIPTION PART NUMBER

1 1 Gasket, Pump Suction 05330-003-75-87

2 2 Hose Clamp 04730-003-15-40

3 1 Hose, Wash Pump Discharge 05700-003-77-62

4 1 Manifold, Pre-wash System 05700-004-31-60

5 3 O-Ring, Silicone, .103 Dia., 2-1/2" x 2-11/16" OD 05330-003-73-71

6 1 Tube, Manifold Riser 05700-003-81-53

7 2 Casting, Pre-wash Manifold 09515-003-77-22

8 2 O-Ring, Silicone, .139 Dia., 2-1/4" ID x 2-1/2" OD 05330-003-73-72

9 1 Pre-wash Arm 05700-003-75-79

10 4 Cap, Threaded 04730-603-12-00

11 1 Pre-wash Arm, Lower 05700-003-80-96

12 1 Gasket, Pump Discharge 05330-003-75-88

PARTS

13 1 Pre-wash Motor See Table Below

PUMP & MOTOR ASSEMBLY PART NUMBER

Pre-Wash Pump, 2HP, 208V, 60Hz, 3-Phase 06105-003-76-12

Pre-Wash Pump, 2HP, 230V, 60Hz, 3-Phase 06105-003-76-12

Pre-Wash Pump, 2HP, 460V, 60Hz, 3-Phase 06105-003-76-12

Pre-Wash Pump, 2HP, 460V, 60Hz, 1-Phase 06105-003-76-14

Pre-Wash Pump, 2HP, 230V, 60Hz, 1-Phase 06105-003-76-14

07610-004-33-05-B

44

Page 52

PARTS

RINSE ASSEMBLY

3

20

2

1

13

17

4

5

6

7

6

8

3

11

9

8

9

10

12

19

21

15

20

14

13

18

17

16