Page 1

AJX-44

Models

AJX-44

Standard Features

• 25” clearance accommodates

larger wares, such as sheet pans,

mixing bowls, etc.

• Exclusive EnergyGuard™ controls

• Fully automatic, including auto-ll

• Electromechanical controls

• Adjust-A-Peak™ adjustable

conveyor speed allows machine

to extend wash time and rinse

contact for heavy soil conditions

Project

Item

Quantity

CSI Section 11400

Approval

Date

• Stainless steel scrap baskets

• Splash shields

• Front dress panel

• Externally operated drain lever

• Adjustable bullet feet

• Stainless steel frame and legs

• Exhaust vent fan control

• 18kW wash tank heater

AJX-44

• Self-draining stainless steel wash

pump

Mandatory Specs Options & Accessories

Specify:

Electric Steam

Specify Voltage______________

Specify Sanitizing Method:

High Temperature

Chemical Sanitizing

Specify Direction of Operation:

Left to Right

Right to Left

Booster Heater

40° F (22.2° C) Rise - 17kW

70° F (38.9° C) Rise - 30kW

Steam Booster Heater

23” (584 mm) Unhooded Side Loader

23” (584 mm) Hooded Side Loader

30” (762 mm) Unhooded Side Loader

30” (762 mm) Hooded Side Loader

1/2” Pressure Regulator

Flanged Feet

Blower Dryer

Vent Cowl Collars (set of 2)

Prison Package

Specifications

High-temperature model uses 0.68 gallons

(2.57 liters) per rack. Chemical-sanitizing

model uses 0.78 gallons (2.95 liters) per rack

High-temperature model cleans 225 racks

per hour. Chemical-sanitizing model cleans

209 racks per hour

8” (203 mm) splash shields on both wash

and rinse ends

25” (635 mm) chamber height clearance

accommodates larger wares

18” (457 mm) wash section with

an 18” (457 mm) separation

between wash and rinse

Durable stainless steel construction

Drain Quench System

Scaltrol

Water Hammer Arrestor

Strikeplate Table Limit Switch

36-Compartment Rack

4-1/8” tall (105 mm)

5 - 5/8” tall (143 mm)

7” tall (178 mm)

Combination Rack

Peg Rack

Sheet Pan Rack

www.jacksonwws.com

Page 2

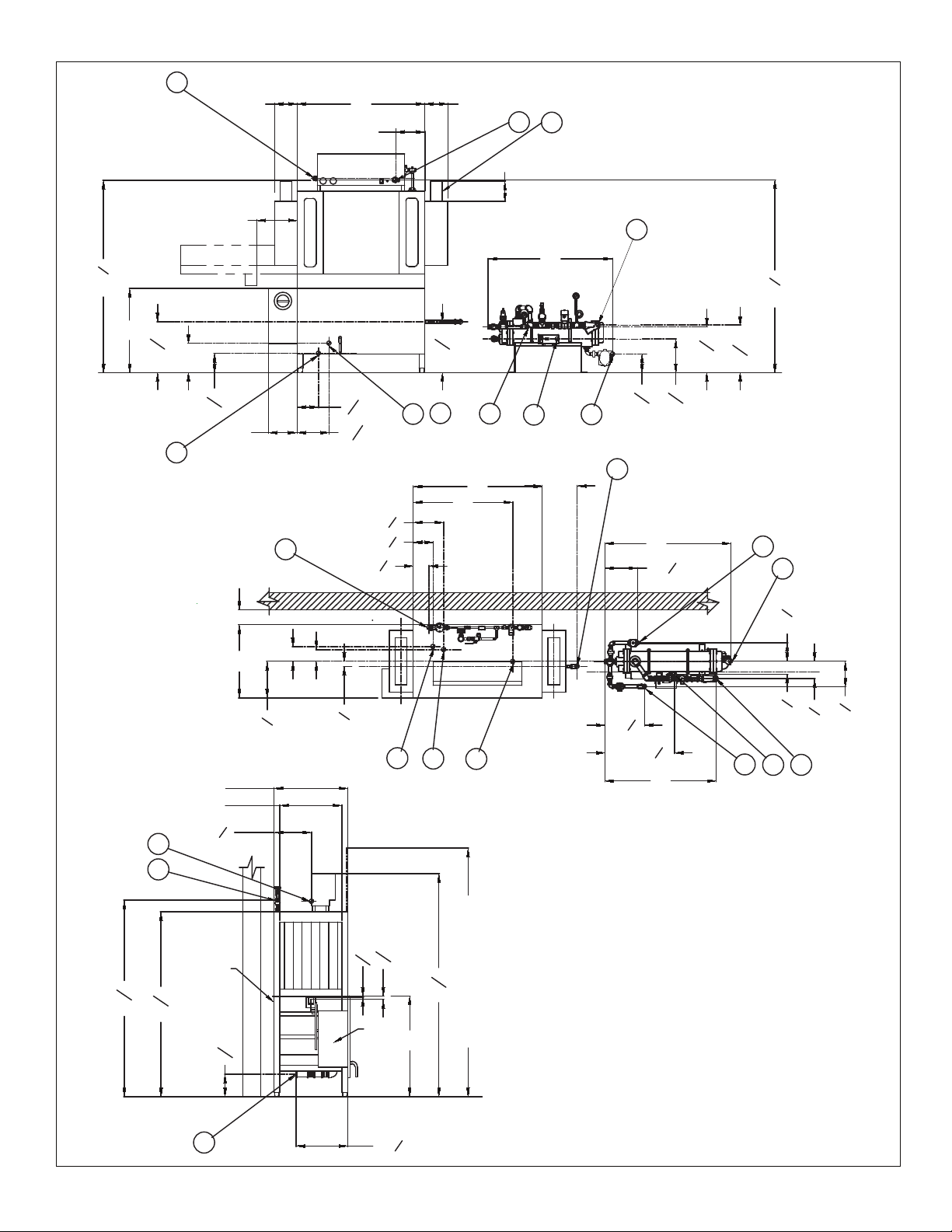

AJX-44

Left to Right

FRONT VIEW

TO OBSTRUCTIONS

2

14" MIN.

8"

44"

10"

8"

7"

1

5A

7

"

2

1

66

"

29"

2

1

17

SIDE VIEW

1

2

"

"

2

1

1

66

62

10"

4

12

REAR OF

MACHINE

2

3

"

2

1

6

10"

TOP VIEW

25"

21"

5

"

8

"

2

1

7

25" 5"

"

2

1

12

43"

"

2

1

65

11

"

2

1

17

"

"

8

8

5

1

"

7

2

1

"

8

3

5

44"

9

6

8

12"

3

6

11

3

"

"

4

16

3

7

15

16

34"

1

10

"

2

7

"

6

5

8

1

"

2

2

43"

11

8

1

"

4

10

"4

8

3

6

5"

4"

"

4

3

1

4

5

1

1

13

2

1'-11

"

3

"

4

9

"

8

3

6

7

"

"

8

8

5

7

8

5

38"

1. Electrical connection

2. 1/2” NPT 180° F water inlet

for wash and nal rinse

3. 3/4” NPT steam connection

4. 3/4” NPT condensate return line

5. 1-1/2“ NPT drain connection

"

"

8

2

1

1

1

"

2

1

5a. Vent connection -

Includes damper. 2 locations

4” I.D. X 16” I.D.

75

STEAM BOOSTER CONNECTIONS

DRIVE

UNIT

34"

84" TOP OF OPEN DOOR

6. Electrical connection

7. 1” NPT steam connection

8. 3/4” NPT condensate connection

9. 3/4” NPT incoming 110° F water

connection

10. 3/4” NPT 180° water connection

17

1

"

2

to dishmachine

www.jacksonwws.com

Page 3

AJX-44

Right to Left

8"

1

5A

44"

10"

7"

7

8"

2

FRONT VIEW

14" MIN.

TO OBSTRUCTIONS

"

2

1

65

"

"

4

16

3

7

15

16

"

"

8

8

5

3

6

11

11

43"

1

4

"

8

10

"4

8

3

6

"

8

5

8

"

8

"

3

8

7

5

9

6

7

13

1'-11

38"

1. Electrical connection

2. 1/2” NPT 180° F water inlet

for wash and nal rinse

3. 3/4” NPT steam connection

4. 3/4” NPT condensate return line

5. 1-1/2“ NPT drain connection

5a. Vent connection -

Includes damper. 2 locations

4” I.D. X 16” I.D.

STEAM BOOSTER CONNECTIONS

6. Electrical connection

7. 1” NPT steam connection

8. 3/4” NPT condensate connection

9. 3/4” NPT incoming 110° F water

connection

10. 3/4” NPT 180° water connection

to dishmachine

43"

"

2

1

66

"

29"

2

1

17

10"

"

1

"

7

11

2

1

"

8

3

8

9

6

5

10"

3

12"

44"

2

1

6

4

34"

10

6

5

1

"

2

7

"

8

1

"

2

TOP VIEW

2

5"

25" 5"

4"

"

4

1

"

2

3

"

4

1

4

5

"

2

1

3

1

75

84" TOP OF OPEN DOOR

34"

17

1

"

2

1

"

2

12

25"

21"

5

12

8

REAR OF

MACHINE

"

2

1

7

3

SIDE VIEW

"

1

2

"

1

62

"

2

2

1

66

www.jacksonwws.com

Page 4

AJX-44

Recommended

Table Fabrication

Note: Tub Will Accept

a Table Flange

Up to 24 7/8"

(632 mm)

3/4" (19 mm) Table

Turndown Flange 3/4" Max

MODEL NO.

AJX-44

DIMENSION REQUIREMENTS

Wall Clearance (minimum)

OPERATING CAPACITY

OPERATING TEMPERATURES

Wash (minimum)

Rinse (minimum)

ELECTRICAL REQUIREMENTS

460V/60HZ/3PH

BOOSTER HEATER OPTIONS

208V/60HZ/3PH

230V/60HZ/3PH

460V/60HZ/3PH

HOW TO SPECIFY:

MACHINE DIMENSIONS

HEIGHT

75-1/2”

(1919 mm)

AJX-44

21" (533 mm)

HEIGHT WITH

DOOR OPEN

84”

(2134 mm)

40° F (22.2° C) Minimum Rise 70° F (38.9° C) Minimum Rise

LENGTH

BETWEEN

DISHTABLES

44”

(1118 mm)

kW AMPS kW AMPS

17.2

18

DEPTH WEIGHT CLASS CUBE HEIGHT WIDTH DEPTH

25”

(635 mm)

4-1/2” (114 mm)

34” (864 mm)Standard Table Height

25” (635 mm)Inside Clearance

Chemical SanitizingHigh-Temperature

Chemical SanitizingHigh-Temperature

140° F (60° C)160° F (71° C)

140° F (60° C) 180° F (82° C)

Approximate Total Load AMPS

Electric

56.7

96.8

51.9

88.6

26.0

47.8 30 83.4

45.2 30 75.4

22.6 30 37.718

Table

Connection

Rack Rail Height

Above Dishtable

1/4" (6mm) - 5/16" (8mm)

DRAIN

HEIGHT

(191 mm)

209225Racks per Hour

Steam

10.3208V/60HZ/1PH

10.3230V/60HZ/1PH

SHIPPING INFORMATION

7-1/2”

6.7208V/60HZ/3PH

6.7230V/60HZ/3PH

3.4

Rack Rail

Use Silicone Sealer

Between Table and

Lip of Machine to

Prevent Leakage

Tub

641 lbs

(291 kg)

92.5

137.2

cu. ft.

78”

(1981 mm)

WATER REQUIREMENTS

Inlet Temperature (minimum)

With 40° F (22.2° C) Rise Booster Heater

With 70° F (38.9° C) Rise Booster Heater

Gallons per Hour - High-Temperature

Gallons per Hour - Chemical Sanitizing

Gallons per Rack - High-Temperature

Gallons per Rack - Chemical Sanitizing

Waterline Size IPS (minimum)

Drainline Size IPS (minimum)

Flow Pressure (PSI)

Flow Rate (minimum) - High -Temperature

Flow Rate (minimum) - Chemical Sanitizing

Wash Tank Capacity

WASH PUMP

Wash Pump Motor

CONVEYOR

Conveyor Motor

Conveyor Speed (feet per minute highest speed)

VENTING REQUIREMENTS

Input End

200 CFM

STEAM COIL TANK HEAT (STEAM MODELS ONLY)

Steam Connection IPS

76”

(1930 mm)

270 GPM (1022 LPM)Wash Pump Capacity

6.2 FPM (1.9 MPM)High-Temperature

5.75 FPM (1.75 MPM)Chemical Sanitizing

Output End

400 CFM

Table

40”

(1016 mm)

140° F (60° C)

110° F (43° C)

153 gal (579 L)

163 gal (617 L)

.68 gal (2.6 L)

.78 gal (3.0 L)

1/2”

1-1/2”

15

2.6 GPM (9.8 LPM)

2.7 GPM (10.2 LPM)

21 gal (79.5 L)

2 hp

1/4 hp

Total CFM

600 CFM

3/4”

10-20Steam Flow Pressure (PSIG)

60Consumption @ 15 PSIG (lbs/hr)

Jackson WWS, Inc.

Shipping Address: 6209 North U.S. Highway 25E, Gray, KY 40734

www.jacksonwws.com

Mailing Address: P.O. Box 1060, Barbourville, KY 40906

Telephone: 888-800-5672 • Fax: 606-523-1799

Email: info@jacksonwws.com

07610-003-60-58 [12/17/15]

We reserve the right to change specications in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Loading...

Loading...