2.8Lserieshigh-enddieselenginesaremanufacturedbyJAC.Withthedisadvantagesofcompactstructure,high

power,littlevibration,lownoiseandlowprice,itisanidealpowerfor0.5-4tonserieslighttruckandallkindsofvariants

ormechanisms.

Beingused,dieselenginewillrunabnormallyduetoreasonsofpartswearing,tighteningpartsloosening,clearance

change,oilgoingbad.Ifitisfoundstartingdifficultly,powerfalling,oilconsumptionadding,pleasedoregularmainte鄄

nanceofcleaning,checking,lubricating,adjustingorreplacingpartsaccordingtothetechnicalstateandworkingtime

orvehicletraveleddistance.

Pleasereadthismanualbeforeusing2.8Lseriesdieselengineandoperateitstrictlywiththemanualsoastomake

thebestperformanceoftheengineandreducethepossibilityofrepairingit.

JACwillreservethemodificationrightsonthismanual.Wewillnotmakeothernoticeonanymodificationonthe

contentofthismanual.

AnhuiJianghuaiAutomobileCO.,LTD

Preface

Chapter 玉 Enginespecificationsandtechnicalparameters

玉 Maintechnical parameters1

域Mainparts specifications3

芋Maincheckingandadjusting parameters4

郁Mainboltandnut torque5

Chapter 域 Starting,running&stopping

玉 Before starting9

域Proceduresof starting9

芋Checkingduring operating10

郁 Stopping10

Chapter 芋 UsingandMaintenance

玉 Dailymainteanceandnoticeof using11

域 Break-inofnew engine11

芋 Oil choosing12

郁 Mainteancetimeandmainteance content13

Chapter 郁 Perseveringandreusingofengine

玉 Long-timeperseveranceof engine21

域 Reusingof engine21

Appendix1 High-mortalityparts list(4DA1) 23

Appendix2 High-mortalityparts list(4DA1-1) 24

Appendix3 High-mortalitypartslist(4DA1-2Band 4DA1-2B1) 25

Contents

1

Chapter 玉 Enginespecificationsandtechnicalparameters

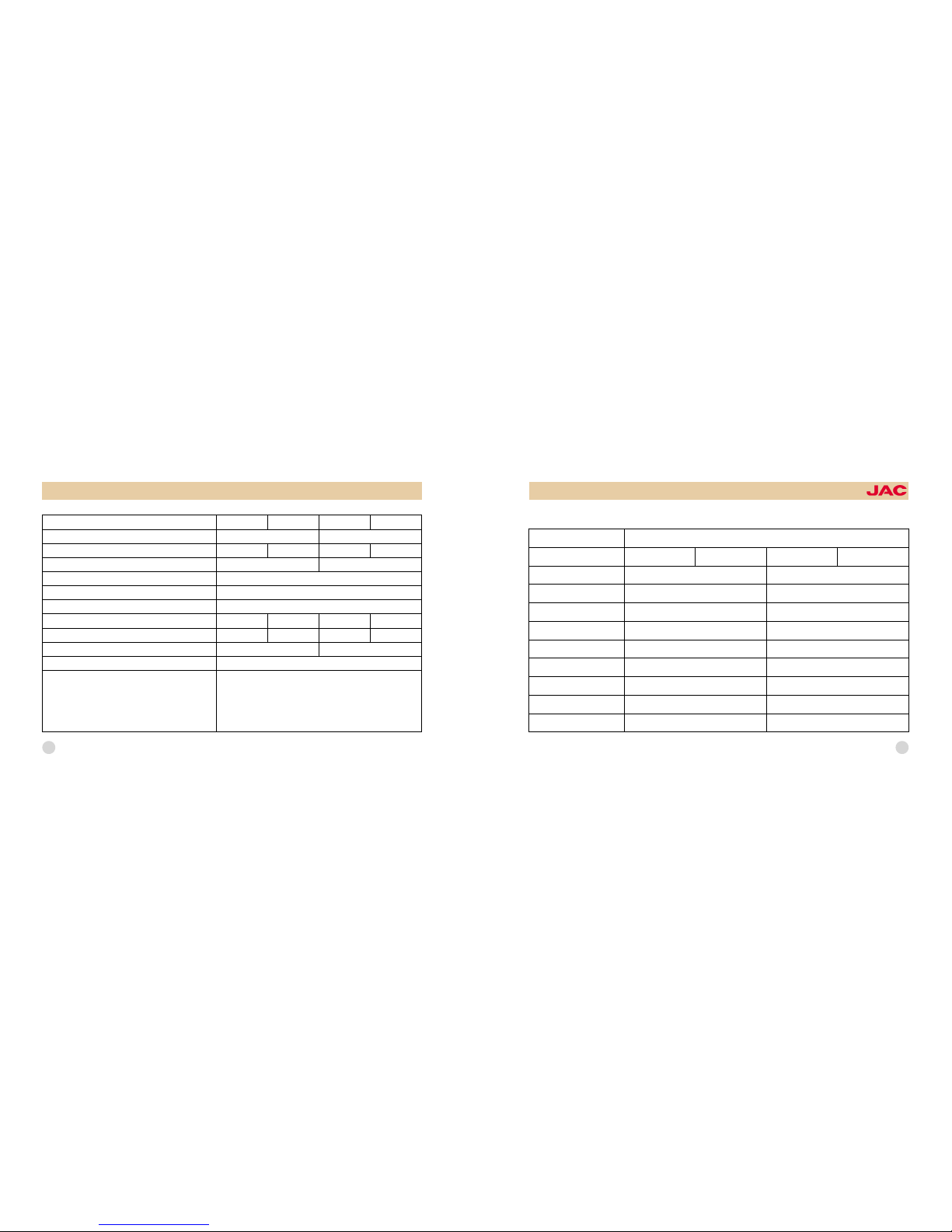

玉.Maintechnicalparameters

1.Mode HFC4DA1-1

2.Type

Vertical,turbochargerintercooler,

directinjection,

drytypethin-wall

ch-romeplatingliner

3.Cylindersnumber 4

4.Bore(mm) 93

5.Stroke(mm) 102

6.Totaldisplacement(L) 2.771

7.Compressionratio 17.5

8.Ratedpower(KW) 68

9.Ratedrotatedspeed(rpm) 3600

HFC4DA1

Vertical,intercooler,

directinjectiondry

typethin-wall

chromeplating

liner,4stroke

18.2

57

HFC4DA1-2B HFC4DA1-2B1

Vertical,turbochargerintercooler,

directinjection,

drytypeliner

Verticalturbochargerintercooler,

di-rectinjection,

drytypeliner

18.2 18.2

68 80

3

域.Mainpartsspecifications

Fuelfilter

Oilfilter

Oilpump

Coolingwaterpmp

Thermostar

Generator

Starter

Fuelinjection-pump

Fuel-injector

Fullflow Fullflow

Full-flowspin-onoilfilter Full-flowspin-onoilfilter

externallymeshedgeartype externallymeshedgeartype

Centrifugaltype Centrifugaltype

Waxmode Waxmode

Alternatoroutput Alternatoroutput

Deceleratinglow-speedhightorquestarter Deceleratinglow-speedhightorquestarter

VEdistributorpump Electropump

Fiveholes袁pressurechamber Electroinjector

HFC4DA1-1 HFC4DA1 HFC4DA1-2B HFC4DA1-2B1

Partsname Technicalfeature

13.Idlespeed(rpm) 750依50

14.Firingsequence 1-3-4-2

15.Directionofcrankshaft渊facingtoflywheel冤 Counterclockwise

16.Lubricatingmethod Pressureandsplashlubrication

17.Overalldimensions 764伊616伊698

18.Netmass 240kg

19.Oilcapacityinoilsump(L) 6

20.Coolingwatercapacity(L)(notincludingradiator) 10

valvetiming(usethecrankshaftangletocount)

(1)Intakevalveopen(beforetopdeadcenter)

(2)Intakevalveclose(afterbottomtopdeadcenter)

(3)Exhaustvalveopen(beforebottomtopdeadcenter)

(4)Exhaustvalveclose(aftertopdeadcenter)

24.5毅

55.5毅

54毅

26毅

754伊568伊698

230kg

800依50

764伊622伊714 764伊622伊714

250kg 250kg

7.5

12.Minoilconsumptionratio(g/Kw窑h) 218 230 212 208

11.Rotatespeedatmaxtorque(rpm) 1800耀2000 2000耀2200

10.Maxtorque(N窑m) 216 174 210 240

2

OWNER爷SMANUAL

2.8LSeriesDieselEngine

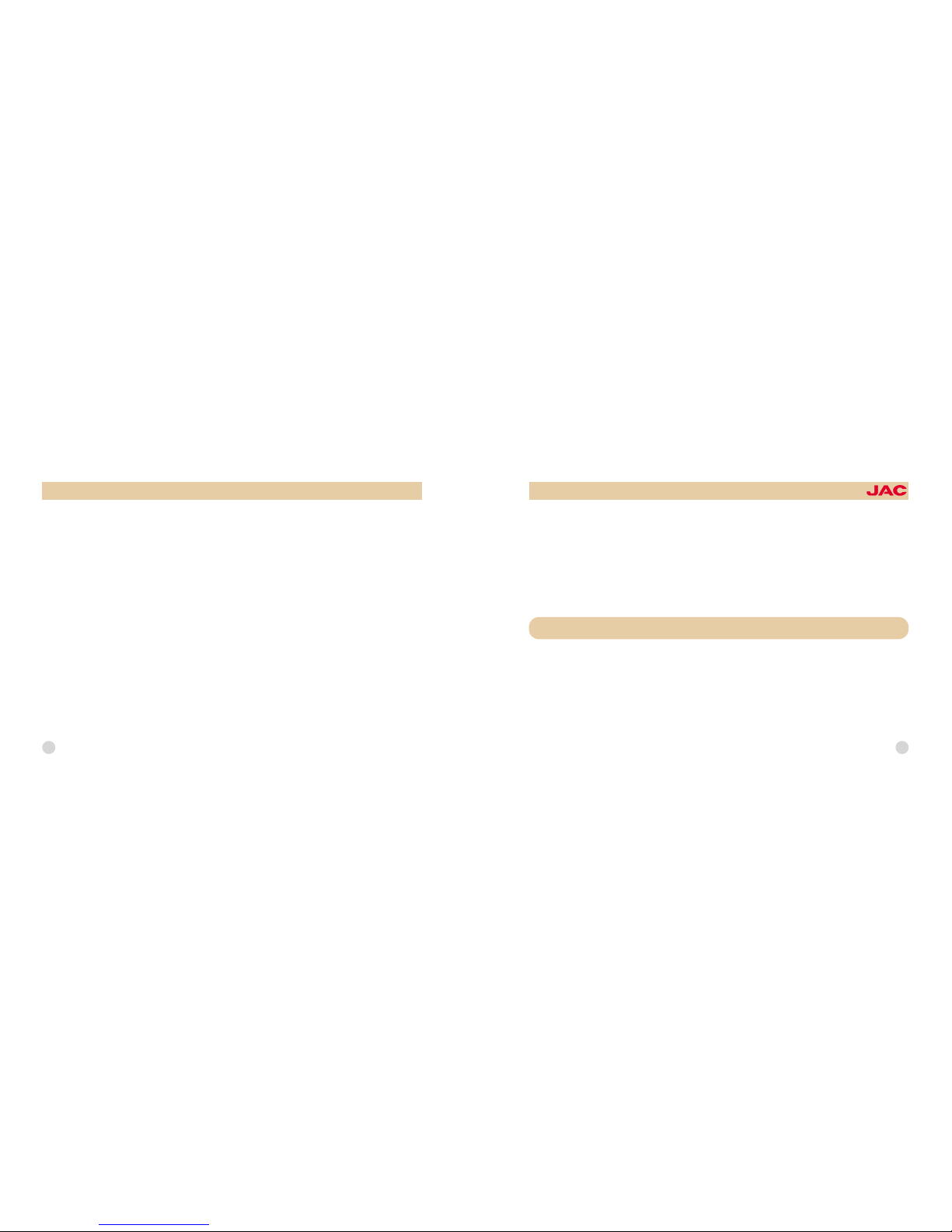

Name Description Torque渊N窑m冤

Cylinderheadbolt M11伊127-4h 105依5

Crankshaftinstallingbolt M12伊1.5伊47 110依10

IdlegearAinstallingbolt M8伊55 25依5

IdlegearAinstallingbolt M12伊1.25伊66 110依10

Exhaustmanifoldinstallingbolt M8伊35 30依5

Connectingrodbolt M11伊1.25 85依5

Dampedbeltinstallingbolt M16伊1.5伊29 210依15

Mainbearinghousinginstallingbolt M14伊1.5伊89 170依10

Flywheelbaffleinstallingbolt M12 85依10

Flywheelinstallingbolt M13伊1.25伊36.5 120依10

Cylinderheadcoverinstallingbolt M8伊11 13依5

Rockerinstallingbolt M10 55依5

5

郁.MainBoltandnuttorque

HFC4DA1andHFC4DA1-1

Mode

Valveclearance

Oilpressure渊idle冤

Exhausttemperature(mainpipe)

Oiltemperature(mainoilgallery)

Temperatureofthermostat

Temperatureoffull-openthermostat

Projectedheightofglowplug

Projectedheightofinjector

Staticfuelsupplyadvancedangle

(beforetopdeadcenter)

HFC4DA1-1 HFC4DA1

0.3耀0.4mm 0.3耀0.4mm

逸98kpa 逸98kpa

臆650益 臆700益

臆130 益 臆130 益

82益 82益

95益 95益

5.3耀6.8mm 5.3耀6.8mm

2.1耀3.0mm 3.7耀4.3mm

12毅

HFC4DA1-2B HFC4DA1-2B1

0.3耀0.4mm 0.3耀0.4mm

逸98kpa 逸98kpa

臆700益 臆700益

臆130 益 臆130 益

82益 82益

95益 95益

5.6耀6.9 5.6耀6.9

2.1耀3.0 2.1耀3.0

16毅

4

芋.Maincheckingandadjustingparameters

OWNER爷SMANUAL

2.8LSeriesDieselEngine

7

Name Description Torque渊N窑m冤

Cylinderheadbolt M11伊1.5伊127 105依5

Crankshaftinstallingbolt M12伊1.5伊47 110依10

IdlegearAinstallingbolt M8 25依5

IdlegearAinstallingbolt M8 20耀25

Exhaustmanifoldinstallingbolt M8 30依5

Connectingrodbolt M11伊1.25 85依5

Dampedbeltinstallingbolt M16伊1.5伊55 210依15

Mainbearinghousinginstallingbolt M14伊1.5伊85 180耀200

Flywheelbaffleinstallingbolt M12 85依10

Flywheelinstallingbolt M13伊1.25伊36.5 140依10

Cylinderheadcoverinstallingbolt M8伊11 13依5

Rockerinstallingbolt M10 55依5

HFC4DA1-2BandHFC4DA1-2B1

Name Description Torque渊N窑m冤

Inletmanifoldinstallingbolt M8伊25 20依5

Inletbendingpipeinstallingbolt M10伊30 30依5 30依5

Timinggearchamberinstalling M825依5 25依5

Camshaftthrustplateinstallingbolt M825依5 25依5

Injectionpumpgearinstallingbolt M865依 5 65依5

Waterinletinstallingbolt M825依5 25依5

Oilsumpboltandnut M820耀27 20耀27

Oilpumpinginstallingbolt M8伊30 25依5 25依5

Highpressurefuelpipenut M1230依5 30依5

Injectionpressingplatebolt M10伊70 40依5 40依5

Injectionpumpflangetighteningbolt M8 30耀40 30耀40

Injectionpumptighteningbolt M825依5 25依5

Oilfilterseatinstallingbolt M8伊30 25依5 25依5

Waterpumpinstallingbolt M8伊45 25依 5 25依5

6

OWNER爷SMANUAL

2.8LSeriesDieselEngine

9

Chapter 域 Starting,running&stopping

玉.Beforestarting

Beforestartingtheengine,youshouldchecktheengineasfollows:

1.Checkthecoolingwaterleverintheradiator,thetightnessofallconnectingpartsandthelengthoffanbelt.

2.Checktheoilleverintheoilsump.

3.Checkthefuelleverinthefueltankandthefuelpipelineandallfittingofthefuelsystemtoseewhetherthereisleak鄄

ageonalljoints.

4.Checktheliquidleverofelectrolyteinthebattery

5.Checkthetightnessofjointsonbattery尧generator尧starterandsensor.

6.Youmustaddoilpumpwith60mldieseltomakeaexhaustdisposalbeforethefirststartorafterlong-timepersever鄄

ance.Prohibitrunningtheoilpumpwithoutanydieselinit,inordertopreventitfromfunctionfailure.

域.Startingprocedure

1.Pullthegearshiftoftransmissiontoneutral

2.Pressdowntheclutchpedaltoreducetheburdenwhenenginestarts.

3.Placetheignitionkeyto"START"position,andtheenginewillstart.Donotoperatethestarterformorethan15sec鄄

ondsatatime.Ifitfailstostart,waitfor2minutestostartagain.Ifitfailstoworkafterstartingforseveraltimes,check

thecauseandremedythefault.

Name Description Torque渊N窑m冤

Inletmanifoldinstallingbolt M8 20依5

Inletbendingpipeinstallingbolt M8 20依5

Timinggearchamberinstalling M8 25依5

Camshaftthrustplateinstallingbolt M8 25依5

Injectionpumpgearinstallingbolt M14 70依5

Waterinletinstallingbolt M8 20耀27

Oilsumpboltandnut M8伊30 25依5

Oilpumpinginstallingbolt M8 25依5

Highpressurefuelpipenut M12伊1.5 20依2

Injectionpressingplatebolt M15伊1 27依2

Injectionpumpflangetighteningbolt M8 6耀8+40耀45毅

Injectionpumptighteningbolt M8 30依5

Oilfilterseatinstallingbolt M8 25依5

Waterpumpinstallingbolt M12伊1.5 27依2

8

OWNER爷SMANUAL

2.8LSeriesDieselEngine

Temp 4益 above

DieseloilNo. 0

-5益 above

-10

-14益 above -29益 above

-20 -35

11

Chapter 芋 Operationandmaintenanceoftheengine

玉.Noteforoperation

1.1Maintaintheengineaccordingtothemanual.

2.Checkearthpolarityofbattery.Siliconcommutationdynamousesnegativepoleearthing.

3.Break-inisnecessarybeforeusingnewengine.Donotspeedupsharplyandgettheengineloaded.

4.Fuelmode

SelectlightfuelaccordingwithGB252basedonseasonalternationandlocaltemperature.

5.Stopandcheckiffindinganythingabnormallyduringoperation.

6.Whendrainingcoolingfluid,opentheradiatorcapfirstlyandthenswitchonaftertemperatureofcoolingfluidlowed.

域.Break-inofnewengine

Servicelifeofenginehascloserelationshipwithinitialusingsituation.Drivenewvehicleobeyingthefollowingrulesto

savefuelandprolongservicelifeofvehicleduringofinitial2500Km.

1.Donotdriveathighspeed.

2.Avoidfaststarting,fastspeedingup,fastbrakingandlong-timehighspeedrunning.

10

4.AfterstartingHFC4DA1-1尧HFC4DA1-2BandHFC4DA1-2B1engien,keeptheenginewarming-upinidlespeedfor

2~3minutestomakethesuperchargerlubricatedwellandavoiddamagingspareparts.

芋.Checkingduringoperating

1.Checkwhetherthereareabnormalnoises.

2.Checkwhetherthereisburningsmellfromgeneratororotherelectricalequipmentbecauseoftheirhightemperature.

3.Checkthefuelsystem,coolingsystemandlubricatingsystemforleakage.

4.Checktomakesurethatthegaugesandmetersareperformingproperly.

郁.Stopping

Iftheengineoperatingwithhighloadneedtostop,pleasekeepdeceleratingrotatingspeedofenginefor2~3minutes

andthenstoptoavoiddamagingthesuperchargerandotherpartsbecauseofcoolingsharplyandpreventenginefrom

beingself-combusted.

OWNER爷SMANUAL

2.8LSeriesDieselEngine

郁.Maintenanceperiodandmaintenanceitems

Technicalmaintenanceperiod

Accordingtodifferentlawoftechnicalstateworseningdegreeofeachpart,classifytheregulartechnicalmaintenance

intofourclasses.

1.Dailymaintenance:after8-10hs'workingtime

2.Class-onemaintenance:after100hworkingtimeorrunningfor4000-5000km.

3.Class-twomaintenance:after250hworkingtimeorrunningfor10000-12500km.

4.Class-threemaintenance:after1000hworkingtimeorrunningfor30000-40000km.

Technicalmaintenanceitems

Inordertoguaranteedieselengineoperatenormally,dotechnicalmaintenanceasfollows:

1.Dailymaintenance

荫

Checkoillevelofdieseloil,coolingfluidandoilandfillupifnecessary.

荫

Wipeoffdustonthebatteryandsplashedelectrolytetoensureairventunblocked.

13

Note: Checkoillevelafterdieselenginedying.

Dieseloilspecification:uselightdieseloilaccordingwithGB252,NO.0forsummer,NO.-10or-20forwinter

(warmarea)andNO.-35(coldarea).

Note: Fillingupthefueltankduringoperationisforbidden.Donotfillupoiltankwhenvehiclerunsunderhottem鄄

perature,otherwiseoilwilloverflowbecauseofinflation,onceinflating,wipeitimmediately.

5W/30 NotlowerthanCF-4

Oilmode

15W/40 NotlowerthanCF-4

HFC4DA1 HFC4DA1-2B HFC4DA1-2B1

NotlowerthanCF

Qualityclass

NotlowerthanCF

HFC4DA1-1

Localtemperature

-15益耀40益

9-30益耀5益

Gearposition Enginerotatingspeed

gear玉 0-3200

gear域 1400-1800

gear芋 1400-3500

gear郁 >1350

gear吁 >1350

12

3.KeeprotatingspeedofengineIduringbreaking-inperiodinthefollowingscope

4.Donotexceedthelimitingloading.

芋.Selectingoil

SelectoilaccordingwithGB11122dbasedonseasonalternationandlocaltemperature.

OWNER爷SMANUAL

2.8LSeriesDieselEngine

15

荫

Cleanairfilter.

荫

Checkheatremovalofcoolingfluid.

荫

Checktightnessofdieselengine.

3.Class-twomaintenance

Aftercarryingoutclass-onemaintenance,addthefollowingmaintenancecontentsevery250h (10000-12500km).For

newengineorafterhavingtechnicalmaintenanceengine,themaintenanceshouldbecarried100h(4000~5000km):

荫

Checkinjectorbasedonitsworkingcondition.Correctinjectionpressureandwatchsprayconditionanddoneces鄄

sarycleaningandadjustment.

荫

Checkinjectionpumpandadjustit.

荫

Replaceoilinoilsump.

荫

Replacespin-onoilfilterelementandspin-ondieseloilfilterelement.

荫

Checkvalveclearanceandadjustit.

荫

Checkoverflowsportofwaterpump.Ifbadlyoverflow,replaceit.

荫

Checkelectricalequipmentandwirejoint.Ifburned,replaceit.

荫

Cleanpipewaterdepositofcoolingsystem.

荫

Cleancrankcaseventilationsystem.

Note: Whendisassemblethefuel-injectorandtheoillinecoverthatinthehighpressureoillineinterfaceofthe

guiderail,useyourlefthandtoholdtheinterface.

It'sunnecessarytodomaintenanceundernormalcondition.Doregularcheckonoillevelunderhottemperaturetomake

sureoillevelliesbetweenmarkMINandMAX.Whenelectrolyteinbatteryisnotenough,addaquadistillateintoit.

荫

Checkwhetherthereareoilleakage,waterleakageorairleakageafterstartingdieselengineandshootthetrouble

immediately.

荫

Checktightnessofaccessory.

荫

Afterstartingdieselengine,checkwhetheritrunsnormallyandworkingconditionofmeters.Repairorreplaceitif

founddamage.

荫

Keepdieselengineclean,especiallyelectricalequipmentandradiatoronwatertank.

2.Class-onemaintenance

Aftercarryingoutdailymaintenance,addthefollowingmaintenancecontentsevery100h(4000-5000km).

荫

Checkelectrolyteratioorvoltage

荫

Checklengthoffanbeltandadjustit.

14

Note: It'sforbiddentoaddsupplementedelectrolyteorotheruncleanwater,oritcanmakebatteryundercharge.If

oillevelfallsquickly,takethebatterytoservicestation.

Note: Becauseofthecorrosivenessofelectrolyte,itwillinjureyouoneye,skinandclothes.Ifhappened,washwith

waterimmediately.

Note: ifdieselengineworksindustyenvironment,remembertodismantleairfilterandcleanittokeepitworkwell.

OWNER爷SMANUAL

2.8LSeriesDieselEngine

andwhetherdrivingdeviceisflexible.

5.Seasonalmaintenance

荫

Inwinter,usecoolingsystemfordieselengine.Pleasereplaceantifreezecoolantonceayear.It'snecessarytodrain

offitforalongtimeparkingifnotusingantifreezecoolant.

荫

Uselubricationwhichisonlyforwinterinwinter.

荫

Changeconcentrationofbatteryelectrolytewithseasonchanging.

Technicalmaintenanceoflubricationsystem

1.Chooselubricationfordieselenginelubricationsystemaccordingtosurroundingtemperature.

UseSFdieselengineoilaccordingwithGB11122.

2.Measurementofoillevel.

Oillevelofoilsumpismeasuredbyoilscalemountedontheleftsideofdieselengine.Whenmeasuring,parkthevehi鄄

cleinthehorizontalpositionandstopoperatingthediesel.Pullouttheoilscaleaftertheoillevelstoppingrocking,use

cleaningclothtowrapawayoilonoilscaleandtheninserttheoilscaleintooillevel.Oilscaleshouldbemountedonthe

rightplace,then,pullouttheoilscaletochecktheoillevel.

Therearetwoholesonoilscale,oillevelshouldnotbelowerthantheholesbelow.Ifnot,supplyofoilwillstop.It'sim鄄

propertohaveoilexcessive,forcrankpinofcrankshaftwillstriketheoillevelinthissituationtoformexcessiveoilmist

andsplashoildropandcausecarbondepositofpistonandcombustionchambercarbondeposit.Atthesametime,

17

Note: mixingdifferentoilisforbidden.

16

4.Class-threemaintenance

Class-threemaintenancefocusesonassemblydissembling,cleaning,dismantling,adjustmentandhiddentroublere鄄

moval.Afterclass-twomaintenance,addthefollowingmaintenancecontentsevery1000h(30000-40000km)

荫

Dismantleandcleandieselenginetoremovecarbondeposit,oilydirtandwaterdirt.

荫

Checkwear&tearofvalve,pushrodandrocketcontactarea.Repairandreplacethemifnecessary.

荫

Checkwear&tearofpistonring,cylinderjacket,connectingrodsmallendbushingandconnectingrodbearingoffset.

Replacethemifnecessary.

荫

Checkwear&tearofmainbearinglinerandthrustplate.

荫

Checkwear&tearofdrivemechanismanddrivinggearmeshingsurfaceaswellasmeasuringmeshingclearance.

Repairandreplacethemifnecessary.

荫

Checkwear&tearofinletvalve&outletvalveandinletvalveseat&outletvalveseat.Repair,lapandtestleakage.Re鄄

placethemifnecessary.

荫

Checkinjectorandlaporreplacetheinjectornozzlepairifnecessary.Usetheultrasonicwavetocleanthecarbon

depositwheninstalltheusedfuel-injectionnozzle,prohibitusingsilktowipeorusingcuttertoshaving,preventdamage

thefuel-injectionnozzleandclogtheinjectionhole.

荫

Checkoilpumpanddismantleormeasurethepartsthatareeasytodamageandadjust.

荫

Checkcylindergasketandinletpipeshim&outletpipeshim.Iffindingdamaged,replacethem.

荫

Checksuperchargerandclean.Wear&tearofsuperchargergearandoilsealandreplaceifnecessary.

荫

Checkgeneratorandstarter,cleanpartsandgearandaddnewlubricationafterdrying.Checkwear&tearofstarter

OWNER爷SMANUAL

2.8LSeriesDieselEngine

Technicalmaintenanceofcoolingsystem

Thereshouldbeenoughcoolanttoensureengineworkwellandcoolantintimebeforerunningthevehicle.

Checklengthoffanbelt:beltdeflectionis100Nbelow,newbeltis8-10mm,oldbeltis9-11mm.

Checkwhetherthereiscrackonfanbelt,replacebeltifitfailtotransmit.

Technicalmaintenanceofinjectionpump

Injectionpumpisheartofdieselengine,itiscomposedofmanyaccurateparts.Onlytheinjectionpumpismaintained

right,willitworkwellanditsservicelifewillbeprolonged.

1.HFC4DA1seriesdieselengineadoptsfuelinjectionpumpofVEtypeandislubricatedbylightdieselfuelwhichisac鄄

cordantwithGB252.Wateredfuelisnotallowed,forinjectionpumpofVEtypeislubricatedbydieselfuel.Wateredfuel

willmakeitlubricatedbadlyandcauseinjectionpumppartsdamaged.Dieselfuelshouldbedepositedformorethan

48handbeputintouseafterfiltrated.Usecleantoolsandcontainertofillupthedieselfuel.

19

Note:

荫

Donotusehardwatersuchasrunningwaterandmineralwater.

荫

Donotusebadantifreezecoolantorcoolantofdifferenttypecoolantincaseofcorrodingmachineparts

荫

Ifcoolantisconsumedquickly,itshowedthatthereisleakageoncoolingsystem.Checkitinservicestation.

Note: addedoilshouldbeflownintooilsumpbypushingrodholeonthecylinderheadandonesideoftappet.So

oillevelshouldbecheckedafter5minutes.

pistonringwillbegluedbycokingtomakedieselenginesmokeandcausefuelpermeation.Therefore,apartfrompay鄄

ingattentiontotheoilpressure,checkingoillevelbeforerunningorrunningevery300-500isnecessary.

3.Replacenewoil

Beenusedforalongtime,therewillbeimpurityanddustinoil.Duetounburnedfueloilmakesoilthinandwastedgas

comingintooilwithaceticanhydridemakeoilbadandcorrodeparts,so,replacenewoilafterrunningfor10000kmis

necessary.CFdieseloilaccordingwithGB11122isrecommended.

Ifthereisabundantimpurityinoilsump,beforethenewdieselisputintouse,use5#and7#mechanicalfuel(lightbob鄄

binoil)tocleanlubricationsystem.Petrolorkeroceneisforbidden.

Whencleaninginsideofdieselengine,fill5#and7#mechanicalfuelintooilsump.Ifoillevelrisetocentralpositionof

tworoundholesofoildipstick,dismantleallofthepre-heatingplugandrotatecrankshaftofdieselenginewithjiggle

barfor2-3minutes,anddrainoffcleansingoilatonce.

Afterreplacingnewoileverytime,makedieselenginedono-loadrunningforashorttimetoguaranteelubricationsys鄄

temandotherpositionthatneedsoilfueledenough.

Whenfillingoilfromoilinletthatisoncylinderheadshield,cleanthecylinderhead.Coverthelidafterfilling.

18

Notice: checkoillevelaswellascheckingoilpressure.

Warning: hotoilcaninjurepeople,makesuretodealwitholdoiltoprotectenvironment.Screwmomentandoil

bleedplug,addnewoilandcheckoillevel.

OWNER爷SMANUAL

2.8LSeriesDieselEngine

Chapter 郁 Preservationandreusingofengine

玉.Long-timepreservationofengine

1.Drainoffcoolingwaterinradiator,cylinderandpump,startenginetoevaporatecoolantfor30seconds.

2.Dismantlebattery.

3.Makesuresurfaceofengineclean.

4.Screwofffuel-injector,fillupabout30gdewateringoilandrotatecrankshaftfor15-20circle,thenmountfuel-injec鄄

tor.

5.Adddewateringlubricationintolubricatingpoint.

6.Loosenfanbelt.

7.Drainofffuelinoiltankandcleanoiltank.

8.Useprotectivematerial(canvas,waterproofclothoroiltankpaper)tocoverengine.Sealtheunclosedpipeorifice.

9.Keepstorehousedryanddonotstorecorrosivegoodsandgas.

域.Startafterlong-timepreservation.

1.Removegreaseforantirusting.

2.Addlubricationintolubricatingpoint.

3.Fillupcoolingwater.遥

4.Fillupfuel.

21

2.Afternewvehiclerunsfor2500kmduringbreak-inperiod,cleanorreplacefuelfilter'sspin-onfilterelement.Replace

itforrunningevery10000kmafterwards.

3.Checktightnessofoilcircuitandobservewhetherthereisabnormalvoiceorphenomenonoflocaloverheating.

4.Checkwhetherbindingboltoninjectionpumpuncrownedifworkingfor200h.

5.Injectionpumphasbeenadjustedinfactoryandhasleadseal.Don'tdismantleitwhenused.Userwhodoesn'thave

experimentalcondition,don'tdismantleandadjustinjectionpumpassembly.

6.Ifdieselengineisnotusedforalongtime,drainoffdieselfuelintheinjectionpumpandreplaceantirustoil.

Note:

荫

Obeytechnicalmaintenancerules,maintaindieselenginetoguaranteeitsquality.Especiallywhenworkingbusi鄄

ly,reducingmaintenanceitemorprolongingmaintenanceperiodareforbiddenarbitrarily.2.

荫

Carryingoutclass-threemaintenanceindoorstopreventdustgoingtoinsideofmachine.

荫

Forsomecomplicatedmaintenancesoradjustments,getthehelpoftechnicalpersonnelorservicestation.

20

OWNER爷SMANUAL

2.8LSeriesDieselEngine

No. partnumber

1 1002411FA

2 1002412FA

3 1004026FA

4 1004024FA01

5 1004025FA01

6 1004030FA01

7 1002220FA

8 1307024FA

9 1010300FA

10 1003016FA

11 1002420FA

12 1002430FA

13 1002107FA

14 1002108FA

15 3701310FA

16 1307210FA

Name

Uppermainbearing

Lowermainbearing

Connectingrodbearingshell

Thefirstgas-tightring

Thesecondgas-tightring

Oilring

Cylinder-headgasketassemblyset

Fanbelt

Oilfilterandoilcoolerassembly

Valveoilseal

Crankshaftfrontoilseal

Crankshaftrearoilseal

Camshaftbush(front)

Camshaftbush(middleandrear)

Glowplug

thermostat

Quantity

5

5

8

4

4

4

1

1

1

8

1

1

1

各

1

4

1

No

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

partnumber Name Quantity

1003012FA Inletvalve 4

1003011FA Outletvalve 4

1003209FA Valveadjustingscrew 8

1003211FA Valveadjustingnut 8

1003015FA Valvespring 8

1003018FA Inletmanifoldshim 1

1008015FA01Inletanglepipeshim 1

1002016FA Sight-holecovershim 2

1003020FA01Exhaustmanifoldshim 1

1002011FA Timinggearcaseshim 1

1002013FA

Gearchambercoversealingring

1

1100352FA

Injection-pumpflangesealingring

1

1307229FA Thermostathousingshim 1

1307011FA Waterpumpsealingring 1

1307221FA Wateroutletshim 1

1307741FA Waterinletpipeshim 1

Appendix1院High-mortalitypartslist(4DA1)

23

5.Fillupdieselfuel.

6.Checkelectrolyteinbattery.

7.Connectedwithbatteryandpastevaselineonterminal.

8.Checkelectricalcircuitandtightnessofelectricalpipe.

9.For4DA1-2Bseriesengine,Whenpreservationthemscrewofffuel-injector,fillupabout30gdewateringoilandro鄄

tatecrankshaftfor15-20circle,thenmountfuel-injector.Addoilpumpwith60mldieseltomakeaexhaustdisposal,

prohibitrunningtheoilpumpwithoutanydieselinit,inordertopreventitfromfunctionfailure.

10.Startengineaccordingtotheformeroperationprocedure.

22

OWNER爷SMANUAL

2.8LSeriesDieselEngine

No. partnumber

1 1002411FA

2 1002412FA

3 1004026FA

4 1004024FA01

5 1004025FA01

6 1004030FA01

7 1002220FA

8 1307024FA

9 1010300FA020

10 1003016FA

11 1002420FA

12 1002430FA

13 1002107FA

14 1002108FA

15 3701310FA

16 1307210FA

Name

Uppermainbearing

Lowermainbearing

Connectingrodbearingshell

Thefirstgas-tightring

Thesecondgas-tightring

Oilring

Cylinder-headgasketassemblyset

Fanbelt

Oilfilterandoilcoolerassembly

Valveoilseal

Crankshaftfrontoilseal

Crankshaftrearoilseal

Camshaftbush(front)

Camshaftbush(middleandrear)

Glowplug

thermostat

Quantity

5

5

8

4

4

4

1

1

1

8

1

1

1

各

1

4

1

No

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

partnumber

1003012FA

1003011FA

1003209FA

1003211FA

1003015FA

1003018FA

1008015FA01

1002016FA

1003020FA01

1002011FA

1002013FA

1100352FA

1307229FA

1307011FA

1307221FA

1307741FA

Name

Inletvalve

Outletvalve

Valveadjustingscrew

Valveadjustingnut

Valvespring

Inletmanifoldshim

Inletanglepipeshim

Sight-holecovershim

Exhaustmanifoldshim

Timinggearcaseshim

Gearchambercoversealingring

Injection-pumpflangesealing

ring

Thermostathousingshim

Waterpumpsealingring

Wateroutletshim

Waterinletpipeshim

Quantity

4

4

8

8

8

1

1

1

1

1

1

1

1

1

1

1

25

Appendix3院High-mortalitypartslist(4DA1-2Band4DA1-2B1)

24

No. partnumber

1 1002411FA

2 1002412FA

3 1004026FA

4 1004024FA

5 1004025FA

6 1004030FA

7 1002220FA

8 1307024FA

9 1010300FA

10 1003016FA

11 1002420FA

12 1002430FA

13 1002107FA

14 1002108FA

15 3701310FA

16 1307210FA

Name

Uppermainbearing

Lowermainbearing

Connectingrodbearingshell

Thefirstgas-tightring

Thesecondgas-tightring

Oilring

Cylinder-headgasketassemblyset

Fanbelt

Oilfilterandoilcoolerassembly

Valveoilseal

Crankshaftfrontoilseal

Crankshaftrearoilseal

Camshaftbush(front)

Camshaftbush(middleandrear)

Glowplug

thermostat

Quantity

5

5

8

4

4

4

1

1

1

8

1

1

1

各

1

4

1

No

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

partnumber

1003012FA

1003011FA

1003209FA

1003211FA

1003015FA

1003018FA

1008015FA

1002016FA

1003020FA

1002011FA

1002013FA

1100352FA

1307229FA

1307011FA

1307221FA

1307741FA

Name

Inletvalve

Outletvalve

Valveadjustingscrew

Valveadjustingnut

Valvespring

Inletmanifoldshim

Inletanglepipeshim

Sight-holecovershim

Exhaustmanifoldshim

Timinggearcaseshim

Gearchambercoversealingring

Injection-pumpflangesealingring

Thermostathousingshim

Waterpumpsealingring

Wateroutletshim

Waterinletpipeshim

Quantity

4

4

8

8

8

1

1

2

1

1

1

1

1

1

1

1

Appendix2院High-mortalitypartslist(4DA1-1)

OWNER爷SMANUAL

2.8LSeriesDieselEngine

Loading...

Loading...