JAC HFC1042K2 Service Manual

SHOP MANUAL

4DA1 SERIES

Mainly for the truck HFC1042K2(D800)

JAC INTERNATIONAL

2007.10

JAC motors

4DA1 SERIES

SHOP MANUAL

Foreword

This shop manual was prepared as

reference to properly carry out servicing

and maintenance on JAC vehicles.

Contents

Group

Code

0000 General

Name Page

All the maintenance data in this manual is

based on the model HFC1042K2

( D800/D801). And it also can be as

reference for the other models listed in the

Chapter “General”. Their main common

configurations are as follows:

HFC4DA1(HFC4DA1-1) engine; JAC

MSB-5M transmission, hydraulic brake

and JAC new model cabin.

All information in this manual is the latest

data and status of the vehicle at the time

of publishing for your reference. However,

due to technological advance or product

updating etc., all contents in this manual

are subject to modification. We reserve

the right of modification of this manual

without prior notice.

Please inform Customer Service

Department of JAC International if there is

any mistake, and you will be highly

appreciated.

Tel:0086-0551-2296344

Fax:0086-0551-2296454

Email:hwfw@jac.com.cn

1000 Engine

1600 Clutch

1700 Gearbox

2200 Driveshaft

2400 Rear axle

2901 Front suspension

2911 Rear suspension

3000 Front axle

3400 Steering gear

3500 Brake

3700 Electric system

5000 Cabin

General

General

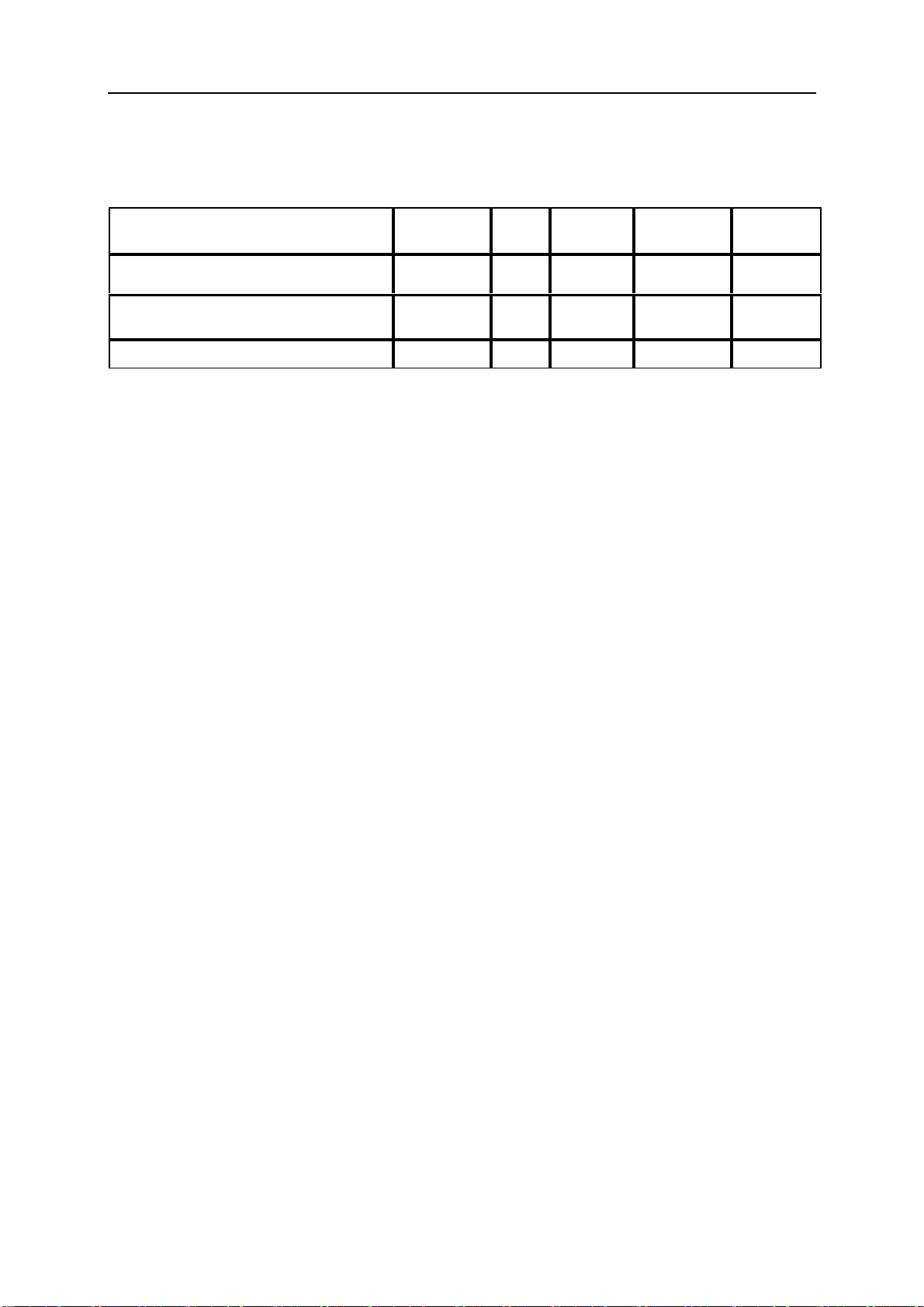

Specifications

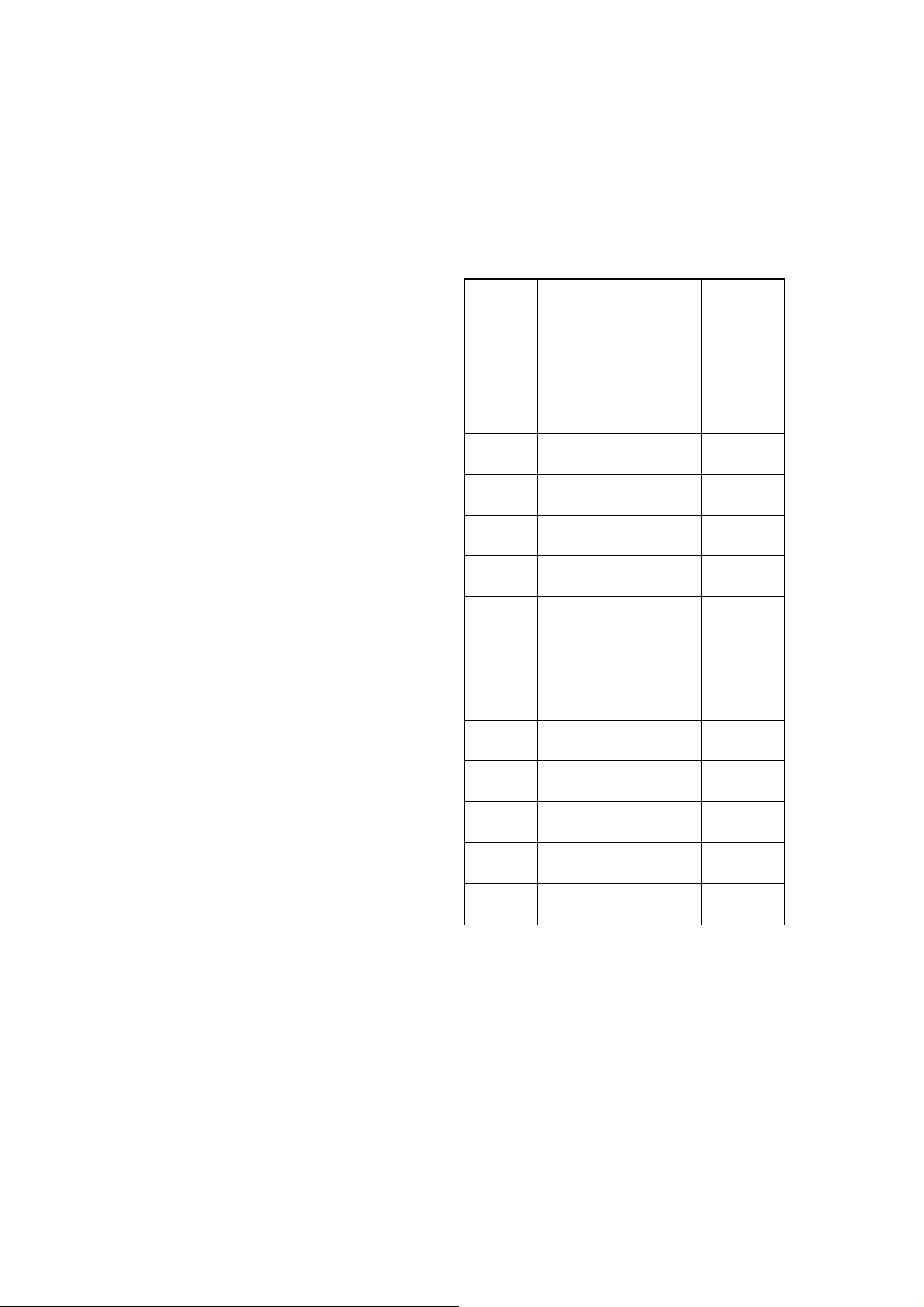

Vehicle Model

VIN

The mechanic performance table of bolts in China

Specifications

Model

Serious Number

Cabin

Final gear ratio

Tyre

L*W*H)

Gross Vehicle

Capacity

Conditioner

teering

heater

Braking

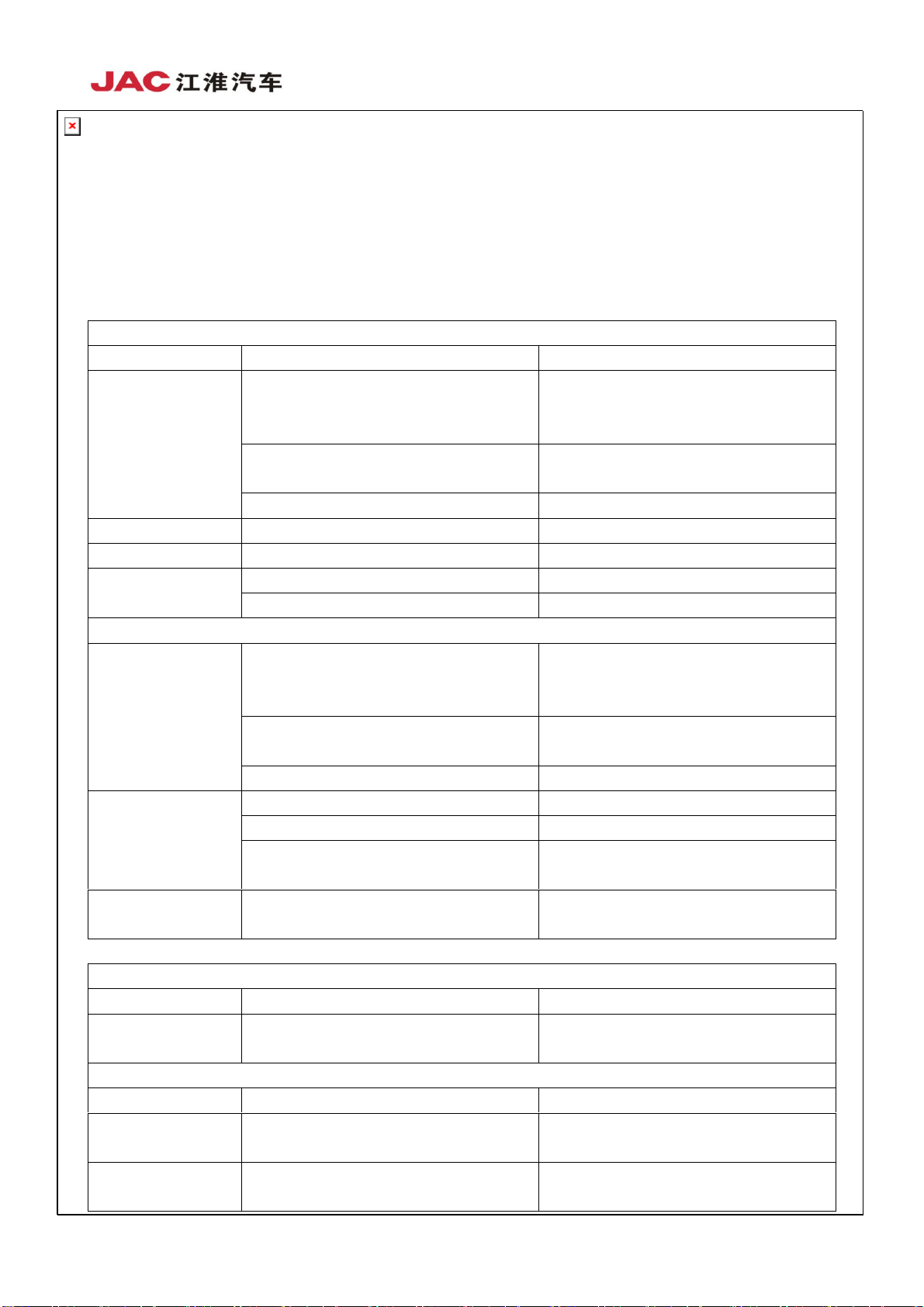

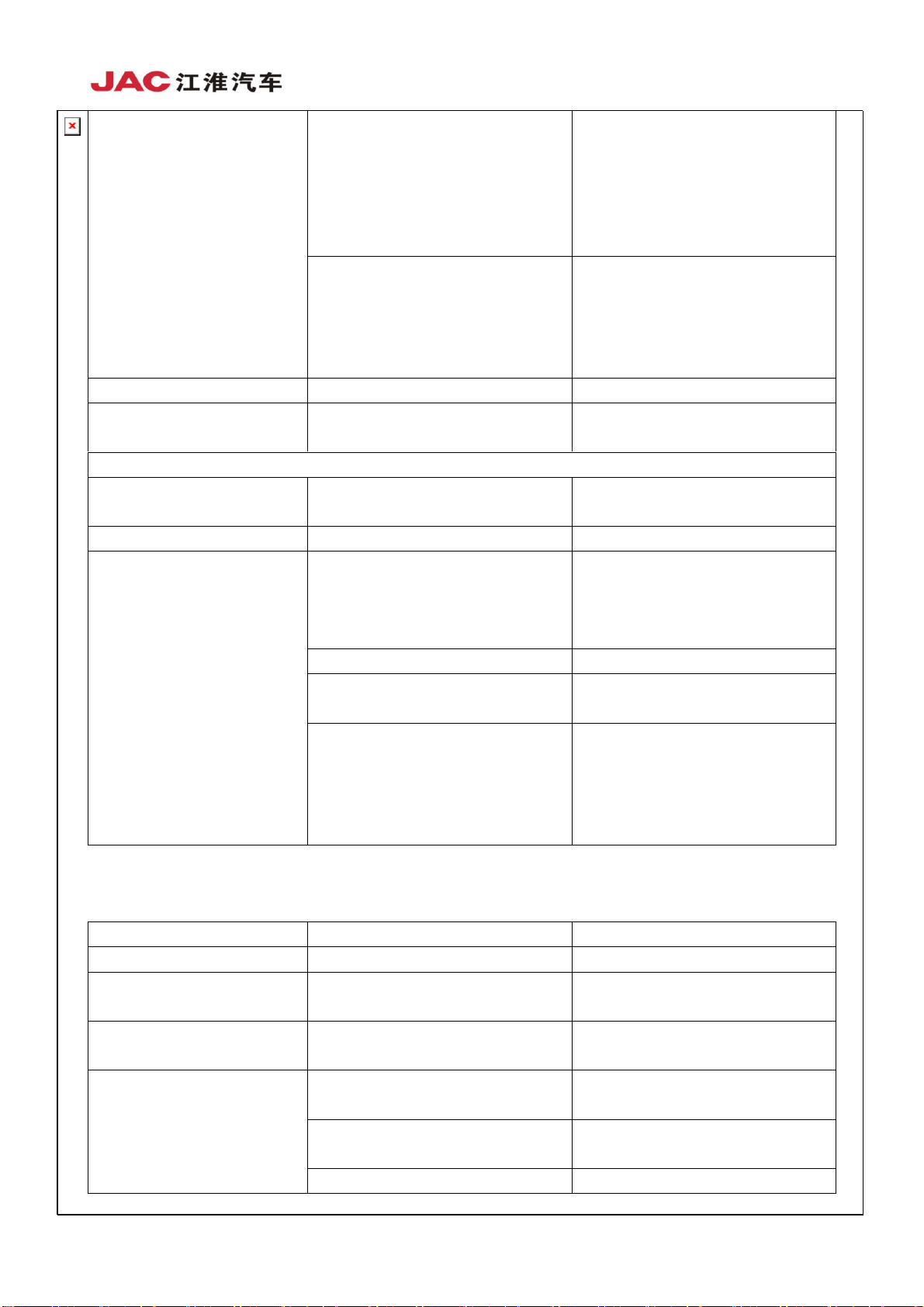

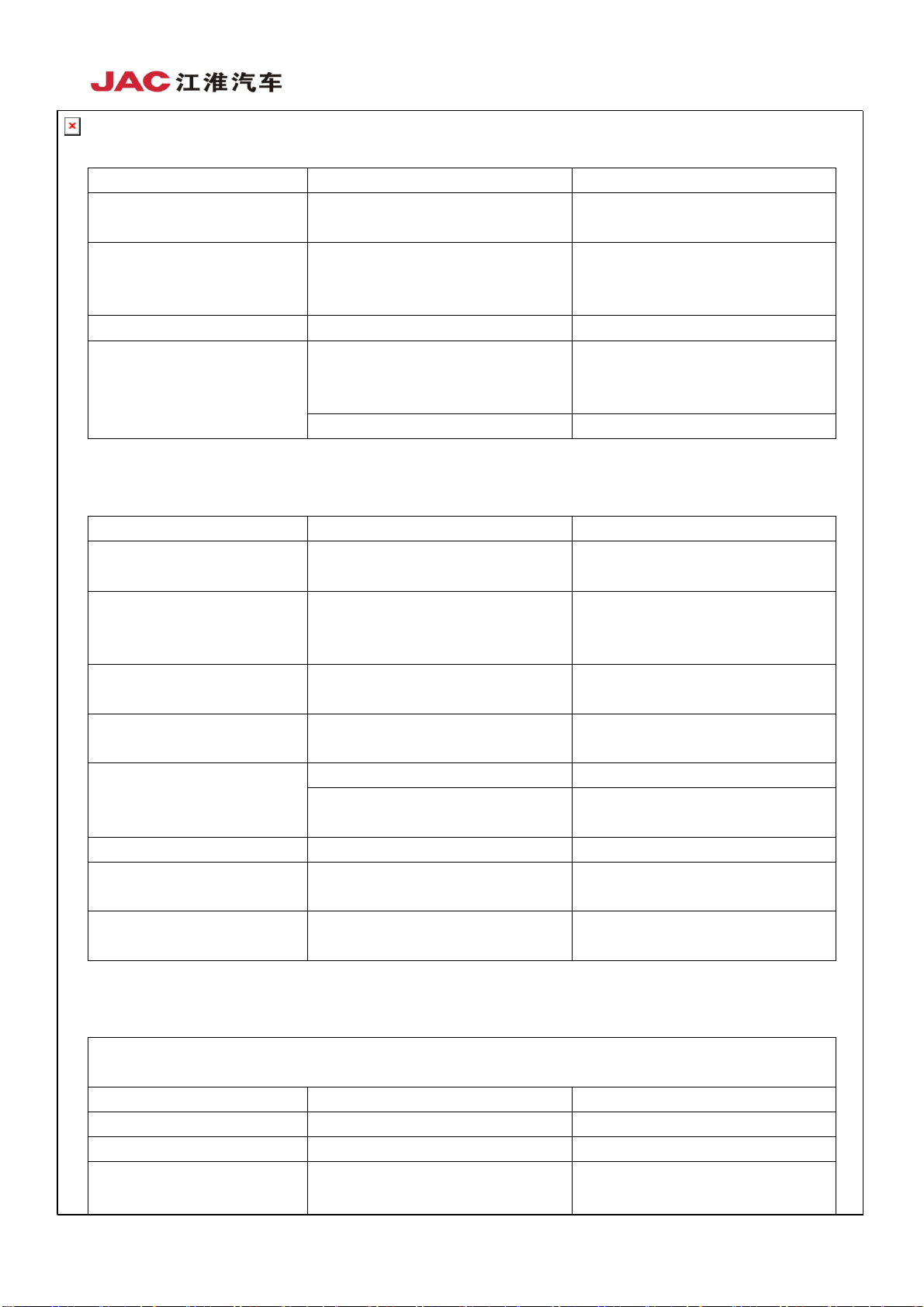

Main specifications of the trucks equipped with 4DA1 engine

The common configurations: HFC4DA1 engine, displacement: 2771cc; Max Power (HP/rpm): 77/3600; Max Torque (N.m/rpm) : 174/2100-2300;

JAC MSB-5M transmission, hydraulic brake, JAC new model cabin, no power assist of clutch.

型号

for produce

结构区别号

驾驶室

后桥速比

轮胎

Overall Size

(mm) (

整车尺寸

Wheelbase

( mm )

轴距

Weight ( kg )

最大质量

Max Speed

( km/h )

最大时速

Seating

额定成员数

Air

空调

Power

S

动转

Pre-

预热

Exhaust

排气制动

HFC1040K/KR1 D803/D804

HFC1035KD D836 Single 5.375

HFC1042K

HFC1045K2

HFC1020K/KR1 D870/D871

Remark:√:Standard Equipment 〇:Optional ●Under develop ×:Not Available

D810 Single D800-6.142 7.00R16 5980*1880*2200 3360 5740

B826/B827

Single/King

Cab

Single/King B1DAB0-6.142

Single/King

Cab

D803-6.142 6.50-16 5745*1866*2213 3000 4930 90 2

D870-6.142 6.50-16 5400*1868*2200 2800 3630 90 2

7.00R16

Rear single

6.50R16/6.50-16 5980*1998*2200 3308 5215 95 3

4850*1730*2240 2490 3900 110 2

100 2

〇 〇 √

〇 〇

〇 √ √ √

√ √ √ √

〇 √ √

×

√

×

×

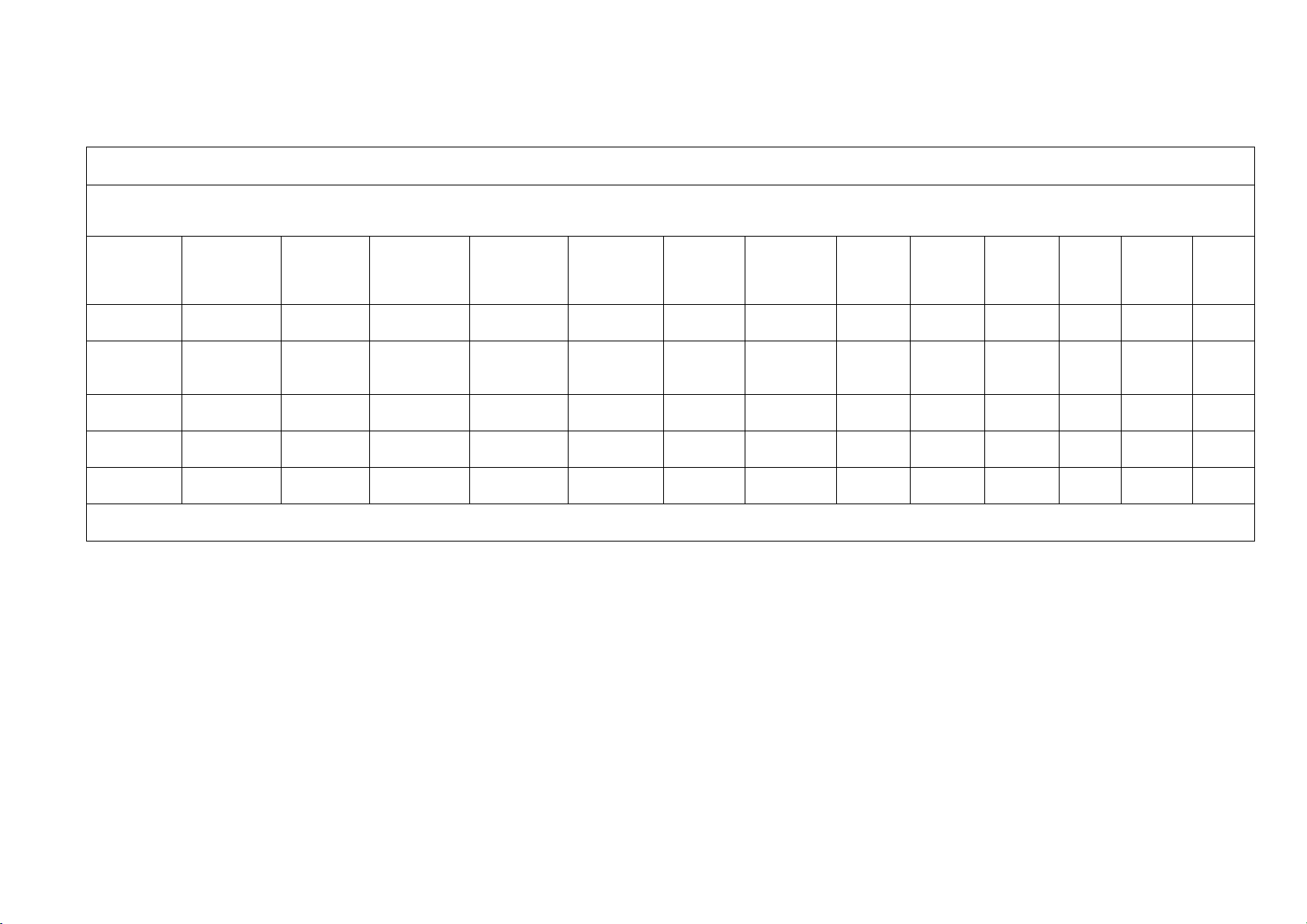

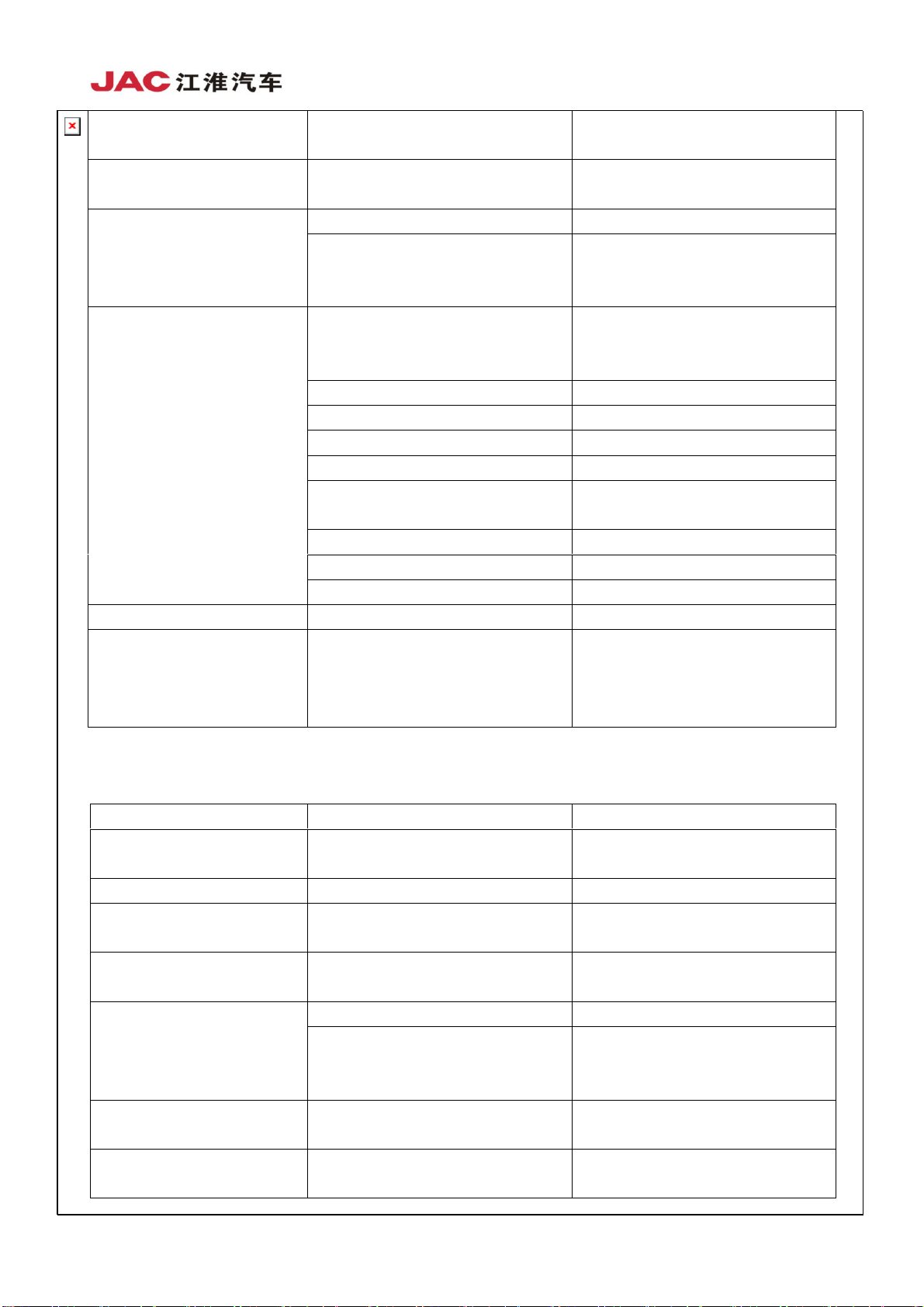

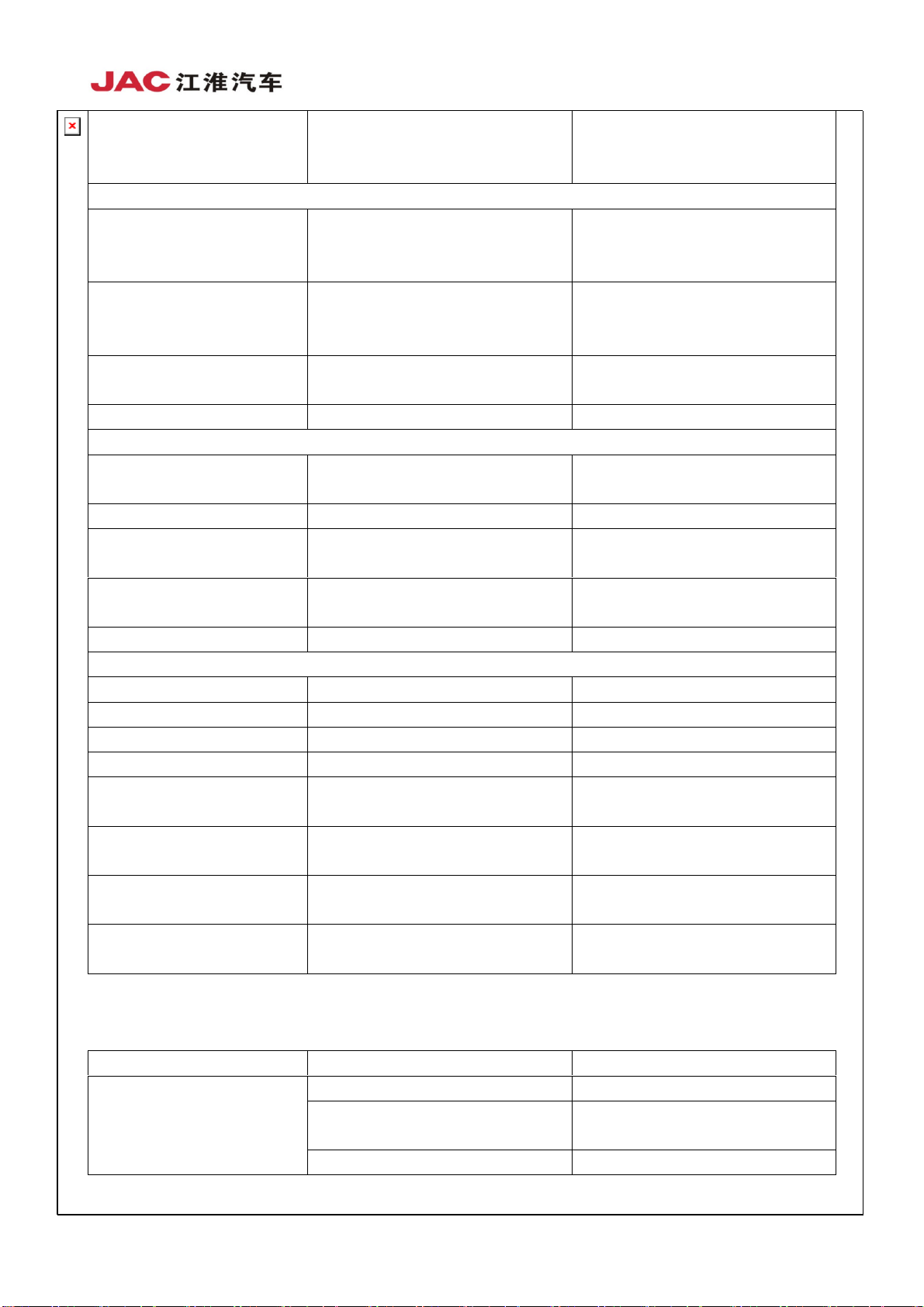

Main specifications of the trucks equipped with 4DA1-1 engine

Model

Number for

Cabin

Final gear ratio

Tyre

mm)

Gross Vehicle

Capacity

Conditioner

Steering

heater

Braking

The common configurations: HFC4DA1-1 engine, displacement: 2771cc; Max Power (HP/rpm): 92/3600; Max Torque (N.m/rpm) : 202/2100-2300;

JAC MSB-5M transmission, hydraulic brake, JAC new model cabin, no power assist of clutch.

Serious

型号

HFC1035KD D817 Single 5.375

HFC1042K2RD D819 Double 5.375

HFC1040K/KR1 D830/D831

HFC1045K2/R1 B802/803

HFC1045K2 B832

HFC1040K2

HFC1042KR

HFC1035KD D874 Single 5.375

Remark:√:Standard Equipment 〇:Optional ●Under develop ×:Not Available

produce

结构区别号

D800/D801

D802 double D800-6.142 7.00R16 5995×1900×2250 3360 4490

驾驶室

Single/King

Cab

Single/King

Cab

Single/King

Cab

Single/King

Cab

后桥速比

D803-6.142 6.50-16 5745*1866*2213 3000 4930 90 2

B1DAB0-5.571

B1DAB0-5.571

D800-6.142 7.00R16 5995*1900*2250 3360 5740

轮胎

7.00R16

Rear single

7.00R16

Rear single

6.50R16/6.50-16 5980*1998*2220 3308 5735 95 3

6.50R16/6.50-16 5980*1998*2220 3308 5735 95 3

7.00R16

Rear single

Overall Size(

(L*W*H) 整

车尺寸

4850*1730*2240 2490 3900 110 2

4875*1715*2215 2490 3900 110 2+3

4850*1730*2240 2490 3900 110 2

Wheelbase

( mm )

轴距

Weight ( kg )

最大质量

Max Speed

( km/h )

最大时速

100 2

100 2+3

Seating

额定成员数

Air

空调

〇 〇

〇 〇

〇 〇 √ √

〇 〇 √ √

〇 √ √ 〇

〇 〇 √ √

〇 〇 √ √

〇 √ √ √

Power

动转

Pre-

预热

Exhaust

排气制动

×

0

√

〇

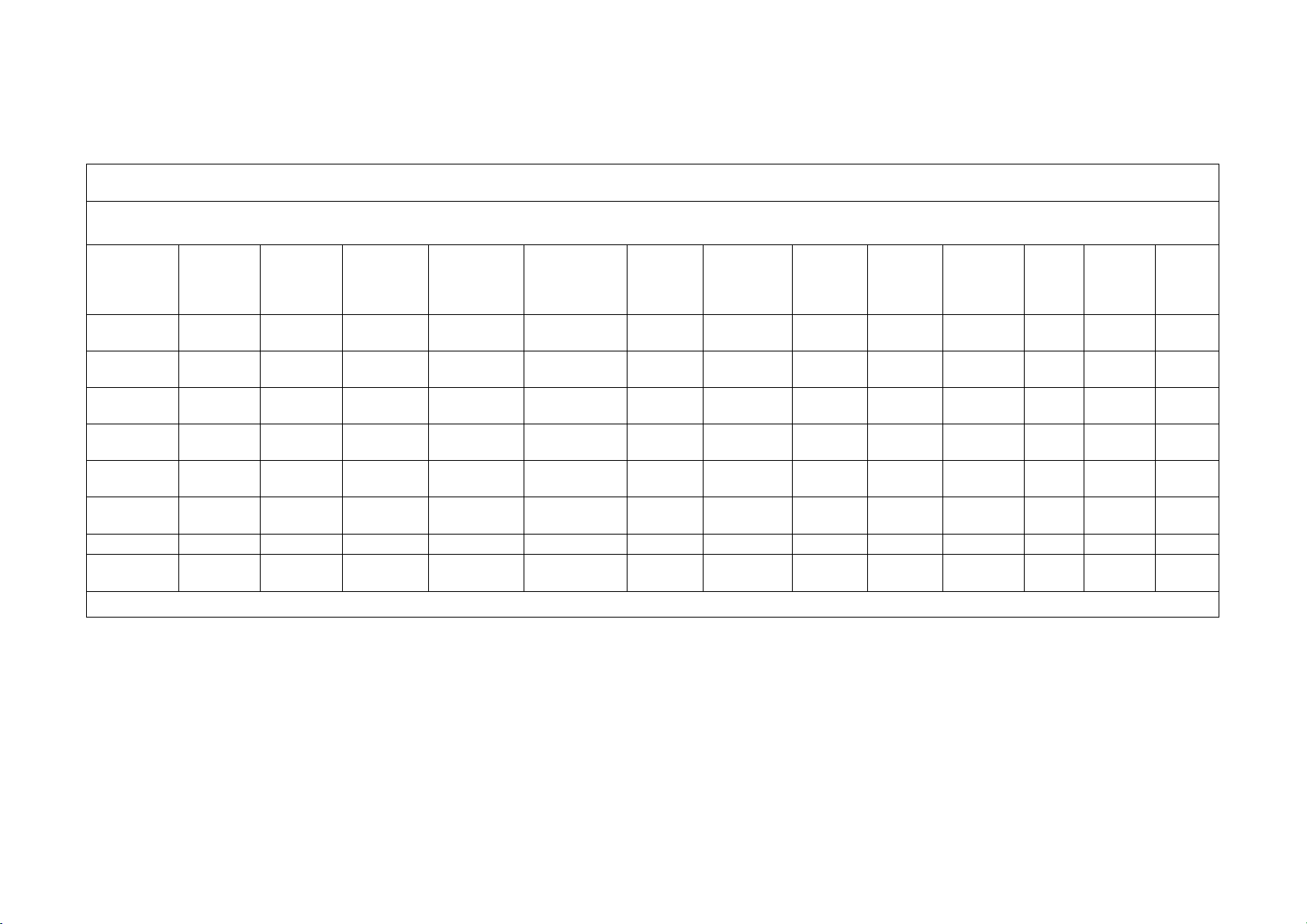

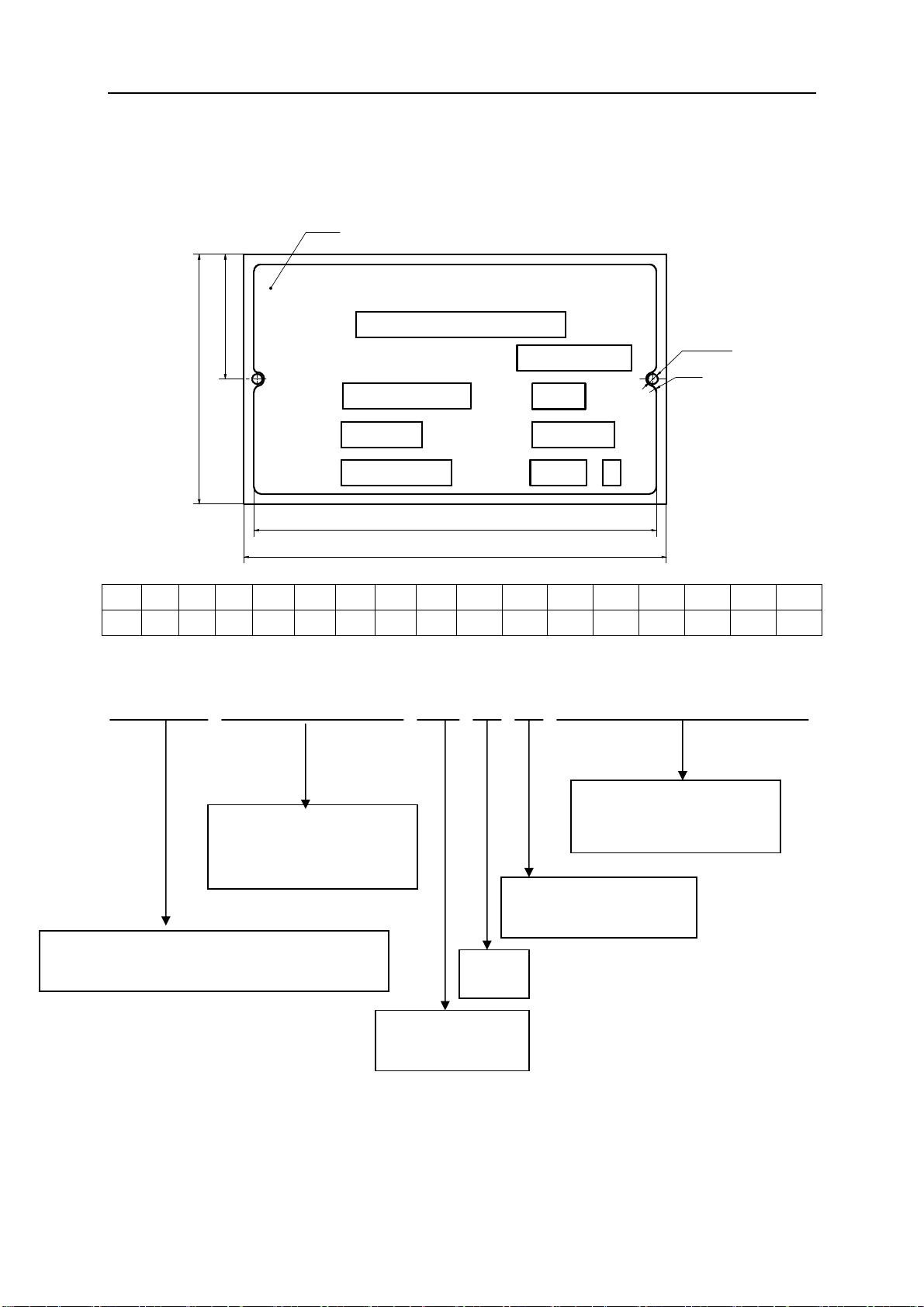

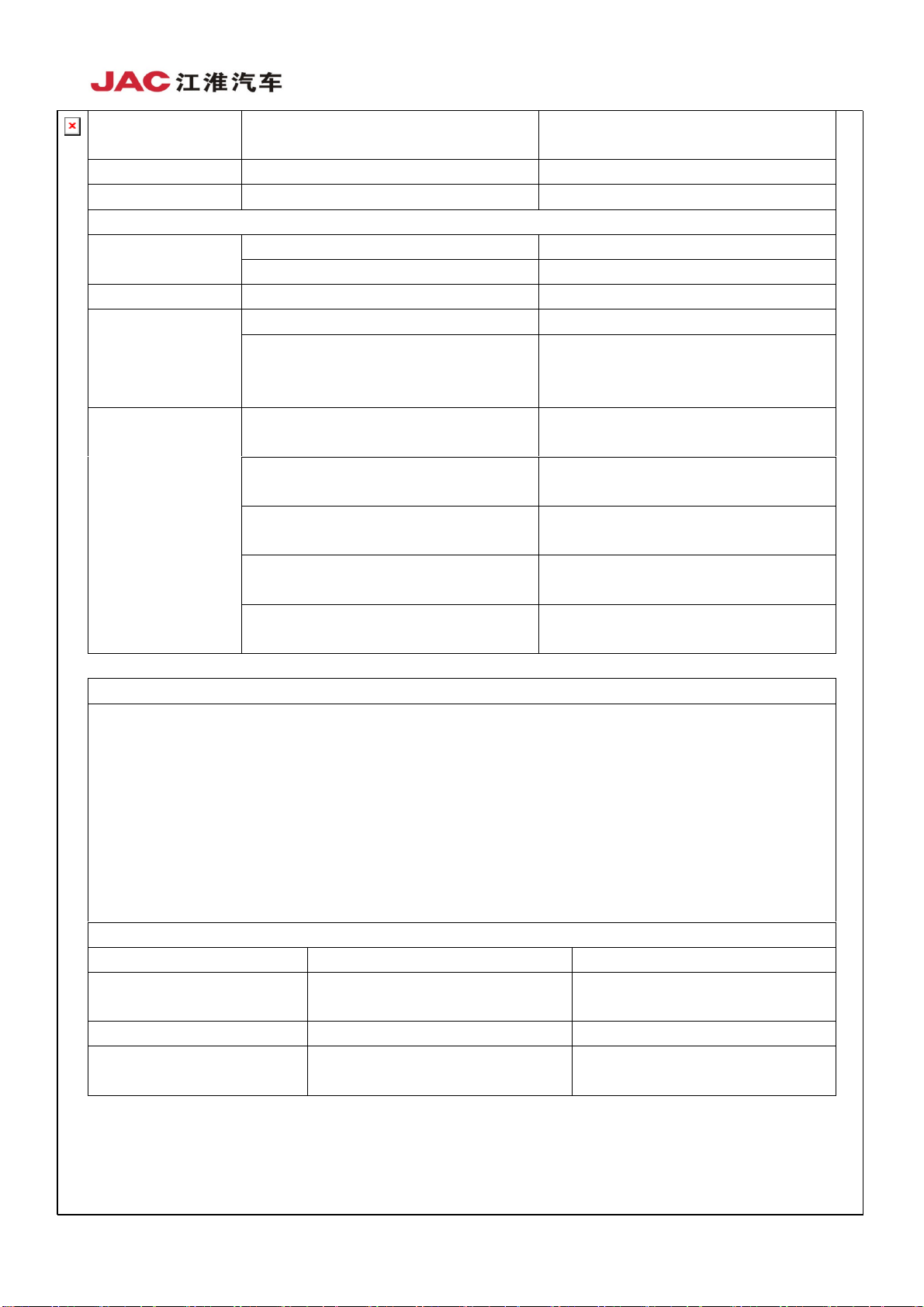

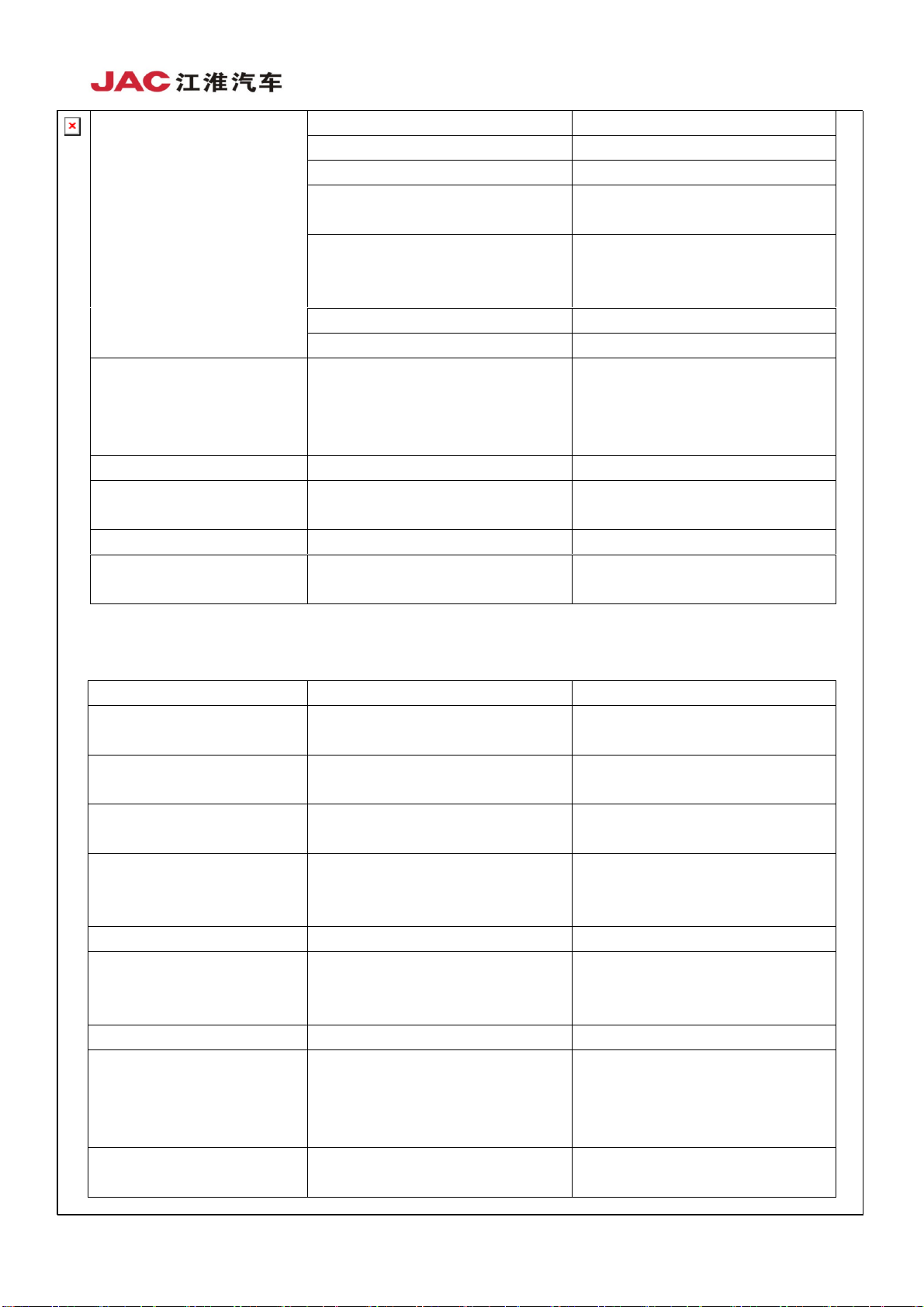

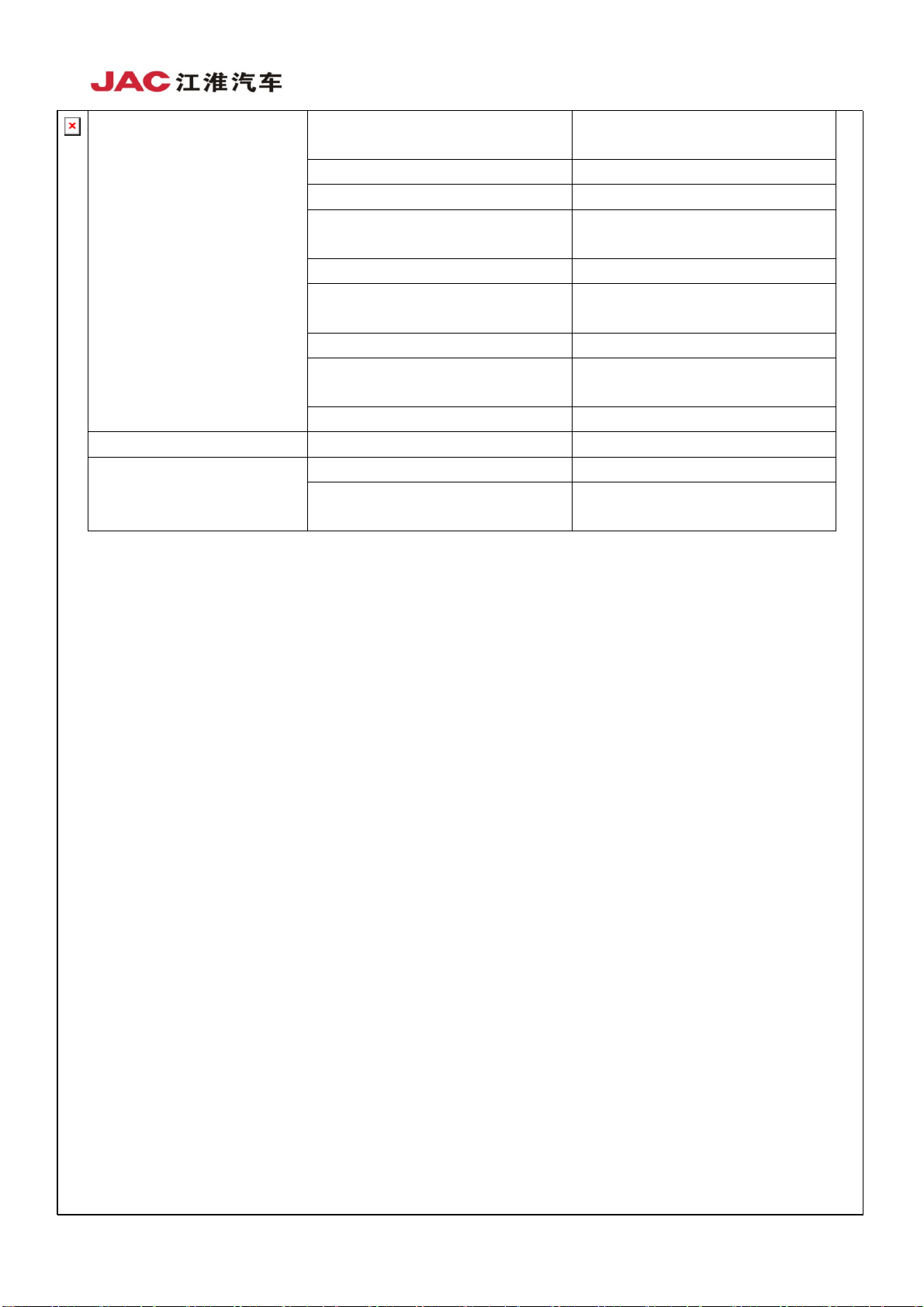

Vehicle Model

General

Company

Code Name

Company Code Name:HFC-----represents JAC motor

Vehicle Type Code:1---Cargo truck 2---Off-road vehicle 3---Dumper

Main Specifications Code:25---represents the maximum gross weight is 25 tons.

Product serial No.: 1---Product development serial No.(1stchange,2nddevelopment)

Code from company:K---Diesel R1---King cabin

For example:HFC3251KR1 represents JAC vehicle with king cab, 25 tons maximum gross weight,

the first change.

Vehicle Type

Code

4---Tractor 5---Special purpose vehicle 6---Passenger car

7---Sedan 9---Semitrailer

Main

Specifications

Code

Product

Serial No.

Code from

company

General

VIN----Vehicle Identification Number

VIN comprises of 17 digits. They separately represent:

黑色

中国安徽江淮汽车股份有限公司 制造

VⅠN

36.5

品 牌 : 江 淮

73

发动机型号

L J 1 1 K D F A 4 4 0 0 0 2 5 2 1

型 号

额定功率

O32-

R2

kW

总 质 量 整 备 质 量

出 厂 编 号 出 厂 日 期

kg

kg

年 月

119

125

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

L J 1 1 K D B C X 8 X X X X X X X

Sequence Number

Vehicle Description

Symbol

World Manufacturer Identification

Assembly Plant

Year

Check Code

General

b

s

The mechanic performance table of bolts in China

Quality Grade( mark) 6.8 8.8 9.8 10.9 12.9

Tensile strength limit

Yield limit

Corresponding to Hyundai standards 4T 6T 7T 8T 10T

The number before the radix point represents one percent of the nominal tensile strength;

The number after the radix point represents ten times of the ratio of the nominal yield limit and

nominal tensile strength.

max(MPa)

max(MPa)

600 800 900 1040 1220

480 640 720 940 1100

Section Ⅰ

Engine

HFC4DA1(4DA1-1)

Introduction

We prepare this manual to help technicians get to know and understand 4DA1

Series engine so that they are able to master quick maintenance and service.

The manual gives you instructions on assembly and disassembly of parts and

systems of 4DA1 Series engine, general maintenance standards, special tools

as well as common fault diagnosis and troubleshooting.

Our products are subject to continuous innovation. If any information in this

manual is not applicable for the innovative products, the discrepancies will be

modified in a second edition.

No part or parts of this manual may be reproduced or illegally used in any form

or by any means without written consent of Jianghuai Automobile.

1

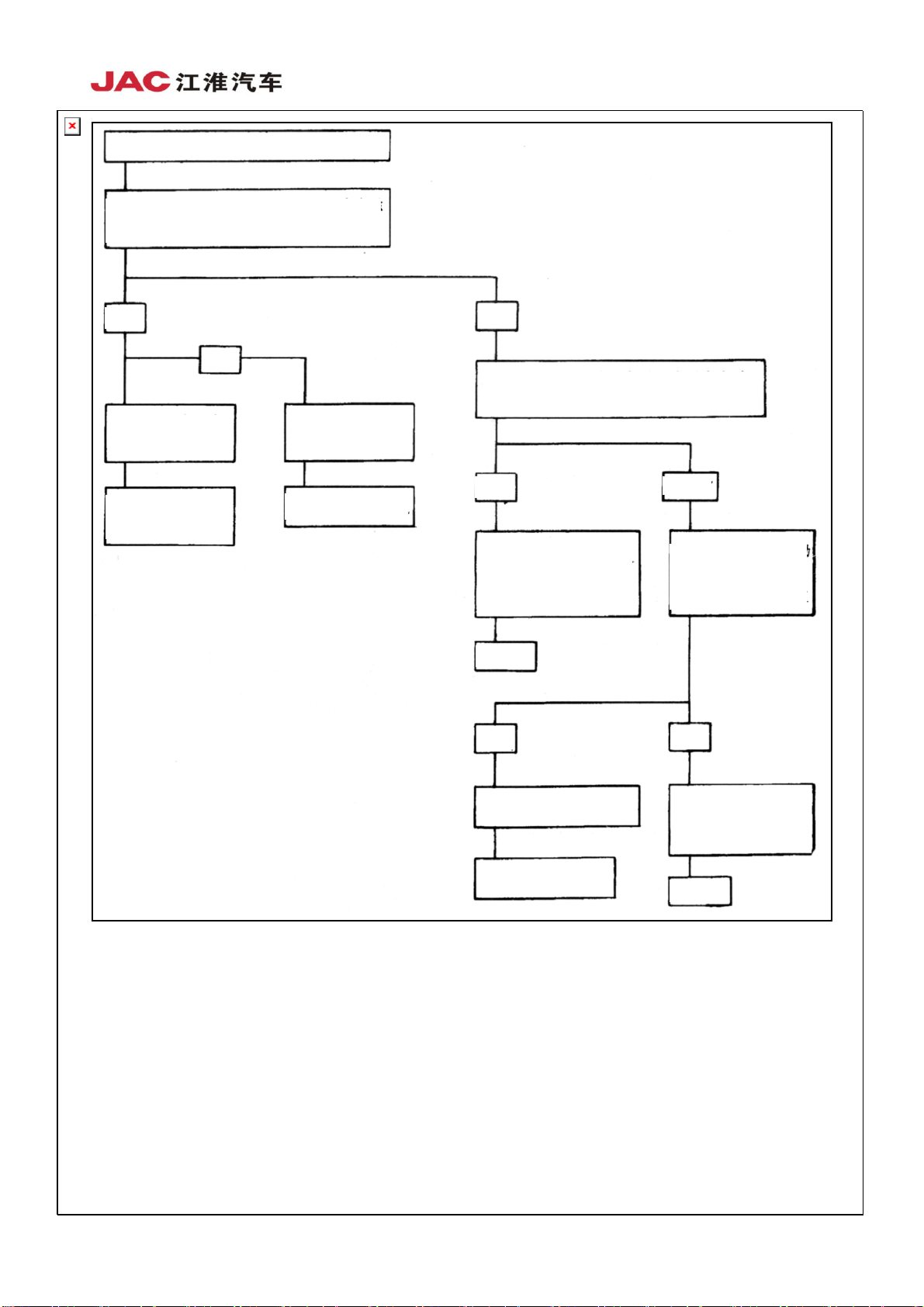

Table of Contents

1. Maintenance.......................................................................................................................................... 5

1.1 Diagnosis and troubleshooting ..................................................................................................... 5

1.1.1 Start problems..................................................................................................................... 5

1.1.2 Unstable idle speed ............................................................................................................ 7

1.1.3 Insufficient power................................................................................................................ 8

1.1.4 High fuel consumption ........................................................................................................ 9

1.1.5 High oil consumption ........................................................................................................ 10

1.1.6 Engine overheating........................................................................................................... 10

1.1.7 White smoke coming out of engine exhaust .................................................................... 10

1.1.8 Black smoke coming out of engine exhaust......................................................................11

1.1.9 Low oil pressure.................................................................................................................11

1.1.10 Abnormal engine noise ....................................................................................................11

1.1.11 Engine cooling problem .................................................................................................. 12

1.2 Data and specifications ............................................................................................................... 20

1.2.1 Data and specifications............................................................................................................ 20

1.2.2 Engine cooling .................................................................................................................. 21

1.2.3 Starting system ................................................................................................................. 21

1.2.4 Charging system............................................................................................................... 22

1.3 Maintenance standards............................................................................................................... 22

1.3.1 Engine mechanical system............................................................................................... 22

1.3.2 General terms for diesel performance.............................................................................. 24

1.4 Maintenance work....................................................................................................................... 26

1.4.1 Air filter.............................................................................................................................. 26

1.4.2 Lubricant system............................................................................................................... 27

1.4.3 Fuel system ...................................................................................................................... 28

1.4.4 Cooling system ................................................................................................................. 30

1.4.5 Drive belt adjustment........................................................................................................ 32

1.4.6 Engine control (governed speed, valve clearance, injection timing, compression pressure)

................................................................................................................................................... 33

1.5 Tightening torque ........................................................................................................................ 39

1.5.1 Torque for cylinder head, cylinder head cover and rocker shaft support ....................... 39

1.5.2 Torque for crankshaft, bearing cap, connecting rod bearing cap, crankshaft damper pulley,

flywheel and oil pan ................................................................................................................. 41

1.5.3 Torque for timing pulley chamber, timing pulley, timing gear and camshaft race ............ 42

1.5.4 Engine fuel system ........................................................................................................... 42

1.5.5 Torque for cooling system and lubricant system .............................................................. 43

1.5.6 Torque for intake manifold, exhaust manifold and exhaust pipe...................................... 44

1.5.7 Engine electrical system................................................................................................... 45

1.5.8 Torque for engine mounting bracket................................................................................. 46

1.6 Special tools ................................................................................................................................ 47

2. Engine mechanical system ............................................................................................................... 49

2

2.1 Cylinder head.............................................................................................................................. 49

2.2 Valve spring, valve guide oil seal, valve guide and push rod ..................................................... 56

2.3 Camshaft and tappet................................................................................................................... 64

2.4. Rocker arm assembly ................................................................................................................ 72

2.5 Oil pump...................................................................................................................................... 75

2.6. Crankshaft.................................................................................................................................. 80

2.7. Piston and connecting rod ......................................................................................................... 95

2.8 Cylinder block............................................................................................................................ 106

3.4 DA1 Series Engine ......................................................................................................................... 118

3.1 General.......................................................................................................................................118

3.2 Right support of engine ..............................................................................................................119

3.3 Left support of engine .......................................................................................................................... 121

3.4 Air-intake manifold..................................................................................................................... 123

3.5 Exhaust manifold....................................................................................................................... 125

3.6 Oil cooler ................................................................................................................................... 127

3.8 Cylinder head cover.................................................................................................................. 130

3.9 Rocker shaft assembly.............................................................................................................. 131

3.10 Valve stem oil seal and valve spring ...................................................................................... 134

3.11 Timing gear.......................................................................................................................................... 138

3.12 Cylinder head assembly and gasket....................................................................................... 146

3.13 Oil pan..................................................................................................................................... 157

3.14 Oil pump assembly ................................................................................................................. 160

3.15 Piston, Piston ring and connecting rod ................................................................................... 164

3.16 Camshaft and tappet............................................................................................................... 177

3.17 Crankshaft front oil seal .......................................................................................................... 197

3.18 Crankshaft rear oil seal ........................................................................................................... 200

3.19 Crankshaft and main bearing.................................................................................................. 207

4 Engine cooling system ..................................................................................................................... 229

4.1 General...................................................................................................................................... 229

4.2 Water pump............................................................................................................................... 232

4.2.1 On-vehicle repair ............................................................................................................ 232

4.2.2 Single-piece repair.......................................................................................................... 236

4.3 Thermostat................................................................................................................................ 239

4.4. Radiator.................................................................................................................................... 241

4.5 Drive belt adjustment ................................................................................................................ 244

5 Fuel system........................................................................................................................................ 246

5.1 General...................................................................................................................................... 246

5.2 Fuel filter assembly................................................................................................................... 250

5.3 Fuel injector............................................................................................................................... 253

5.4 Injection pump assembly .......................................................................................................... 258

5.5 Fuel system related parameters ............................................................................................... 266

5.6 Fuel tank.................................................................................................................................... 267

5.7 Fuel lever gauge ....................................................................................................................... 269

6 Starting system(To mention in a reference) .............................................................................. 270

6.1 General...................................................................................................................................... 270

3

6.2 Starting circuit............................................................................................................................ 271

6.3 Starter motor ............................................................................................................................. 272

7 Intake/exhaust system ...................................................................................................................... 281

7.1 General...................................................................................................................................... 281

7.1 Air filter ...................................................................................................................................... 282

7.2 Exhaust pipe and charger assembly......................................................................................... 284

4

1. Maintenance

1.1 Diagnosis and troubleshooting

1.1.1 Start problems

1. The starter motor fails to work.

Check Causes Remedies

The battery terminal post is loose.

There is bad connection caused by

Battery

Fuse The fuse is short circuited. Replace the fuse with a new one

Starter switch The starter switch or relay has failed. Replace the starter switch or relay

Starter motor

2. The starter motor works well, but the engine fails to run.

Battery

Starter motor

Engine

oxidation or corrosion.

The battery is uncharged or in

shortage of charge.

The belt of fan is loose or broken. Adjust the belt of fan, or replace it

The solenoid switch has failed. Repair or replace the solenoid switch

The starter motor has failed. Repair or replace the starter motor

The battery terminal post is loose.

There is bad connection caused by

oxidation or corrosion.

The battery is uncharged or in

shortage of charge.

The belt of fan is loose or broken. Adjust the belt of fan, or replace it

The pinion is broken. Replace the broken pinion

The solenoid switch has failed. Repair or replace the solenoid switch

The brush is worn or the brush spring

is too soft.

The piston or crankshaft bearing is

jammed or damaged.

Clean and/or tighten the loose terminal

post(s)

Charge the battery or replace the old

battery with a new one

Clean and/or tighten the loose battery

terminal post(s)

Charge the battery or replace the old

battery with a new one

Replace the brush and/or the brush

spring

Repair or replace the damaged part(s)

3. The engine rotates but it cannot be ignited to start.

Check Causes Remedies

Brake mechanism

of engine

The fuel fails to flow into the injection pump.

Fuel The fuel tank is empty. Fill in the fuel tank

Fuel pipe system The fuel pipe is clogged or broken.

Fuel filter The fuel filter overflow valve cannot be

The fuel cut-off solenoid valve is

broken.

The fuel tube joint is loose.

closed.

Replace the fuel cut-off solenoid

Repair or replace the fuel pipe

Retighten the fuel tube joint

Repair or replace the fuel filter

overflow valve

5

A fuel filter component is clogged. Replace the fuel filter component or

the filter element

Fuel system There is air in the fuel system. Release the air from the fuel system

Fuel feed pump The fuel feed pump is broken. Repair or replace the fuel feed pump

The fuel flows into the injection pump.

Fuel

Fuel system There is air in the injection pump. Release the air from the fuel system

Fuel injector

Injection pump

The fuel in service is incorrect. Use the correct fuel

There is water in the fuel system. Replace the fuel

The fuel injector is jammed. Replace the fuel injector

The opening pressure of fuel injector is

too low.

Atomizing is bad.

The damage of fuel injector results in

fuel dripping after injection.

Something is wrong with the control

rack of injection pump.

The injection pump plunger is worn or

jammed.

The drive shaft of injection pump is

jammed or damaged.

The governor spring of injection pump

is jammed.

Adjust or replace the fuel injector

Replace the delivery valve

Repair or replace the control rack of

injection pump

Repair or replace the injection pump

plunger assembly

Replace the drive shaft

Replace the governor spring of

injection pump

4. Quick start system

Preparation work

1. Disconnect the connector of temperature switch

2. Verify whether the glow plug is power on

a) Confirm the start switch is at OFF position

b) Use voltmeter to connect cylinder wall with any glow plug

c) Switch the start switch to the ON position

If the glow plug is power on, the voltmeter indicates 12 V. If the pointer of voltmeter doesn’t

move, it means the glow plug is power off.

3. Trouble shooting

The glow plug is power on.

Check Causes Remedies

The indicator lamp of glow

plug is off.

Quick start timer The quick start timer is broken. Replace the quick start timer

The indicator lamp of glow

plug is on for 0.3 s.

The indicator lamp is broken. Replace the indicator lamp

The quick start timer is broken. Replace the quick start timer

6

After the engine is started, switch

plug is on for 3.5 s.

Temperature switch The temperature switch is broken. Replace the temperature switch

Connectivity of glow plug The connectivity of glow plug is

The glow plug is power off.

The indicator lamp of glow

plug is off.

Quick start timer The quick start timer is broken. Replace the quick start timer

The indicator lamp of glow

plug is on for 3.5 s.

the start switch from ST (start) to

ON. If the relay of glow plug keeps

closed for less than 14 s, it

indicates something is wrong with

the quick start timer.

Switch the start switch from OFF

to ON. If the relay of glow plug

keeps closed for less than 14 s, it

indicates something is wrong with

the quick start timer.

bad.

The fuse of indicator lamp blows

out.

The glow plug relay is broken.

When the start switch is switched

from OFF to ON, the glow plug

relay is not switched on.

The quick start timer is broken. Replace the quick start timer

A line fault occurs in the circuit of

glow plug relay.

The fuse blows out or there is a

line fault.

When the start switch is switched

from OFF to ON, the glow plug

relay is switched on.

Replace the quick start timerThe indicator lamp of glow

Replace the quick start timer

Replace the glow plug

Replace the broken fuse

Replace the glow plug relay

Repair or replace corresponding

line(s)

Replace the fuse or

corresponding line(s)

1.1.2 Unstable idle speed

Check Causes Remedies

Idle speed system The idle speed is not proper. Adjust the idle speed

High idle speed control

device

Throttle control system The adjustment of throttle control

Fuel system

The high idle speed control device

is broken.

system is not proper.

Leakage or blockage occurs in the

fuel system.

There is air in the fuel system. Release the air from the fuel

There is water in the fuel system. Replace the fuel

Repair or replace the high idle

speed control device.

Adjust the throttle control system

Repair or replace the fuel system

system

7

Fuel filter

Fuel feed pump

Fuel injector

Injection pump

Valve clearance The valve clearance is not proper. Adjust the valve clearance

Compression pressure

A fuel filter component is clogged. Replace the fuel filter component

or the filter element.

The fuel feed pump is broken. Repair or replace the fuel feed

pump.

The fuel injector is jammed. Replace the fuel injector

The opening pressure of fuel

injector is too low.

Atomizing is bad.

The damage of delivery valve

results in fuel dripping after

injection.

Injection timing is not proper. Adjust injection timing

The injection volume is too low. Increase injection volume

The idle speed spring is broken. Replace the idle speed spring

The shifter is broken Repair or replace the shifter

The regulator valve is not at

proper position.

The plunger spring is broken Replace the plunger spring

The plunger is worn. Replace the plunger assembly

The cam is worn. Replace the worn cam

The gasket of cylinder head is

worn.

The cylinder liner is worn.

The piston ring is sticky.

Adjust or replace the fuel injector

Replace the delivery valve

Adjust or replace the regulator

valve

Replace relevant parts

1.1.3 Insufficient power

Check Causes Remedies

Air filter

Fuel There is water in the fuel. Replace the fuel

Fuel filter A fuel filter component is clogged.

Fuel feed pump The fuel feed pump is broken.

Fuel injector

High pressure fuel pipe

Injection pump

An air filter component is

clogged.

The fuel injector is jammed. Replace the fuel injector

The opening pressure of fuel

injector is too low.

Atomizing is bad.

The high pressure fuel pipe is

damaged or blocked.

The regulator valve is damaged.

Clean or replace the filter

component

Replace the fuel filter component

or the filter element

Repair or replace the fuel feed

pump

Adjust or replace the fuel injector

Replace the high pressure fuel

pipe

Repair or replace the regulator

valve

8

The delivery valve is damaged. Replace the delivery valve

The timer is broken. Repair or replace the timer

The cam is worn. Replace the worn cam

The control lever doesn’t work

well.

The injection timing is not correct.

The governing spring is too soft. Replace the governing spring

The plunger is worn. Replace the plunger assembly

The gasket of cylinder head is

Compression pressure

Valve clearance The valve clearance is not proper. Adjust the valve clearance

Valve spring

Exhaust system The exhaust pipe is clogged. Clean the exhaust pipe

Seal of full-load adjusting

screw

worn.

The cylinder liner is worn.

The piston ring is sticky.

The valve spring is too soft or

broken.

The seal of adjusting screw is

opened or improperly adjusted.

Adjust or replace the control lever

Adjust injection timing

Repair or replace the injection

pump timer

Replace relevant parts

Replace the valve spring

Properly adjust the seal of

adjusting screw and seal again

1.1.4 High fuel consumption

Check Causes Remedies

Fuel system There is a fuel leak.

Air filter An air filter component is clogged.

Idle speed

Fuel injector

Fuel injection timing Fuel injection timing is not correct. Adjust the fuel injection timing

Injection pump

Valve clearance The valve clearance is not proper. Adjust the valve clearance

Compression pressure

Valve spring

The idle speed is not adjusted

properly.

The opening pressure of fuel

injector is too low.

Atomizing is bad.

The damage of delivery valve

results in fuel dripping after

injection.

The gasket of cylinder head is

worn.

The cylinder liner is worn.

The piston ring is sticky.

The valve spring is too soft or

broken.

Repair or replace corresponding

parts of fuel system

Clean or replace the air filter

component

Adjust the idle speed

Adjust or replace the fuel injector

Replace the delivery valve

Replace relevant parts

Replace the valve spring

9

1.1.5 High oil consumption

Check Causes Remedies

Engine oil

Oil seal and gasket

Air vent The air vent is blocked. Clean the air vent

Intake valve and exhaust

valve

The oil type is not correct. Replace the engine oil

The oil volume is too high. Adjust the oil level

The oil leaks from the oil seal

and/or gasket.

The valve stem and valve guide

are worn.

Replace the oil seal and/or gasket

Replace intake valve, exhaust

valve and valve guide

1.1.6 Engine overheating

Check Causes Remedies

Cooling water The cooling water is insufficient. Supply enough cooling water

Fan clutch The oil leaks from the fan clutch. Replace the fan clutch

Fan belt Loose or damaged fan belt results

in slipping.

Radiator The radiator cap is damaged or

the radiator core is blocked.

Water pump The water pump is broken. Repair or replace the water pump

Cylinder head and cylinder

block

Sealed cap

Thermostat The thermostat is broken. Replace the thermostat

Cooling system The cooling system is clogged by

Fuel injection timing Fuel injection timing is not correct. Adjust the fuel injection timing

Damaged cylinder head results in

leakage of cooling water.

foreign matters.

Replace the fan belt

Replace the radiator cap or clean

the radiator core

Replace the sealed cap

Remove foreign matters from the

cooling system

1.1.7 White smoke coming out of engine exhaust

Check Causes Remedies

Cooling water The cooling water is insufficient. Supply enough cooling water

Fuel There is water in the fuel system. Replace the fuel

Fuel injection timing Fuel injection timing is delayed. Adjust the fuel injection timing

The gasket of cylinder head is

Compression pressure

Intake valve and exhaust

valve

Valve oil seal

worn.

The cylinder liner is worn.

The piston ring is sticky.

The valve oil seal is worn.

The valve stem and valve guide

are worn.

10

Replace relevant parts

Replace valve oil seal, valve and

valve guide

1.1.8 Black smoke coming out of engine exhaust

Check Causes Remedies

Air filter An air filter component is clogged. Clean or replace the air filter

component

Fuel injector The opening pressure of fuel

injector is too low.

Atomizing is bad.

Fuel injection timing Fuel injection timing is not correct. Adjust the fuel injection timing

The damage of delivery valve

results in fuel dripping after

injection.

The injection volume is too high. Reduce injection volume

Adjust or replace the fuel injector

Replace the delivery valveInjection pump

1.1.9 Low oil pressure

Check Causes Remedies

Engine oil The oil viscosity is not correct.

The oil volume is too low.

Oil pressure gauge or

assembly

Oil pressure indicator light

Oil filter An oil filter component is clogged. Replace the oil filter component or

Safety valve and bypass

valve

Rocker shaft The rocker shaft bearing is worn. Replace the rocker shaft bearing

Camshaft The camshaft and its bearing are

Crankshaft and bearing The crankshaft and its bearing are

The oil pressure gauge or

assembly is broken.

The indicator light is broken.

The safety valve is jammed and/or

the bypass valve spring is too soft.

The oil pump strainer is blocked. Clean the oil pump strainerOil pump

A component in the oil pump is

worn.

worn.

worn.

Replace the engine oil

Increase the oil volume

Repair or replace the oil pressure

gauge or assembly

Replace the indicator light

the filter element

Replace the safety valve and/or

bypass valve spring

Replace relevant parts in the oil

pump.

Replace the camshaft and its

bearing

Replace the crankshaft and/or its

bearing

1.1.10 Abnormal engine noise

1. Engine slap

Verify the engine is completely warmed up before troubleshooting.

Check Causes Remedies

Fuel The fuel is not correct. Replace the fuel

Fuel injection timing Fuel injection timing is not proper. Adjust the fuel injection timing

Fuel injector The opening pressure of fuel

injector or atomizing is not proper.

11

Adjust or replace the fuel injector

Compression pressure The gasket of cylinder head is

worn.

The piston ring is broken.

2. Air leak noise

Exhaust pipe The connection of exhaust pipe is

loose.

The exhaust pipe is broken.

Fuel injector and/or glow

plug

Exhaust manifold The connection to exhaust

Cylinder head gasket The cylinder head gasket is worn. Replace the cylinder head gasket

3. Continuous noise

Fan belt The fan belt is loose. Adjust the tightness of fan belt

Cooling fan The cooling fan is loose. Retighten the cooling fan

Water pump bearing The water pump bearing is worn

Alternator or vacuum pump The alternator or vacuum pump is

Valve clearance The valve clearance is not proper. Adjust the valve clearance

4. Clapping noise

Check Causes Remedies

Valve clearance The valve clearance is not proper. Adjust the valve clearance

Rocker arm The rocker arm is broken. Replace the rocker arm

Flywheel The flywheel bolt is loose. Retighten the flywheel bolt

Crankshaft and thrust

bearing

Crankshaft and connecting

rod bearing

Connecting rod bushing and

piston pin

Piston and cylinder liner The piston and cylinder liner is

The fuel injector and/or glow plug

are loose.

manifold is loose.

or damaged.

broken.

The crankshaft and/or thrust

bearing is worn or damaged.

The crankshaft and/or connecting

rod bearing is worn or damaged.

The connecting rod bushing and

piston pin are worn or damaged.

worn or damaged.

Replace the gasket of cylinder

head or piston ring

Tighten the connection of exhaust

pipe

Replace the exhaust pipe

Replace the gasket

Tighten the fuel injector and/or

glow plug

Tighten the connection to exhaust

manifold

again.

Replace the water pump bearing

Repair or replace the alternator or

vacuum pump

Replace the crankshaft and/or

thrust bearing

Replace the crankshaft and/or

connecting rod bearing

Replace the connecting rod

bushing and/or piston pin

Replace the piston and cylinder

liner

1.1.11 Engine cooling problem

Check Causes Remedies

Engine overheating

The coolant level is too low. Fill in the coolant

The thermostatic control is

broken.

The thermostat is broken. Replace the thermostat

Replace the thermostatic control

12

Something is wrong with the

cooling element.

The radiator is blocked. Clean or replace the radiator

The radiator cap is damaged. Replace the radiator cap

The oil level is too low or the oil is

disqualified.

The cylinder head gasket is worn. Replace the cylinder head gasket

The exhaust system is blocked. Clean the exhaust system or

The fan belt is loose. Adjust the fan belt

The fuel injection volume is too

high.

The injection timing is not correct. Adjust the injection timing

Engine overcooling The thermostat is broken. Replace the thermostat

The thermostat is broken. Replace the thermostatLong engine preheating

time

Check the battery and make the following diagnosises.

The thermostatic control is

broken.

Repair or replace the cooling

element

Fill in or replace the oil

replace the damaged parts

Adjust the fuel injection

Replace the thermostatic control

13

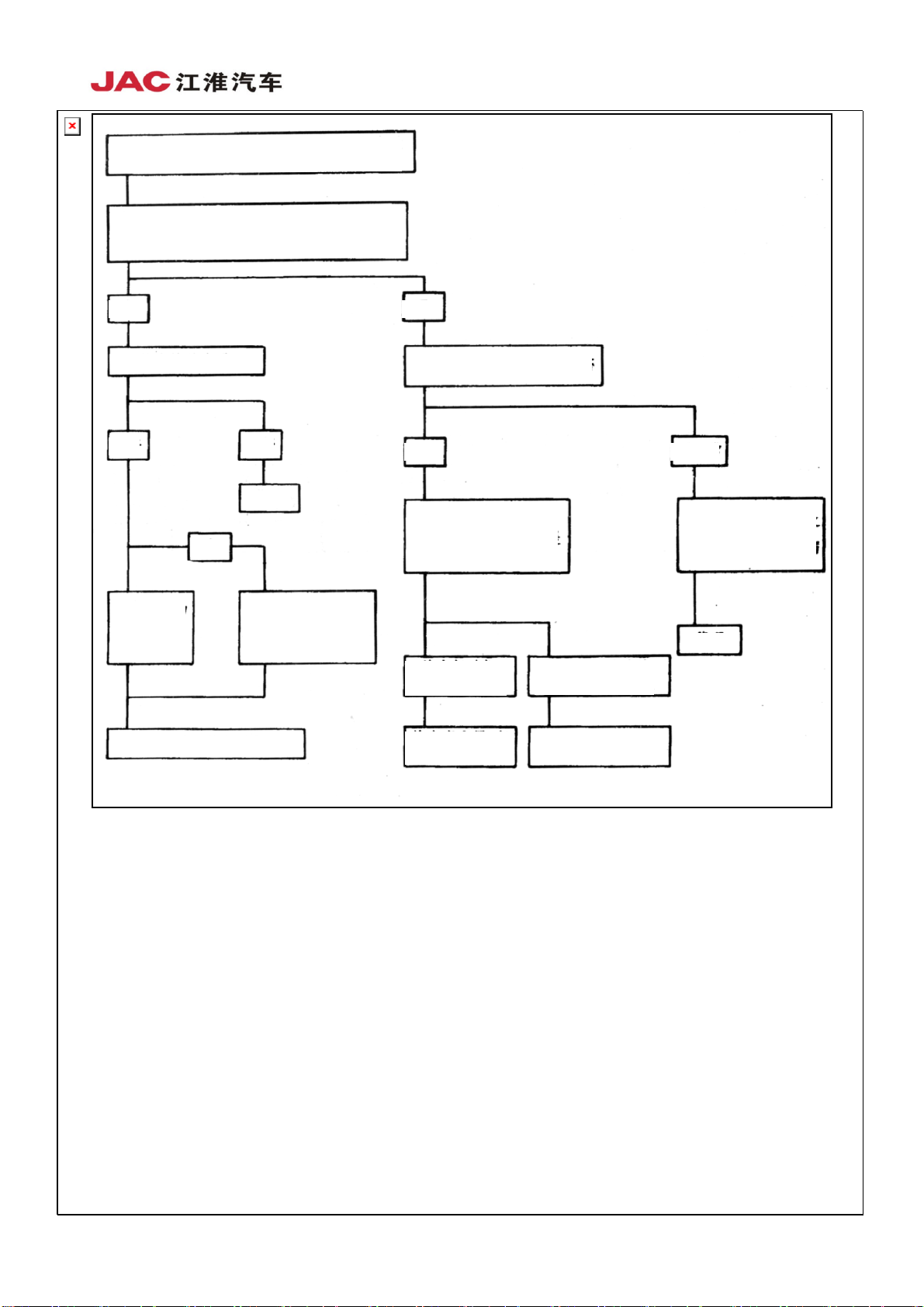

The starter doesn’t run.

battery is expired.

Check the battery

Charging is invalid or the life of

Check the battery

Connection is interrupted.

Clean the battery terminal post and reconnect it.

The battery is normal.

Check the terminal post

The terminal post is OK.

Check the starter or the starter switch

Faulty

Turn on the headlamp and starter switch

The headlamp is off or dim.

a) The battery has insufficient charge.

b) The starter coil is short-circuited.

c) A starter part is faulty.

Repair or replace

The headlamp is bright.

a) The starter circuit has open circuit.

b) The starter coil has open circuit.

c) The starter switch is faulty.

14

The engagement between the pinion and tooth

sliding resistance

connector of solenoid switch on the starter relay is

normal

starte

r

the connection between them

is

faulty

.

Abnormal

, or

them is

faulty

.

When the starter switch is switched to ST (start)

position, check whether there is voltage at the

terminal post "S" of solenoid switch.

Yes

The pinion and gear

ring are worn badly.

Repair or replace the

starter, and replace

the gear ring.

Or

The

of starter is too high.

Repair or replace the

No

In this case, check whether the voltage at 3BW

Normal

There is an open circuit

between the starter switch

and the solenoid switch, or

Repair

Yes No

Check there is voltage at

3BW connector of starter

switch on the starter relay

The connection of starter

switch is faulty.

Replace the starter

switch

There is an open circuit

between the starter

switch and the battery

the connection between

Repair

15

The starter switch is switched to ST (start) position, but

the solenoid swi

tch doesn't work.

Verify the circuit between the

terminal post "S" of solenoid

The solenoid switch or

coil has an open circuit

indicator light is normal

When the starter switch is switched to ST (start)

position, check whether there is voltage at the terminal

Yes No

post "S" of solenoid switch.

Check the grounding cable

Good Bad

Repair

Or

The sliding

part of pinion

doesn’t move.

Repair or replace the starter.

or is burned out.

Check whether the instrument

Normal Abnormal

There is an open circuit

starter switch and the

switch.

Check the starter

relay

Check the clutch

and starter switch

The starter switch

connection is faulty.

Replace the starter

switch

between the battery and

the starter switch, or the

connection is faulty.

Repair

16

The pinion engages with the gear ring well, but

the engine doesn't run.

has an open circuit or

The exciting coil has

n open circuit or is

damaged.

The clutch of

Check the grounded cable

Good

A fault occurs between

the brush and rectifier.

Repair or replace the starter

The solenoid starter

switch is burned out.

Bad

Repair or replace the

grounding cable

a

The armature coil

pinion slips.

is damaged.

17

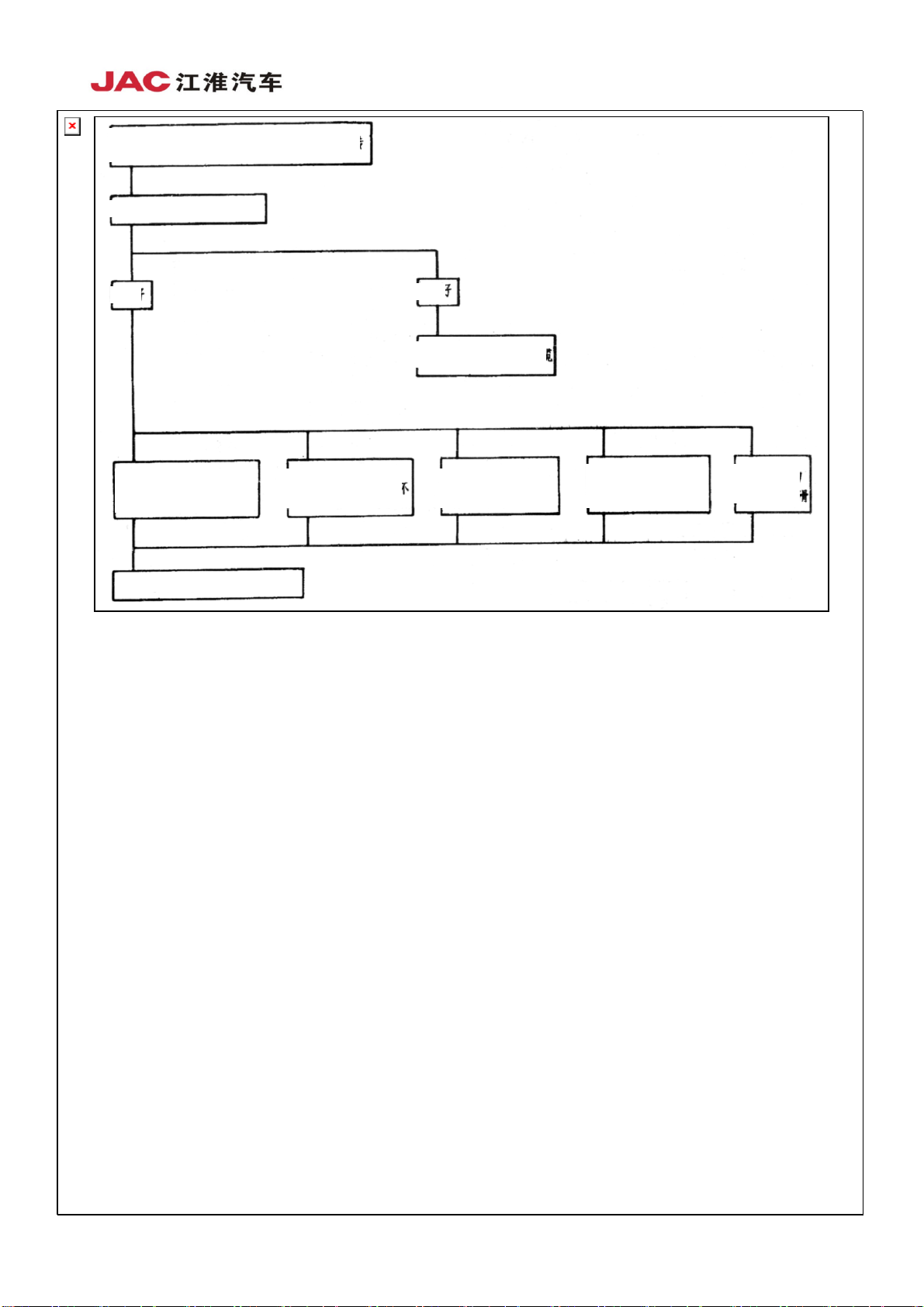

The starter switch

is switched from ST to ON,

Terminal Post No.

Terminal Post No.

The position of

ON

Access

ory

but the starter doesn't stop.

Disconnect the wiring of starter switch and verify the operation of starter switch

Connector No.

starter switch

OFF

Locked

ON

Start

Besides the wiring mentioned above, other circuits should be opening.

Yes

The solenoid switch contact is

melted and hard to move.

Otherwise, the return spring is

broken or damaged.

Replace the starter switch

No

Replace the solenoid switch

18

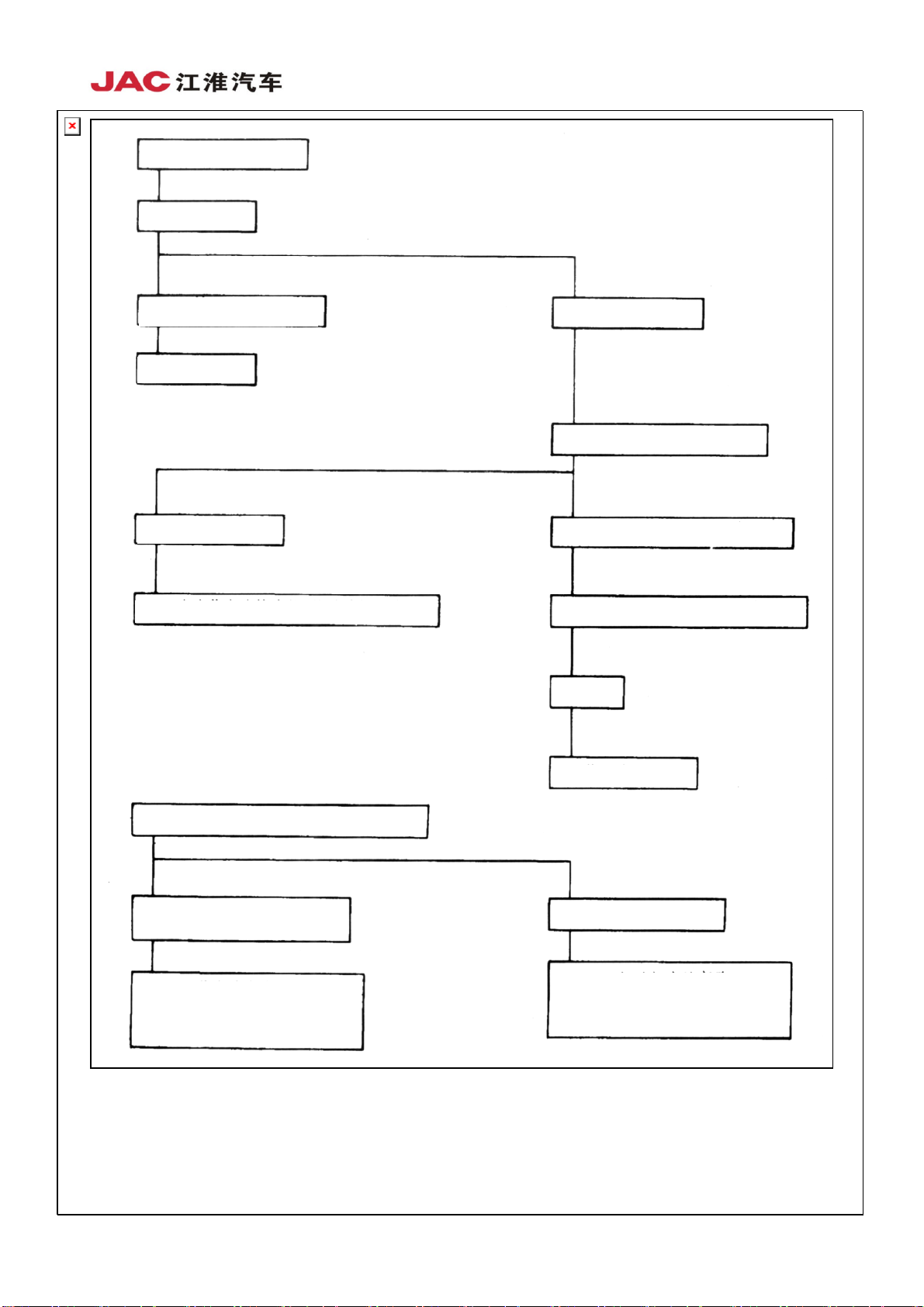

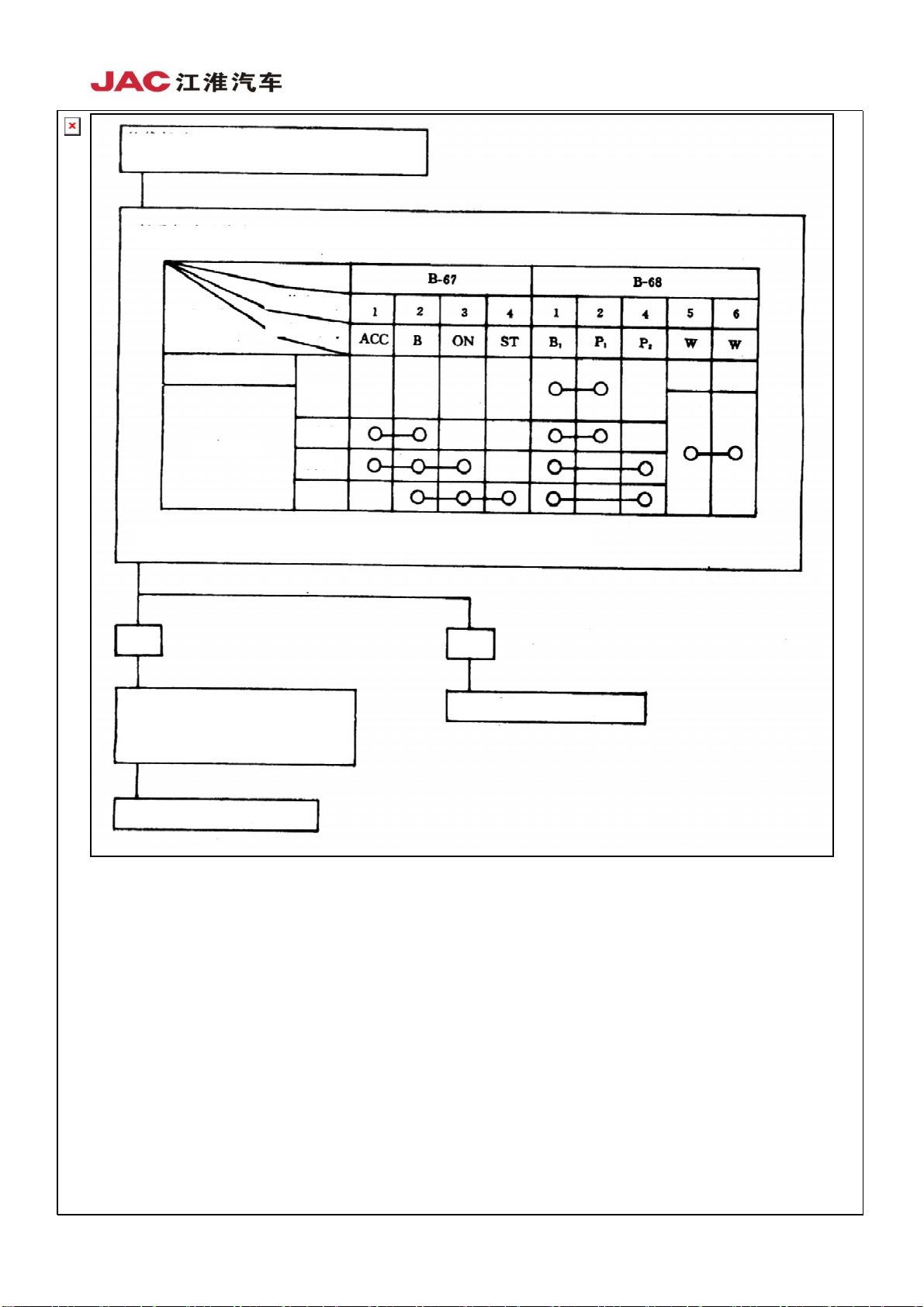

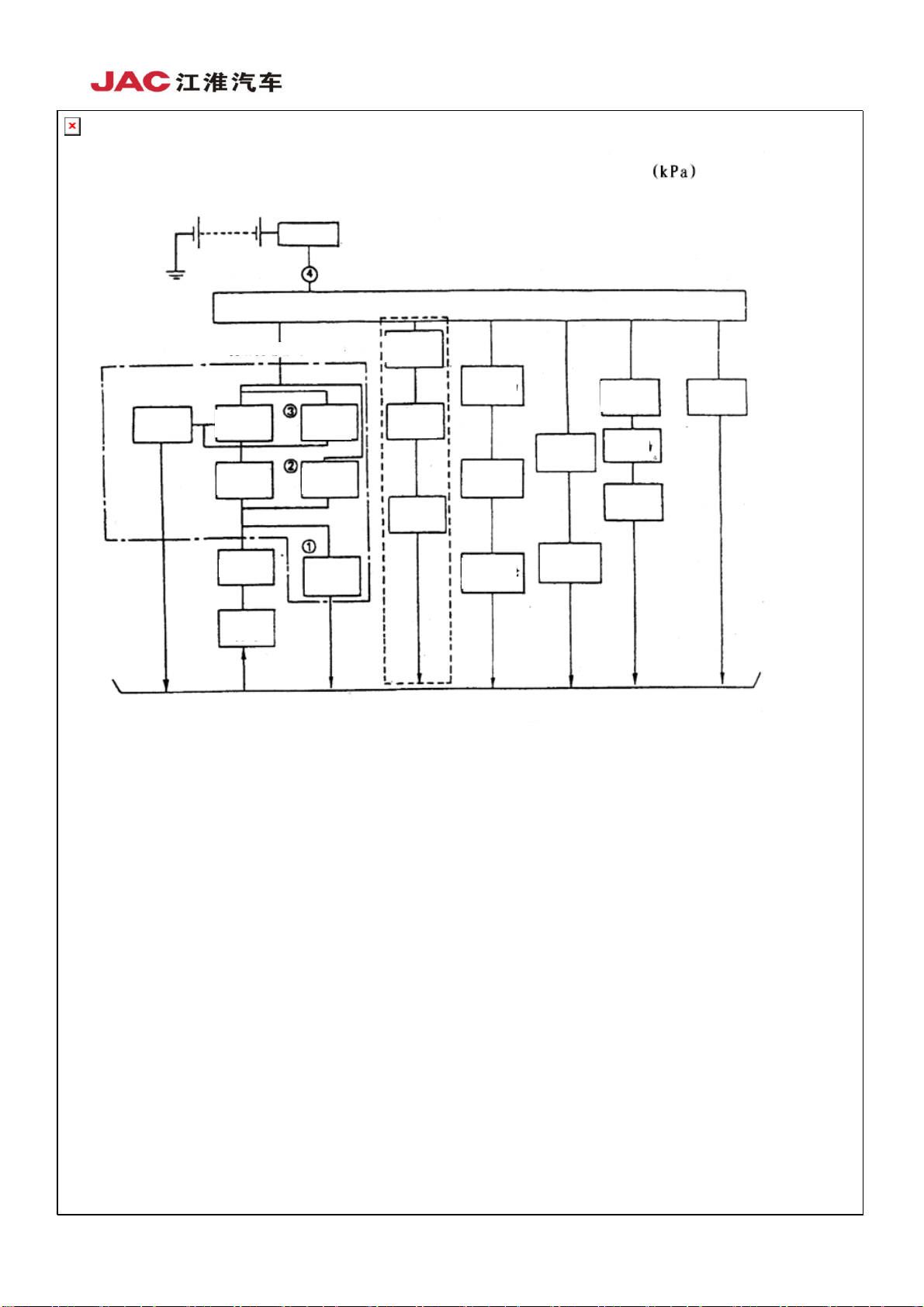

4DA1 Series oil filter and oil cooler

Indicator

light

R

egulator

pump

shaft

arm

C

rankshaft

Connecting

valve

strainer

with bypass-type filter

Battery

Oil pressure switch

Vertical cylinder oil gallery

Bypass

filter

Oil filter and cooler

Full-flow

oil filter

Oil

cooler

Oil pump

Oil

Safety

valve

Safety

Relief

valve

valve

Oil

nozzle

Piston

Oil pan

Idler gear

shaft

Oil pipe

Timing

gear

Camshaft

bearing

Rocker

bearing

Rocker

rod bearing

① Opening pressure of relief valve at oil filter: 430-470kPa

Vacuum

② Opening pressure of safety valve at oil filter: 960-100kPa

The lubrication system for 4DA1 Series engine is full-flow type.

The lubricant flows from the oil pump to the vertical cylinder oil gallery through oil cooler

and oil filter pump (the replaceable oil filter is equipped on the oil filter).And then, the

lubricant is delivered from the vertical cylinder oil gallery to the main parts of engine.

19

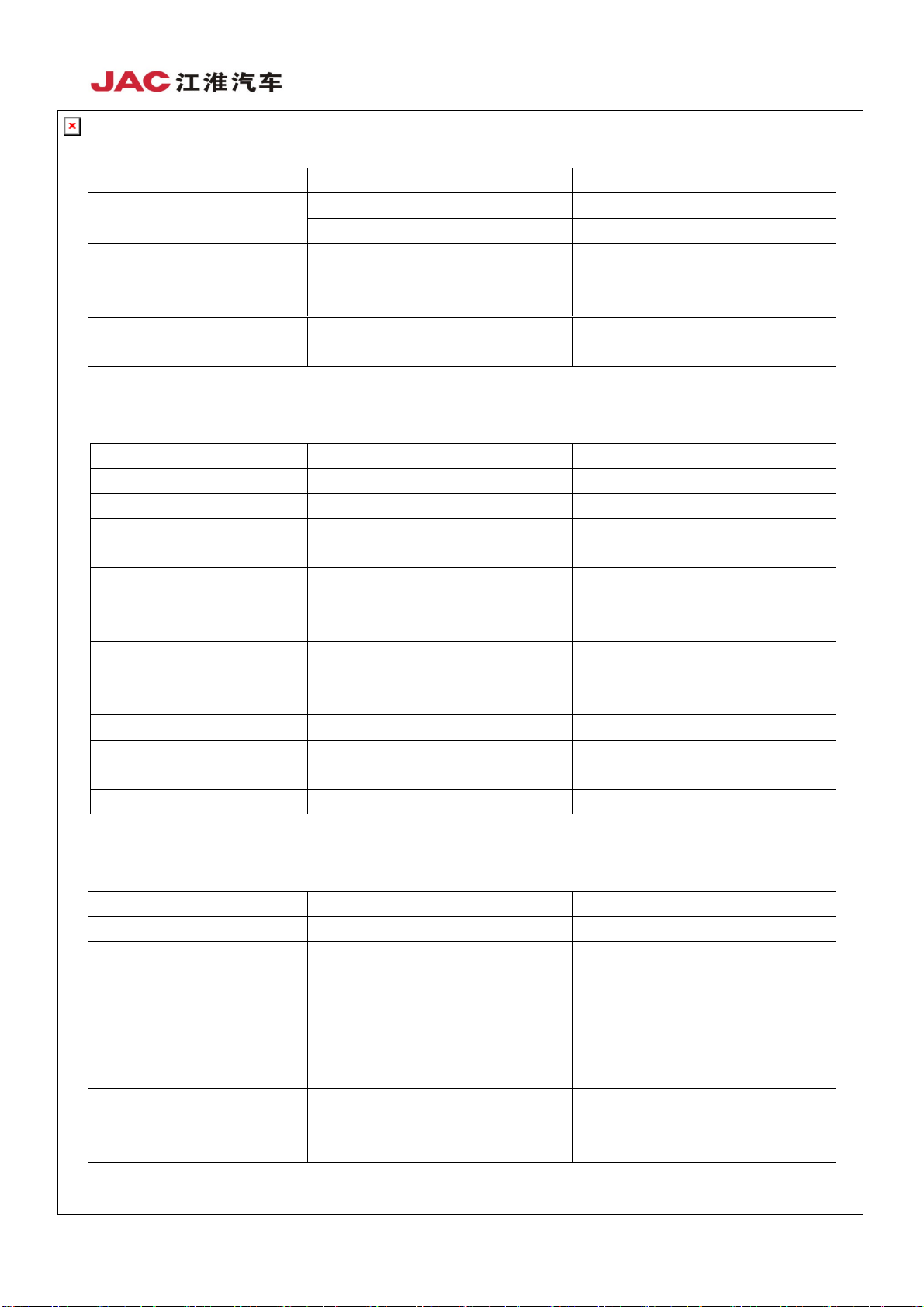

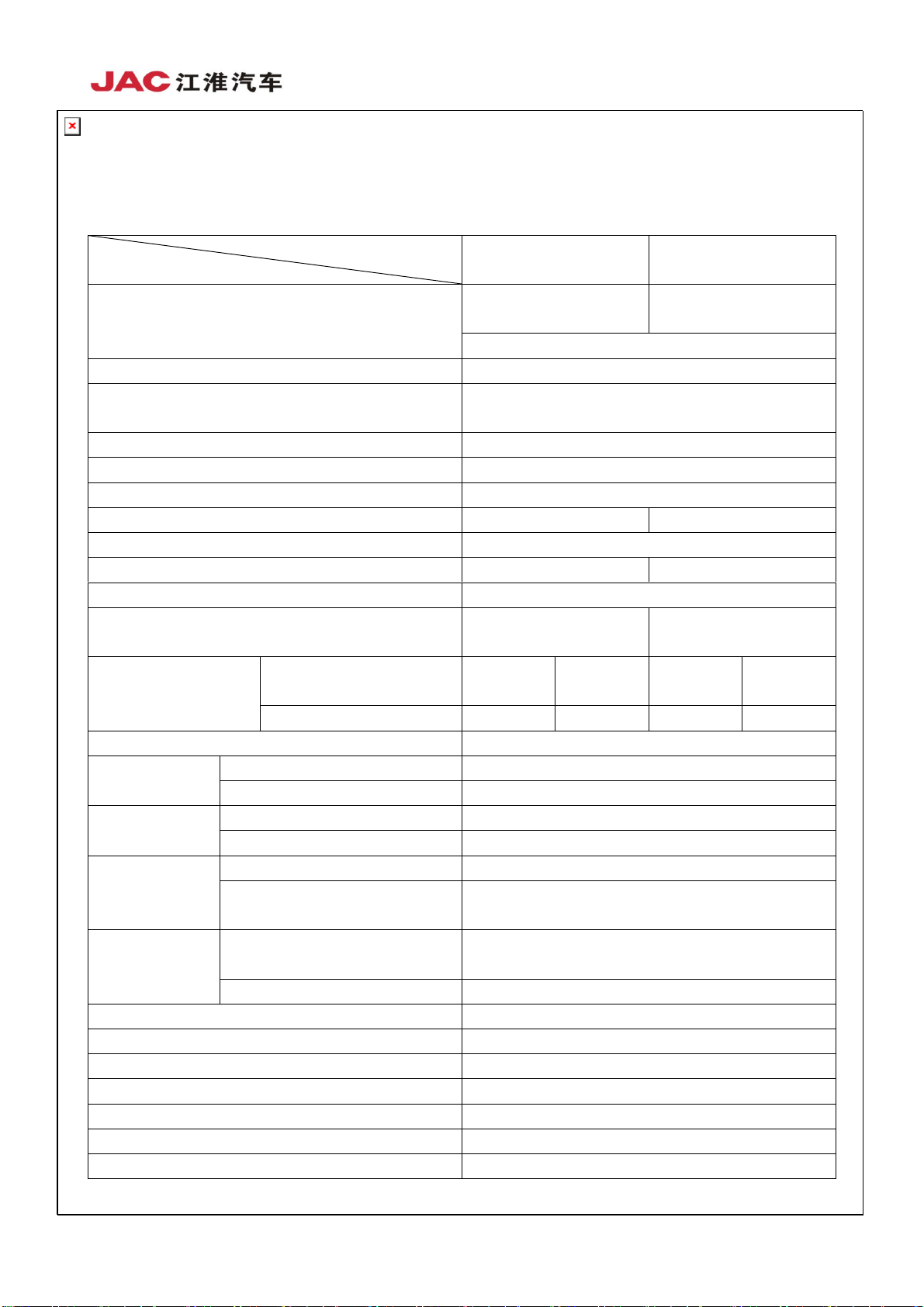

1.2 Data and specifications

1.2.1 Data and specifications

Engine model

Item

Natural admission (NA)

Four strokes, high mounted valve, water cooling

Combustion chamber type

Cylinder liner type

Cylinder number - cylinder bore stroke mm

Number of piston ring 2 gas rings, 1 oil ring

Total piston displacement L 2.771

Compression ratio 18.2 17.5

Design compression pressure kPa 3040

Engine weight (net) kg 230 240

Fuel injection sequence 1— 3— 4— 2

Fuel injection timing

Required fuel type

Idle speed r/min

Valve clearance

(cold)

(hot)

Intake valve

Exhaust valve

Lubricant system

Lubrication method Pressure feed lubrication and spray lubrication

Required oil (class AP1) CF-4 15W-40

Oil pump type External gearing

Oil filter type Full-flow type, paper element, replaceable

Oil volume (including oil filter) L 6

Oil cooler type Water cooling

Ambient temperature

Light diesel fuel type 0 # -10 # -20 # -35 #

Intake valve mm

Exhaust valve mm

Intake valve mm 0.30Valve clearance

Exhaust valve mm 0.30

Open (before top dead center)

Close (after bottom top dead

center)

Open (before bottom top dead

center)

Close (after top dead center)

Dry type, thin-wall chrome-plated steel cylinder

16 to the top dead

Above 4 ℃

4DA1 4DA1-1

Inter-cooling (TCI)Engine type

ω type direct injection

liner

4— 93×102

12 to the top dead

center (before)

Above -5℃Above -14℃Above -29

750±50

0.30~0.40

0.30~0.40

24.5

55.5

54

26

center (before)

Turbocharged

℃

20

Loading...

Loading...