MCO 500

High Power Thyristor Modules

V

RSM

V

DSM

V

RRM

V

DRM

Type

VV

1300 1200 MCO 500-12io1

1500 1400 MCO 500-14io1

1700 1600 MCO 500-16io1

1900 1800 MCO 500-18io1

Symbol Test Conditions Maximum Ratings

T

I

TRMS

I

T(AV)M

I

TSM

2

t T

I

(di/dt)

cr

(dv/dt)

cr

P

GM

P

GAV

V

RGM

T

VJ

T

VJM

T

stg

V

ISOL

M

d

= T

VJ

VJM

TC = 85°C; 180° sine A

T

= 45°C t = 10 ms (50 Hz) A

VJ

VR = 0 t = 8.3 ms (60 Hz) A

= T

T

VJ

VJM

VR = 0 t = 8.3 ms (60 Hz) A

= 45°C t = 10 ms (50 Hz) A2s

VJ

VR = 0 t = 8.3 ms (60 Hz) A2s

= T

T

VJ

VJM

VR = 0 t = 8.3 ms (60 Hz) A2s

T

= T

VJ

VJM

f = 50 Hz, tP = 200 ms

VD = 2/3 V

IG= A, non repetitive, IT = I

diG/dt = A/ms

T

= T

= T

VJM

VJM

T(AV)M

; VDR = 2/3 V

VJ

RGK = ¥; method 1 (linear voltage rise)

T

VJ

IT = I

t = 10 ms (50 Hz) A

t = 10 ms (50 Hz) A2s

repetitive, IT =A A/ms

DRM

1 500

960 100

T(AV)M

1

DRM

tP = 30 msW

tP = 500 msW

50/60 Hz, RMS t = 1 min V~

£ 1 mA t = 1 s V~

I

ISOL

Mounting torque (M6) Nm/lb.in.

Terminal connection torque (M8) Nm/lb.in.

Weight Typical including screws g

3542

880

A

560

17000

16000

13000

14400

1445000

1062000

845000

813000

A/ms

1000

V/ms

120

60

30

10

-40...140

140

-40...125

W

V

°C

°C

°C

3000

3600

4.5-7/40-62

11-13/97-115

650

I

TRMS

I

T(AV)M

V

= 880 A

= 560 A

= 1200-1800 V

RRM

2

3

5

Features

●

International standard package

●

Direct copper bonded Al2O3-ceramic

with copper base plate

●

Planar passivated chips

●

Isolation voltage 3600 V~

●

UL registered E 72873

●

Keyed gate/cathode twin pins

Applications

●

Motor control, softstarter

●

Power converter

●

Heat and temperature control for

industrial furnaces and chemical

processes

●

Lighting control

●

Solid state switches

Advantages

●

Simple mounting

●

Improved temperature and power

cycling

●

Reduced protection circuits

4

Data according to IEC 60747 refer to a single thyristor/diode unless otherwise stated.

IXYS reserves the right to change limits, test conditions and dimensions

© 2000 IXYS All rights reserved

030

1 - 4

MCO 500

52

Symbol Test Conditions Characteristic Values

I

RRM

V

T

V

T0

r

T

V

GT

I

GT

V

GD

I

GD

I

L

I

H

t

gd

t

q

R

thJC

R

thJK

d

S

d

A

a Maximum allowable acceleration m/s

Optional accessories for modules

Keyed Gate/Cathode twin plugs with wire length = 350 mm, gate = yellow, cathode = red

Type ZY 180 L (L = Left for pin pair 4/5)

TVJ= T

IT=A; T

For power-loss calculations only (T

VD= 6 V; T

VD= 6 V; T

TVJ= T

TVJ= T

T

= 25°C; VD = 6 V; tP = msmA

VJ

diG/dt = A/ms; IG =A

TVJ= 25°C; VD = 6 V; RGK = ¥ mA

TVJ= 25°C; VD = 1/2 V

diG/dt = A/ms; IG = A

T

= T

VJ

dv/dt = V/ms; IT = A; -di/dt = A/ms

DC current K/W

DC current K/W

Creeping distance on surface mm

Creepage distance in air mm

; VR = V

VJM

1200 1.3

;VD = 2/3 V

VJM

;VD = 2/3 V

VJM

RRM

= 25°CV

VJ

= T

VJ

= 25°CV

VJ

T

= -40°CV

VJ

= 25°CmA

VJ

T

= -40°CmA

VJ

DRM

DRM

)V

VJM

0.38

300

400

0.25

30 400

11

300

11

DRM

; VR = 100 V; VD = 2/3 V

VJM

; tP = 200 ms typ. ms

DRM

350

50 500 10

0.072

0.096

12.7

40

0.8

10

9.6

mA

mW

2

3

V

mA

ms

2

50

UL 758, style 1385,

CSA class 5851, guide 460-1-1

10

1: IGT, T

2: I

V

3: I

V

G

1

0.1

-3

10

GT

GT

IGD, T

, T

, T

VJ

10

= 140°C

VJ

= 25°C

VJ

= -40°C

VJ

= 140°C

-2

3

2

1

-1

10

Fig. 1 Gate trigger characteristics

100

µs

t

gd

typ.

2

10

Limit

6

5

4

4: P

= 20 W

GM

= 60 W

5: P

GM

6: P

= 120 W

GM

0

1

10

10

I

G

T

VJ

A

= 25°C

2

10

1

Dimensions in mm (1 mm = 0.0394")

0.01 0.1 1 10

A

I

G

Fig. 2 Gate trigger delay time

M8x20

49

10

© 2000 IXYS All rights reserved

2 - 4

MCO 500

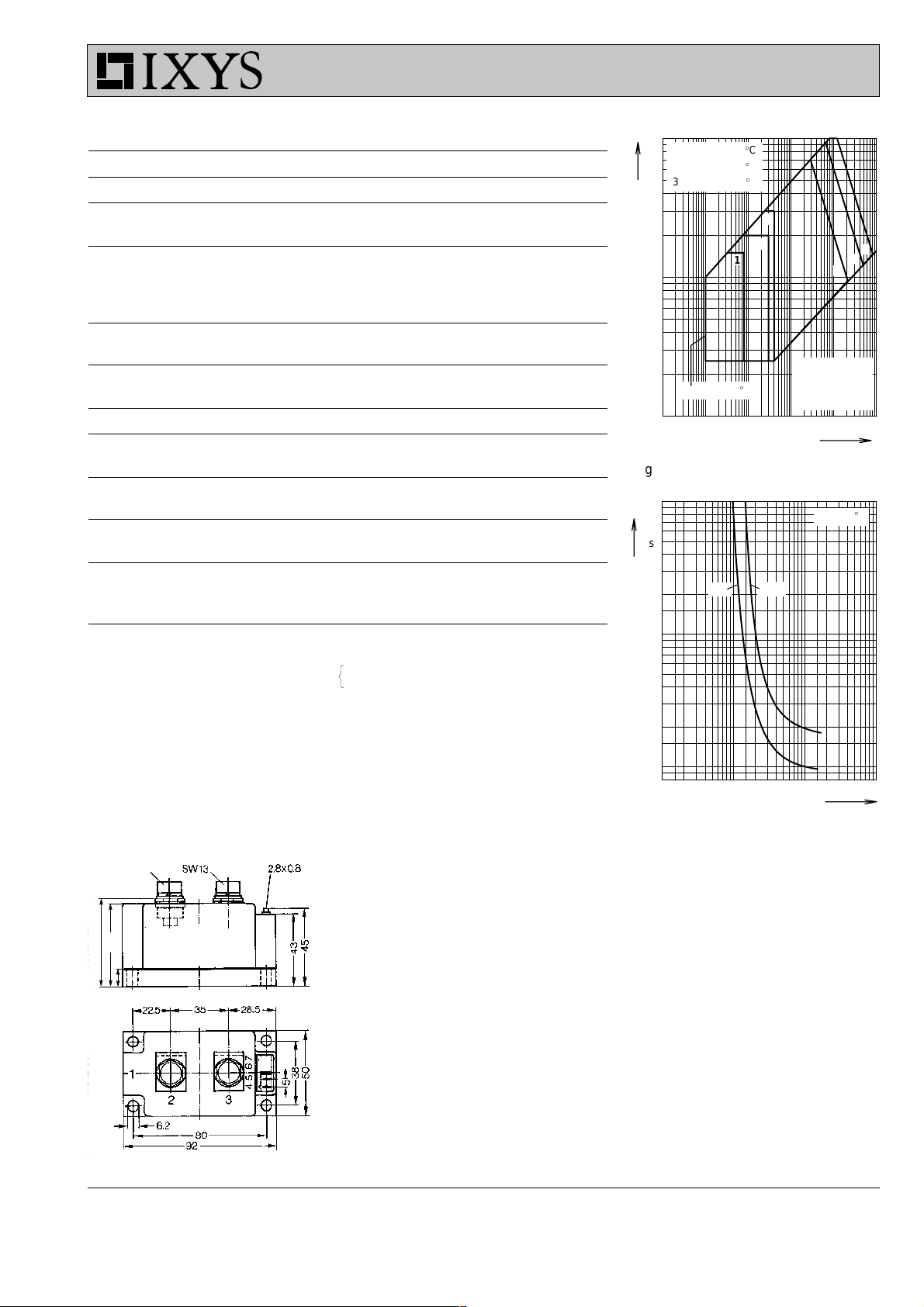

14000

I

TSM

12000

A

10000

8000

6000

4000

2000

0

0.001 0.01 0.1 1

Fig. 3 Surge overload current

I

, I

: Crest value, t: duration

TSM

FSM

1200

P

tot

W

1000

800

600

400

200

50 Hz

80 % V

RRM

TVJ = 45°C

= 140°C

T

VJ

DC

180° sin

120°

60°

30°

7

10

VR = 0V

I2t

A2s

6

10

TVJ = 45°C

TVJ = 140°C

5

10

s

t

110

ms

t

Fig. 4 òi2dt versus time (1-10 ms) Fig. 5 Maximum forward current

1000

A

900

I

TAVM

800

700

600

500

400

300

200

100

0

0 25 50 75 100 125 150

DC

180° sin

120°

60°

30°

T

C

°C

at case temperature

R

thKA

0.03

0.07

0.12

0.2

0.3

0.4

0.6

K/W

Fig. 6 Power dissipation versus on-

state current and ambient

temperature

0

0 200 400 600 800

5000

W

4500

4000

P

tot

3500

3000

2500

2000

1500

1000

500

0

0 300 600 900 1200 1500

Circuit

B6

6xMCO500

I

TAVM

0 255075100125150

A

/ I

FAVM

°C

T

A

R

K/W

thKA

0.01

0.02

0.03

0.045

0.06

0.08

0.12

0 25 50 75 100 125 150

A

I

dAVM

°C

T

Fig. 7 Three phase rectifier bridge:

Power dissipation versus direct

output current and ambient

temperature

A

© 2000 IXYS All rights reserved

3 - 4

MCO 500

5000

W

4500

4000

P

tot

3500

3000

2500

2000

1500

1000

500

0

0 300 600 900 1200

0.12

K/W

0.10

0.08

Z

thJC

0.06

0.04

0.02

0.00

-3

10

Circuit

W3

6xMCO500

-2

10

A

0 25 50 75 100 125 150

I

RMS

30°

60°

120°

180°

DC

-1

10

0

10

R

K/W

thKA

0.01

0.02

0.03

0.045

0.06

0.08

0.12

°C

T

A

1

10

s

t

Fig. 8 Three phase AC-controller:

Power dissipation versus RMS

output current and ambient

temperature

Fig. 9 Transient thermal impedance

junction to case (per thyristor)

R

for various conduction angles d:

thJC

d R

thJC

DC 0.072

180° 0.0768

120° 0.081

60° 0.092

30° 0.111

calculation:

thJC

(K/W) ti (s)

thi

2

10

Constants for Z

iR

1 0.0035 0.0054

2 0.0186 0.098

3 0.0432 0.54

(K/W)

4 0.0067 12

0.14

K/W

0.12

Z

thJK

0.10

0.08

0.06

0.04

0.02

0.00

-3

10

-2

10

© 2000 IXYS All rights reserved

Fig.10Transient thermal impedance

junction to heatsink (per thyristor)

R

for various conduction angles d:

thJK

d R

thJK

(K/W)

DC 0.096

180° 0.1

120° 0.105

30°

60°

120°

180°

DC

-1

10

0

10

1

10

s

t

2

10

60° 0.116

30° 0.135

Constants for Z

iR

calculation:

thJK

(K/W) ti (s)

thi

1 0.0035 0.0054

2 0.0186 0.098

3 0.0432 0.54

4 0.0067 12

5 0.024 12

4 - 4

Loading...

Loading...