Page 1

Page 2

INTRODUCTION

The Decimator ProRack noise reduction system defines a new standard for excellence

in real time noise reduction performance. The Decimator ProRack was designed to

provide the maximum possible performance in a rack mount dual channel noise

reduction system. The Decimator ProRack has dual processing channels incorporating

both low-level downward expansion and dynamically controlled low-pass filtering in a

very easy to use single rack space unit. The Decimator ProRack is based on ISP

Technologies patent pending “Time Vector Processing” which provides the most

adaptively dynamic release response characteristics of any real time noise reduction

system. The patent pending Time Vector Processing dynamic response circuit is used

to control the release time constant of both the downward expander and dynamic filter.

Please read this manual carefully for a through explanation of the Decimator ProRack

and its functions.

PRECAUTIONS

NOTE: IT IS VERY IMPORTANT THAT YOU READ THIS SECTION TO PROVIDE YEARS OF

TROUBLE FREE USE. THIS UNIT REQUIRES CAREFUL HANDELING.

All warnings on this equipment and in the operation instructions should be adhered to and

all operating instructions should be followed.

Do not use this equipment near water. Care should be taken so that objects do not fall onto

and liquids are not spilled into the unit through any openings.

The power cord should be unplugged from the outlet when the unit is left unused for a long

period of time.

DO NOT ATTEMPT TO SERVICE THIS EQUIPMENT. THIS EQUIPMENT SHOULD BE

SERVICED BY QUALIFIED SERVICE PERSONNELL ONLY. DO NOT MAKE ANY INTERNAL

ADJUSTMENTS OR ADDITIONS TO THIS EQUIPMENT AT ANY TIME. DO NOT TAMPER

WITH INTERNAL ELECTRONIC COMPONENTS AT ANY TIME. FAILURE TO FOLLOW THESE

INSTRUCTIONS WILL VOID THE WARRANTY OF THIS EQUIPMENT, AND MAY CAUSE A

SHOCK HAZZARD.

POWER REQUIREMENTS

This unit accepts power from the 9V AC power adaptor supplied with the unit. This 9V RMS

AC voltage is internally processed by a voltage doubler, which generates a bi-polar + and –

15V power supply to maintain the headroom and sound quality of professional, studio

quality equipment. Using an external power source minimizes excessive noise and hum

problems often associated with internal transformers, providing optimal performance for the

user.

Page 3

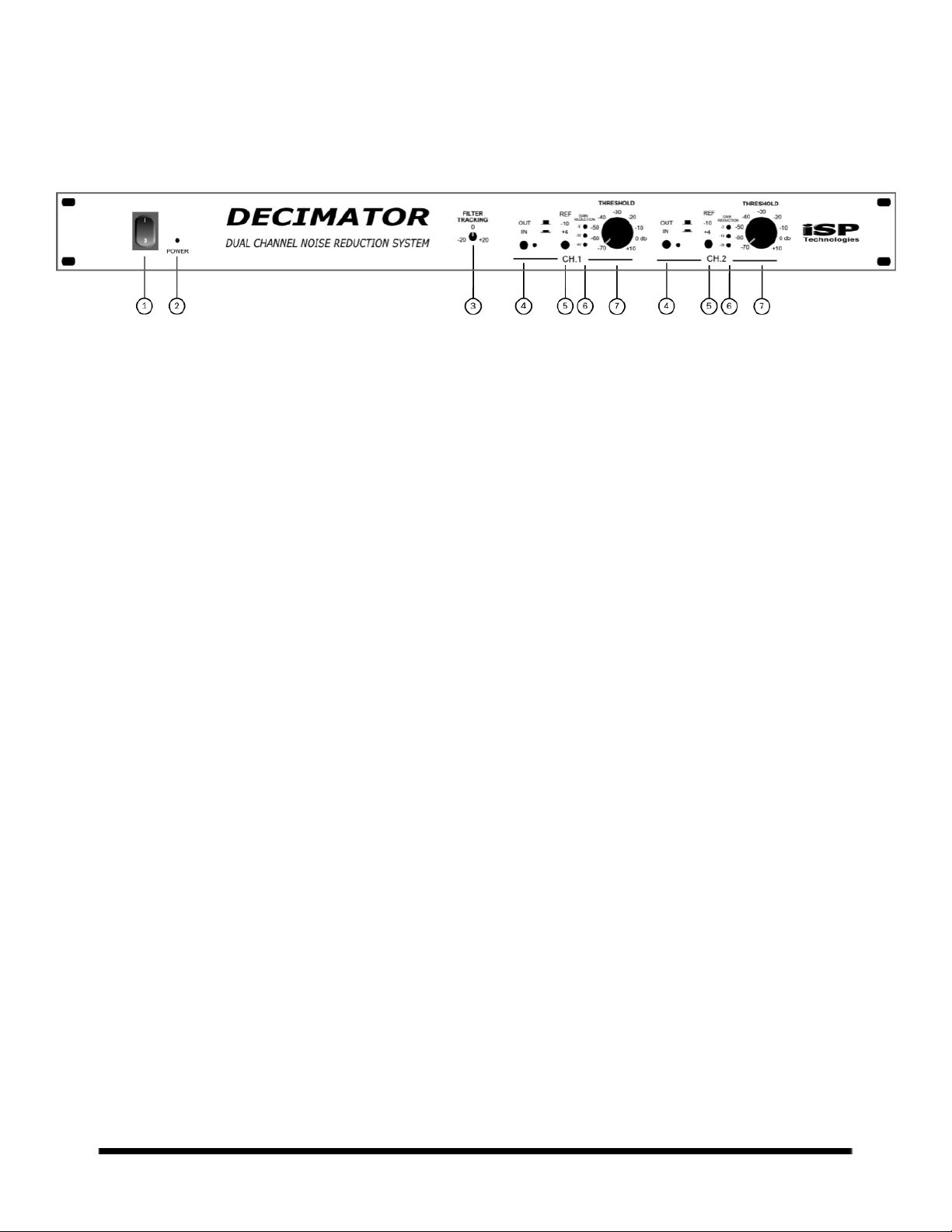

FRONT PANEL

1. POWER SWITCH

Switches the unit on and off.

2. POWER LED

Indicates when the power is on.

3. FILTER TRACKING CONTROL

This control adjusts the sensitivity of the filter threshold in relation to the downward

expander threshold. Turning this control clockwise increases the level at which the

dynamic filter opens. Turning this control counterclockwise decreases the level at

which the dynamic filter opens.

4. CHANNEL IN/OUT SWITCH AND LED

This switch is used to switch each individual channel in or out of the circuit path.

When the led is lit, the channel is active.

5. INPUT/OUTPUT REFERENCE LEVEL SWITCH

This switch changes the input and output operating reference level of each

individual channel from –10dbu when switched out, to +4dbu when switched in.

6. GAIN REDUCTION METER

This meter indicates the current amount of gain reduction (in decibels) taking place

in each channel.

7. CHANNEL THRESHOLD

This is the master threshold for each individual channel. This control is used to

adjust the threshold for both the dynamically controlled low pass filter and the low

level downward expander. NOTE: Adjusting the

the sensitivity of the dynamic filter in relation to the sensitivity of the downward

expander.

Filter Tracking

control will shift

Page 4

REAR PANEL

1. CHANNEL 1 INPUT JACK

This ¼ inch mono jack provides the high impedance input for connection to your audio

device.

2. CHANNEL 1 OUTPUT JACK

This ¼ inch mono jack provides the unbalanced output signal for channel 1.

3. CHANNEL 2 INPUT JACK

This ¼ inch mono jack provides a balanced input for the audio path channel 2.

4. CHANNEL 2 OUTPUT JACK

This ¼ inch mono jack provides the unbalanced output signal for channel 2.

5. GROUND LIFT SWITCHES*

All switches eliminate the ground connection for the illustrated channel input or output.

6. POWER INPUT JACK

This jack connector accepts power from the 9V AC adaptor supplied with the unit.

Page 5

OPERATION

When properly used, the Decimator ProRack should be completely transparent, it

should have no effect on the audio signal other than to remove the background

noise. To maximize the performance of the Decimator, it is necessary to understand

both the operation of the controls and the principles of how the internal circuit

operates. After this understanding, it will be easier to set up the Decimator ProRack

to suit any application.

Principles of the Decimator ProRack operation:

The Decimator achieves noise reduction by employing two individual noise reduction

processes, which work cohesively together to attain superior results. These two

processes are:

1. Dynamic Low Pass Filtering

2. Low Level Downward Expansion

Dynamic Low Pass Filtering is done by use of a high quality voltage controlled

sliding filter. A frequency sensitive audio level detection circuit incorporating ISP

Technologies patent pending Time Vector Processing circuit controls the dynamic

filter. When the audio input signal contains high frequency information the

dynamic filter increases in bandwidth to allow the audio signal to pass unaltered and

shown in the simplified graph below.

When the high frequency information in the input signal decreases the dynamic filter

bandwidth will track the decrease in high frequency and eliminate high frequency noise

that remains in the input signal. The simplified graph below shows the dynamic filter

response when there is no high frequency audio above 1KHz.

The release time of the dynamic filter is controlled by the Time Vector Processing

circuit, which determines the release characteristics of the input signal and

automatically varies the release response of the dynamic filter.

Page 6

Low Level Downward Expansion is performed by use of a high quality voltage

The GAIN REDUCTION meter on each channel indicates the

amount of gain reduction in decibels that the downward

expander is providing at any time.

The THRESHOLD control adjusts both the expander and

dynamic filter sensitivity. Start by setting both the Threshold

and Filter Tracking for minimum, full counterclockwise. Turn

the Threshold control clockwise until the desired effect of the

downward expander is achieved. The expander should start to

operate when there are gaps in the audio or as the input signal

gets close to the noise floor. NOTE: Setting this control to high

will cause the expander to start to cut off the input signal to

soon.

controlled amplifier controlled by an RMS based audio level detection circuit. A

second Time Vector Processing circuit that varies the release response over a 1000

to 1 ratio controls the release response of the Downward Expander. The release

response will be extremely fast, on the order of 2 milliseconds, if the input signal

has a fast decaying envelope and upwards of 2 seconds if the input signal has a

slow decaying signal. Downward Expansion takes place when the input signal level

drops below the preset threshold. For example: if the threshold is set for 0db and

input signal of 0db with produce no expansion. As the input signal drops below 0db

downward expansion starts and increases exponentially the farther the input signal

drops below the threshold point. The graph below shows the response of the

Expander with a 0db threshold.

To set up the Decimator ProRack for proper operation first determine the reference

level of the system that the Decimator will be connected to. Most professional

products operate at a +4dbu reference level. Music equipment typically operates at

–10dbu. Once the proper reference level is determined set the reference level

switch on both channels accordingly.

SETTING THE DECIMATOR THRESHOLD

Page 7

SETTING THE FILTER TRACKING CONTROL

The FILTER TRACKING control adjusts the relationship

between the sensitivity of the Dynamic Filter and the Expander.

Once the THRESHOLD control is set for proper operation of the

downward expander increase the FILTER TRACKING control

until the desired dynamic filter operation is achieved. Setting

this control to high will cause the filter to not fully open when

high frequency signals are present. Setting this control to low

will not provide any high frequency noise reduction. The Filter

Tracking adjusts the tracking for both channels.

Input Impedance

Maximum Input Level

Input / Output Jack

Frequency Response

Total Harmonic Distortion

Dynamic Range

Effective Noise Reduction

Dynamic Filter Attenuation Slope

Noise Floor

Power Requirements

Dimensions

24K ohms

+19dbu typical

¼ Balanced / ¼ Unbalanced

+.1,-.5db, 20Hz to 30KHz

Less than .02% Typical

115db, Peak to A weighted floor

Greater than 60db

6db per Octave

-110 A weighted typical –10 ref

9V AC 385ma

19” x 6” x 1¾”

Once the filter is set correctly the dynamic filter will provide high frequency noise

reduction at all input signal levels. For example; if a high level input signal is present at

the input that contains low and mid frequency information but little or no high

frequency information the filter bandwidth will close to a point just above the highest

input frequency. The instant the input signal contains a high frequency audio signal

the bandwidth of the filter will open so as to allow the highs to pass unaltered. Since

the ear cannot detect a low level signal in the presence of a higher level signal in the

same frequency band the input signal will mask the audibility of the high frequency

noise. As the high frequency information in the input signal decays the filter will close

to reduce the audible level of the background noise. When set properly, the Decimator

should virtually eliminate all background noise and should operate with total

transparency.

SPECIFICATIONS

NOTE: ODBU = .775V RMS

Page 8

WARRANTY AND SERVICE

The unit, parts and workmanship are fully guaranteed to be free of defects under

normal use and service for a period of 2 years from the date of purchase.

Any damage resulting from the misuse or the failure to follow the precautions and

instructions will void the warranty.

In the event that the unit needs to be repaired, please return the unit to ISP

Technologies directly. Simply repack the unit, send a copy of the original receipt, a

note stating the problem, and send it to:

ISP Technologies, LLC

5479 Perry Drive Unit B

Waterford, MI 48329

Attn: Repair Dept.

All shipping charges must be fully prepaid.

ISP will not be responsible for any damages incurred in shipping of any unit. Any

claim will need to be settled with the shipping company.

The warranty will be voided if the serial number has been tampered with in any way.

The warranty card must also be filled out and returned in order to activate the

warranty.

Should you have any questions for the repair department prior to returning the

product please call 1-(248)-673-7790

ISP TECHNOLOGIES, LLC

5479 PERRY DRIVE SUITE B

WATERFORD, MI. 48329

248-673-7790

FAX: 248-673-7696

WWW.ISPTECHNOLOGIES.COM

Loading...

Loading...