ISA T1000 Introductory Manual

Istrumentazioni Sistemi Automatici S.r.l.

VIA BERGAMO 41 - 21020 TAINO (VA) - ITALY

OFFICES TEL. +39.0331.956081 - FAX +39.0331.957091

LAB: TEL. +39.0331.956483 -

E-MAIL isa@isatest.com

WEB www.isatest.com

DATE: 25/04/2006 DOC.MIE12093 REV. 1

T1000

INTRODUCTORY GUIDE

DOC. MIE12093 Rev. 1 Page 2 of 52

REVISIONS SUMMARY VISA

N PAGE DATE

1 All 25/04/2006 Preliminary issue Lodi.

DOC. MIE12093 Rev. 1 Page 3 of 52

SHORT FOREWORD .......................................................................................................................................................4

INTRODUCTION.............................................................................................................................................................5

1 TEST SET EXPLANATION ........................................................................................................................................7

1.1 CONNECTION TO THE RELAY AND POWER-ON.............................................................................................................7

1.2 TEST CONTROL...........................................................................................................................................................7

1.3 CURRENT GENERATION............................................................................................................................................ 10

1.4 AC VOLTAGE GENERATION FROM MAIN OUTPUT ......................................................................................................11

1.5 DC VOLTAGE GENERATION FROM MAIN OUTPUT......................................................................................................12

1.6 AC VOLTAGE GENERATION FROM THE AUXILIARY OUTPUT ...................................................................................... 12

1.7 DC VOLTAGE GENERATION FROM THE AUXILIARY OUTPUT ......................................................................................14

1.8 AUXILIARY CONTACT............................................................................................................................................... 15

1.9 THE TIMER...............................................................................................................................................................15

1.10 FINDING RELAY THRESHOLDS.................................................................................................................................16

1.10.1. Introduction.................................................................................................................................................16

1.10.2. First threshold trip and drop-off..................................................................................................................17

1.10.3. Second threshold trip and drop-off .............................................................................................................18

1.11 FINDING RELAY TIMINGS ........................................................................................................................................18

1.12 BASIC TEST PRINCIPLES.......................................................................................................................................... 20

1.12.1. Introduction..................................................................................................................................................20

1.12.2. Parameter vs. time characteristic ................................................................................................................20

1.12.3. Parameter vs. parameter characteristic....................................................................................................... 21

1.13 USE OF THE TEST SET AS A MULTIMETER................................................................................................................23

2 TEST SET AND POP-UP MENU ..............................................................................................................................25

2.1 THE FRONT PANEL....................................................................................................................................................25

2.2 DISPLAY AND CONTROL LIGHTS................................................................................................................................27

2.3 THE POP-UP MENU....................................................................................................................................................27

3 THE HELL, IT DOESN’T WORK............................................................................................................................34

3.1 INTRODUCTION ........................................................................................................................................................ 34

3.2 ERROR MESSAGES....................................................................................................................................................35

3.3 TROUBLE SHOOTING ................................................................................................................................................36

3.4 PHYSICAL DESCRIPTION ...........................................................................................................................................37

4.4.1 Protection fuses...............................................................................................................................................39

4.4.2 Auxiliary supplies............................................................................................................................................39

4.4.3 No power at power-on.....................................................................................................................................40

3.5 AUXILIARY DC VOLTAGE FAULT ................................................................................................................... 40

3.6 NO OUTPUT FROM THE MAIN CURRENT AND VOLTAGE .............................................................................................41

3.7 DOES NOT MEASURE THE MAIN CURRENT ................................................................................................................41

3.8 THE DISPLAY BACKLIGHT DOES NOT TURN ON.......................................................................................................... 42

3.9 THE AC VOLTAGE MEASUREMENT IS NOT STABLE ................................................................................................... 43

3.10 THE TRIP INPUT IS NOT DETECTED OR TIMING ERROR .............................................................................................43

3.11 PROBLEMS DURING UPGRADE ................................................................................................................................43

3.12 THE ENCODER IS BROKEN ......................................................................................................................................44

3.13 THE FAULT CANNOT BE FIXED................................................................................................................................ 44

3.14 CALIBRATION......................................................................................................................................................... 46

3.14.1 Introduction..................................................................................................................................................46

3.14.2 Calibration procedure.................................................................................................................................. 46

3.14.3 T/1000 output calibration............................................................................................................................47

3.14.4 T/1000 external measurements calibration................................................................................................. 49

APPENDIX 1 SPARE PARTS LIST.............................................................................................................................50

DOC. MIE12093 Rev. 1 Page 4 of 52

SHORT FOREWORD

Dear T/1000 user,

I often wondered why the user’s manual is not very much used, even if it includes valuable

information. As me too I am a user of such manuals, the answer I have given myself is that valuable

information are concealed somewhere in the thick thing, and I do not have time to waste to find it.

So, either the manual is actually of help, or I ignore it.

This is why I decided to split the T/1000 manual in three: specification, with all performance

details; application manual, with instructions about how to use it one its operation is understood;

introductory guide, with the device description and basic information. The idea is that you may read

once the introductory guide or the specification, while you need to follow application examples

more than once; so, why not to split the manual in three?

Have a good work with T/1000!

Primo Lodi

Q&A Manager

DOC. MIE12093 Rev. 1 Page 5 of 52

INTRODUCTION

The single phase relay test set mod. T/1000 is suited for the testing and adjustments of the following

types of relays; the table lists also the paragraph that explains the test procedure.

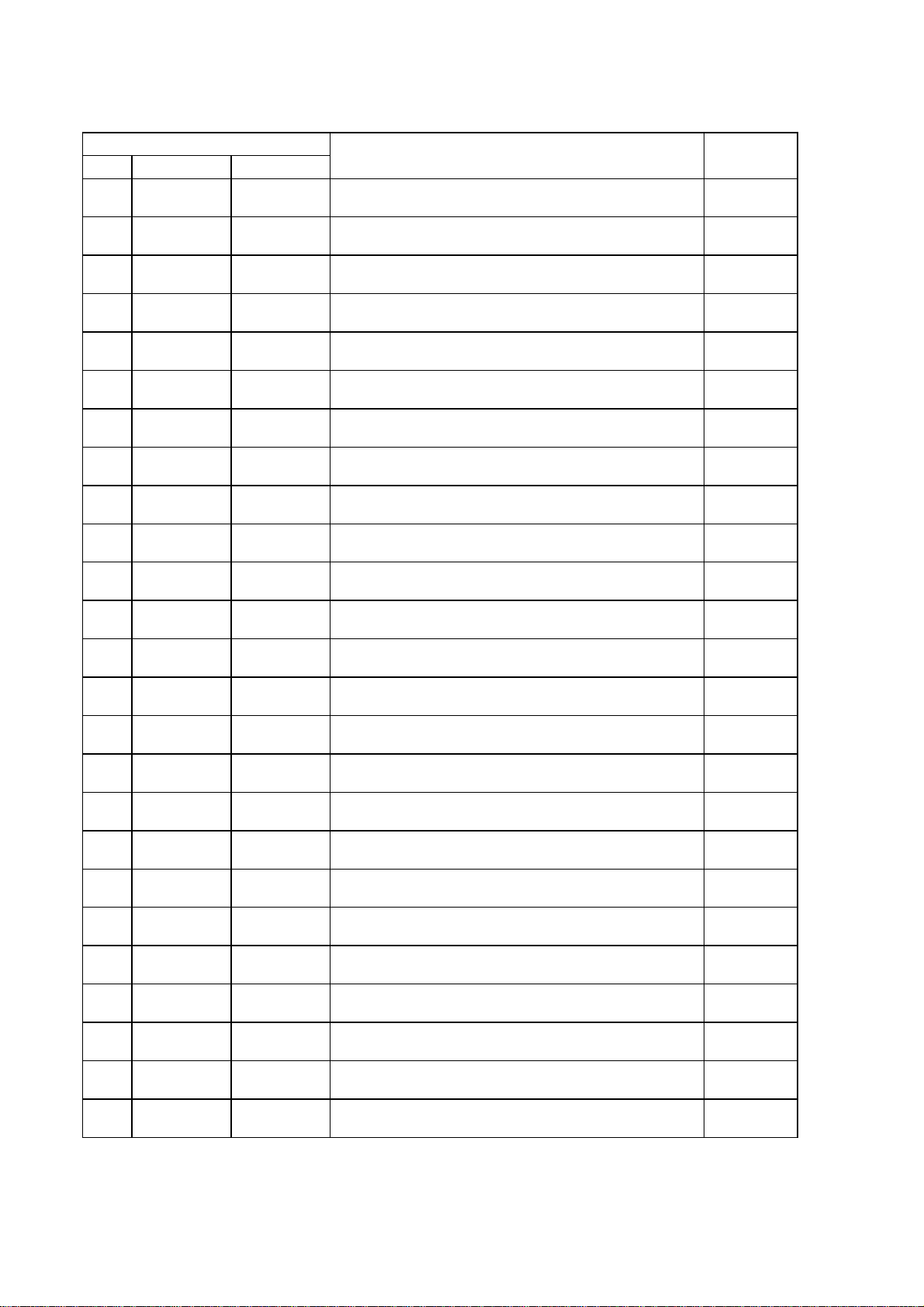

Type of relay IEEE code PARAGRAPH

- Distance* 21 1.12

- Synchronizing 25 1.8

- Over/under-voltage 27 - 59 1.2

- Power, varmetric or wattmetric 32 - 92 1.4

- Under current 37 1.1

- Loss of field 40 1.10

- Reverse phase current 46 1.4

- Instantaneous overcurrent 50 1.1

- Ground fault 50N 1.1

- Timed overcurrent 51 1.1

- Power factor 55 1.4

- Directional overcurrent 67 1.5

- Directional ground fault 67N 1.5

- Automatic reclose 79 1.11

- DC voltage 80 1.3

- Frequency 81 1.6

- Frequency rate of change 81 1.7

- Motor protection 86 1.1

- Differential ** 87 1.1

- Directional voltage 91 1.5

- Tripping relay 94 1.9

- Voltage regulation 1.2

- Thermal 1.1

- Timers 1.9

* For distance relays three T/1000 are necessary.

** Differential starter circuit

In addition to the above, T/1000 can test:

. Converters: V; I; f°; p.f.; W; VAr; f., both 0 to 5 and 4 to 20 mA.

. Energy meters, single phase or three phase.

The instrument contains three separate generators:

. Main generator, which generates either AC current, AC voltage; DC voltage;

. Auxiliary a.c voltage generator, that generates an independent, phase shifting a.c voltage;

. Auxiliary DC voltage generator, that generates the DC voltage that feeds the relay under test.

All outputs are adjustable and metered at the meantime on the large, graphic LCD display. With the

multi-purpose knob and the LCD display it is possible to enter the MENU mode that allows setting

many functions, which make T/1000 a very powerful testing device, with manual and semiautomatic testing capabilities, and with the possibility to transfer test results to a PC via the RS232

interface. These results can be recorded, displayed and analyzed by the powerful TDMS software,

DOC. MIE12093 Rev. 1 Page 6 of 52

which operates with all WINDOWS versions, and allows creating a data base of all tests in the

plant.

The basic T/1000 function is to generate current and voltages and to stop generation as the relay

trips. Test results are kept in memory, and can be transferred to a PC at a later time, along with

settings.

The ease of operation has been the first goal of T/1000: this is why the LCD is graphic, and so large.

With it, the dialogue in MENU mode is made easy. Besides, all T/1000 outputs are continuously

measured, and output values are displayed, with no extra effort to the operator. Also the show

waveform feature can be of help: any doubt about strange measurements, distortion and so on can

be solved.

This is also why we have added the reduced power feature. Modern relays have a very low burden.

As current output is a low impedance voltage generator, adjusting low currents and/or current on

low burdens is quite difficult because one has to operate at the very beginning of the adjustment

knob. In this situation it is possible to connect resistors in series; however, one must be careful not

to exceed the maximum current rating, and the wiring is more complicated. The solution to this

problem is just to reduce the available power: this is easily performed via the multi-function knob.

With less power, the maximum voltage is reduced by a factor of 4.4; the adjustment span on the

knob is increased accordingly.

Additional features are:

. Two meters, current and voltage, with independent inputs, allow measuring T/1000 outputs or any

other source;

. An auxiliary contact, that follows START and STOP inputs, allows simulating the circuit breaker;

. A set of resistors allows easing output adjustment.

The instrument is housed in a transportable aluminum box, that is provided with removable cover

and handles for ease of transportation.

NOTE: WINDOWS is a trademark of MICROSOFT inc.

DOC. MIE12093 Rev. 1 Page 7 of 52

1 TEST SET EXPLANATION

1.1 CONNECTION TO THE RELAY AND POWER-ON

At first, be sure that the main control knob (6)is turned (rotated) to the zero position (complete

counter-clockwise). The reason is that the current generator is actually a high current voltage

generator. If the output is connected to the load (typically low impedance), as soon as the test is

started, a very high current can circulate in the circuit.

Next connect the mains supply cable to the instrument and then to the supply. THE SUPPLY

VOLTAGE MUST BE THE SAME AS INDICATED ON THE PLATE.

Power-on T-1000: a diagnostic sequence controls:

. Key microprocessor board components;

. Auxiliary supply voltages.

If something is wrong, the operator is alerted by a message.

At the end of it, default selections are active; T-1000 is in the OFF state.

Perform the first selections, according to the type of relay to be tested:

. Main output socket, acting on the selector push-button (57).

. Auxiliary AC voltage: range; type of generation; value.

. Auxiliary DC voltage: range; value.

. Start and Stop timer inputs.

Connect the relay to be tested to the output sockets that have the indication light (LED) on.

The following is the list of protections that avoid damaging T-1000 in case of errors.

. Fuse on the mains supply.

. Thermal NTC sensor on the main and auxiliary transformers. In case of over-temperature, an alarm

message is displayed.

. Thermal sensors on the SCR that controls current injection, and of the internal temperature. In case

of over-temperature, an alarm message is displayed.

1.2 TEST CONTROL

The T-1000 front panel is explained in next paragraph.

T-1000 generation is controlled by the two keys < (55) and > (56).

Settings and menu selections are controlled by the multi-function knob with switch (22): see next

paragraph for menu selections description. At power-on T-1000 generation is OFF, as confirmed by

LED (50). The ON selection serves for finding relay thresholds; selections ON+TIME and

OFF+TIME serve to measure relay timing.

DOC. MIE12093 Rev. 1 Page 8 of 52

Normal (default)

Trip + pulse time

Reclose mode

Maintained

Momentary

Timed

External

OFF delay

1

period

8 periods

Save min

Save max

Don’t save

Automatic at trip

Confirm at trip

Manual

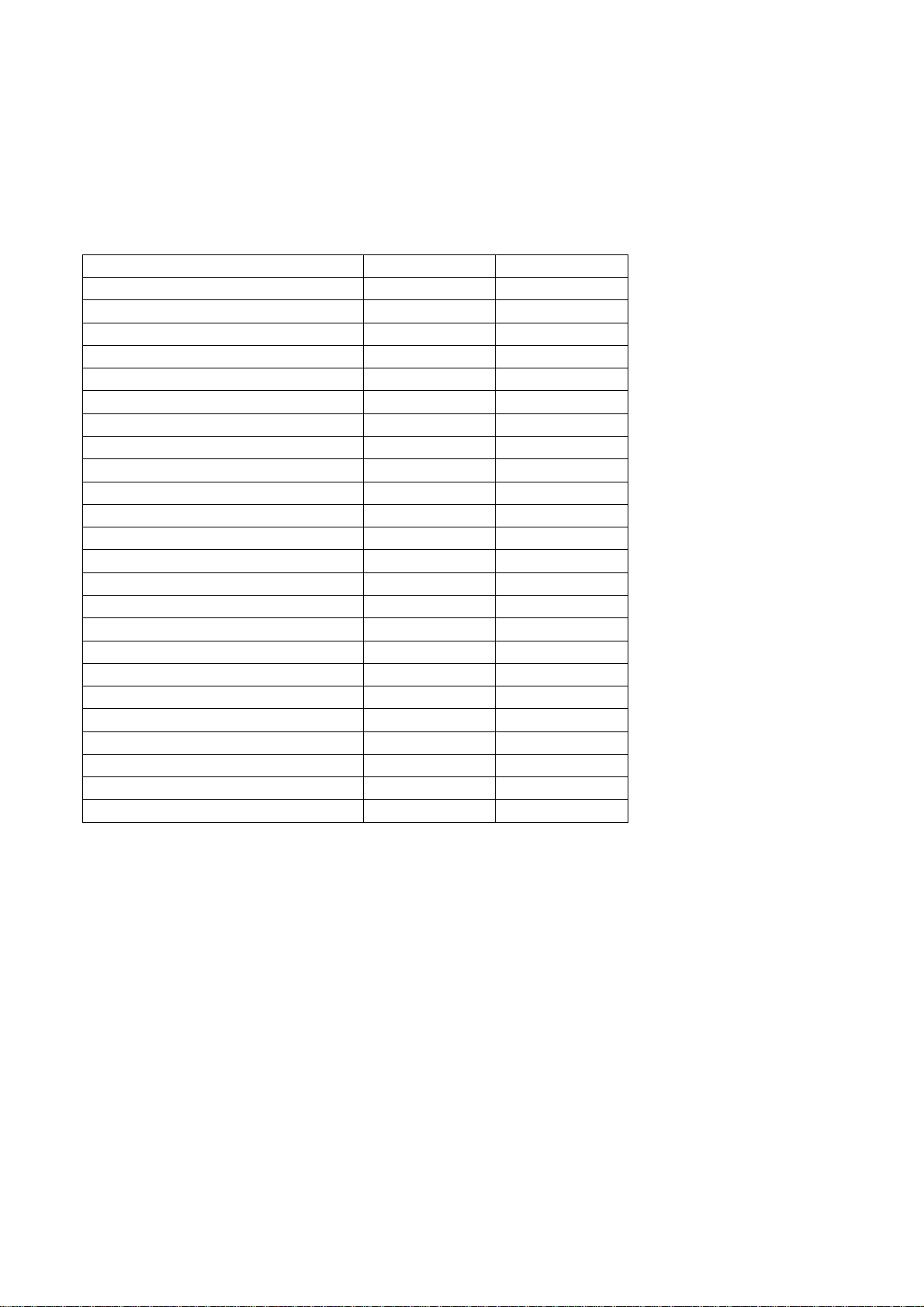

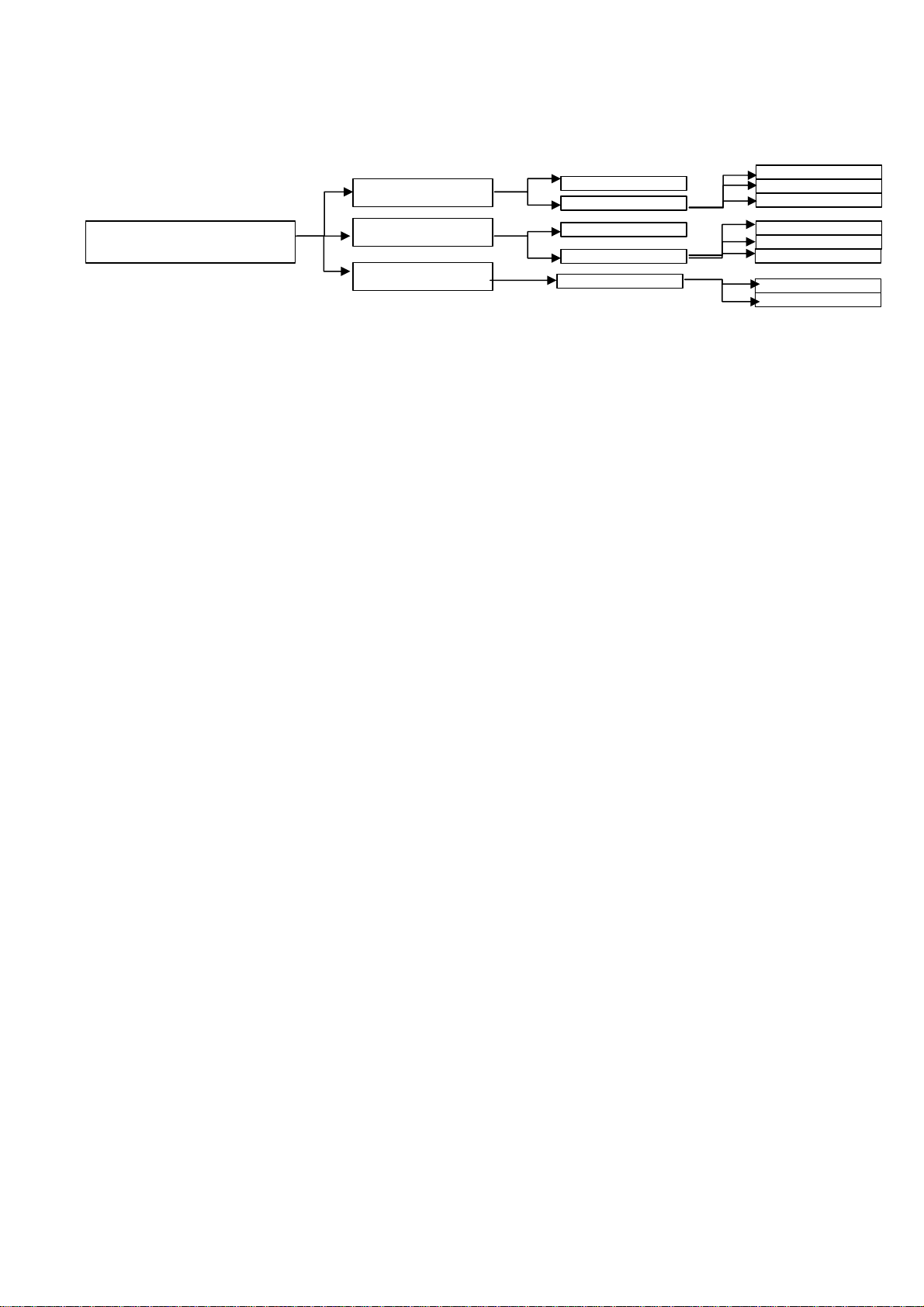

The following flow diagram summarises all available test control selections.

Test mode

Fault injection

TEST CONTROL

Test power

Save

Auxiliary contact

The performance of T-1000 in Normal Test mode is the following.

. OFF: main outputs are not generated; Vac aux is generated, and it can be either the pre-fault value

or the fault value, according to selections; Vdc aux is generated. In this condition, any trip of Stop

input is ignored.

. ON: timer starts; main outputs are generated; Vac aux has the fault value; Vdc aux does not

change. In this situation any trip at Stop input is detected; it is possible to verify and memorize the

relay threshold, both trip and reset. As the relay trips, the TRIP LED (43) turns on for 5 seconds;

during 5 seconds, parameters at trip are displayed; then, the standard measurement is restored. Test

results can be saved according to Save selections.

. From OFF to ON + TIME: main outputs are generated and the timer starts according to selections;

as Stop trips or resets, T-1000 returns to OFF, the TRIP LED (43) turns on and parameters at trip

are displayed until ON or ON+TIME are selected. Test results can be saved according to Save

selections.

. From ON to OFF + TIME: main outputs are removed the timer starts according to selections; as

STOP is sensed, T-1000 returns OFF, the TRIP LED (43) turns on and parameters at trip are

displayed until ON or ON+TIME are selected. Test results can be saved according to Save

selections.

Other test mode selections:

. Trip + pulse time: the timer measures the delay and the duration of the trip impulse.

. Reclose test. It is possible to select via menu the test of a reclosing scheme. In this operating mode

T-1000 automatically applies current as soon as the RECLOSE command is sensed at START

input. The test set measures and stores the trip delay and the delay between trip falling edge and

RECLOSE trailing edge (see figure 4). Maximum number of Reclose commands: 49; maximum test

commands for all Reclose commands: 9999 s.

DOC. MIE12093 Rev. 1 Page 9 of 52

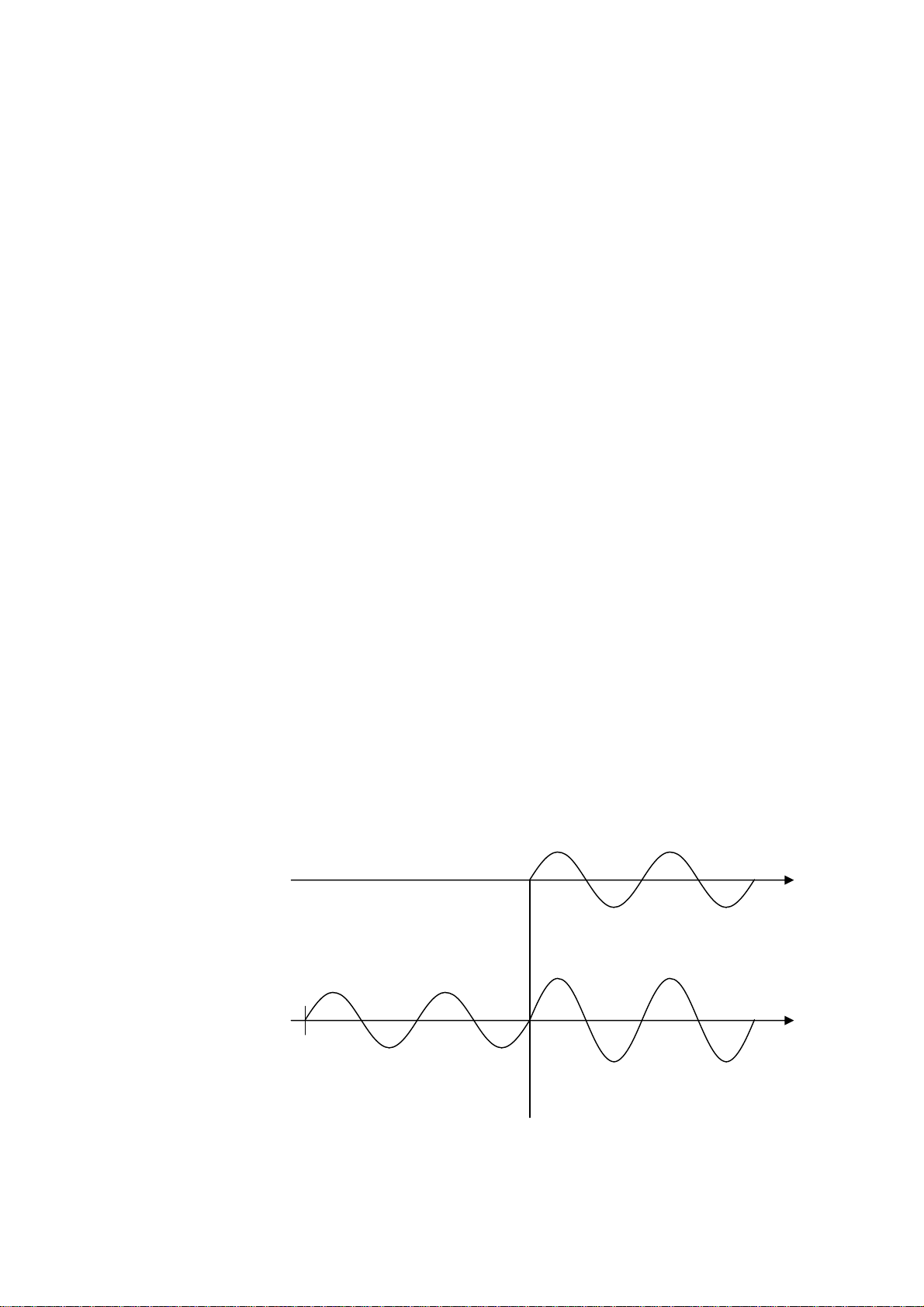

FAULT 1 2

TRIP (STOP) 1 2

RECLOSE (START) 1 2

TIME MEASUREMENTS D1 R1 D2 R2

Other Fault injection selections:

. Maintained (default):

.. ON mode: fault outputs are generated until OFF is selected.

.. ON+TIME or OFF+TIME: as the STOP input is sensed, T-1000 returns OFF.

. Momentary: in ON mode, main outputs are generated until the > push-button is pressed;

. Timed: in all modes (ON; ON+TIME; OFF+TIME), fault outputs are generated for the

programmed maximum time; after this, T-1000 returns OFF. Any trip after this time is not sensed.

. External. This mode allows for the synchronization of more T-1000: they start generating upon

reception of the START input, that is selected in External mode.

. OFF delay: fault parameters can be maintained for the specified time after relay trips: this allows

simulating the circuit breaker delay.

Test power selection: it allows reducing the available power; this increases the adjustment

sensitivity for low current tests on low burden relays.

Save selections:

. No automatic saving.

. Automatic test data saving as relay trips. A pop-up window confirms the saving and tells the test

number.

. Test data can be saved after confirmation. After relay trip, pressing the multi-function knob the

operator can save the test result.

. Manual test data saving. This selection can be used any time: it serves if the trip is confirmed by a

light and not by a contact.

Test data selections. Data to be saved can be measured the following way:

. One period before the trip: this is the standard selection for timing measurement, and for threshold

test, provided that trip time is not long;

. Eight periods before the trip (less if eight are not available): this is used in case of unstable test

results due to waveform distortion;

. Save the minimum period within 0,5 s before trip: this is used for high threshold measurement,

when the timing is long;

. Save the maximum period within 0,5 s before trip: this is used for low threshold measurement,

when the timing is long.

Auxiliary contact delay: the switch of the auxiliary contact can be timed with respect to test start.

DOC. MIE12093 Rev. 1 Page 10 of 52

1.3 CURRENT GENERATION

If the following current limits and time duration of main current outputs are trespassed, the

generation is interrupted, and the operator is warned by an alarm message.

1) MAXIMUM POWER 300 VA

RANGE

A AC

100

40

10

2) MAXIMUM POWER 60 VA

RANGE

A AC

100

40

10

This generator serves for the test of current, power, directional, distance relays, where current or

current and voltage are necessary. The procedure is the following.

CURRENT

OUTPUT

A

30 300 STEADY 50 30 min 100

75 600 45

100 800 60 15

150 3 10

250 1000 1 5

12 300 STEADY -

20 30 min 100

30 600 45

40 800 60 15

60 3 10

80 1000 1 5

5 400 STEADY -

7.5 15 min 45

10 800 60 15

15 5 10

20 1000 2 5

CURRENT

OUTPUT

A

30 60 STEADY 38 10 min 45

53 60 10

70 0.75 2

12 60 STEADY 17 10 min 45

23 60 10

36 1 2

5 60 STEADY 6 10 min 45

7 60 2

10 1,5 2

MAXIMUM

POWER

VA

MAXIMUM

POWER

VA

LOAD

TIME

s

LOAD

TIME

s

RECOVERY

TIME

min

RECOVERY

TIME

min

DOC. MIE12093 Rev. 1 Page 11 of 52

. At first, be sure that the main control knob (6) is turned (rotated) to the zero position (complete

counter-clockwise).

. Power-on T-1000.

. Select by the push-button (57) the measurement on the desired output sockets (13), according to

the maximum current to be generated: the LED turns on; the AC voltage value is displayed.

. Connect the relay to be tested to sockets (13). Consider that for tests of 40 A up it is necessary to

connect the relay by a wire having at least a cross section of 10 sq. mm; for lower currents, a cross

section of 2.5 sq. mm can be used.

. Press ON and adjust the output current to the desired value with knob (6).

. After you have started the test, if the burden is a short circuit made of a short cable, you measure

at zero knob position a current that usually is less than 3% of the range. This value does not

influence at all the measurement of the current you are generating: it is not an error of the

measurement instrument. If the current is a problem, select the 60 VA power, and/or connect

resistors in series.

. There are two more possible problems: the desired current cannot be reached; the adjustment is

difficult because the current is reached too easily.

.. If it is impossible to reach the desired value, this is because the burden is too high. Very often the

problem comes from connection wires; so, to perform the test it is necessary either to shorten them,

or to increase the cross section (or both).

.. If the adjustment is reached within 1/5th of the knob rotation, then it is possible to increase the

ease of adjustment by reducing the test power as follows.

TEST CONTROL > TEST POWER (Power) ESC

.. It is also possible to increase the ease of adjustment by connecting a resistor of the set in series to

the relay. Resistors are rated 50 W; so, compute the resistance value as follows:

(RESISTANCE) = 50 / (TEST CURRENT)^2

Maximum test current values are resumed here below.

RESISTANCE

MAX ITEST

Note that the test starts and stops as the current passes the zero.

0.5 1 22 470 1000 2200

10 7 1.5 0.3 0.2 0.15

1.4 AC VOLTAGE GENERATION FROM MAIN OUTPUT

If the current of 3.5 A is exceeded on main AC voltage output, the generation is interrupted, and the

operator is warned by an alarm message.

This generator serves for the test of synchronism relays, where two voltages are necessary. The

procedure is the following.

. At first, be sure that the main control knob (6) is turned (rotated) to the zero position (complete

counter-clockwise).

. Power-on T-1000.

. Select by the push-button (57) the measurement on output sockets (60): the LED turns on; the AC

voltage value is displayed.

. Modern relays have a burden that is negligible: the burden is mainly caused by the connection

wires. If high test currents are to be generated, use connection wires with a suitable cross section: 10

sq. mm for 40 to 100 A tests (short time); 2.5 sq. mm. for lower currents. There are two possible

situations:

DOC. MIE12093 Rev. 1 Page 12 of 52

.. Power is not enough; the desired test current cannot be adjusted. If this occurs at high currents, the

problem is that the burden is too high; the solution is either shortening wires or increasing their

cross section (or both).

.. Power is too much: the desired current is reached with a little movement of knob (6). This is the

case with low test currents. If the knob movement is less than 1/5th of its span, it is possible

There are two ranges available: 250 V at 300 W continuous (full power); 57 V at 60 W continuous

(reduced power). The default at power-on is full power; if 57 V are enough, for a better adjustment,

reduce the power as follows.

TEST CONTROL > TEST POWER (Power) ESC

. Adjust the output voltage to the desired value with knob (6).

. Connect the relay to be tested to sockets (60). Check that the adjusted voltage does not drop as

you connect the relay; else, this would mean that T-1000 is overloaded (or that you are connecting

to a live wire). In this situation, remove the cause of error and connect again.

1.5 DC VOLTAGE GENERATION FROM MAIN OUTPUT

If the current of 3.5 A is exceeded on main DC voltage output, the generation is interrupted, and the

operator is warned by an alarm message.

This generator serves for the test of timers and all devices that are driven by a DC voltage. The

auxiliary DC voltage generator cannot be used to this purpose as it is continuously generated: no

time measurement can be performed. To this purpose, act as follows.

. At first, be sure that the main control knob (6) is turned (rotated) to the zero position (complete

counter-clockwise).

. Power-on T-1000.

. Select by the push-button (57) the measurement on output sockets (61): the LED turns on; the DC

voltage value is displayed.

. There are two ranges available: 300 V at 300 W continuous (full power); 68 V at 60 W continuous

(reduced power). The default at power-on is full power; if necessary, reduce the power as follows.

TEST CONTROL > TEST POWER (Power) ESC

. Adjust the output voltage to the desired value with knob (6).

. Connect the relay to be tested to sockets (61). Check that the adjusted voltage does not drop as

you connect the relay; else, this would mean that T-1000 is overloaded (or that you are connecting

to a live wire). In this situation, remove the cause of error and connect again.

1.6 AC VOLTAGE GENERATION FROM THE AUXILIARY OUTPUT

The auxiliary AC voltage is protected by an electronic circuit that stops the voltage generation and

opens the connection to outputs socket in case of overload (short circuit included). In case of

intervention, an alarm message is displayed. Via the control knob the operator can reset the alarm

and close the relay to restore operation.

The auxiliary AC voltage is also protected by a thermo switch that intervenes in case of overheating. In case of intervention, an alarm message is displayed.

The auxiliary AC voltage is used to test relays that need voltage and current at the meantime. In this

situation, the voltage is continuously generated; usually, it is adjusted to the nominal value, and it is

DOC. MIE12093 Rev. 1 Page 13 of 52

not changed during all tests. It is possible to phase shift the current with respect to voltage;

selections are the following.

. Power-on T-1000: the AC voltage value is displayed.

. There are three ranges available: 65; 130 or 260 V AC; the power is 30 W continuous; 40 W peak

for 1 minute. For increased power and accuracy, it is better to select the range that is closest to the

value to be generated. The default at power-on is 65 V; if necessary, select the desired range. The

operating mode is pre-selected as Fault: do not change it. Do not change also the pre-selected

frequency, as Locked to mains. Last, set the desired current phase angle; however, to perform this,

T-1000 must be ON, and some current must circulate. Selections are performed as follows.

AUX VAC/VDC > Aux Vac control > Range > (Range) RET

Phase > Reference: current > (Phase) ESC

This performed, adjust the voltage to the desired value with knob (20). Eventually, connect the relay

to be tested to sockets (62). Check that the adjusted voltage does not change or the overload

message pops up as you connect the relay; else, this would mean that T-1000 is overloaded (or that

you are connecting to a live wire). In this situation, remove the cause of error and connect again

(reset the alarm if it popped up).

Execute the test, modifying the phase angle as necessary.

This output is also used for the test of voltage relays, frequency relays, synchronism relays;

frequency rate of change relays. In these instances, it is necessary to use the Pre-fault + Fault

selection. This feature allows adjusting two different values: the pre-fault voltage, that simulates the

situation prior to fault, and the fault voltage.

The pre-fault voltage adjustment is performed by the control knob, while knob (20) adjusts the fault

value. Voltage output selection is automatic: pre-fault voltage with test stopped; fault voltage with

test started. The switch from a value to the other one is performed without falling to zero. The main

current or voltage is generated at the zero crossing; the fault one is generated at the meantime of

main voltage or current. The selection of the reference is performed automatically, following the

selection of main output measurement. If the main DC voltage is selected the reference is taken on

the main AC voltage.

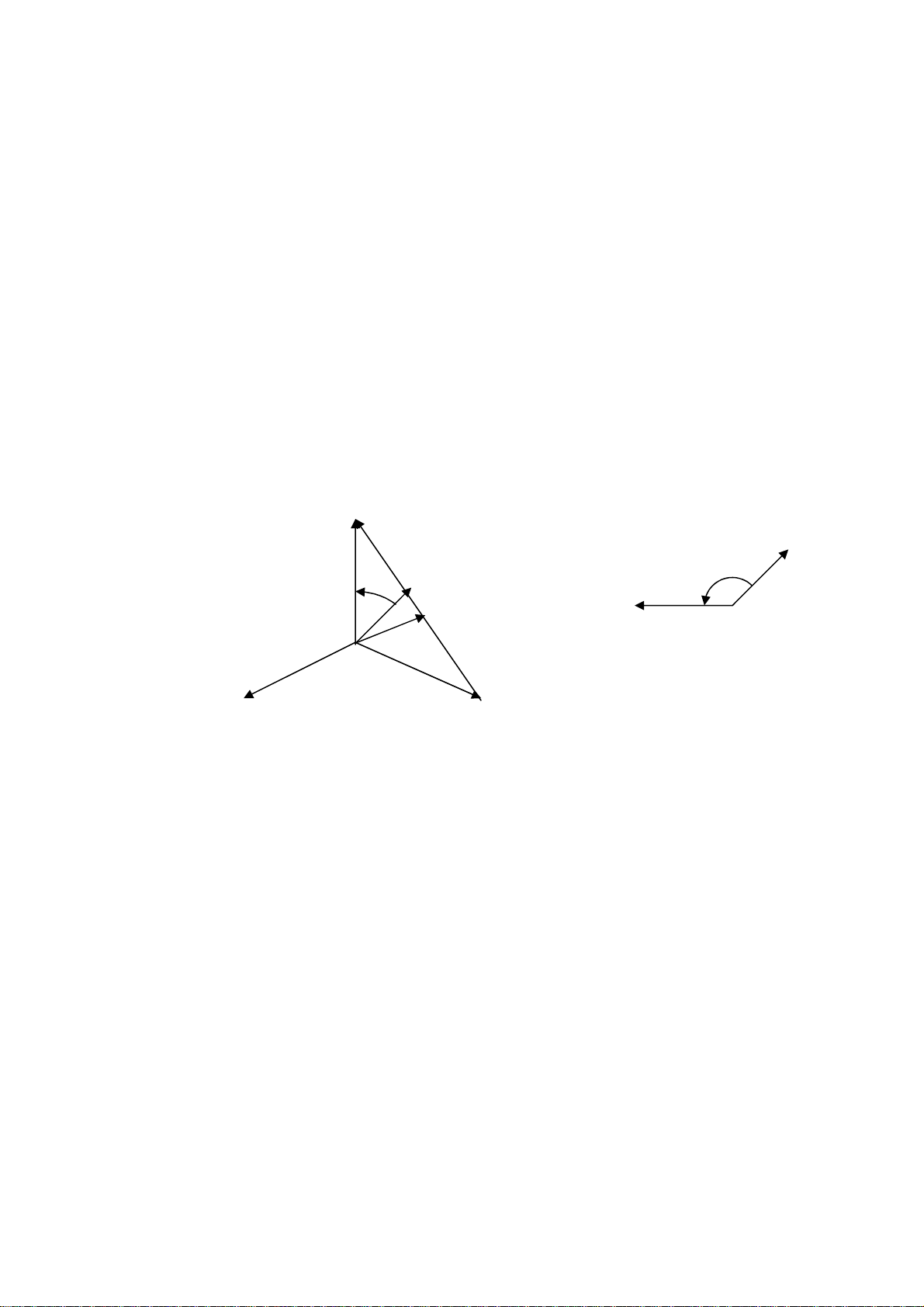

MAIN AC CURRENT

(MAIN AC VOLTAGE)

AUXILIARY

VOLTAGE

TEST START

The Pre-fault + Fault selection is performed as follows.

AUX VAC/VDC > Aux Vac control > Mode > Pre-fault+Fault > Pre-fault amplitude ESC

DOC. MIE12093 Rev. 1 Page 14 of 52

Once the nominal voltage is adjusted to the pre-fault value, it is possible to change the amplitude

(V, SYN relays) or frequency (F, SYN relays), or angle (SYN relays: in this instance, the angle is

referred to V main rather than to I main) or frequency rate of change (dF relays) of the fault voltage.

The pre-fault (nominal) frequency is always the mains one; the fault one is adjusted by the control

knob, in the range 40 Hz to 500 Hz. Switching from nominal frequency to fault frequency is

performed without altering the output voltage amplitude and phase. The frequency adjustment is

performed as follows.

AUX VAC/VDC > Aux Vac control > Frequency > Adjust > (Frequency value) ESC

The angle adjustment is performed as explained above; the difference is that the adjustment is

applied only when T-1000 is ON; with the instrument OFF, the pre-fault voltage is normally in

phase with the current. It is also possible to phase shift the pre-fault voltage with respect to the fault

voltage. This parameter is necessary during the test of distance relays, when phase to phase faults

are simulated: as test starts, the auxiliary voltage changes amplitude and phase with respect to the

pre-fault value.

V1 PRE-FAULT

V1 FAULT

FAULT ANGLE

V1 FAULT

PRE-FAULT ANGLE

I1 FAULT

V2 V3

The pre-fault angle adjustment is performed as follows.

AUX VAC/VDC > Aux Vac control > Mode > Pre-fault+Fault > Phase (phase) ESC

This angle is referred to the fault voltage; so, for its adjustment is not necessary to have T-1000 ON.

Last, it is possible to test frequency rate of change relays, by setting both the starting frequency, as

before, and the frequency ROC range, with range from ± 0.01 to ± 99.99 Hz/s. The frequency

change stops at 40 or 70 Hz. The frequency ROC adjustment is performed as follows.

AUX VAC/VDC > Aux Vac control > Frequency > Adjust > Frequency ROC (ROC) ESC

As test starts, the frequency goes to the pre-set frequency, and from that value starts increasing or

decreasing with the pre-set ROC.

1.7 DC VOLTAGE GENERATION FROM THE AUXILIARY OUTPUT

The auxiliary DC voltage is protected by a current limiter. The user notices the low voltage and

removes the overload. The fuse protects the case of counter-feed.

DOC. MIE12093 Rev. 1 Page 15 of 52

The second auxiliary generator can be used to supply the auxiliary DC voltage for the relay to be

tested. To this purpose, the voltage is continuously available at sockets (63). Use this generator as

follows.

. Power-on T-1000: the DC voltage value is displayed.

. There are two ranges available: 130 or 240 V DC; the power is 90 W. For increased power and

accuracy, it is better to select the range that is closest to the value to be generated. The default at

power-on is 130 V; if necessary, select the desired range as follows.

AUX VAC/VDC > Aux Vdc control > (Range) ESC

This performed, adjust the voltage to the desired value. Eventually, connect the relay to be tested to

sockets (63). Check that the adjusted voltage does not change as you connect the relay; else, this

would mean that T-1000 is overloaded (or that you are connecting to a live wire). In this situation, if

it is not a connection error, it is possible to reduce the voltage until the voltage does not drop: relays

tolerate a wide range of DC supply voltages.

1.8 AUXILIARY CONTACT

- The auxiliary make and break contact, closes (opens) at test start, and opens (closes) as current is

cut off after the STOP input is sensed. Maximum time error between current and make/break

contact: 1 ms.

- The contact can also be used to simulate the circuit breaker state. Maximum error between current

start after the trip command and make/break: 1 ms.

- Possibility to delay the auxiliary contact switch with respect to test start. Delay range: from 0 to

99.99 s.

- Contacts range: 5 A; 250 V AC; 120 V DC

1.9 THE TIMER

Timer inputs are protected against wrong selections. If the voltage free input is selected and a

voltage is applied less than 250 V ac or 275 V DC, circuits will not be damaged.

The auxiliary contact is protected by a re-triggering fuse: if it trips, remove the source of the

problem and then restore it.

Characteristics of Start and Stop inputs:

. Inputs do not have any common point, and are opto-coupled from the instrument at 1.35 kV AC;

. Inputs connection: two banana sockets per input;

. Type of input: either clean or under voltage; maximum input: 250V a.c or 275 V DC;

. Inputs may be independently selected as Normal Open or Normal Close or Edge: the latter means

that the timer is stopped by any transition;

. Selections are displayed on the front panel by 10 dedicated lights;

. For both inputs, when the input is closed or with voltage an LED turns on;

. When the relay intervenes the TRIP light turns on.

DOC. MIE12093 Rev. 1 Page 16 of 52

Internal

External

Clean-voltage

N.O.-N.C.-Edge Count

Internal

External

Clean-vo

ltage N.O.-N.C.-Edge

Unit

s (default)

cycles

Count

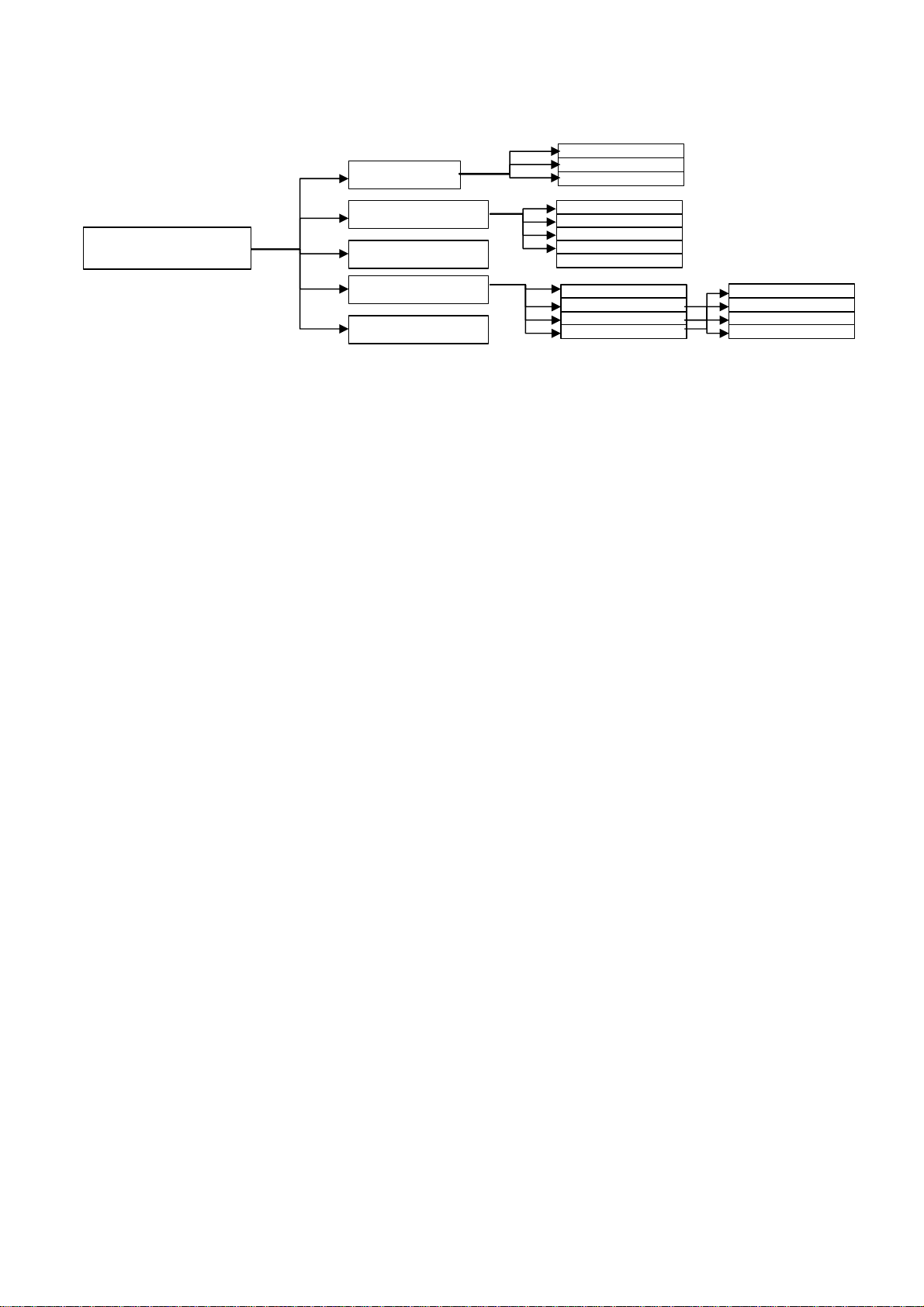

The timer offers a number of possible selections to permit many different types of testing depending

on the selection by the operator. The following flow shows all possible selections.

Start

TIMER START/STOP

Stop

Timer

The default selection is the following.

. Timer start: internal; as test is started. External start allows synchronizing more T-1000.

. Timer stop: external. Internal stop means that the timer is stopped as T-1000 goes OFF.

With this selection, the timer meters the elapsed time between START and STOP. Alternative

selections:

.. Elapsed time plus the duration of STOP input; the selection is performed as follows:

TEST CONTROL > Test mode > Trip + pulse time ESC

.. Impulse counting:: this mode is foreseen for the test of energy meters. Maximum input frequency:

10 kHz; voltage threshold can be set as for tripping. It is possible to select this mode via menu, and

to set the number of impulses; the test set measures the time corresponding to the set number of

complete periods applied to STOP input after ON and during all generation, and measures the

corresponding energy (if selected). The selection is performed as follows:

TIMER START/STOP > STOP > External > Count > (number of counts) ESC

If the count is selected on START, time measurement will be performed after the set number of

counts has expired: this serves to pass the start-up of the energy meter.

Input thresholds. When the contact has voltage applied, two thresholds can be selected. The low

setting applies to nominal voltages of 24 and 48 V; the high setting to 110 V up. The selection is

performed as follows:

TIMER START/STOP > STOP > External > Clean-voltage > Voltage threshold ESC

Time can be metered as seconds or cycles (second is the default). The selection is performed as

follows:

TIMER START/STOP > Units > s or Cycles ESC

1.10 FINDING RELAY THRESHOLDS

1.10.1. Introduction

There are different types of relay characteristic curves: time depending or independent; single

threshold or multiple thresholds. Let us consider the following example, that applies to an

overcurrent relay with a time-dependent curve and one (or more) time-independent threshold. Of

this relay we want to find and save trip and drop-off I> and I>> thresholds.

Loading...

Loading...