Page 1

®

iQ

200 Sprint ™

Service Manual

Iris Diagnostics, a Division of Iris International, Inc.

Page 2

Table of Contents

1 - Introduction

Intended Use ...................................................................................................... 1-2

How to use this Manual ......................................................................................1-2

Precautions and Warnings .................................................................................1-4

Notes .................................................................................................................. 1-4

Cautions .............................................................................................................1-4

Warnings ............................................................................................................1-4

Biological Warning..............................................................................................1-4

Warranty.............................................................................................................1-5

Limitation of Liability........................................................................................... 1-6

Use of Third Party Computer Products ..............................................................1-6

Iris Diagnostics Contact Information...................................................................1-7

2 - Installation Procedures

Installation Requirements...................................................................................2-2

Space Requirements..........................................................................................2-2

Workstation ........................................................................................................2-2

Location.............................................................................................................. 2-2

Requirements .....................................................................................................2-2

Installation ..........................................................................................................2-2

Shipping Cartons................................................................................................2-3

Instrument Carton...............................................................................................2-3

Starter Kit A Carton ............................................................................................ 2-4

Starter Kit B Carton (needs refrigeration)...........................................................2-4

Optional .............................................................................................................. 2-4

Installation ..........................................................................................................2-5

Precautions ........................................................................................................2-5

Connecting the Sampler.....................................................................................2-6

Adjust the Height of the Analyzer .......................................................................2-6

Adjust Sampler ...................................................................................................2-7

Installing the Lamina Container..........................................................................2-7

Connecting the Drain Tubing..............................................................................2-7

Computer Connections.......................................................................................2-8

iQ200 Rear Panel SIC Connection Configurations ............................................2-9

iQ200 / AX-4280 Connection Bridge Instructions............................................. 2-10

Optional Load/Unload Station Installation ........................................................ 2-15

Load Station - iQ200 Connection ..................................................................... 2-15

Load Station - AX-4280 Connection.................................................................2-17

Unload Station..................................................................................................2-19

Startup..............................................................................................................2-21

Run Focus ........................................................................................................ 2-22

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1

Page 3

Table of Contents

Run Calibration Rack .......................................................................................2-22

Run Control Rack .............................................................................................2-22

Verify Load/Unload and Bridge Connections ...................................................2-22

Preparation for Starting Operation ...................................................................2-22

Perform Setup .................................................................................................. 2-22

3 – Components

Sample Transport Mechanism ...........................................................................3-3

Sampler # 700-3006...........................................................................................3-3

Specimen Tube Detector # 700-3725 ................................................................3-4

Barcode Reader # 700-3315 ..............................................................................3-5

Specimen Presentation Assembly # 700-3700 ..................................................3-6

Crash Detect Function........................................................................................3-6

Waste/Rinse Well # 700-3830............................................................................3-7

Diaphragm Pumps..............................................................................................3-8

Air Pump # 700-3877 .........................................................................................3-8

Waste Pump # 700-3809....................................................................................3-8

Rinse Pump # 700-3874.....................................................................................3-8

Fill Pump # 700-3874 ......................................................................................... 3-8

Peristaltic Pumps # 700-3820 ..........................................................................3-10

Cannula Pump..................................................................................................3-10

Lamina Pump ................................................................................................... 3-10

Evacuation Pump ............................................................................................. 3-10

Pump Cover Closed and Cassette-In-Place Detection ....................................3-10

Lamina Tank # 700-3784 .................................................................................3-12

Air Tank # 700-3802.........................................................................................3-13

Valves...............................................................................................................3-14

Solenoid Valves................................................................................................3-14

Drain Valve # 700-3844....................................................................................3-14

Evacuation Bypass Valve # 700-3843..............................................................3-14

Lamina Bypass Valve # 700-3842....................................................................3-14

Cannula Bypass Valve # 700-3881 ..................................................................3-14

Pipettor Bypass Valve # 700-3880 ...................................................................3-14

Air Valves ......................................................................................................... 3-15

Air Mix Valve # 700-3887 .................................................................................3-15

Air Charge Valve # 700-3888 ...........................................................................3-15

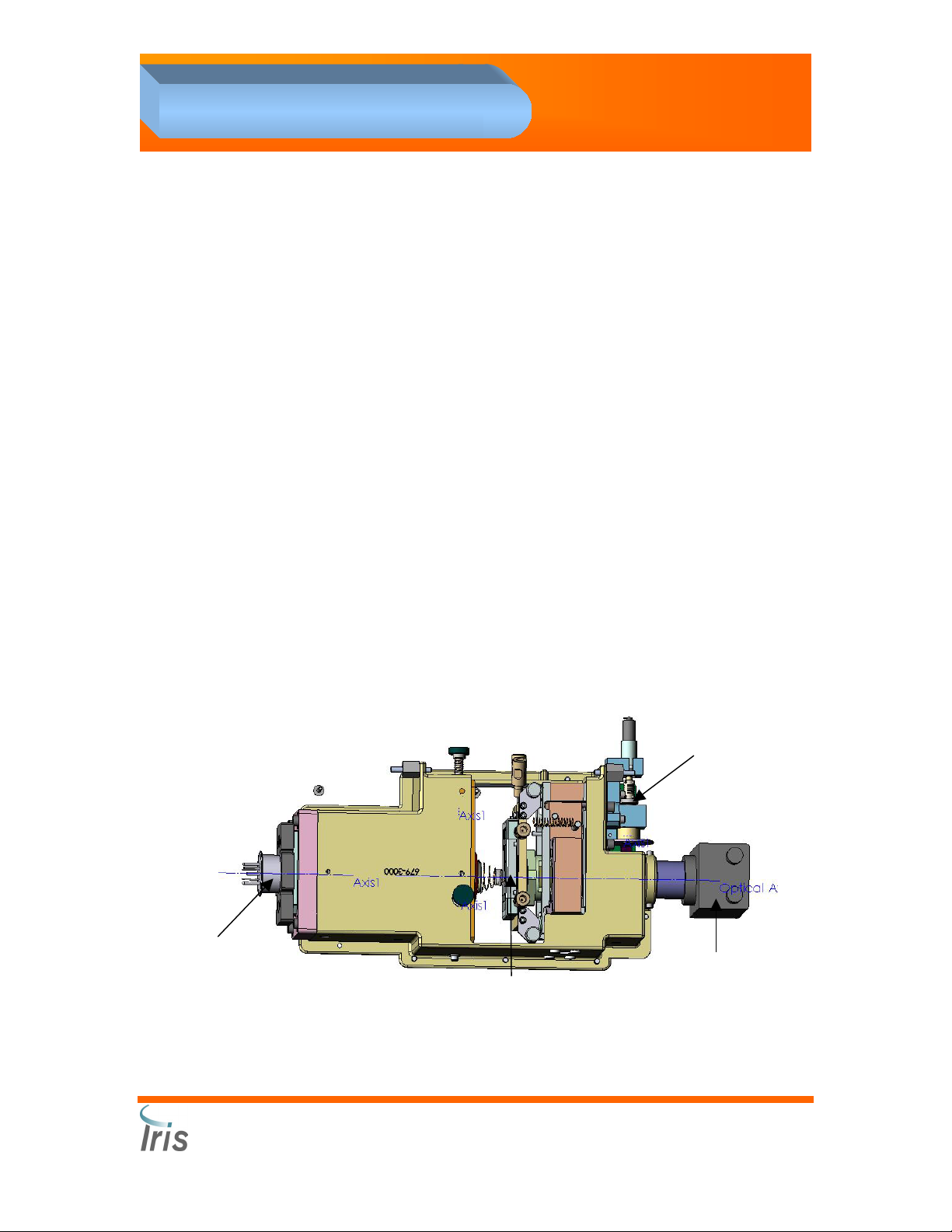

Optical Bench Assembly #700-3500 ................................................................ 3-16

Flow Cell # 525-3077 .......................................................................................3-17

Strobe Light # 065-0059...................................................................................3-17

CCD Camera # 700-3565.................................................................................3-17

20 x Objective # 220-3009 ...............................................................................3-17

Auto Focus System # 700-3505 .......................................................................3-17

Power System Assembly # 230-3000 ..............................................................3-18

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2

Page 4

Table of Contents

Cooling Fans # 700-3892 & 700-3412 .............................................................3-18

Fuses and Visible LEDs ...................................................................................3-18

Backplane Fuses and LEDs ............................................................................. 3-19

PCBA Summary ...............................................................................................3-21

Cardcage..........................................................................................................3-22

High Level Control Board (HLCB), # 101-5000 ................................................3-22

Motor/Scanner Control Board (MSCB), # 101-5001.........................................3-22

DC Valve Board (DCVB), # 101-5043 ..............................................................3-22

Stepper/Scanner/Motor Board (SSMB), # 101-5007........................................3-23

Backplane # 101-5003 .....................................................................................3-23

Signal Interface Concentrators (SICs)..............................................................3-24

Power SIC # 101-5020 .....................................................................................3-24

Pump SIC #101-5020.......................................................................................3-25

FSV SIC # 101-5045 ........................................................................................ 3-25

SPA SIC # 101-5004 ........................................................................................3-27

SPA SIC Visible LEDs......................................................................................3-27

SPA SIC Push-Button Switches .......................................................................3-27

OBA SIC #101-5053.........................................................................................3-28

Do-All SIC # 101-5046 .....................................................................................3-29

Rear Panel SIC # 101-5030 ............................................................................. 3-30

STM SIC # 101-5014........................................................................................3-30

Other PCBAs....................................................................................................3-30

ESN Board # 101-5049 .................................................................................... 3-30

Lamina ESN # 101-5048 ..................................................................................3-30

FITD PCBA # 101-5041 ...................................................................................3-30

SM Status Board PCBA # 101-5032 ................................................................3-31

STD PCBA # 101-5034 .................................................................................... 3-31

Pressure Transducer Board #101-5016 ...........................................................3-31

SPA Optical Board # 101-5052 ........................................................................ 3-31

LED Visual Indicators ....................................................................................... 3-31

4 – Adjustments

Accessing the Service Screen............................................................................4-3

Calibration Table ................................................................................................ 4-4

Calibration Auto-Sets .........................................................................................4-4

Sampler Calibration............................................................................................4-6

Material required ................................................................................................4-6

Procedure...........................................................................................................4-6

Specimen Tube Detector Alignment...................................................................4-7

Material required ................................................................................................4-7

Procedure...........................................................................................................4-7

Specimen Tube Detector Calibration .................................................................4-8

Material required ................................................................................................4-8

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 3

Page 5

Table of Contents

Procedure...........................................................................................................4-8

STD Verification Procedure................................................................................4-9

Specimen Presentation Assembly (SPA) and Waste/Rinse Well Calibration ..4-10

Material required ..............................................................................................4-10

Procedure.........................................................................................................4-10

Waste Well Positioning.....................................................................................4-10

Test Tube Centering Position...........................................................................4-11

Test Tube Depth Positioning ............................................................................ 4-11

Waste Well Depth Positioning ..........................................................................4-12

Lamina Consumption Adjustment ....................................................................4-12

Air Pressure Calibration ...................................................................................4-13

Material required ..............................................................................................4-13

Procedure.........................................................................................................4-13

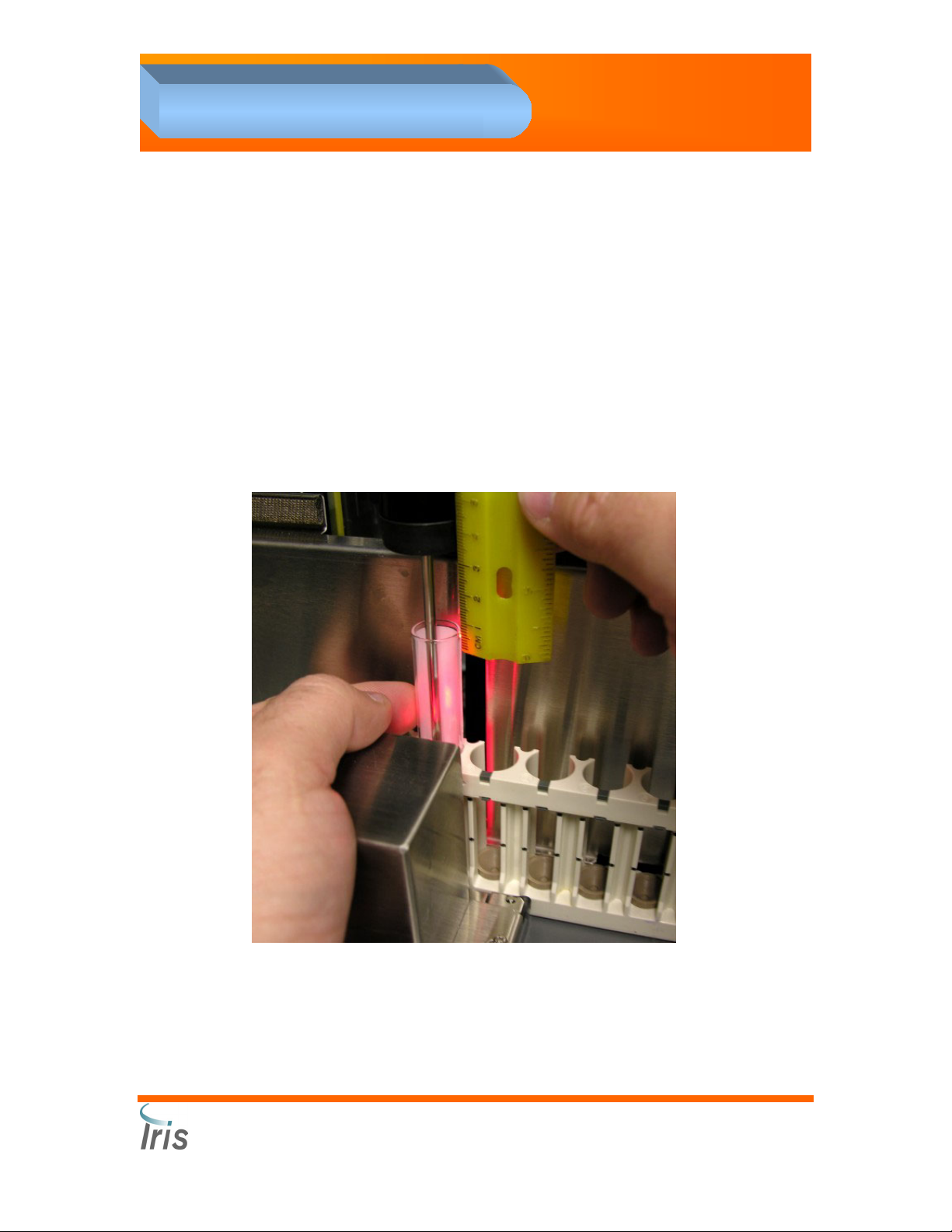

Barcode Reader Alignment .............................................................................. 4-14

Material Required .............................................................................................4-14

Procedure.........................................................................................................4-14

Prepare Barcode Reader Connections ............................................................4-14

Load the Alignment Tool ..................................................................................4-15

Perform barcode alignment ..............................................................................4-15

Validation..........................................................................................................4-18

Collimation........................................................................................................4-19

What is a Collimation?......................................................................................4-19

Condenser Alignment.......................................................................................4-19

Run Auto Focus................................................................................................4-20

Flow Cell Replacement ....................................................................................4-21

Flow Cell Removal ...........................................................................................4-21

Flow Cell Installation ........................................................................................4-21

Flow Cell Lateral Adjustment............................................................................4-22

Flow Cell Tilt Adjustment..................................................................................4-23

5 - Service Application Software

Accessing the Service Screen............................................................................5-3

Startup................................................................................................................5-3

Establishing Link ................................................................................................5-4

Live Operation ....................................................................................................5-5

Tree View Pane..................................................................................................5-5

Commands .........................................................................................................5-6

Preset Moves .....................................................................................................5-6

Sensors ..............................................................................................................5-6

Register 0x0A.....................................................................................................5-7

Calibration Table ................................................................................................ 5-7

Calibration Auto-Sets .........................................................................................5-7

Sequences .........................................................................................................5-7

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 4

Page 6

Table of Contents

Fluid Schematic Pane ........................................................................................5-8

Diaphragm Pumps..............................................................................................5-8

Peristaltic Pumps................................................................................................5-8

3-Way Valves ..................................................................................................... 5-9

2-Way Valves ..................................................................................................... 5-9

Motors ................................................................................................................5-9

Tube Connectors..............................................................................................5-10

Other Regions of Interest ................................................................................. 5-10

Menu Bar..........................................................................................................5-10

File Menu..........................................................................................................5-10

View Event Log ................................................................................................5-10

Show Versions Report......................................................................................5-11

Exit ...................................................................................................................5-11

Edit Menu ......................................................................................................... 5-11

View Menu........................................................................................................5-11

Toolbar .............................................................................................................5-11

Status Bar.........................................................................................................5-12

Polling...............................................................................................................5-12

Video ................................................................................................................5-12

Record Video Statistics .................................................................................... 5-12

Terminal ...........................................................................................................5-12

Jog Menu..........................................................................................................5-13

Status Bar.........................................................................................................5-13

Current Message Status...................................................................................5-13

Link Status........................................................................................................5-14

“Starting ASTM”................................................................................................5-14

“Establishing link (may take a minute)” ............................................................5-14

“Could not establish link”..................................................................................5-15

Troubleshooting Failure to Establish Link ........................................................5-15

“Connection established”..................................................................................5-15

“Sending initialization messages”..................................................................... 5-16

“Sending initial query messages” ..................................................................... 5-16

“Sending query messages” ..............................................................................5-16

“Idle” .................................................................................................................5-16

Caps Lock Status .............................................................................................5-16

Num Lock Status ..............................................................................................5-16

Scroll Lock Status.............................................................................................5-16

Sequences & Sensor Identifications for Troubleshooting.................................5-17

Master (Master Controller) ...............................................................................5-17

Sequences .......................................................................................................5-17

Level sensors ...................................................................................................5-17

SPA .................................................................................................................. 5-17

Pumps/Evacuation pump/Sensors ...................................................................5-18

STM..................................................................................................................5-18

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 5

Page 7

Table of Contents

Sensors ............................................................................................................5-18

FBA ..................................................................................................................5-18

Pumps/Sheath pump/Sensors..........................................................................5-18

Pumps/Cannula pump/Sensors........................................................................5-18

Program Operation...........................................................................................5-19

Frequently Asked Questions (FAQ) .................................................................5-19

Why Does a Sensor Display the Wrong Value?...............................................5-19

Which Controller Does Component X (Pump, Valve, etc.) Belong To? ...........5-19

What Are the Communication Addresses of the Major System Components? 5-20

What Should I Do If the Service Application Appears to Hang?.......................5-20

Service Tree .....................................................................................................5-21

Master ..............................................................................................................5-21

SPA Motors ......................................................................................................5-22

SPA Pumps and Valves ...................................................................................5-23

FBA Pumps and Sequences ............................................................................5-25

STM Motors 1...................................................................................................5-26

STM Motors 2, Sensors, Calibration Table and Sequences ............................5-27

OBA..................................................................................................................5-28

Versions 1 ........................................................................................................5-29

Versions 2 ........................................................................................................5-30

6 - Troubleshooting

Bypassing Error Condition..................................................................................6-2

Decoding the Valves field in Valve Error Reports ..............................................6-2

Iris Diagnostics Contact Information...................................................................6-2

Troubleshooting Guide ....................................................................................... 6-3

System locked up ...............................................................................................6-3

Autofocus failed.................................................................................................. 6-3

IQ 200 fails to go to Standby .............................................................................. 6-4

ID errors .............................................................................................................6-4

Illumination/Sequential errors.............................................................................6-5

Valve failure to open or close .............................................................................6-5

System does not go into Standby mode.............................................................6-5

Samples take more than 60 secs to process and complete...............................6-5

Positive control failure ........................................................................................6-5

Calibration rack failed......................................................................................... 6-5

Non uniform flow in Runfile ................................................................................6-6

Inconsistent cell count from run to run in Runfile ...............................................6-6

SP-FLI (spatial flow index) is high in all Runfiles................................................6-6

SP-KSP are high in all Runfiles..........................................................................6-6

Bubbles are present in fluid system ...................................................................6-6

Waste well overflow............................................................................................6-6

Event Log Error Messages.................................................................................6-7

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 6

Page 8

Table of Contents

7 - Electronics

Electronics..........................................................................................................7-2

General Functions .............................................................................................. 7-2

Cabling Diagram Overview.................................................................................7-3

View of Backplane inside Cardcage...................................................................7-4

Rear view of Backplane -- Fuses and Connections to Internal parts of Microscopy

Module................................................................................................................7-5

Addresses and Summary ................................................................................... 7-6

Hardware Bit Assignments and Details ............................................................7-11

Hardware Assignment Cross Reference ..........................................................7-21

ESN I2C Addresses .........................................................................................7-27

8 - Schematics

998-3006 SM SMCS Assemblies Block Diagram...............................................8-3

700-3800 System Fluid Assembly......................................................................8-4

Master Controller State records .........................................................................8-5

SPA State records............................................................................................8-21

FBA State records ............................................................................................ 8-25

STM State records ...........................................................................................8-27

9 - Preventive Maintenance

Material...............................................................................................................9-2

Semi-Annual PM kit Part Number 799-3050 ......................................................9-2

Annual PM Kit Part Number 799-3051 ..............................................................9-2

Cleaning .............................................................................................................9-3

Instrument Clean Up ..........................................................................................9-3

Fluidics Clean Up ............................................................................................... 9-3

Rinse/Waste Well Clean Up ...............................................................................9-3

Air blow...............................................................................................................9-3

Computers Clean Up..........................................................................................9-3

Laser Printer.......................................................................................................9-3

Fluidics ...............................................................................................................9-4

Liquid Waste.......................................................................................................9-4

Peristaltic pump cassette replacement...............................................................9-4

Tubing replacements..........................................................................................9-4

Adjustment verification ....................................................................................... 9-5

Sampler Rack alignment .................................................................................... 9-5

Specimen Tube Detector verification .................................................................9-5

Barcode Reader alignment verification ..............................................................9-5

SPA alignment verification .................................................................................9-5

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 7

Page 9

Table of Contents

Fluidic inspection................................................................................................9-6

Autofocus run .....................................................................................................9-6

Optical Bench Verification .................................................................................. 9-6

Replenish Consumables ....................................................................................9-6

Performance verification.....................................................................................9-7

Software ............................................................................................................. 9-7

Calibration run .................................................................................................... 9-7

Control run..........................................................................................................9-7

Documenting the Preventive Maintenance.........................................................9-7

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 8

Page 10

1. Introduction

1

Introduction

Intended Use.................................................................................................................. 1-2

How to use this Manual..................................................................................................1-2

Precautions and Warnings ............................................................................................. 1-4

Notes ..........................................................................................................................1-4

Cautions .....................................................................................................................1-4

Warnings ....................................................................................................................1-4

Biological Warning...................................................................................................... 1-4

Warranty.........................................................................................................................1-5

Limitation of Liability.......................................................................................................1-6

Use of Third Party Computer Products ..........................................................................1-6

Iris Diagnostics Contact Information ..............................................................................1-7

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-1

Page 11

1. Introduction

Intended Use

This Service Manual is intended for the

generation Automated Urine Microscopy Analyzer – HVL (High Volume

Laboratory).

There are two HVL configurations:

• The

• The

These instruments have a new fluidic design, the capability of connecting

Load and Unload stations, and improved error reporting.

The

vitro diagnostic use device composed of the

Microscopy Analyzer (

the AUTION MAX™ AX-4280 Automated Urine Chemistry Analyzer (AX-

4280), and a workstation. The

complete routine urinalysis profile, including urine test strip chemistry

panel, specific gravity, color, clarity, and microscopic analysis, providing

quantitative or qualitative counts of formed elements, such as cells, casts,

crystals, and organisms.

Optionally, the

as a stand-alone device for microscopic analysis, and the results from the

iQ

This manual is intended to be used by Iris Diagnostics trained personnel.

®

iQ

®

200 can be combined with other urine chemistry results.

®

iQ

200 Sprint and the

®

iQ

200 Sprint can process 101 samples per hour

iQ

200 Sprint™ Automated Urinalysis System (

nd

200 2

generation can process 60 samples per hour

iQ

®

iQ

200), connected physically and electronically to

®

iQ

200 System is used to automate the

®

iQ

200 Automated Urine Microscopy Analyzer can be used

®

iQ

200 2

®

iQ

200 System) is an in-

®

200 Automated Urine

nd

How to use this Manual

References are made to other sections within the Manual. In order to

avoid searching for a specific document or section, electronic hyperlinks

have been created to let you jump to other locations and to give you

immediate access to related information.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-2

Page 12

1. Introduction

To follow a link:

1. Select the hand tool

2. Links are indicated in the following manner:

• The text is colored blue and underlined. Example: Iris Diagnostics

Contact Information.

3. Position the pointer over the linked area on the page until the pointer

changes to the hand with a pointing finger . Then click the link.

4. To return to the

previous section, click

on the Go to Previous

View button.

5. The Bookmark pane,

located on the left side

of the screen, can be

used as a “linked” table

of contents. Click on

the + or - sign located

next to the title to

expand or collapse the

selection for a

bookmark. Clicking on

a bookmark will take you automatically to the starting page of the

selected section.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-3

Page 13

1. Introduction

Precautions and Warnings

The Manual includes information and warnings that must be observed by

the operator to ensure safe operation of the system. Important messages

are highlighted with borders and special icons identifying the type of

message enclosed.

There are four types of messages.

Notes

NOTE: Highlights important facts, gives helpful information and tips, and

clarifies procedures.

Cautions

CAUTION: Electrical caution! Unplug before handling.

CAUTION: If any liquid is spilled onto the Sampler, wipe the area clean

before testing. Leaving the spill may cause crystals to form and block the

movement of the sample racks.

Warnings

WARNING: Identifies potentially hazardous situations that could result in

serious injury to laboratory personnel.

Biological Warning

WARNING: Wear protective gloves to prevent exposure to pathogens.

Discard contaminated materials according to applicable regulations.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-4

Page 14

1. Introduction

Warranty

Iris Diagnostics, a subsidiary of Iris International, (Iris) warrants that the

products manufactured by it, its divisions or subsidiaries and sold

hereunder shall be free from defects in material and/or workmanship,

under normal use and service, for the period expiring twelve (12) months

from the completion of installation under standard procedure by Iris

Diagnostics or an authorized Iris Diagnostics distributor, or upon

Purchaser’s signature on Iris Warranty/Acceptance form, or eighteen (18)

months from shipment, whichever occurs first. Iris Diagnostics makes no

warranty whatsoever regarding products manufactured by persons other

than Iris Diagnostics, its Divisions or Subsidiaries and Purchaser’s sole

source of warranty therefore, if any, is the original manufacturer’s

warranty.

No warranty extended by Iris Diagnostics shall apply to any products

which have been modified, altered, or repaired by persons others than

those authorized or approved by Iris or to products sold as “used.”

Iris Diagnostics’ obligation under this warranty is limited SOLELY to the

repair or replacement, at Iris Diagnostics’ option, of defective parts,

F.O.B. warehouse or local Iris office, or as otherwise specified by Iris.

Repairs or replacement deliveries shall not interrupt or prolong the term of

this warranty. Iris Diagnostics warranty does not apply to consumable

materials, except as specially stated in writing, not to products or parts

thereof manufactured by Purchaser.

This limited warranty is made on condition that immediate written notice

of any defect be given to Iris Diagnostics and that Iris inspection reveals

that the Purchaser’s claim is valid under the terms of this warranty.

Iris Diagnostics makes no warranty other than the one set forth herein or

that which may be provided in a separate warranty covering the

applicable product category. Such limited warranty is in lieu of all other

warranties, expressed or implied, including but not limited to any

expressed or implied warranty of merchantability or fitness for particular

purposes and such constitutes the only warranty made with respect to the

products.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-5

Page 15

1. Introduction

Limitation of Liability

Iris Diagnostics shall not be liable for any loss of use, revenue or

anticipated profits, or for any consequential or incidental damages

resulting from the sale or use of the products.

Use of Third Party Computer Products

Iris Diagnostics does not recommend that the workstation provided as a

®

iQ

functional part of the

®

iQ

200 System be employed for performing any software or hardware-

based applications other than those specifically furnished to operate and

support the Iris instrument system, or those recommended and offered by

Iris Diagnostics specifically as accessories or enhancements for the Iris

instrument system. No other third party application software should be

installed in these microcomputers in addition to those provided or

recommended by Iris Diagnostics, without the expressed approval of Iris

Diagnostics Technical Services, in order to avoid potential performance

and reliability problems which can result from incompatibility factors,

errors in use of such software, or software-based “viruses.”

Installation of such third party software, or non-approved electronic cards

or other devices, without advance Iris Diagnostics approval may affect the

terms of or void any Iris Diagnostics warranty otherwise in effect, covering

Iris Diagnostics supplied software and hardware on the microcomputers

and the overall performance and reliability of the entire Iris Diagnostics

instrument system.

200 Automated Urine Microscopy Analyzer or the

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-6

Page 16

1. Introduction

Iris Diagnostics Contact Information

Iris Diagnostics

A Division of Iris International, Inc.

9172 Eton Avenue

Chatsworth, CA 91311

USA

Telephone:

From U.S. locations (800) PRO-IRIS (776-4747)

From outside the U.S. +1-818-709-1244

Fax: +1-(818) 700-9661

e-mail: sales@proiris.com

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 1-7

Page 17

2. Installation Procedures

2

Installation

Procedures

Installation Requirements ..............................................................................................2-2

Space Requirements .................................................................................................. 2-2

Workstation.................................................................................................................2-2

Location......................................................................................................................2-2

Requirements .............................................................................................................2-2

Installation ..................................................................................................................2-2

Shipping Cartons ...........................................................................................................2-3

Instrument Carton.......................................................................................................2-3

Starter Kit A Carton ....................................................................................................2-4

Starter Kit B Carton (needs refrigeration) ...................................................................2-4

Optional ......................................................................................................................2-4

Installation......................................................................................................................2-5

Precautions.................................................................................................................2-5

Connecting the Sampler .............................................................................................2-6

Adjust the Height of the Analyzer ...............................................................................2-6

Adjust Sampler ...........................................................................................................2-7

Installing the Lamina Container..................................................................................2-7

Connecting the Drain Tubing...................................................................................... 2-7

Computer Connections...............................................................................................2-8

iQ200 Rear Panel SIC Connection Configurations.....................................................2-9

iQ200 / AX-4280 Connection Bridge Instructions.....................................................2-10

Optional Load/Unload Station Installation ................................................................2-16

Load Station - iQ200 Connection.......................................................................... 2-16

Load Station - AX-4280 Connection .....................................................................2-20

Unload Station ......................................................................................................2-24

Startup .........................................................................................................................2-27

Run Focus ................................................................................................................2-28

Run Calibration Rack................................................................................................2-28

Run Control Rack .....................................................................................................2-28

Verify Load/Unload and Bridge Connections............................................................2-28

Preparation for Starting Operation ...............................................................................2-29

Perform Setup....................................................................................................... 2-29

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-1

Page 18

2. Installation Procedures

Installation Requirements

Space Requirements

®

iQ

The

0.9m) height countertop of approximately 36 inches wide by 24 inches

deep (91cm by 61cm), with vertical clearance of at least 24 inches

(61cm).

With optional Load and Unload stations, the width requirement is 60

inches (147 cm.)

Workstation

The Workstation is composed of a desktop computer, video monitor,

keyboard and mouse requiring a suitable counter or desktop, providing

comfortable access and a good viewing angle. It is suggested that, if

possible, the WorkStation be placed in a work area, which can be semidarkened to increase screen display visibility and reduce glare.

The data connections are made between the

(and the AX-4280 and the WorkStation, if applicable) via the special

cables provided.

200 is a tabletop unit requiring free space on a standard (36 inch:

®

iQ

200 and the Workstation

Location

For most laboratories, the

area which can be used for preparation of urine tubes and sample racks.

All data transmissions from the

routed to the Workstation, which manages and controls all

communications to the Laboratory Information System (LIS) via serial

connections.

Requirements

The

nor frequency parameters are customer configurable. Uninterruptible

power supplies are recommended and available from Iris Diagnostics for

the

system operation during short power outages and brownouts. This allows

for an orderly shutdown of instruments without the loss of data.

Installation

The

Diagnostics.

®

iQ

200 is placed near an open benchtop work

®

iQ

200 (and the Ax-4280, if used) are

®

iQ

200 uses 90 to 240V AC, 50-60Hz input source. Neither voltage

®

iQ

200 and the Workstation (and the AX-4280 if applicable) to maintain

®

iQ

200 will be installed by a factory-trained representative from Iris

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-2

Page 19

2. Installation Procedures

Shipping Cartons

®

iQ

The

Instrument Carton

Item number Description Qty

800-3320

800-3322

700-3103 Printer

250-3082 Printer Cable 1

700-3120

210-3004

700-3101

700-3022

700-3008

700-3007

700-3781

700-3701

700-3702

250-3501

700-3011

200 is shipped in three cartons.

iQ

Computer Version 3.0

Flat Panel Monitor

Keyboard and Mouse

Sample Racks (1 Set of 9) 1

Calibrator Rack

Control/Focus Rack

iQ Lamina Cap & Filter

Drain Tubing

Lamina Tubing

Serial Cable, PC to Microscopy Module

Operators Manual CD

®

200 60/hour or

®

iQ

200 Sprint

TM

101/hour

1

1

1

1

1

1

1

1

1

1

1

1

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-3

Page 20

2. Installation Procedures

Starter Kit A Carton

Item number Description Qty

475-0047

475-0021

475-0003

660-0036

800-3211

®

iQ

200 Lamina

Iris Diluent

Iris System Cleanser

Culture Tube, 16x100 250 pack

®

iQ

200 Dilution Labels Package

Starter Kit B Carton (needs refrigeration)

Item number Description Qty

800-3104

800-3103

®

iQ

200 Control/Focus Set (four bottles)

®

iQ

200 Calibrator (four bottles)

1

1

1

1

1

1

1

Optional

Item number Description Qty

800-3810

800-3514

800-3515

800-3501

Load and Unload Set

Load Station (only)

Unload Station (only)

Ax-4280 Bridge Connection Kit

1

1

1

1

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-4

Page 21

2. Installation Procedures

Installation

To ensure safety, we advise you to read these installation instructions

very carefully and take all proper precautions.

Precautions

The entire unit weighs approximately 140 lbs (63.5k). The Load and

Unload Stations weigh 14 lbs (6.35) each. Choose a place to set up the

unit before completing its assembly.

If the unit must be moved, separate the Sampler from the analyzer before

moving. If these two units come apart while being carried, it may result in

injury or severe damage.

Always keep a distance of at least 2 inches (5 cm) between the rear of

the unit and the wall. If this distance is not maintained, the connecting

tubes and cables may overheat and / or be subjected to mechanical

stress.

Do NOT use power frequencies or voltage other than those specified in

this document. Connection to an inappropriate power source may

damage the instrument.

Make certain that the power supply for the

that provides power to no other instruments or appliances. If power is not

clean and steady, a UPS and/or power conditioner is recommended.

Do NOT disassemble or modify the unit. Doing so may cause injury

and/or instrument malfunction.

Place the unit on a stable and level surface free of vibration. Failure to do

so may cause injury or malfunction of the unit.

Do NOT place the unit where it may be affected by chemicals, corrosive gases

or electronic noise. Doing so may cause injury or malfunction of the unit.

Do NOT place the unit where it may be affected by water, direct sunlight

or draft. This may yield incorrect results, and the unit may be damaged.

Select a room to set up the unit where the temperature can be controlled

between 50

80%.

o

F (10oC) and 86oF (30oC), and humidity in a range of 20% to

®

iQ

200 is from a dedicated line

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-5

Page 22

2. Installation Procedures

Unpacking the Instrument

Carefully remove the instrument from the shipping container. Remove all

packing material from inside the instrument surrounding the SPA, the

microscope and the waste well.

Connecting the Sampler

In order to protect the Analyzer and Sampler from damage during

transport, each section is secured with tape. Follow the procedure below

before installing the unit.

1. Remove the left side panel of

the analyzer and the EMI

shielding panel.

2. Remove the four screws

securing the STM SIC and

diaphragm pumps.

3. Connect the grey ribbon cable

from the sampler to J01 on

PCBA 101-5014 STM SIC.

4. Connect the multi-colored

wiring cable to J02 on PCBA

101-5014 STM SIC.

5. Connect the black specimen tube detector cable to J9 on PCBA 1015014 STM SIC.

6. Connect the ground cables to the chassis of the microscopy module.

7. Insert the hooks of the sampler into the slots of the analyzer. Be

careful not to catch the cables.

8. Reattach the STM SIC and diaphragm pumps to the chassis.

Ground

Adjust the Height of the Analyzer

• Using a 7/16” wrench, loosen the

locking nuts located under the

analyzer.

• Adjust the height of the Sampler by

rotating the feet. The space between

the bench top and the analyzer must

be ¾ inch.

• After adjusting the height, tighten the

locking nuts.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-6

¾ inch

Page 23

2. Installation Procedures

Adjust Sampler

Two adjustment feet are located under the Sampler. They are accessed

from the top of the Sampler. Each foot must be in contact with the

benchtop.

• Using a flat head

screwdriver, remove the two

rubber caps located on the

front corners of the

Sampler. The top of the

feet (screws) can be seen.

• Using a Phillips screwdriver

(+), turn each of the two

screws clockwise until the

adjustment feet touch the

bench top.

• Reinsert the rubber caps.

CAUTION: Make sure the height of the Sampler is adjusted correctly.

Otherwise, the Sampler and the Probe may be damaged.

Installing the Lamina Container

• Install the Lamina cap with

filter on a fresh Lamina

container.

• Connect one end of the

Lamina tubing to the top

fitting on the right side of

the analyzer. Connect the

other end to the fitting of

the Lamina cap.

Connecting the Drain Tubing

• Connect the drain tubing to the bottom fitting on the right side of

the analyzer.

• The Drain Tubing can be directed to the designated waste area

according to local regulations.

• If direct drainage is not an option, slide the Drain Tubing inside a

waste container (approximately 2 in. (5cm)) Make sure the waste

container is lower than the microscopy module.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-7

Page 24

2. Installation Procedures

Computer Connections

1. Connect the video monitor cable to the video monitor and the video port.

2. Connect the keyboard cable to the keyboard port.

3. Connect the mouse cable to the mouse port.

4. Connect the power cord into the power inlet, and then plug into an

electrical outlet.

5. Connect the printer cable to the printer and the printer port.

6. Connect the 100-pin camera data cable to the frame grabber port.

7. Connect one end of the RS232 cable to the serial port on the

computer; connect the other end to the serial port 1 (top port) on the

®

back of the

iQ

200.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-8

Page 25

2. Installation Procedures

iQ200 Rear Panel SIC Connection Configurations

WARNING: Before making any connections to Load or Unload ports on

the Rear Panel SIC of the iQ200, ensure the jumpers are in the correct

configuration depending on the system options.

AX-4280 Connection to the iQ200

The second port labeled

“Load” should have all

three jumpers removed

from the port. CAUTION! If

the jumpers are not

removed, a fuse will blow

on the backplane of the

card cage (F10) inside the

Microscopy Module.

Load Station Connection to the

iQ200

The second port labeled

“Load” should have all

three jumpers installed in

the port. CAUTION! If the

jumpers are not in place,

the connection will not

work and no power will be

supplied to the Load

Station.

Unload Station Connection to

the iQ200

The third port labeled

“Unload” should have all

three jumpers installed in

the port. CAUTION! If the

jumpers are not in place,

the connection will not

work and no power will be

supplied to the unload

Station. Currently, the only

configuration for this port is

all three jumpers in place.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-9

Page 26

2. Installation Procedures

iQ200 / AX-4280 Bridge Installation Instructions

“iQ200-AX4280 Sample bridge kit” PN 800-3501.

1. Remove left side cover from the AX-4280

sampler.

2. Unplug connector # S1-10 (white label) from

the circuit board and replace with connector#

S1-10 (Side Sampler) stored in bottom of

sampler.

3. At the bottom of the sampler, remove the

screw (as indicated on the picture on the right)

securing carry arm stop post. Remove the

post from the sampler.

4. Extend the lever from the sampler. Attach the

rack push arm to the lever with two (2, M3x5)

flat head and one (1, M3x6 pan head) screws.

5. Break the tab on the side cover to allow the

rack to transfer from the Load Station to the

sampler.

6. Replace left side cover.

7. Back out the screw located inside the right

frame of the test strip disposal compartment to

hold the spring loaded return plate.

8. Install the new waste box provided with the

connection kit.

9. Install an alignment bracket under each

analyzer aligning the pins with the two holes

located under the front of each instrument.

Align the brackets and join with the connection

bracket. Secure with four (4, M3x10 pan head)

screws.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-10

Page 27

2. Installation Procedures

10. Install the bridge faceplate between the two

samplers. Center and secure with the

thumbscrews located underneath the

faceplate.

11. Secure the bridge between the two samplers

with two (2, M3x6 flat head) screws. Make

sure the guide spring points to the left. Check

for proper alignment and adjust the analyzer

level and/or position to provide a smooth

transition.

12. Make the cable connections between the

analyzers, and the computer according to the layout diagram.

NOTE: Do not use the grey cable provided with the Arkray kit, the pin out

for this cable will not work due to incorrect pin positioning.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-11

Page 28

REMOVE jumpers on

COM2 “Load” port

before connecting

directly to AX-4280

2. Installation Procedures

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-12

Page 29

2. Installation Procedures

13. Power up the AX-4280 while holding the STOP button to access the

Service mode.

a. Press -4280-.

b. Press 1: “User set up” then press 2: “User detail”.

c. Press ENTER until “Sampler” is displayed.

d. Press the “-” button until [LOWER] is displayed and then press

ENTER.

e. Save these settings when prompted.

f. Press ESC until the first menu is displayed.

g. Press 2: “Adjust”. Press 2: “Pulse & LED”. Press 1: “Pulse

adjust”.

h. Press the “-“ button until [RACK] is displayed, then press ENTER.

i. Press the “-“ button until [Carry send] is displayed. Place a rack

on the left side of the AX-4280 sampler in the area where the rack

can be transferred to the iQ200 from the AX-4280 and press

ENTER. Verify that the carry arm moves the rack to the iQ

sampler and is positioned on the iQ 200 sampler fully.

j. If the distance needs to be adjusted, change the pulse number on

the AX-4280 to the proper position. A larger number carries the

rack further. Use the keypad to change the value.

Press 7 to increase the pulse number by 1

Press 4 to decrease the pulse number by 1

Press 9 to increase the pulse number by 10

Press 6 to decrease the pulse number by 10

k. Press MENU until the third menu is displayed.

l. Press 2: System Option. Press 1: Edit rack ID.

m. Enter the following rack ID information-

Rack numbers 1-11 Standard ID

Rack number 12 Start

Rack numbers 13-24 Standard ID

Rack numbers 25-27 Standard ID

Rack number 28 STAT/CTRL

Rack numbers 29-30 PASS

Rack number 31 NONE

14. Save these settings when prompted.

15. Return to Standby mode.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-13

Page 30

2. Installation Procedures

16. Load the AX Connectivity CD PN 700-3106 on the Analysis

Processor.

17. From the Main Menu screen of the iQ, click on the Settings button.

18. Click on Interfaces.

19. Verify that the “Enable direct connection” checkbox with the AX-

4280 is selected.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-14

Page 31

2. Installation Procedures

20. Run a patient barcoded sample tube with diluent on the AX-4280 and

verify the rack transfers to the iQ 200 without error and the chemistry

results attach to the microscopy results.

21. If the chemistry results do not cross over to the worklist, check the LIS

output on the AX-4280 for correct setup:

i. Enter “-4280-“

ii. Enter “1” for user setup

iii. Press “MENU”

iv. Press “2” for Online

v. Press “ENTER” until “RS232C Normal” is displayed

vi. Change “RS232C Normal” to ”ON” by pressing “-“, then press

ENTER

vii. Change “RS232C STAT” to “ON” by pressing “-“, then press ENTER

viii. Change “RS232C Ctrl” to “ON” by pressing “-“, then press ENTER

ix. SAVE? Yes (1) No (0) Press “1” to save

x. Press “ESC”, then press “STOP”, AX-4280 will initialize

22. If the chemistry cross over but do not attach to the microscopy, make

sure the barcode reader is setup correctly and reads the label the

same on both units. The label ID’s should match in order to attach the

chemistry and microscopy results together.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-15

Page 32

2. Installation Procedures

Optional Load/Unload Station Installation

Load Station - iQ200 Connection

NOTE: The Load Station may be connected to either the AX-4280 or the

iQ200.

1. Remove the right side cover from the iQ200 sampler.

2. Break the tab on the side cover to allow the rack to transfer from the

Load Station to the Sampler.

3. Reinstall the right side cover. DO NOT install the bottom screw

located on the backside of the sampler cover.

4. Assemble the bridge (see picture below)

Note

position of

guide plate

Securing

Brace

Load station bridge assembly

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-16

Page 33

2. Installation Procedures

5. Connect the assembled bridge between the iQ200 sampler and the

load station. (see picture below)

6. Attach the load station cable to port 2 labeled “Load” on the Rear

Panel SIC (jumpers in.)

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-17

Page 34

2. Installation Procedures

7. Adjust the leveling feet under the Load Station to assure a smooth

transfer of racks.

8. Attach the securing brace to the bottom screw port on the backside of

the iQ200 sampler side cover. The brace mount is attached to the

Load Station with an adhesive strip. Secure the brace to the brace

mount using the setscrew. (see picture below.)

Brace

Mount

Securing

Brace

Set Screw

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-18

Page 35

2. Installation Procedures

NOTE: Smooth rack transfer between stations and samplers is critical for

proper operation.

9. Turn “ON” the power switch located on the back of the Load Station.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-19

Page 36

2. Installation Procedures

Load Station - AX-4280 Connection

1. Remove the right side cover from the AX-4280 sampler.

2. Break the tab on the side cover to allow the rack to transfer from the

Load Station to the Sampler.

3. Disconnect and remove the optical sensor from the right side of the

sampler.

4. Unplug connector # S2-22 (white label) from the circuit board and

replace with connector# S2-22 (side sampler) stored in the bottom of

the sampler. Push the sensor cable inside the sampler cover.

5. Remove the metal base plate from the STAT station.

6. Extract the sensor cable located on the right side of the STAT holder.

7. Install the new metal base plate, (included in with the load station) in

the STAT station, passing the sensor cable through the hole on the

right of the plate.

8. Attach the new metal base plate using the screws from the original

plate.

9. Remove the black optical sensor from the mounting bracket, and

connect it to the sensor cable at the STAT station.

10. Secure the black optical sensor to the side of the base plate touching

the front of the sampler, using the hardware included in the bridge

connection kit. (see picture below)

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-20

Page 37

2. Installation Procedures

11. Install and secure the sensor cover to the base plate. (see picture

below)

Note

position of

guide plate

12. Reinstall the right side cover. DO NOT install the bottom screw

located on the backside of the sampler cover.

13. Assemble the bridge (see picture below)

Load station bridge assembly

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-21

Page 38

2. Installation Procedures

14. Connect the assembled bridge between the AX-4280 sampler and

the load station. (see picture below)

15. Adjust the leveling feet under the Load Station to assure a smooth

transfer of racks.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-22

Page 39

2. Installation Procedures

16. Attach the securing brace to the bottom screw port on the backside of

the AX-4280 sampler cover (see picture below.)

Brace

Mount

Securing

Brace

Set Screw

NOTE: Smooth rack transfer between stations and samplers is critical for

proper operation.

17. Attach the load station cable to port labeled “Start” on the Rear Panel

of the AX-4280.

18. Power up the AX-4280 while holding the STOP button to access the

Service mode.

a. Press -4280-.

b. Press 1: “User set up” then press 2: “User detail”.

c. Press ENTER until “Sampler” is displayed.

d. Press the “-” button until [UP & LOW] is displayed and then press

ENTER.

19. Save these settings when prompted.

20. Turn “ON” the power switch located on the back of the Load Station.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-23

Page 40

2. Installation Procedures

Unload Station

1. Remove left side cover from the iQ200

sampler.

2. Unplug connector # S1-10 (white label) from

the circuit board and replace with connector#

S1-10 (side sampler) stored in the bottom of

the sampler.

3. On the bottom side of the sampler, remove

the screw (as indicated on the picture on the

right) securing the carry arm stop post.

Remove the post from the inside of the

sampler.

4. Extend the lever from the sampler. Attach the

rack push arm to the lever with two (2, M3x5)

flat head and one (1, M3x6 pan head) screws.

5. Break the tab on the side cover to allow the

leaver to extend when the cover is in place.

6. Reinstall the left side sampler cover. DO NOT install the bottom

screw located on the backside of the sampler cover.

7. Assemble the bridge (see picture below)

Note

position of

guide plate

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-24

Unload station bridge assembly

Iris Diagnostics, a Division of Iris International, Inc.

Page 41

2. Installation Procedures

8. Connect the assembled bridge between the iQ200 sampler and the

Unload station. (see picture below)

9. Adjust the leveling feet under the Unload Station to assure a smooth

transfer of racks.

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-25

Page 42

2. Installation Procedures

10. Attach the securing brace to the bottom screw port on the backside of

the iQ200 sampler cover. (see picture on the right)

NOTE: Smooth rack transfer between stations and samplers is critical for

proper operation.

11. Attach the unload station cable to port 3

labeled “Unload” on the Rear Panel SIC

(jumpers in.)

12. Turn “ON” the power switch located on the

back of the Unload Station.

13. Enter the Service Application and calibrate

the STM Unload station cal value cal[3]

“Distance to eject to stock yard” so the

rack transfers the correct distances onto

the unload station. The rack should

transfer smoothly and end up 3mm from

the left side of the unload station.(See

Sampler Calibration Chapter 4)

Iris Diagnostics, a Division of Iris International, Inc.

®

iQ

200 Sprint™ (2G) Automated Urine Microscopy Analyzer Service Manual 300-4949 Rev A 01/2005 2-26

Page 43

2. Installation Procedures

Startup