Page 1

Digital488/80A User's Manual

80-Bit IEEE 488 / Digital I/O Interface

the smart approach to instrumentation ™

IOtech, Inc.

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail:

Internet: www.iotech.com

Digital488/80A User's Manual

80-Bit IEEE 488 / Digital I/O Interface

p/n 196-0901 Rev 1.2

Released Per EO # 1941R5

sales@iotech.com

© 1998 through 2004 by IOtech, Inc. 967695 Printed in the United States of America.

Page 2

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior

written consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their

respective holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs)

may only be used on one installation. You may make archival backup copies.

CE Notice

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is

not covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Quality Notice

IOtech has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and

review our documentation to assure the highest quality in all aspects. In a spirit of continuous improvement, IOtech

welcomes your suggestions.

Page 3

Introduction to this Manual

This manual covers the setup and operation of the Digital488/80A 80-bit IEEE 488 / Digital I/O interface

system. This manual is organized as follows:

• Chapter 1 - Digital488/80A Overview gives an overview of the basic features of a Digital488/80A

system. Digital488/80A accessories and specifications are also provided.

• Chapter 2 - Digital488/80A Setup explains in detail the various hardware features of the

Digital488/80A unit.

• Chapter 3 - Digital488/80A Power & Assembly provides detailed instructions on line-voltage

selection and fuse replacement, rack-mount and bench-top installation, as well as power-up activation.

• Chapter 4 - Digital488/80A Operation explains the Digital488/80A internal operation. Descriptions

of the handshaking/control lines, as well as IEEE 488 bus support, are provided.

• Chapter 5 - IEEE 488 Background describes the history and the basic concepts of IEEE 488

operation, including the various IEEE 488 bus lines and bus commands.

• Chapter 6 - Digital488/80A Commands discusses the entire command set covering the

Digital488/80A unit. The command syntax, groups, and reference are provided. The description

format of the individual commands includes the command type, syntax, description, and an example

program excerpt.

• Chapter 7 - Troubleshooting provides a reference for possible solutions to technical problems. Before

calling for technical assistance, refer to this chapter.

• Appendix A provides the Digital488/80A HVCX1 Configuration Record for recording hardware and

software settings, and recording DB-50 connector wiring information.

• Appendix B provides background information concerning the IEEE 488 bus, the serial bus, and ASCII

controls.

• The Index provides a comprehensive alphabetical listing of the main terms and topics in this manual.

Also, the Abbreviations on the last pages of this manual, provides an overall list of abbreviations,

including acronyms and ASCII control codes, as an additional reference for this manual and for other

related literature.

CAUTION

Using this equipment in ways other than described in this manual can cause personal

injury or equipment damage. Before setting up and using your equipment, you should

read all documentation that covers your system. Pay special attention to cautions and

warnings formatted like this one.

Digital488/80A User’s Manual i

Page 4

Table of Contents

1 - Digital488/80A Overview

Introduction…… 1

Addressing Modes…… 1

Digital I/O Lines…… 1

Handshaking/Control Lines…… 1

HVCX1 High Voltage/Current Interface

Option…… 2

Power-Up & Setup Configuration…… 2

Internal Buffer…… 2

Software Programmable Features…… 2

Accessories…… 2

Specifications…… 3

Digital I/O…… 3

IEEE 488…… 3

General…… 3

Data Transfer Speeds…… 4

2 - Digital488/80A Setup

The Package…… 5

Hardware Setup…… 6

Front & Rear Panel Layouts…… 6

Default DIP Switch Settings…… 7

IEEE 488 Bus Address Selection…… 7

Addressing Mode Selection…… 7

Dual Primary Addressing Mode…… 8

Secondary Addressing Mode…… 8

HVCX1 Option Setup…… 10

Determining Ports Setup…… 11

To Set Up Input Ports…… 12

To Set Up Handshaking Input Lines…… 13

To Set Up Output Ports…… 14

To Set Up Handshaking Output Lines…… 14

To Install the HVCX1 Option…… 16

Digital I/O Ports…… 17

Using the HVCX1 Option for High Voltage/Current

Options…… 18

3 - Digital488/80A Power & Assembly

Introduction…… 19

Internal Components…… 19

Factory Service…… 19

Power Line & Fuse Configuration…… 20

Line Voltage Selection…… 20

To Select the Line Voltage…… 21

Fuse Replacement…… 22

To Replace the Fuse…… 22

Rack-Mount & Bench-Top Assembly…… 23

Rack Mount…… 23

Bench Top…… 23

Power-Up & Programming Tests…… 24

Power-Up Activation…… 24

Programming Examples……25

KYBDCTRL.BAS Program…… 25

To Run the Keyboard Controller Program…… 25

Digital488/80A Command Responses…… 26

4 - Digital488/80A Operation

Introduction…… 29

Handshaking/Control Lines…… 29

Clear (Pin 41)…… 30

Data Strobe (Pin 42)…… 30

Trigger (Pin 43)…… 30

Inhibit (Pin 44)…… 31

Service (Pin 45)…… 31

External Data Ready (Pin 46)…… 31

IEEE 488 Bus Support…… 32

Bus Lines…… 32

Bus Commands…… 32

Bus Addresses…… 34

Bus Terminators…… 34

5 - IEEE 488 Background

History…… 35

General Bus Structure…… 35

Bus Lines & Bus Commands…… 36

Bus Management Lines…… 36

Handshake Lines…… 37

Data Transfer Lines…… 37

Bus Command Groups…… 38

More On Service Requests…… 39

6 - Digital488/80A Commands

Introduction…… 41

Command Syntax…… 42

Command Set & Support…… 43

Command Summary…… 44

Command Reference…… 46

A - Bit Set…… 47

B - Bit Clear…… 48

C - Configuration…… 49

D - Data Output…… 50

E? - Query Error Status…… 51

F - Data Format…… 53

G - Bus Input/Output…… 57

H - Handshake…… 58

I - Invert…… 59

K - End-Or-Identify…… 60

L - Buffer…… 61

M - Service Request Mask…… 62

O - Recall Configuration…… 63

P - Port Select…… 64

Q - Inhibit…… 65

R - Data Ready…… 66

S - Save Configuration…… 67

T - Test…… 68

U - User Status…… 69

V - View Configuration…… 72

V? - View Version…… 73

X - Execute…… 74

Y - Bus Terminator…… 75

? - Query…… 76

Serial Poll Status Byte…… 77

ii Digital488/80A User’s Manual

Page 5

7 - Troubleshooting

Radio Interference Problems…… 79

Electrostatic Discharge (ESD) Damage……

79

Other Issues…… 79

Power-Up Activation…… 79

Buffer Overrun…… 80

Query Error Status…… 80

A - Appendix A

Digital488/80A HVCX1 Configuration

Record…… 81

Hardware Setup…… 81

Software Setup…… 82

DB-50 Connector Wiring Reference…… 83

B - Appendix B

IEEE 488 Bus & Serial Bus Lines…… 81

IEEE 488 Bus Commands…… 86

ASCII Codes…… 87

ASCII Code Summary…… 87

Decimal Values 00 to 63 - ACG, UCG & LAG……

87

Decimal Values 64 to 127 - TAG & SCG…… 88

ASCII Code Details…… 89

Decimal Values 00 to 31 - ACG & UCG

Characteristics…… 89

Decimal Values 00 to 31 - ACG & UCG

Descriptions…… 90

Decimal Values 32 to 63 - LAG…… 91

Decimal Values 64 to 95 - TAG…… 92

Decimal Values 96 to 127 - SCG…… 93

Index…… 95

Abbreviations…… 98

Digital488/80A User’s Manual iii

Page 6

Notes

iv Digital488/80A User’s Manual

Page 7

Digital488/80A Overview 1

Introduction…… 1

Addressing Modes…… 1

Digital I/O Lines…… 1

Handshaking/Control Lines…… 1

HVCX1 High Voltage/Current Interface Option…… 2

Power-Up & Setup Configuration…… 2

Internal Buffer…… 2

Software Programmable Features…… 2

Accessories…… 2

Specifications…… 3

Digital I/O…… 3

IEEE 488…… 3

General…… 3

Data Transfer Speeds…… 4

Introduction

The Digital488/80A is a digital input and output interface to the IEEE 488 bus that enables an IEEE 488

controller to program 80 bits of TTL level signals as either inputs or outputs. It includes six

handshake/control lines for each 40-bit channel and two addressing modes. The unit is fully

programmable, including the power-up configuration, which is stored in non-volatile RAM. The internal

data buffer in the Digital488/80A can store up to 2,000 40-byte words. With the addition of the HVCX1

High Current/High Voltage Interface option, the I/O lines can be configured as high voltage inputs or as

high current/high voltage outputs to allow interfacing with solenoids, switching relays and other high

voltage/high current devices.

Addressing Modes

Two addressing modes are available in the Digital488/80A. Dual primary addressing permits two channels

to reside at two consecutive primary IEEE 488 bus addresses. Secondary addressing allows two channels

to reside at the same primary IEEE 488 bus address with two consecutive secondary addresses.

When addressed to Talk, the Digital488/80A outputs data from all forty bits of the selected channel or a

selected eight bit port. When addressed to Listen, the unit accepts input data and programming information

from the controller and outputs the data to the appropriate I/O port.

Digital I/O Lines

The Digital488/80A has 80 TTL level digital I/O lines that are divided into two 40-bit channels. Each

channel is divided into five eight-bit ports. Six high level ASCII commands configure the ports to be all

inputs, all outputs or combinations in between. Thus, a configuration can range from 80 input lines to 80

output lines or combinations in between in multiples of 8 bits.

Handshaking/Control Lines

Each 40-bit channel has six handshaking/control lines. The Clear (Pin 41) output line is pulsed whenever a

Device Clear (

DCL) or Selected Device Clear (SDC) command is received from the IEEE 488 controller.

The Data Strobe (Pin 42) output is pulsed when the IEEE 488 controller presents new data on the I/O lines.

The Trigger (Pin 43) output signal is pulsed when a Group Execute Trigger (

GET) command is received on

the bus. The Inhibit (Pin 44) output line is asserted while the IEEE 488 controller is reading data from

input lines. The Service (Pin 45) line is an edge-triggered input that generates a Service Request on the

bus. The External Data Ready (Pin 46) input line is used to latch digital input data on the I/O lines.

Digital488/80A User’s Manual Digital488/80A Overview 1

Page 8

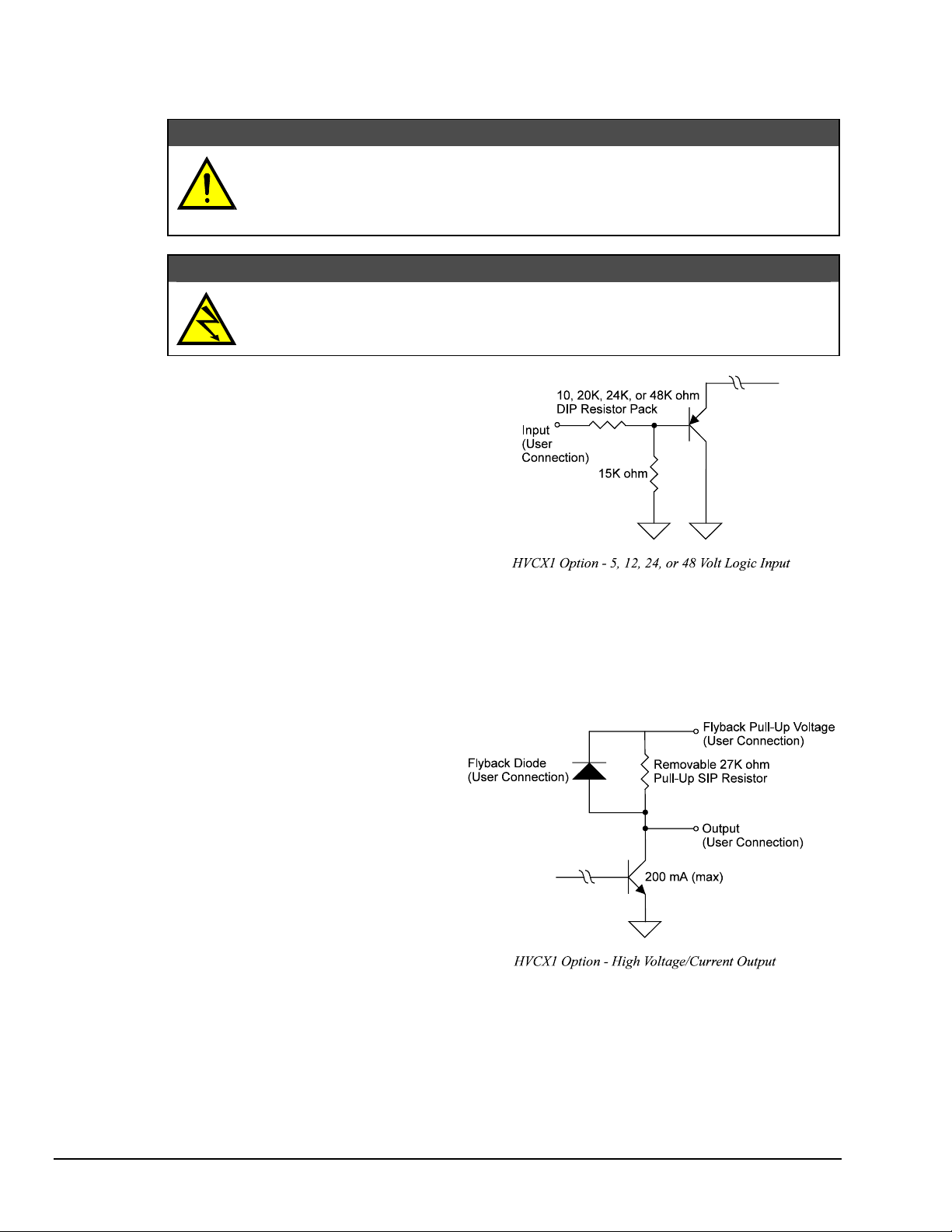

HVCX1 High Voltage/Current Interface Option

The HVCX1 option permits the I/O lines to be configured as high voltage (up to 50 V) inputs or as high

voltage/high current outputs (up to 200 mA sink capability) to allow interfacing with solenoids, switching

relays and other high voltage/high current devices using an external voltage source. It allows interfacing to

non-TTL level devices by offering compatibility with 12, 24 and 48 volt logic. The individual 8-bit ports

can be configured to control high current open collector drivers. Each high current driver has an internal

fly-back diode for protection when switching inductive devices such as relays. When the HVCX1 option is

used, the six handshake and control lines can also interface to 12, 24, or 48 volt logic.

Power-Up & Setup Configuration

The Digital488/80A allows up to 100 configurations for each channel to be created. The configurations are

stored in non-volatile memory, which enables the input/output status and logic level of every I/O line to be

defined when power is applied. The configurations can be called from a single pre-defined command from

the IEEE 488 controller. This allows easy configuration of the device for a variety of applications.

Internal pull-up resistors ensure a logic "high" the instant power is applied. When using the HVCX1

option with high current driver outputs, the internal pull-up resistors ensure that the high current driver

outputs are switched off the instant power is applied -- a requirement for process control applications.

Internal Buffer

A built-in data buffer in the Digital488/80A can store up to 8,000 bytes, which is large enough to capture

two thousand patterns from one 40-bit I/O channel. When interfacing to slow devices, the data buffer

relieves the controller of the need to constantly read data from the Digital488/80A.

Software Programmable Features

The software programmable features on the Digital488/80A include data formats, individual bit set and bit

clear commands and terminators. The six available data formats are ASCII hexadecimal, ASCII character,

ASCII binary, binary, high speed binary and ASCII decimal. The programmable terminators facilitate

interfacing to various controllers. Using the User Status (

programmed status of the Digital488/80A at any time. With the Query (

Digital488/80A command, user-defined status command strings can be built to request the status

information needed for a given application.

Accessories

Additional accessories that can be ordered for the Digital488/80A include:

• CA-1: Power cable

• CA-7-1: 1.5-foot IEEE 488 cable

• CA-7-3: 6-foot shielded IEEE 488 cable

• CA-7-4: 6-foot reverse entry IEEE 488 cable

• CA-88: 6-foot 50-pin D-shell ribbon cable

• CN-20: Right-angle IEEE 488 adapter, male and female

• CN-22: IEEE 488 multi-tap bus strip, four female connectors in parallel

• CN-23: IEEE 488 panel-mount feed-through connector, male and female

U) command, the controller can check the

?) option offered with each

2 Digital488/80A Overview 11-07-02 Digital488/80A User's Manual

Page 9

Specifications

Digital I/O

Terminal Installation Category: Standard: Not Applicable. CE: Category 1.

Digital I/O Capability: Dual Channels, each with five 8-bit ports, programmable as inputs or outputs.

Also included per channel are programmable handshake lines, data latching cap ability, a Service

Request (SRQ) input and Clear and Trigger outputs.

Logic Levels: Outputs drive 2 TTL loads (3.2 mA). Optional 12, 24, 48 volt logic support available with

the HVCX1 High Voltage/Current Interface option.

High-Current Outputs: With the HVCX1 option, the outputs can be configured, in groups of eight, as

high current outputs. Each high-current output is capable of sinking up to 200 mA at 50 VDC

maximum. Total current sinking capability is 8 A maximum.

Update Rate: In binary mode, the Digital488/80A can update one 40-bit I/O channel at over 2 Kbytes per

second.

I/O Port Connections: Two 50-pin male D-shell connectors. Mating solder tab connectors are supplied.

Input Ranges, Nominal Logic Low/High Voltages (±10%), and Input Resistances (HVCX1 option

only):

0-5 Volt Range: 0.8 volts low / 2.4 volts high; 15 Kohms.

0-12 Volt Range: 1.9 volts low / 5.75 volts high; 35 Kohms.

0-24 Volt Range: 4.2 volts low / 11.5 volts high; 61 Kohms.

0-48 Volt Range: 8.4 volts low / 23 volts high; 135 Kohms.

Please read this manual carefully! If equipment is used in any manner not specified in

this manual, the protection provided by the equipment may be impaired.

CAUTION

IEEE 488

General

The IEEE 488 terminal must only be used to control a non-isolated IEEE 488 system.

The common mode voltage (cable shell to earth) must be zero.

Terminal Installation Category: Standard: Not Applicable. CE: Category 1.

Implementation: SH1, AH1, T4, TE8, L4, LE4, SR1, RL0, PP0, DC1, DT1, C0, E1.

Terminators: Ignored on input. Selectable CR, LF, LF-CR or CR-LF, with or without EOI.

Programmable: IEEE Bus Terminators, EOI Control, SRQ Mask, Port Data, Active Levels, Handshake

Lines, Format, and Configuration.

Connector: Standard IEEE 488 connector with metric studs.

WARNING

Service: Fuse replacement and the changing of selected line voltage must be

performed by qualified service personnel. Never open the case while it is connected to

the AC line. Internal voltage potentials exist which could cause bodily injury or death.

CAUTION

Digital488/80A User’s Manual Digital488/80A Overview 3

Page 10

Terminal Installation Category: Standard: Not Applicable. CE: Category 2 for Line Voltage Input

terminal. All other terminals are Category 1.

Dimensions: 425 mm wide x 45 mm high x 203 mm deep (16.75" x 1.75" x 8").

Weight: 2 kg. (4.5 lbs).

Environment: Standard: Indoor use, 0° to 50°C; 0 to 95% RH (non-condensing).

CE: Indoor use at altitudes below 2000 meters, 0° to 40°C; 0 to 80% RH up to 31°C decreasing

linearly 4% RH/°C to 40°C.

Controls: Power switch (external), line voltage selection switch (internal), and DIP switch (external) for

IEEE 488 addressing mode and IEEE 488 address.

Indicators: LED indicators for TALK, LISTEN, SRQ, ERROR, TEST and POWER.

Power: Internally selectable 105-125 or 210-250 VAC; 50/60 Hz, 30 VA maximum.

Fuse: 1/2A Slo Blo 3AG (for 105-125 V power line) or 1/4A Slo Blo 3AG (for 210-250 V power line).

CAUTION

Line Voltage: The protective conductor terminal on the AC line connector must be

connected to an external protective earthing system. Failure to make such a

connection will impair protection from shock.

CAUTION

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry. If a

fuse blows, contact a qualified service representative. Replacement fuses are to be

installed by qualified service personnel with the unit disconnected from the power

source and with all other terminals disconnected. If the line voltage selector is

changed, then the fuse designated for that line voltage must be used.

Data Transfer Speeds

The Digital488/80A has been measured to perform at the approximate speeds listed below. The testing

was done in such a way that the limiting factor was the Digital488/80A and not the IEEE 488 bus

controller driving it. All explanations discuss only one channel although the specifications given are valid

for either channel.

• Collection and Storage of Data: The Digital488/80A has an internal data buffer capable of storing

2000 readings of 40-bit data per channel. When operating in the

buffered on an External Data Ready transition), a transition on the EDR input causes the

Digital488/80A to collect the current value of all 40 bits and store the reading in the buffer. This

collection and storage of 40 bits of data can occur at a maximum rate of once every 140 microseconds.

• Output of Data to Ports: When sending data to the outputs on a Digital488/80A channel, the fastest

format mode is high-speed binary mode: Format (

data are accepted from the bus and sent directly to the Digital488/80A outputs (all 40 bits). This

constitutes one data transfer. The data transfer rate in this mode is approximately 1400 transfers per

second.

• IEEE 488 Bus Communication: The fastest data transfer rate across the IEEE 488 bus to the

IEEE 488 controller is approximately 1 byte every 140 microseconds whether reading data from the

internal data buffer, or accepting commands or data from the bus.

• Transistor-Transistor Logic (TTL) Levels: The data and handshake output lines drive two TTL loads.

In addition, Ports 1 and 2 on each channel can function as 5-volt CMOS-compatible outputs. All input

lines are less than 1.5 TTL loads. Normal precautions should be taken to limit the input voltages to the

range of -0.3 to +7.0 volts. All I/O lines are referenced to I/O Common (Ground; DB-50 Pin 50).

R2 mode (data are latched and

F) command F5. In this mode, 5 bytes of binary

4 Digital488/80A Overview 11-07-02 Digital488/80A User's Manual

Page 11

Digital488/80A Setup 2

The Package…… 5

Hardware Setup…… 6

Front & Rear Panel Layouts…… 6

Default DIP Switch Settings…… 7

IEEE 488 Bus Address Selection…… 7

Addressing Mode Selection…… 7

Dual Primary Addressing Mode…… 8

Secondary Addressing Mode…… 8

HVCX1 Option Setup…… 10

Determining Ports Setup…… 11

To Set Up Input Ports…… 12

To Set Up Handshaking Input Lines…… 13

To Set Up Output Ports…… 14

To Set Up Handshaking Output Lines…… 14

To Install the HVCX1 Option…… 16

Digital I/O Ports…… 17

Using the HVCX1 Option for High Voltage/Current Options…… 18

The Package

All Digital488/80A components are carefully inspected prior to shipment. When you receive your IEEE

488 / digital I/O interface, carefully unpack all items from the shipping carton and check for any damage

which may have occurred during shipment. Promptly report the damage to the shipping agent and your

sales representative. Retain all shipping materials in case you must return the unit to the factory.

Every Digital488/80A package includes the following items listed by part number:

• Digital488/80A: 80-Bit IEEE 488 / Digital I/O Interface

• 196-0901: Digital488/80A User’s Manual

• PR-2: Warranty Card

• 196-0800: Accessories Kit for Digital488/80A, which includes the following:

• CA-1: Power Cable

• HA-41-6: Rack Screws (4)

• FE-1: Rubber Feet (4)

• EN-6: Rack Ears (2)

• FU-1-.25: 1/4A Replacement Fuse

• FU-1-.5: 1/2A Replacement Fuse

• CN-18-50: Mating Connector for DB-50 (2)

In addition, if the High Voltage/Current Interface Option (HVCX1) is included, you will have the

following items:

• 196-4050: PCB Sub-Assembly, which includes a HVCX1 High Voltage/Current Interface

• 196-0801: Accessories Kit, HVCX1 Option for Digital488/80A, which includes the following:

• RN-3-20K: 20 Kohms Resistor, 16-pin DIP Pack (12)

• RN-3-56K: 56 Kohms Resistor, 16-pin DIP Pack (12)

• RN-3-120K: 120 Kohms Resistor, 16-pin DIP Pack (12)

• RN-9-27K: 27 Kohms Pullup Resistor, 9-pin SIP Pack (10)

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 5

Page 12

Hardware Setup

Do not use the Digital488/80A unit outdoors! This unit is intended for indoor use only!

Unexpected outdoor conditions could result in equipment failure, bodily injury or

death!

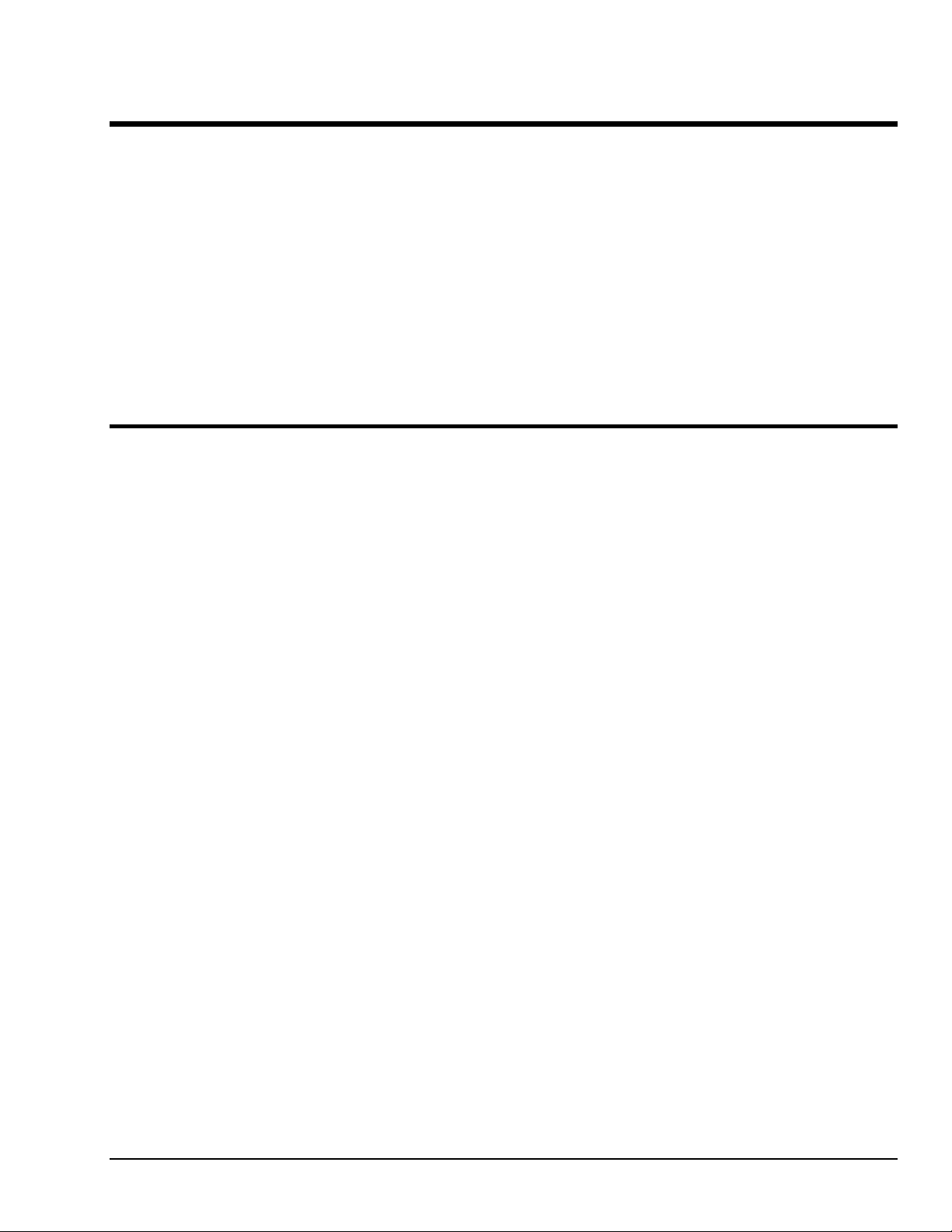

Front & Rear Panel Layouts

Six LED indicators on the Digital488/80A front panel, display the unit status. The following list describes

the functions of these indicators:

• TALK: ON when Digital488/80A is in the Talker state; OFF when in the Idle or Listener state.

• LISTEN: ON when Digital488/80A is in the Listener state; OFF when in the Idle or Talker state.

• SRQ: ON when Digital488/80A generated a service request; OFF when no SRQ is pending.

• ERROR: ON when an error has occurred; OFF when no error condition exists.

WARNING

• TEST: ON when used in conjunction with the Test (

T) command to verify that communication has

been established with the Digital488/80A.

• POWER: ON when power is being applied while the power switch is in the ON position; OFF when

power is not present.

6 Digital488/80A Setup Digital488/80A User's Manual

Page 13

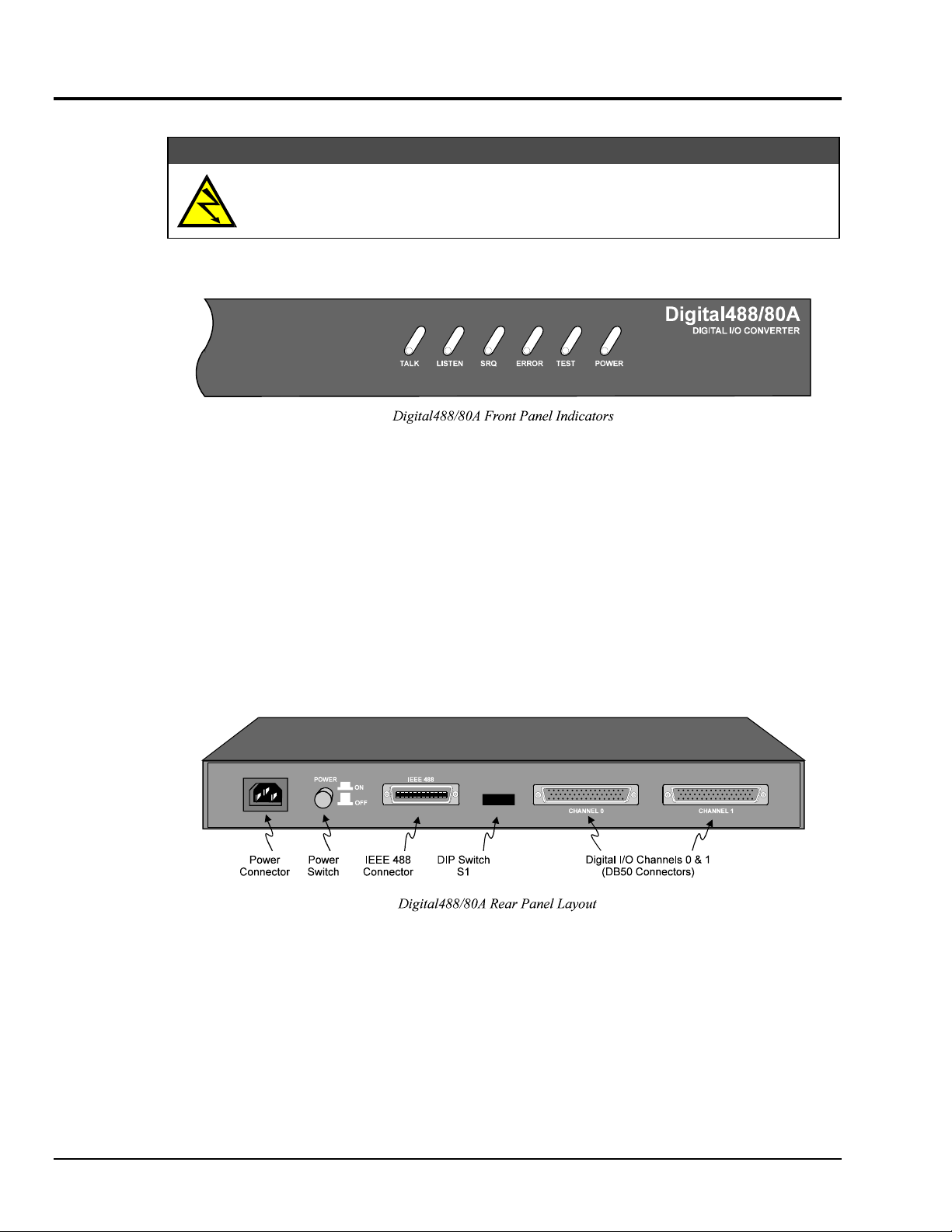

Default DIP Switch Settings

The Digital488/80A unit may be operated from either 110 VAC or 220

VAC. The operating voltage is set by an internal switch. The factory

set operating voltage appears on the label placed over the power jack on

the rear panel. To change the operating voltage, see section Line

Voltage Selection in Chapter 3: Digital488/80A Power & Assembly.

The Digital488/80A unit has one 8-microswitch DIP switch (S1)

accessible from the rear panel. This DIP switch determines the IEEE

488 bus address and its addressing mode. The switch is read only when

the unit is powered on and should be set prior to applying power. The

figure illustrates the factory default for the DIP microswitch settings:

IEEE 488 bus address = 8, and Addressing Mode = Dual Primary. In

the Dual Primary addressing mode, DIP microswitches 6 and 7 are

ignored.

Note: DIP switch S1 is read only during power up. For this reason you must make any setting changes

prior to applying power to the unit.

To modify the default settings, disconnect the power cord from the AC line and change the microswitch

settings using a small screwdriver. The enclosure does not need to be opened to change the DIP

microswitch settings.

IEEE 488 Bus Address Selection

The IEEE 488 bus address is set by positioning the

rear-panel DIP microswitches 1 through 5. The

address can be set from 0 through 30 and is read

only at power on. The address is selected by

simple binary weighting with microswitch 1 being

the Least Significant Bit (LSB; with a value of 1)

and microswitch 5 the Most Significant Bit (MSB;

with a value of 16). The factory default setting is

address 8, as shown in the diagram.

Note: If address 31 is selected, it defaults to

address 30 because the IEEE 488

standard has reserved address 31.

Note: The Digital488/80A bus address must

agree with the IEEE 488 controller

address.

Addressing Mode Selection

The Digital488/80A can be operated in one of two

addressing modes: Dual Primary addressing mode

or Secondary addressing mode, which are selected

by the rear-panel DIP microswitch 8. The factory

default setting for microswitch 8 is Dual Primary

addressing mode, in the "up" position as shown in

the diagram. A detailed description of the Dual

Primary and Secondary addressing modes is

provided in the following text.

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 7

Page 14

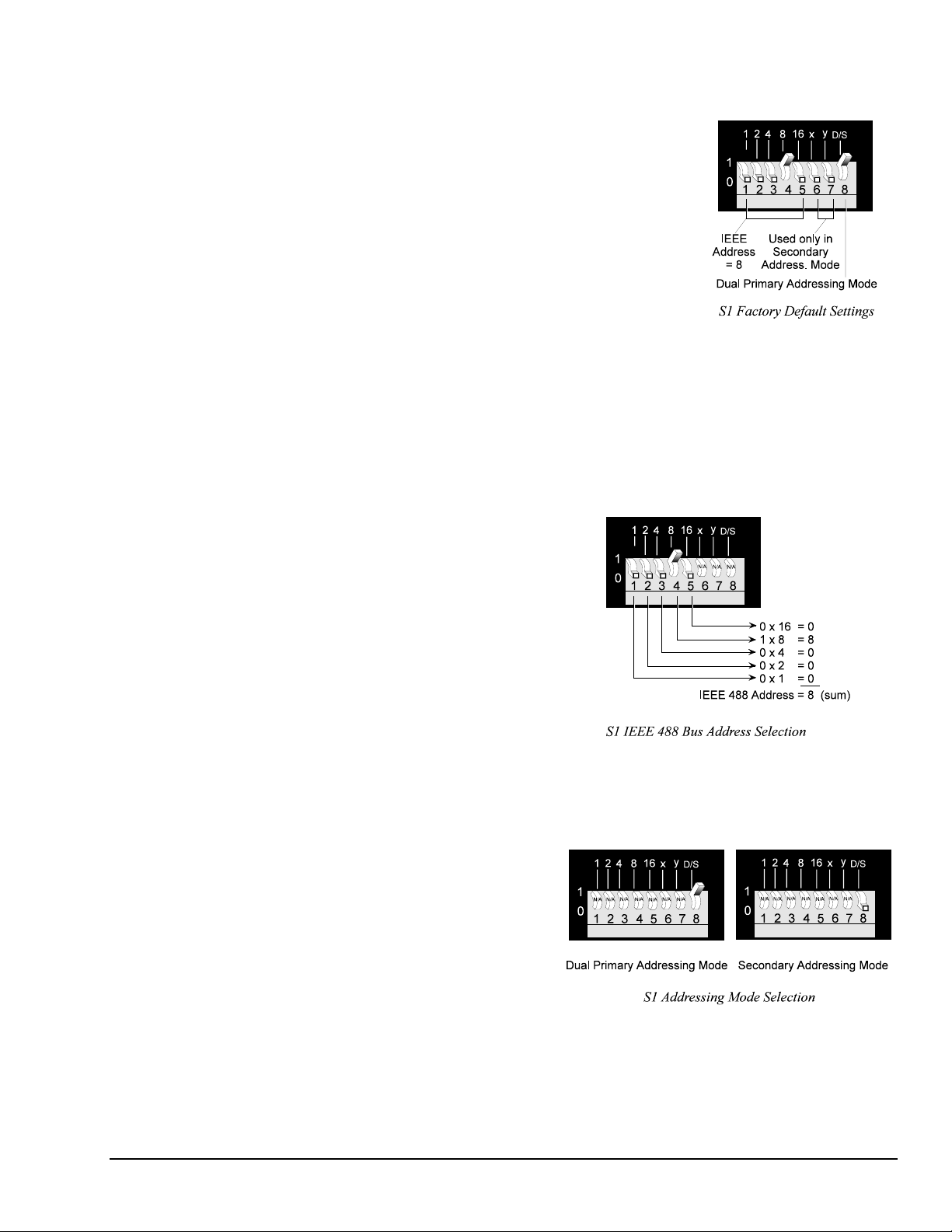

Dual Primary Addressing Mode

The Digital488/80A can be thought of as two identical IEEE 488-to-digital I/O interfaces. Each interface

occupies one bus address and has one I/O channel. For this reason the Digital488/80A occupies two bus

addresses in an IEEE 488 system.

The default addressing mode on the Digital488/80A is "Dual Primary,” in which two consecutive bus

addresses are used. Dual Primary addressing offers ease of use at the expense of two bus address

locations. This may not be practical for applications in which the bus address locations are required by

other equipment. In these situations, “Secondary" addressing mode may be used. Secondary addressing

uses a single bus address for multiple interfaces.

When Dual Primary addressing mode is selected with DIP microswitch 8 in the "up" position, then

microswitch 1 (LSB of the address) is ignored. The Channel 0 interface resides at an even numbered bus

address, while the Channel 1 interface resides at the next higher odd address. For example, if the address

switches are set for IEEE 488 bus address 8, Channel 0’s interface resides at bus address 8 and Channel 1’s

interface resides at bus address 9.

Note: Because the IEEE 488 standard has reserved address 31, if address 30 is selected when in Dual

Primary addressing mode, then the Digital488/80A defaults to address 28 for Channel 0, and to

address 29 for Channel 1.

Secondary Addressing Mode

When Secondary addressing mode is selected with

DIP microswitch 8 in the "down" position, then up

to four Digital488/80A units can reside at the same

primary bus addresses. The Secondary addresses

at which Channel 0 and Channel 1 reside, are

selected with microswitches 6 and 7, as indicated

in the adjacent figure.

Note: When in the Secondary address mode, if

IEEE 488 primary address 31 is selected,

the Digital488/80A unit will

automatically default to primary address

30.

For example, if two Digital488/80A units are

configured for primary address 08, with the first

unit being configured for Secondary addresses 0

and 1, and the second unit configured for

Secondary addresses 2 and 3, then the

communication is as indicated by the following

table.

Communication Example

To Communicate With: Use Primary Address: Use Secondary Address:

Unit 1 Channel 0 08 00

Channel 1 08 01

Unit 2 Channel 0 08 02

Channel 1 08 03

2

1

8

4

1

0

1

0

N/A

N/A

N/A

N/A

2 3

1

4

Addresses 0 and 1

2

1

8

4

N/A

N/A

N/A

N/A

2 3

1

4

Addresses 4 and 5

16

5

16

5

N/A

N/A

y

x

6 7 8

y

x

6 7 8

D/S

D/S

2

1

1

N/A

N/A

0

2 3

1

Addresses 2 and 3

2

1

1

N/A

N/A

0

2 3

1

Addresses 6 and 7

Secondary Address Settings

4

N/A

N/A

4

4

8

N/A

N/A

4

5

16

5

N/A

N/A

6 7 8

y

x

6 7 8

D/S

D/S

y

8

16

x

8 Digital488/80A Setup Digital488/80A User's Manual

Page 15

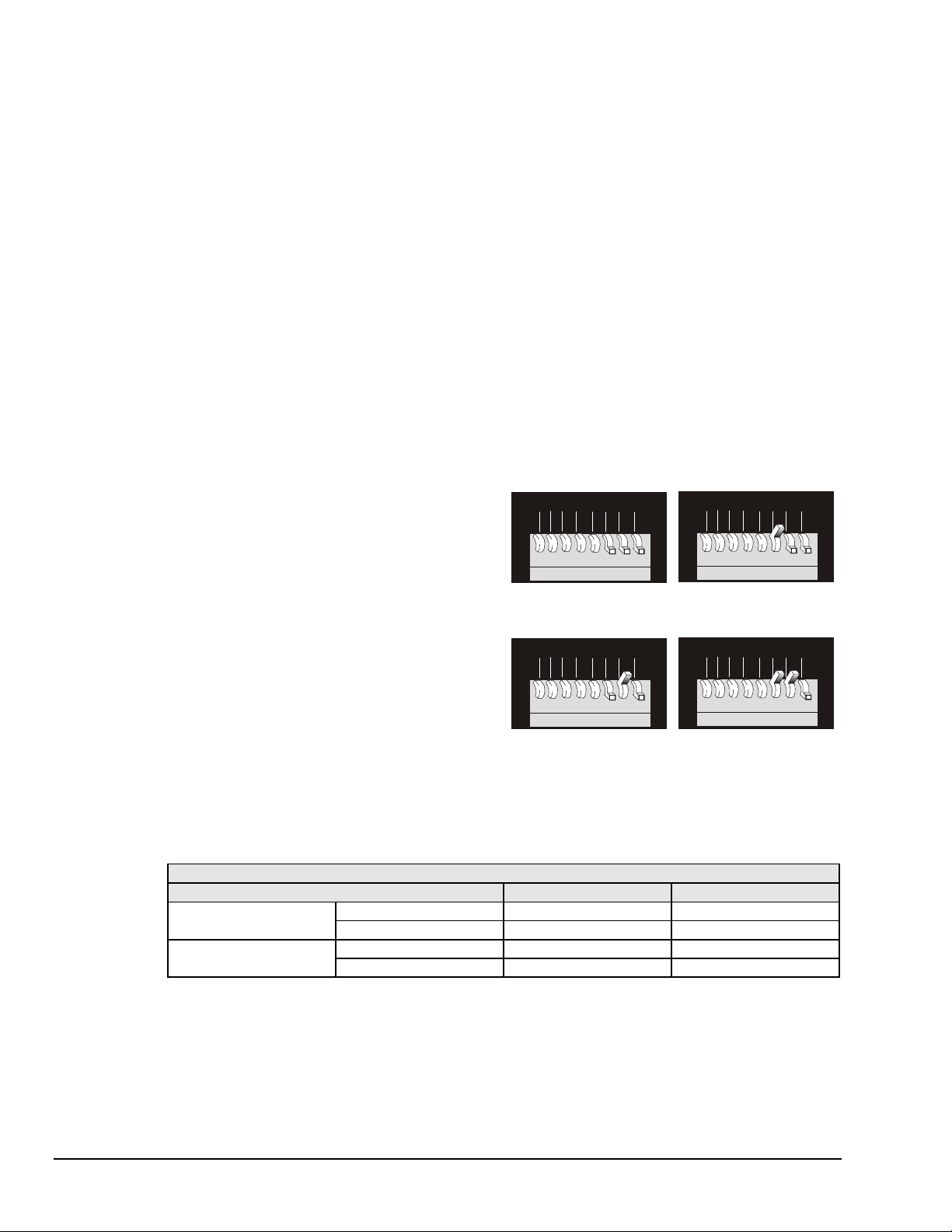

The following figure compares the Dual Primary and the Secondary addressing modes.

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 9

Page 16

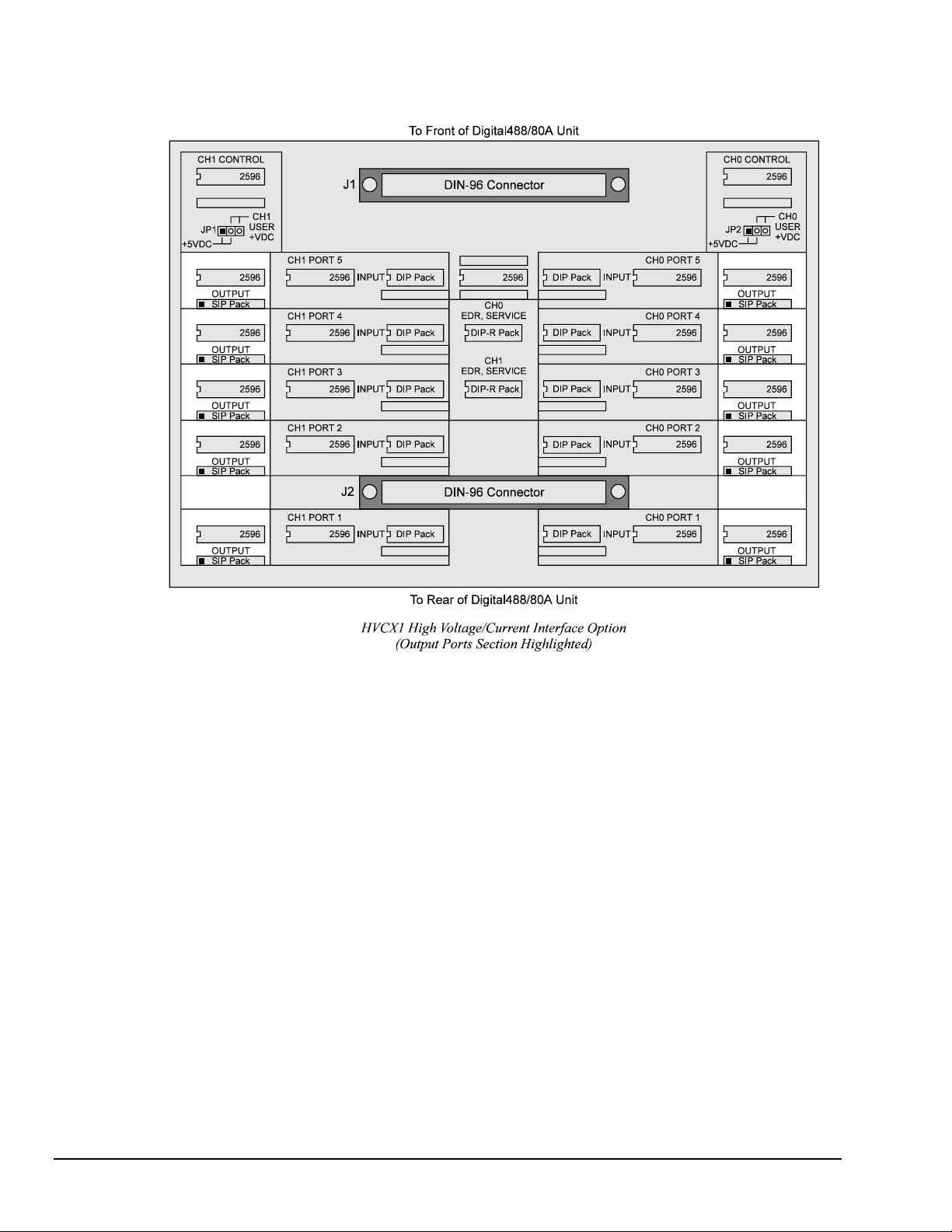

HVCX1 Option Setup

If you would like to experiment with the Digital488/80A unit and the example

programs, do not install the HVCX1 option until after experimenting with the unit to

avoid software/hardware configuration conflicts. If the HVCX1 option is already

installed, replace it with the jumper board to run the example programs.

Never disassemble the Digital488/80A case while it is connected to the AC power line!

Internal voltage potentials exist which could cause bodily injury or death!

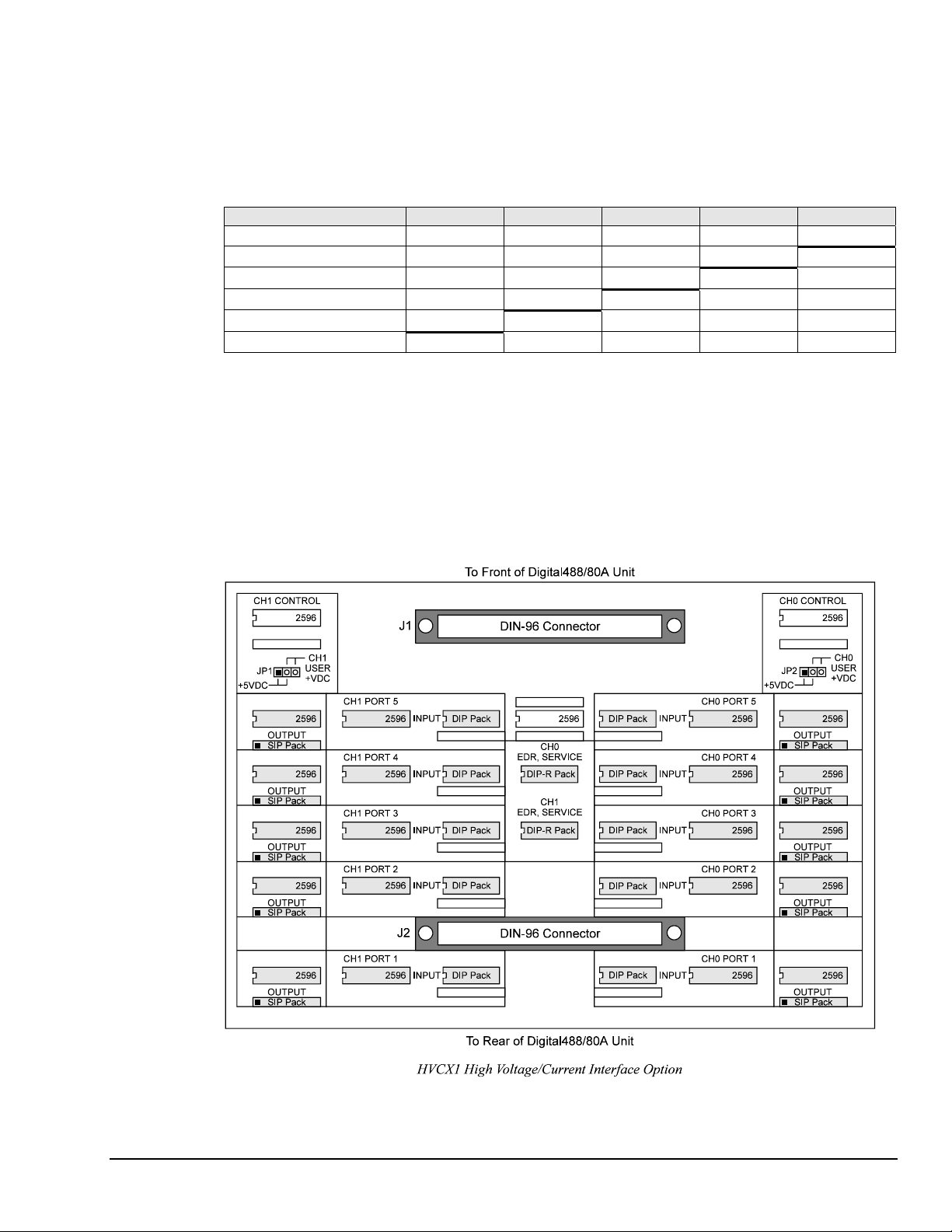

The HVCX1 High Voltage/Current

Interface option is a configurable daughter

board that allows the Digital488/80A to be

used with solenoids, switching relays and

other high voltage / high current devices.

When using the HVCX1 with an exte

rnal

voltage source, the I/O lines may be

configured as high voltage inputs (up to 50

V) or as high voltage / high current ou

tputs.

The factory default is all 5 V I/O and

handshaking f

or both channels with all ports

set as inputs.

Inputs are configured on a port-by-port

basis (in groups of 8 bits). Inputs can be

configured to be compatible with 5, 12, 24

and 48 volt logic. The interface voltage fo

each port ma

y be set independently from

other ports.

CAUTION

WARNING

r

When the HVCX1 option is used, the data

lines of both channels can be configured as

high voltage / high current outputs. Outputs

can support up to 50 VDC at 200 mA no

t to

exceed 8 A total. When the outputs are

configured as high voltage, using internal

pull-up resistors (such as the 27K ohm SIP

),

all 40 output lines on a channel have their

pull-ups and integral flyback diodes pulled

up to the flyback pin (Pin 48) on the DB-50

connector. When used in this mode, outputs

are configured on a per-channel basis. T

his

flyback pin should be connected to the

positive supply lead of the power supply

used with the external devices. The flyback

diode suppl

ies protection against inductive

transients.

Pin 48 sets the pull-up logic level for all output lines on a channel. Lines configured with the pull-up can

only be used as outputs. These outputs can sink up to 200 mA in the ON state and withstand voltages up to

50 VDC throu

gh the use of open collector drivers with integral flyback diodes for inductive load transient

suppression.

For more information, see the "Specifications" section in Chapter 1: Digital488/80A Overview.

10 Digital488/80A Setup Digital488/80A User's Manual

Page 17

Determining Ports Setup

Before configuring the HVCX1 option, determine which ports are going to be set up for inputs and which

ports for outputs. Determine what voltages are desired for the inputs: 0-5 V, 0-12 V, 0-24 V or 0-48 V.

The following chart shows which combinations of outputs and inputs are permitted (limitations set by the

Configuration (

Configuration Command Port 5 Port 4 Port 3 Port 2 Port 1

C) software command).

C0

C1

C2

C3

C4

C5

Input Input Input Input Input

Input Input Input Input Output

Input Input Input Output Output

Input Input Output Output Output

Input Output Output Output Output

Output Output Output Output Output

Note: If no chips are installed in the input or output side of a port, the Digital488/80A lines are

pulled up and the user will receive "FF" from that port.

For convenience, you may want to program the Digital488/80A to power up with your configuration.

Refer to the Configuration (

the Configuration (

C) command. To save the input/output status as the new setting for the power-up

default, it must be saved as part of the Recall Configuration (

configuration upon power on, the Save Configuration (

C) and Save Configuration (S) commands. Input or output status is set using

O) command. To set the unit to a particular

S) command must be used once all the desired

options have been selected.

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 11

Page 18

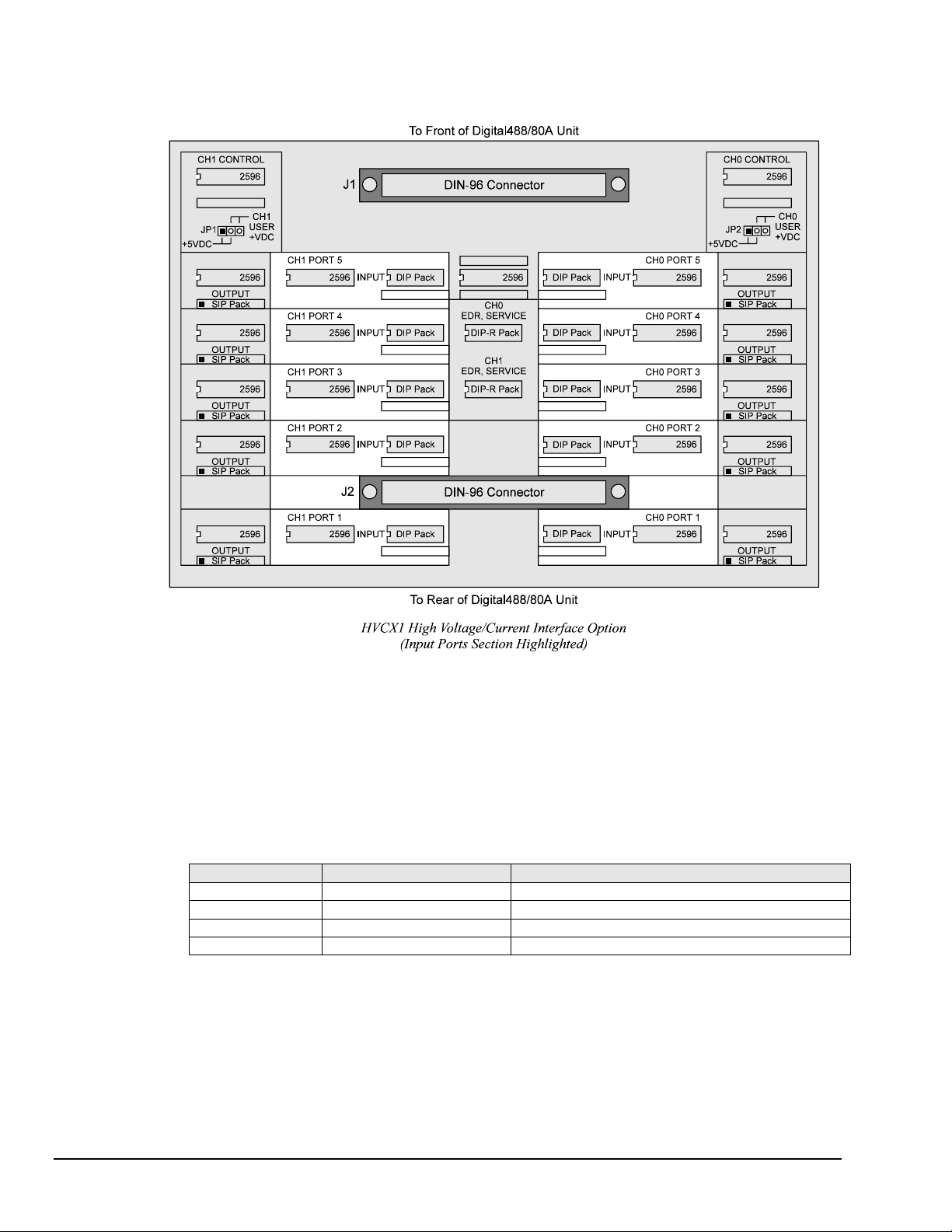

To Set Up Input Ports

Note: All of the components mentioned below are for the port section of the HVCX1 board

labelled INPUT.

1. Locate the two 5-port sections (one in the right half, one in the left half) of the HVCX1 board labelled

INPUT.

2. Place the 2596 IC chip into the IC input socket of the port being configured. The notched end of the IC

must be to the left (see above figure for the proper orientation).

3. Install the DIP (dual in-line) pack for the voltage desired. See the chart below for the DIP pack

labeling. The notched end of the DIP pack must be to the left (see above figure for the proper

orientation).

0-5 V 10 ohms 4116R-001-100

0-12 V 20K ohms 4116R-001-203

0-24 V 56K ohms 4116R-001-563

0-48 V 120K ohms 4116R-001-124

Inputs DIP Resistor Values Label of DIP Pack Supplied with HVCX1 Option

4. Verify that no components (the 2596 and SIP pack) are in the OUTPUT section of a port being

configured as an input. Having components for the output and input installed in the same port will

cause damage to the unit.

12 Digital488/80A Setup Digital488/80A User's Manual

Page 19

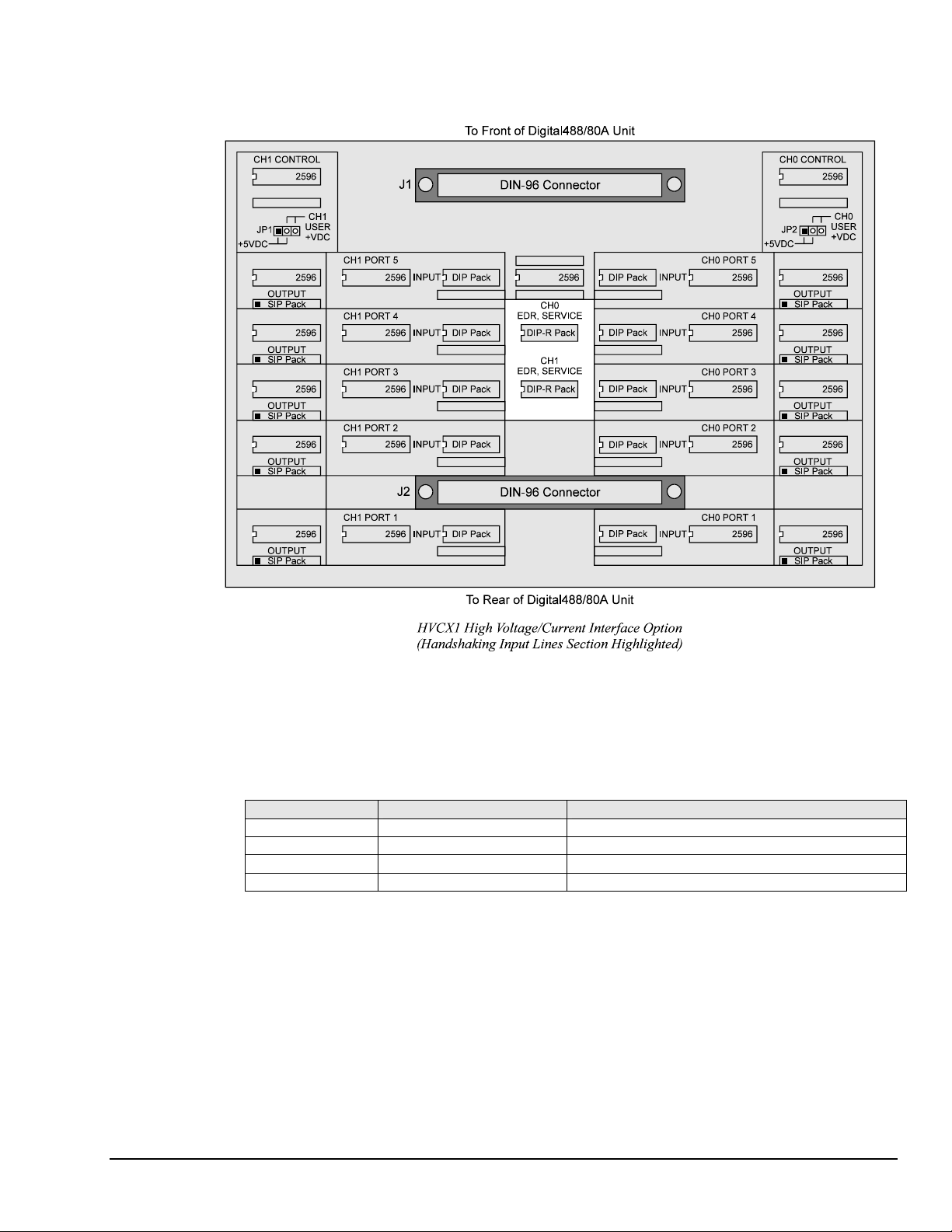

To Set Up Handshaking Input Lines

Note: All of the components mentioned below are for the central section of the HVCX1 board

labelled EDR, SERVICE.

1. Locate the center of the HVCX1 board labelled CH0 EDR, SERVICE and CH1 EDR, SERVICE.

2. Install the DIP (dual in-line) pack for the input handshaking voltage desired. See the chart below for

the DIP pack labeling. The notched end of the DIP pack must be to the left (see above figure for the

proper orientation).

0-5 V 10 ohms 4116R-001-100

0-12 V 20K ohms 4116R-001-203

0-24 V 56K ohms 4116R-001-563

0-48 V 120K ohms 4116R-001-124

Inputs DIP Resistor Values Label of DIP Pack Supplied with HVCX1 Option

3. Verify that the appropriate DIP packs are installed in the CH0 EDR, SERVICE section fo r the Channel

0 settings, and in the CH1 EDR, SERVICE section for the Channel 1 settings.

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 13

Page 20

To Set Up Output Ports

Note: All of the components mentioned below are for the port section of the HVCX1 board

labelled OUTPUT.

1. Locate the two 5-port sections (one in the right end, one in the left end) of the HVCX1 board labelled

OUTPUT.

2. Place the 2596 IC chip into the IC input socket of the port being configured. The notched end of the IC

must be to the left (see above figure for the proper orientation).

3. When configuring the option for high voltage, install the 27K SIP (single in-line) pack pull-up resistor

network (labeled 9X-1-273) in the SIP socket in the OUTPUT section. Make sure Pin 1 of the SIP

pack, as denoted by the square dot, is toward the left (see above figure for the proper orientation). This

pin must be connected to an external voltage supply in order to achieve the desired logic level.

4. Verify that no components (the 2596 and DIP pack) are in the INPUT section of a port being

configured as an output. Having components for the output and input installed in the same port will

cause damage to the unit.

To Set Up Handshaking Output Lines

With the HVCX1 option, the Digital488/80A handshaking outputs (Trigger, Inhibit, Strobe and Clear) can

be set. The user-defined voltage is the voltage supplied through Pin 48 of the channel (voltage is the same

as the data lines for ports configured as outputs). Handshaking output lines are changed as a group and

cannot have their sense reconfigured; handshaking inputs are always inputs, and handshaking outputs are

always outputs. There is one group of handshaking output lines per channel (i.e. CH0 has handshaking set

and CH1 has handshaking set). Handshaking may be done at TTL levels even if digital I/O is set for a

higher range.

14 Digital488/80A Setup Digital488/80A User's Manual

Page 21

Note: All of the components mentioned below are for the upper-corner sections of the HVCX1

board labelled CONTROL.

1. Locate the upper corners of the HVCX1 board labelled CH1 CONTROL and CH0 CONTROL.

2. In these CH1 CONTROL and CH0 CONTROL sections, the handshaking outputs are set by jumpers

JP1 and JP2, for either +5 VDC (TTL) or a user-defined voltage (see following figure for the proper

jumper settings).

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 15

Page 22

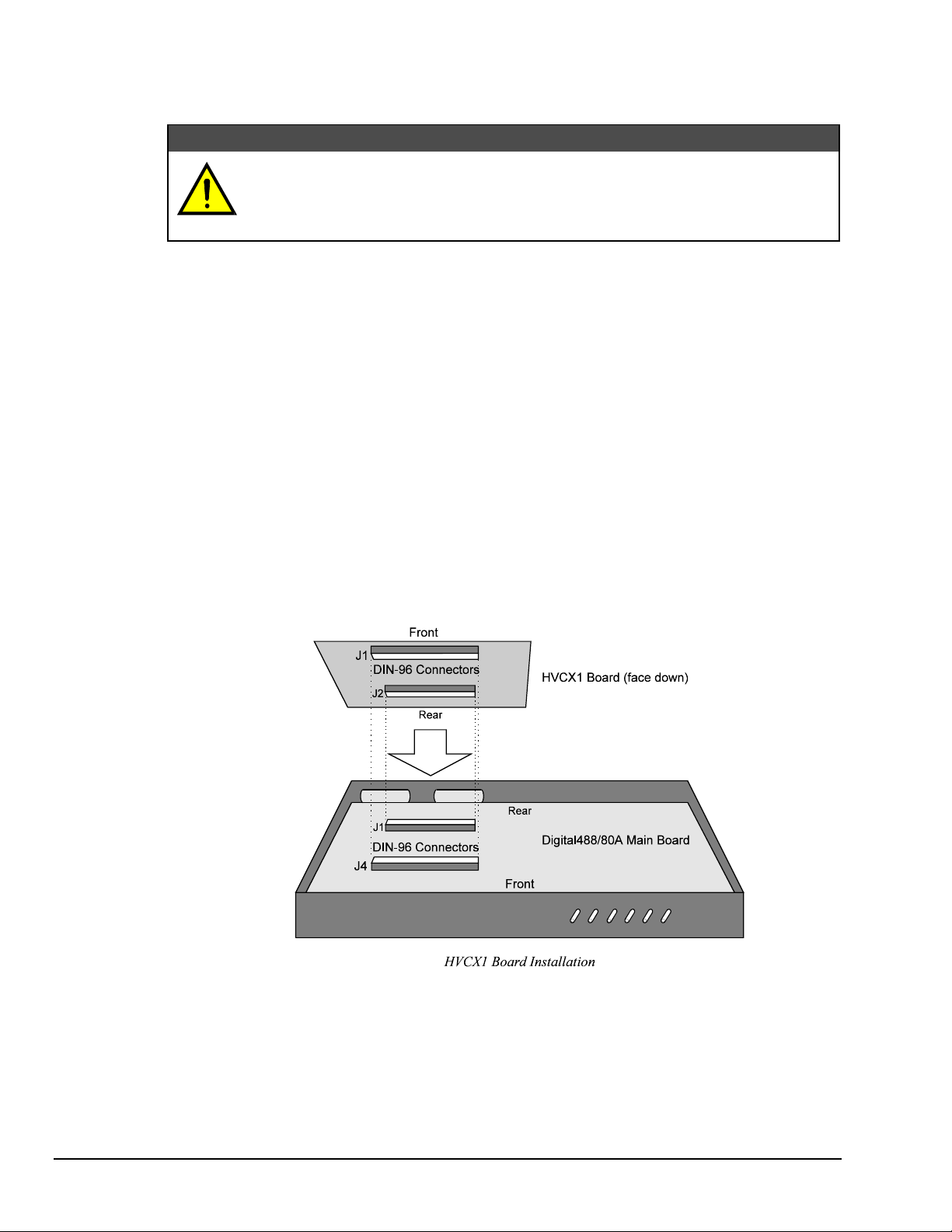

To Install the HVCX1 Option

Note: If disassembly or disconnections are necessary, first turn off the power, next disconnect the AC

1. When the input and output port configurations on the HVCX1 option are complete, record the settings

on the Digital488/80A HVCX1 Configuration Record supplied with your user's manual or provided in

Appendix A of this manual.

2. Turn off the power. Next, disconnect the AC power line cord, and then all other test cables from the

unit.

3. Place the unit on a flat surface. Remove the four screws on top of the case and remove the top cover.

4. Locate the two DIN-96 connectors on the HVCX1 board labelled J1 and J2, and the two DIN-96

connectors on the Digital488/80A main board labelled J4 and J1.

Note: If the HVCX1 option was not factory installed, the DIN-96 connectors have a jumper board

5. Hold the HVCX1 board upside down, with the label FRONT toward the front of the Digital488/80A

and the label REAR toward the back of the Digital488/80A.

6. Line up the J1 DIN-96 on the HVCX1 board with the J4 DIN-96 on the Digital488/80A main board.

Line up the J2 DIN-96 on the HVCX1 board with the J1 DIN-96 on the Digital488/80A main board.

When the HVCX1 option is used, the I/O lines are hardware configured as either

inputs or outputs. The hardware and software configurations for the input and output

ports must agree. The Digital488/80A unit is protected from configuration conflict,

but the I/O lines will not respond properly.

power line, and then any other cables, prior to disassembly.

plugged into them. Remove the jumper board.

CAUTION

7. Press down the HVCX1 board gently but firmly to plug together the DIN-96 connectors. Be careful not

to bend any DIN-96 connector pins.

8. Carefully reassemble the unit.

Note: For re-assembly, first reconnect the AC power line, and then any other cables, prior to reapplying

power to the entire system.

16 Digital488/80A Setup Digital488/80A User's Manual

Page 23

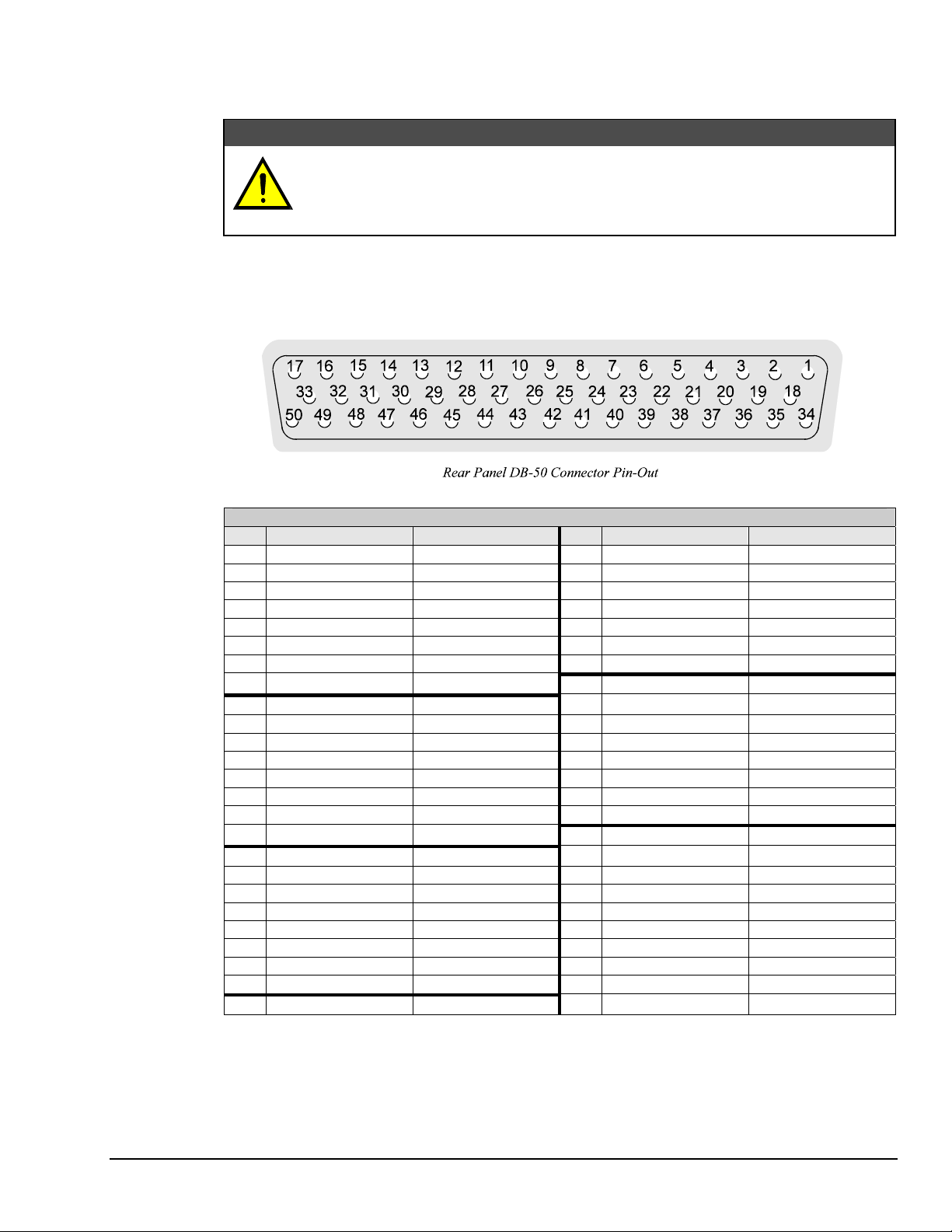

Digital I/O Ports

CAUTION

When the HVCX1 option is used, the I/O lines are hardware configured as either

inputs or outputs. The hardware and software configurations for the input and output

ports must agree. The Digital488/80A unit is protected from configuration conflict,

but the I/O lines will not respond properly.

The Digital488/80A has two DB-50 connectors -- Channel 0 and Channel 1 -- each of which provides 40

data lines programmable in groups of 8 bits as either input or output ports. The following figure illustrates

one of the digital I/O DB-50 connectors as viewed from the rear panel of the Digital488/80A. Both

Channel 0 and Channel 1 DB-50 connectors are identical.

DB-50 Con or nect

Pin Description Comment Pin Description Comment

1 Port 1 Bit 1 I/O, Port 1 LSB 26 Port 4 Bit 2 Input/Output

2 Port 1 Bit 2 Input/Output 27 Port 4 Bit 3 Input/Output

3 Port 1 Bit 3 Input/Output 28 Port 4 Bit 4 Input/Output

4 Port 1 Bit 4 Input/Output 29 Port 4 Bit 5 Input/Output

5 Port 1 Bit 5 Input/Output 30 Port 4 Bit 6 Input/Output

6 Port 1 Bit 6 Input/Output 31 Port 4 Bit 7 Input/Output

7 Port 1 Bit 7 Input/Output 32 Port 4 Bit 8 I/O, Port 4 MSB

8 Port 1 Bit 8 I/O, Port 1 MSB 33 Port 5 Bit 1 I/O, Port 5 LSB

9 Port 2 Bit 1 I/O, Port 2 LSB 34 Port 5 Bit 2 Input/Output

10 Port 2 Bit 2 Input/Output 35 Port 5 Bit 3 Input/Output

11 Port 2 Bit 3 Input/Output 36 Port 5 Bit 4 Input/Output

12 Port 2 Bit 4 Input/Output 37 Port 5 Bit 5 Input/Output

13 Port 2 Bit 5 Input/Output 38 Port 5 Bit 6 Input/Output

14 Port 2 Bit 6 Input/Output 39 Port 5 Bit 7 Input/Output

15 Port 2 Bit 7 Input/Output 40 Port 5 Bit 8 I/O, Port 5 MSB

16 Port 2 Bit 8 I/O, Port 2 MSB 41 Clear Output only

17 Port 3 Bit 1 I/O, Port 3 LSB 42 Data Strobe Output only

18 Port 3 Bit 2 Input/Output 43 Trigger Output only

19 Port 3 Bit 3 Input/Output 44 Inhibit Output only

20 Port 3 Bit 4 Input/Output 45 Service Input Input only

21 Port 3 Bit 5 Input/Output 46 External Data Ready Input only

22 Port 3 Bit 6 Input/Output 47 (Not Used) (Not Used)

23 Port 3 Bit 7 Input/Output 48 HVCX1 Flyback Flyback

24 Port 3 Bit 8 I/O, Port 3 MSB 49 +5 V 50 mA maximum load

25 Port 4 Bit 1 I/O, Port 4 LSB 50 I/O Common Ground

Digital488/80A User’s Manual 11-08-02 Digital488/80A Setup 17

Page 24

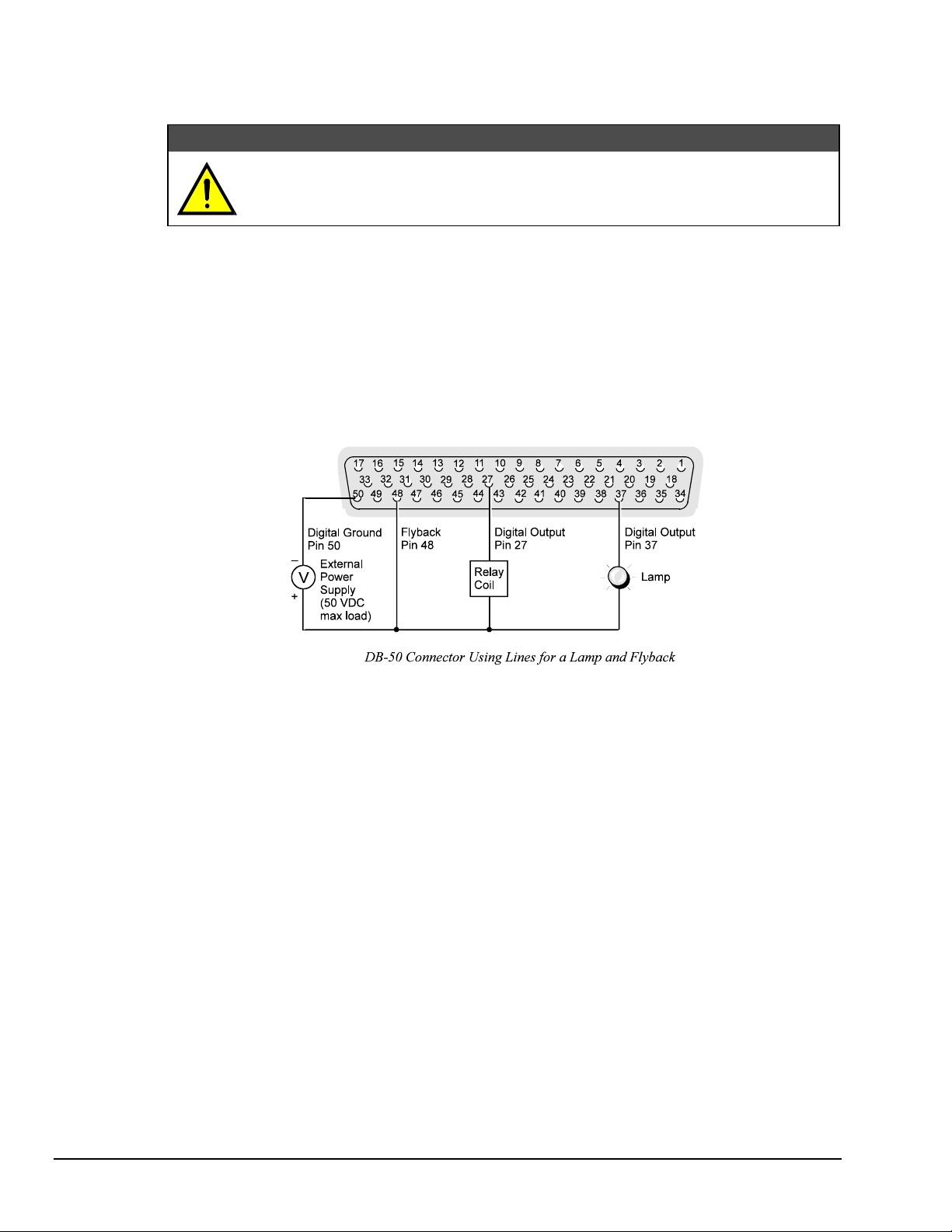

Using the HVCX1 Option for High Voltage/Current Outputs

The HVCX1 option provides buffering for all the digital I/O lines on the Digital488/80A. This means that

the HVCX1 option has 80 digital I/O lines that are divided into two 40-bit channels -- Channel 0 and

Channel 1. Each channel is divided into five eight-bit ports. Six high-level ASCII commands configure

the ports to be all inputs, all outputs or combinations in between. Thus, a configuration can range from 80

input lines to 80 output lines or combinations in between in multiples of 8 bits.

Once the Channel port(s) are configured for high level operation, they can be used to drive devices such as

switching relays, solenoids and displays. For example, a typical application may require a lamp and a relay

to be driven by the Digital488/80A. The relay is connected to data line 27 (Port 4) and the lamp is

connected to data line 37 (Port 5). These two ports must be configured as high-level outputs. These

devices would be connected as shown in the following figure.

Never connect external high-level devices to a Channel 0 port or to a Channel 1 port

which has not first been configured for this purpose. Failure to do so may result in

damage to the Digital488/80A.

CAUTION

Since a relay is used for this application, the flyback terminal is connected to the positive terminal of the

external power supply. Note also that the Ground lead of the power supply should be connected to Pin 50

on the DB-50 connector. Remember that ports configured as high-level outputs can only be used as

outputs.

18 Digital488/80A Setup Digital488/80A User's Manual

Page 25

Digital488/80A Power & Assembly 3

Introduction…… 19

Internal Components…… 19

Factory Service…… 19

Power Line & Fuse Configuration…… 20

Line Voltage Selection…… 20

To Select the Line Voltage…… 21

Fuse Replacement…… 22

To Replace the Fuse…… 22

Rack-Mount & Bench-Top Assembly…… 23

Rack Mount…… 23

Bench Top…… 23

Power-Up & Programming Tests…… 24

Power-Up Activation…… 24

Programming Examples……25

KYBDCTRL.BAS Program…… 25

To Run the Keyboard Controller Program…… 25

Digital488/80A Command Responses…… 26

Introduction

Internal Components

The heart of the Digital488/80A is a 6809 microprocessor [U1] supported by 8K bytes of firmware

EPROM [U2] and 32K bytes of battery-backed-up RAM [U3]. Interface to the IEEE 488 bus is

accomplished by a 9914 interface chip [U13]. A 65B22 [U14] generates real-time interrupts for the

firmware operating system and also drives the front panel LED indicators. The digital I/O ports are

controlled through 6821 interface chips [U7, U8, U9, U10, U11, U16]. High-voltage, high-current output

capability is provided on both channels if the HVCX1 option is used. Power is supplied by an on-board

transformer and full-wave rectifier. Regulation to the required +5 volts is provided by an 78T05CT [U15].

The memory space allocation on the Digital488/80A is:

Factory Service

Chapter 7: Troubleshooting provides a troubleshooting reference for possible solutions to technical

problems. Before calling for technical assistance, refer to this chapter.

However, if problems in using the Digital488/80A still persist, you should contact the factory. Many

problems can be resolved by discussing the problems with the appropriate applications department. If the

problem cannot be solved by this method, you will be instructed as to the proper return procedure.

Address Device Part Number Function

$0000-$7FFF U3 84256 32K x 8 RAM

$8010-$8014 U7 68B21 Digital I/O

$8020-$8024 U8 68B21 Digital I/O

$8040-$8044 U9 68B21 Digital I/O

$8080-$8084 U10 68B21 Digital I/O

$8100-$8104 U11 68B21 Digital I/O

$8200-$8204 U16 68B21 Digital I/O

$8800-$8810 U14 65B22 Timer, Digital I/O

$9000-$9907 U13 TMS9914A IEEE 488 Interface

$E000-$FFFF U2 2764 Programmed EPROM

Digital488/80A User’s Manual Digital488/80A Power & Assembly 19

Page 26

Power Line & Fuse Configuration

The power configuration of the Digital488/80A unit consists of selecting the line voltage and replacing the

fuses. Each Digital488/80A unit has a factory default to operate at 105-125 volts AC. However, each unit

may be operated at either 105-125 or 210-250 VAC.

To change the operating voltage of the Digital488/80A unit, it is necessary to open the enclosure.

However, before modifying the voltage, disconnect any input or output connections from the rear panel of

the affected unit and then disconnect the power cord from the power line terminal.

Line voltage must be set for 105-125 or 210-250 VAC to match the power being supplied to the

Digital488/80A unit. If the line voltage is changed

text for the line

Line Voltage Selection

As already mentioned, the Digital488/80A may be operated with 105-125 or 210-250 VAC, 50-60 Hz

power, as set by its internal line-voltage switch (labeled S4). Each unit is shipped from the factory with

this operating voltage setting marked on its rear panel. If this is not the appropriate power setting to be

supplied to the unit, then the line voltage and power fuse must be changed to avoid damage to the unit.

The line-voltage selection procedure is outlined in the following steps.

WARNING

Do not use the Digital488/80A unit outdoors! The unit is intended for indoor use only!

Outdoor conditions could result in equipment failure, bodily injury or death!

WARNING

Never disassemble the Digital488/80A case while it is connected to the AC power line!

Internal voltage potentials exist which could cause bodily injury or death!

, the fuse must also be changed. Refer to the following

voltage switch and fuse locations.

CAUTION

Service: Fuse replacement and the changing of selected line voltage must be

performed by qualified service personnel. Never open the Digital488/80A case while it

is connecte

or death!

d to the AC line. Contact with voltage potentials could cause bodily injury

20 Digital488/80A Power & Assembly Digital488/80A User's Manual

Page 27

Note: If disassembly or disconnection is necessary, first turn off the power, next disconnect the AC

power line, and then any other cables, prior to disassembly.

To Select the Line Voltage

1. Turn off the power. Next, disconnect the AC power line cord, and then all other test cables from the

unit.

2. Place the unit on a flat surface. Remove the four screws on top of the case and remove the top cover.

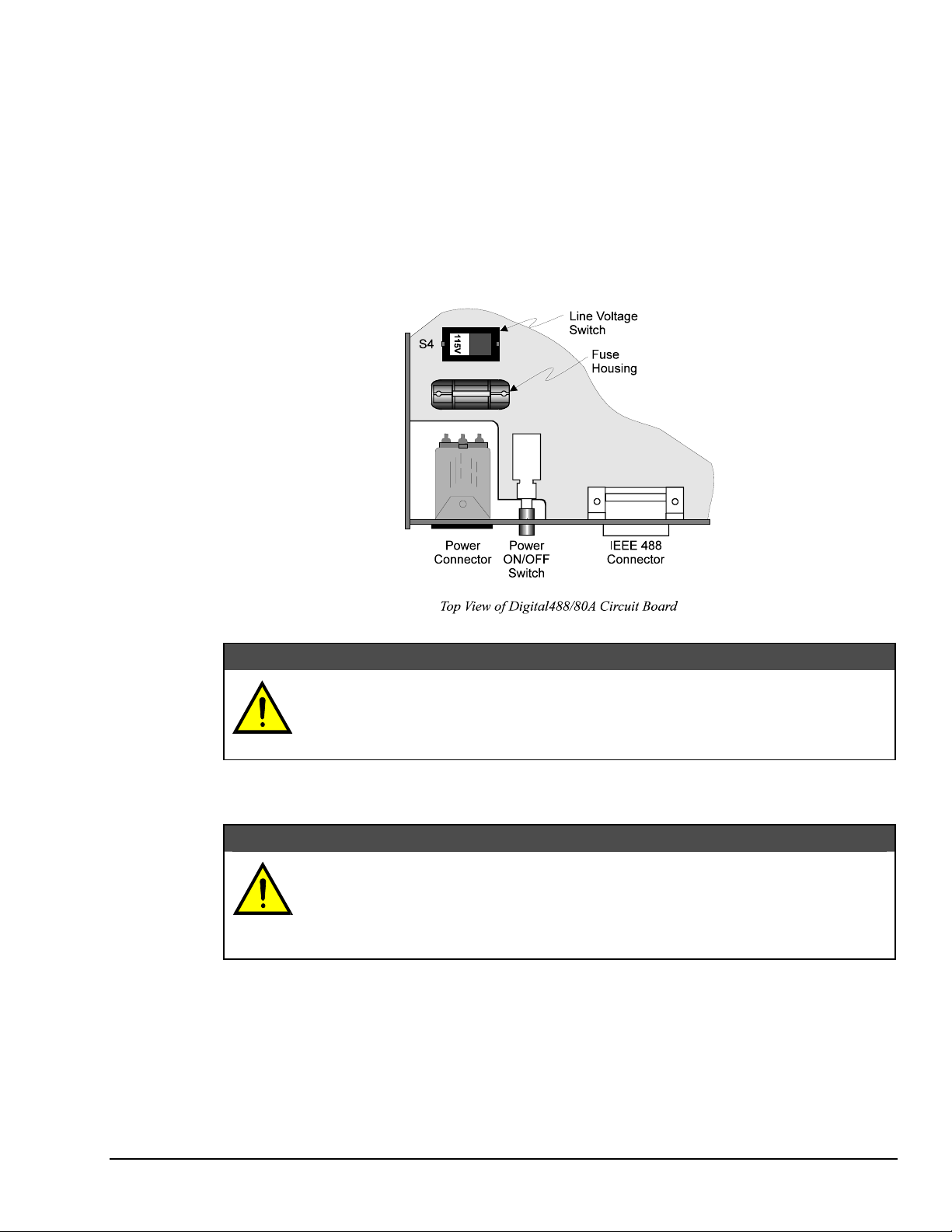

3. Located next to the main power supply transformer is the line voltage selection switch (labeled S4).

Using a small screwdriver, insert the tip of the screwdriver into the slot of the switch and slide the

switch to the left or right until it "clicks" into place with the desired line voltage selection visible.

CAUTION

It is possible to place the line voltage switch (S4

cause equipment damage or malfunction. Whe

V or 220 V selection. The switch will “click” into place when properly positioned.

voltage selection swi

tch (S4), make sure the switch is completely positioned to the 115

) in a partial position which could

n changing the position of the line

4. Install a power line fuse appropriate for the line voltage. See section Fuse Replacement – Step 3,

following this section.

CAUTION

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry. If

a fuse blows, contact a qualified service representative. Replacement fuses are to be

installed by qualified service personnel with the unit disconnected from the power

source and with all other terminals disconnected. If the line voltage selector is

changed, then the fuse designated for that line voltage must be used.

5. Make note of the new voltage setting for later reference.

6. Carefully reassemble the unit.

Note: For re-assembly, first reconnect the AC power line, and then any other cables, prior to reapplying

power to the entire system.

Digital488/80A User’s Manual Digital488/80A Power & Assembly 21

Page 28

Fuse Replacement

The Digital488/80A unit contains an internal AC line fuse. The fuse is located next to the internal linevoltage switch (S4). You may replace the fuse by using the procedures found in the following text.

Note: If disassembly or disconnection is necessary, first turn off the power, next disconnect the AC

To Replace the Fuse

1. Turn off the power. Next, disconnect the AC power line cord, and then all other cables from the unit.

2. Place the unit on a flat surface. Remove the four screws on top of the case and remove the top cover.

3. Located next to the line-voltage selection switch (labeled S4) is the power fuse. Gently pull upward

on the plastic fuse housing. The entire housing with the fuse inside should be removed.

4. Open the fuse housing by pushing up on the tab on the bottom of the housing. Remove the fuse, and

replace it with the proper type using the following list as a guide:

• For line voltage 105-125 V, use fuse type 1/2 A, Slo Blo, 3AG

• For line voltage 210-250 V, use fuse type 1/4 A, Slo Blo, 3AG

Service: Fuse replacement and the changing of selected line voltage must be

performed by qualified service personnel. Never open the Digital488/80A case while it

is connected to the AC line. Contact with voltage potentials could cause bodily injury

or death!

power line, and then any other cables, prior to disassembly.

CAUTION

5. Close the housing. Insert the fuse into the fuse holder.

6. Make note of the new fuse rating for later reference. If you have also changed the operating line-

voltage selection, return to the previous section Line Voltage Selection – Step 5.

7. Carefully reassemble the unit.

Note: For re-assembly, first reconnect the AC power line, and then any other cables, prior to reapplying

Fuse Failure: Fuse failure indicates a possible problem within the device circuitry. If

a fuse blows, contact a qualified service representative. Replacement fuses are to be

installed by qualified service personnel with the unit disconnected from the power

source and with all other terminals disconnected. If the line voltage selector is

changed, then the fuse designated for that line voltage must be used.

power to the entire system.

CAUTION

22 Digital488/80A Power & Assembly Digital488/80A User's Manual

Page 29

Rack-Mount & Bench-Top Assembly

The Digital488/80A includes accessories for rack-mount or bench-top assembly.

Rack Mount

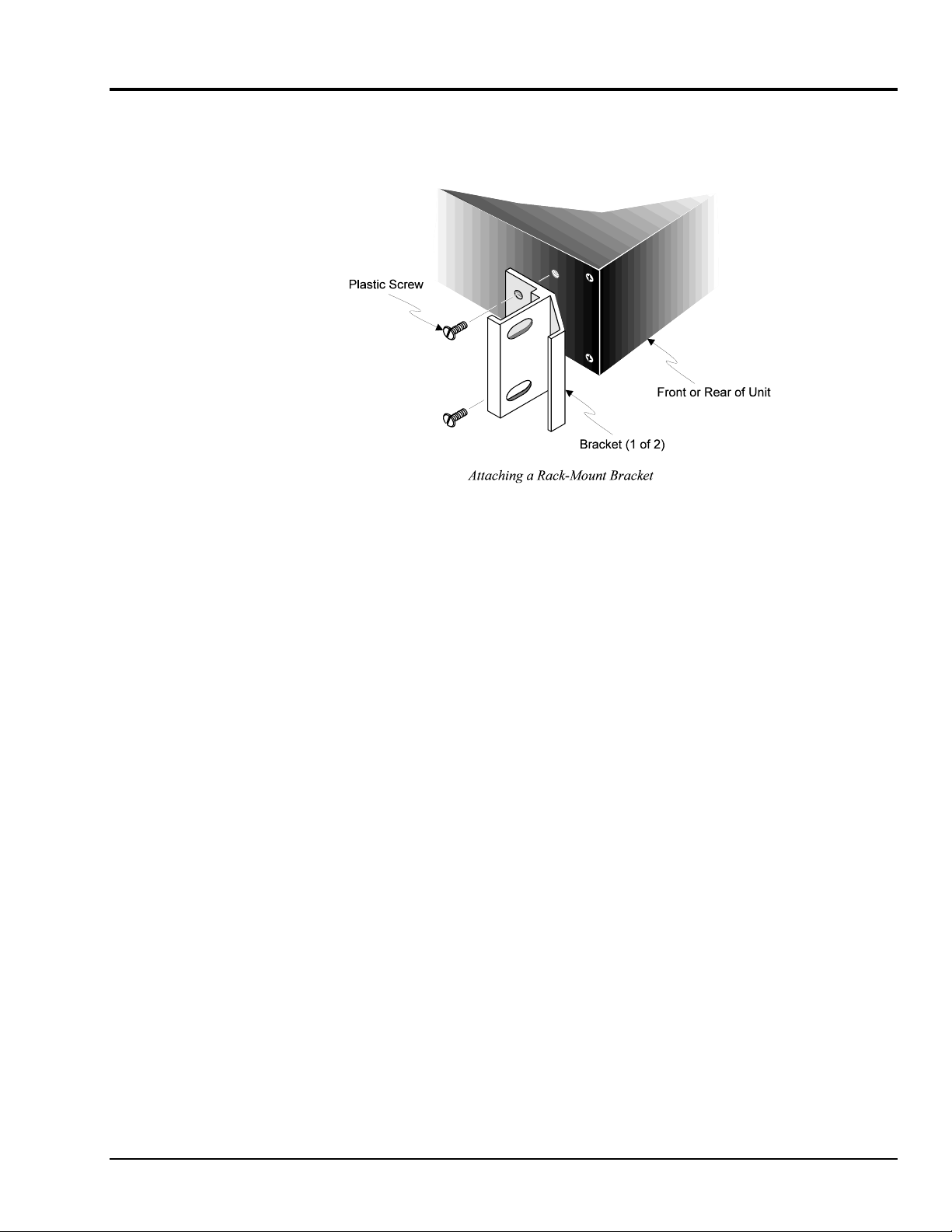

If rack-mount assembly is required, remove the two plastic screws from the pre-drilled holes on each side

of the unit. Since the unit can be mounted with the front or rear panel facing the front of the rack fixture,

remove only those screws from the set of holes that will be toward the front of the rack. Attach the two

rack ears using the enclosed screws.

Bench Top

If bench-top assembly is required, install the self-adhesive rubber feet on the bottom of the unit

approximately one inch from each corner.

Digital488/80A User’s Manual Digital488/80A Power & Assembly 23

Page 30

Power-Up & Programming Tests

Power-Up Activation

Condition

Normal (No Errors)

ROM Error

RAM Error

NV-RAM Checksum Error

No Power

With the power cord plugged in and connected to the Digital488/80A, turn on the unit by depressing the

rear-panel power switch. All of the front-panel LED indicators should light up for approximately one

second while the Digital488/80A performs an internal ROM and RAM self-check. At the end of this selfcheck all of the LED indicators should turn off except for POWER.

Otherwise, the Digital488/80A may be in an error condition according to the one of the four following

LED patterns:

• If all of the LED indicators remain on: Then a ROM error has occurred.

• If the POWER LED indicator remains on while the rest of the LED indicators flash continuously:

Then a RAM error has occurred. Try cycling the power to the Digital488/80A to determine that the

error is repeatable.

Line Voltage: The protective conductor terminal on the AC line connector must be

connected to an external protective earthing system. Failure to make such a

connection will impair protection from shock.

LED Patterns for Error Conditions

LED Indicators

TALK LISTEN SRQ ERROR TEST POWER

(Off) (Off) (Off) (Off) (Off) ON

ON ON ON ON ON ON

FLASHING FLASHING FLASHING FLASHING FLASHING ON

(Off) (Off) (Off) ON (Off) ON

(Off) (Off) (Off) (Off) (Off) (Off)

CAUTION

• If the POWER and ERROR LED indicator remain on while the rest of the LED indicators are off:

Then a checksum error on Non-Volatile RAM occurred, and the saved configurations may be lost.

The checksum error condition may be cleared by doing a save of a configuration using the Save

Configuration (

S) command.

Note: The error condition cannot be cleared by using the Query Error Status (E?) command.

• If all of the LED indicators are off: Then there may not be any power being supplied to the

Digital488/80A. In this event, check to make sure that the AC power cable is securely connected at

both ends. Otherwise, there may be a problem with the fuse. For more information, see section Power

Line & Fuse Configuration earlier in this chapter.

For convenience, you may want to program the Digital488/80A to power up with your configuration.

Refer to the Configuration (

the Configuration (

C) command. To save the input/output status as the new setting for the power-up

default, it must be saved as part of the Recall Configuration (

configuration upon power on, the Save Configuration (

C) and Save Configuration (S) commands. Input or output status is set using

O) command. To set the unit to a particular

S) command must be used once all the desired

options have been selected.

24 Digital488/80A Power & Assembly Digital488/80A User's Manual

Page 31

Programming Examples

The Digital488/80A programming examples use the Personal488 PC/IEEE 488 controller interface and the

BASIC Keyboard Controller (KBC) program. This KBC program

and is listed below.

KYBDCTRL.BAS Program

10 ' Personal488 Keyboard Controller Program

20 '

30 ' For use with the IOtech Personal488

40 ' IEEE 488 interface

50 '

100 OPEN "\DEV\IEEEOUT" FOR OUTPUT AS #1

110 IOCTL#1,"BREAK"

120 PRINT#1,"RESET"

130 OPEN "\DEV\IEEEIN" FOR INPUT AS #2

140 '

150 ON ERROR GOTO 300

160 PRINT#1,"ERROR OFF"

170 '

180 LINE INPUT "CMD> ",CMD$

190 PRINT#1,CMD$

200 '

210 IF IOCTL$(2)<>"1" THEN 180

220 PRINT INPUT$(1,2);

230 GOTO 210

290 '

300 ' Error Handler

310 '

320 IOCTL#1,"BREAK"

330 PRINT#1,"STATUS"

340 INPUT#2,ST$

350 PRINT CHR$(7);"Error #";MID$(ST$,15,2);": ";MID$(ST$,27)

360 RESUME NEXT

KYBDCTRL.BAS is included on the disk

The Keyboard Controller (KBC) program allows direct communication with the Digital488/80A (or any

IEEE 488 device on the bus) via the keyboard, and displays any responses on the screen. This program is a

convenient method of exercising the Digital488/80A and becoming familiar with the commands and their

actions.

To Run the Keyboard Controller Program

CAUTION

This programming example will not work properly if the HVCX1 option is installed.

Remove the HVCX1 board and replace it with the jumper board to run this example.

1. First, verify that the rear-panel DIP switch S1 is set for Dual Primary addressing mode (factory

default), and for IEEE 488 bus primary address 8 (factory default).

2. Connect an IEEE 488 cable from the IEEE 488 connector on the Digital488/80A to the IEEE 488

connector on the Personal488 PC/IEEE 488 controller interface card.

3. Turn on the Digital488/80A by depressing the rear-panel power switch. All of the front-panel LED

indicators should light up for approximately one second while the Digital488/80A performs an internal

ROM and RAM self-check. At the end of this self-check all of the LED indicators should turn off

except for POWER.

4. From the MS-DOS prompt on your computer screen, run the Keyboard Controller Program

KYBDCTRL.BAS and verify that the CMD> prompt appears on the screen.

Digital488/80A User’s Manual Digital488/80A Power & Assembly 25

Page 32

Digital488/80A Command Responses

(1) CMD>

(2) CMD>OUTPUT 08;T1X

(3) CMD>OUTPUT 08;T0X

(4) CMD>CLEAR

(5) CMD>OUTPUT 08;U0X

(6) CMD>ENTER 08

1.0 C0 E0 F0 G0 I000 K0 L0000 M000 P0 R0 Y0

(7) CMD>OUTPUT 09;U0X

(8) CMD>ENTER 09

1.0 C0 E0 F0 G0 I000 K0 M000 P0 R0 Y0

(9) CMD>OUTPUT 08;C?

(10) CMD>ENTER 08

C0

(11) CMD>OUTPUT 08;C5X

(12) CMD>OUTPUT 08;C?

(13) CMD>ENTER 08

C5

(14) CMD>OUTPUT 09;C?

(15) CMD>ENTER 09

C0

(16) CMD>OUTPUT 08;G2 R0 X

(17) CMD>OUTPUT 08;D123Z X

(18) CMD>ENTER 08

0000000123

(19) CMD>OUTPUT 08;A37 X

(20) CMD>ENTER 08

1000000123

The above is a listing of the commands given to the Digital488/80A and the response received. Some

commands and command responses are separated by extra vertical and horizontal spaces for clarity

although these spaces will not actually appear when using the program. These command responses are

explained as follows:

26 Digital488/80A Power & Assembly Digital488/80A User's Manual

Page 33

• Line 1: Initial command prompt from the Keyboard Controller program.

• Line 2: Instruct the Digital488/80A to turn on its TEST LED indicator. The TEST LED indicator

should light up.

• Line 3: Instruct the Digital488/80A to turn off its TEST LED indicator. The TEST LED indicator

should turn off.

• Line 4: Reset the Digital488/80A.

• Line 5: Retrieve the Channel 0 status (IEEE 488 bus address 08).

• Line 6: The status message shows that all default options are in use.

• Line 7: Retrieve the Channel 1 status (IEEE 488 bus address 09).

• Line 8: The status message shows that all default options are in use.

• Line 9: Retrieve the status of the port configuration mode for Channel 0.

• Line 10: The status message shows that the default port configuration

C0 is in use.

• Line 11: Program all the Channel 0 Ports as outputs.

• Line 12: Retrieve the status of the port configuration mode for Channel 0.

• Line 13: The status message shows that the Configuration (

C) command C5 was executed.

• Line 14: Retrieve the status of the port configuration mode for Channel 1.

• Line 15: The status message shows that the default port configuration

C0 is in use.

• Line 16: Program the Digital488/80A Channel 0 to send output data when addressed to Talk.

• Line 17: Send the data 123 to Channel 0.

• Line 18: Read the data from Channel 0. The message shows the data 123.

• Line 19: Program the Digital488/80A to set Bit 37 on Channel 0.

• Line 20: Read the data from Channel 0. The message shows that Bit 37 is set, and also the previous

data 123.

The above examples may also be repeated using Secondary addressing mode. To do this, turn off the

Digital488/80A, and set the rear-panel DIP switch S1 for Secondary addressing mode. Then repeat the

above commands, substituting IEEE 488 bus address 0800 for 08, and address 0801 for 09, in all of the

commands.

Digital488/80A User’s Manual Digital488/80A Power & Assembly 27

Page 34

Notes

28 Digital488/80A Power & Assembly Digital488/80A User's Manual

Page 35

Digital488/80A Operation 4

Introduction…… 29

Handshaking/Control Lines…… 29

Clear (Pin 41)…… 30

Data Strobe (Pin 42)…… 30

Trigger (Pin 43)…… 30

Inhibit (Pin 44)…… 31

Service (Pin 45)…… 31

External Data Ready (Pin 46)…… 31

IEEE 488 Bus Support…… 32

Bus Lines…… 32

Bus Commands…… 32

Bus Addresses…… 34

Bus Terminators…… 34

Introduction

Each 40-bit channel has six handshaking/control lines, as follows:

• Clear (Pin 41): This output line is pulsed whenever a Device Clear (

SDC) command is received from the IEEE 488 controller.

(

• Data Strobe (Pin 42): This output is pulsed when the IEEE 488 controller presents new data on the

I/O lines.

• Trigger (Pin 43): This output signal is pulsed when a Group Execute Trigger (

received on the bus.

• Inhibit (Pin 44): This output line is asserted while the IEEE 488 controller is reading data from input

lines.

• Service (Pin 45): This line is an edge-triggered input that generates a Service Request on the bus.

• External Data Ready (Pin 46): This input line is used to latch digital input data on the I/O lines.

These lines are more-fully discussed in the following text.

Handshaking/Control Lines

The six control lines on each channel enable handshaking of digital I/O data transfer to the Digital488/80A.

They are automatically activated with the corresponding I/O activity and can also be independently

activated with the Handshake (

and action of a given line is true for both channels except where noted.

DCL) or Selected Device Clear

GET) command is

H) command. For all descriptions that follow, information on the function

Digital488/80A User’s Manual Digital488/80A Operation 29

Page 36

Clear (Pin 41)

The Clear output can be pulsed for approximately 50 microseconds after a Device Clear (DCL), Selected

Device Clear (

(

effect depends o

channels in this mode have their command interpreter re-enabled and then they are returned to the A

Hexadecimal (

channels are n

both channe

microsecond

SDC), or Interface Clear (IFC) command has been sent on the bus, determined by the Form

F) mode of each channel. Execution of an SDC to either channel or a DCL affects both channels.

n whether either channel is in the High Speed Binary (

F0) mode. All other parameters remain unchanged. In addition, the Clear lines on

ot pulsed. If neither channel is in the

F5 mode, an SDC DCL returns

F5) mode. If in the F5 mode, the

to either channel or a

ls to their power-up configuration and pulses both Clear lines for approximately 50

s.

at

The

SCII

both

The Clear line is normally active high. The Invert (

Handshake (

operations.

Data Strobe (Pin 42)

The Data Strobe output is pulsed for approximately 50 microseconds after new data are output on the I/O

port. The Data Strobe line is normally active high, but ay be programmed active low (

I) command. The Handshake (H) command can pulse the Data Strobe line (H1), independent of any I/

(

operations. The Data Strobe output is not pulsed when Bit Set (

Trigger (Pin

43)

I) command programs it active low (I8). The

H) command can pulse the Clear line of either channel (H0), independent of any I/O

m

A) or Bit Clear (B) commands are executed

I4) by the Invert

O

.

The Trigger output is pulsed for approximately 50 microseconds after a Group Execute Trigger (GET)

command is received from the bus controller. The trigger pulse is normally active high, but can be made

active low (

Trigger line (

30 Digital488/80A Operation Digital488/80A User's Manual

I2) with the Invert (I) command. The Handshake (H) command can independently pulse the

H2), independent of any bus activity.

Page 37

Inhibit (Pin 44)

The Inhibit output is asserted while data on the selected I/O port are being read into the I/O port buffer.

This line is normally active high but may be programmed active low (

Inhibit line can be programmed independent of any I/O operations with the Inhibit (

I1) by the Invert (I) command. The

Q) command.

The Inhibit line is asserted once for each data read operation for all Format (

binary (

On the last data byte transfer, the data are read again with Inhibit asserted in anticipation of another data

transfer. If Inhibit is used to sequence external hardware, you should be aware that this line pulses N+1

times where N is the number of total 5-byte data transfers.

The Inhibit Line is not pulsed when reading a particular bit status using the User Status (

Service (Pin 45)

The Service input is an edge sensitive input capable of generating a bus Service Request (SRQ). It is

enabled with the Service Request Mask (

command can be used to program it to be falling-edge sensitive (

F) modes except high speed

F5). In this mode, it is asserted for the first data read after the Digital488/80A is addressed to talk.

U) command.

M) command and defaults to rising-edge sensitive. The Invert (I)

I64).

External Data Ready (Pin 46)

The External Data Ready (EDR) line is an edge sensitive input used to latch input data. It is used in

conjunction with the Data Ready (

must have a rise and fall time of less than one microsecond. The EDR line is normally rising-edge

sensitive but can be programmed with the Invert (

When using the EDR line with the Data Ready (

is addressed to talk, as it is read with command

line transitions.

When using the EDR line with the

the EDR line transitions. The Digital488/80A only outputs data when there is data in the buffer to output.

EDR is not functional in the high speed binary (

R) command. The EDR signal must be at least 1 microsecond wide and

I) command to be falling-edge sensitive (I32).

R) command R1, data is not read when the Digital488/80A

R0. The Digital488/80A only outputs data when the EDR

R2 command, data is read and stored in an internal data buffer each time

F5) format.

Digital488/80A User’s Manual Digital488/80A Operation 31

Page 38

IEEE 488 Bus Support

The Digital488/80A implements many of the capabilities defined by the IEEE 488 1978 specification.

These capabilities are discussed in the following text. However, the bus lines (uniline) and bus commands

(multiline) that the Digital488/80A does not support, or respond to, include the following:

REN

GTL

LLO

PP

Bus Lines

The following IEEE 488 bus management lines are supported by Digital488/80A:

Remote Enable (uniline)

Go to Local

Local Lock Out

Parallel Poll

PPC

PPD

PPU

TCT

Parallel Poll Configure

Parallel Poll Disable

Parallel Poll Unconfigure

Take Control

• Interface Clear (

IFC): IFC places the Digital488/80A in the Talker/Listener Idle State, and pulses the

Clear output line for approximately 50 microseconds.

• Service Request (

SRQ): Whenever the Digital488/80A generates a Service Request (SRQ), a Serial

Poll of either channel will return a Serial Poll Status byte of at least 64 (decimal) showing that the

was generated by the Digital488/80A.

In order to determine which channel generated the SRQ, use the Service Request Mask (M) command

with the Query (

M0 if SRQs are disabled, or returns a response between either M1 through M7, or M16 through

returns

M23, depending on what SRQs conditions are selected.

?) option, or M?, to recall what SRQ conditions are selected. The Digital488/80A

The following BASIC program illustrates one approach for handling Service Requests:

PRINT#1,"SPOLL08"

INPUT#2,SRQ08

PRINT#1,"SPOLL09"

INPUT#2,SRQ09

PRINT#1,"OUTPUT08;M?"

PRINT#1,"ENTER08"

INPUT#2,M08$

PRINT#1,"OUTPUT09;M?"

PRINT#1,"ENTER09"

INPUT#2,M09$

IF M08$="M0" THEN GOTO 500

IF M08$="M1" AND SRQ08 = 65 THEN GOTO 600

IF M08$="M2" AND SRQ08 = 66 THEN GOTO 700

EDR

IF M08$="M4" AND SRQ08 = 70 THEN GOTO 800

Note:

To allow the Digital488/80A to detect each of the above conditions, the Service Request

Mask (

Serial Poll Status Byte and the

M) command must be executed for each condition. More extensive comparisons of the

M? response are needed if multiple SRQ conditions are

selected. Refer to the Service Request Mask (

Serial poll Channel 0

Serial poll Channel 1

Retrieve

Retrieve

SRQ selection(s) from Channel 0

SRQ selection(s) from Channel 1

SRQs disabled Channel 0, test Channel 1

Service input transition routine, Channel 0

EDR input transition routine, Channel 0

Bus error routine, Channel 0

M) command in Chapter 6: Digital488/80A

Commands.

SRQ

The Digital488/80A unit may be programmed to generate an

Ready option (

M16) of the Service Request Mask (M) command, and saving this selection as part of the

SRQ on power-up by selecting the SRQ on

power-up configuration (Configuration 0).

Bus Commands

The following IEEE 488 bus commands are supported by Digital488/80A:

32 Digital488/80A Operation Digital488/80A User's Manual

Page 39

• Device Clear (DCL): In the F0 through F4 formats, Device Clear resets the Digital488/80A to its

power on default state, and pulses the Clear output line for approximately 50 microseconds.

If either channel is in the high-speed binary data format (F5), a DCL or SDC to either channel enables

the command interpreter on the channel in the

parameters remain unchanged. In addition, the Clear output line is not pulsed by

either channel is in the

F5 mode. This is the only programmable method to exit the F5 format.

F5 mode, and then changes the format to F0. All other

DCL or SDC when

• Group Execute Trigger (

GET): When the Digital488/80A recognizes a GET on either channel, it

pulses the Trigger output lines on both channels for approximately 50 microseconds. The Handshake

H) command should be issued to the desired channel, if it is desired to pulse only one handshake line

(

H2).

(

• My Listen Address (

MLA): When the Digital488/80A is addressed to Listen in the F0 through F4

format, it accepts characters from the Active Talker and interprets these characters as commands and

command parameters.

In the high-speed binary format (F5), the command interpreter is disabled. The Digital488/80A treats

all bytes received as data to be output to the digital I/O ports. Each time it receives 5 bytes or detects

EOI, it pulses the Data Strobe for approximately 15 microseconds. Data is expected in a PORT5,

PORT4, PORT3, PORT2, PORT1 sequence.