Page 1

USER’S MANUAL

IOtech 652u

1170-0901 rev 1.0

IOtech

25971 Cannon Road

Cleveland, OH 44146-1833

(440) 439-4091

Fax: (440) 439-4093

sales@iotech.com

productsupport@iotech.com

www.iotech.com

*372562A-01*

372562A-01

Requires one of the following

Operating Systems:

Windows 2000 SP4

Windows XP

Windows Vista

IOtech 652u

10 Channel Dynamic Signal Analyzer for

Vibration Analysis and Monitoring

Page 2

Warranty Information

Your IOtech warranty is as stated on the product warranty card. You may contact IOtech by phone,

fax machine, or e-mail in regard to warranty-related issues.

Phone: (440) 439-4091, fax: (440) 439-4093, e-mail: sales@iotech.com

Many IOtech products carry the CE marker indicating they comply with the safety and emissions standards of the

European Community. As applicable, we ship these products with a Declaration of Conformity stating which

specifications and operating conditions apply.

Refer all service to qualified personnel. This caution symbol warns of possible personal injury or equipment damage

under noted conditions. Follow all safety standards of professional practice and the recommendations in this manual.

Using this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Limitation of Liability

IOtech, Inc. cannot be held liable for any damages resulting from the use or misuse of this product.

Copyright, Trademark, and Licensing Notice

All IOtech documentation, software, and hardware are copyright with all rights reserved. No part of this product may be

copied, reproduced or transmitted by any mechanical, photographic, electronic, or other method without IOtech’s prior

written consent. IOtech product names are trademarked; other product names, as applicable, are trademarks of their

respective holders. All supplied IOtech software (including miscellaneous support files, drivers, and sample programs)

may only be used on one installation. You may make archival backup copies.

CE Notice

Warnings, Cautions, Notes, and Tips

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, IOtech calibrates its hardware to published specifications. Periodic hardware calibration is

not covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

Page 3

Table of Contents

F

Quick Start

Chapter 1 – What is the IOtech 652u?

Chapter 2 – Block Diagram

Chapter 3 – Connectors, Indicators, and Cables

Front Panel (Analog) Connectors …… 3-1

Introduction …. 3-1

Analog Common …… 3-1

Current Source (IEPE) with Transducer Fault Detection ……. 3-1

Input Coupling …… 3-2

Anti-Aliasing …… 3-2

Analog Triggers …… 3-2

Rear Pannel Connectors and Indicators …… 3-2

External Power ……3-3

Digital I/O (requires eZ-TOMAS)…… 3-3

#6-32 Machine Screw (chassis to earth ground)…… 3-4

USB2.0 …… 3-4

LED Indicators …… 3-4

Chapter 4 – CE Compliance and Noise Considerations

Overview …… 4-1

CE Standards and Directives …… 4-1

Safety Conditions ……4-2

Emissions/Immunity Conditions …… 4-3

CE Rules of Thumb for 652u …… 4-3

Noise Considerations …… 4-4

Chapter 5 – Software Options for 600 Series Devices

eZ-Analyst …… 5-2

eZ-TOMAS …… 5-3

eZ-Balance …… 5-4

eZ-NDT …… 5-5*

Chapter 6 – Product Care and Customer Support

Electrostatic Discharge (ESD), Handling Notice…… 6-1

Product Care …… 6-1

ReadMe Files and the Install CD-ROM …… 6-2

Customer Support …… 6-2

Chapter 7.a – Specifications, IOtech 652u Series

7.b – Specifications, Data Plots

Appendix A – Changing the Device Name

*eZ-NDT does not support IOtech 652u.

IOtech 652u User’s Manual 956991 i

Page 4

This page is intentionally blank.

ii 956991 IOtech 652u User’s Manual

Page 5

IOtech 652u Quick Start

Before you get started

verify that you have the following items and meet or exceed the

minimum requirements listed.

IOtech 652u

TR-2U Power Supply

USB2.0 port [on PC] and USB Cable

Dynamic Signal Analysis CD

License Keys for purchased software;

e.g., eZ-Analyst, eZ-TOMAS

Monitor: SVGA, 1024 x 768 screen resolution

Windows 2000 SP4 and Windows XP users:

Intel

™

Pentium [or equivalent], 1 GHz

512 MB memory; 10 GB disk space

Windows Vista users:

PC must be Windows Vista Premium Ready

Step 1 - Install Software

1. Close all running applications on the host PC.

2. Insert the Dynamic Signal Analysis CD into your CD-ROM drive and wait for the CD to auto-run. An Opening

Screen will appear. As an alternative, you can download software from: www.iotech.com/ftp.html

3. Click the <ENTER SETUP> button.

Note: If you are downloading software from our website, follow instructions provided there.

4. From the hardware selection screen [which follows a licensing agreement], select the 652u

from the drop-down list and follow the on-screen instructions.

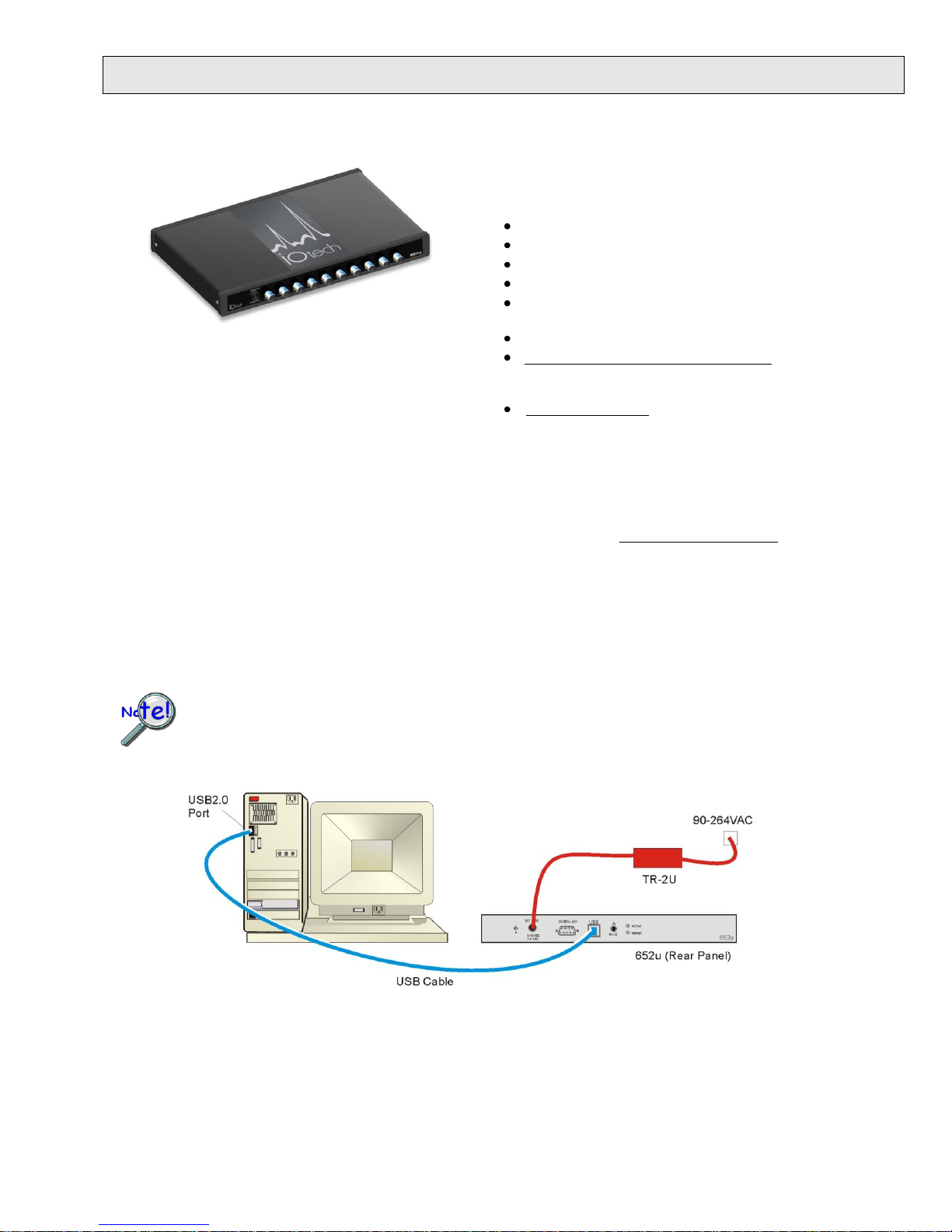

Supply power from the TR-2U to the 652u before connecting the USB cable to the computer. This allows the

652u to inform the host computer (upon connection of the USB cable) that the unit requires minimal power

from the computer’s USB port. When disconnecting a 652u from the PC, unplug the USB cable before

unplugging the TR-2U power cable.

10-Channel, USB2.0 Dynamic Signal Analyzer for Vibration Analysis & Monitoring

Step 2 - Connect the 652u to Power and to the Computer

1. Connect the TR-2U to a standard AC outlet.

2. Connect the TR-2U to the External Power connector on the 652u.

3. Using a USB cable, connect the 652u to a USB2.0 port on the computer. USB2.0 port is required.

4. Follow the computer screen prompts as directed to allow the computer to detect your new hardware.

1170-0940 rev 1.0 324996A-01

Page 6

IOtech

25971 Cannon Road

Cleveland, OH 44146-1833

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail: sales@iotech.com

E-mail: productsupport@iotech.com

Internet: www.iotech.com

LED Notes: The “Power” LED blinks during device detection and initialization; then remains on solid as long as

CAUTION

Turn off power to the system devices and externally connected equipment before

connecting cables. Electric shock or damage to equipment can result even under

low-voltage conditions.

Take ESD precautions (packaging, proper handling, grounded wrist strap, etc.)

Reference Notes:

Adobe Acrobat PDF versions of documents pertaining to IOtech 652u are automatically installed onto

your PC’s hard-drive as a part of product support at the time of software installation. The default

location is the Programs group. It can be accessed via the Windows Desktop Start Menu.

*324996A-01*

324996A-01

Digital I/O

Channel

Designation

the module has power. If there is insufficient power the LED will go off. The “Active” LED is on whenever active

communication is taking place between 652u and the host PC. It will be on solid during data acquisitions.

Step 3 - Connect Data Acquisition Signal Lines

The 652u has 10 analog channel inputs (CH1 through CH10) via front panel BNC connectors and 8 digital I/O

lines via rear panel DB9 connector.

Prior to making signal connections review the Specifications chapter of your user’s manual to ensure that the input

signals do not exceed the specified limits. The manual is included in PDF format on the CD.

Printed in Hungary

Page 7

What is the IOtech 652u? 1

Model

Interface

Analog

Input

Channels

High Pass

Filter

Cutoff

Analog

Input

Range

Analog

Output

Channels

Digital I/O

Channels

External Power

Connector

652u

USB2.0

10

0.1 Hz

±40 V 0 8

6 to 16 VDC

1 amp (max.)

eZ-Analyst

Records and analyzes time history data and performs impact (resonance) testing.

eZ-Balance

Provides a solution for multi-plane field balance applications of rotating machinery. The

application computes the optimal balance weights and their locations based on vibration

data collected from the analyzer.

eZ-TOMAS

Acquires, monitors, and analyzes rotating machinery data for steady-state and transient

conditions.

eZ-TOMAS Remote

An optional add-on which allows you to remotely monitor and/or control operation of

eZ-TOMAS. The option is sold separate.

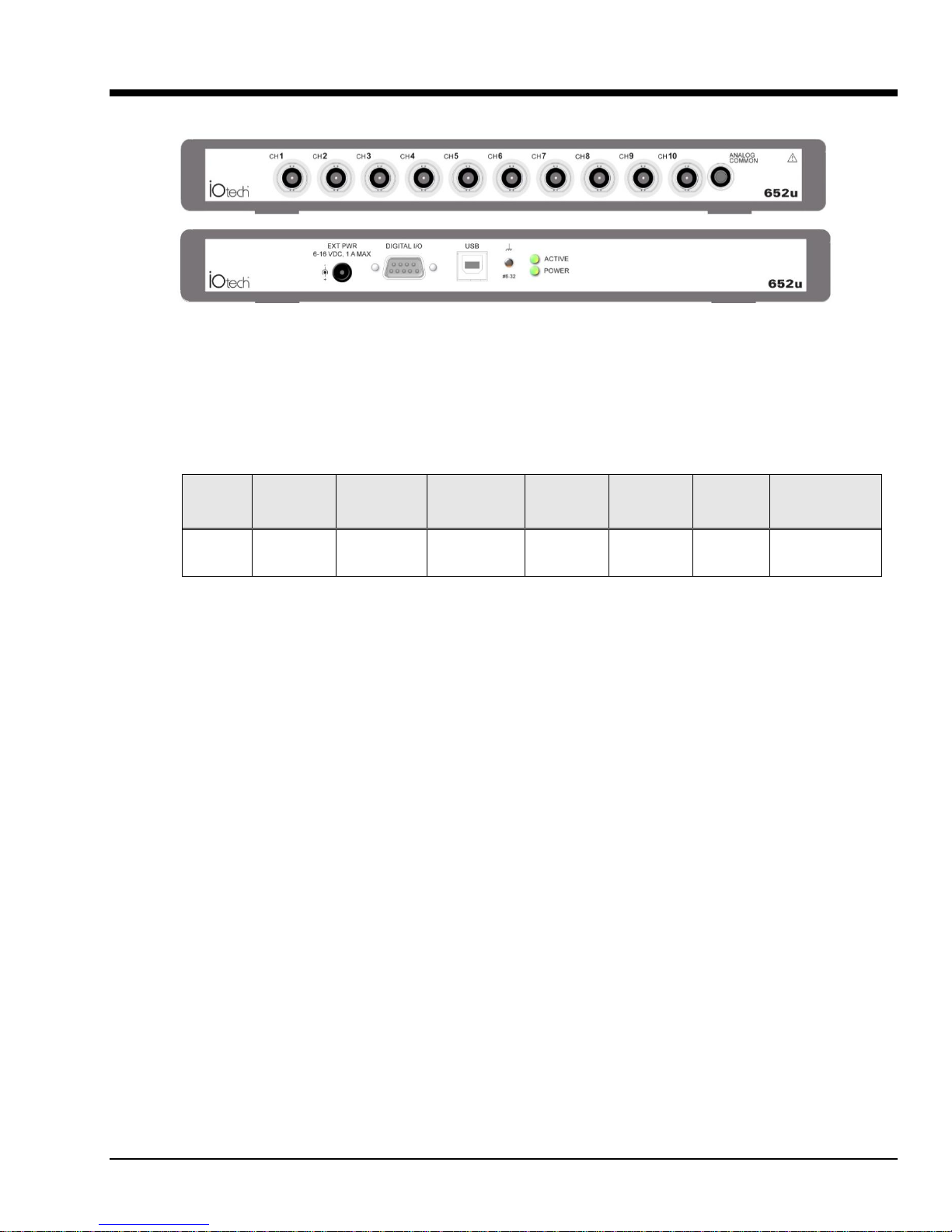

IOtech 652u Front and Rear Panels

IOtech 652u is a dynamic signal analyzer used for monitoring and analyzing machinery and structures in regard to

sound, vibration, and rotation. The device hardware is the signal conditioning and acquisition engine, while the

software defines the specific analysis and monitoring features of the system. Since the software [in the host PC]

determines which capabilities will be used, it is easy to upgrade the system and add more capabilities over time.

Basic profile:

There are currently four end-user software application packages available for IOtech 652u. A brief description of

each follows. For more information refer to Chapter 5, Software Options. For detailed information refer to the

specific software user’s manual. The DSA CD includes PDF versions of the software documents.

The IOtech 652u includes a high-speed USB2.0 engine. The USB interface allows all acquired data to be

transferred to the PC in real time at 1.05 Meg samples/sec. This means that every acquired data point can reside on

the host PC’s hard drive, making re-creation and post acquisition analysis of acquired data as precise as possible.

Many other analyzers simply store frequency-domain information, which results in play-back that is less precise

than the original real-time measurement. In comparison, the 652u (and also our 640 and 650 models) transmit all

time-domain measurements. This means there is no data loss when analyzing acquired waveforms. Since the data

is already on the host PC’s hard drive there is no time lost transferring data.

Another advantage of the 652u architecture is that there is virtually no limit to the length of time continuous data

can be acquired. Many other systems do not offer continuous time-domain transfer to the PC, and as a result the

waveform length is limited by the amount of built-in data storage. In regard to our 652u, the only limitation is the

amount of available hard disk memory on the host PC, or that which can be accessed by a PC on a network.

IOtech 652u User’s Manual 938791 What is the IOtech 652u? 1-1

Page 8

Features of the Dynamic Signal Inputs

o a current source for transducer biasing (IEPE)

o detection of a transducer fault

o AC coupling: 0.1 Hz; or DC coupling

o ±40 V range

o anti-aliasing filters: 3-pole low pass filter in hardware;

software FIR filters are automatically set for each analysis rate

o pseudo-differential inputs

o support for TEDS (Transducer Electronic Data Sheet) in eZ-Analyst

o any analog input channel can serve as a tach input

o tight channel-to-channel phase matching

USB2.0 ready - Easy Connection to USB2.0-ready Notebooks, Desktop PCs, or USB2.0 Hubs.

Note that the USB2.0 port allows a continuous stream of data to be collected and stored in the host PC.

Analog Input Channels: 10 BNC connectors

8 Digital I/O Channels: DB9 connector for connection of Digital I/O signal lines.

Note: eZ-NDT or eZ-TOMAS software must be used to make use of the Digital I/O.

Analog Channel Triggering

Pre- and Post-Trigger Readings

1-2 What is the IOtech 652u? 938791 IOtech 652u User’s Manual

Page 9

Block Diagram 2

IOtech 652u User’s Manual 948491 Block Diagram 2-1

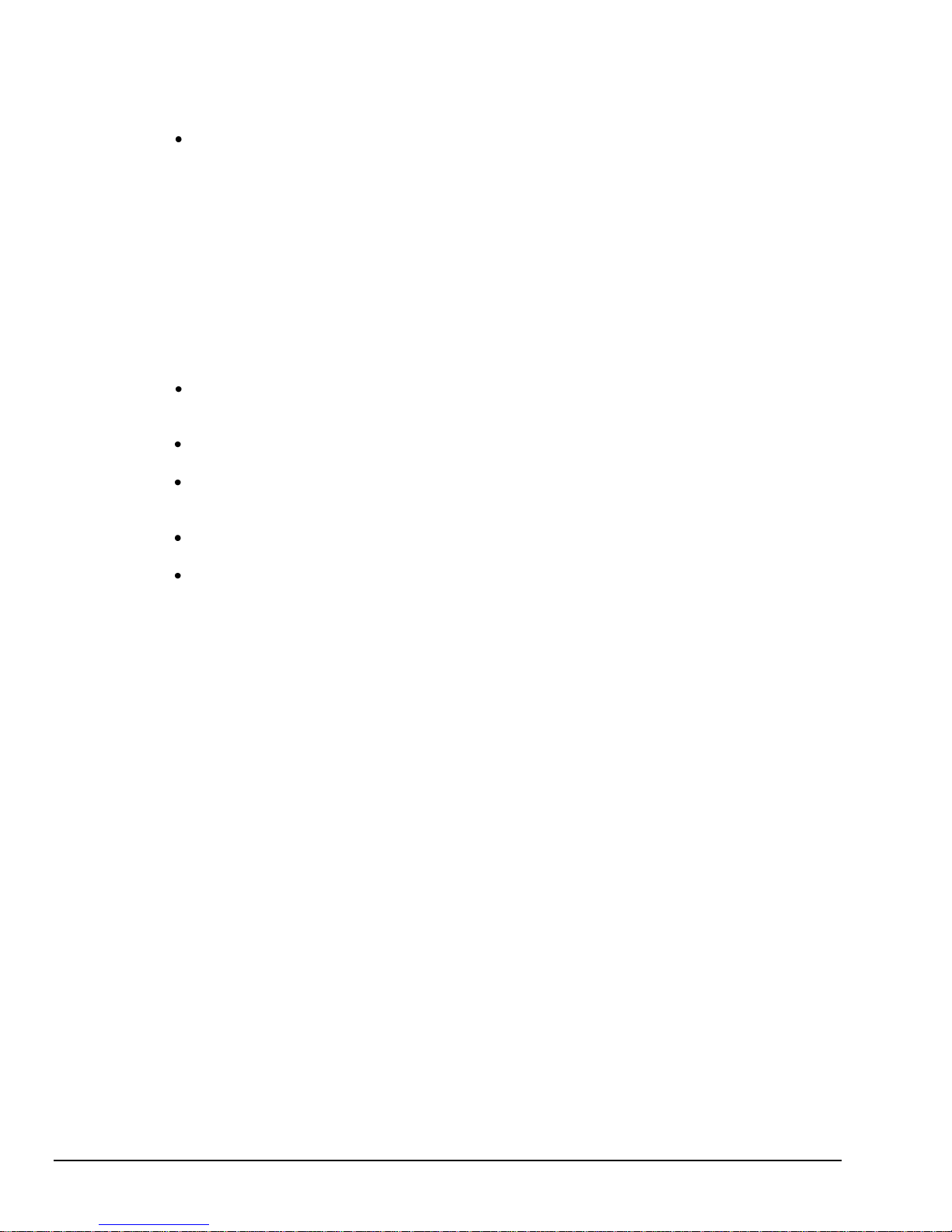

IOtech 652u Block Diagram

Page 10

USB2.0

The IOtech 652u transfers acquired data to the PC via a USB2.0 connection. It is important to note that

USB ports and USB hubs cannot supply sufficient power to a 652u.

Power

Power (6 to 16VDC at 400mA) is typically supplied by a TR-2U power adapter connected to the External

Power Jack. An equivalent source of DC power can be used in place of a TR-2U.

LEDs

Active

The Active LED is on whenever active communication is taking place between the 652u and

the host PC. Note that the Active LED will be on solid during a data acquisition.

Power

The “Power” LED blinks during device detection and initialization; then remains on solid

as long as the module has power. If there is insufficient power the LED will go off.

Digital

I/O

To make use of the Digital I/O feature the 652u must be operating with eZ-TOMAS or eZ-NDT.

The 8-bits of digital I/O are provided via a rear panel DB9 connector. Each bit is programmable as

input or output.

BNCs

Up to ten BNC connectors, designated as Channels 1 through 10, can be used to connect analog input

signals to the 652u. The BNC center-conductor is the signal HI and the BNC shell is the signal LO.

General Comments

The following short descriptions are provided to supplement the preceding block diagram. For additional information

refer to Chapter 3, Connectors, Indicators, and Cables.

2-2 Block Diagram 948491 IOtech 652u User’s Manual

Page 11

Connectors, Indicators, and Cables 3

Front Panel (Analog) Connectors …… 3-1

Introduction …. 3-1

Analog Common …… 3-1

Current Source (IEPE) with Transducer Fault Detection ……. 3-1

Input Coupling …… 3-2

Anti-Aliasing …… 3-2

Analog Triggers …… 3-2

Rear Pannel Connectors and Indicators …… 3-3

External Power ……3-3

Digital I/O (requires eZ-TOMAS)…… 3-3

#6-32 Machine Screw (chassis to earth ground)…… 3-4

USB2.0 …… 3-4

LED Indicators …… 3-4

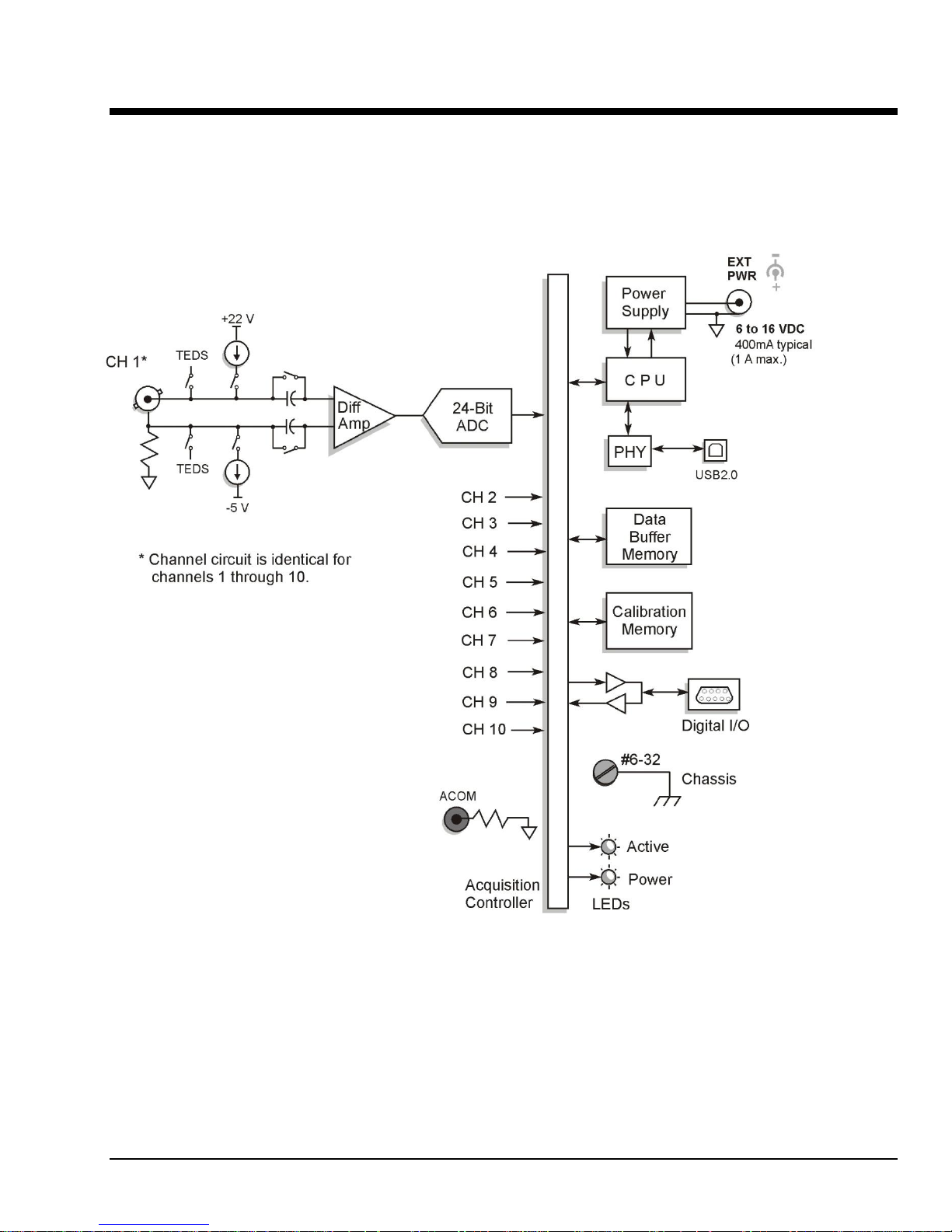

The front panel includes ten BNC connectors for voltage input. These are labeled CH1 through CH10. The front

panel also includes analog common. The IOtech 652u includes circuitry for dynamic analog signal conditioning.

The circuitry typically interfaces with piezoelectric transducers that include, but are not limited to: accelerometers,

microphones, tachometers, and force/pressure transducers.

TIP: Additional measurement noise may be present when using earth grounded transducers.

For best results electrically isolate the input transducers from earth ground.

Front Panel (Analog) Connectors

652u Front Panel

Introduction

Features of the 652u’s dynamic signal conditioning circuit include:

o current source for transducer biasing (IEPE)

o detection of a transducer fault

o AC or DC coupling

o ±40 V range

o anti-aliasing filters: 3-pole low pass filter in hardware; programmable digital filtering via software

o pseudo-differential inputs

o support for TEDS (Transducer Electronic Data Sheet), requires eZ-Analyst

o any analog input channel can serve as a tach input

o channel-to-channel phase matching

o signal parameters are independently controlled in software on a per channel basis

Analog Common

The BNC shells for the analog input channels have a 1k ohm resistance from the BNC shell to analog ground. The

BNC center-conductor is the signal HI and the BNC shell is the signal LO. Each BNC shell is connected to the

chassis ground through its own channel-dedicated 1 k resistor. Consequently, the shell is not meant to be driven

with respect to earth ground more than ±10V.

If the host computer is a desktop PC, then the computer ground will likely connect to the AC power line ground.

If the host computer is a notebook PC, then the computer ground could be: (a) floating, for example, when operating

on batteries, or (b) connected to a vehicle ground, for example, when using an automotive cigarette lighter adapter in

conjunction with the vehicle’s battery.

652u User’s Manual 957091 Connectors, Indicators, and Cables 3-1

Page 12

Current Source (IEPE) with Transducer Fault Detection

Reference Notes:

For detailed information, refer to the applicable software document, i.e., eZ-TOMAS or eZ-Analyst.

PDF versions of the documents can be accessed via the <View PDFs> button on the Dynamic Signal

Analysis (DSA) CD’s opening screen.

In addition to software documentation, information regarding aliasing, anti-aliasing, sensors,

accelerometers, sound and vibration, and transducers may prove useful to your application. The

internet is a great source for this material.

In regard to TEDS (Transducer Electronic Data Sheet), you may find the IEEE 1451 standard to be of

interest.

Note: IEPE current source can only be enabled when AC Coupling is selected.

If IEPE is selected in software, a constant current is supplied to bias IEPE transducers. The bias current is sourced

through the center conductor of the input channel BNC connector and returns to the conditioning circuit by the outer

conductor. The current source features a voltage operating compliance and is short-circuit and over-voltage

protected as stated in the specifications. Operating compliance refers to the highest voltage that can be sourced

without change of the current source value. In the absence of a transducer, the current source will output a higher

open circuit voltage. For unused channels and for other applications that do not require bias, the current

source should be disabled from the input via software control, on a per channel basis.

When the current source is enabled, the input voltage is continuously monitored with level detection circuitry for

indicating an open transducer (high voltage) or a transducer short (low voltage). Existence of either condition

triggers a transducer fault for the associated channel. This error is communicated to the user on the monitor via

software and is also available through a software status request at the end of an acquisition. Faults are detected and

communicated when present. Detection of a fault does not alter the acquisition process or its data.

Input Coupling

The analog input channels can be independently set in software to AC Coupling or to DC Coupling. When AC

Coupling is selected, the input signal passes through a high pass filter. When DC Coupling is selected the high-pass

filter is bypassed.

Anti-Aliasing

The 652u analyzer includes three-pole anti-aliasing filters and 24-bit sigma/delta analog-to-digital converters (ADC).

The converters exhibit an alias frequency band between 1.69MHz and 6.75MHz, which eases the requirements of the

anti-aliasing filters. Transducers seldom have significant energy at these high frequencies. However, should there

happen to be such energy, the filters will attenuate it. Refer to the specifications chapter for details, including a

response chart.

Analog Triggers

The IOtech 652u signal analyzer can be triggered per software configuration relevant to the 10 analog input

channels. Refer to the associated software documentation regarding the various types of triggers and how to set

them.

3-2 Connectors, Indicators, and Cables 957091 652u Users Manual

Page 13

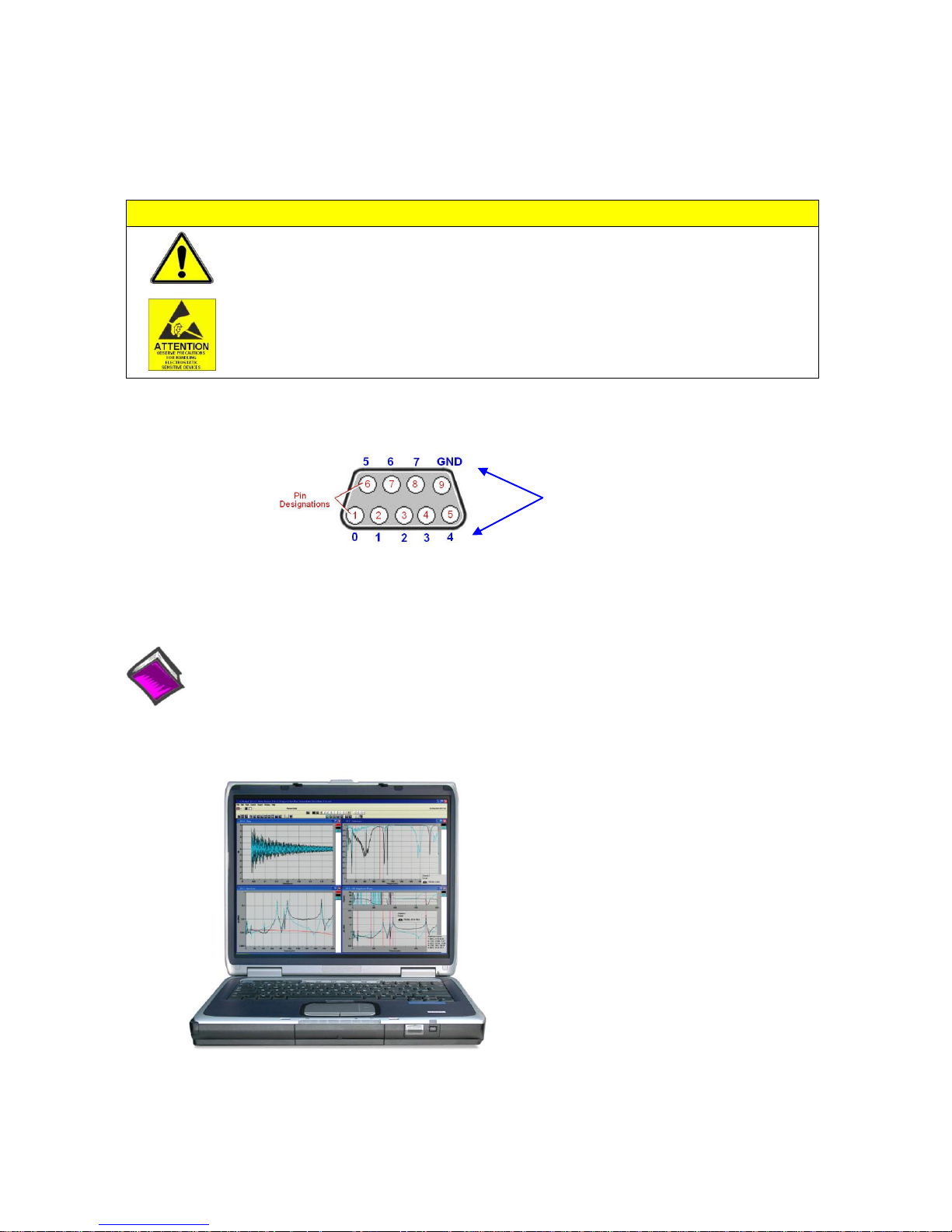

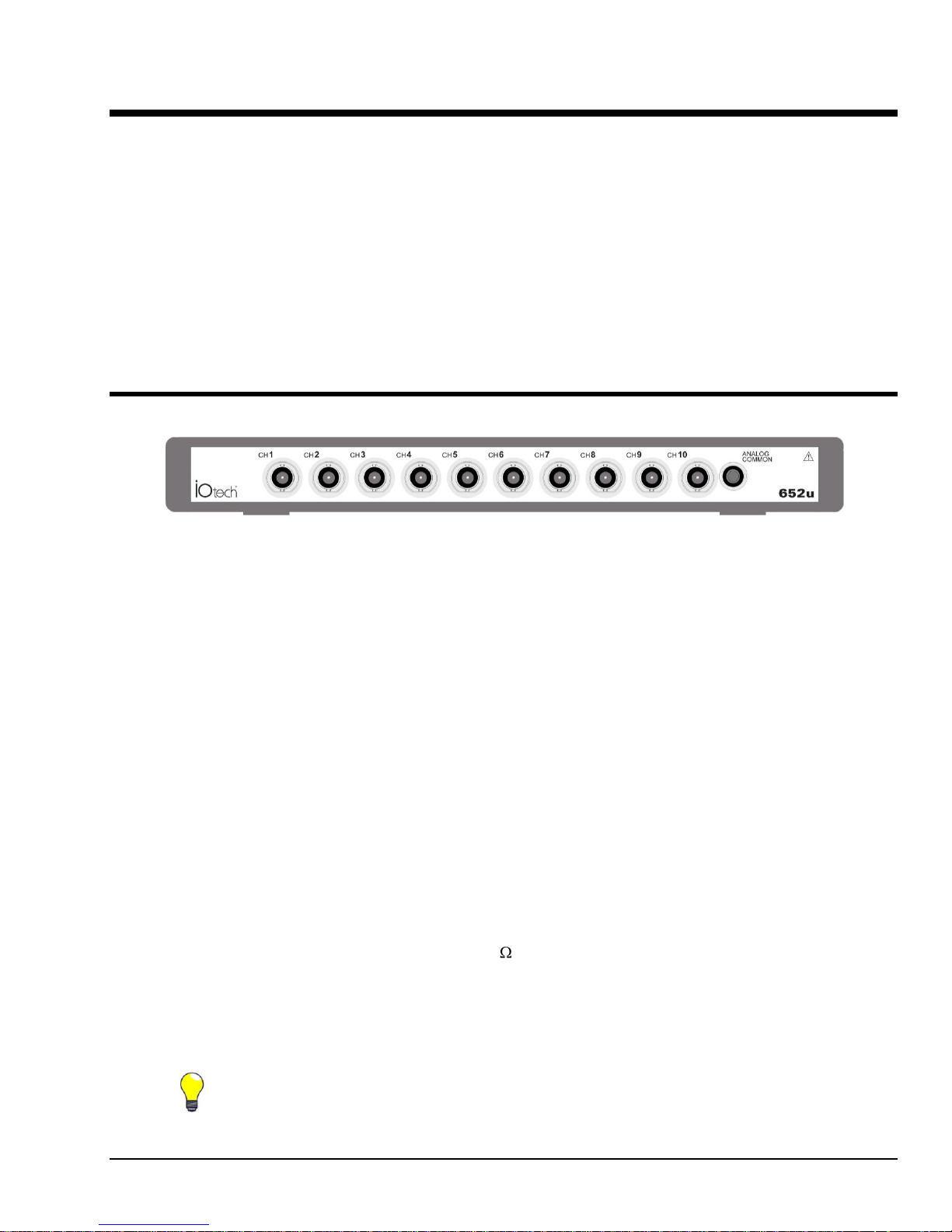

Digital I/O Connector

DB9 –on rear panel

Digital I/O

Channel

Numbers

Rear Panel Connectors and Indicators

IOtech 652u Rear Panel, Partial View

The rear panel includes, from left to right: an External Power connector, DB9-Digital I/O port, USB2.0 connector, a #6-32

chassis ground, and two status LEDs (ACTIVE and POWER).

EXT POWER: +6 to +16 VDC, 1 amp (maximum). Power is typically supplied from a TR-2U power adapter.

The TR-2U is an AC-to-DC conversion power supply with the following ratings:

o Input voltage to TR-2U: 90-264 VAC

o TR-2U voltage output (supply to 652u): typically 9VDC

o Max Current Output: 1.7 amp; but will typically output 400mA to meet

the 652u’s relatively small power demand.

DIGITAL I/O (Note: requires eZ-TOMAS installed on the host PC)

Eight digital I/O lines are accessible via a 9-pin, female DSub connector. Each bit of digital I/O can be programmed

individually to be either an input or an output. By hardware default, the digital I/O port boots up as an input. This is

to prevent any 652u digital output from possibly damaging external hardware.

The digital I/O can be read synchronously or asynchronously. It can also be read asynchronously while being in a

synchronous acquisition. Synchronously, the digital I/O will be read at the same rate as the analog channels, and

thus can be read as fast as 105.469 kHz. Since all of the analog signals are read simultaneously along with the digital

I/O channel in synchronous mode, there is no delay between any analog signal and the digital I/O channel.

Asynchronously, the digital I/O can be either read or written to, as opposed to the synchronous mode, which is readonly.

Points to note:

To use the 652u’s Digital I/O, the host PC must have eZ-TOMAS software installed.

All configurations pertaining to Digital I/O are controlled by software and can be updated by the

software at any time.

All 8 digital inputs can be read back as part of the scan group of an acquisition.

652u User’s Manual 957091 Connectors, Indicators, and Cables 3-3

Page 14

Reference Note:

eZ-TOMAS User’s Manual. A PDF version is included on the DSA CD.

#6-32 machine screw (chassis to earth ground):

The machine screw on the rear panel is used to connect the chassis to solid earth ground.

USB2.0: This port is intended for USB2.0 high-speed (480Mbps). In regard to 652u, connection to a USB2.0 port on the

host PC is required. The use of a High-Speed USB Cable is recommended. IOtech cable part numbers CA-179-1, -3, and -

5 are 1m, 3m, and 5m in length, respectively.

The IOtech 652u transfers acquired data to the PC via USB. When a computer has a board with USB 2.0 ports, an

“Enhanced” USB controller can be found in the Device Manager. The Device Manager will also show two other USB

controllers due to the fact that USB2.0 circuitry includes 3 chips [one for the actual USB2.0 capable devices and two for

backward USB1.1 compatibility]. Thus a USB 2.0 motherboard can host any USB device (version 2.0 or lower), assuming

there are no defects with the board, system, and/or device.

o IOtech 652u requires connection to USB2.0

o USB 1.1 (obsolete) hubs will work on USB 2.0 ports, but cannot utilize USB 2.0 capabilities.

o Hi-Speed and Full/Low-Speed USB devices can coexist on USB 2.0 hubs.

o USB 2.0 hubs can be used on computers with USB 1.1 ports, but will not exhibit USB 2.0 capabilities.

o Minimize hub use and keep USB cables as short as possible.

o USB ports and USB hubs cannot supply sufficient power to a 652u.

LED Indicators

ACTIVE This indicator is on whenever active communication is taking place between the 652u and

the host PC. Note that the ACTIVE LED is on solid during data acquisitions.

POWER This indicator blinks during device detection and initialization; and then remains on solid, as long

as there is sufficient power. If there is insufficient power the POWER LED will go off.

3-4 Connectors, Indicators, and Cables 957091 652u Users Manual

Page 15

CE Compliance & Noise Considerations 4

Overview ……4-1

CE Standards and Directives …… 4-1

Safety Conditions ……4-2

Emissions/Immunity Conditions ……4-3

CE Rules of Thumb for 652u …… 4-3

Noise Considerations …… 4-4

CE compliant products bear the “CE” mark and include a Declaration of Conformity stating the

particular specifications and conditions that apply. The test records and supporting documentation

that validate the compliance are kept on file at the factory.

Overview

The European Union established CE standards in 1985. The standards include specifications for safety,

EMI emissions, and immunity from electromagnetic interference. Products that are intended for placement

in the European Union must meet or exceed the standards and bear the “CE” mark.

Although not required in the USA, meeting or exceeding the CE standards is considered good engineering

practice, since doing so enhances safety while reducing noise and ESD problems.

In contracted and in-house testing most acquisition products met the required specifications. In many cases

products that were not originally in compliance were redesigned accordingly. In noted instances alternate

product versions, shield plates, edge guards, special connectors, or add-on kits are required to meet CE

compliance.

CE Standards and Directives

The electromagnetic compatibility (EMC) directives specify two basic requirements:

1. The device must not interfere with radio or telecommunications.

2. The device must be immune from electromagnetic interference from RF transmitters, etc.

The standards are published in the Official Journal of European Union under direction of CENELEC

(European Committee for Electrotechnical Standardization). The specific standards relevant to data

acquisition equipment are listed on the product’s Declaration of Conformity.

The safety standard that applies to data acquisition products is EN 61010-1 : 1993 (Safety Requirements

for Electrical Equipment for Measurement, Control, and Laboratory Use, Part 1: General Requirements).

Environmental conditions include the following:

indoor use

altitude up to 2000 m

temperature 5°C to 40°C (41°F to 104°F)

maximum relative humidity 80% for temperatures up to 31°C (87.8°F) decreasing linearly

to 50% relative humidity at 40°C (104°F)

mains supply voltage fluctuations not to exceed ±10% of the nominal voltage

other supply voltage fluctuations as stated by the manufacturer

transient overvoltage according to installation categories (overvoltage categories) I, II and III

For mains supply, the minimum and normal category is II

652u User’s Manual 957791 CE-Compliance & Noise Considerations 4-1

pollution degree I or II in accordance with IEC 664

Page 16

For clarification, terms used in some Declarations of Conformity include:

This WARNING symbol is used in documentation and/or on hardware to warn of

possible injury or death from electrical shock under noted conditions.

This WARNING/CAUTION symbol is used to warn of possible personal injury or

equipment damage under noted conditions.

This CAUTION symbol warns of possible equipment damage due to electrostatic

discharge. The discharge of static electricity can damage some electronic

components. Semiconductor devices are especially susceptible to ESD damage. You

should always handle components carefully, and you should never touch connector

pins or circuit components unless you are following ESD guidelines in an appropriate

ESD-controlled area. Such guidelines include the use of properly grounded mats and

wrist straps, ESD bags and cartons, and related procedures.

Unless otherwise stated our data acquisition products contain no user-serviceable

parts. Only qualified personnel are to provide service to the devices.

pollution degree: any addition of foreign matter, solid, liquid or gaseous (ionized gases) that may

produce a reduction of dielectric strength or surface resistivity. Pollution Degree I has no influence

on safety and implies: the equipment is at operating temperature with non-condensing humidity

conditions; no conductive particles are permitted in the atmosphere; warm-up time is sufficient to

avert any condensation or frost; no hazardous voltages are applied until completion of the warm-up

period. Pollution Degree II implies the expectation of occasional condensation.

overvoltage (installation) category: classification with limits for transient overvoltage, dependent

on the nominal line voltage to earth. Category I implies signals without high transient values.

Category II applies to typical mains power lines with some transients.

Safety Conditions

Users must comply with all relevant safety conditions as stated in the user’s manual and in the pertinent

Declarations of Conformity. Both the documentation and the associated hardware make use of the

following Warning and Caution symbols. If you see any of these symbols on a product or in a document,

carefully read the related information and be alert to the possibility of personal injury and/or equipment

damage.

The specific safety conditions for CE compliance vary by product; but general safety conditions include the

following bulleted items:

The operator must observe all safety cautions and operating conditions specified in the

documentation for all hardware used.

The host computer and all connected equipment must be CE compliant.

All power must be off to the device and externally connected equipment before internal access to the

device is permitted.

Isolation voltage ratings: do not exceed documented voltage limits for power and signal inputs.

All wire insulation and terminal blocks in the system must be rated for the isolation voltage in use.

Voltages above 30 Vrms or ±60 VDC must not be applied if any condensation has formed on the

device.

Current and power use must not exceed specifications. Do not defeat fuses or other over-current

protection.

4-2 CE-Compliance & Noise Considerations 957791 652u User’s Manual

Page 17

Emissions/Immunity Conditions

The specific immunity conditions for CE compliance vary by product; but general immunity conditions

include:

Cables must be shielded, braid-type with metal-shelled connectors. Input terminal connections are to

be made with shielded wire. The shield should be connected to the chassis ground with the hardware

provided.

The host computer must be properly grounded.

In low-level analog applications some inaccuracy is to be expected when I/O leads are exposed to

RF fields or transients over 3 or 10 V/m as noted on the Declaration of Conformity.

CE Rules of Thumb for 652u

IOtech 652u units are CE Compliant at the time they leave the factory and should remain in compliance as

long as the conditions stated on the Declaration of Conformity continue to be met.

A few general rules of thumb:

Use short cables.

When possible use shielded cables.

When assembling or disassembling components, take ESD precautions,

including the use of grounded wrist straps.

Ensure that the host computer is CE Compliant.

Review the most recent Declaration of Conformity for the 652u.

Ensure all system components are properly grounded.

652u User’s Manual 957791 CE-Compliance & Noise Considerations 4-3

Page 18

Noise Considerations

Controlling electrical noise is imperative because it can present problems even with the best measurement

equipment. Most laboratory and industrial environments suffer from multiple sources of electrical noise.

For example, AC power lines, heavy equipment (particularly if turned on and off frequently), local radio

stations, and electronic equipment can create noise in a multitude of frequency ranges.

Local radio stations are a source of high frequency noise, while computers and other electronic equipment

can create noise in all frequency ranges. Creating a completely noise-free environment for test and

measurement is seldom practical. Fortunately, simple techniques such as using shielded/twisted pair wires,

filtering, and differential voltage measurement are available for controlling the noise in our measurements.

Some techniques prevent noise from entering the system; other techniques remove noise from the signal.

While many techniques for controlling noise in signals provide a means of removing the noise that is

already present, the preferred solution is to prevent the occurrence of noise in the signal in the first place.

The following practices, some of which are required for CE compliance, should be employed to minimize

noise.

Make a solid earth ground connection. Using insulated low resistance wire, connect the

652u chassis (via the rear panel #6-32 machine screw) to solid earth ground. This practice:

(a) keeps radiated emissions low by keeping the chassis electrically quiet,

(b) keeps potential common-mode voltages low,

(c) improves user safety, and

(d) provides a safe path for Electrostatic Discharge energy back to earth ground.

Use short USB cables. The use of short USB cables will reduce noise. The shorter the cable

the better.

Use shielded cables. Loose wires are effective antennae for radio frequency pickup and can

form loops for inductive pickup. The use of properly connected shields will greatly reduce

such noise.

Minimize ambient EMI. The lower the ambient EMI, the better. Sources of electromagnetic

interference include solenoids, motors, computer equipment, high power distribution wiring,

etc.

Distance cables. Route signal cables away from Ethernet lines, Mains and other high voltage

cables and equipment to minimize signal interference from radiated noise.

4-4 CE-Compliance & Noise Considerations 957791 652u User’s Manual

Page 19

Software Options for 600 Series Devices 5

eZ-Analyst

Real- Time Vibration & Acoustic Analysis Software …… 5-2

eZ-TOMAS

On-line Rotating Machine Monitoring and Analysis Software …… 5-3

eZ-TOMAS Remote*

Remote monitor and control application …… 5-3

eZ- Balance

Rotating Machine, Field Balancing Software …… 5-4

eZ-NDT **

Non-Destructive Test Software …… 5-5

Reference Notes:

For detailed information regarding software, refer to one or more of the following as

applicable.

eZ-Analyst User’s Manual

eZ-TOMAS and eZ-TOMAS Remote User’s Manual

eZ-Balance User’s Manual

eZ-NDT User’s Manual**

A PDF version of each is included on the installation CD and on our website.

This chapter offers a glimpse of the eZ software packages that can be used with an IOtech 600 series device,

with exceptions as noted. The software is usually purchased when the hardware is ordered; but should your

acquisition needs change, additional software packages can be ordered at a later time.

* eZ-TOMAS Remote requires use of a licensed copy of eZ-TOMAS. For eZ-TOMAS Remote to operate,

the version numbers of the two applications (eZ-TOMAS and eZ-TOMAS Remote) must match.

652u User’s Manual 928291 Software Options 5-1

** eZ-NDT does not support IOtech 652u.

Page 20

eZ-Analyst

Real-Time Vibration & Acoustic Analysis Software

eZ-Analyst is the result of more than ten years

of software development and customer input.

This software adds real-time continuous and

transient data acquisition to an IOtech 600

series system. Analysis can be in the time,

frequency, or order domain.

eZ-Analyst is operated through a series of

setup windows that display only the information deemed important to your test. Acquisition configuration involves selecting desired

acquisition parameters from user-friendly

menus.

Features

Real-time FFT analysis

Easy-to-use graphical user interface provides fast setup

Large number of display options: Time Waveform, Spectrum, Auto Spectrum,

FRF, Cross, PSD, Transfer Function, Coherence, Octave, and Waterfall

Order Normalization and Order Tracked Plots

Multiple Plot Overlays using exported data files

Export to Excel, ME Scope, SMS Star, or UFF Type 58 ASCII or Binary

Save/Recall display setups with multiple display windows and overlays

Wide selection of real-time analysis features, including integration/differentiation

averaging, and much more

5-2 Software Options 928291 652u User’s Manual

Page 21

eZ-TOMAS (On-Line Rotating Machine Monitoring & Analysis Software) and

eZ-TOMAS Remote (Remote monitor and control application)

eZ-TOMAS provides an economical means of continuously monitoring and analyzing rotating machinery.

eZ-TOMAS records the change in vibration condition, and

quickly provides information for making important

operational decisions regarding the machine. You can

display and analyze historical data while eZ-TOMAS

continues to collect, monitor, and store data.

An IOtech 600 series system running with eZ-TOMAS can

be easily moved from machine to machine with very short

setup times. You can use the system to reduce downtime,

improve data collection, troubleshoot, and recondition the

machine.

eZ-TOMAS Remote is a software application that allows you

to remotely monitor and/or control eZ-TOMAS applications

through client/server architecture. The server, an eZTOMAS application, interacts with the hardware; and can be

in a remote location. Each client (eZ-TOMAS Remote)

communicates with eZ-TOMAS via TCP/IP.

Features

Transient and Steady State rotating machinery analysis

Easy-to-use graphical user interface and multiple project configurations provide fast setup

Overall, spectral amplitude, and phase gauges with peak hold indicators

Spectral limit checking, with output relays and alarm event logging

Limit sets for specific RPM ranges

Event data storage based on user defined triggers, with automatic backup

Rotating Machinery Analysis: Time Waveform, Orbit, Spectrum, Waterfall, Polar,

Bode, Shaft Center Line, and Trend displays

Machine and Bearing Fault analysis and limit checking

Save/Recall display setups with multiple display windows and overlays

Integration and differentiation for acceleration, velocity, and displacement inputs

Harmonic, Sideband, and Peak cursors for time waveform and spectrum displays

Statistical analysis report with automatic limit generation

Generate production test cell reports

Export data to Excel, UFF Type 58 Binary, or ASCII format

Copy/Paste graphs and data into Microsoft applications

Remotely monitor and/or control eZ-TOMAS with purchase of eZ-TOMAS Remote

652u User’s Manual 928291 Software Options 5-3

Page 22

eZ-Balance

Rotating Machine Balancing

An IOtech 600 series system using eZ-Balance

provides a solution for multi-plane field balance

applications of rotating machinery. eZ-Balance

computes the optimal balance weights and their

locations, based on vibration data collected from the

analyzer. The data is displayed in a convenient

Polar plot that indicates the magnitude and phase of

the unbalance as well as time and spectrum data.

eZ-Balance determines a balance solution by

calculating the change in vibration condition based

on adding trial weights. The balance process is a

series of well defined steps.

Accelerometers, velocity probes, or displacement

probes may be used to measure the vibration level

at each balance plane. A tachometer measures the

rotation speed and provides a phase reference.

Features

Single, Multi-plane, and trim balancing

Polar, time, and spectral displays

Computes and stores influence coefficients for future trim balancing

Vibration data can be acquired from the analyzer or entered manually

Balancing toolkit

- Trial weight calculations

- Weight splitting

- Centrifugal force

- Stock weights

- Weight removed

- Unbalance tolerance

Balance solution can be based on multiple response points

5-4 Software Options 928291 652u User’s Manual

Page 23

eZ-NDT Does not support 652u

Non-Destructive Test Software

eZ-NDT (non-destructive test) uses resonance

to identify part variations caused by process

inconsistencies and defects. Using eZ-NDT with

an IOtech 600 series device is a fast and

inexpensive method for performing 100%

inspection of production parts. Inspection parts

include, but are not limited to: powder metal,

ceramics, and composites.

An eZ-NDT system applies energy to target parts

and analyzes the resonant frequencies. The

system compares the results to the acoustic

signature of a known-good part.

Testing a part takes less than one second and

requires no special tooling, dyes, chemicals,

cleaning, magnetization, or expensive and time

consuming visual inspection equipment.

Features

Provides inspection of metal, ceramic, and hard plastic parts

Removes the ambiguity that is common in other inspection systems

Requires no parts preparation, making the test fast and inexpensive

Tests parts in less than 1 second

Quantifies and documents the first natural frequency for end user

comparison to final assembly resonant frequencies

Time and Spectrum Display

Easy-to-use graphical user interface provides fast setup

Overlay good and bad baselines

Investigation and Inspection Modes

652u User’s Manual 928291 Software Options 5-5

Page 24

This page is intentionally blank.

5-6 Software Options 928291 652u User’s Manual

Page 25

Product Care and Customer Support 6

The discharge of static electricity can damage some electronic components. Semiconductor devices are

especially susceptible to ESD damage. You should always handle components carefully, and you should

never touch connector pins or circuit components unless you are following ESD guidelines in an

appropriate ESD-controlled area. Such guidelines include the use of properly grounded mats and wrist

straps, ESD bags and cartons, and related procedures.

Electrostatic Discharge (ESD) Handling Notice…… 6-1

Product Care …… 6-1

ReadMe Files and the Install CD-ROM ……6-2

Customer Support …… 6-2

Electrostatic Discharge (ESD) Handling Notice

Product Care

IOtech 652u is essentially maintenance free and requires only a minimal amount of care. The 652u should be

treated much like any other high-tech piece of equipment. In general:

The units should be operated in ventilated and relatively dust-free environments.

Keep the units clear of harsh chemicals and abrasive elements.

Avoid exposing the products to extreme heat; for example, avoid setting the units near boilers and

furnaces.

Avoid extreme shock and vibration.

Avoid subjecting the units to liquids and extremely fine air particulate, such as silica dust.

Never open the unit. The unit should only be opened by qualified service technicians.

A “common-sense” approach to handling acquisition components will go a long way in protecting them from

inadvertent damage.

Note that you can use lint-free rags and Isopropyl Alcohol (Rubbing Alcohol) to clean the outer surfaces of the

IOtech 652u.

IOtech 652u User’s Manual 958991 Product Care and Customer Support 6-1

Page 26

ReadMe Files and the Install CD-ROM

The Install CD-ROM includes ReadMe Files. These files often contain late-breaking information that may not

appear in the user documentation. During installation you should review the ReadMe files when prompted to by the

program.

The Install CD-ROM includes:

Windows drivers

eZ-Anlayst*

eZ-TOMAS*

eZ-Balance*

eZ-NDT*

Daq Configuration Control Panel Applet

User documentation in Adobe® PDF format

30-day trial codes for the eZ-software packages

*Requires an authorization code for installation. Authorization codes are supplied with the purchase of the

associated software. Note that the CD does include 30-day trial codes.

Customer Support

If you need to report problems or request product support . . .

Note: Please do not return any equipment to the factory unless it has an RMA number (Return Merchandise

Authorization number). RMA numbers are issued by the factory.

To report problems or request support, contact our Applications Department. Contact information follows shortly.

When you contact us, please have the following information available, as applicable:

Hardware model numbers and software version numbers.

Operating system, type of computer, and device information in the Windows control panel, such as

interrupts and address settings for our hardware and others.

Results of tests, such as the Daq Configuration control panel.

Hardware setup and software configuration.

Information on input signals, including voltage ranges, signal impedance ranges, noise content, and

common mode voltages.

The name of a contact person from your company who can discuss the problems encountered.

Instructions for return shipping.

All troubleshooting notes and comments on tests performed, and all problem-related conditions.

Note: Before calling for assistance, take a few minutes to read all parts of the manual that may be relevant to the

problem. Also, please review the troubleshooting material.

You can reach IOtech by one of the following means:

Phone: (440) 439-4091

Fax: (440) 439-4093

E-mail Product Information/Sales: sales@iotech.com

E-mail Technical Support/Applications Department: productsupport@iotech.com

Internet: www.iotech.com

Mail: IOtech 25971 Cannon Road Cleveland, Ohio 44146-1833

All equipment returned to the manufacturer must have an RMA (Return Material Authorization) number. You can

obtain an RMA number from our Applications Department. When returning the equipment, use the original shipping

container (or equivalent) to prevent damage. Put the RMA number on your shipping label to ensure that your

shipment will be handled properly. After receiving your equipment, we will fax a confirmation form that

summarizes the charges (if applicable) and expected return date.

6-2 Product Care and Customer Support 958991 IOtech 652u User’s Manual

Page 27

Specifications – IOtech 652u 7.a

Section 7.b, Specifications, Data Plots, contains a great deal of information in the form of plotted data. References

to the plots appear in this section (7.a) when applicable.

General Specifications

Environment:

Operating Temperature: -40˚ to 60˚C

Humidity: 0˚ to 95% RH, non-condensing

Vibration: IEC 60068-2-64

Shock: IEC 60068-2-27

Emissions: EN61326, 89/366EEC

Safety: EN61010

Ingress: IP 40

Power Consumption:

<3.5W max

Input Voltage Range:

6.0 to 16 VDC

PC Communication:

USB2.0

Dimensions: 10.9” W x 6.685” D x 1.2”H

(276.9mm W x 169.8mm D x 30.5mm H)

Weight: 2.7 lbs. (1.2 kg)

Warm-up: 10 minutes to rated specifications

Analog Specifications

Analog Measurements

ADC converter resolution: 24 bits

ADC converter type: Delta-sigma

Sample rates: up to 105,468 samples per second

Sample rate accuracy: ±50ppm

Channels: 10 input channels

Input connector: 1 BNC per channel

Input impedance:

High to ground: 800kΩ || 120 pF

Low to ground: 1kΩ

High to low: 801kΩ

Input coupling: DC, AC, or AC + IEPE; software programmable per channel basis

High-pass filter (AC coupling cutoff): 0.1Hz

Figure 1. Measurement High Pass Filter Response

Input range: ±40V peak

Input protection: BNC Shell to BNC Center: ±60V Max without damage

BNC Shell to Earth Ground: ±5V Max without damage

Over-range indication: Software

Low-pass filter (software programmable per channel)

Figure 2. Measurement Delay vs. Frequency, DC-Coupled

Figure 3. Measurement Delay vs. Frequency, AC-Coupled

IOtech 652u User’s Manual 927791 Specifications 7.a-1

Page 28

Specifications are subject to change without notice.

Analysis

Frequency

(Hz)

Typical Noise*

(µV rms)

20

11

50

15

100

20

200

26

500

37

1000

48

2000

62

5000

89

10000

116

20000

151

40000

197

Type: Anti-Aliasing hardware 3-pole 360kHz, Software selectable FIR filter

(automatically selected by software on a per analysis rate basis).

Figure 4. Measurement Antialiasing Filter Performance

Any unwanted signals above 27MHz is lost in the noise floor of a 64k FFT.

Amplitude accuracy:

AC at 1kHz: 0.1dB typ ±0.15dB max

DC: (0.2% of reading + 15mV)

Amplitude -3dB: 0.49 x sample rate

Amplitude flatness: 0.05 dB typ ±0.10dB max DC to 20kHz

Figure 8. Analog Measurement Flatness

Total harmonic distortion: -100dB typical 1kHz, -97dB typical 10kHz

SFDR including harmonics: 108dB typical DC to 50kHz

SFDR (@-60dB): 128dB typical DC to 50kHz

Channel-to-channel crosstalk: <-100dB at 1kHz

Channel-to-channel phase matching:

<0.06º / kHz + 0.1º

Common mode rejection ratio:

Wideband noise:

Figure 7. Measurement THD+N

Figure 9. SFDR

Figure 10. Channel-to-Channel Cross Talk

Figure 11. Phase-Matching vs. Frequency, AC-Coupled

-56dB typ; -41dB max, at 1kHz

Figure 12. Typical CMRR

*Maximum noise @ <50°C = 1.4x; @> 50°C = 2.1x (where x is the typical value given in the above table).

7.a-2 Specifications 927791 IOtech 652u User’s Manual

Page 29

IEPE bias source:

DB9 – As viewed from the rear panel.

Input / Output Circuit

Digital I/O

Channel

Current: 4.0mA, 22V compliance (on/off software programmable per channel)

Impedance: >255kΩ

IEPE fault detection thresholds: <1V (short), >20V (open)

IEPE fault indication: Software indicator, per channel

Tachometer Inputs

Any analog input channel may be used as a tachometer input.

Digital I/O Lines

Note: To make use of Digital I/O, eZ-TOMAS or eZ-NDT software must be running in the host PC.

Channels: 8 Digital I/O, programmable as inputs or outputs on a line by line basis

Ports: 1 x 8-bit, Each bit is programmable as input or

output

Power-up mode: Inputs pulled low

Connector: DB-9 female (figure)

Input Scanning Modes: 2 programmable scanning modes asynchronous, under program control at any

Input Protection: ±5.6V

Input Levels:

Low: 0 to +0.8V

High: +2.0V to +5.0V

Input pull-down resistor: 10kΩ

Output voltage range: 0 to +3.3V, may be pulled up to +5V

Output resistance: 100Ω

Output Levels:

Low: < 0.8V

High: >3.0V with no load

Sampling:

105,468Hz, maximum

Note: A Digital I/O example is located in section 7.b.

See Figure 13. Digital I/O I-V Curve

Output timing: Outputs are always written asynchronously.

Specifications are subject to change without notice.

time relative to analog scanning; synchronous with analog scanning

IOtech 652u User’s Manual 927791 Specifications 7.a-3

Page 30

Specifications are subject to change without notice.

This page is intentionally blank.

7.a-4 Specifications 927791 IOtech 652u User’s Manual

Page 31

Specifications, Data Plots IOtech 652u 7.b

-35

-30

-25

-20

-15

-10

-5

0

5

0.01 0.10 1.00 10.00

Amplitude (dB)

Frequency

Fig. 1 Measurement High Pass Filter Response

Fig. 1

Measurement High Pass Filter Response ……………..

1

Fig. 2

Measurement Delay vs. Frequency, DC-Coupled ……

2

Fig. 3

Measurement Delay vs. Frequency, AC-Coupled ……

2

Fig. 4

Antialiasing Attenuation ………………………………….

3

Fig. 5

Antialiasing Filter & Analog Input Circuit Response ….

3

Fig. 6

High Frequency Artifacts ………………………………..

4

Fig. 7

Measurement THD+N ……………………………………

4

Fig. 8

Analog Measurement Flatness …………………………

5

Fig. 9

SFDR ……………………………………………………..

5

Fig. 10

Channel-to-Channel Crosstalk …………………………

6

Fig. 11

Phase-Matching vs. Frequency, AC-Coupled ……….

6

Fig. 12

Typical CMRR ……………………………………………

7

Fig. 13

Digital I/O I-V Curve ……………………………………..

7

IOtech 652u User’s Manual 957091 Specifications, Data Plots 7.b-1

Page 32

Specifications are subject to change without notice.

-2.0E-6

-1.5E-6

-1.0E-6

-500.0E-9

-20.0E-21

0 10000 20000 30000 40000 50000

Delay (sec)

Frequency (Hz)

Fig. 2 Measurement Delay vs Frequency, DC-Coupled

000.0E+0

1.0E-6

2.0E-6

3.0E-6

4.0E-6

5.0E-6

0 10000 20000 30000 40000 50000

Delay (sec)

Frequency (Hz)

Fig. 3 Measurement Delay vs Frequency AC-Coupled

7.b-2 Specifications, Plotted Data 957091 IOtech 652u User’s Manual

Page 33

Specifications are subject to change without notice.

-120

-100

-80

-60

-40

-20

0

0 2,000,000 4,000,000 6,000,000 8,000,000 10,000,000

Attenuation (dB)

Frequency (Hz)

Fig. 4 Antialiasing Attenuation

-70

-60

-50

-40

-30

-20

-10

0

10

1,000 10,000 100,000 1,000,000 10,000,000

Amplitude (dB)

Frequency

Fig. 5 Antialiasing Filter & Analog Input Circuit Response

Sample Rate = 26368 samples per second

IOtech 652u User’s Manual 957091 Specifications, Plotted Data 7.b-3

Page 34

Specifications are subject to change without notice.

-120

-100

-80

-60

-40

-20

0

- 1,000 2,000 3,000 4,000 5,000 6,000 7,000 8,000 9,000 10,000

Attenuation (dBFS)

Frequency (kHz)

Fig. 6 High Frequency Artifacts

-110

-105

-100

-95

-90

-85

-80

-75

-70

10 100 1,000 10,000 100,000

THD+N (dB)

Frequency

Fig. 7 Measurement THD+N

________ DC Coupled

- - - - - - AC Coupled

7.b-4 Specifications, Plotted Data 957091 IOtech 652u User’s Manual

Page 35

Specifications are subject to change without notice.

-0.1

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

100 1000 10000 100000

Error (dB)

Frequency

Fig. 8 Analog Measurement Flatness (Measurement Accuracy)

Ch 1

Ch 2

Ch 3

Ch 4

Specification limit

Specification limit

Fig. 9 SFDR Full-Scale is +29dBV; Input is -30dBV

IOtech 652u User’s Manual 957091 Specifications, Plotted Data 7.b-5

Page 36

Specifications are subject to change without notice.

-130

-120

-110

-100

-90

-80

-70

100 1,000 10,000 100,000

Crosstalk (dBFS)

Frequency (Hz)

Fig. 10 Channel-to-Channel Crosstalk

1-2

1-3

1-4

1-5

2-1

2-3

2-4

2-5

3-1

3-2

3-4

3-5

4-1

4-2

Specification -100dB typical

Measurement noise

Legend Format (aggressor - victim)

-1.5

-1.0

-0.5

0.0

0.5

1.0

1.5

1 10 100 1,000 10,000 100,000

Phase Match (degrees)

Frequency (Hz)

Fig. 11 Phase Matching vs Frequency, AC-Coupled

Comparison of phase differences

among five channels of a representative

unit

Spec

Spec

Vin = -0.5dB FS

7.b-6 Specifications, Plotted Data 957091 IOtech 652u User’s Manual

Page 37

Specifications are subject to change without notice.

-15

-10

-5

0

5

10

15

-1 0 1 2 3 4 5

Volts

Current (mA)

Digital

Input

Digital Output

High

Digital Output

Low

Common Mode Voltage = 6V RMS

-120

-100

-80

-60

-40

-20

0

1

10

100

1,000

10,000

100,000

Frequency

CMRR (dB)

thin line & hollow symbol = DC coupled

thick line solid symbol = AC coupled

Fig. 12 Typical CMRR

Fig. 13 Digital I/O I-V Curve

IOtech 652u User’s Manual 957091 Specifications, Plotted Data 7.b-7

Page 38

Specifications are subject to change without notice.

This page is intentionally blank.

7.b-8 Specifications, Plotted Data 957091 IOtech 652u User’s Manual

Page 39

Appendix A – Changing the Device Name A

If you need to find the name of your device, and in fact, even want to change it, you can.

To find the device name, navigate from the Windows Desktop to the Device Manager.

The navigation path is:

Start

Settings

Control Panel

System

Hardware (Tab)

Device Manager

DaqX PnP Devices

You will see the device listed in the format of 652u as in the following figure.

You can now change the device name from the 652u default to a “friendly” name.

1. Right-click on the device name (preceding figure). This opens its properties dialog box.

2. Click on the Properties tab (following figure).

3. Enter the desired name in the “FriendlyName” text field.

4. Click <OK>.

652u User’s Manual 957591 Appendix A – Device Name A-1

Page 40

This page is intentionally blank.

A-2 Appendix A – Device Name 957581 652u User’s Manual

Loading...

Loading...