Applications

A

l High Frequency Point-of-Load

Synchronous Buck Converter for

Applications in Networking &

Computing Systems.

Benefits

l Very Low R

l Low Gate Charge

l Fully Characterized Avalanche Voltage

DS(on)

at 4.5V V

GS

and Current

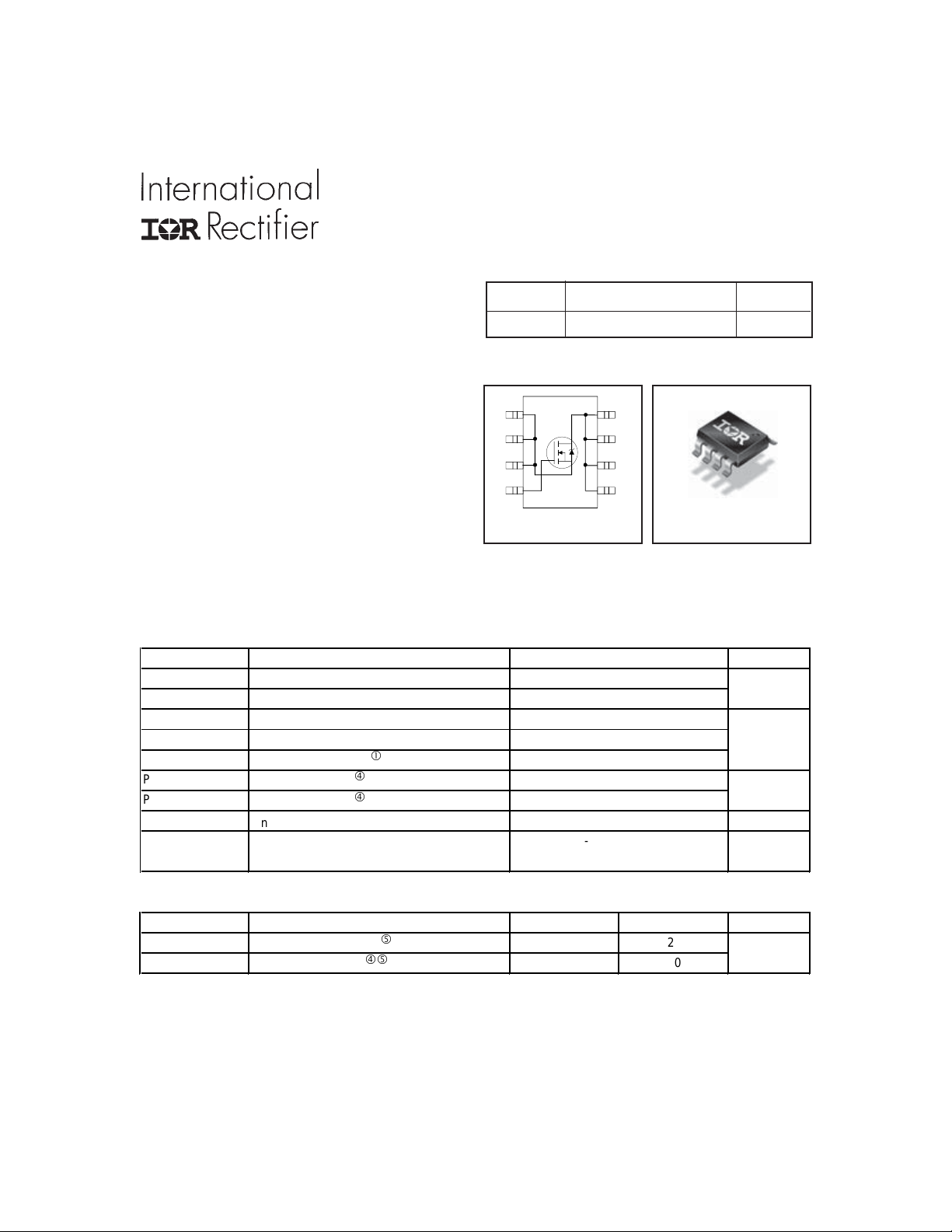

HEXFET® Power MOSFET

V

DSS

30V 9.1mW@V

1

S

2

S

3

S

4

Top View

8

7

6

5

R

DS(on)

A

D

D

D

DG

PD - 94579B

IRF7821

max Qg(typ.)

= 10V 9.3nC

GS

SO-8

Absolute Maximum Ratings

V

DS

V

GS

@ TA = 25°C

I

D

@ TA = 70°C

I

D

I

DM

PD @TA = 25°C

@TA = 70°C

P

D

T

J

T

STG

Parameter Units

Drain-to-Source Voltage V

Gate-to-Source Voltage

Continuous Drain Current, V

Continuous Drain Current, V

Pulsed Drain Current

Power Dissipation

Power Dissipation

Linear Derating Factor W/°C

Operating Junction and °C

Storage Temperature Range

c

f

f

@ 10V

GS

@ 10V

GS

Max.

30

± 20

13.6

11

100

2.5

1.6

0.02

-55 to + 155

A

W

Thermal Resistance

Parameter Typ. Max. Units

R

θJL

R

θJA

Junction-to-Drain Lead

Junction-to-Ambient

fg

g

––– 20 °C/W

––– 50

Notes through are on page 10

www.irf.com 1

1/14/03

IRF7821

/

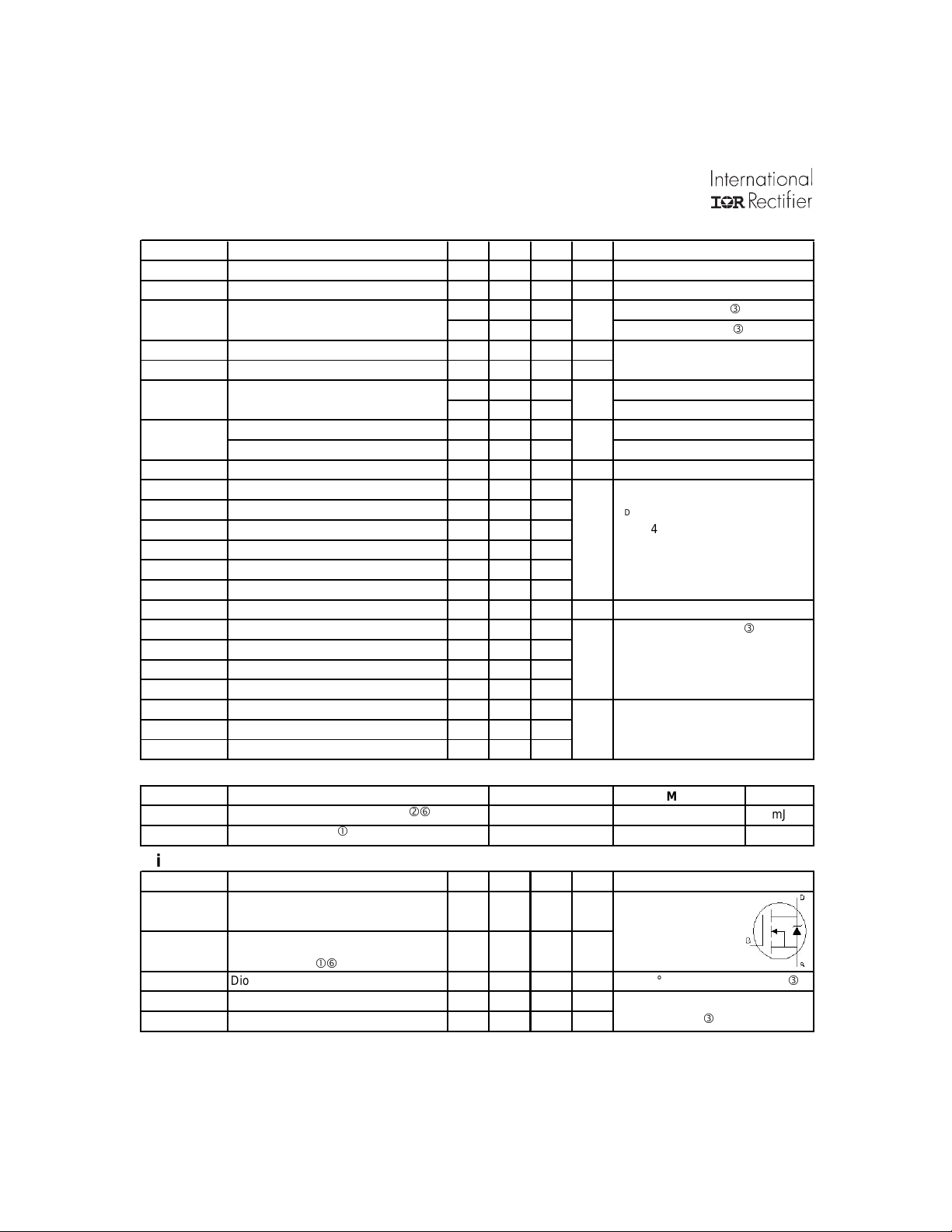

Static @ TJ = 25°C (unless otherwise specified)

Parameter Min. Typ. Max. Units

BV

DSS

∆ΒV

DSS

R

DS(on)

V

GS(th)

∆V

GS(th)

I

DSS

I

GSS

gfs Forward Transconductance 22 ––– ––– S

Q

g

Q

gs1

Q

gs2

Q

gd

Q

godr

Q

sw

Q

oss

t

d(on)

t

r

t

d(off)

t

f

C

iss

C

oss

C

rss

Drain-to-Source Breakdown Voltage 30 ––– ––– V

∆T

Breakdown Voltage Temp. Coefficient ––– 0.025 ––– V/°C

J

Static Drain-to-Source On-Resistance ––– 7.0 9.1

––– 9.5 12.5

Gate Threshold Voltage 1.0 ––– ––– V

Gate Threshold Voltage Coeffic i ent ––– - 4.9 ––– mV/°C

Drain-to-Source Leakage Current ––– ––– 1.0 µA

––– ––– 150

Gate-to-Source Forward Leakage ––– ––– 100 nA

Gate-to-Source Reverse Leakage ––– ––– -100

Total Gate Charge ––– 9.3 14

Pre-Vth Gate-to-Source Charge ––– 2.5 –––

Post-Vth Gate-to-Sourc e Charge ––– 0.8 ––– nC

Gate-to-Drain Charge ––– 2.9 –––

Gate Charge Overdrive ––– 3.1 ––– See Fig. 16

Switch Charge (Q

gs2

+ Qgd)

––– 3.7 –––

Output Charge ––– 6.1 ––– nC

Turn-On Delay Time ––– 6.3 –––

Rise Time ––– 2.7 –––

Turn-Off Delay Time ––– 9.7 ––– ns

Fall Time ––– 7.3 –––

Input Capacitance ––– 1010 –––

Output Capacitance ––– 360 ––– pF

Reverse Transfer Capacitance ––– 110 –––

VGS = 0V, ID = 250µA

Reference to 25°C, I

V

mΩ

= 10V, ID = 13A

GS

= 4.5V, ID = 10A

V

GS

V

= VGS, ID = 250µA

DS

= 24V, VGS = 0V

V

DS

V

= 24V, VGS = 0V, TJ = 125°C

DS

V

= 20V

GS

V

= -20V

GS

V

= 15V, ID = 10A

DS

= 15V

V

DS

VGS = 4.5V

= 10A

I

D

V

= 10V, VGS = 0V

DS

V

= 15V, VGS = 4.5V

DD

ID = 10A

Clamped Inductive Load

V

= 0V

GS

V

= 15V

DS

ƒ = 1.0MHz

Conditions

= 1mA

D

e

e

e

Avalanche Characteristics

E

AS

I

AR

Single Pulse Avalanche Energy

Avalanche Current

c

dh

Parameter Units

Typ.

–––

–––

Max.

44

10

mJ

A

Diode Characteristics

Parameter Min. Typ. Max. Units

I

S

Continuous Source Current ––– ––– 3.1

(Body Diode) A

I

SM

V

SD

t

rr

Q

rr

Pulsed Source Current ––– ––– 100

(Body Diode)

ch

Diode Forward Voltage ––– ––– 1.0 V

Reverse Recovery Time ––– 28 42 ns

Reverse Recovery Charge ––– 23 35 nC

MOSFET symbol

showing the

integral reverse

p-n junction diode.

TJ = 25°C, IS = 10A, VGS = 0V

= 25°C, IF = 10A, VDD = 10V

T

J

di/dt = 100A/µs

Conditions

e

e

2 www.irf.com

IRF7821

100

)

A

(

t

n

e

r

10

r

u

C

e

c

r

u

o

S

-

o

t

-

1

n

i

a

r

D

,

D

I

2.5V

20µs PULSE WIDTH

Tj = 25°C

0.1

0.1 1 10 100

VDS, Drain-to-Source Voltage (V)

100.0

TJ = 150°C

)

Α

(

t

n

e

r

10.0

r

u

C

e

c

r

u

o

S

-

o

t

-

1.0

n

i

a

r

D

,

D

I

0.1

2.0 3.0 4.0 5.0 6.0

TJ = 25°C

V

= 15V

DS

20µs PULSE WIDTH

VGS, Gate-to-Source Voltage (V)

VGS

TOP 10V

4.5V

3.7V

3.5V

3.3V

3.0V

2.7V

BOTTOM 2.5V

100

)

A

(

t

n

e

r

r

u

C

e

c

r

10

u

o

S

-

o

t

-

n

i

a

r

D

,

D

I

2.5V

20µs PULSE WIDTH

VGS

TOP 10V

4.5V

3.7V

3.5V

3.3V

3.0V

2.7V

BOTTOM 2.5V

Tj = 150°C

1

0.1 1 10 100

VDS, Drain-to-Source Voltage (V)

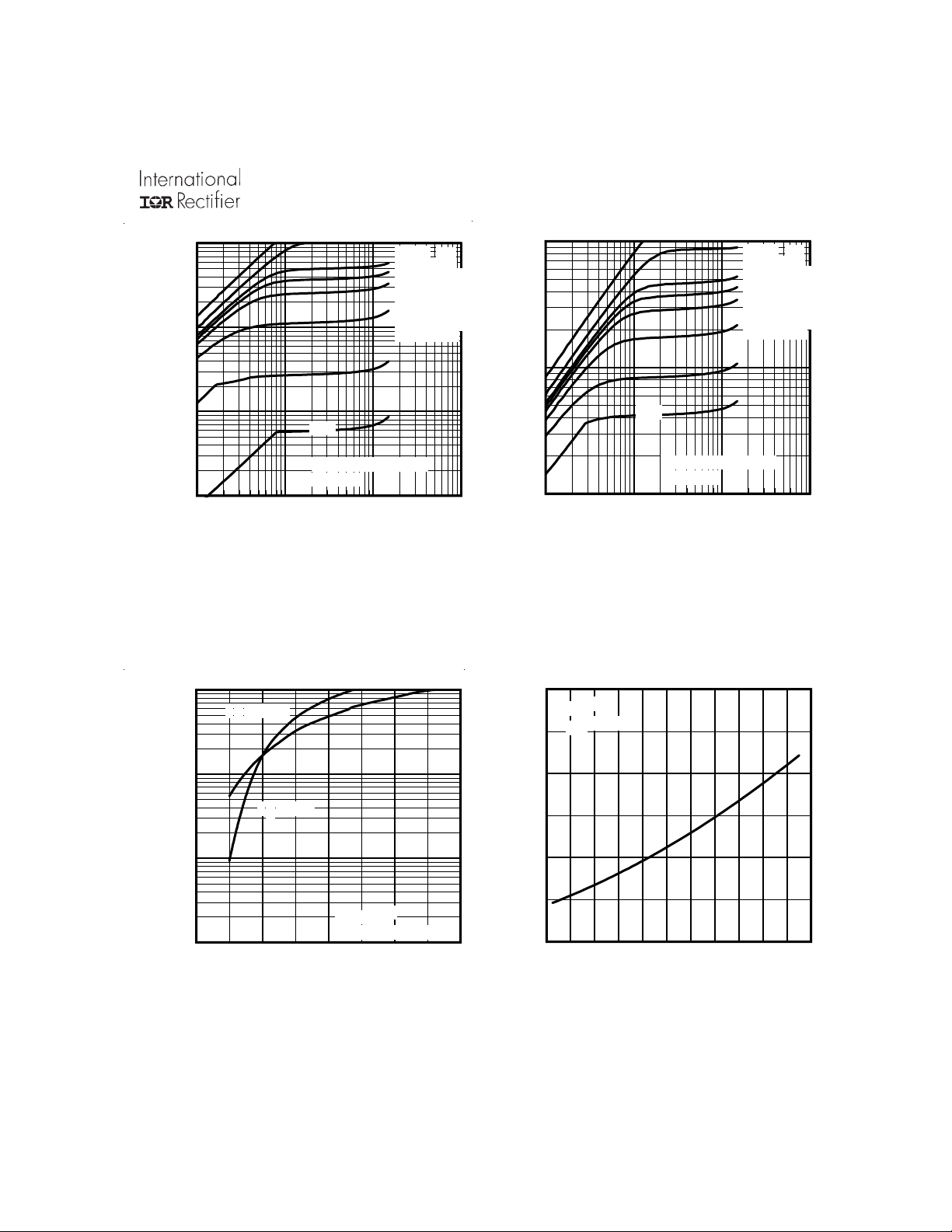

Fig 2. Typical Output CharacteristicsFig 1. Typical Output Characteristics

2.0

e

c

n

a

t

s

i

s

e

R

n

O

e

c

r

u

o

S

-

o

t

-

n

i

a

r

D

,

)

n

o

(

S

D

R

ID = 13A

V

= 10V

GS

1.5

)

d

e

z

i

l

a

m

r

o

N

(

1.0

0.5

-60 -40 -20 0 20 40 60 80 100 120 140 160

TJ , Junction Temperature (°C)

Fig 3. Typical Transfer Characteristics

Fig 4. Normalized On-Resistance

Vs. Temperature

www.irf.com 3

IRF7821

)

F

p

(

e

c

n

a

t

i

c

a

p

a

C

,

C

10000

1000

100

10

1 10 100

V

= 0V, f = 1 MHZ

GS

C

= C

= C

= C

gs

gd

ds

Ciss

Coss

Crss

+ Cgd, C

+ C

iss

C

rss

C

oss

VDS, Drain-to-Source Voltage (V)

Fig 5. Typical Capacitance Vs.

Drain-to-Source Voltage

12

SHORTED

ds

gd

)

V

(

e

g

a

t

l

o

V

e

c

r

u

o

S

-

o

t

-

e

t

a

G

,

V

ID= 10A

10

8

6

4

S

2

G

0

0 5 10 15 20

Q

VDS= 24V

VDS= 15V

Total Gate Charge (nC)

G

Fig 6. Typical Gate Charge Vs.

Gate-to-Source Voltage

100.0

)

A

(

t

n

e

r

10.0

r

u

C

n

i

a

r

D

e

s

r

e

v

1.0

e

R

,

D

S

I

0.1

TJ = 150°C

TJ = 25°C

0.0 0.5 1.0 1.5

VSD, Source-toDrain Voltage (V)

Fig 7. Typical Source-Drain Diode

V

GS

= 0V

1000

)

A

(

t

100

n

e

r

r

u

C

e

c

r

u

10

o

S

-

o

t

-

n

i

a

r

1

D

,

D

I

Tc = 25°C

Tj = 150°C

Single Pulse

0.1

0.1 1.0 10.0 100.0 1000.0

V

OPERATION IN THIS AREA

LIMITED BY RDS(on)

, Drain-toSource Voltage (V)

DS

100µsec

1msec

10msec

Fig 8. Maximum Safe Operating Area

Forward Voltage

4 www.irf.com

IRF7821

14

12

)

10

A

(

t

n

e

r

8

r

u

C

n

i

6

a

r

D

,

4

D

I

2

0

25 50 75 100 125 150

TJ , Junction Temperature (°C)

Fig 9. Maximum Drain Current Vs.

Case Temperature

2.6

)

V

(

e

g

2.2

a

t

l

o

V

d

l

o

h

s

1.8

e

r

h

t

e

t

a

G

)

h

1.4

t

(

S

G

V

1.0

-75 -50 -25 0 25 50 75 100 125 150

TJ , Temperature ( °C )

ID = 250µA

Fig 10. Threshold Voltage Vs. Temperature

100

)

A

J

h

t

Z

(

e

s

n

o

p

s

e

R

l

a

m

r

e

h

T

D = 0.50

10

1

0.1

0.01

1E-006 1E-005 0.0001 0.001 0.01 0.1 1 10 100

0.20

0.10

0.05

0.02

0.01

SINGLE PULSE

( THERMAL RESPONSE )

t1 , Rectangular Pulse Duration (sec)

Fig 11. Maximum Effective Transient Thermal Impedance, Junction-to-Ambient

www.irf.com 5

IRF7821

A

)

Ω

30

m

(

e

c

n

25

a

t

s

i

s

e

R

20

n

O

e

c

r

15

u

o

S

o

t

10

-

n

i

a

r

D

5

,

)

n

o

(

S

0

D

R

2.0 4.0 6.0 8.0 10.0

VGS, Gate-to-Source Voltage (V)

ID = 13A

TJ = 125°C

TJ = 25°C

100

)

J

m

(

y

g

80

r

e

n

E

e

h

c

60

n

a

l

a

v

A

e

40

s

l

u

P

e

l

g

n

i

20

S

,

S

A

E

0

25 50 75 100 125 150

Starting TJ, Junction Temperature (°C)

I

TOP

D

4.5A

8.0A

10A

BOTTOM

Fig 12. On-Resistance Vs. Gate Voltage

Fig 13c. Maximum Avalanche Energy

Vs. Drain Current

L

D.U.T

D

V

DD

15V

DRIVER

+

-

V

DD

R

V

20V

V

DS

G

GS

t

L

D.U.T

I

AS

0.01

p

Ω

Fig 13a. Unclamped Inductive Test Circuit

V

(BR)DSS

t

p

V

DS

V

GS

Pulse Width < 1µs

Duty Factor < 0.1%

Fig 14a. Switching Time Test Circuit

V

DS

90%

10%

V

GS

I

AS

Fig 13b. Unclamped Inductive Waveforms

t

t

d(on)

f

Fig 14b. Switching Time Waveforms

t

d(off)

t

r

6 www.irf.com

IRF7821

D.U.T

+

-

R

G

Current Regulator

Same Type as D.U.T.

+

Circuit Layout Considerations

• Low Stray Inductance

• Ground Plane

-

• Low Leakage Inductance

Current Transformer

-

• dv/dt controlled by R

• Driver same type as D.U.T.

• ISD controlled by Duty Factor "D"

• D.U.T. - Device Under Test

G

Driver Gate Drive

P.W.

D.U.T. ISDWaveform

Reverse

Recovery

+

-

Current

Re-Applied

Voltage

D.U.T. VDSWaveform

Inductor Curent

* V

GS

+

V

DD

Period

Body Diode Forward

Current

di/dt

Diode Recovery

dv/dt

Body Diode Forward Drop

Ripple ≤ 5%

= 5V for Logic Level Devices

Fig 15. Peak Diode Recovery dv/dt Test Circuit for N-Channel

HEXFET® Power MOSFETs

Vds

D =

P.W.

Period

VGS=10V

V

DD

I

SD

*

Id

Vgs

12V

.2µF

50KΩ

.3µF

D.U.T.

+

V

DS

-

Vgs(th)

V

GS

3mA

I

G

Current Sampling Resistors

I

Fig 16. Gate Charge Test Circuit

D

Qgs1

Qgs2 Qgd Qgodr

Fig 17. Gate Charge Waveform

www.irf.com 7

IRF7821

)

Power MOSFET Selection for Non-Isolated DC/DC Converters

Control FET

Special attention has been given to the power losses

in the switching elements of the circuit - Q1 and Q2.

Power losses in the high side switch Q1, also called

the Control FET, are impacted by the R

MOSFET, but these conduction losses are only about

one half of the total losses.

Power losses in the control switch Q1 are given

by;

P

= P

loss

This can be expanded and approximated by;

P

loss

conduction

= I

()

rms

+ I ×

+ Qg× Vg× f

()

Q

+

This simplified loss equation includes the terms Q

and Q

charge that is included in all MOSFET data sheets.

The importance of splitting this gate-source charge

into two sub elements, Q

Fig 16.

the gate driver between the time that the threshold

voltage has been reached and the time the drain current rises to I

gins to change. Minimizing Q

reducing switching losses in Q1.

put capacitance of the MOSFET during every switching cycle. Figure A shows how Q

parallel combination of the voltage dependant (nonlinear) capacitances Cds and Cdg when multiplied by

the power supply input buss voltage.

which are new to Power MOSFET data sheets.

oss

Q

is a sub element of traditional gate-source

gs2

Q

indicates the charge that must be supplied by

gs2

Q

is the charge that must be supplied to the out-

oss

+ P

2

× R

ds(on )

Q

gd

× Vin× f

i

g

oss

×Vin× f

2

at which time the drain voltage be-

dmax

switching

and Q

gs1

+ P

+ I ×

+ P

drive

Q

gs2

i

gs2

g

, can be seen from

gs2

is a critical factor in

is formed by the

oss

of the

ds(on)

output

× Vin× f

Synchronous FET

The power loss equation for Q2 is approximated

by;

P

= P

loss

conduction

P

= I

loss

+ Qg× Vg× f

+

rms

()

Q

*dissipated primarily in Q1.

For the synchronous MOSFET Q2, R

portant characteristic; however, once again the im-

portance of gate charge must not be overlooked since

it impacts three critical areas. Under light load the

MOSFET must still be turned on and off by the control IC so the gate drive losses become much more

significant. Secondly, the output charge Q

verse recovery charge Qrr both generate losses that

are transfered to Q1 and increase the dissipation in

that device. Thirdly, gate charge will impact the

MOSFETs’ susceptibility to Cdv/dt turn on.

gs2

The drain of Q2 is connected to the switching node

of the converter and therefore sees transitions between ground and Vin. As Q1 turns on and of f there is

a rate of change of drain voltage dV/dt which is capacitively coupled to the gate of Q2 and can induce

a voltage spike on the gate that is sufficient to turn

the MOSFET on, resulting in shoot-through current .

The ratio of Qgd/Q

potential for Cdv/dt turn on.

Figure A: Q

+ P

2

× R

ds(on)()

oss

×Vin× f

2

must be minimized to reduce the

gs1

Characteristic

oss

drive

*

+ P

output

+ Qrr× Vin× f

(

ds(on)

oss

is an im-

and re-

8 www.irf.com

SO-8 Package Details

IRF7821

D B

8X b

5

65

4312

e1

CAB

A1

H

0.25 [.010]

A

A

C

0.10 [.004]

A

87

6

E

e

6X

0.25 [.010]

NOTE S:

1. DIMENSIONING & TOLE RANCING PER ASME Y14.5M-1994.

2. CONTROLLING DIMENSION: MILLIMETER

3. DIME NS IONS ARE S HOWN IN MILL IMET ER S [INCHES ].

4. OUT LINE CONFORMS T O JEDEC OUTL INE MS-012AA.

5 DIMENS ION DOES NOT INCLUDE MOLD PROT RUS IONS.

MOLD PROTRUS IONS NOT T O EXCEED 0.15 [.006].

6 DIMENS ION DOES NOT INCLUDE MOLD PROT RUS IONS.

MOLD PROTRUS IONS NOT T O EXCEED 0.25 [.010].

7 DIMENS ION IS TH E L E NGTH OF L EAD FOR S OLDE RING TO

A S U BS T RAT E .

y

3X 1.27 [.050]

DIM

MI N MAX

A

.0532

A1

b

c .0075 .0098 0.19 0.25

D

E

e

e1

H

K

L

y

K x 45°

8X L

7

6.46 [.255]

.0688

.0040

.0098

.013

.020

.189

.1968

.1497

.1574

.050 BASI C

.025 BASI C 0.635 BASIC

.2284

.2440

.0099

.0196

.016

.050

0°

8°

8X c

F OOT P R I NT

8X 0.72 [.028]

MI LL I ME T E R SINCHES

MI N MAX

1.35

1.75

0.10

0.25

0.33

0.51

4.80

5.00

3.80

4.00

1.27 BASI C

5.80

6.20

0.25

0.50

0.40

1.27

8°

0°

8X 1.78 [.070]

SO-8 Part Marking

EXAMPLE: T HIS IS AN IRF7101 (MOSF ET )

DAT E CODE (YWW)

Y = LAS T DIGIT OF T HE YEAR

YWW

XXXX

INTERNATIONAL

F7101

RECT IFIER

LOGO

www.irf.com 9

WW = WEEK

LOT CODE

PART NUMBER

IRF7821

SO-8 Tape and Reel

TERMINAL NUMBER 1

12.3 ( .484 )

11.7 ( .461 )

8.1 ( .318 )

7.9 ( .312 )

NOTES:

1. CONTROLLING DIMENSION : MILLIMETER.

2. ALL DIMENSIONS ARE SHOWN IN MILLIMETERS(INCHES).

3. OUTLINE CONFORMS TO EIA-481 & EIA-541.

330.00

(12.992)

MAX.

NOTES :

1. CONTROLLING DIMENSION : MILLIMETER.

2. OUTLINE CONFORMS TO EIA-481 & EIA-541.

Notes:

Repetitive rating; pulse width limited by

max. junction temperature.

Starting T

RG = 25Ω, I

= 25°C, L = 0.87mH

J

= 10A.

AS

Pulse width ≤ 400µs; duty cycle ≤ 2%.

When mounted on 1 inch square copper board

R

is measured at TJ approximately 90°C

θ

This product has been designed and qualified for the Industrial market.

FEED DIRECTION

14.40 ( .566 )

12.40 ( .488 )

Data and specifications subject to change without notice.

Qualification Standards can be found on IR’s Web site.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7903

Visit us at www.irf.com for sales contact information.1/04

10 www.irf.com

Loading...

Loading...