®

ISL6269A

Data Sheet May 30, 2007

High-Performance Notebook PWM

Controller

The ISL6269A IC is a Single-Phase Synchronous-Buck

PWM controller featuring Intersil's Robust Ripple Regulator

3

(R

) technology that delivers truly superior dynamic

response to input voltage and output load transients.

Integrated MOSFET drivers and bootstrap diode result in

fewer components and smaller implementation area.

Intersil’s R

3

technology combines the best features of fixedfrequency PWM and hysteretic PWM while eliminating many

of their shortcomings. R

modulator that synthesizes an AC ripple voltage signal V

3

technology employs an innovative

,

R

analogous to the output inductor ripple current. The AC

signal V

threshold is the error amplifier output V

threshold is a programmable voltage reference V

in generation of the PWM signal. The voltage reference V

enters a window comparator where the lower

R

, and the upper

COMP

resulting

W,

W

sets the steady-state PWM frequency. Both edges of the

PWM can be modulated in response to input voltage

transients and output load transients, much faster than

conventional fixed-frequency PWM controllers. Unlike a

conventional hysteretic converter, the ISL6269A has an error

amplifier that provides ±1% voltage regulation at the FB pin.

The ISL6269A has a 1.5ms digital soft-start and can be

started into a pre-biased output voltage. A resistor divider is

used to program the output voltage setpoint. The ISL6269A

can be configured to operate in continuous-conductionmode (CCM) or diode-emulation-mode (DEM), which

improves light-load efficiency. In CCM the controller always

operates as a synchronous rectifier however, when DEM is

enabled the low-side MOSFET is permitted to stay off,

blocking negative current flow into the low-side MOSFET

from the output inductor.

Pinout

ISL6269A

(16 LD 4x4 QFN)

TOP VIEW

PGOODUGPHASE

1516 14 13

BOOT

FN9253.2

Features

• High performance R3 technology

• Fast transient response

• ±1% regulation accuracy: -10°C to +100°C and

-40°C to +100°C

• Wide input voltage range: +5.0V to +25.0V

• Output voltage range: +0.6V to +3.3V

• Wide output load range: 0A to 25A

• Selectable diode emulation mode for increased light load

efficiency

• Programmable PWM frequency: 200kHz to 600kHz

• Pre-biased output start-up capability

• Integrated MOSFET drivers and bootstrap diode

• Internal digital soft-start

• Power good monitor

• Fault protection

- Undervoltage protection

- Soft crowbar overvoltage protection

- Low-side MOSFET r

overcurrent protection

DS(ON)

- Over-temperature protection

- Fault identification by PGOOD pull down resi stance

• Pb-free plus anneal available (RoHS compliant)

Applications

• PCI express graphical processing unit

• Auxiliary power rail

•VRM

• Network adapter

Ordering Information

TEMP

PART NUMBER

(Note)

ISL6269ACRZ* 62 69ACRZ -10 to +100 16 Ld 4x4 QFN L16.4x4

PART

MARKING

RANGE

(°C)

PACKAGE

(Pb-free)

PKG.

DWG. #

VIN

VCC

FCCM

EN

VO

PVCC

12

LG

11

10

PGND

9

ISEN

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

1

2

3

4

GND

6578

FB

COMP

FSET

1

ISL6269AIRZ* 62 69AIRZ -40 to +100 16 Ld 4x4 QFN L16.4x4

*Add “-T” suffix for tape and reel.

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2005, 2006, 2007. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

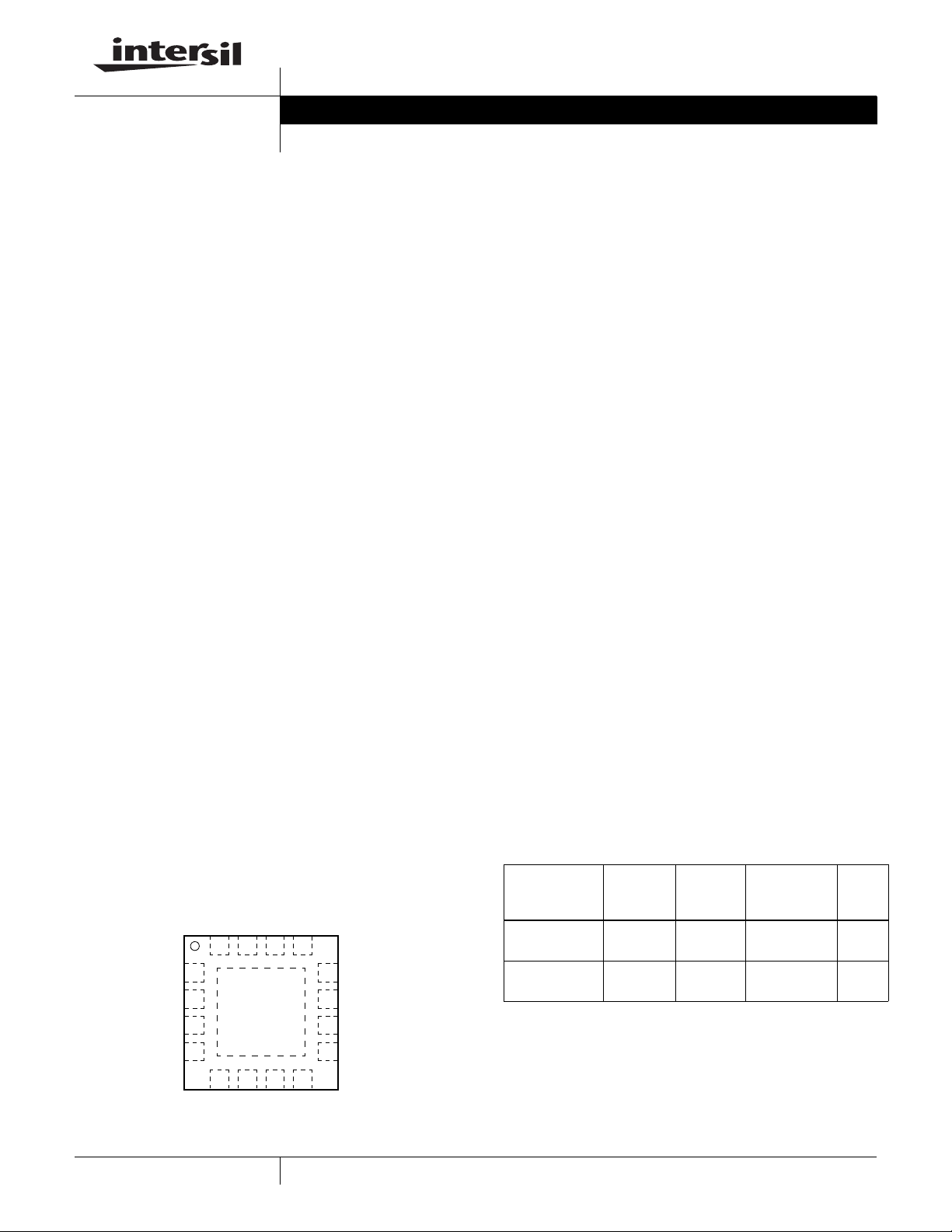

Block Diagram

VIN

GND

VCC

2

EN

PACKAGE BOTTOM

V

REF

−

OVP

+

−

UVP

+

+

+

gmV

−

gmV

−

PWM FREQUENCY

CONTROL

−

+

IN

V

W

−

+

R

PWM

V

R

O

+

C

R

V

COMP

−

+

Q

S

−

VO

FSET

ISL6269A

BOOT

+

EA

FB

−

EA

POR

DRIVER

DIGITAL SOFT-START

UG

COMP

ISEN

PGOOD

May 30, 2007

FN9253.2

−

I

OC

OCP

+

30Ω

90Ω

FIGURE 1. SCHEMATIC BLOCK DIAGRAM

60Ω

150°OT

PWM CONTROL

SHOOT THROUGH

PROTECTION

DRIVER

PHASE

PVCC

LG

PGND

FCCM

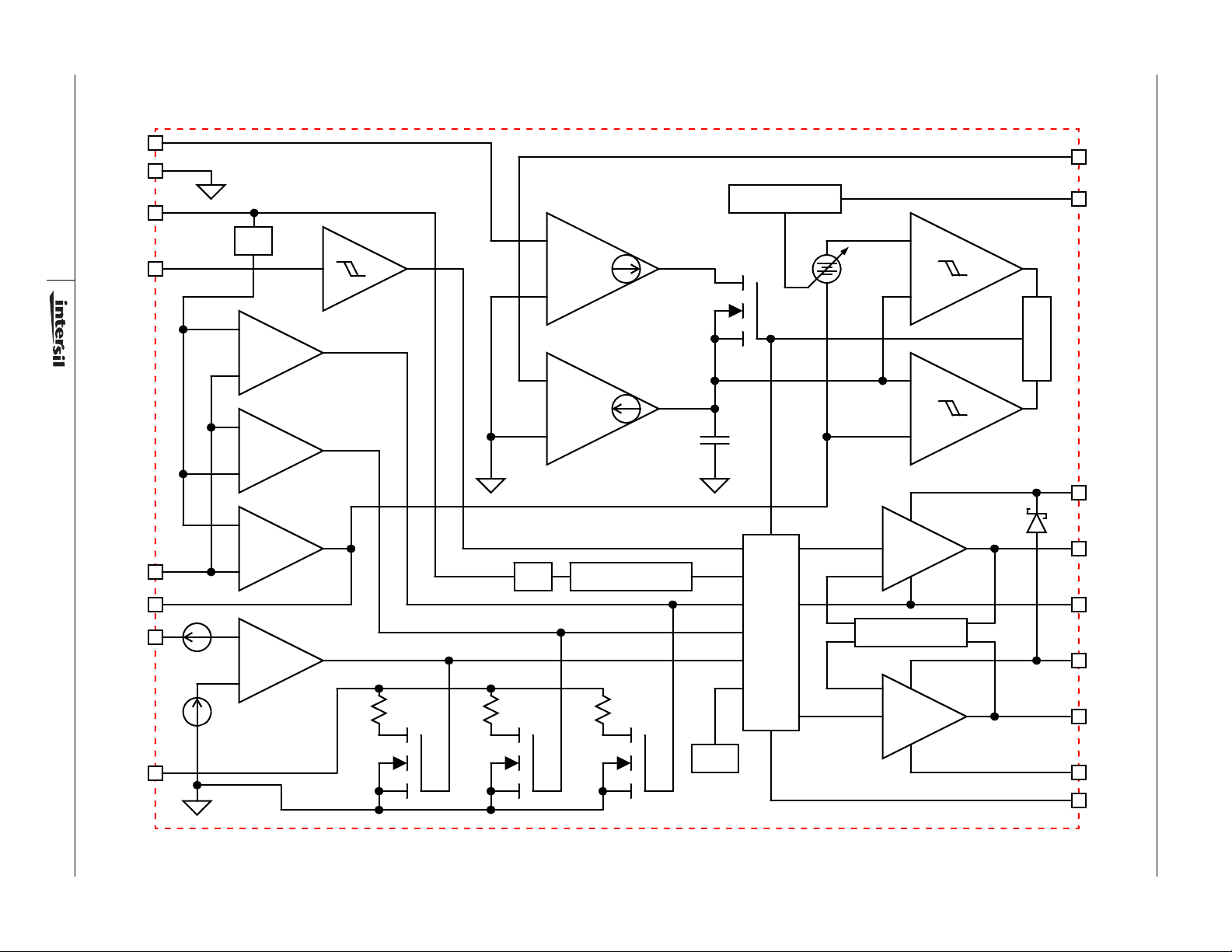

Typical Application

5V

R

VCC

R

PGOOD

PGOOD

PVCC

ISL6269A

ISL6269A

VIN

UG

V

IN

5V TO 25V

C

IN

Q

HIGH_SIDE

C

PVCC

R

COMP

C

VCC

C

COMP1

VCC

GND

FCCM

EN

COMP

BOOT

PHASE

ISEN

LG

PGND

C

BOOT

R

SEN

L

OUT

Q

LOW_SIDE

V

OUT

0.6V TO 3.3V

C

OUT

C

COMP2

R

BOTTOM

R

FB

VO

TOP

FSET

FIGURE 2. ISL6269A TYPICAL APPLICATION SCHEMATIC

3

R

FSET

C

FSET

FN9253.2

May 30, 2007

ISL6269A

Absolute Voltage Ratings

ISEN, VIN to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +28V

VCC, PGOOD to GND. . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +7.0V

PVCC to PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +7.0V

GND to PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +0.3V

EN, FCCM . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to GND, VCC +3.3V

VO, FB, COMP, FSET . . . . . . . . . . . . . . . -0.3V to GND, VCC +0.3V

PHASE to GND (DC). . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +28V

(<100ns Pulse Width, 10μJ). . . . . . . . . . . . . . . . . . . . . . . . . -5.0V

BOOT to GND, or PGND. . . . . . . . . . . . . . . . . . . . . . .-0.3V to +33V

BOOT to PHASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +7V

UG (DC). . . . . . . . . . . . . . . . . . . . . . .-0.3V to PHASE, BOOT +0.3V

(<200ns Pulse Width, 20μJ) . . . . . . . . . . . . . . . . . . . . . . . . -4.0V

LG (DC) . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to PGND, PVCC +0.3V

(<100ns Pulse Width, 4μJ). . . . . . . . . . . . . . . . . . . . . . . . . . -2.0V

Thermal Information

Thermal Resistance (Typical, Notes 1, 2) θJA (°C/W) θJC (°C/W)

QFN Package. . . . . . . . . . . . . . . . . . . . 48 11.5

Junction Temperature Range. . . . . . . . . . . . . . . . . .-55°C to +150°C

Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ISL6269ACRZ . . . . . . . . . . . . . . . . . . . . . . . . . . .-10°C to +100°C

ISL6269AIRZ . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +100°C

Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-free reflow profile . . . . . . . . . . . . . . . . . . . . . . . . . .see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

Recommended Operating Conditions

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ISL6269ACRZ . . . . . . . . . . . . . . . . . . . . . . . . . . .-10°C to +100°C

ISL6269AIRZ . . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to +100°C

Supply Voltage (VIN to GND) . . . . . . . . . . . . . . . . . . . . . . 5V to 25V

VCC to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5V ±5%

PVCC to PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5V ±5%

CAUTION: Stress above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational section of this specification is not implied.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

1. θ

JA

Tech Brief TB379.

2. For θ

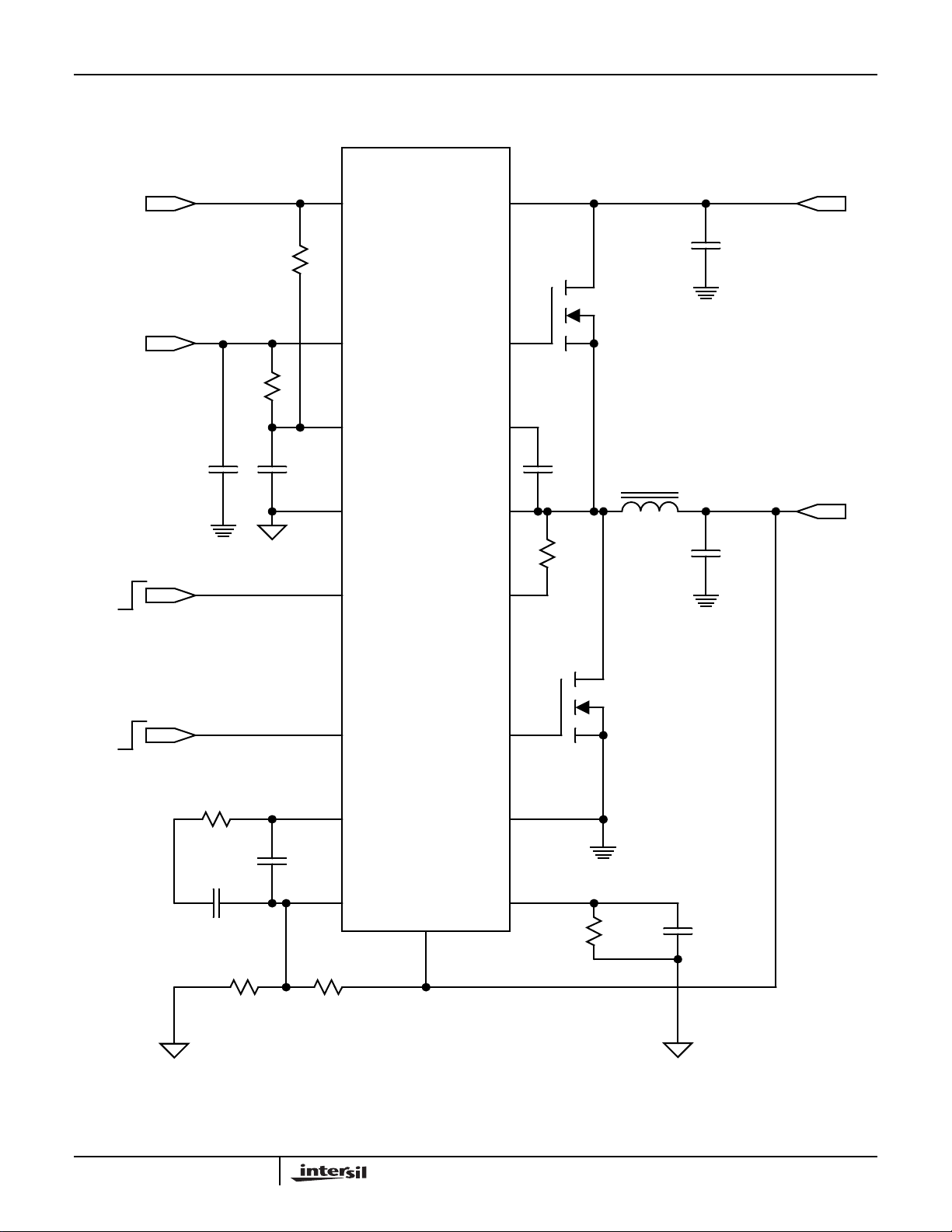

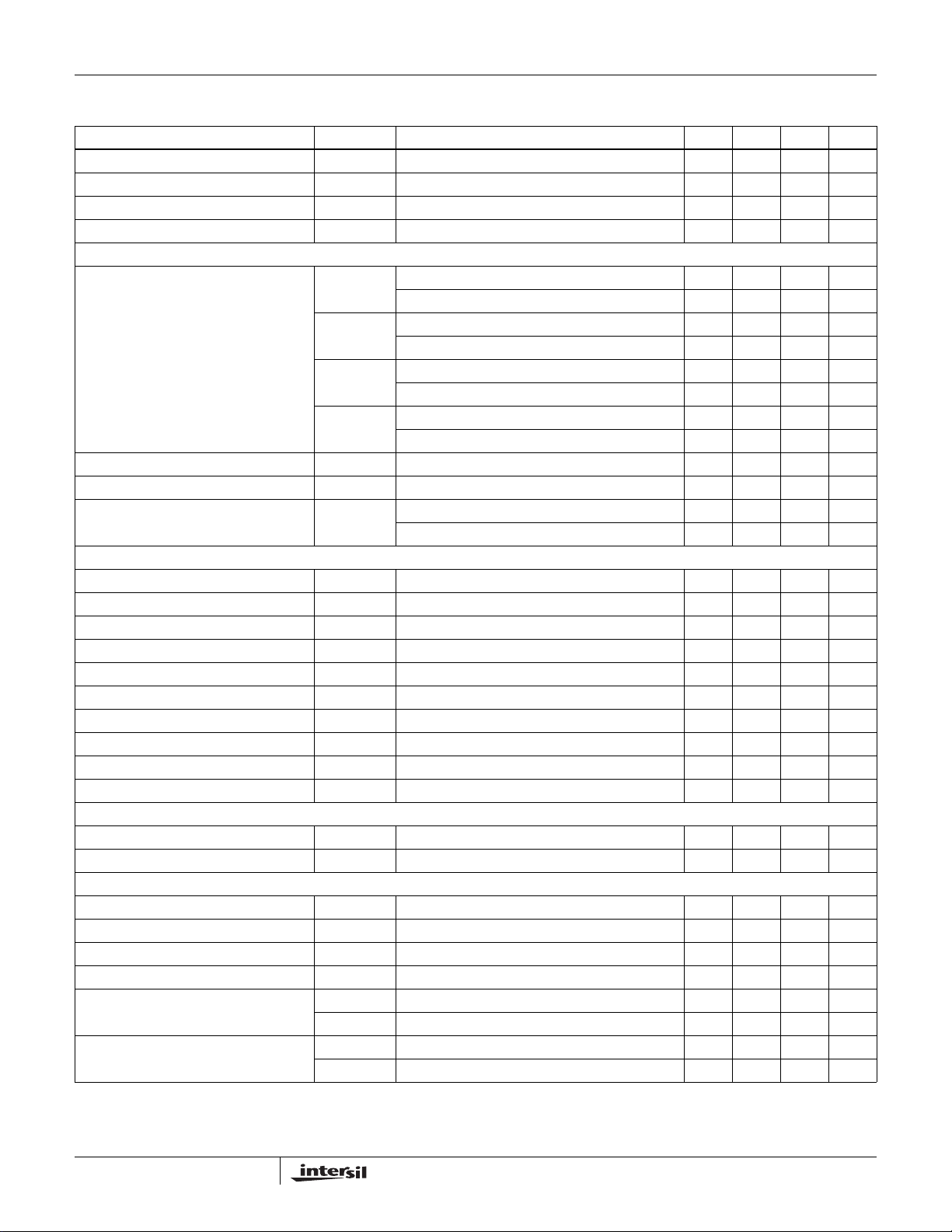

Electrical Specifications These specifications apply for V

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

= 15V, TA = -40°C to +100°C, unless otherwise stated.

All typical specifications T

IN

= +25°C, VCC = 5V, PVCC = 5V, VIN = 15V

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

VIN

VIN Input Bias Current I

VIN

EN = 5V, VIN = 5V - 6.5 10 μA

EN = 5V, VIN = 25V - 26 35 μA

VIN Shutdown Current I

VIN_SHDN

EN = GND, VIN = 25V - 0.1 1.0 μA

VCC and PVCC

VCC Input Bias Current I

VCC Shutdown Current I

PVCC Shutdown Current I

VCC_SHDN

PVCC_SHDN

VCC

EN = 5V, FCCM = GND, FB = 0.65V - 1.7 2.5 mA

EN = GND, VCC = 5V - 0.1 1.0 μA

EN = GND, PVCC = 5V - 0.1 1.0 μA

VCC POR THRESHOLD

Rising VCC POR Threshold Voltage V

VCC_THRTA

= -10°C to +100°C 4.35 4.45 4.55 V

4.33 4.45 4.55 V

Falling VCC POR Threshold Voltage

V

VCC_THFTA

= -10°C to +100°C 4.10 4.20 4.30 V

4.08 4.20 4.30 V

REGULATION

Reference Voltage V

REF

- 0.6 - V

Regulation Accuracy FB connected to COMP -1 - +1 %

PWM

Frequency Range f

SW

Frequency-Set Accuracy f

VO Range V

VO Input Leakage

VO

I

VO

FCCM = 5V 200 - 600 kHz

= 300kHz -12 - +12 %

SW

0.60 - 3.30 V

VO = 0.60V - 1.3 - μA

VO = 3.30V - 7.0 - μA

ERROR AMPLIFIER

FB Input Bias Current I

FB

FB = 0.60V -0.5 - +0.5 μA

4

FN9253.2

May 30, 2007

ISL6269A

Electrical Specifications These specifications apply for V

All typical specifications T

= 15V, TA = -40°C to +100°C, unless otherwise stated.

IN

= +25°C, VCC = 5V, PVCC = 5V, VIN = 15V (Continued)

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

COMP Source Current I

COMP Sink Current I

COMP High Clamp Voltage V

COMP Low Clamp Voltage V

COMP_SRC

COMP_SNK

COMP_HC

COMP_LC

FB = 0.40V, COMP = 3.20V - 2.5 - mA

FB = 0.80V, COMP = 0.30V - 0.3 - mA

FB = 0.40V, Sink 50μA 3.10 3.40 3.65 V

FB = 0.80V, Source 50μA 0.09 0.15 0.21 V

POWER GOOD

PGOOD Pull-down Impedance R

PG_SS

PGOOD = 5mA Sink, TA = -10°C to +100°C 75 95 125 Ω

PGOOD = 5mA Sink 67 95 125 Ω

R

PG_UV

PGOOD = 5mA Sink, TA = -10°C to +100°C 75 95 125 Ω

PGOOD = 5mA Sink 67 95 125 Ω

R

PG_OV

PGOOD = 5mA Sink, TA = -10°C to +100°C 50 63 85 Ω

PGOOD = 5mA Sink 45 63 85 Ω

R

PG_OC

PGOOD = 5mA Sink, TA = -10°C to +100°C 25 32 45 Ω

PGOOD = 5mA Sink 22 32 45 Ω

PGOOD Leakage Current I

PGOOD

PGOOD = 5V - 0.1 1.0 μA

PGOOD Maximum Sink Current (Note 3) - 5.0 - mA

PGOOD Soft-Start Delay t

SS

EN High to PGOOD High, TA = -10°C to +100°C 2.20 2.75 3.30 ms

EN High to PGOOD High 2.20 2.75 3.50 ms

GATE DRIVER

UG Pull-Up Resistance R

UG Source Current (Note 3) I

UG Sink Resistance R

UG Sink Current (Note 3) I

LG Pull-Up Resistance R

LG Source Current (Note 3) I

LG Sink Resistance R

LG Sink Current (Note 3) I

UG to LG Deadtime t

LG to UG Deadtime t

UGPU

UGSRC

UGPD

UGSNK

LGPU

LGSRC

LGPD

LGSNK

UGFLGR

LGFUGR

200mA Source Current - 1.0 1.5 Ω

UG - PHASE = 2.5V - 2.0 - A

250mA Sink Current - 1.0 1.5 Ω

UG - PHASE = 2.5V - 2.0 - A

250mA Source Current - 1.0 1.5 Ω

LG - PGND = 2.5V - 2.0 - A

250mA Sink Current - 0.5 0.9 Ω

LG - PGND = 2.5V - 4.0 - A

UG falling to LG rising, no load - 21 - ns

LG falling to UG rising, no load - 14 - ns

BOOTSTRAP DIODE

Forward Voltage V

Reverse Leakage I

R

PVCC = 5V, IF = 2mA - 0.58 - V

F

VR = 25V - 0.2 - μA

CONTROL INPUTS

EN High Threshold V

EN Low Threshold V

FCCM High Threshold V

FCCM Low Threshold V

FCCMTHR

FCCMTHF

EN Leakage I

FCCM Leakage I

I

ENTHR

ENTHF

ENL

I

ENH

FCCML

FCCMH

EN = 0V - 0.1 1.0 μA

EN = 5.0V - 0.1 1.0 μA

FCCM = 0V - 0.1 1.0 μA

FCCM = 5.0V - 2.0 - μA

2.0 --V

--1.0 V

2.0 --V

--1.0 V

5

FN9253.2

May 30, 2007

ISL6269A

Electrical Specifications These specifications apply for V

All typical specifications T

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

PROTECTION

ISEN OCP Threshold I

ISEN Short-Circuit Threshold I

UVP Threshold V

OVP Rising Threshold V

OVP Falling Threshold V

OTP Rising Threshold (Note 3) T

OTP Hysteresis (Note 3) T

NOTE:

3. Guaranteed by characterization.

OC

SC

UV

OVR

OVF

OTR

OTHYS

= +25°C, VCC = 5V, PVCC = 5V, VIN = 15V (Continued)

A

ISEN sourcing, TA = -10°C to +100°C 19 26 33 μA

ISEN sourcing 17 26 33 μA

ISEN sourcing - 50 - μA

Functional Pin Descriptions

GND (Bottom Pad)

Signal common of the IC. Unless otherwise stated, signals

are referenced to the GND pin, not the PGND pin.

VIN (Pin 1)

The VIN pin measures the converter input voltage which is a

required input to the R3 PWM modulator. Connect across

the drain of the high-side MOSFET to the GND pin.

VCC (Pin 2)

The VCC pin is the input bias voltage for the IC. Connect

+5V from the VCC pin to the GND pin. Decouple with at least

1µF of a MLCC capacitor from the VCC pin to the GND pin.

FCCM (Pin 3)

The FCCM pin configures the controller to operate in forcedcontinuous-conduction-mode (FCCM) or diode-emulationmode (DEM.) DEM is disabled when the FCCM pin is pulled

above the rising threshold voltage V

FCCMTHR

DEM is enabled when the FCCM pin is pulled below the

falling threshold voltage V

FCCMTHF.

EN (Pin 4)

The EN pin is the on/off switch of the IC. The soft-start

sequence begins when the EN pin is pulled above the rising

threshold voltage V

reset (POR) rising threshold voltage

and VCC is above the power-on

ENTHR

V

VCC_THR

EN pin is pulled below the falling threshold voltage V

PWM immediately stops.

COMP (Pin 5)

The COMP pin is the output of the control-loop error

amplifier. Compensation components for the control-loop

connect across the COMP and FB pins.

FB (Pin 6)

The FB pin is the inverting input of the control-loop error

amplifier. The converter output voltage regulates to 600mV

, conversely

. When the

ENTHF

= 15V, TA = -40°C to +100°C, unless otherwise stated.

IN

81 84 87 %

113 116 119 %

100 103 106 %

- 150 - °C

- 25 - °C

from the FB pin to the GND pin. Program the desired output

voltage with a resistor network connected across the VO,

FB, and GND pins. Select the resistor values such that FB to

GND is 600mV when the converter output voltage is at the

programmed regulation value.

FSET (Pin 7)

The FSET pin programs the PWM switching frequency.

Program the desired PWM frequency with a resistor and a

capacitor connected across the FSET and GND pins.

VO (Pin 8)

The VO pin measures the converter output voltage and is

used exclusively as an input to the R

Connect at the physical location where the best output

voltage regulation is desired.

ISEN (Pin 9)

The ISEN pin programs the threshold of the OCP

overcurrent fault protection. Program the desired OCP

threshold with a resistor connected across the ISEN and

PHASE pins. The OCP threshold is programmed to detect

the peak current of the output inductor. The peak current is

the sum of the DC and AC components of the inductor

current.

PGND (Pin 10)

The PGND pin conducts the turn-off transient current

through the LG gate driver. The PGND pin must be

connected to complete the pulldown circuit of the LG gate

driver. The PGND pin should be connected to the source of

the low-side MOSFET through a low impedance path,

preferably in parallel with the trace connecting the LG pin to

the gate of the low-side MOSFET. The adaptive shootthrough protection circuit, measures the low-side MOSFET

gate-source voltage from the LG pin to the PGND pin.

3

PWM modulator.

6

FN9253.2

May 30, 2007

ISL6269A

LG (Pin 11)

The LG pin is the output of the low-side MOSFET gate

driver. Connect to the gate of the low-side MOSFET.

PVCC (Pin 12)

The PVCC pin is the input voltage bias for the LG low-side

MOSFET gate driver. Connect +5V from the PVCC pin to the

PGND pin. Decouple with at least 1µF of an MLCC capacitor

across the PVCC and PGND pins.

BOOT (Pin 13)

The BOOT pin stores the input voltage for the UG high-side

MOSFET gate driver. Connect an MLCC capacitor across

the BOOT and PHASE pins. The boot capacitor is charged

through an internal boot diode connected from the PVCC pin

to the BOOT pin, each time the PHASE pin drops below

PVCC minus the voltage dropped across the internal boot

diode.

UG (Pin 14)

The UG pin is the output of the high-side MOSFET gate

driver. Connect to the gate of the high-side MOSFET.

PHASE (Pin 15)

The PHASE pin detects the voltage polarity of the PHASE

node and is also the current return path for the UG high-side

MOSFET gate driver. Connect the PHASE pin to the node

consisting of the high-side MOSFET source, the low-side

MOSFET drain, and the output inductor.

The negative slope of V

V

RNEGgmVOUT

Where g

⋅=

is the gain of the transconductance amplifier.

m

can be written as:

R

(EQ. 2)

A window voltage VW is referenced with respect to the error

amplifier output voltage V

which the ripple voltage V

V

is set by a resistor connected across the FSET and GND

W

pins. The V

R, VCOMP,

comparator in which V

and V

is the higher threshold voltage. Figure 3 shows

W

and VW signals feed into a window

COMP

PWM pulses being generated as V

V

thresholds . The PWM switching frequency is

COMP

, creating an envelope into

COMP

is compared. The amplitude of

R

is the lower threshold voltage

traverses the VW and

R

proportional to the slew rates of the positive and negative

slopes of V

proportional to the voltage between V

Ripple Capacitor Voltage C

the PWM switching frequency is inversely

R;

R

Error Amplifier Voltage V

and V

W

Window Voltage V

COMP.

W

COMP

PGOOD (Pin 16)

The PGOOD pin is an open-drain output that indicates when

the converter is able to supply regulated voltage. Connect

the PGOOD pin to +5V through a pull-up resistor.

Theory of Operation

Modulator

The ISL6269A is a hybrid of fixed frequency PWM control,

and variable frequency hysteretic control. Intersil’s R

technology can simultaneously affect the PWM switching

frequency and PWM duty cycle in response to input voltage

and output load transients. The term “Ripple” in the name

“Robust-Ripple-Regulator” refers to the converter output

inductor ripple current, not the converte r ou tp u t rip p l e

voltage. The R

3

modulator synthesizes an AC signal VR,

which is an ideal representation of the output inductor ripple

current. The duty-cycle of V

is the result of charge and

R

discharge current through a ripple capacitor C

through C

is provided by a transconductance amplifier gm

R

that measures the VIN and VO pin voltages. The positive

slope of V

V

RPOSgm

can be written as:

R

()VINV

–()•=

OUT

3

. The current

R

(EQ. 1)

PWM

FIGURE 3. MODULA TOR W A VEFORMS DURING LOAD

TRANSIENT

Power-On Reset

The ISL6269A is disabled until the voltage V

increased above the rising power-on reset (POR)

threshold voltage. The controller will become once again

disabled when the voltage

POR

V

VCC_THF

threshold voltage.

V

decreases below the falling

VCC

VCC

has

V

VCC_THR

EN, Soft-Start, and PGOOD

The ISL6269A uses a digital soft-start circuit to ramp the

output voltage of the converter to the programmed regulation

setpoint at a predictable slew rate. The slew rate of the

soft-start sequence has been selected to limit the inrush

current through the output capacitors as they charge to the

desired regulation voltage. When the EN pin is pulled above

the rising EN threshold voltage V

Soft-Start Delay t

starts and the output voltage begins to

SS

rise. The output voltage enters regulation in approximately

1.5ms and the PGOOD pin goes to high impedance once t

has elapsed.

ENTHR

the PGOOD

SS

7

FN9253.2

May 30, 2007

1.5ms

VOUT

VCC and PVCC

ISL6269A

connected across the BOOT and PHASE pins. The boot

capacitor is charged from a 5V bias supply through a “boot

diode” each time the low-side MOSFET turns on, pulling the

PHASE pin low. The ISL6269A has an integrated boot diode

connected from the PVCC pin to the BOOT pin.

EN

PGOOD

2.75ms

FIGURE 4. SOFT-START SEQUENCE

The PGOOD pin indicates when the converter is capable of

supplying regulated voltage. The PGOOD pin is an

undefined impedance if

POR threshold

threshold

V

VCC_THF

V

V

has not reached the rising

VCC

VCC_THR

, or if V

is below the falling POR

VCC

. The ISL6269A features a unique faultidentification capability that can drastically reduce troubleshooting time and effort. The pull-down resistance of the

PGOOD pin corresponds to the fault status of the controller.

During soft-start or if an undervoltage fault occurs, the

PGOOD pulldown resistance is 95Ω, or 30Ω for an

overcurrent fault, or 60Ω for an overvoltage fault.

TABLE 1. PGOOD PULL-DOWN RESISTANCE

CONDITION PGOOD RESISTANCE

VCC Below POR Undefined

Soft Start or Undervoltage 95Ω

Overvoltage 60Ω

Overcurrent 30Ω

MOSFET Gate-Drive Outputs LG and UG

The ISL6269A has internal gate-drivers for the high-side and

low-side N-Channel MOSFETs. The LG gate-driver is

optimized for low duty-cycle applications where the low-side

MOSFET conduction losses are dominant, requiring a low

r

order to clamp the gate of the MOSFET below the V

turnoff. The current transient through the gate at turnoff can

be considerable because the switching charge of a low

r

protection prevents a gate-driver output from turning on until

the opposite gate-driver output has fallen below

approximately 1V. The dead-time shown in Figure 5. is

extended by the additional period that the falling gate voltage

stays above the 1V threshold. The high-side gate-driver

output voltage is measured across the UG and PHASE pins

while the low-side gate-driver output voltage is measured

across the LG and PGND pins. The power for the LG

gate-driver is sourced directly from the PVCC pin. The power

for the UG gate-driver is sourced from a “boot” capacitor

MOSFET. The LG pulldown resistance is small in

DS(ON)

MOSFET can be large. Adaptive shoot-through

DS(ON)

GS(th)

at

UG

LG

t

LGFUGR

50%

50%

FIGURE 5. LG AND UG DEAD-TIME

t

UGFLGR

Diode Emulation

The ISL6269A normally operates in continuous-conductionmode (CCM), minimizing conduction losses by forcing the

low-side MOSFET to operate as a synchronous rectifier. An

improvement in light-load efficiency is achieved by allowing

the converter to operate in diode-emulation-mode (DEM),

where the low-side MOSFET behaves as a smart-diode,

forcing the device to block negative inductor current flow.

The ISL6269A can be configured to operate in DEM by

setting the FCCM pin low. Setting the FCCM pin high will

disable DEM.

Positive-going inductor current flows from either the source

of the high-side MOSFET, or the drain of the low-side

MOSFET. Negative-going inductor current usually flows into

the drain of the low-side MOSFET. When the low-side

MOSFET conducts positive inductor current, the phase

voltage will be negative with respect to the GND and PGND

pins. Conversely, when the low-side MOSFET conducts

negative inductor current, the phase voltage will be positive

with respect to the GND and PGND pins. Negative inductor

current occurs when the output load current is less than ½

the inductor ripple current. Sinking negative inductor current

through the low-side MOSFET lowers efficiency through

unnecessary conduction losses. Efficiency can be further

improved with a reduction of unnecessary switching losses

by reducing the PWM frequency. It is characteristic of the R

architecture for the PWM frequency to decrease while in

diode emulation. The extent of the frequency reduction is

proportional to the reduction of load current. Upon entering

DEM, the PWM frequency makes an initial step-reduction

because of a 33% step-increase of the window voltage V

With FCCM pulled low, the converter will automatically enter

DEM after the PHASE pin has detected positive voltage,

W

3

.

8

FN9253.2

May 30, 2007

ISL6269A

while the LG gate-driver pin is high, for eight consecutive

PWM pulses. The converter will return to CCM on the

following cycle after the PHASE pin detects negative

voltage, indicating that the body diode of the low-side

MOSFET is conducting positive inductor current.

Overcurrent and Short-Circuit Protection

The overcurrent protection (OCP) and short circuit protection

(SCP) setpoint is programmed with resistor R

connected across the ISEN and PHASE pins. The PHASE

pin is connected to the drain terminal of the low-side

MOSFET.

The SCP setpoint is internally set to twice the OCP setpoint.

When an OCP or SCP fault is detected, the PGOOD pin will

pulldown to 30Ω

and latch off the converter. The fault will

remain latched until the EN pin has been pulled below the

falling EN threshold voltage V

below the falling POR threshold voltage

ENTHF

or if V

V

VCC_THF

The OCP circuit does not directly detect the DC load current

leaving the converter. The OCP circuit detects the peak of

positive-flowing output inductor current. The low-side

MOSFET drain current I

is assumed to be equal to the

D

positive output inductor current when the high-side MOSFET

is off. The inductor current develops a negative voltage

across the r

of the low-side MOSFET that is

DS(ON)

measured shortly after the LG gate-driver output goes high.

The ISEN pin sources the OCP sense current I

the OCP programming resistor R

forcing the ISEN pin to

SEN,

zero volts with respect to the GND pin. The negative voltage

across the PHASE and GND pins is nulled by the voltage

dropped across R

fault occurs if I

I

while attempting to null the negative voltage across the

OC

PHASE and GND pins. I

PWM pulses that occur within 20µs. If I

as I

SEN

rises above the OCP threshold current

SEN

conducts through it. An OCP

SEN

must exceed IOC on all the

SEN

SEN

on a PWM pulse before 20µs has elapsed, the timer will be

reset. An SCP fault will occur within 10µs when I

exceeds twice I

The relationship between ID and I

OC.

written as:

I

• I

SENRSEN

The value of R

⎛⎞

I

⎝⎠

R

----------------------------------------------------------------------------

=

SEN

FL

+

SEN

I

PP

-------- -

•=

DrDS ON()

is then written as:

• r

•

OC

SP

2

I

DS ON()

OC

that is

SEN

has decayed

VCC

.

through

SEN,

falls below IOC

SEN

SEN

(EQ. 3)

(EQ. 4)

is

Where:

-R

(Ω) is the resistor used to program the

SEN

overcurrent setpoint

is the current sense current that is sourced from

-I

SEN

the ISEN pin

-I

OC

is the I

threshold current sourced from the ISEN

SEN

pin that will activate the OCP circuit

is the maximum continuous DC load current

-I

FL

is the inductor peak-to-peak ripple current

-I

PP

-OC

is the desired overcurrent setpoint expressed as

SP

a multiplier relative to I

FL

Overvoltage Protection

When an OVP fault is detected, the PGOOD pin will pull

down to 60Ω

remain latched until V

POR threshold voltage

and latch-off the converter. The OVP fault will

has decayed below the falling

VCC

V

VCC_THF

.

The OVP fault detection circuit triggers after the voltage

across the FB and GND pins has increased above the rising

overvoltage threshold V

Although the converter has

OVR.

latched-off in response to an OVP fault, the LG gate-driver

output will retain the ability to toggle the low-side MOSFET

on and off, in response to the output voltage transversing the

V

OVR

and V

thresholds.

OVF

Undervoltage Protection

When a UVP fault is detected, the PGOOD pin will pull down

to 95Ω

and latch-off the converter. The fault will remain

latched until the EN pin has been pulled below the falling EN

threshold voltage V

falling POR threshold voltage

ENTHF

or if V

V

has decayed below the

VCC

VCC_THF.

The UVP fault

detection circuit triggers after the voltage across the FB and

GND pins has fallen below the undervoltage threshold V

UV

Over-Temperature

When the temperature of the ISL6269A increases above the

rising threshold temperature T

state that suspends the PWM , forcing the LG and UG

gate-driver outputs low. The status of the PGOOD pin does

not change nor does the converter latch-off. The PWM

remains suspended until the IC temperature falls below the

hysteresis temperature T

OTHYS

operation resumes. The OTP state can be reset if the EN pin

is pulled below the falling EN threshold voltage V

V

decays below the falling POR threshold voltage

VCC

V

VCC_THF

. All other protection circuits function normally

during OTP. It is likely that the IC will detect an UVP fault

because in the absence of PWM, the output voltage

immediately decays below the undervoltage threshold V

the PGOOD pin will pulldown to 95Ω and latch-off the

converter. The UVP fault will remain latched until the EN pin

has been pulled below the falling EN threshold voltage

V

threshold voltage

ENTHF

or if V

has decayed below the falling POR

VCC

V

VCC_THF

, the IC will enter an OTP

OTR

at which time normal PWM

ENTHF

.

or if

UV

.

;

9

FN9253.2

May 30, 2007

ISL6269A

Programming the Output Voltage

When the converter is in regulation there will be 600mV from

the FB pin to the GND pin. Connect a two-resistor voltage

divider across the VO pin and the GND pin with the output

node connected to the FB pin. Scale the voltage-divider

network such that the FB pin is 600mV with respect to the

GND pin when the converter is regul a ti ng at the desired

output voltage. The output voltage can be programmed from

600mV to 3.3V.

Programming the output voltage is written as:

R

V

REFVOUT

BOTTOM

•=

---------------------------------------------------

R

+

TOPRBOTTOM

Where:

-V

-V

is the desired output voltage of the converter

OUT

is the voltage that the converter regulates to

REF

between the FB pin and the GND pin

-R

is the voltage-programming resistor that connects

TOP

from the FB pin to the VO pin. In addition to setting the

output voltage, this resistor is part of the loop

compensation network

-R

BOTTOM

is the voltage-programming resistor that

connects from the FB pin to the GND pin

Beginning with R

R

BOTTOM

R

BOTTOM

is written as:

V

-------------------------------------

=

V

between 1kΩ to 5kΩ, calculating

TOP

R•

REF

TOP

–

OUTVREF

Programming the PWM Switching Frequency

The ISL6269A does not use a clock signal to produce PWM.

The PWM switching frequency f

resistor R

that is connected from the FSET pin to the

FSET

is programmed by the

SW

GND pin. The approximate PWM switching frequency is

written as:

SW

Estimating the value of R

R

FSET

⋅

KR

------------------

=

Kf

FSET

1

•

SW

is written as:

FSET

1

---------------------------

f

=

Where:

is the PWM switching frequency

-f

SW

-R

- K = 75 x 10

is the fSW programming resistor

FSET

-12

It is recommended that whenever the control loop

compensation network is modified, f

should be checked

SW

for the correct frequency and if necessary, adjust R

Compensation Design

The LC output filter has a double pole at its resonant frequency

that causes the phase to abruptly roll downward. The R

modulator used in the ISL6269A makes the LC output filter

resemble a first order system in which the closed loop stability

can be achieved with a Type II compensation network.

(EQ. 5)

(EQ. 6)

(EQ. 7)

(EQ. 8)

FSET

3

.

R2

COMP

-

EA

C2

C1

R1

FB

+

REF

FSET

R

FSET

R3 MODULATOR

VO

VOUT

VIN

Q

UG

PHASE

GATE DRIVERS

Q

LG

GND

ISL6269A

FIGURE 6. COMPENSATION REFERENCE CIRCUIT

VIN

HIGH_SIDE

L

OUT

LOW_SIDE

DCR

C

OUT

C

ESR

C

FSET

Your local Intersil representative ca n pro v i d e a PC -b ase d

tool that can be used to calculate compensation network

component values and help simulate the loop frequency

response. The compensation network consists of the internal

error amplifier of the ISL6269A and the external components

R1, R2, C1, and C2 as well as the frequency setting

components R

FSET

, and C

are identified in the

FSET,

schematic Figure 6.

General Application Design Guide

This design guide is intended to provide a high-level

explanation of the steps necessary to create a single-phase

power converter. It is assumed that the reader is famil iar with

many of the basic skills and techniques referenced below. In

10

FN9253.2

May 30, 2007

Δ

ISL6269A

addition to this guide, Intersil provides complete reference

designs that include schematics, bills of materials, and

example board layouts.

Selecting the LC Output Filter

The duty cycle of an ideal buck converter is a function of the

input and the output voltage. This relationship is written as:

V

OUT

--------------- -

D

=

V

IN

The output inductor peak-to-peak ripple current is written as:

V

1D–()•

OUT

--------------------------------------

=

I

PP

fSWL

•

OUT

A typical step-down DC/DC converter will have an I

20% to 40% of the maximum DC output load current. The

value of I

is selected based upon several criteria such as

PP

MOSFET switching loss, inductor core loss, and the resistive

loss of the inductor winding. The DC copper loss of the

inductor can be estimated by:

P

COPPERILOAD

Where I

LOAD

2

DCR•=

is the converter output DC current.

The copper loss can be significant so attention has to be

given to the DCR selection. Another factor to consider when

choosing the inductor is its saturation characteristics at

elevated temperature. A saturated inductor could cause

destruction of circuit components, as well as nuisance OCP

faults.

A DC/DC buck regulator must have output capacitance

C

into which ripple current IPP can flow. Current IPP

OUT

develops a corresponding ripple voltage V

across C

PP

which is the sum of the voltage drop across the capacitor

ESR and of the voltage change stemming from charge

moved in and out of the capacitor. These two voltages are

written as:

ΔV

ESRIPP

E• SR=

and

I

PP

-------------------------------------

V

=

C

8C

f•

•

OUT

SW

If the output of the converter has to support a load with high

pulsating current, several capacitors will need to be parallel ed

to reduce the total ESR until the required V

is achieved.

PP

The inductance of the capacitor can cause a brief voltage dip

if the load transient has an extremely high slew rate. Low

inductance capacitors constructed with reverse package

geometry are available. A capacitor dissipates heat as a

function of RMS current and frequency . Be sure tha t I

shared by a sufficient quantity of paralleled capacitors so that

they operate below the maximum rated RMS current at f

Take into account that the rated value of a capacitor can fade

as much as 50% as the DC voltage across it increases.

(EQ. 9)

(EQ. 10)

of

PP

(EQ. 11)

OUT,

(EQ. 12)

(EQ. 13)

is

PP

SW

.

Selection of the Input Capacitor

The important parameters for the bulk input capacitance are

the voltage rating and the RMS current rating. For reliable

operation, select bulk capacitors with voltage and current

ratings above the maximum input voltage and capable of

supplying the RMS current required by the switching circuit.

Their voltage rating should be at least 1.25 times greater

than the maximum input voltage, while a voltage rating of 1.5

times is a preferred rating. Figure 7 is a graph of the input

RMS ripple current, normalized relative to output load current,

as a function of duty cycle that is adjusted for converter

efficiency. The ripple current calculation is written as:

I

IN_RMS

2

I

-----------------------------------------------------------------------------------------------------

=

MAX

DD2–()⋅()xI

⎛⎞

+

⎝⎠

I

MAX

2

D

MAX

------

12

⋅⋅

(EQ. 14)

Where:

-I

is the maximum continuous I

MAX

of the converter

LOAD

- x is a multiplier (0 to 1) corresponding to the inductor

peak-to-peak ripple amplitude expressed as a

percentage of I

(0% to 100%)

MAX

- D is the duty cycle that is adjusted to take into account

the efficiency of the converter which is written as:

V

OUT

--------------------------

D

=

VINEFF⋅

(EQ. 15)

In addition to the bulk capacitance, some low ESL ceramic

capacitance is recommended to decouple between the drain

of the high-side MOSFET and the source of the low-side

MOSFET.

0.60

0.55

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

NORMALIZED INPUT RMS RIPPLE CURRENT

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

FIGURE 7. NORMALIZED RMS INPUT CURRENT FOR x = 0.8

x = 1

x = 0.75

x = 0.50

x = 0.25

x = 0

DUTY CYCLE

MOSFET Selection and Considerations

Typically, a MOSFET cannot tolerate even brief excursions

beyond their maximum drain to source voltage rating. The

MOSFETs used in the power stage of the converter should

have a maximum V

upper voltage tolerance of the input power source and the

voltage spike that occurs when the MOSFET switches off.

rating that exceeds the sum of the

DS

There are several power MOSFET s readily available that are

optimized for DC/DC converter applications. The preferred

11

FN9253.2

May 30, 2007

ISL6269A

high-side MOSFET emphasizes low switch charge so that

the device spends the least amount of time dissipating

power in the linear region. Unlike the low-side MOSFET

which has the drain-source voltage clamped by its body

diode during turn off, the high-side MOSFET turns off with

V

IN-VOUT-VL

emphasizes low r

across it. The preferred low-side MOSFET

when fully saturated to minimize

DS(ON)

conduction loss.

For the low-side MOSFET, (LS), the power loss can be

assumed to be conductive only and is written as:

P

CON_LSILOAD

r⋅

DS ON()_LS

1D–()•≈

(EQ. 16)

2

For the high-side MOSFET, (HS), its conduction loss is

written as:

P

CON_HSILOAD

2

r•

DS ON()_HS

D•=

(EQ. 17)

For the high-side MOSFET, its switching loss is written as:

P

SW_HS

VINI

VALLEYtON

---------------------------------------------------------------- -

2

f•

••

V

INIPEAKtOFF

SW

-------------------------------------------------------------

+=

f•

••

2

SW

(EQ. 18)

Where:

-I

is the difference of the DC component of the

VALLEY

inductor current minus 1/2 of the inductor ripple current

-I

is the sum of the DC component of the inductor

PEAK

current plus 1/2 of the inductor ripple current

is the time required to drive the device into

-t

ON

saturation

is the time required to drive the device into cut-off

-t

OFF

Selecting The Bootstrap Capacitor

The selection of the bootstrap capacitor is written as:

C

BOOT

------------------------

=

ΔV

g

BOOT

(EQ. 19)

Q

Where:

is the total gate charge required to turn on the

-Q

g

high-side MOSFET

- ΔV

, is the maximum allowed voltage decay across

BOOT

the boot capacitor each time the high-side MOSFET is

switched on

As an example, suppose the high-side MOSFET has a total

gate charge Q

, of 25nC at VGS= 5V, and a ΔV

g

BOOT

of

200mV . The calculated bootstrap capacitance is 0.125µF; for

a comfortable margin select a capacitor that is double the

calculated capacitance, in this example 0.22µF will suffice.

Use an X7R or X5R ceramic capacitor.

Layout Considerations

As a general rule, power should be on the bottom layer of

the PCB and weak analog or logic signals are on the top

layer of the PCB. The ground-plane layer should be adjacent

to the top layer to provide shielding. The ground plane layer

should have an island located under the IC, the compensation

components, and the FSET components. The island should be

connected to the rest of the ground plane layer at one point.

VIAS TO

GROUND

PLANE

INDUCTOR

HIGH-SIDE

MOSFETS

FIGURE 8. TYPICAL POWER COMPONENT PLACEMENT

GND

VOUT

PHASE

NODE

VIN

OUTPUT

CAPACITORS

SCHOTTKY

DIODE

LOW-SIDE

MOSFETS

INPUT

CAPACITORS

Signal Ground and Power Ground

The bottom of the ISL6269A QFN package is the signal

ground (GND) terminal for analog and logic signals of the IC.

Connect the GND pad of the ISL6269A to the island of

ground plane under the top layer using several vias, for a

robust thermal and electrical conduction path. Connect the

input capacitors, the output capacitors, and the source of the

lower MOSFETs to the power ground plane.

PGND (Pin 10)

This is the return path for the pull-down of the LG low-side

MOSFET gate driver. Ideally, PGND should be connected to

the source of the low-side MOSFET with a low-resistance,

low-inductance path .

VIN (Pin 1)

The VIN pin should be connected close to the drain of the

high-side MOSFET, using a low resistance and low

inductance path.

VCC (Pin 2)

For best performance, place the decoupling capacitor very

close to the VCC and GND pins.

PVCC (Pin 12)

For best performance, place the decoupling capacitor very

close to the PVCC and PGND pins, preferably on the same

side of the PCB as the ISL6269A IC.

FCCM (Pin 3), EN (Pin 4), and PGOOD (Pin 16)

These are logic inputs that are referenced to the GND pin.

Treat as a typical logic signal.

COMP (Pin 5), FB (Pin 6), and VO (Pin 8)

For best results, use an isolated sense line from the output

load to the VO pin. The input impedance of the FB pin is

high, so place the voltage programming and loop

compensation components close to the VO, FB, and GND

pins keeping the high impedance trace short.

FSET (Pin 7)

This pin requires a quiet environment. The resistor R

and capacitor C

should be placed directly adjacent to

FSET

FSET

this pin. Keep fast moving nodes away from this pin.

12

FN9253.2

May 30, 2007

ISL6269A

ISEN (Pin 9)

Route the connection to the ISEN pin away from the traces

and components connected to the FB pin, COMP pin, and

FSET pin.

LG (Pin 11)

The signal going through this trace is both high dv/dt and

high di/dt, with high peak charging and discharging current.

Route this trace in parallel with the trace from the PGND pin.

These two traces should be short, wide, and away from

other traces. There should be no other weak signal traces in

proximity with these traces on any layer.

BOOT (Pin 13), UG (Pin 14), and PHASE (Pin 15)

The signals going through these traces are both high dv/dt

and high di/dt, with high peak charging and discharging

current. Route the UG and PHASE pins in parallel with short

and wide traces. There should be no other weak signal

traces in proximity with these traces on any layer.

Copper Size for the Phase Node

The parasitic capacitance and parasitic inductance of the

phase node should be kept very low to minimize ringing. It is

best to limit the size of the PHASE node copper in strict

accordance with the current and thermal management of the

application. An MLCC should be connected directly across

the drain of the upper MOSFET and the source of the lower

MOSFET to suppress the turn-off voltage spike.

13

FN9253.2

May 30, 2007

ISL6269A

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

L16.4x4

16 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

(COMPLIANT TO JEDEC MO-220-VGGC ISSUE C)

MILLIMETERS

SYMBOL

A 0.80 0.90 1.00 -

A1 - - 0.05 -

A2 - - 1.00 9

A3 0.20 REF 9

b 0.23 0.28 0.35 5, 8

D 4.00 BSC -

D1 3.75 BSC 9

D2 1.95 2.10 2.25 7, 8

E 4.00 BSC -

E1 3.75 BSC 9

E2 1.95 2.10 2.25 7, 8

e 0.65 BSC -

k0.25 - - -

L 0.50 0.60 0.75 8

L1 - - 0.15 10

N162

Nd 4 3

Ne 4 3

P- -0.609

θ --129

NOTES:

1. Dimensioning and tolerances conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

8. Nominal dimensions are provided to assist w ith PCB Land Pattern

Design efforts, see Intersil Technical Brief TB389.

9. Features and dimensions A2, A3, D1, E1, P & θ are present when

Anvil singulation method is used and not present for saw

singulation.

10. Depending on the method of lead termination at the edge of the

package, a maximum 0.15mm pull back (L1) maybe present. L

minus L1 to be equal to or greater than 0.3mm.

NOTESMIN NOMINAL MAX

Rev. 5 5/04

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

14

FN9253.2

May 30, 2007

Loading...

Loading...