Low Cost Multi-Chemistry Battery Charger Controller

ISL6251, ISL6251A

The ISL6251, ISL6251A is a highly integrated battery charger

controller for Li-Ion/Li-Ion polymer batteries and NiMH

batteries. High efficiency is achieved by a synchronous buck

topology and the use of a MOSFET, instead of a diode, for

selecting power from the adapter or battery. The low side

MOSFET emulates a diode at light loads to improve the light

load efficiency and prevent system bus boosting.

The constant output voltage can be selected for 2, 3 and 4

series Li-Ion cells with 0.5% accuracy over-temperature. It can

be also programmed between 4.2V+5%/cell and 4.2V-5%/cell

to optimize battery capacity. When supplying the load and

battery charger simultaneously, the input current limit for the

AC adapter is programmable to within 3% accuracy to avoid

overloading the AC adapter, and to allow the system to make

efficient use of available adapter power for charging. It also

has a wide range of programmable charging current. The

ISL6251, ISL6251A provides outputs that are used to monitor

the current drawn from the AC adapter, and monitor for the

presence of an AC adapter. The ISL6251, ISL6251A

automatically transitions from regulating current mode to

regulating voltage mode.

Ordering Information

TEMP

PART NUMBER

(Notes 1, 2, 3)

ISL6251HRZ ISL 6251HRZ -10 to +100 28 Ld 5x5 QFN L28.5×5

ISL6251HAZ ISL 6251HAZ -10 to +100 24 Ld QSOP M24.15

ISL6251AHRZ ISL6251 AHRZ -10 to +100 28 Ld 5x5 QFN L28.5×5

ISL6251AHAZ ISL6251 AHAZ -10 to +100 24 Ld QSOP M24.15

NOTES:

1. Add “-T*” suffix for tape and reel. Please refer to TB347

reel specifications.

2. These Intersil Pb-free plastic packaged products employ special Pbfree material sets, molding compounds/die attach materials, and

100% matte tin plate plus anneal (e3 termination finish, which is

RoHS compliant and compatible with both SnPb and Pb-free

soldering operations). Intersil Pb-free products are MSL classified at

Pb-free peak reflow temperatures that meet or exceed the Pb-free

requirements of IPC/JEDEC J STD-020.

3. For Moisture Sensitivity Level (MSL), please see device information

page for ISL6251

see techbrief TB363

PART

MARKING

, ISL6251A. For more information on MSL please

.

RANGE

(°C)

PACKAGE

(Pb-Free)

PKG.

DWG. #

for details on

Features

• ±0.5% Charge Voltage Accuracy (-10°C to +100°C)

• ±3% Accurate Input Current Limit

• ±3% Accurate Battery Charge Current Limit

• ±25% Accurate Battery Trickle Charge Current Limit

(ISL6251A)

• Programmable Charge Current Limit, Adapter Current Limit

and Charge Voltage

• Fixed 300kHz PWM Synchronous Buck Controller with Diode

Emulation at Light Load

• Output for Current Drawn from AC Adapter

• AC Adapter Present Indicator

• Fast Input Current Limit Response

• Input Voltage Range 7V to 25V

• Supports 2, 3 and 4 Cells Battery Pack

• Up to 17.64V Battery-Voltage Set Point

•Thermal Shutdown

• Support Pulse Charging

• Less than 10µA Battery Leakage Current

• Charge Any Battery Chemistry: Li-Ion, NiCd, NiMH, etc.

• Pb-Free (RoHS Compliant)

Applications

• Notebook, Desknote and Sub-notebook Computers

• Personal Digital Assistant

March 13, 2014

FN9202.3

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

Intersil (and design) is a trademark owned by Intersil Corporation or one of its subsidiaries.

|Copyright Intersil Americas LLC 2005-2006, 2014. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

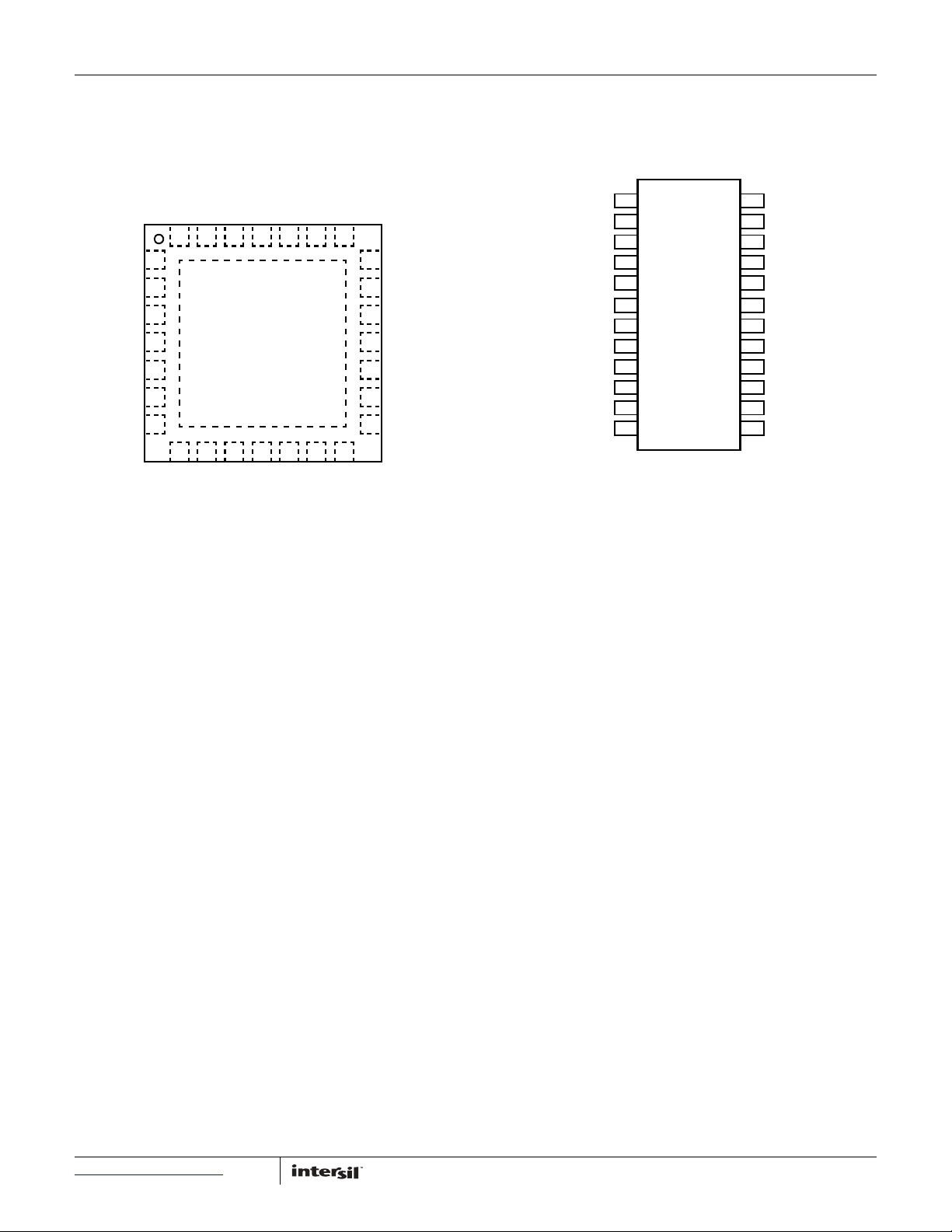

Pin Configurations

1

2

3

4

5

6

7

21

20

19

18

17

16

15

28 27 26 25 24 23 22

8 9 10 11 12 13 14

EN

CELLS

ICOMP

VCOMP

ICM

VREF

CHLIM

ACLIM

PGND

LGATE

VDDP

BOOT

CSOP

PHASE

UGATE

ACSET

DCIN

ACPRN

CSON

VADJ

GND

CSIN

CSIP

NA

NA

NA

VDD

NA

DCIN

124

VDD

223

ACPRN ACSET

322

CSON

421

CSOP

EN

520

CSIN

CELLS

619

CSIP

ICOMP

718

VCOMP

817

ICM

916

PHASE

VREF

10 15

UGATE

CHLIM

11 14

BOOT

ACLIM

12 13

VDDP

VADJ LGATE

GND PGND

ISL6251, ISL6251A

(28 LD QFN)

TOP VIEW

ISL6251, ISL6251A

ISL6251, ISL6251A

(24 LD QSOP)

TOP VIEW

Submit Document Feedback

2

FN9202.3

March 13, 2014

ISL6251, ISL6251A

Absolute Maximum Ratings Thermal Information

DCIN, CSIP, CSON to PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +28V

CSIP-CSIN, CSOP-CSON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +0.3V

PHASE to PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -7V to 30V

BOOT to PGND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +35V

ACLIM, ACPRN, CHLIM, VDD to GND . . . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

BOOT-PHASE, VDDP-PGND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 7V

ICM, ICOMP, VCOMP to GND . . . . . . . . . . . . . . . . . . . . . . .-0.3V to VDD+0.3V

VREF, CELLS to GND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to VDD+0.3V

EN, VADJ, PGND to GND . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to VDD+0.3V

UGATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PHASE-0.3V to BOOT+0.3V

LGATE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PGND-0.3V to VDDP+0.3V

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product

reliability and result in failures not covered by warranty.

NOTES:

4. When the voltage across ACSET is below 0V, the current through ACSET should be limited to less than 1mA.

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See Tech

5. θ

JA

Brief TB379

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

6. θ

JA

7. Fo r θ

8. BOOT-PHASE voltage is -0.3V to -0.7V during start-up. This is due to a small current (<1mA) that flows from the battery to the PHASE pin and to an

internal current sink on the BOOT pin through an internal diode. This does not harm the part.

.

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

Thermal Resistance θ

QFN Package (Notes 5, 7) . . . . . . . . . . . . . . 39 9.5

QSOP Package (Note 6). . . . . . . . . . . . . . . . 88 N/A

Junction Temperature Range . . . . . . . . . . . . . . . . . . . . . . .-10°C to +150°C

Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . .-10°C to +100°C

Storage Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-Free Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see link below

http://www.intersil.com/pbfree/Pb-FreeReflow.asp

(°C/W) θJC (°C/W)

JA

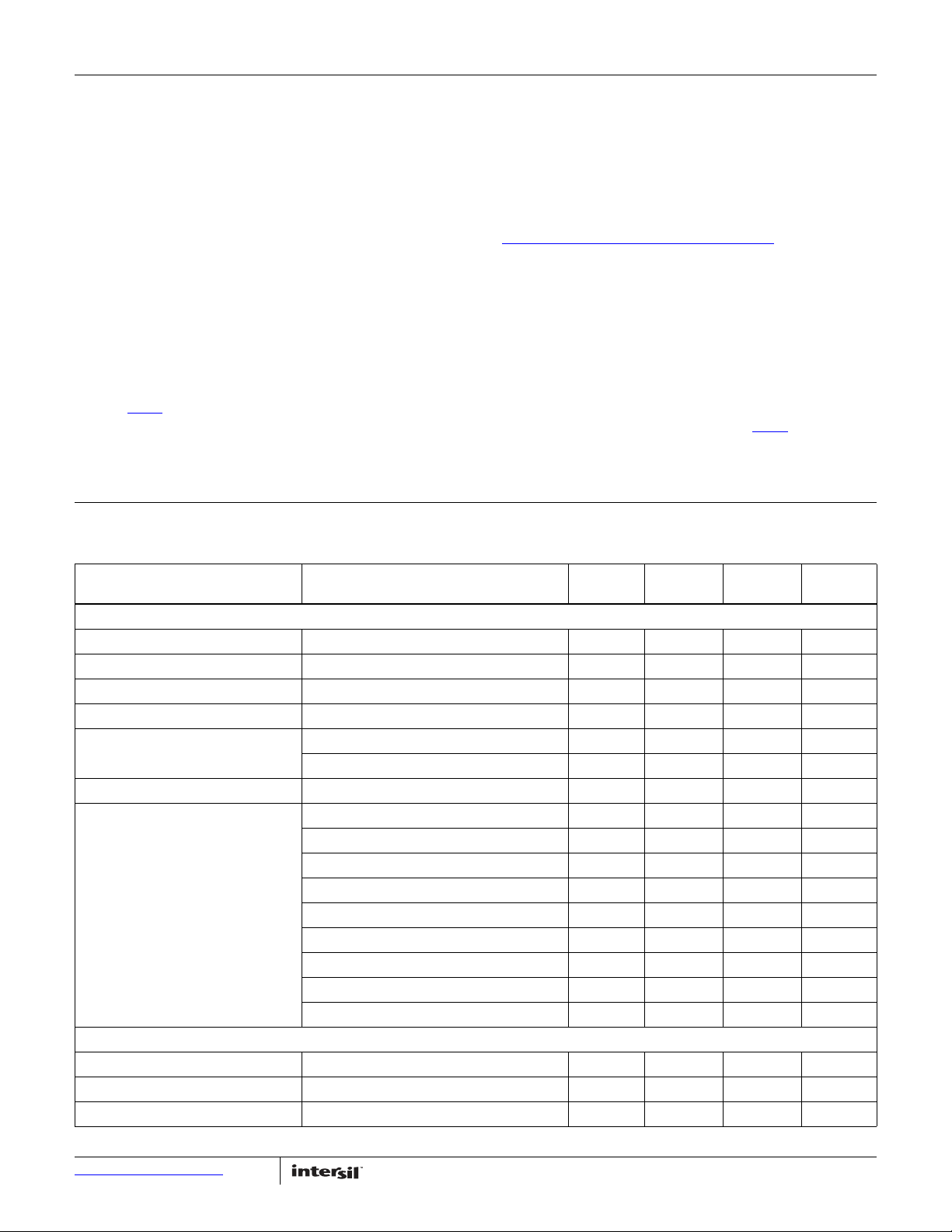

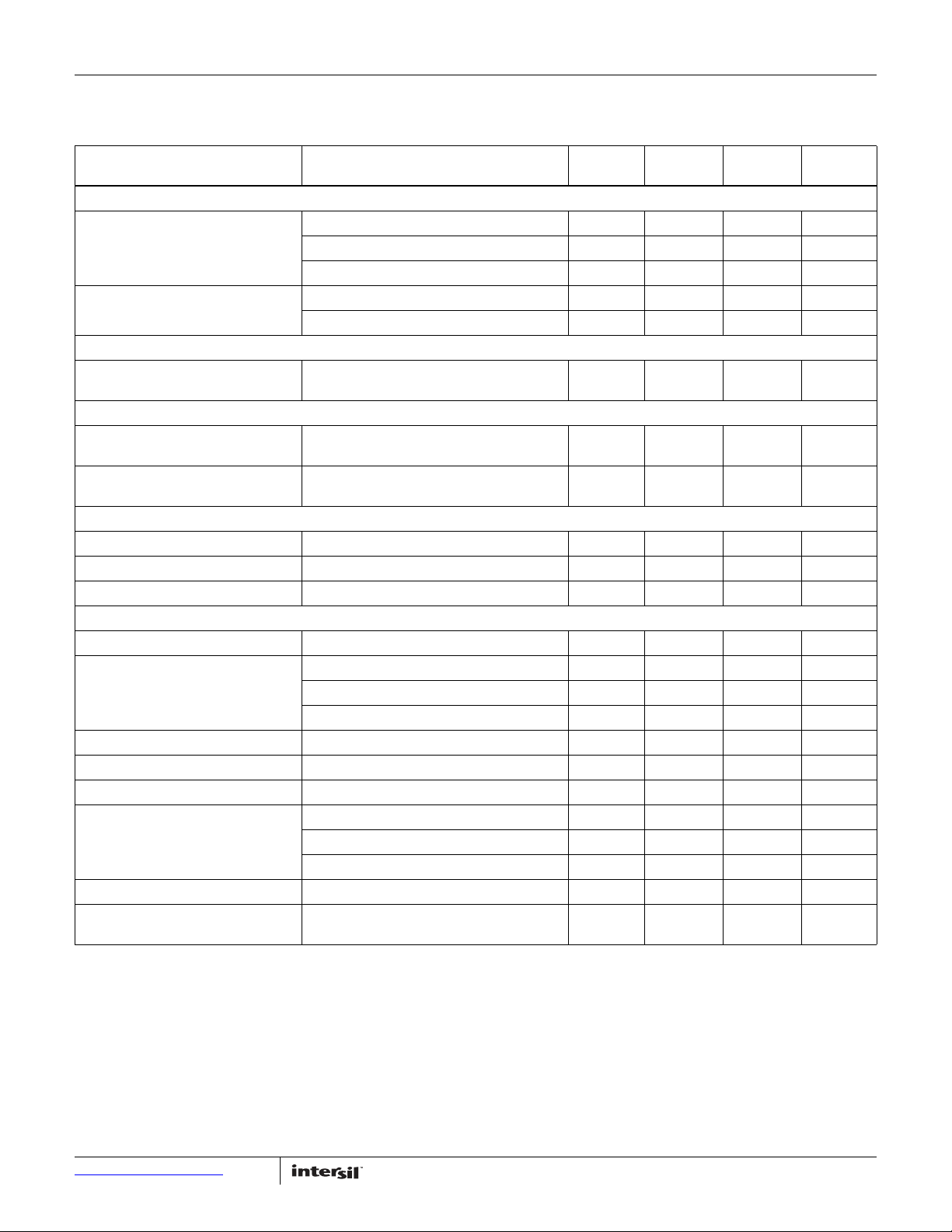

Electrical Specifications DCIN = CSIP = CSIN = 18V, CSOP = CSON = 12V, ACSET = 1.5V, ACLIM = VREF, VADJ = Floating, EN = VDD = 5V,

BOOT-PHASE = 5.0V, GND = PGND = 0V, C

the operating temperature range, -10°C to +100°C.

PARAMETER TEST CONDITIONS

SUPPLY AND BIAS REGULATOR

DCIN Input Voltage Range 725V

DCIN Quiescent Current EN = VDD or GND, 7V ≤ DCIN ≤ 25V 1.4 3 mA

Battery Leakage Current (Note 9) DCIN = 0, no load 3 10 µA

VDD Output Voltage/Regulation 7V ≤ DCIN ≤ 25V, 0 ≤ I

VDD Undervoltage Lockout Trip Point VDD Rising 4.0 4.4 4.6 V

Reference Output Voltage VREF 0 ≤ I

Battery Charge Voltage Accuracy CSON = 16.8V, CELLS = VDD, VADJ = Float -0.5 0.5 %

TRIP POINTS

ACSET Threshold 1.24 1.26 1.28 V

ACSET Input Bias Current Hysteresis 2.2 3.4 4.4 µA

ACSET Input Bias Current ACSET ≥ 1.26V 2.2 3.4 4.4 µA

= 1µF, I

VDD

Hysteresis 200 250 400 mV

VREF

CSON = 12.6V, CELLS = GND, VADJ = Float -0.5 0.5 %

CSON = 8.4V, CELLS = Float, VADJ = Float -0.5 0.5 %

CSON = 17.64V, CELLS = VDD, VADJ = VREF -0.5 0.5 %

CSON = 13.23V, CELLS = GND, VADJ = VREF -0.5 0.5 %

CSON = 8.82V, CELLS = Float, VADJ = VREF -0.5 0.5 %

CSON = 15.96V, CELLS = VDD, VADJ = GND -0.5 0.5 %

CSON = 11.97V, CELLS = GND, VADJ = GND -0.5 0.5 %

CSON = 7.98V, CELLS = Float, VADJ = GND -0.5 0.5 %

= 0mA, TA = -10°C to +100°C, TJ≤ 125°C, unless otherwise noted. Boldface limits apply over

VDD

MIN

(Note 10) TYP

≤ 30mA 4.925 5.075 5.225 V

VDD

≤ 300µA 2.365 2.39 2.415 V

MAX

(Note 10) UNITS

Submit Document Feedback

3

FN9202.3

March 13, 2014

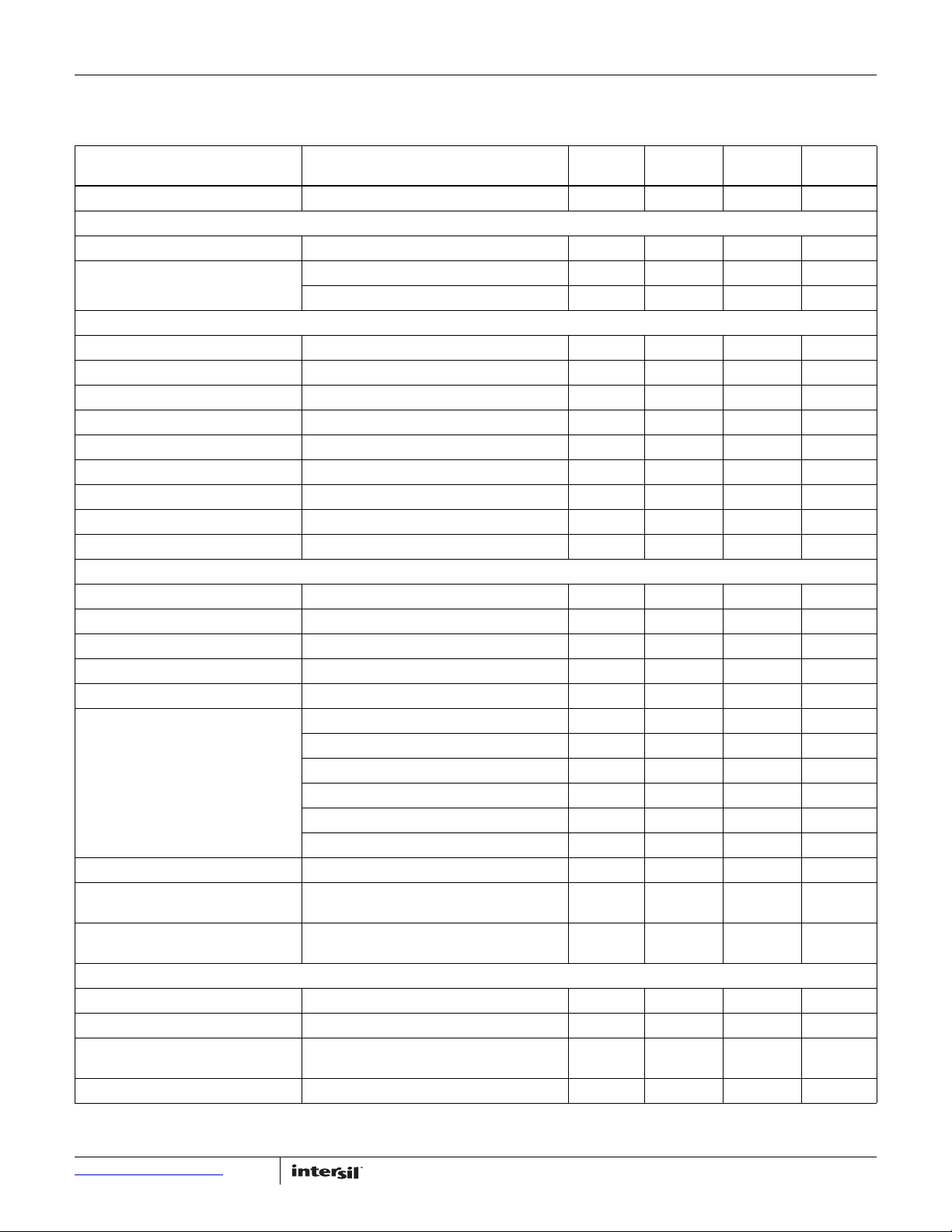

ISL6251, ISL6251A

Electrical Specifications DCIN = CSIP = CSIN = 18V, CSOP = CSON = 12V, ACSET = 1.5V, ACLIM = VREF, VADJ = Floating, EN = VDD = 5V,

BOOT-PHASE = 5.0V, GND = PGND = 0V, C

the operating temperature range, -10°C to +100°C.

PARAMETER TEST CONDITIONS

ACSET Input Bias Current ACSET < 1.26V -1 0 1 µA

OSCILLATOR

Frequency 245 300 355 kHz

PWM Ramp Voltage (Peak-Peak) CSIP = 18V 1.6 V

SYNCHRONOUS BUCK REGULATOR

Maximum Duty Cycle 97 99 99.6 %

UGATE Pull-Up Resistance BOOT-PHASE = 5V, 500mA source current 1.8 3.0 Ω

UGATE Source Current BOOT-PHASE = 5V, BOOT-UGATE = 2.5V 1.0 A

UGATE Pull-Down Resistance BOOT-PHASE = 5V, 500mA sink current 1.0 1.8 Ω

UGATE Sink Current BOOT-PHASE = 5V, UGATE-PHASE = 2.5V 1.8 A

LGATE Pull-Up Resistance VDDP-PGND = 5V, 500mA source current 1.8 3.0 Ω

LGATE Source Current VDDP-PGND = 5V, VDDP-LGATE = 2.5V 1.0 A

LGATE Pull-DOWN Resistance VDDP-PGND = 5V, 500mA sink current 1.0 1.8 Ω

LGATE Sink Current VDDP-PGND = 5V, LGATE = 2.5V 1.8 A

CHARGING CURRENT SENSING AMPLIFIER

Input Common-Mode Range 018V

Input Offset Voltage Note 11 -2.5 0 2.5 mV

Input Bias Current at CSOP 0 < CSOP < 18V 0.25 2 µA

Input Bias Current at CSON 0 < CSON < 18V 75 100 µA

CHLIM Input Voltage Range 03.6V

CSOP to CSON Full-Scale Current Sense

Voltage

CHLIM Input Bias Current CHLIM = GND or 3.3V, DCIN = 0V -1 1 µA

CHLIM Power-Down Mode Threshold

Voltage

CHLIM Power-Down Mode Hysteresis

Voltage

ADAPTER CURRENT SENSING AMPLIFIER

Input Common-Mode Range

Input Offset Voltage Note 11 -2 2 mV

Input Bias Current at CSIP and CSIN

Combined

Input Bias Current at CSIN 0 < CSIN < DCIN (Note 11) 0.10 1 µA

= 1µF, I

VDD

CSIP = 11V 1 V

ISL6251: CHLIM = 3.3V 157 165 173 mV

ISL6251A, CHLIM = 3.3V 160 165 170 mV

ISL6251: CHLIM = 2.0V 95 100 105 mV

ISL6251A: CHLIM = 2.0V 97 100 103 mV

ISL6251: CHLIM = 0.2V 5.0 10 15.0 mV

ISL6251A: CHLIM = 0.2V 7. 5 10 12.5 mV

CHLIM rising 80 88 95 mV

CSIP = CSIN = 25V 100 130 µA

= 0mA, TA = -10°C to +100°C, TJ≤ 125°C, unless otherwise noted. Boldface limits apply over

VDD

(Continued)

MIN

(Note 10) TYP

15 25 40 mV

7 25 V

MAX

(Note 10) UNITS

Submit Document Feedback

4

FN9202.3

March 13, 2014

ISL6251, ISL6251A

Electrical Specifications DCIN = CSIP = CSIN = 18V, CSOP = CSON = 12V, ACSET = 1.5V, ACLIM = VREF, VADJ = Floating, EN = VDD = 5V,

BOOT-PHASE = 5.0V, GND = PGND = 0V, C

the operating temperature range, -10°C to +100°C.

PARAMETER TEST CONDITIONS

ADAPTER CURRENT LIMIT THRESHOLD

CSIP to CSIN Full-Scale Current Sense

Voltage

ACLIM Input Bias Current ACLIM = VREF 10 16 20 µA

VOLTAGE REGULATION ERROR AMPLIFIER

Error Amplifier Transconductance from

CSON to VCOMP

CURRENT REGULATION ERROR AMPLIFIER

Charging Current Error Amplifier

Transconductance

Adapter Current Error Amplifier

Transconductance

BATTERY CELL SELECTOR

CELLS Input Voltage for 4 Cell Select 4.3 V

CELLS Input Voltage for 3 Cell Select 2 V

CELLS Input Voltage for 2 Cell Select 2.1 4.2 V

LOGIC INTERFACE

EN Input Voltage Range 0VDDV

EN Threshold Voltage Rising 1.030 1.06 1.100 V

EN Input Bias Current EN = 2.5V 1.8 2.0 2.2 µA

ACPRN Sink Current ACPRN = 0.4V 3 8 11 mA

ACPRN Leakage Current ACPRN = 5V -0.5 0.5 µA

ICM Output Accuracy

(Vicm = 19.9 x (Vcsip-Vcsin))

Thermal Shutdown Temperature 150 °C

Thermal Shutdown Temperature

Hysteresis

NOTES:

9. This is the sum of currents in these pins (CSIP, CSIN, BOOT, UGATE, PHASE, CSOP, CSON) all tied to 16.8V. No current in pins EN, ACSET, VADJ, CELLS,

ACLIM, CHLIM.

10. Parameters with MIN and/or MAX limits are 100% tested at +25°C, unless otherwise specified. Temperature limits established by characterization

and are not production tested.

11. Limits established by characterization and are not production tested.

= 1µF, I

VDD

ACLIM = VREF 97 100 103 mV

ACLIM = Float 72 75 78 mV

ACLIM = GND 47 50 53 mV

ACLIM = GND -20 -16 -10 µA

CELLS = VDD 30 µA/V

Falling 0.985 1.000 1.025 V

Hysteresis 30 60 90 mV

CSIP - CSIN = 100mV -3 0 +3 %

CSIP - CSIN = 75mV -4 0 +4 %

CSIP - CSIN = 50mV -5 0 +5 %

= 0mA, TA = -10°C to +100°C, TJ≤ 125°C, unless otherwise noted. Boldface limits apply over

VDD

(Continued)

MIN

(Note 10) TYP

50 µA/V

50 µA/V

25 °C

MAX

(Note 10) UNITS

Submit Document Feedback

5

FN9202.3

March 13, 2014

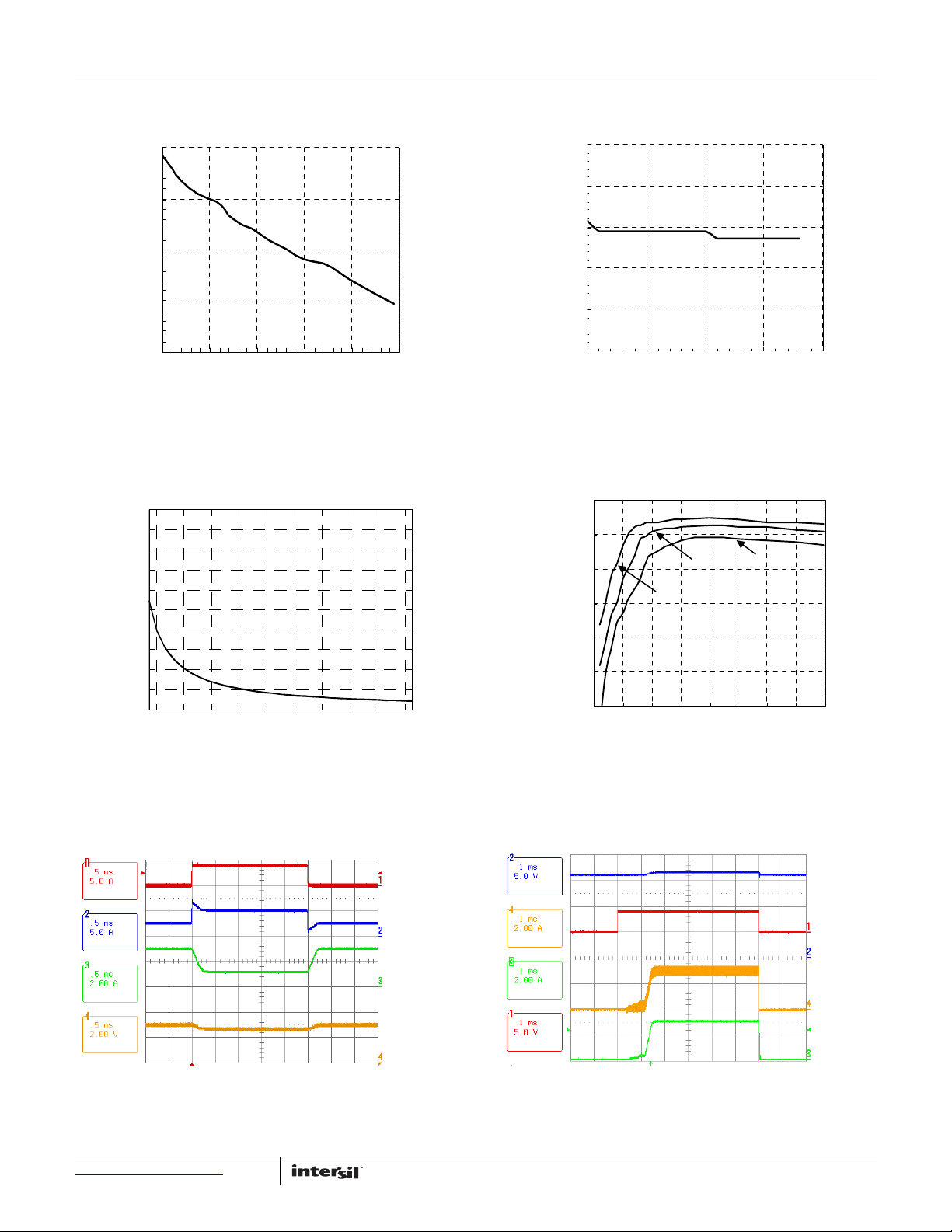

ISL6251, ISL6251A

-0.6

-0.3

0

0.3

0.6

0 8 16 24 32 40

VDD LOAD REGULATION A CCURACY (% )

VDD=5.075V

EN=0

LOAD CURRENT (mA)

-0.6

-0.3

0

0.3

0.6

0 8 16 24 32 40

VDD LOAD REGULATION A CCURACY (% )

VDD=5.075V

EN=0

LOAD CURRENT (mA)

0

0.02

0.04

0.06

0.08

0.1

0 100 200 300 400

VREF LOAD REGULATION A CCURACY (%)

VREF=2.390V

LOAD CURRENT (µA)

0

0.02

0.04

0.06

0.08

0.1

0 100 200 300 400

VREF LOAD REGULATION A CCURACY (%)

VREF=2.390V

LOAD CURRENT (µA)

CSIP-CSIN (mV)

0

1

2

3

4

5

6

7

8

9

10

10 20 30 40 50 60 70 80 90

100

|

ICM ACCURACY

|

(%)

0.76

0.8

0.84

0.88

0.92

0.96

1

00.511.522.533.54

EFFICIENCY (% )

CHARGE CURRENT (A)

VCSON=16.8V

4 CELLS

VCSON=12.6V

(3 CELLS)

VCSON=8.4V

2 CELLS

0.76

0.8

0.84

0.88

0.92

0.96

1

00.511.522.533.54

EFFICIENCY (% )

CHARGE CURRENT (A)

VCSON=16.8V

4 CELLS

VCSON=12.6V

(3 CELLS)

VCSON=8.4V

2 CELLS

LOAD

CURRENT

5A/div

A

CURRENT

5A/div

CHARGE

CURRENT

2A/div

BATTERY

VOLTAGE

2V/div

LOAD STEP: 0-4A

CHARGE CURRENT: 3A

A

A

CSON

5V/div

EN

5V/div

INDUCTOR

CURRENT

2A/div

CHARGE

CURRENT

2A/div

CSON

5V/div

EN

5V/div

INDUCTOR

CURRENT

2A/div

CHARGE

CURRENT

2A/div

Typical Operating Performance DCIN = 20V, 4S2P Li-Battery, T

FIGURE 1. VDD LOAD REGULATION

FIGURE 2. VREF LOAD REGULATION

= 25°C, unless otherwise noted.

A

FIGURE 3. ICM ACCURACY vs AC ADAPTER CURRENT FIGURE 4. SYSTEM EFFICIENCY vs CHARGE CURRENT

Submit Document Feedback

C ADAPTER CURRENT LIMI T: 5.15

FIGURE 5. LOAD TRANSIENT RESPONSE FIGURE 6. CHARGE ENABLE AND SHUTDOWN

DAPTER

6

FN9202.3

March 13, 2014

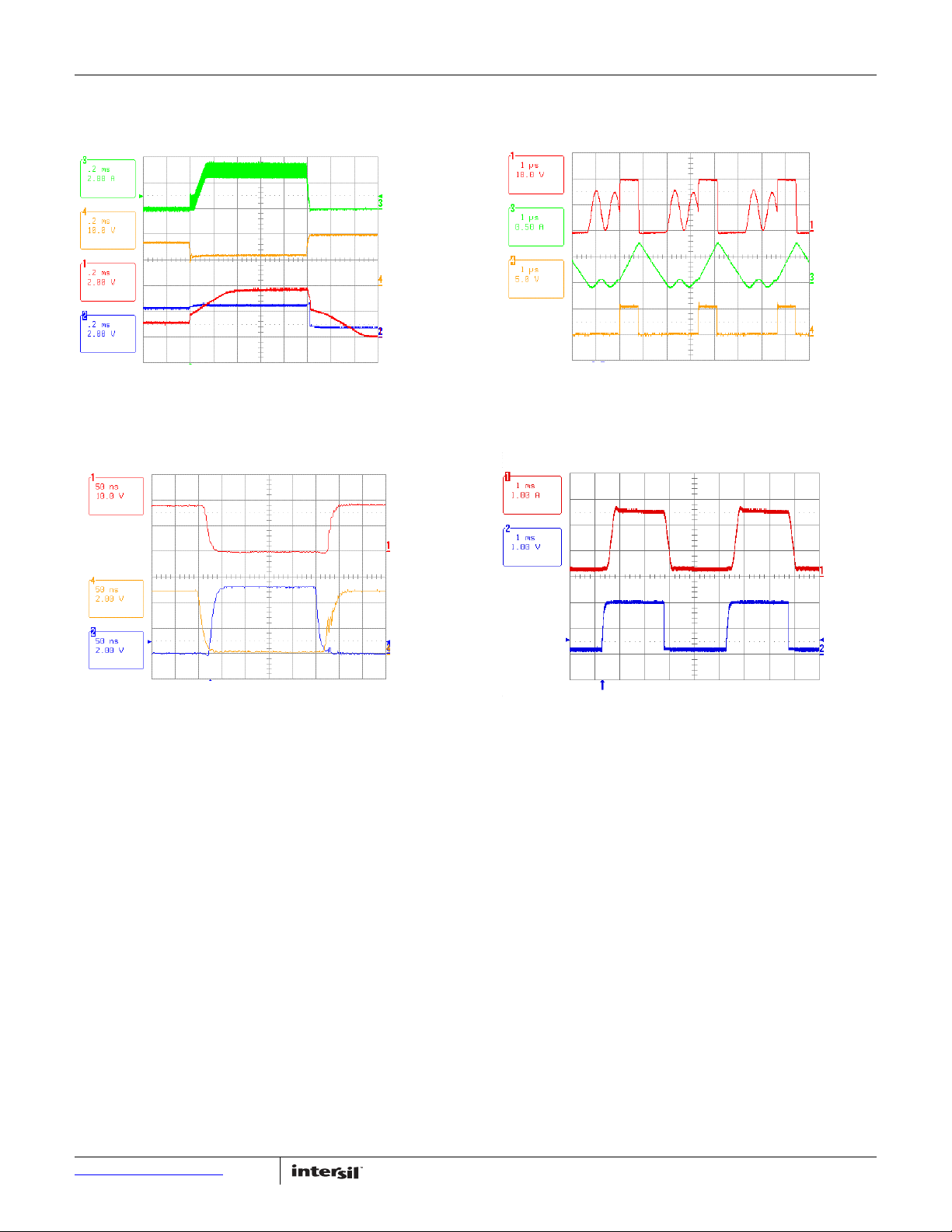

ISL6251, ISL6251A

INDUCTOR

CURRENT

2A/div

CSON

10V/div

VCOMP

ICOMP

BATTERY

INSERTION

BATTERY

REMOVAL

VCOMP

2V/div

ICOMP

2V/div

INDUCTOR

CURRENT

2A/div

CSON

10V/div

VCOMP

ICOMP

BATTERY

INSERTION

BATTERY

REMOVAL

VCOMP

2V/div

ICOMP

2V/div

PHASE

10V/div

INDUCTOR

CURRENT

1A/div

UGATE

5V/div

CHLIM=0.2V

CSON=8V

PHASE

10V/div

INDUCTOR

CURRENT

1A/div

UGATE

5V/div

PHASE

10V/div

INDUCTOR

CURRENT

1A/div

UGATE

5V/div

CHLIM=0.2V

CSON=8V

PHASE

10V/div

LGATE

2V/div

UGATE

2V/div

PHASE

10V/div

LGATE

2V/div

UGATE

2V/div

CHLIM

1V/div

CHARGE

CURRENT

1A/div

Typical Operating Performance DCIN = 20V, 4S2P Li-Battery, T

FIGURE 7. BATTERY INSERTION AND REMOVAL FIGURE 8. SWITCHING WAVEFORMS AT DIODE EMULATION

= 25°C, unless otherwise noted. (Continued)

A

FIGURE 9. SWITCHING WAVEFORMS IN CC MODE FIGURE 10. TRICKLE TO FULL-SCALE CHARGING

Submit Document Feedback

7

FN9202.3

March 13, 2014

ISL6251, ISL6251A

Functional Pin Descriptions

BOOT

Connect BOOT to a 0.1µF ceramic capacitor to PHASE pin and

connect to the cathode of the bootstrap schottky diode.

UGATE

UGATE is the high side MOSFET gate drive output.

LGATE

LGATE is the low side MOSFET gate drive output; swing between

0V and VDDP.

PHASE

The Phase connection pin connects to the high side MOSFET

source, output inductor, and low side MOSFET drain.

CSOP/CSON

CSOP/CSON is the battery charging current sensing

positive/negative input. The differential voltage across CSOP and

CSON is used to sense the battery charging current, and is

compared with the charging current limit threshold to regulate

the charging current. The CSON pin is also used as the battery

feedback voltage to perform voltage regulation.

CSIP/CSIN

CSIP/CSIN is the AC adapter current sensing positive/negative

input. The differential voltage across CSIP and CSIN is used to

sense the AC adapter current, and is compared with the AC

adapter current limit to regulate the AC adapter current.

GND

GND is an analog ground.

DCIN

The DCIN pin is the input of the internal 5V LDO. Connect it to the

AC adapter output. Connect a 0.1μF ceramic capacitor from DCIN

to PGND.

ACSET

ACSET is an AC adapter detection input. Connect to a resistor

divider from the AC adapter output.

ACPRN

Open-drain output signals AC adapter is present. ACPRN pulls low

when ACSET is higher than 1.26V; and pulled high when ACSET is

lower than 1.26V.

PGND

PGND is the power ground. Connect PGND to the source of the

low side MOSFET for the low side MOSFET gate driver.

VDD

VDD is an internal LDO output to supply IC analog circuit. Connect

a 1μF ceramic capacitor to ground.

VDDP

VDDP is the supply voltage for the low-side MOSFET gate driver.

Connect a 4.7Ω resistor to VDD and a 1μF ceramic capacitor to

power ground.

ICOMP

ICOMP is a current loop error amplifier output.

VCOMP

VCOMP is a voltage loop amplifier output.

CELLS

This pin is used to select the battery voltage. CELLS = VDD for a

4S battery pack, CELLS = GND for a 3S battery pack, CELLS =

Float for a 2S battery pack.

VADJ

VADJ adjusts battery regulation voltage. VADJ = VREF for

4.2V+5%/cell; VADJ = Floating for 4.2V/cell; VADJ = GND for

4.2V-5%/cell. Connect to a resistor divider to program the

desired battery cell voltage between 4.2V-5% and 4.2V+5%.

CHLIM

CHLIM is the battery charge current limit set pin. CHLIM input

voltage range is 0.1V to 3.6V. When CHLIM = 3.3V, the set point

for CSOP-CSON is 165mV. The charger shuts down if CHLIM is

forced below 88mV.

ACLIM

ACLIM is the adapter current limit set pin. ACLIM = VREF for

100mV, ACLIM = Floating for 75mV, and ACLIM = GND for 50mV.

Connect a resistor divider to program the adapter current limit

threshold between 50mV and 100mV.

VREF

VREF is a 2.39V reference output pin. It is internally

compensated. Do not connect a decoupling capacitor.

EN

EN is the Charge Enable input. Connecting EN to high enables the

charge control function, connecting EN to low disables charging

functions. Use with a thermistor to detect a hot battery and

suspend charging.

ICM

ICM is the adapter current output. The output of this pin produces

a voltage proportional to the adapter current.

Submit Document Feedback

8

FN9202.3

March 13, 2014

FIGURE 11. FUNCTIONAL BLOCK DIAGRAM

T

V

V

-

ge

g

r

P

E

A

t

V

M+-

Min

e

r

V

+

+

-

r

-+-

A

A

CSE

T

A

V

M

-

r

r

E

V

2

M+-PWM+-

V

2

V

-+-

DCIN

×

2

×

0

A

r

t

t

Current

r

V

-

-

-

-

F

K

K

r

e

r

F

K

K

F

K

K

T

V

V

-

ge

g

r

g

r

P

E

A

t

V

M+-PWM+-

Min

e

r

Min

e

r

V

++

+

-

r

r

-+-

A

A

T

A

V

M

-

r

r

E

V

2

M+-PWM+-

V

2

V

-+-

DCIN

×

2

×

0

A

r

t

t

Current

r

Current

r

V

-

-

-

-

F152

k

2

k

r

e

r

F

F

k

k

CSE

CPRN

CPRN

CLIM

CLIM

ICOMP

ICOMP

VCOM P

VCOM P

VADJ

VADJ

VADJ

VADJ

CELLS

CELLS

VRE

VRE

VRE

VRE

152

152

152

152

15

Current Limit Se

Current Limit Se

VRE

VRE

514

514

514

514

ISL6251, ISL6251A

CSIP

IC

CSIP

IC

+

+

CA1

+

+

+

+

CA2

CA2

gm3

gm3

gm3

gm3

CA1

CA1

Current

Current

Current

Buffe

Buffe

Buffe

Buffe

Buffe

Buffe

CA

CA

CA2

CA2

CA

CA

Min

Min

Min

Min

Min

Min

CA1

+

+

2.1

2.1

Volta

Volta

Selector

Selector

+

+

+

+-+

-

-

dapter

dapter

+

+

gm1

gm1

-

-

1.26

1.26

dapte

dapte

1.27

1.27

Curren

Curren

Limit Se

Limit Se

gm1

gm1

2.1

2.1

Voltage

Voltage

Selecto

Selecto

+

+

Min

Min

Voltag

Voltag

Voltag

Voltag

Voltag

Buffe

Buffe

Buffe

Buffe

Buffe

0.25

0.25

0.25

0.25

19.9

19.9

CSIN

CSIN

gm2

gm2

gm2

gm2

LDO

LDO

Regulato

Regulato

Regulato

Regulato

LDO

LDO

LDO

ulato

ulato

ulato

Re

Re

Re

PW

PW

PW

PW

VDDP

VDDP

+

+

VDD

VDD

BOO

BOO

UGATE

UGATE

PHASE

PHASE

VDD

VDD

LGA T

LGA T

LGA T

LGA T

PGND

PGND

1.06

VDD

VDD

VDD

VDD

2

2

CA2

CA2

-

-

CA

CA

+

VREF

VREF

VREF

VREF

Reference

Reference

Reference

Reference

GND

GND

GND

GND

CSON

CSON

+

CSOP

CSOP

CHLIM

CHLIM

CHLIM

CHLIM

1.06

1.065V

1.065V

+

+

+

+

EN

EN

EN

EN

Submit Document Feedback

9

FN9202.3

March 13, 2014

ISL6251, ISL6251A

FIGURE 12. ISL6251, ISL6251A TYPICAL APPLICATION CIRCUIT WITH FIXED CHARGING PARAMETERS

CSIP

CSIN

BOOT

UGATE

PHASE

LGATE

PGND

CSOP

CSON

CELLS

ICM

GND

DCIN

ACSET

VDDP

VDD

ACPRN

ICOMP

VCOMP

VADJ

EN

CHLIM

ACLIM

VREF

Q1

Q2

L

10µH

C1

10µF

SYSTEM LOAD

C10

10µF

R1

40mΩ

AC ADAPTER

R2

20mΩ

R3

18Ω

R4

2.2Ω

R6:10k

R5

100k

R8

130k

1%

R9

10.2k

1%

C2

0.1µF

C4

0.1µF

C3

1µF

C5:10nF

C6:6.8nF

C9

1µF

ISL6251

ISL6251A

FLOATING

4.2V/CELL

R10

4.7Ω

C7

1µF

3.3V

Battery

Pack

BAT+

BAT-

VDD

4 CELLS

D1

Optional

D2

VDDP

VREF

R12

20k 1%

R11

130k

1%

R13

1.87k

1%

2.6A CHARGE LIMIT

253mA Trickle Charge

C11

3300pF

Q3

Trickle Charge

D4

To Host

Controller

CHARGE

ENABLE

CSIP

CSIN

BOOT

UGATE

PHASE

LGATE

PGND

CSOP

CSON

CELLS

ICM

GND

DCIN

ACSET

VDDP

VDD

ACPRN

ICOMP

VCOMP

VADJ

EN

CHLIM

ACLIM

VREF

Q1

C8

0.1µF

ISL6251,

ISL6251A

FLOATING

4.2V/CELL

C7

D3

R7: 100Ω

CHARGE

ENABLE

Submit Document Feedback

10

FN9202.3

March 13, 2014

ISL6251, ISL6251A

DCIN

ACSET

VDDP

VDD

ACPRN

CHLIM

EN

ICM

ACLIM

VREF

ICOMP

VCOMP

VADJ

Q1

Q2

L

10µH

C1

10µF

C10

10µF

R1

40mΩ

AC ADAPTER

R2

20mΩ

R4

2.2Ω

R5

100k

R8

130k

1%

R9

10.2k,1%

C2

0.1µF

C4

0.1µF

C3

1µF

6.8nF

C9

1µF

C8

0.1µF

ISL6251

ISL6251A

C5

10nF

FLOATING

4.2V/CELL

R6

10k

C7

1µF

R10

4.7Ω

Battery

Pack

BAT+

SCL

SDL

TEMP

BAT-

SCL

SDL

A/D INPUT

GND

5.15A INPUT

CURRENT LIMIT

3 CELLS

HOST

R11, R12, R13

10k

D1

Optional

VDDP

D2

D3

R7: 100Ω

CSIP

CSIN

BOOT

UGATE

PHASE

LGATE

PGND

CSOP

CSON

CELLS

GND

C11

3300pF

D4

SYSTEM LOAD

DCIN

ACSET

VDDP

VDD

ACPRN

CHLIM

EN

ICM

ACLIM

VREF

ICOMP

VCOMP

VADJ

R3: 18Ω

C6

ISL6251,

ISL6251A

Battery

Pack

BAT+

SCL

SDL

TEMP

BAT-

Battery

Pack

BAT+

SCL

SDL

TEMP

BAT-

VCC

OUTPUT

D/A OUTPUT

A/D INPUT

DIGITAL

INPUT

AVDD/VREF

CSIP

CSIN

BOOT

UGATE

PHASE

LGATE

PGND

CSOP

CSON

CELLS

GND

FIGURE 13. ISL6251, ISL6251A T YPICAL APPLICATION CIRCUIT WITH MICRO-CONTROLLER

Submit Document Feedback

11

FN9202.3

March 13, 2014

ISL6251, ISL6251A

V 3.99V 175.0V

VADJCELL

+=

(EQ. 1)

V

VADJ

VREF

R

bot_VADJ

514k

||

R

top_VADJ 514k R

bot_VADJ

514k

||

+

||

-------------------------------------------------------------------------------------------------

×

=

(EQ. 2)

Theory of Operation

Introduction

The ISL6251, ISL6251A includes all of the functions necessary to

charge 2 to 4 cell Li-Ion and Li-polymer batteries. A high

efficiency synchronous buck converter is used to control the

charging voltage and charging current up to 10A. The ISL6251,

ISL6251A has input current limiting and analog inputs for setting

the charge current and charge voltage; CHLIM inputs are used to

control charge current and VADJ inputs are used to control

charge voltage.

The ISL6251, ISL6251A charges the battery with constant

charge current, set by the CHLIM input, until the battery voltage

rises up to a programmed charge voltage set by VADJ input; then

the charger begins to operate at a constant voltage charge

mode.

The EN input allows shutdown of the charger through a

command from a micro-controller. It also uses EN to safely

shutdown the charger when the battery is in extremely hot

conditions. The amount of adapter current is reported on the ICM

output. Figure 11 shows the IC functional block diagram.

The synchronous buck converter uses external N-channel

MOSFETs to convert the input voltage to the required charging

current and charging voltage. Figure 12 shows the ISL6251,

ISL6251A typical application circuit with charging current and

charging voltage fixed at specific values. The typical application

circuit shown in Figure 13 shows the ISL6251, ISL6251A typical

application circuit, which uses a micro-controller to adjust the

charging current set by CHLIM input. The voltage at CHLIM and

the value of R1 sets the charging current. The DC/DC converter

generates the control signals to drive two external N-channel

MOSFETs to regulate the voltage and current set by the ACLIM,

CHLIM, VADJ and CELLS inputs.

The ISL6251, ISL6251A features a voltage regulation loop

(VCOMP) and two current regulation loops (ICOMP). The VCOMP

voltage regulation loop monitors CSON to ensure that its voltage

never exceeds the voltage and regulates the battery charge

voltage set by VADJ. The ICOMP current regulation loops regulate

the battery charging current delivered to the battery to ensure

that it never exceeds the charging current limit set by CHLIM; and

the ICOMP current regulation loops also regulate the input

current drawn from the AC adapter to ensure that it never

exceeds the input current limit set by ACLIM, and to prevent a

system crash and AC adapter overload.

PWM Control

The ISL6251, ISL6251A employs a fixed frequency PWM current

mode control architecture with a feed forward function. The

feed-forward function maintains a constant modulator gain of 11

to achieve fast line regulation as the buck input voltage changes.

When the battery charge voltage approaches the input voltage,

the DC/DC converter operates in dropout mode, where there is a

timer to prevent the frequency from dropping into the audible

frequency range. It can achieve a duty cycle of up to 99.6%.

To prevent boosting of the system bus voltage, the battery

charger operates in standard-buck mode when CSOP-CSON

drops below 4.25mV. Once in standard-buck mode, hysteresis

does not allow synchronous operation of the DC/DC converter

until CSOP-CSON rises above 12.5mV.

An adaptive gate drive scheme is used to control the dead time

between two switches. The dead time control circuit monitors the

LGATE output and prevents the upper side MOSFET from turning

on until LGATE is fully off, preventing cross-conduction and

shoot-through. In order for the dead time circuit to work properly,

there must be a low resistance, low inductance path from the

LGATE driver to MOSFET gate, and from the source of MOSFET to

PGND. The external Schottky diode is between the VDDP pin and

BOOT pin to keep the bootstrap capacitor charged.

Setting the Battery Regulation Voltage

The ISL6251, ISL6251A uses a high-accuracy trimmed band-gap

voltage reference to regulate the battery charging voltage. The

VADJ input adjusts the charger output voltage, and the VADJ

control voltage can vary from 0 to VREF, providing a 10%

adjustment range (from 4.2V -5% to 4.2V +5%) on CSON

regulation voltage. An overall voltage accuracy of better than

0.5% is achieved.

The per-cell battery termination voltage is a function of the

battery chemistry. Consult the battery manufacturers to

determine this voltage.

• Float VADJ to set the battery voltage V

the cells,

• Connect VADJ to VREF to set 4.41V × number of cells,

• Connect VADJ to ground to set 3.99V × number of the cells.

So, the maximum battery voltage of 17.6V can be achieved. Note

that other battery charge voltages can be set by connecting a

resistor divider from VREF to ground. The resistor divider should

be sized to draw no more than 100µA from VREF; or connect a

low impedance voltage source like the D/A converter in the

micro-controller. The programmed battery voltage per cell can be

determined by Equation 1:

An external resistor divider from VREF sets the voltage at VADJ

according to Equation 2:

where R

bot_VADJ

and R

top_VADJ

are external resistors at VADJ. To

minimize accuracy loss due to interaction with VADJ’s internal

resistor divider, ensure the AC resistance looking back into the

external resistor divider is less than 25k.

Connect CELLS as shown in Table 1 to charge 2, 3 or 4 Li+ cells.

When charging other cell chemistries, use CELLS to select an

output voltage range for the charger. The internal error amplifier

gm1 maintains voltage regulation. The voltage error amplifier is

compensated at VCOMP. The component values shown in

Figure 12 provide suitable performance for most applications.

Individual compensation of the voltage regulation and currentregulation loops allows for optimal compensation.

= 4.2V × number of

CSON

Submit Document Feedback

12

FN9202.3

March 13, 2014

ISL6251, ISL6251A

I

CHG

165mV

R

1

-------------------

V

CHLIM

3.3V

--------------------- -

=

(EQ. 3)

I

CHG

165mV

R

1

-------------------

V

CHLIM trickle,

3.3V

--------------------------------------- -

=

(EQ. 4)

⎟

⎠

⎞

⎜

⎝

⎛

+= 050.0V

VREF

05.0

R

1

I

ACLIM

2

INPUT

(EQ. 5)

V

ACLIM

VREF

R

bot_ACLIM

152k

||

R

top_ACLIM 152k R

bot_ACLIM

152k

||

+

||

------------------------------------------------------------------------------------------------------

×

=

(EQ. 6)

ACSET

9

8

rise,th

V1

R

R

V •

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+=

(EQ. 7)

8hysACSET

9

8

fall,th

RIV1

R

R

V −•

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+=

(EQ. 8)

TABLE 1. CELL NUMBER PROGRAMMING

CELLS CELL NUMBER

VDD 4

GND 3

Float 2

Setting the Battery Charge Current Limit

The CHLIM input sets the maximum charging current. The current

set by the current sense-resistor connects between CSOP and

CSON. The full-scale differential voltage between CSOP and

CSON is 165mV for CHLIM = 3.3V, so the maximum charging

current is 4.125A for a 40mΩ sensing resistor. Other battery

charge current-sense threshold values can be set by connecting a

resistor divider from VREF or 3.3V to ground, or by connecting a

low impedance voltage source like a D/A converter in the

micro-controller. Unlike VADJ and ACLIM, CHLIM does not have an

internal resistor divider network. The charge current limit

threshold is given by Equation 3:

To set the trickle charge current for the dumb charger, a resistor

in series with a switch Q3 (Figure 12) controlled by the microcontroller is connected from CHLIM pin to ground. The trickle

charge current is determined by Equation 4:

When the CHLIM voltage is below 88mV (typical), it will disable

the battery charger. When choosing the current sensing resistor,

note that the voltage drop across the sensing resistor causes

further power dissipation, reducing efficiency. However, adjusting

CHLIM voltage to reduce the voltage across the current sense

resistor R1 will degrade accuracy due to the smaller signal to the

input of the current sense amplifier. There is a trade-off between

accuracy and power dissipation. A low pass filter is

recommended to eliminate switching noise. Connect the resistor

to the CSOP pin instead of the CSON pin, as the CSOP pin has

lower bias current and less influence on current-sense accuracy

and voltage regulation accuracy.

Setting the Input Current Limit

The total input current from an AC adapter, or other DC source, is

a function of the system supply current and the battery-charging

current. The input current regulator limits the input current by

reducing the charging current, when the input current exceeds

the input current limit set point. System current normally

fluctuates as portions of the system are powered up or down.

Without input current regulation, the source must be able to

supply the maximum system current and the maximum charger

input current simultaneously. By using the input current limiter,

the current capability of the AC adapter can be lowered, reducing

system cost.

The ISL6251, ISL6251A limits the battery charge current when

the input current-limit threshold is exceeded, ensuring the

battery charger does not load down the AC adapter voltage. This

constant input current regulation allows the adapter to fully

power the system and prevent the AC adapter from overloading

and crashing the system bus.

An internal amplifier gm3 compares the voltage between CSIP

and CSIN to the input current limit threshold voltage set by

ACLIM. Connect ACLIM to REF, Float and GND for the full-scale

input current limit threshold voltage of 100mV, 75mV and 50mV,

respectively, or use a resistor divider from VREF to ground to set

the input current limit as shown in Equation 5:

An external resistor divider from VREF sets the voltage at ACLIM

according to Equation 6:

where R

bot_ACLIM

and R

top_ACLIM

are external resistors at

ACLIM. To minimize accuracy loss due to interaction with ACLIM’s

internal resistor divider, ensure the AC resistance looking back into

the external resistor divider is less than 25k.

When choosing the current sense resistor, note that the voltage

drop across this resistor causes further power dissipation,

reducing efficiency. The AC adapter current sense accuracy is

very important. Use a 1% tolerance current-sense resistor. The

highest accuracy of ±3% is achieved with 100mV current-sense

threshold voltage for ACLIM = VREF, but it has the highest power

dissipation. For example, it has 400mW power dissipation for

rated 4A AC adapter and 1W sensing resistor may have to be

used. ±4% and ±6% accuracy can be achieved with 75mV and

50mV current-sense threshold voltage for ACLIM = Floating and

ACLIM = GND, respectively.

A low pass filter is suggested to eliminate the switching noise.

Connect the resistor to CSIN pin instead of CSIP pin because

CSIN pin has lower bias current and less influence on the

current-sense accuracy.

AC Adapter Detection

Connect the AC adapter voltage through a resistor divider to

ACSET to detect when AC power is available, as shown in

Figure 12. ACPRN is an open-drain output and is high when

ACSET is less than V

V

th,fall

Where I

. V

and V

th,rise

is the ACSET input bias current hysteresis and V

hys

, and active low when ACSET is above

th,rise

are given by Equations 7 and 8:

th,fall

ACSET

= 1.24V (min), 1.26V (typ) and 1.28V (max). The hysteresis is

I

hysR8

, where I

= 2.2µA (min), 3.4µA (typ) and 4.4µA (max).

hys

Current Measurement

Use ICM to monitor the input current being sensed across CSIP

and CSIN. The output voltage range is 0 to 2.5V. The voltage of

ICM is proportional to the voltage drop across CSIP and CSIN, and

Submit Document Feedback

13

FN9202.3

March 13, 2014

ISL6251, ISL6251A

ICM 19.9 I

INPUTR2

••=

(EQ. 9)

sMAX,IN

BAT

L

BATMAX,IN

f V

V

I

VV

L

Δ

−

=

(EQ. 10)

MAXBAT,L

I30%I ⋅=

Δ

(EQ. 11)

LMAX,BATPeak

I

2

1

II

Δ

+=

(EQ. 12)

()

D1 D

f L 12

V

I

s

MAX,IN

RMS

−=

(EQ. 13)

is given by Equation 9:

where I

is the DC current drawn from the AC adapter. ICM

INPUT

has ±3% accuracy.

A low pass filter connected to ICM output is used to filter the

switching noise.

LDO Regulator

VDD provides a 5.075V supply voltage from the internal LDO

regulator from DCIN and can deliver up to 30mA of current. The

MOSFET drivers are powered by VDDP, which must be connected

to VDDP as shown in Figure 12. VDDP connects to VDD through

an external resistor. Bypass VDDP and VDD with a 1µF capacitor.

Shutdown

The ISL6251, ISL6251A features a low-power shutdown mode.

Driving EN low shuts down the charger. In shutdown, the DC/DC

converter is disabled, and VCOMP and ICOMP are pulled to

ground. The ICM, ACPRN outputs continue to function.

EN can be driven by a thermistor to allow automatic shutdown

when the battery pack is hot. Often a NTC thermistor is included

inside the battery pack to measure its temperature. When

connected to the charger, the thermistor forms a voltage divider

with a resistive pull-up to the VREF. The threshold voltage of EN is

1.06V with 60mV hysteresis. The thermistor can be selected to

have a resistance vs temperature characteristic that abruptly

decreases above a critical temperature. This arrangement

automatically shuts down the charger when the battery pack is

above a critical temperature.

Another method for inhibiting charging is to force CHLIM below

88mV (typ).

Short Circuit Protection and 0V Battery

Charging

Since the battery charger will regulate the charge current to the

limit set by CHLIM, it automatically has short circuit protection

and is able to provide the charge current to wake up an extremely

discharged battery.

Over-Temperature Protection

If the die temp exceeds +150°C, it stops charging. Once the die

temp drops below +125°C, charging will start up again.

Application Information

The following battery charger design refers to the typical

application circuit in Figure 12, where typical battery

configuration of 4S2P is used. This section describes how to

select the external components including the inductor, input and

output capacitors, switching MOSFETs, and current sensing

resistors.

Inductor Selection

The inductor selection has trade-offs between cost, size and

efficiency. For example, the lower the inductance, the smaller the

size, but ripple current is higher. This also results in higher AC

losses in the magnetic core and the windings, which decrease

the system efficiency. On the other hand, the higher inductance

results in lower ripple current and smaller output filter

capacitors, but it has higher DCR (DC resistance of the inductor)

loss, and has slower transient response. So, the practical

inductor design is based on the inductor ripple current being

±(15-20)% of the maximum operating DC current at maximum

input voltage. The required inductance can be calculated from

Equation 10:

, V

Where V

IN,MAX

, and fs are the maximum input voltage,

BAT

battery voltage and switching frequency, respectively. The

inductor ripple current

ΔI is found from Equation 11:

where the maximum peak-to-peak ripple current is 30% of the

maximum charge current is used.

For V

IN,MAX

= 19V, V

= 16.8V, I

BAT

BAT,MAX

= 2.6A, and

fs= 300kHz, the calculated inductance is 8.3µH. Choosing the

closest standard value gives L = 10µH. Ferrite cores are often the

best choice since they are optimized at 300kHz to 600kHz

operation with low core loss. The core must be large enough not

to saturate at the peak inductor current I

Peak

:

Output Capacitor Selection

The output capacitor in parallel with the battery is used to absorb

the high frequency switching ripple current and smooth the

output voltage. The RMS value of the output ripple current I

given by Equation 13:

where the duty cycle D is the ratio of the output voltage (battery

voltage) over the input voltage for continuous conduction mode

which is typical operation for the battery charger. During the

battery charge period, the output voltage varies from its initial

battery voltage to the rated battery voltage. So, the duty cycle

change can be in the range of between 0.53 and 0.88 for the

minimum battery voltage of 10V (2.5V/Cell) and the maximum

battery voltage of 16.8V.

For V

= 19V, VBAT = 16.8V, L = 10µH, and fs= 300kHz, the

IN,MAX

maximum RMS current is 0.19A. A typical 10F ceramic capacitor

is a good choice to absorb this current and also has very small

size. The tantalum capacitor has a known failure mechanism

when subjected to high surge current.

EMI considerations usually make it desirable to minimize ripple

current in the battery leads. Beads may be added in series with

the battery pack to increase the battery impedance at 300kHz

switching frequency. Switching ripple current splits between the

battery and the output capacitor depending on the ESR of the

output capacitor and battery impedance. If the ESR of the output

rms

is

Submit Document Feedback

14

FN9202.3

March 13, 2014

ISL6251, ISL6251A

DSON

2

BAT

IN

OUT

Conduction,1Q

RI

V

V

P =

(EQ. 14)

s INrr

ksin,g

gd

sLPIN

source,g

gd

sLVINSwitching,1Q

fVQ

I

Q

f IV

2

1

I

Q

f IV

2

1

P ++=

(EQ. 15)

DSON

2

BAT

IN

OUT

2Q

RI

V

V

1P

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

−=

(EQ. 16)

s

GATE

GATE

f

I

Q ≤

(EQ. 17)

()

IN

OUTINOUT

BATrms

V

VVV

II−=

(EQ. 18)

capacitor is 10mΩ and battery impedance is raised to 2Ω with a

bead, then only 0.5% of the ripple current will flow in the battery.

MOSFET Selection

The Notebook battery charger synchronous buck converter has

the input voltage from the AC adapter output. The maximum AC

adapter output voltage does not exceed 25V. Therefore, 30V logic

MOSFET should be used.

The high side MOSFET must be able to dissipate the conduction

losses plus the switching losses. For the battery charger

application, the input voltage of the synchronous buck converter

is equal to the AC adapter output voltage, which is relatively

constant. The maximum efficiency is achieved by selecting a

high side MOSFET that has the conduction losses equal to the

switching losses. Ensure that ISL6251, ISL6251A LGATE gate

driver can supply sufficient gate current to prevent it from

conduction, which is due to the injected current into the drain-tosource parasitic capacitor (Miller capacitor C

the voltage rising rate at phase node at the time instant of the

high-side MOSFET turning on; otherwise, cross-conduction

problems may occur. Reasonably slowing turn-on speed of the

high-side MOSFET by connecting a resistor between the BOOT pin

and gate drive supply source, and the high sink current capability

of the low-side MOSFET gate driver help reduce the possibility of

cross-conduction.

For the high-side MOSFET, the worst-case conduction losses

occur at the minimum input voltage:

), and caused by

gd

For the low-side MOSFET, the worst-case power dissipation

occurs at minimum battery voltage and maximum input voltage:

Choose a low-side MOSFET that has the lowest possible onresistance with a moderate-sized package like the SO-8 and is

reasonably priced. The switching losses are not an issue for the

low side MOSFET because it operates at zero-voltage-switching.

Choose a Schottky diode in parallel with low-side MOSFET Q2

with a forward voltage drop low enough to prevent the low-side

MOSFET Q2 body-diode from turning on during the dead time.

This also reduces the power loss in the high-side MOSFET

associated with the reverse recovery of the low-side MOSFET Q2

body diode.

As a general rule, select a diode with DC current rating equal to

one-third of the load current. One option is to choose a combined

MOSFET with the Schottky diode in a single package. The

integrated packages may work better in practice because there

is less stray inductance due to a short connection. This Schottky

diode is optional and may be removed if efficiency loss can be

tolerated. In addition, ensure that the required total gate drive

current for the selected MOSFETs should be less than 24mA. So,

the total gate charge for the high-side and low-side MOSFETs is

limited by Equation 17:

The optimum efficiency occurs when the switching losses equal

the conduction losses. However, it is difficult to calculate the

switching losses in the high-side MOSFET since it must allow for

difficult-to-quantify factors that influence the turn-on and turn-off

times. These factors include the MOSFET internal gate

resistance, gate charge, threshold voltage, stray inductance, pullup and pull-down resistance of the gate driver. The following

switching loss calculation provides a rough estimate.

Where Q

: drain-to-gate charge, Qrr: total reverse recovery

gd

charge of the body-diode in low side MOSFET, ILV: inductor valley

current, I

Inductor peak current, I

LP:

g,sink

and Ig,

source

are the

peak gate-drive source/sink current of Q1, respectively.

To achieve low switching losses, it requires low drain-to-gate

charge Q

. Generally, the lower the drain-to-gate charge, the

gd

higher the on-resistance. Therefore, there is a trade-off between

the on-resistance and drain-to-gate charge. Good MOSFET

selection is based on the Figure of Merit (FOM), which is a

product of the total gate charge and on-resistance. Usually, the

smaller the value of FOM, the higher the efficiency for the same

application.

Where I

than 24mA. Substituting I

is the total gate drive current and should be less

GATE

=24mA and fs= 300kHz into the

GATE

above equation yields that the total gate charge should be less

than 80nC. Therefore, the ISL6251, ISL6251A easily drives the

battery charge current up to 10A.

Input Capacitor Selection

The input capacitor absorbs the ripple current from the

synchronous buck converter, which is given by Equation 18:

This RMS ripple current must be smaller than the rated RMS

current in the capacitor datasheet. Non-tantalum chemistries

(ceramic, aluminum, or OSCON) are preferred due to their

resistance to power-up surge currents when the AC adapter is

plugged into the battery charger. For Notebook battery charger

applications, it is recommend that ceramic capacitors or polymer

capacitors from Sanyo be used due to their small size and

reasonable cost.

Table 2 shows the component lists for the typical application

circuit in Figure 12.

TABLE 2. COMPO NENT LIST

PARTS PART NUMBERS AND MANUFACTURER

C1, C10 10

C2, C4, C8 0.1

μF/25V ceramic capacitor, Taiyo Yuden

TMK325 MJ106MY X5R (3.2x2.5x1.9mm)

μF/50V ceramic capacitor

Submit Document Feedback

15

FN9202.3

March 13, 2014

ISL6251, ISL6251A

M

11

V

IN

---------

.=

(EQ. 19)

()

1

Q

SS

S

1

V

d

ˆ

v

ˆ

SF

po

2

o

2

esr

in

o

1

++

+

==

ω

ω

ω

(EQ. 20)

,

CR

1

oc

esr

=

ω

L

C

RQ

o

op

≈

o

o

LC

1

=

ω

()

1

Q

SS

S

1

RR

V

d

ˆ

i

ˆ

SF

po

2

o

2

z

Lo

inL

2

++

+

+

==

ω

ω

ω

oo

z

CR

1

≈

ω

TiS() 0.25 RTF2S()M=

(EQ. 21)

TvS() KM F1S()AVS()=

(EQ. 22)

o

FB

V

V

K =

()

()

ST1

ST

)S(L

i

v

v

+

=

(EQ. 23)

LVS()

4

V

FB

V

O

-------------- -

ROR

L

+()

R

T

----------------------------- -

1

S

ω

esr

------------

+

1

S

ω

P

-------

+

------------------------

AVS()

ω

P

1

R

OCO

-----------------

≈

,=

(EQ. 24)

p

ω

TAB LE 2 . COMPONENT LIST (Continued)

PARTS PART NUMBERS AND MANUFACTURER

C3, C7, C9 1μF/10V ceramic capacitor, Taiyo Yuden

LMK212BJ105MG

C5 10nF ceramic capacitor

C6 6.8nF ceramic capacitor

C11 3300pF ceramic capacitor

D1 30V/3A Schottky diode, EC31QS03L (optional)

D2, D3 100mA/30V Schottky Diode, Central Semiconductor

D4 8A/30V Schottky rectifier, STPS8L30B (optional)

L10

Q1, Q2 30V/35m

Q3 Signal N-channel MOSFET, 2N7002

R1 40m

R2 20m

R3 18

R4 2.2

R5 100k

R6 10k,

R7 100

R8, R11 130k,

R9 10.2k

R10 4.7

R12 20k

R13 1.87k

μH/3.8A/26mΩ, Sumida, CDRH104R-100

Ω, FDS6912A, Fairchild.

Ω, ±1%, LRC-LR2512-01-R040-F, IRC

Ω, ±1%, LRC-LR2010-01-R020-F, IRC

Ω, ±5%, (0805)

Ω, ±5%, (0805)

Ω, ±5%, (0805)

±5%, (0805)

Ω, ±5%, (0805)

±1%, (0805)

Ω, ±1%, (0805)

Ω, ±5%, (0805)

Ω, ±1%, (0805)

Ω, ±1%, (0805)

Loop Compensation Design

ISL6251, ISL6251A uses constant frequency current mode

control architecture to achieve fast loop transient response. An

accurate current sensing resistor in series with the output

inductor is used to regulate the charge current, and the sensed

current signal is injected into the voltage loop to achieve current

mode control to simplify the loop compensation design. The

inductor is not considered as a state variable for current mode

control and the system becomes single order system. It is much

easier to design a compensator to stabilize the voltage loop than

voltage mode control. Figure 14 shows the small signal model of

the synchronous buck regulator.

Power Stage Transfer Functions

Transfer fun ction F1(S) from control to output voltage is:

Where ,

Transfer fun ction F2(S) from control to inductor current is:

, where .

Current loop gain Ti(S) is expressed as shown in Equation 21:

where R

equal to the product of the charging current sensing resistance

and the gain of the current sense amplifier, CA2. For ISL6251,

ISL6251A, R

The voltage gain with open current loop is:

Where , VFB is the feedback voltage of the voltage error

amplifier. The Voltage loop gain with current loop closed is given

by Equation 23:

If T

From the above equation, it is shown that the system is a single

order system, which has a single pole located at before the

half switching frequency. Therefore, simple type II compensator

can be easily used to stabilize the system.

is the trans-resistance in current loop. RT is usually

T

=20R1.

T

(S)>>1, then it can be simplified as follows:

i

PWM Comparator Gain Fm:

The PWM comparator gain Fm for peak current mode control is

given by Equation 19:

16

Submit Document Feedback

FN9202.3

March 13, 2014

ISL6251, ISL6251A

FIGURE 14. SMALL SIGNAL MODEL OF SYNCHRONOUS BUCK

REGULATOR

dˆV

in

dˆI

L

in

v

ˆ

in

i

ˆ

L

+

1:D

+

L

i

ˆ

Co

Rc

Ro

-Av(S)

d

ˆ

comp

v

ˆ

R

T

11/Vin

+

T

i

(S)

K

o

v

ˆ

Tv(S)

dˆV

in

dˆI

L

in

v

ˆ

in

i

ˆ

L

+

1:D

+

L

i

ˆ

Rc

Ro

-Av(S)

d

ˆ

comp

v

ˆ

R

T

-

T

i

(S)

K

o

v

ˆ

Tv(S)

V

CA2

0.25V

CA2

dˆVindˆV

in

dˆILdˆI

L

in

v

ˆ

in

v

ˆ

in

i

ˆ

in

i

ˆ

L

+

1:D

+

L

i

ˆ

L

i

ˆ

Co

Rc

Ro

-Av(S)

dˆd

ˆ

comp

v

ˆ

comp

v

ˆ

R

T

11/Vin

+

T

i

(S)

K

o

v

ˆ

o

v

ˆ

Tv(S)

dˆVindˆV

in

dˆILdˆI

L

in

v

ˆ

in

v

ˆ

in

i

ˆ

in

i

ˆ

L

+

1:D

+

L

i

ˆ

L

i

ˆ

Rc

Ro

-Av(S)

dˆd

ˆ

comp

v

ˆ

comp

v

ˆ

R

T

-

T

i

(S)

K

o

v

ˆ

o

v

ˆ

Tv(S)

V

CA2

0.25V

CA2

()

SC

S

1

g

v

ˆ

v

ˆ

SA

1

cz

m

FB

comp

v

ω

+

==

(EQ. 25)

CR

1

11

cz

=

ω

-

+

R1

C1

V

REF

V

FB

Vo

g

m

V

COMP

-

+

Vo

+

R1

C1

V

REF

V

FB

Vo

g

m

V

COMP

+

Vo

FIGURE 15. VOLTAGE LOOP COMPENSATOR

s

f

20

1

5

1

⎟

⎠

⎞

⎜

⎝

⎛

−

()

oo

cz

CR

1

31 −=

ω

(EQ. 26)

R

1

8π fCVOCOR

T

gmV

FB

---------------------------------------

=

(EQ. 27)

cz 1

1

R

1

C

ω

=

(EQ. 28)

Figure 15 shows the voltage loop compensator, and its transfer

function is expressed as follows:

where

The loop gain T

(S) at cross over frequency of fc has unity gain.

v

Therefore, the compensator resistance R1 is determined by

Equation 27:

where g

is the trans-conductance of the voltage loop error

m

amplifier. Compensator capacitor C1 is then given by

Equation 28:

Example: V

= 19V, Vo= 16.8V, Io=2.6A, fs= 300kHz,

in

Co=10μF/10mΩ, L = 10μH, gm= 250μs, RT=0.8Ω,

VFB=2.1V, fc= 20kHz, then compensator resistance R1= 10kΩ.

Choose R

compensator capacitor is C

loop compensator: R

= 10kΩ. Put the compensator zero at 1.5kHz. The

1

1

= 6.5nF. Therefore, choose voltage

1

= 10k, C1=6.5nF.

PCB Layout Considerations

Power and Signal Layers Placement on the

PCB

As a general rule, power layers should be close together, either

on the top or bottom of the board, with signal layers on the

opposite side of the board. As an example, layer arrangement on

a 4-layer board is shown below:

Compensator design goal:

•High DC gain

• Loop bandwidth f

:

c

• Gain margin: >10dB

•Phase margin: 40°

The compensator design procedure is as follows:

1. Put compensator zero at:

2. Put one compensator pole at zero frequency to achieve high

DC gain, and put another compensator pole at either ESR zero

frequency or half switching frequency, whichever is lower.

Submit Document Feedback

17

1. Top Layer: signal lines, or half board for signal lines and the

other half board for power lines

2. Signal Ground

3. Power Layers: Power Ground

4. Bottom Layer: Power MOSFET, Inductors and other Power

traces

Separate the power voltage and current flowing path from the

control and logic level signal path. The controller IC will stay on

the signal layer, which is isolated by the signal ground to the

power signal traces.

Component Placement

The power MOSFET should be close to the IC so that the gate

drive signal, the LGATE, UGATE, PHASE, and BOOT, traces can be

short.

Place the components in such a way that the area under the IC

has less noise traces with high dv/dt and di/dt, such as gate

signals and phase node signals.

Signal Ground and Power Ground

Connection.

At minimum, a reasonably large area of copper, which will shield

other noise couplings through the IC, should be used as signal

ground beneath the IC. The best tie-point between the signal

ground and the power ground is at the negative side of the output

capacitor on each side, where there is little noise; a noisy trace

beneath the IC is not recommended.

FN9202.3

March 13, 2014

ISL6251, ISL6251A

GND and VDD Pin

At least one high quality ceramic decoupling cap should be used

to cross these two pins. The decoupling cap can be put close to

the IC.

LGATE Pin

This is the gate drive signal for the bottom MOSFET of the buck

converter. The signal going through this trace has both high dv/dt

and high di/dt, and the peak charging and discharging current is

very high. These two traces should be short, wide, and away from

other traces. There should be no other traces in parallel with

these traces on any layer.

PGND Pin

PGND pin should be laid out to the negative side of the relevant

output cap with separate traces. The negative side of the output

capacitor must be close to the source node of the bottom

MOSFET. This trace is the return path of LGATE.

PHASE Pin

This trace should be short, and positioned away from other weak

signal traces. This node has a very high dv/dt with a voltage

swing from the input voltage to ground. No trace should be in

parallel with it. This trace is also the return path for UGATE.

Connect this pin to the high-side MOSFET source.

UGATE Pin

This pin has a square shape waveform with high dv/dt. It

provides the gate drive current to charge and discharge the top

MOSFET with high di/dt. This trace should be wide, short, and

away from other traces similar to the LGATE.

BOOT Pin

This pin’s di/dt is as high as the UGATE; therefore, this trace

should be as short as possible.

CSOP, CSON Pins

The current sense resistor connects to the CSON and the CSOP

pins through a low pass filter. The CSON pin is also used as the

battery voltage feedback. The traces should be away from the

high dv/dt and di/di pins like PHASE, BOOT pins. In general, the

current sense resistor should be close to the IC. Other layout

arrangements should be adjusted accordingly.

EN Pin

This pin stays high at enable mode and low at idle mode and is

relatively robust. Enable signals should refer to the signal ground.

DCIN Pin

This pin connects to AC adapter output voltage, and should be

less noise sensitive.

Copper Size for the Phase Node

The capacitance of PHASE should be kept very low to minimize

ringing. It would be best to limit the size of the PHASE node

copper in strict accordance with the current and thermal

management of the application.

Identify the Power and Signal Ground

The input and output capacitors of the converters, the source

terminal of the bottom switching MOSFET PGND should connect

to the power ground. The other components should connect to

signal ground. Signal and power ground are tied together at one

point.

Clamping Capacitor for Switching MOSFET

It is recommended that ceramic caps be used closely connected

to the drain of the high-side MOSFET, and the source of the lowside MOSFET. This capacitor reduces the noise and the power

loss of the MOSFET.

For additional products, see www.intersil.com/en/products.html

Intersil products are manufactured, assembled and tested utilizing ISO9001 quality systems as noted

in the quality certifications found at www.intersil.com/en/support/qualandreliability.html

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time

without notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be

accurate and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

Submit Document Feedback

18

FN9202.3

March 13, 2014

Package Outline Drawing

located within the zone indicated. The pin #1 identifier may be

Unless otherwise specified, tolerance : Decimal ± 0.05

Tiebar shown (if present) is a non-functional feature.

The configuration of the pin #1 identifier is optional, but must be

between 0.15mm and 0.30mm from the terminal tip.

Dimension b applies to the metallized terminal and is measured

Dimensions in ( ) for Reference Only.

Dimensioning and tolerancing conform to AMSE Y14.5m-1994.

6.

either a mold or mark feature.

3.

5.

4.

2.

Dimensions are in millimeters.1.

NOTES:

BOTTOM VIEW

DETAIL "X"

TYPICAL RECOMMENDED LAND PATTERN

TOP VIEW

BOTTOM VIEW

SIDE VIEW

5.00

A

5.00

B

INDEX AREA

PIN 1

6

(4X) 0.15

28X 0.55 ± 0.10 4

A

28X 0.25

M0.10 C B

14

8

4X

0.50

24X

3.0

6

PIN #1 INDEX AREA

3 .10 ± 0 . 15

0 . 90 ± 0.1

BASE PLANE

SEE DETAIL "X"

SEATING PLANE

0.10

C

C

0.08 C

0 . 2 REF

C

0 . 05 MAX.

0 . 00 MIN.

5

( 3. 10)

( 4. 65 TYP )

( 24X 0 . 50)

(28X 0 . 25 )

( 28X 0 . 75)

15

22

21

7

1

28

+ 0.05

- 0.07

L28.5x5

28 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

Rev 2, 10/07

ISL6251, ISL6251A

Submit Document Feedback

19

FN9202.3

March 13, 2014

ISL6251, ISL6251A

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of Publication

Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Package length does not include mold flash, protrusions or gate burrs. Mold

flash,

protrusion and gate burrs shall not exceed 0.15mm (0.006 inch) per side.

4. Package width does not include interlead flash or protrusions. Interlead flash and

protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, a visual index feature

must be located within the crosshatched area.

6. Terminal numbers are shown for reference only.

7. Lead width does not include dambar protrusion. Allowable dambar protrusion

shall be 0.10mm (0.004 inch) total in excess of “B” dimension at maximum material condition.

8. Controlling dimension: MILLIMETER.

INDEX

AREA

24

1

-B-

0.17(0.007)

CAM

BS

-A-

M

-C-

SEATING PLANE

0.10(0.004)

x 45°

0.25

0.010

GAUGE

PLANE

3.98

3.81

6.19

5.80

4

0.25(0.010) B

M

M

1.27

0.41

0.49

0.26

5

8°

0°

1.54

0.25

0.18

8.74

8.55

3

1.75

1.35

0.25

0.10

0.30

0.20

7

0.635 BSC

5.59

4.06

7.11

0.635

DETAIL “X”

SIDE VIEW 1

TYPICAL RECOMMENDED LAND PATTERN

TOP VIEW

SIDE VIEW 2

5

0.38

Package Outline Drawing

M24.15

24 LEAD SHRINK SMALL OUTLINE PLASTIC PACKAGE (QSOP/SSOP)

0.150” WIDE BODY

Rev 3, 2/13

Submit Document Feedback

20

FN9202.3

March 13, 2014

Loading...

Loading...