®

ISL6227

December 21, 2006Data Sheet FN9094.4

Dual Mobile-Friendly PWM Controller with

DDR Option

The ISL6227 dual PWM controller delivers high efficiency

precision voltage regulation from two synchronous buck DC/DC

converters. It was designed especially to provide power

regulation for DDR memory, chip sets, graphics and other

system electronics in Notebook PCs. The ISL6227’s wide

input voltage range capability allows for voltage conversion

directly from AC/DC adaptor or Li-Ion battery pack.

Automatic mode transition of constant-frequency synchronous

rectification at heavy load, and hysteretic (HYS) diodeemulation at light load, assure high efficiency over a wide range

of conditions. The HYS mode of operation can be disabled

separately on each PWM converter if constant-frequency

continuous-conduction operation is desired for all load levels.

Efficiency is further enhanced by using the lower MOSFET

r

Voltage-fe ed-forward ramp modulation, current mode control,

and internal feedback compensation provide fast response to

input voltage and load transients. Input current ripple is

minimized by channel-to-channel PWM phase shift of 0°, 90° or

180° (determined by input voltage and status of the DDR pin).

The ISL6227 can control two inde pendent ou tput volt ages

adjustable from 0.9V to 5.5V, or by activating the DDR pin,

transform into a complete DDR memory power supply solution.

In DDR mode, CH2 output voltage VTT tracks CH1 output

voltage VDDQ. CH2 output can bo th source and sink current, an

essential power supply feature for DDR memory. The reference

voltage VREF required by DDR memory is generated as well.

In dual power supply applications the ISL6227 monitors the

output voltage of both CH1 and CH2. An independent PGOOD

(power good) signal is asserted for each channel after the

soft-start sequence has completed, and the output voltage is

within PGOOD window. In DDR mode CH1 generates the only

PGOOD signal.

Built-in overvoltage protection prevents the output from going

above 115% of the set point by holding the lower MOSFET on

and the upper MOSFET off. When the output voltage re-enters

regulation, PGOOD will go HIGH and normal operation

automatically resumes. Once the soft-start sequence has

completed, undervoltage protection latches the offending

channel off if the output drops below 75% of its set point value.

Adjustable overcurrent protection (OCP) monitors the voltage

drop across the r

current-sensing is required, an external current sense resistor

may be used.

as the current sense element.

DS(ON)

DS(ON)

of the lower MOSFET. If more precise

Features

• Provides regulated output voltage in the range 0.9V–5.5V

• Operates from an input battery voltage range of 5V to 24V

or from 3.3V/5V system rail

• Complete DDR1 and DDR2 memory power solution with

VTT tracking VDDQ/2 and a VDDQ/2 buffered reference

output

• Flexible PWM or HYS plus PWM mode selection with HYS

diode emulation at light loads for higher system efficiency

•r

current sensing

DS(ON)

• Excellent dynamic response with voltage feed-forward and

current mode control accommodating wide range LC filter

selections

• Undervoltage lock-out on VCC pin

• Power-good, overcurrent, overvoltage, undervoltage

protection for both channels

• Synchronized 300kHz PWM operation in PWM mode

• Pb-free plus anneal available (RoHS compliant)

Applications

• Notebook PCs and Desknotes

• Tablet PCs/Slates

• Hand-held portable instruments

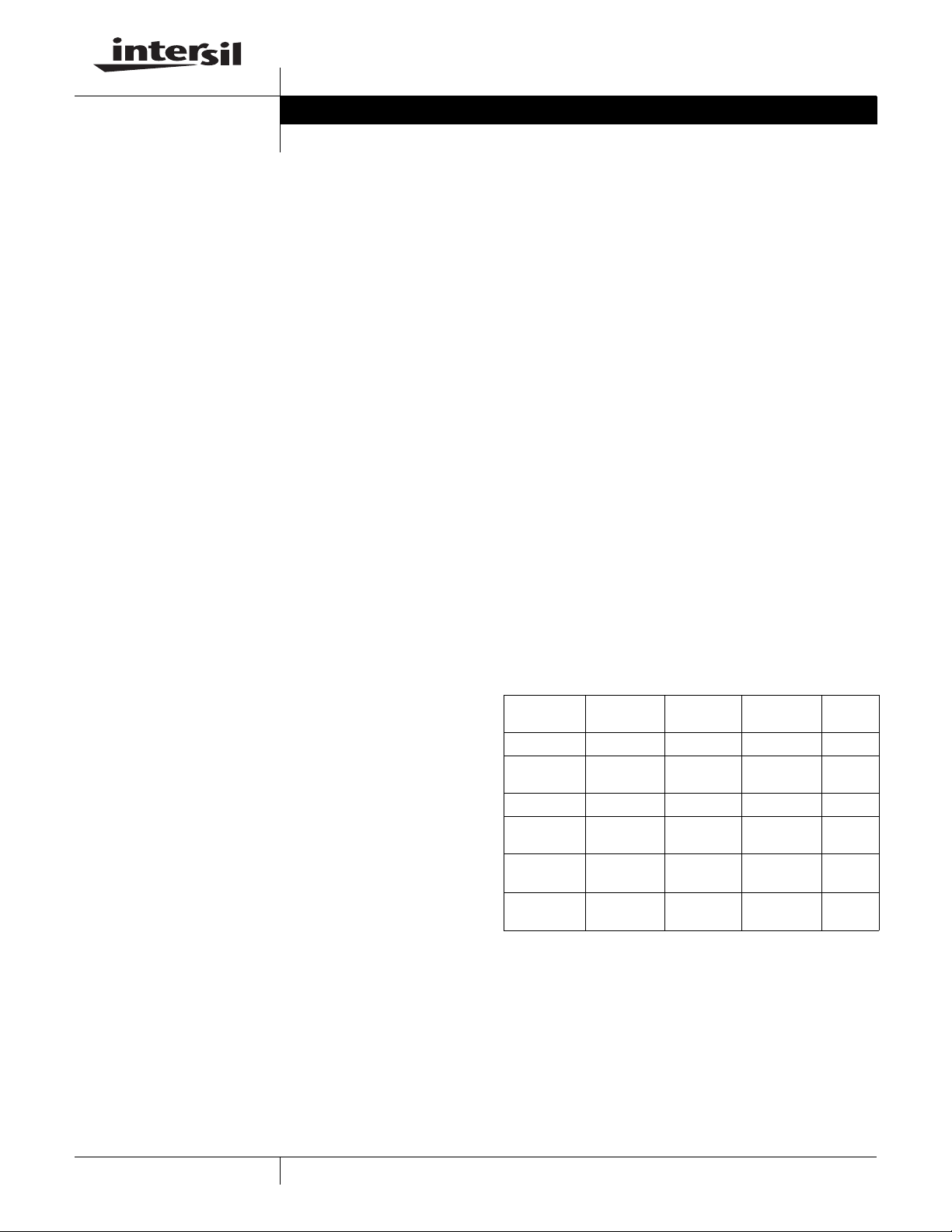

Ordering Information

PART

PART #

ISL6227CA ISL6227CA -10 to +100 28 Ld QSOP M28.15

ISL6227CAZ

(Note)

ISL6227IA ISL6227IA -40 to +100 28 Ld QSOP M28.15

ISL6227IAZ

(Note)

ISL6227HRZ

(Note)

ISL6227IRZ

(Note)

Add -T to part number for Tape and Reel

NOTE: Intersil Pb-free plus anneal product s empl oy special Pb -free

material sets; molding compounds/die attach materials and 100% matte

tin plate termination finish, which are RoH S compliant and comp atible

with both SnPb and Pb-free soldering operations. Intersil Pb-free

products are MSL classifie d at Pb-fre e peak ref low te mperat ures tha t

meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

MARKING

ISL6227CAZ -10 to +100 28 Ld QSOP

ISL6227IAZ -40 to +100 28 Ld QSOP

ISL6227HRZ -10 to +100 28 Ld QFN

ISL6227IRZ -40 to +100 28 Ld QFN

TEMP.

RANGE (°C)

PACKAGE

(Pb-free)

(Pb-free)

(Pb-free)

(Pb-free)

PKG.

DWG. #

M28.15

M28.15

L28.5x5

L28.5x5

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright Intersil Americas Inc. 2004-2006. All Rights Reserved

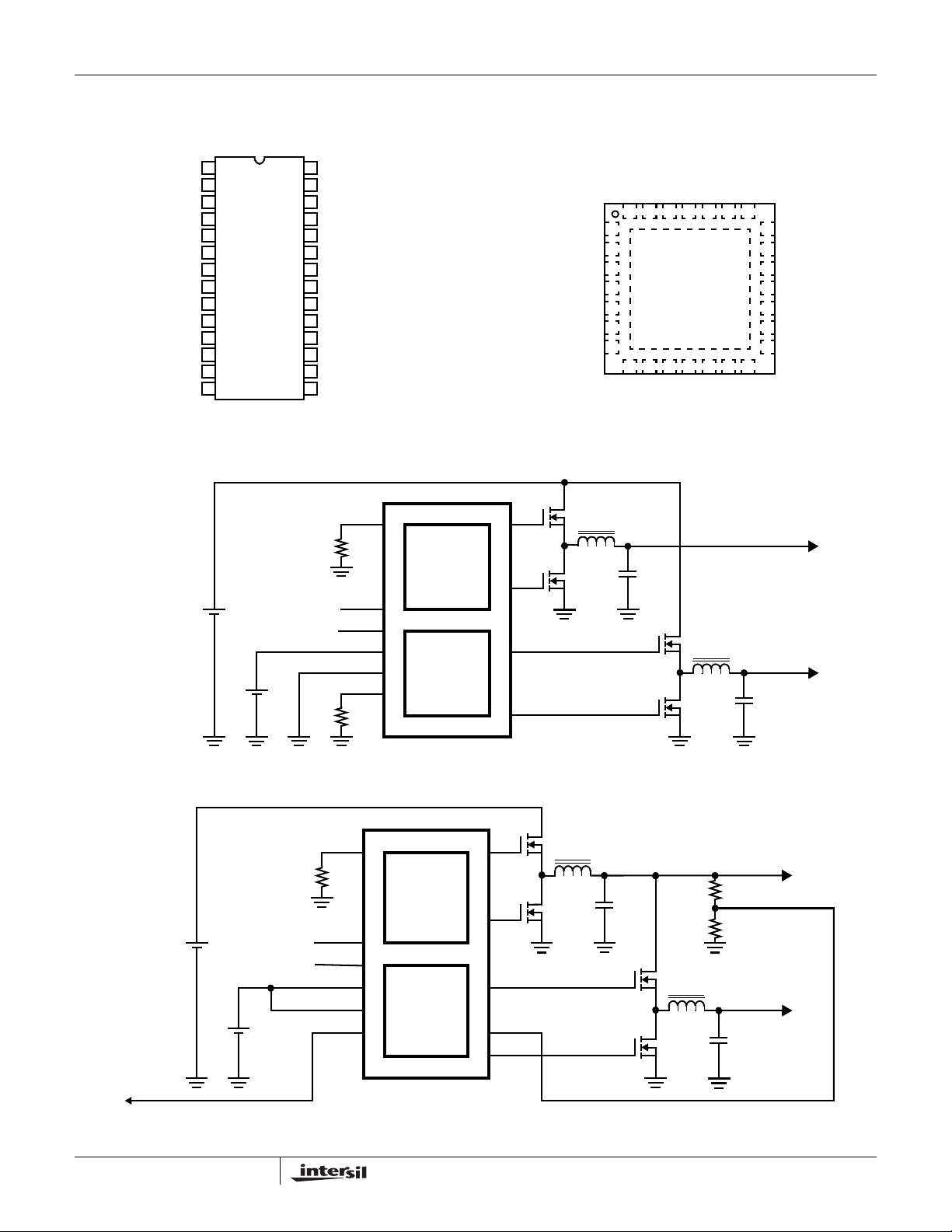

Pinouts

28LD SSOP

TOP VIEW

ISL6227

28 LD 5X5 QFN

TOP VIEW

1

GND

LGATE1

PHASE1

UGATE1

2

3

PGND1

4

5

6

BOOT1

7

ISEN1

8

EN1

9

VOUT1

10

VSEN1

11

SOFT1 SOFT2

12

DDR

13

VIN PG1

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

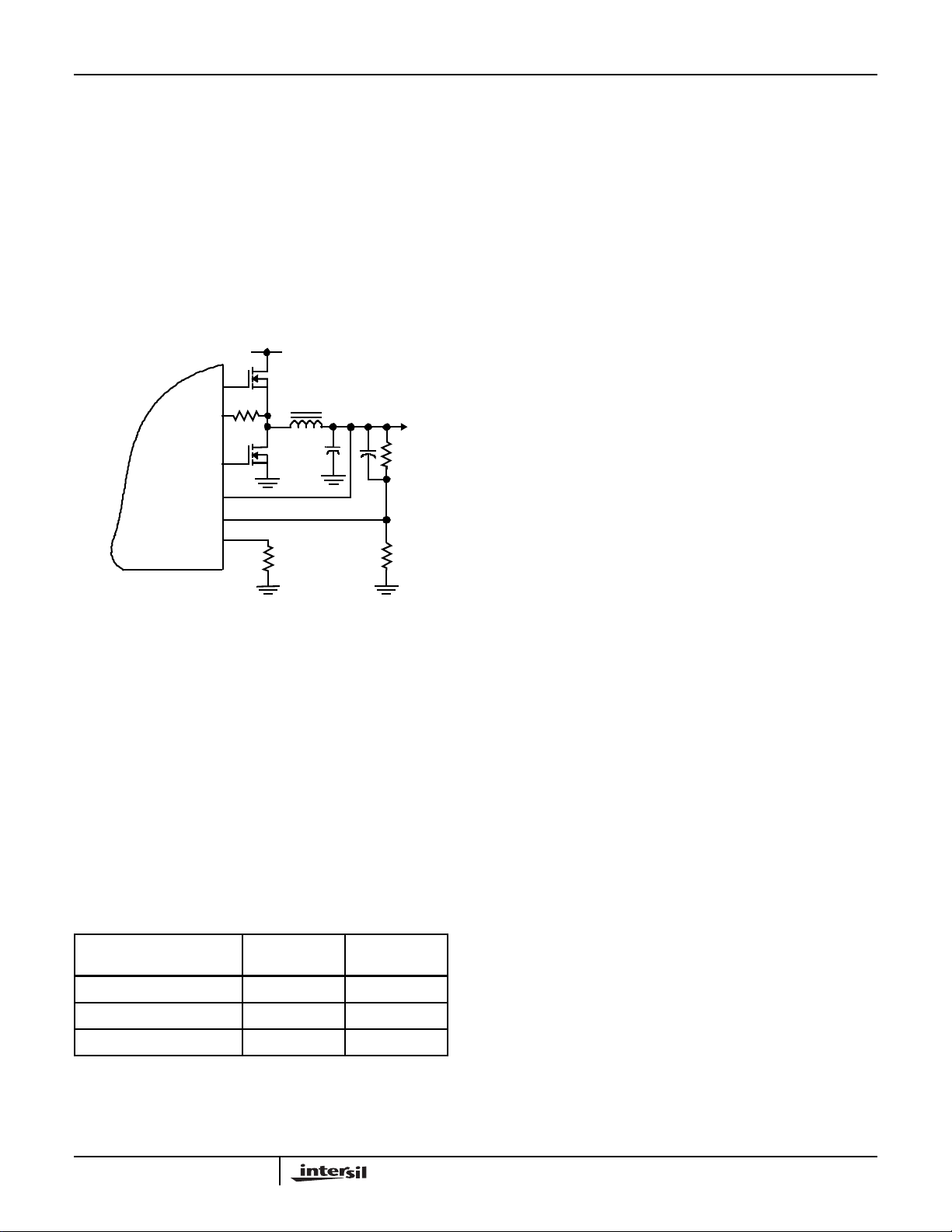

Generic Application Circuits

V

IN

+5V to +24V

+5V

VCC

LGATE2

PGND2

PHASE2

UGATE2

BOOT2

ISEN2

EN2

VOUT2

VSEN2

OCSET2OCSET1

PG2/REF

OCSET1

OCSET2

EN1

EN2

VCC

DDR

PWM1

PWM2

Q1

Q2

PHASE1

UGATE1

BOOT1

ISEN1

EN1

VOUT1

VSEN1

PGN1

LGATE1

28 27 26 25 24 23 22

1

2

3

4

5

6

7

8 9 10 11 12 13 14

SOFT1

OCSET1

L1

+

C1

Q3

Q4

GND

GND

29

DDR

VCC

LGATE2

PGND2

PHASE2

21

UGATE2

20

BOOT2

19

ISEN2

18

EN2

17

VOUT2

16

VSEN2

15

OCSET2

VIN

PG1

SOFT2

PG2/REF

V

OUT1

+1.80V

L2

C2

V

OUT2

+1.20V

+

V

IN

+5V to 24V

VREF

+1.25V

ISL6227 APPLICATION CIRCUIT FOR TWO CHANNEL POWER SUPPLY

+5V

OCSET1

EN1

EN2

VCC

DDR

PG2/VREF

PWM1

PWM2

Q1

Q2

OCSET2

L1

C1

+

Q3

Q4

ISL6227 APPLICATION CIRCUIT FOR COMPLETE DDR MEMORY POWER SUPPLY

2

L2

C2

VDDQ

+2.50V

VTT

+1.25V

+

FN9094.4

December 21, 2006

ISL6227

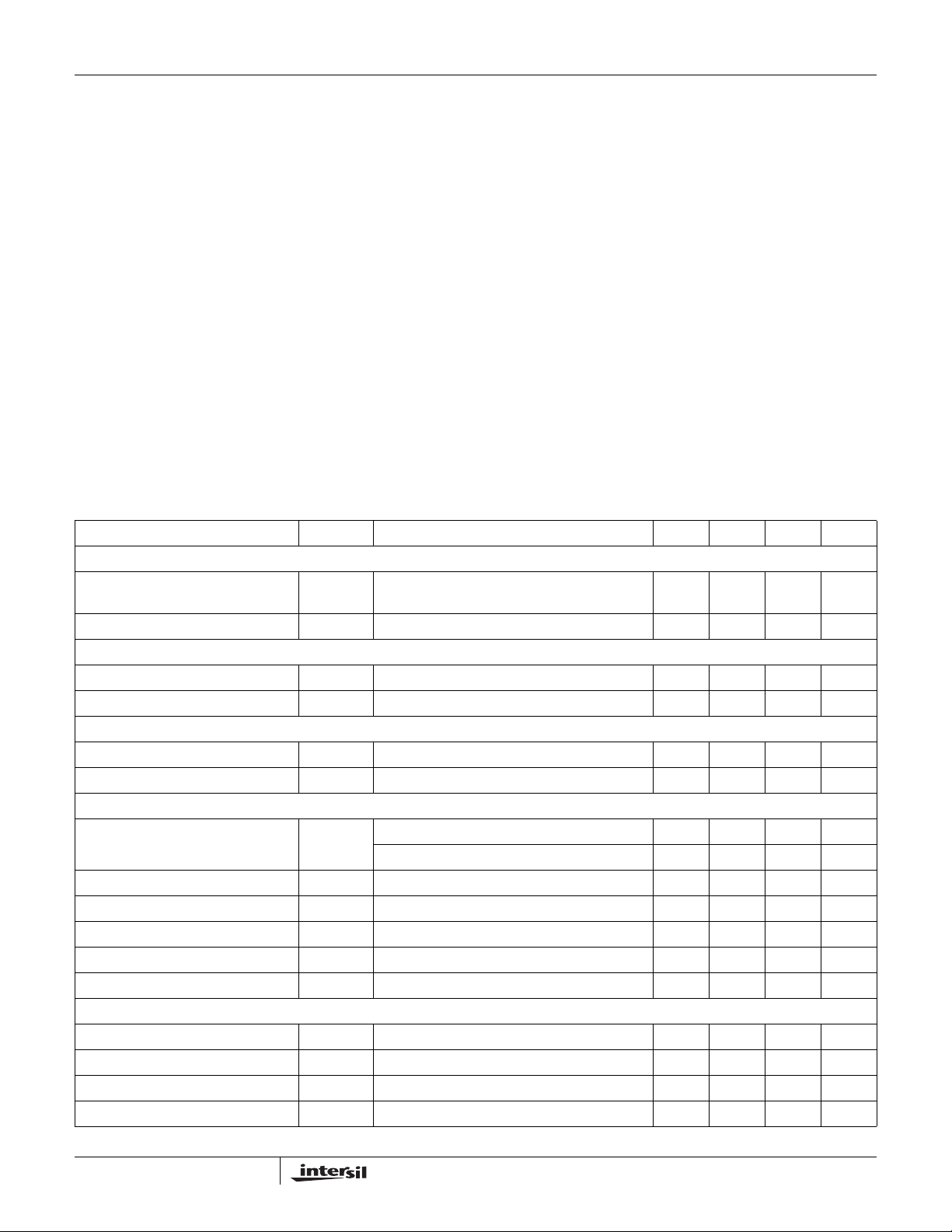

Absolute Maximum Ratings

Bias Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +6.5V

Input Voltage, V

PHASE, UGATE . . . . . . . . . . . . . . . . . . . .GND-5V (Note 1) to 33.0V

BOOT, ISEN . . . . . . . . . . . . . . . . . . . . . . . . . . . GND-0.3V to +33.0V

BOOT with Respect to PHASE . . . . . . . . . . . . . . . . . . . . . . . . + 6.5V

All Other Pins. . . . . . . . . . . . . . . . . . . . . . GND -0.3V to V

. . . . . . . . . . . . . . . . . . . . . . GND - 0.3V to +25.0V

IN

+ 0.3V

CC

Thermal Information

Thermal Resistance (Typical) θJA (°C/W) θJC (°C/W)

SSOP Package (Note 2)

QFN Package(Notes 3, 4)

Maximum Junction Temperature (Plastic Package). . . . . . . . +150°C

. . . . . . . . . . . . . .

. . . . . . . . . . . .

Maximum Storage Temperature Range. . . . . . . . . .-65°C to +150°C

80 N/A

36 6

Recommended Operating Conditions

Bias Voltage, VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5.0V ± 5%

Input Voltage, V

. . . . . . . . . . . . . . . . . . . . . . . . . . .+5.0V to +24.0V

IN

Ambient Temperature Range . . . . . . . . . . . . . . . . . -10°C to +100°C

Junction Temperature Range. . . . . . . . . . . . . . . . . -10°C to +125°C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. 250ns transient. See Confining The Negative Phase Node Voltage Swing in Application Information Section

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

2. θ

JA

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See T ech

3. θ

JA

Brief TB379.

4. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted.

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

VCC SUPPLY

Bias Current I

Shut-down Current I

CC

CCSN

LGATEx, UGATEx Open, VSENx forced above

regulation point, V

IN

> 5V

VCC UVLO

Rising VCC Threshold V

Falling VCC Threshold V

V

IN

Input Voltage Pin Current (Sink) I

Shut-Down Current I

CCU

CCD

VIN

VINS

OSCILLATOR

PWM1 Oscillator Frequency F

Commercial, ISL6227C 255 300 345 kHz

c

Industrial, ISL6227I 240 300 345 kHz

Ramp Amplitude, pk-pk V

Ramp Amplitude, pk-pk V

Ramp Offset V

Ramp/V

Ramp/V

Gain G

IN

Gain G

IN

ROFF

RB1 VIN

RB2

VIN = 16V, by design - 2 - V

R1

VIN = 5V, by design - 0.625 - V

R2

By design - 1 - V

≥ 4.2V, by design - 125 - mV/V

VIN ≤ 4.1V by design - 250 - mV/V

REFERENCE AND SOFT-START

Internal Reference Voltage V

REF

Reference Voltage Accuracy -1.0 - +1.0 %

Soft-Start Current During Start-Up I

Soft-Start Comple te Threshold V

SOFT

ST

By design - 1.5 - V

-1.83.0mA

--1μA

4.3 4.45 4.5 V

44.144.34V

--35μA

--1μA

-0.9- V

--4.5- μA

3

FN9094.4

December 21, 2006

ISL6227

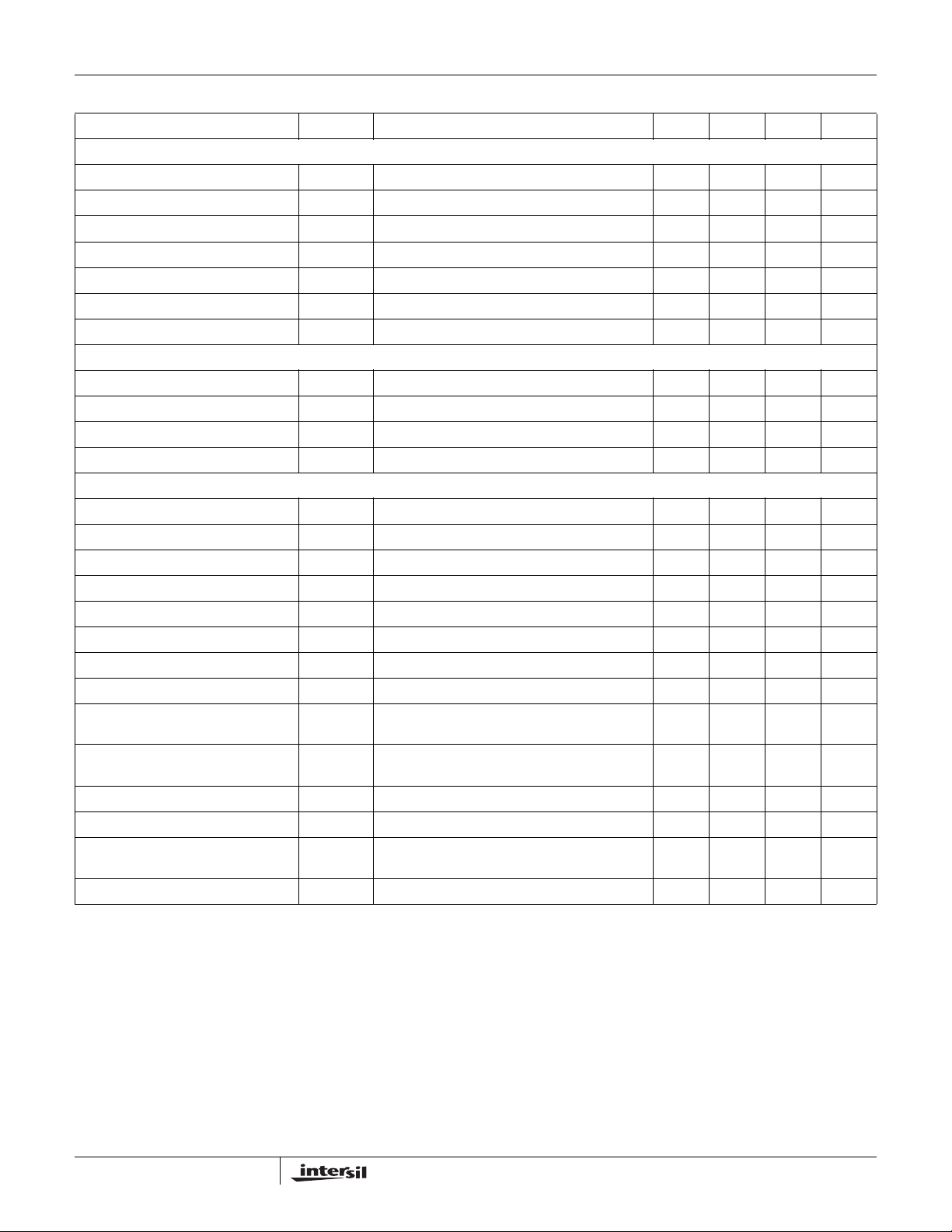

Electrical Specifications Recommended Operating Conditions, Unless Otherwise Noted. (Continued)

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

PWM CONVERTERS

Load Regulation 0.0mA < I

VSEN Pin Bias Current I

Minimum Duty Cycle D

Maximum Duty Cycle D

VOUT Pin Input Impedance I

Undervoltage Shut-Down Level V

Overvoltage Protection V

VSEN

max

VOUT

UVL

OVP1

By design - 80 - nA

min

VOUT = 5V - 134 - kΩ

Fraction of the set point; ~2μs noise filter 70 75 80 %

Fraction of the set point; ~2μs noise filter 110 115 - %

< 5.0A; 5.0V < V

VOUT1

GATE DRIVERS

Upper Drive Pull-Up Resistance R

Upper Drive Pull-Down Resistance R

Lower Drive Pull-Up Resistance R

Lower Drive Pull-Down Resistance R

2UGPUPVCC

2UGPDNVCC

2LGPUPVCC

2LGPDNVCC

= 5V - 4 8 Ω

= 5V - 2.3 4 Ω

= 5V - 4 8 Ω

= 5V - 1.1 3 Ω

POWER GOOD AND CONTROL FUNCTIONS

Power Good Lower Threshold V

Power Good Higher Threshold V

PGOODx Leakage Current I

PGOODx Voltage Low V

PG-

PG+

PGLKGVPULLUP

PGOODIPGOOD

Fraction of the set point; ~3μs noise filter 84 89 92 %

Fraction of the set point; ~3μs noise filter. 110 115 120 %

= 5.5V - - 1 μA

= -4mA - 0.5 1 V

ISEN Sourcing Current By design - - 260 μA

OCSET Sourcing Current Range 2-20μA

EN - Low (Off) --0.8V

EN - High (On) 2.0 - - V

Continuous-Conduction-Mode(CCM)

VOUTX pulled low - - 0.1 V

Enforced (HYS Operation Inhibited)

Automatic CCM/HYS Operation

VOUTX connected to the output 0.9 - - V

Enabled

DDR - Low (Off) --0.8V

DDR - High (On) 3--V

DDR REF Output Voltage V

DDR REF Output Current I

DDREF

DDREF

DDR = 1, I

DDR = 1. Guaranteed by design. - 10 12 mΑ

= 0...10mA 0.99*

REF

< 24.0V -2.0 - +2.0 %

BATT

-4-%

-87-%

V

OC2

V

OC2

1.01*

V

OC2

V

4

FN9094.4

December 21, 2006

Typical Operation Performance

ISL6227

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.01 0.1 1 10

LOAD CURRENT (A)

EFF@ 5V

EFF@ 12V

EFF@ 19.5V

EFF@ 5V, PWM

EFF@ 12V, PWM

EFF@ 19.5V, PWM

FIGURE 1. EFFICIENCY OF CHANNEL 1, 2.5V ,

HYS/PWM MODE

2.54

2.53

2.52

2.51

Vout @ 5V

Vout @ 12V

Vout @ 19.5V

Vout @ 5V, PWM

Vout @ 12V, PWM

Vout @ 19.5V, PWM

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.01 0.1 1 10

LOAD CURRENT (A)

EFF@ 5V

EFF@ 12V

EFF@ 19.5V

EFF@ 5V, PWM

EFF@ 12V, PWM

EFF@ 19.5V, PWM

FIGURE 2. EFFICIENCY OF CHANNEL 2, 1.8V,

HYS/PWM MODE

1.83

1.82

1.81

Vout @ 5V

Vout @ 12V

Vout @ 19.5V

Vout @ 5V, PWM

Vout @ 12V, PWM

Vout @ 19.5V, PWM

2.5

2.49

OUTPUT VOLTAGE (V)

2.48

2.47

012345

LOAD CURRENT (A)

1.8

OUTPUT VOLTAGE (V)

1.79

1.78

012345

LOAD CURRENT (A)

FIGURE 3. OUTPUT VOLTAGE OF CHANNEL 1 vs LOAD FIGURE 4. OUTPUT VOLTAGE OF CHANNEL 2 vs LOAD

308

306

304

302

300

298

296

FREQUENCY (KHz)

294

292

290

288

286

-20 0 20 40 60 80 100

75% Quantile

Frequency Mean

25% Quantile

TEMPERATURE (°C)

120

0.9025

0.902

0.9015

0.901

0.9005

0.9

VREF (V)

0.8995

0.899

0.8985

0.898

0.8975

-20 0 20 40 60 80 100 120

75% Quantile

Vref Mean

25% Quantile

TEMPERATURE (°C)

FIGURE 5. SWITCHING FREQUENCY OVER TEMPERATURE FIGURE 6. REFERENCE VOLTAGE ACCURACY OVER

TEMPERATURE

5

FN9094.4

December 21, 2006

Typical Operation Performance (Continued)

ISL6227

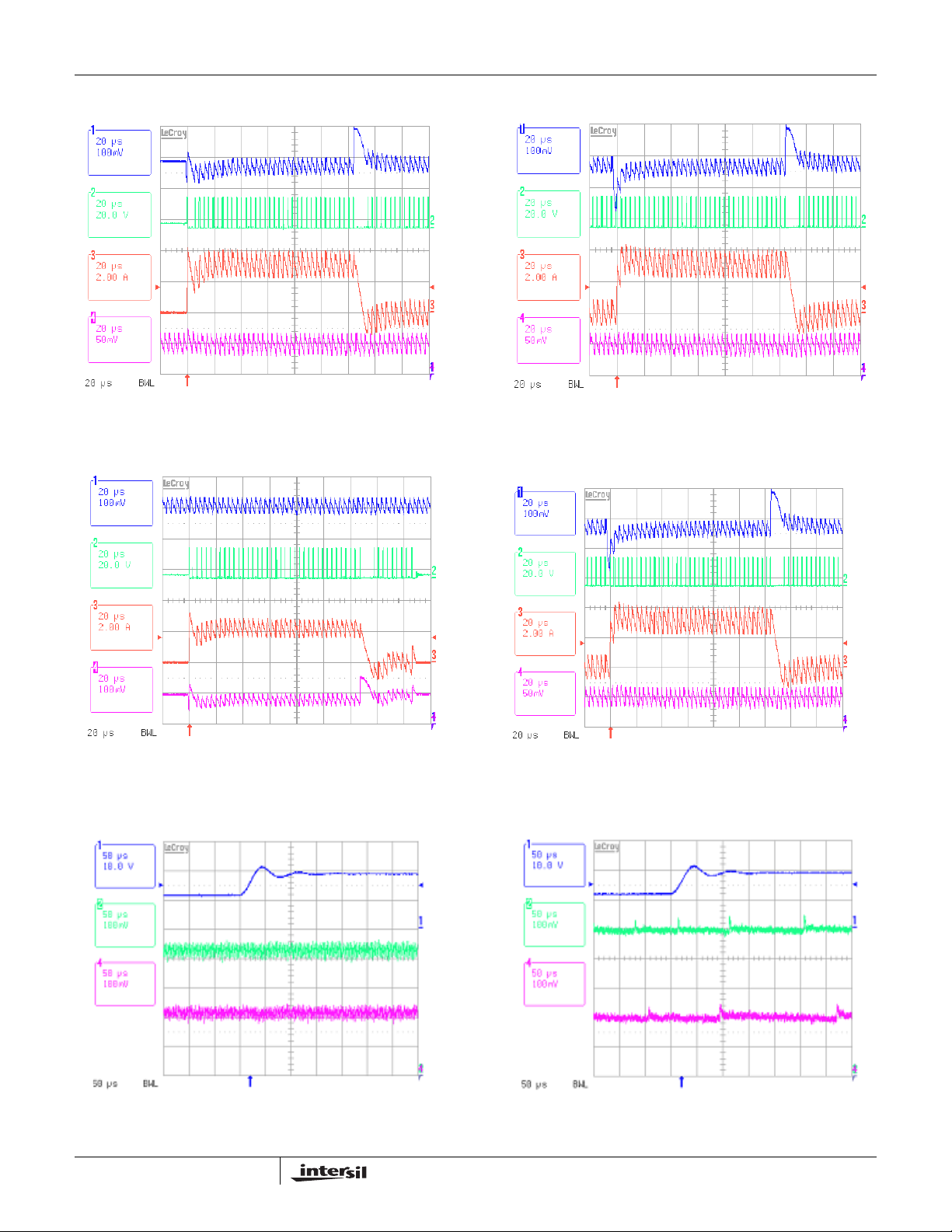

Vo1

Vphase1

Ilo1

Vo2

FIGURE 7. LOAD TRANSIENT (0 - 3A AT CHANNEL 1)

(DIODE EMULATION MODE)

Vo1

Vphase2

Vo1

Vphase1

Ilo1

Vo2

FIGURE 8. LOAD TRANSIENT (0 - 3A AT CHANNEL 1)

(FORCED PWM MODE)

Vo1

Vphase2

Ilo2

Vo2

FIGURE 9. LOAD TRANSIENT (0 - 2A AT CHANNEL 2)

(DIODE EMULATION MODE)

Vin1

Vo1

Vo2

Ilo2

Vo2

FIGURE 10. LOAD TRANSIENT (0 - 3A AT CHANNEL 2)

(FORCED PWM MODE)

Vin1

Vo1

Vo2

FIGURE 11. INPUT STEP-UP TRANSIENT AT PWM MODE FIGURE 12. INPUT STEP-UP TRANSIENT AT HYS MODE

6

FN9094.4

December 21, 2006

Typical Operation Performance (Continued)

ISL6227

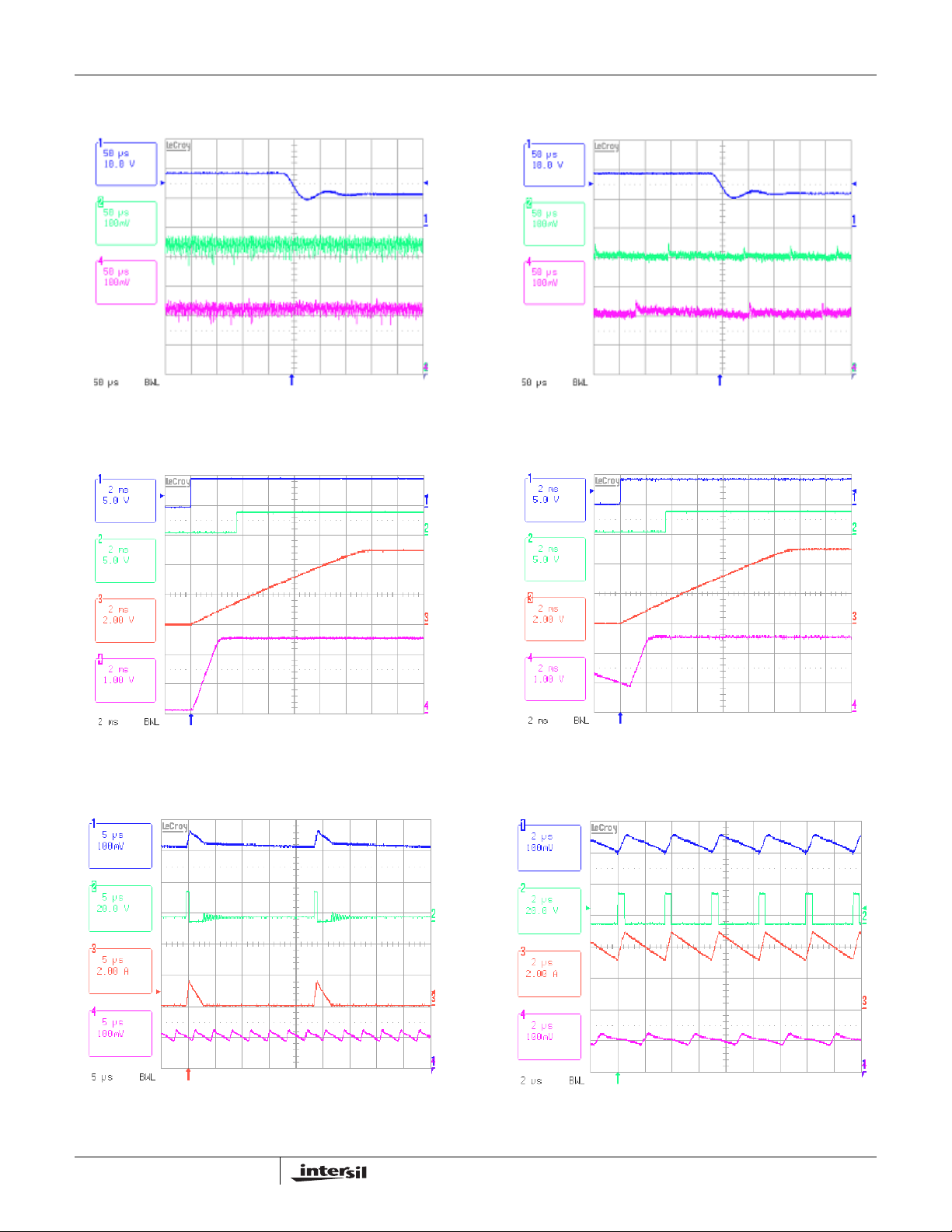

Vin1

Vo1

Vo2

FIGURE 13. INPUT STEP-DOWN TRANSIENT AT PWM MODE FIGURE 14. INPUT STEP-DOWN TRANSIENT AT HYS MODE

EN1

PG1

Vin1

Vo1

Vo2

EN1

PG1

SOFT1

Vo1

FIGURE 15. SOFT-START INTERVAL AT ZERO INITIAL

VOLTAGE OF VO

Vo1

Vphase1

Ilo1

Vo2

SOFT1

Vo1

FIGURE 16. SOFT-ST ART INTERVAL WITH NON-ZERO INITIAL

VOLTAGE OF VO

Vo1

Vphase1

Ilo1

Vo2

FIGURE 17. OPERATION A T LIGHT LOAD OF 100mA,

CHANNEL 1

7

FIGURE 18. OPERATION AT HEAVY LOAD OF 4A,

CHANNEL 1

December 21, 2006

FN9094.4

Typical Operation Performance (Continued)

ISL6227

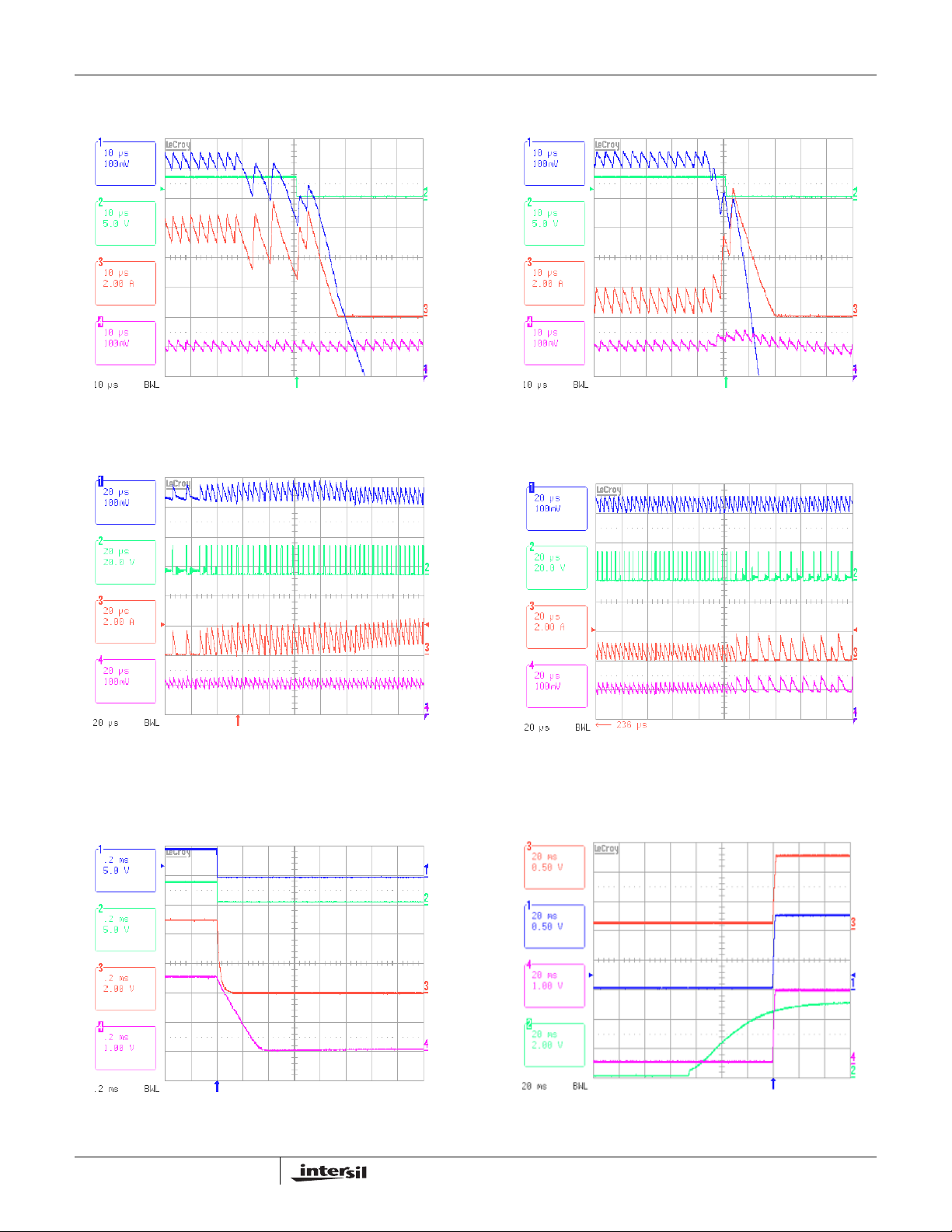

Vo1

PG1

Ilo1

Vo2

FIGURE 19. OVERCURRENT PROTECTION AT CHANNEL 1 FIGURE 20. SHORT-CIRCUIT PROTECTION AT CHANNEL 1

Vo1

Vphase1

Vo1

PG1

Ilo1

Vo2

Vo1

Vphase2

Ilo1

Vo2

FIGURE 21. MODE TRANSITION OF HYS

EN1

PG1

SOFT1

Vo1

→ _PWM

Ilo2

Vo2

FIGURE 22. MODE TRANSITION OF PWM

VTT

OCSET

VDDQ

VCC

→ HYS

FIGURE 23. SOFT SHUTDOWN INTERVAL

8

FIGURE 24. V

POWER-UP IN DDR MODE

CC

FN9094.4

December 21, 2006

Typical Operation Performance (Continued)

ISL6227

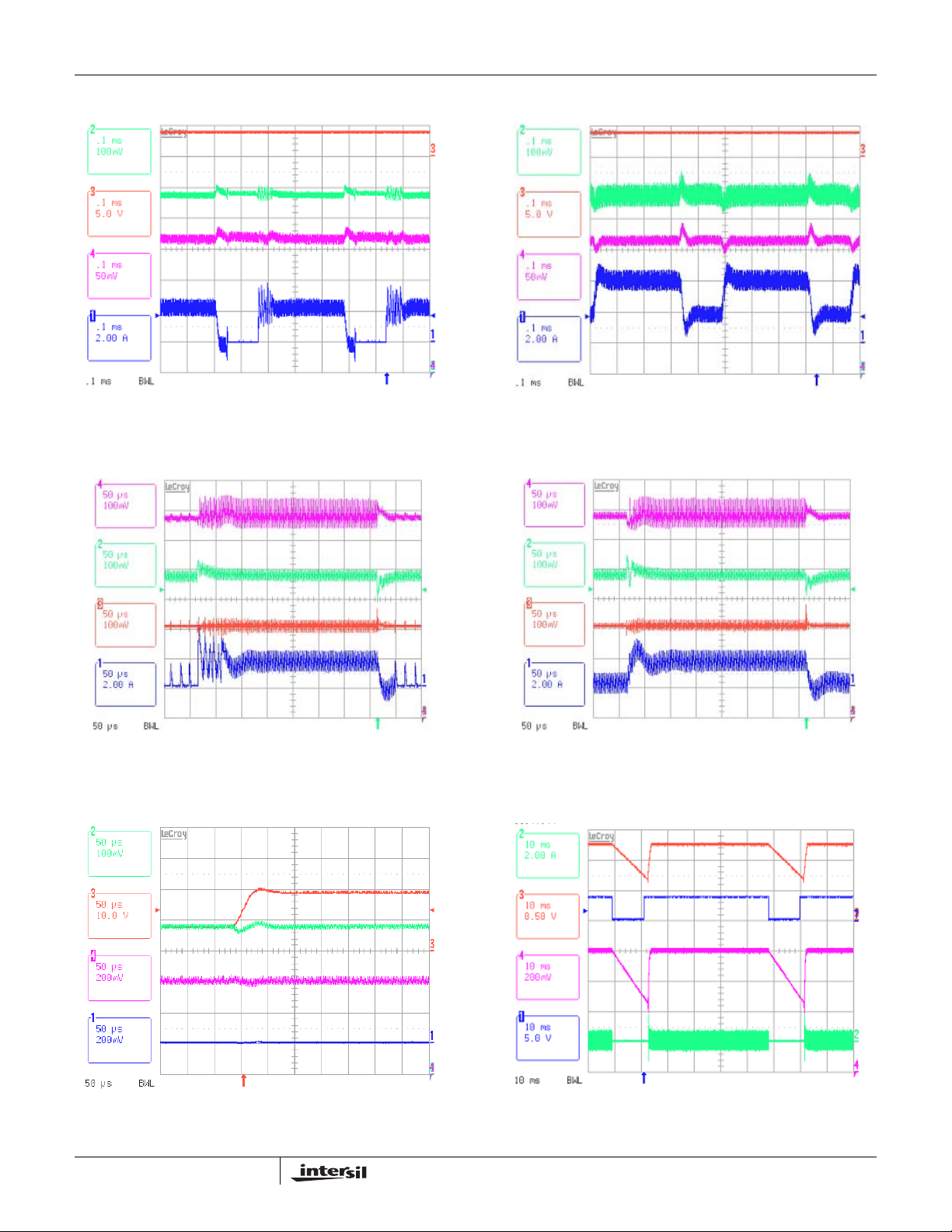

VDDQ

PGOOD1

VTT

IL1

FIGURE 25. VIN = 19V, VDDQ 3A STEP LOAD, VTT 0A LOAD FIGURE 26. VIN = 19V, VDDQ 3A STEP LOAD, VTT 3A LOAD

VDDQ

VTT

VDDQ

PGOOD1

VTT

IL1

VDDQ

VTT

OCSET2

IL2

FIGURE 27. VIN = 19V , LOAD STEP ON VTT,

VDDQ HYS MODE, 0.14A

VDDQ

Vin

VTT

OCSET2

OCSET2

IL2

FIGURE 28. VIN = 19V, LOAD STEP ON VTT,

VDDQ PWM MODE, 0.14A

VTT

EN1

VDDQ

IL1

FIGURE 29. INPUT LINE TRANSIENT IN DDR MODE FIGURE 30. VTT FOLLOWS VDDQ, ENABLE 2 IS HIGH

9

FN9094.4

December 21, 2006

ISL6227

Functional Pin Description

GND

Signal ground for the IC.

LGATE1, LGATE2

These are the outputs of the lower MOSFET drivers.

PGND1, PGND2

These pins provide the return connection for lower gate

drivers, and are connected to sources of the lower

MOSFETs of their respective converters.

PHASE1, PHASE2

The PHASE1 and PHASE2 points are the junction points of

the upper MOSFET sources, output filter inductors, and

lower MOSFET drains. Connect these pins to the respective

converter’s upper MOSFET source.

UGATE1, UGATE2

These pins provide the gate drive for the upper MOSFETs.

BOOT1, BOOT2

These pins power the upper MOSFET drivers of the PWM

converter. Connect this pin to the junction of the bootstrap

capacitor with the cathode of the bootstrap diode. The anode

of the bootstrap diode is connected to the VCC voltage.

ISEN1, ISEN2

These pins are used to monitor the voltage drop across the

lower MOSFET for current feedback and Overcurrent

protection. For precise current detection these inputs can be

connected to the optional current sense resistors placed in

series with the source of the lower MOSFETs.

EN1, EN2

These pins enable operation of the respective converter

when high. When both pins are low, the chip is disabled and

only low leakage current is taken from VCC and VIN. EN1

and EN2 can be used independently to enable either

channel 1 or channel 2.

VOUT1, VOUT2

These pins, when connected to the converter’s respective

outputs, set the converter operating in a mixed hysteretic

mode or PWM mode, depending on the load conditions. It

also provides the voltage to the chip to clamp the PWM error

amplifier in hysteretic mode to achieve smooth HYS/PWM

transition. When connected to ground, these pins command

forced continuous conduction mode (PWM) at all load levels.

VSEN1, VSEN2

These pins are connected to the resistive dividers that set

the desired output voltage. The PGOOD, UVP, and OVP

circuits use this signal to report output voltage status.

OCSET1

This pin is a buffered 0.9V internal reference voltage. A

resistor from this pin to ground sets the overcurrent

threshold for the first controller.

SOFT1, SOFT2

These pins provide soft-start function for their respective

controllers. When the chip is enabled, the regulated 4.5µA

pull-up current source charges the capacitor connected from

the pin to ground. The output voltage of the converter follows

the ramping voltage on the SOFT pin in the soft-start

process with the SOFT pin voltage as reference. When the

SOFT pin voltage is higher than 0.9V, the error amplifier will

use the internal 0.9V reference to regulate output voltage.

In the event of undervoltage and overcurrent shutdown, the

soft-start pin is pulled down though a 2k resistor to ground to

discharge the soft-start capacitor.

DDR

When the DDR pin is low, the chip can be used as a dual

switcher controller. The output voltage of the two channels

can be programmed independently by VSENx pin resistor

dividers. The PWM signals of channel 1 and channel 2 will

be synchronized 180 degrees out-of-phase. When the DDR

pin is high, the chip transforms into a complete DDR memory

solution. The OCSET2 pin becomes an input through a

resistor divider tracking to VDDQ/2. The PG2/REF pin

becomes the output of the VDDQ/2 buffered voltage. The

VDDQ/2 voltage is also used as the reference to the error

amplifier by the second channel. The channel phase-shift

synchronization is determined by the VIN pin when DDR = 1

as described in VIN below.

VIN

This pin has multiple functions. When connected to battery

voltage, it provides battery voltage to the oscillator as a feedforward for the rejection of input voltage variation. The ramp

of the PWM comparator is proportional to the voltage on this

pin (see Table 1 and Table 2 for details). While the DDR pin

is high in the DDR application, and when the VIN pin voltage

is greater than 4.2 volt when connecting to a battery, it

commands 90°

the second channel lagging the first channel, to reduce

inter-channel interference. When the pin voltage is less than

4.2V, this pin commands in-phase channel synchronizatio n.

out-of-phase channel synchronization, with

PG1

PGOOD1 is an open drain output used to indicate the status

of the output voltage. This pin is pulled low when the first

channel output is out of -11% to +15% of the set value.

10

FN9094.4

December 21, 2006

ISL6227

PG2/REF

This pin has a double function, depending on the mode of

operation.

When the chip is used as a dual channel PWM controller

(DDR = 0), the pin provides an open drain PGOOD2 function

for the second channel the same way as PG1. The pin is

pulled low when the second channel output is out of

-11% to +15% of the set value.

In DDR mode (DDR = 1), this pin is the output of the buffer

amplifier that takes VDDQ/2 voltage applied to OCSET2 pin

from the resister divider. It can source a typical 10mA

current.

OCSET2

In a dual channel application with DDR = 0, a resistor from

this pin to ground sets the overcurrent threshold for the

second channel controller. Its voltage is the buffered internal

0.9V reference.

In the DDR application with DDR = 1, this pin connects to the

center point of a resistor divider tracking the VDDQ/2. This

voltage is then buffered by an amplifier voltage follower and

sent to the PG2/REF pin. It sets the reference voltage of

channel 2 for its regulation.

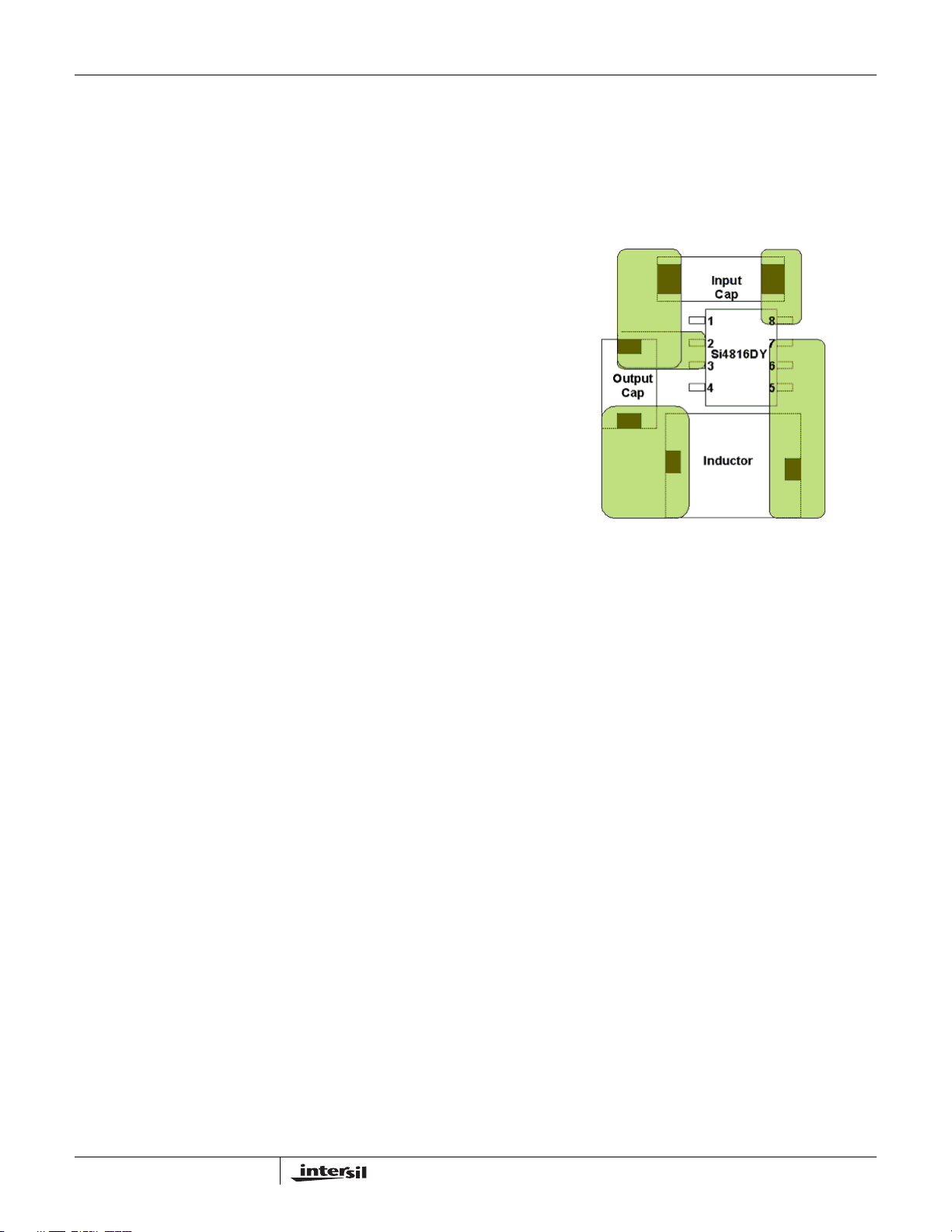

Typical Application

Figures 31 and 32 show the application circuits of a dual

channel DC/DC converter for a notebook PC.

The power supply in Figure 31 provides +2.5V and +1.8V

voltages for memory and the graphics interface chipset from

a +5.0-24VDC battery voltage.

Figure 32 illustrates the application circuit for a DDR memory

power solution. The power supply shown in Figure 32

generates +2.5V VDDQ voltage from a battery. The +1.25V

VTT termination voltage tracks VDDQ/2 and is derived from

+2.5V VDDQ. To complete the DDR memory power

requirements, the +1.25V reference voltage is provided

through the PG2 pin.

VCC

This pin powers the controller.

11

FN9094.4

December 21, 2006

V1 (2.5V)

Rfb11

17.8k

Cfb1

µ

0.01 F

Rfb12

Rfb12

10k

10k

Co11

220 F

220 F

ISL6227

V

IN

Cdc

Cdc

4.7µF

D1

BAT54W

Cin1

Cin1

10 F

10 F

µ

Lo1

4.7µH

Co12

F

4.7

µ

µ

Csoft1

Csoft1

0.01 F

0.01 F

Cb

Cbt1

0.15µF

Q1

Q1

FDS6912A

FDS6912A

µ

Rbt1

0Ω

Rs1

2.0k

Rset1

100k

VIN

GND

BOOT1

UGATE1

PHASE1

ISEN1

LGATE1

PGND1

VOUT1

VSEN1

PG1

EN1

SOFT1

OCSET1

VCC

U1

U1

ISL6227

DDR

BOOT2

UGATE2

PHASE2

ISEN2

LGATE2

PGND2

VOUT2

VSEN2

PG2

EN2

SOFT2

OCSET2

Rset2

100k

Rbt2

0Ω

Rs2

2.0k

D2

BAT54W

Cbt2

Cbt2

0.15µF

Q2

Q2

FDS6912A

FDS6912A

Csoft2

0.01µF

VCC (5V)

VCC (5V)

Cin2

Cin2

10µF

Lo2

Lo2

4.7µH

Co21

Co21

220 µF

V2 (1.8V)

V

Co22

µF

4.7

Rfb21

10k

Rfb22

10k

Cfb2

µF

0.01

FIGURE 31. TYPICAL APPLICATION CIRCUIT AS DUAL SWITCHER, VOUT1 = 2.5V, VOUT = 1.8V

VDDQ (2.5V)

VDDQ (2.5V)

Cfb1

Cfb1

0.01 F

0.01µ F

Rfb1

Rfb1

17.8k

Rfb12

Rfb12

10K

Co13

Co13

220 F

220 F

Vin

Vin

Cdc

Cdc

µ

4.7 F

4.7 F

D1

BAT54W

Cin1

Cin1

10 F

10 F

µ

Lo1

Lo1

4.6 H

4.6µ H

Co11

Co11

4.7 F

4.7 F

µ

µ

Cbt1

0.15µF

Q1

Q1

FDS6912A

FDS6912A

Csoft1

0.01µF

Rbt1

0Ω

Rs1

Rs1

2.0k

Rset1

100k

GND

BOOT1

UGATE1

PHASE1

ISEN1

LGATE1

PGND1

VOUT1

VSEN1

PG1

EN1

SOFT1

OCSET1

VCC

VCC

UGATE2

PHASE2

LGATE2

LGATE2

PG2_REF

PG2_REF

U1

U1

ISL6227

VIN

VIN

DDR

DDR

BOOT2

ISEN2

PGND2

PGND2

VSEN2

VSEN2

VOUT2

VOUT2

EN2

EN2

SOFT2

SOFT2

Rs2

1.0k

OCSET2_VDDQ/2

Rbt2

0Ω

D2

BAT54W

Cbt2

0.15µF

FDS6912A

Csoft2 (N/U)

0.01µF

Q2

Q2

VDDQ

Lo2

1.5µH

1.5

Co21

220µF

Vref

Cref

4.7µF

Cf

Cf

0.1

0.1µF

VCC (5V)

VCC (5V)

Cin2

4.7µF

(VDDQ/2)

Rd1

10k

VDDQ/2

Rd2

10k

VTT (1.25V)

Co22

4.7µF

VDDQ

FIGURE 32. TYPICAL APPLICATION AS DDR MEMORY POWER SUPPLY, VDDQ = 2.5V, VTT = 1.25V

12

FN9094.4

December 21, 2006

Block Diagram

13

BOOT1

UGATE1

PHASE1

PGND1

LGATE1

VCC

MODE CHANGE COMP 1

HYSTERETIC COMPARATOR 1

+

140Ω

300kΩ

0.9V

REF

CURRENT

SAMPLE

VSEN1

SOFT1

ISEN1

OCSET1

ADAPTIVE DEAD-TIME

DIODE EMULATION

V/I SAMPLE TIMING

PWM/HYS TRANSITION

SAME STATE FOR

8 CLOCK CYCLES

REQUIRED TO CHANGE

PWM OR HYS MODE

1MΩ

500kΩ

1.25pF

ERROR AMP 1

0.9V REFERENCE

+

ΔV

HYS

CURRENT

SAMPLE

=15mV

15pF

4.4kΩ

PG1

OV UV

PGOOD

VOLTS/SEC

CLAMP

VOUT1 VOUT2

PWM1

DUTY CYCLE RAMP GENERATOR

PWM CHANNEL PHASE CONTROL

DDR EN1 EN2 VIN

011

111

VCC

GNDEN1 EN2 REF/PG2

POR

ENABLE

BIAS SUPPLIES

REFERENCE

FAULT LATCH

SOFT START

DDR MODE

CONTROL

OC1 DDR

OC2

CH1 CH2

0 ⇔ 24.0V

4.2 < VIN < 24.0V

180º

90º

VIN < 4.2

BOOT2

UGATE2

DDR=0

+

0.9V

REF

140Ω

DDR=0

PHASE2

PGND2

LGATE2

VCC

ISL6227

VSEN2

SOFT2

DDR=1

ISEN2

OCSET2

DDR=1

DDR=1

DDR=0

OV UV

PGOOD

VOLTS/SEC

PWM2

CLAMP

ADAPTIVE DEAD-TIME

DIODE EMULATION

V/I SAMPLE TIMING

PWM/HYS TRANSITION

SAME STATE FOR

8 CLOCK CYCLES

REQUIRED TO CHANGE

PWM OR HYS MODE

ΔV

=15mV

HYS

15pF

4.4kΩ

1MΩ

1.25pF

ERROR AMP 2

MODE CHANGE COMP 2

HYSTERETIC COMPARATOR 2

500kΩ

300kΩ

(200kΩ, DDR=1)

φ

CURRENT

0º

CURRENT

SAMPLE

0.9V REFERENCE

SAMPLE

+

OC2OC1

December 21, 2006

1/2.9

OCSET1

FN9094.4

1/33.1

ISEN1

SAME STATE FOR

8 CLOCK CYCLES

REQUIRED TO LATCH

OVERCURRENT FAULT

VIN

DDR

VCC

SAME STATE FOR

8 CLOCK CYCLES

REQUIRED TO LATCH

OVERCURRENT FAULT

1/33.1

ISEN2

DDR VREF

BUFFER AMP

1/2.9

OCSET2

DDR VTT

REFERENCE

ISL6227

Theory of Operation

Operation

The ISL6227 is a dual channel PWM controller intended for

use in power supplies for graphic chipsets, SDRAM, DDR

DRAM, or other low voltage power applications in modern

notebook and sub-notebook PCs. The IC integrates two

control circuits for two synchronous buck converters. The

output voltage of each controller can be set in the range of

0.9V to 5.5V by an external resistive divider.

The synchronous buck converters can operate from either

an unregulated DC source, such as a notebook battery, with

a voltage ranging from 5.0V to 24V, or from a regulated

system rail of 3.3V or 5V. In either operational mode the

controller is biased from the +5V source.

The controllers operate in the current mode with input

voltage feed-forward which simplifies feedback loop

compensation and rejects input voltage variation. An

integrated feedback loop compensation dramatically

reduces the number of external components.

Depending on the load level, converters can operate either

in a fixed 300kHz frequency mode or in a HYS mode.

Switch-over to the HYS mode of operation at light loads

improves converter efficiency and prolongs battery life. The

HYS mode of operation can be inhibited independently for

each channel if a variable frequency operation is not

desired.

The ISL6227 has a special means to rearrange its internal

architecture into a complete DDR solution. When the DDR

pin is set high, the second channel can provide the capability

to track the output voltage of the first channel. The buffered

reference voltage required by DDR memory chips is also

provided.

Initialization

The ISL6227 initializes if at least one of the enable pins is

set high. The Power-On Reset (POR) function continually

monitors the bias supply voltage on the VCC pin, and

initiates soft-start operation when EN1 or EN2 is high after

the input supply voltage exceeds 4.45V. Should this voltage

drop lower than 4.14V, the POR disables the chip.

Soft-Start

When soft-start is initiated, the voltage on the SOFT pin of

the enabled channel starts to ramp up gradually with the

internal 4.5

output voltage follows the soft-start voltage with the

converter operating at 300kHz PWM switching frequency.

μA current charging the soft-start capacitor. The

When the SOFT pin voltage reaches 0.9V, the output volt age

comes into regulation, (see block diagram). When the SOFT

voltage reaches 1.5V, the power good (PGOOD) and the

mode control is enabled. The soft-start process is depicted in

Figure 33.

1

2

3

4

Ch1 5.0V

Ch3 1.0V

EN

1.5V

0.9V

PGOOD

SOF T

VOUT

Ch2 2.0V

Ch4 5.0V

FIGURE 33. START-UP

M1.00ms

Even though the soft-start pin voltage continues to rise after

reaching 1.5V, this voltage does not affect the output

voltage. During the soft-start, the converter always operates

in continuous conduction mode independent of the load level

or VOUT pin connection.

The soft-start time (the time from the moment when EN

becomes high to the moment when PGOOD is reported) is

determined by the following equation:

T

SOFT

----------------------------------

=

4.5μ A

(EQ. 1)

1.5V Csoft×

The time it takes the output voltage to come into regulation

can be obtained from the following equation.

0.6 T

T

RISE

×=

SOFT

(EQ. 2)

During soft-start stage before the PGOOD pin is ready, the

undervoltage protection is prohibited. The overvoltage and

overcurrent protection functions are enabled.

If the output capacitor has residue voltage before startup,

both lower and upper MOSFETs are in off-state until the softstart capacitor charges equal the VSEN pin voltage. This will

ensure the output voltage starts from its existing voltage

level.

14

FN9094.4

December 21, 2006

ISL6227

Output Voltage Program

The output voltage of either channel is set by a resistive divider

from t h e o u t put to ground. The center point of the divider is

connected to the VSEN pin as shown in Figure 34. The

output voltage value is determined by the following equation.

0.9V R1 R2+()•

----------------------------------------------

V

=

O

R2

(EQ. 3)

where 0.9V is the value of the internal reference. The VSEN

pin voltage is also used by the controller for the power good

function and to detect undervoltage and overvoltage

conditions.

V

IN

Q1

UGATE

LGATE

ISL6227

FIGURE 34. OUTPUT VOLTAGE PROGRAM

OCSET

ISEN

VOUT

VSEN

Q2

R

CS

L1

C1

R

OC

V

O

C

Z

R1

R2

Operation Mode Control

VOUTx pin programs the two channels of ISL6227 in two

different operational modes:

1. If VOUTx is connected to ground, the channel will be put

into a fixed switching frequency of 300kHz CCM, also

known as forced PWM mode regardless of load

conditions.

2. If the VOUTx is connected to the output voltage, the

channel will operate in either fixed 300kHz PWM mode or

HYS mode, depending on the load conditions. It operates

in the PWM mode when the load current exceeds the

critical discontinuous conduction value, otherwise it will

operate in a HYS mode, as shown in the following table.

INDUCTOR

VOUT PIN

GND Any value Forced PWM

Connects to output voltage ≤ I

Connects to output voltage >I

CURRENT

HYS

HYS1

OPERATION

MODE

HYS

PWM

The two channels can be programmed to operate in different

modes depending on the VOUTx connection and the load

current. Once both channels operate in the PWM mode,

however, they will be synchronized to the 300kHz switching

clock. The 180° phase shift reduces the noise couplings

between the two channels and reduces the input current ripple.

The critical discontinuous conduction current value for the

PWM to HYS mode switch-over can be calculated by the

following expression.

VINVO–()VO•

I

----------------------------------------------------

=

HYS

2F

SWLOVIN

•••

The HYS mode to PWM switch-over current I

HYS1

(EQ. 4)

is

determined by the activation time of the HYS mode

controller. It is affected by the ESR, the inductor value, the

input and output voltage.

The HYS mode control can improve converter efficiency with

reduced switching frequency. The efficiency is further

improved by the diode emulat i o n sch eme in discontinuous

conduction mode. The diode emulation scheme does not

allow the inductor sink current from the output capacitor,

thereby reducing the circulating energy. It is achieved by

sensing the free-wheeling current going through the

synchronous MOSFET through Phase node voltage polarity

change after the upper MOSFET is turned off. Before the

current reverses direction, the lower MOSFET gate pulses

are terminated.

The PWM-HYS and HYS-PWM switch-over is provided

automatically by the mode control circuit, which constantly

monitors the inductor current through phase voltage polarity,

and alters the way the gate driver pulse signal is generated.

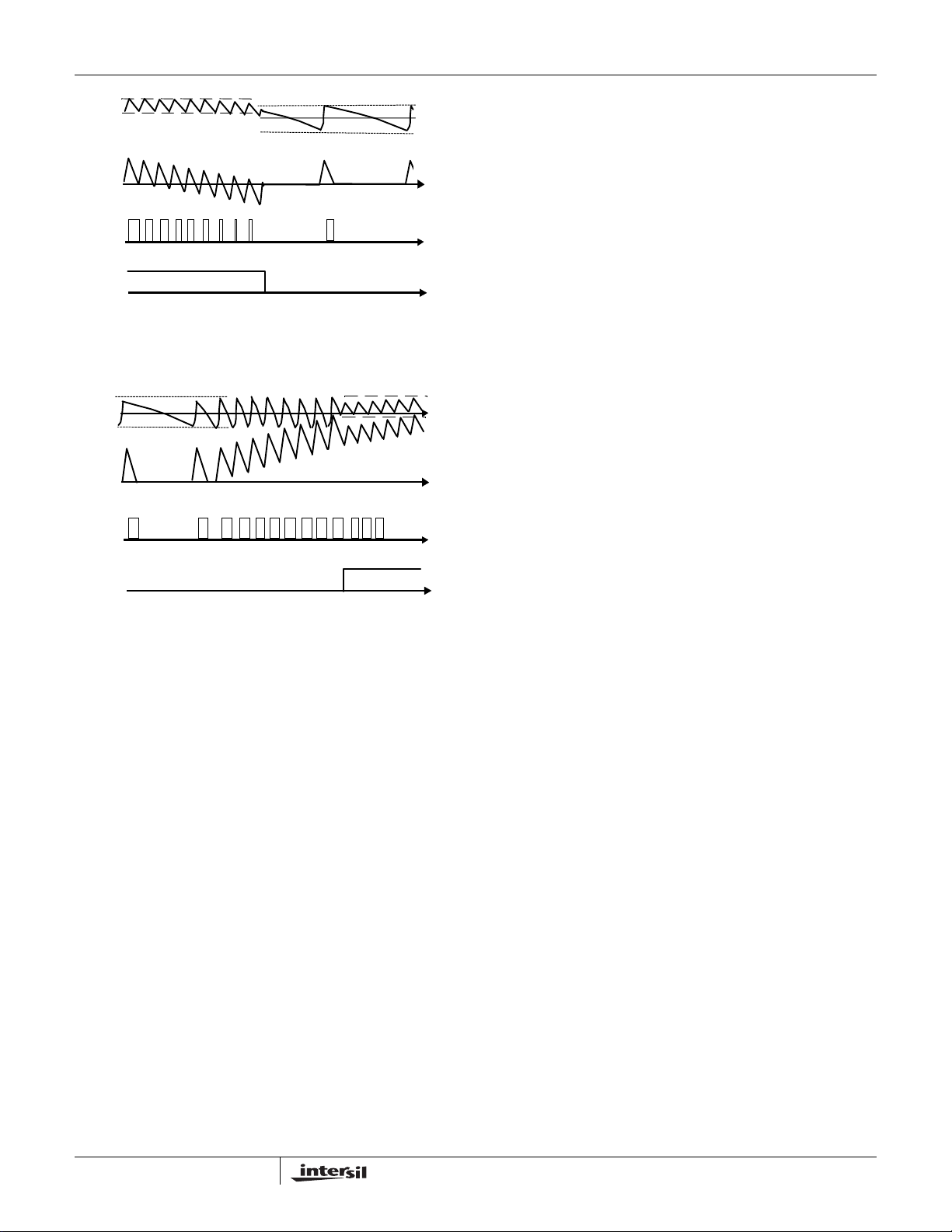

Mode Transition

For a buck regulator, if the load current is higher than critical

value I

in the free-wheeling period is always negative, and vice

versa. The mode control circuit monitors the phase node

voltage in the off-period. The polarity of this voltage is used

as the criteria for whether the load current is greater than the

critical value, and thus determines whether the converter will

operate in PWM or HYS mode.

To prevent chatter between operating modes, the circuit

looks for eight sequentially matching polarity signals before it

decides to perform a mode change. The algorithm is true for

both CCM-HYS and HYS-CCM transitions.

In the HYS mode, the PWM comparator and the error

amplifier, that provided control in the CCM mode, are put in a

clamped stage and the hysteretic comparator is activated. A

change is also made to the gate logic. The synchronous

MOSFET is controlled in diode emulation fashion, hence the

current in the synchronous MOSFET will be kept in one

direction only. Figures 35 and 36 illustrate the mode change

by counting eight switching cycles.

, the voltage drop on the synchronous MOSFET

HYS1

15

FN9094.4

December 21, 2006

ISL6227

VOUT

IIND

PHASE

COMP

MODE

OF

OPERA T ION

1 2 3 4 5 6 7 8

PWM

FIGURE 35. CCM—HYSTERETIC TRANSITION

Hysteretic

t

t

t

t

VOUT

IIND

PHASE

COMP

MODE

OF

OPERA T ION

FIGURE 36. HYSTERETIC—CCM TRANSITION

1 2 3 4 5 6 7 8

Hysteretic

PWM

If load current slowly increases or decreases, mode

transition will occur naturally, as described above; however,

if there is an instantaneous load current increase resulting in

a large output voltage drop before the hysteretic mode

controller responds, a comparator with threshold of 20mV

below the reference voltage will be tripped, and the chip will

jump into the forced PWM mode immediately. The PWM

controller will process the load transient smoothly.

Once the PWM controller is engaged, 8 consecutive

switching cycles of negative inductor current are required to

transition back to the hysteretic mode. In this way, chattering

between the two modes is prevented. Current sinking during

the 8 PWM switching cycle dumps energy to input,

smoothing output voltage load step-down.

As a side effect to this design, the comparator may be

triggered consistently if the ESR of the capacitor is so big

that the output ripple voltage exceeds the 20mV window,

resulting in a pure PWM pulse.

The PWM error amplifier is put in clamped voltage during the

hysteretic mode. The output voltage through the VOUT pin

and the input voltage through the VIN pin are used to

determine the error amplifier output voltage and the duty

cycle. The error amplifier stays in an armed state while

t

t

t

t

waiting for the transition to occur. The transition decision

point is aligned with the PWM clock. When the need for

transition is detected, there is a 500ns delay between the

first/last pulse of the PWM controller from the last/first pulse

of the hysteretic mode controller.

Current Sensing

The current on the lower MOSFET is sensed by measuring

its voltage drop within its on-time. In order to activate the

current sampling circuitry, two conditions need to be met.

(1) the Lgate is high and (2) the phase pin sees a negative

voltage for regular buck operation, which means the current

is freewheeling through lower MOSFET. For the second

channel of the DDR application, the phase pin voltage needs

to be higher than 0.1V to activate the current sensing circuit

for bidirectional current sensing. The current sampling

finishes at about 400ns after the lower MOSFET has turned

on. This current information is held for current mode control

and overcurrent protection. The current sensing pin can

source up to 260µA. The current sense resistor and OCSET

resistor can be adjusted simultaneously for the same

overcurrent protection level, however, the current sensing

gain will be changed only according to the current sense

resistor value, which will affect the current feedback loop

gain. The middle point of the Isen current can be at 75µA,

but it can be tuned up and down to fit application needs.

If another channel is switching at the moment the current

sample is finishing, it could cause current sensing error and

phase voltage jitter. In the design stage, the duty cycles and

synchronization have to be analyzed for all the input voltage

and load conditions to reduce the chance of current sensing

error. The relationship between the sampled current and

MOSFET current is given by:

I

SENRCS

140+()r

= (EQ. 5)

DS ON()ID

Which means the current sensing pin will source current to

make the voltage drop on the MOSFET equal to the voltage

generated on the sensing resistor, plus the internal resistor,

along the ISEN pin current flowing path.

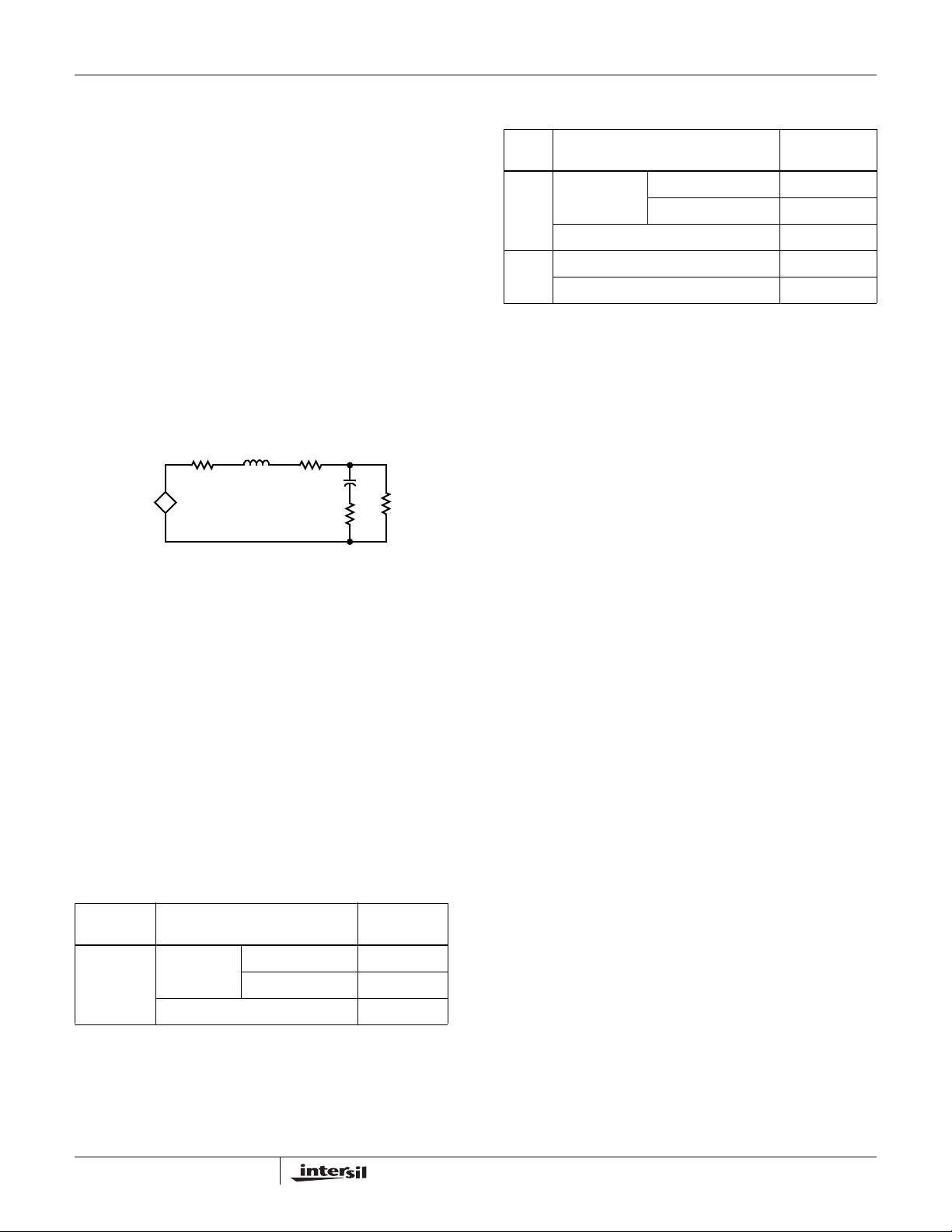

Feedback Loop Compensation

Both channel PWM controllers have internally compensated

error amplifiers. To make internal compensation possible

several design measures were taken.

• The ramp signal applied to the PWM comparator has been

made proportional to the input voltage by the VIN pin. This

keeps the product of the modulator gain and the input

voltage constant even when the input voltage varies.

• The load current proportional signal is derived from the

voltage drop across the lower MOSFET during the PWM

off time interval, and is subtracted from the error amplifier

output signal before the PWM comparator input. This

effectively creates an internal current control loop.

16

FN9094.4

December 21, 2006

ISL6227

The resistor connected to the ISEN pin sets the gain in the

current sensing. The following expression estimates the

required value of the current sense resistor, depending on

the maximum continuous load current, and the value of the

MOSFETs r

, assuming the ISEN pin sources 75µA

DS(ON)

current.

I

•

MAXrDS ON()

------------------------------------------

R

= 140Ω–

CS

75μ A

(EQ. 6)

Because the current sensing circuit is a sample-and-hold

type, the information obtained at the last moment of the

sampling is used. This current sensing circuit samples the

inductor current very close to its peak value. The current

feedback essentially injects a resistor R

in series with the

i

original LC filter as shown in Figure 37, where the sampleand-hold effect of the current loop has been ignored. Vc and

Vo are small signal components extracted from its DC

operation points.

Ri Lo DCR

+

Ro Vo

-

Gm*Vc

Co

+

-

ESR

TABLE 2. PWM COMP ARA TOR RAMP VOL TAGE AMPLITUDE

FOR DDR APPLICATION

VIN PIN CONNECTION

Ch1 Input Voltage Input voltage >4.2V Vin/8

Input voltage <4.2V 1.25V

GND 1.25V

Ch2 Input voltage >4.2V 0.625V

GND 1.25V

VRAMP

AMPLITUDE

The small signal transfer function from the error amplifier

output voltage V

to the output voltage Vo can be written in

c

the following expression:

s

⎛⎞

-------- -

1+

⎝⎠

Wz

s

⎛⎞

------------ -

1+

⎝⎠

Wp2

1+

(EQ. 8)

Gs() G

=

R

---------------------------------------

m

RiDCR R

++

o

---------------------------------------------------------

s

⎛⎞

o

------------ -

⎝⎠

Wp1

The dc gain is derived by shorting the inductor and opening

the capacitor. There is one zero and two poles in this transfer

function. The zero is related to ESR and the output

capacitor.

FIGURE 37. THE EQUIVALENT CIRCUIT OF THE POWER

STAGE WITH CURRENT LOOP INCLUDED

The value of the injected resistor can be estimated by:

r

V

IN

-----------------

R

i

V

R

is in kΩ, and RDS and R

i

V

ramp

DS ON()

ramp

----------------------------

R

CS

4.4kΩ•=

140+

are in Ω . VIN divided by

CS

, is defined as Gm, which is a constant 8 or 18 dB for

both channels in dual switcher applications, when V

(EQ. 7)

is

IN

above 3V . Refer to Table 1 for the ramp amplitude in different

V

pin connections. The feed-forward effect of the VIN is

IN

reflected in Gm. V

is defined as the error amplifier output

c

voltage.

TABLE 1. PWM COMP ARATOR RAMP AMPLITUDE FOR

DUAL SWITCHER APPLICATION

VRAMP

VIN PIN CONNECTIONS

Ch1 and Ch2 Input Voltage Input voltage >4.2V Vin/8

Input voltage <4.2V 1.25V

GND 1.25V

AMPLITUDE

The first pole is a low frequency pole associated with the

output capacitor and its charging resistors. The inductor can

be regarded as short. The second pole is the high frequency

pole related to the inductor. At high frequency the output

capacitor can be regarded as a short circuit. By

approximation, the poles and zero are inversely proportional

to the time constants, associated with inductor and capacitor,

by the following expressions:

Wz

Wp1

Wp2

ESR*C

o

------------------------------------------------------------------------------ -

=

ESR R

DCR ESR++ R

R

i

----------------------------------------------------------

=

1

+()*C

i

L

o

||

DCR+()R

||

o

o

o

(EQ. 9)

(EQ. 10)

(EQ. 11)

1

----------------------- -

=

Since the current loop separates the LC resonant poles into

two distant poles, and ESR zero tends to cancel the high

frequency pole, the second order system behaves like a first

order system. This control method simplifies the design of

the internal compensator and makes it possible to

accommodate many applications having a wide range of

parameters.

17

FN9094.4

December 21, 2006

ISL6227

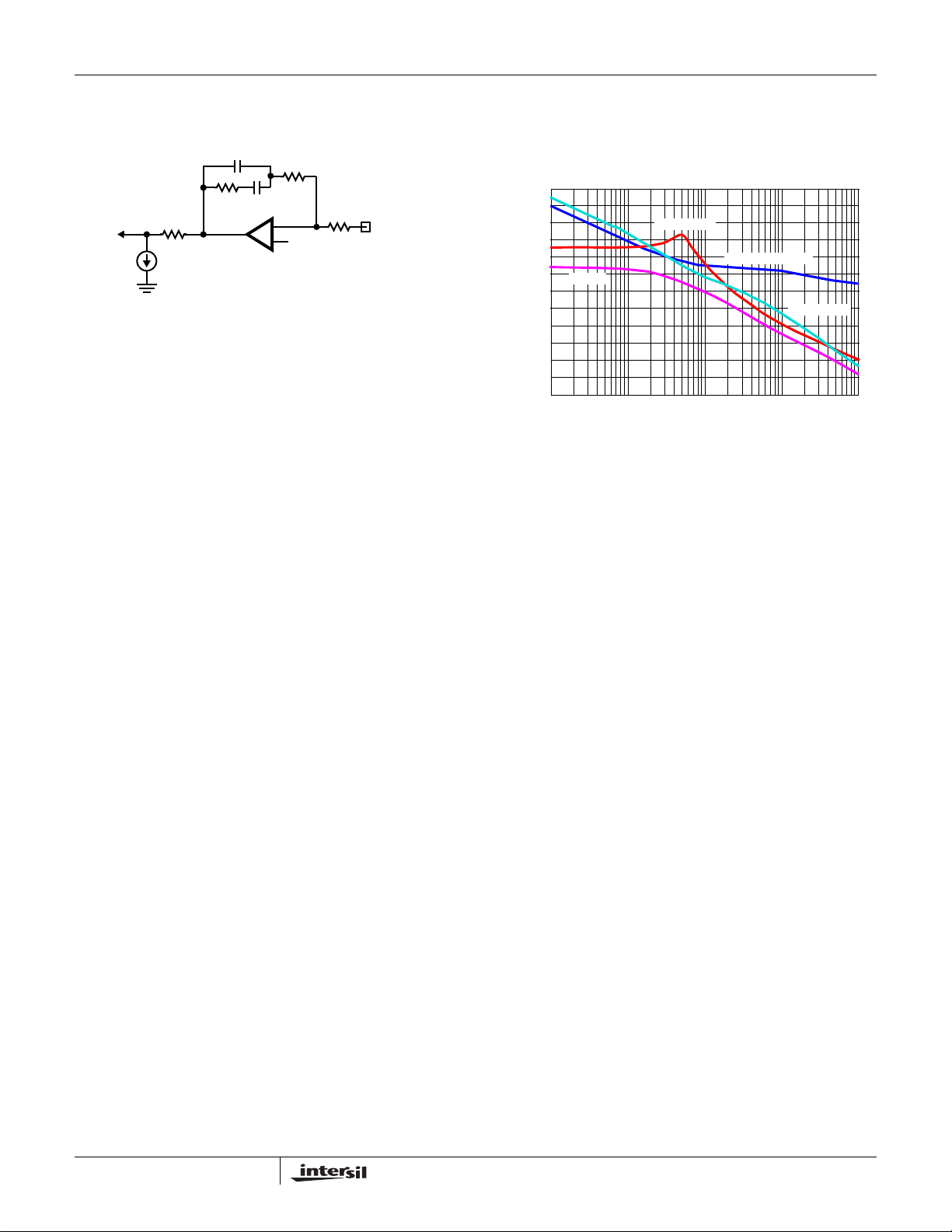

The schematics for the internal compensator is shown in

Figure 38.

1.25pF

TO PWM

COMPARATOR

4.4K

ISEN

FIGURE 38. THE INTERNAL COMPENSATOR

1M 15pF

Vc

500K

-

+

300K

0.9V

VSEN

Its transfer function can be written as the following:

5

Gcomp s()

s

⎛⎞

1.857 10

-------------------------------------------------------------------------------------------- -

=

---------------

•

⎝⎠

2π f

z1

s

⎛⎞

---------------

s

⎝⎠

2π f

p1

s

⎛⎞

---------------

1+

⎝⎠

1+

2π f

1+

z2

(EQ. 12)

where

f

= 6.98kHz, f

z1

= 380kHz, and f

z2

= 137kHz

p1

Outside the ISL6227 chip, a capacitor Cz can be placed in

parallel with the top resistor in the feedback resistor divider,

as shown in Figure 34. In this case th e transfer fu nction from

the output voltage to the middle point of the divider can be

written as:

Gfd s()

R1R2+

---------------------

=

The ratio of R

R

sR

2

--------------------------------------------- -

()C

sR

1R2

and R2 is determined by the output voltage

1

1Cz

||

1+

1+

z

(EQ. 13)

set point; therefore, the position of the pole and zero

frequency in the above equation may not be far apart;

however, they can improve the loop gain and phase margin

with the proper design.

The C

can bring the high frequency transient output voltage

z

variation directly to the VSEN pin to cause the PGOOD drop.

Such an effect should be considered in the selection of C

.

z

From the analysis above, the system loop gain can be

written as:

Gloop s() Gs() Gcomp s()• Gfd•= s()

(EQ. 14)

Figure 39 shows the composition of the system loop gain. As

shown in the graph, the power stage becomes a well

damped second order system as compared to the LC filter

characteristics. The ESR zero is so close to the high

frequency pole that they cancel each other out. The power

stage behaves like a first order system. With an internal

compensator, the loop gain transfer function has a cross

over frequency at about 30kHz. With a given set of

parameters, including the MOSFET r

DS(ON)

, current sense

resistor R

, output LC filter, and voltage feedback network,

CS

the system loop gain can be accurately analyzed and

modified by the system designers based on the application

requirements.

60

50

40

30

20

10

VO/VC

0

-10

GAIN (dB)

-20

-30

-40

-50

-60

100 1•10

FIGURE 39. THE BODE PLOT OF THE LC FILTER,

COMPENSATOR, CONTROL TO OUTPUT

VOLTAGE TRANSFER FUNCTION, AND SYSTEM

LOOP GAIN

LC FILTER

3

FREQUENCY (Hz)

COMPENSATOR

4

1•10

LOOP GAIN

5

1•10

1•10

Gate Control Logic

The gate control logic translates generated PWM signals

into gate drive signals providing necessary amplification,

level shift, and shoot-through protection. It bears some

functions that help to optimize the IC performance over a

wide range of the operational conditions. As MOSFET

switching time can vary dramatically from type to type, and

with the input voltage, the gate control logic provides

adaptive dead time by monitoring real gate waveforms of

both the upper and the lower MOSFETs.

Dual-Step Conversion

The ISL6227 dual channel controller can be used either in

power systems with a single-stage power conversion, when

the battery power is converted into the desired output

voltage in one step, or in the systems where some

intermediate voltages are initially established. The choice of

the approach may be dictated by the overall system design

criteria, or the approach may be a matter of voltages

available to the system designer, as in the case of PCI card

applications.

When the output voltage is regulated from low voltage such

as 5V, the feed-forward ramp may become too shallow,

creating the possibility of duty-factor jitter; this is particularly

relevant in a noisy environment. Noise susceptibility, when

operating from low level regulated power sources, can be

improved by connecting the VIN pin to ground, by which the

feed-forward ramp generator will be internally reconnected

from the VIN pin to the VCC pin, and the ramp slew rate will

be doubled.

6

18

FN9094.4

December 21, 2006

A

Ω

ISL6227

Voltage Monitor and Protections

The converter output is monitored and protected against

extreme overload, short circuit, overvoltage, and

undervoltage conditions. A sustained overload on the output

sets the PGOOD low and latches off the offending channel of

the chip. The controller operation can be restored by cycling

the VCC voltage or toggling both enable (EN) pins to low to

clear the latch.

Power Good

In the soft-start process, the PGOOD is established after the

soft pin voltage is at 1.5V. In normal operation, the PGOOD

window is 100mV below the 0.9V and 135mV higher than

0.9V. The VSEN pin has to stay within this window for

PGOOD to be high. Since the VSEN pin is used for both

feedback and monitoring purposes, the output voltage

deviation can be coupled directly to the VSEN pin by the

capacitor in parallel with the voltage divider as shown in

Figure 4. In order to prevent false PGOOD drop, capacitors

need to parallel at the output to confine the voltage deviation

with severe load step transient. The PGOOD comparator

has a built-in 3µs filter. PGOOD is an open drain output.

Overcurrent Protection

In dual switcher application, both PWM controllers use the

lower MOSFETs on-resistance r

DS(ON),

current for protection against shorted outputs. The sensed

current from the ISEN pin is compared with a current set by

a resistor connected from the OCSET pin to ground:

10.3V

R

where, I

R

---------------------------------------------------------

=

SET

is the value of the current sense resistor conne cte d to

CS

•

I

OCrDS ON()

--------------------------------------

R

140Ω+

CS

is a desired overcurrent protection threshold and

OC

8μ A+

the ISEN pin. The 8µA is the offset current added on top of

the sensed current from the ISEN pin for internal circuit

biasing.

If the lower MOSFET current exceeds the overcurrent

threshold, a pulse skipping circuit is activated. The upper

MOSFET will not be turned on and the lower MOSFET

keeps conducting as long as the sampled current is higher

than the threshold value, limiting the current supplied by the

DC voltage source. The current in the lower MOSFET will be

sampled at the internal 300kHz oscillator frequency and

monitored. When the sampled current is lower than the OC

threshold value, the following UGATE pulse will be released

and it allows turning on the upper MOSFET based on the

voltage regulation loop. This kind of operation remains for

eight clock cycles after the overcurrent comparator was

tripped for the first time. If after the first eight clock cycles the

sampled current exceeds the overcurrent threshold again,

within a time interval of another eight clock cycles, the

overcurrent protection latches and disables the offending

channel. If the overcurrent condition goes away during the

to monitor the

(EQ. 15)

first eight clock cycles, normal operation is restored and the

overcurrent circuit resets itself at the end of sixteenth clock

cycles; see Figure 40.

1

2

3

Ch3 1.0

FIGURE 40. OVERCURRENT PROTECTION

Due to the nature of the used current sensing technique,

and to accommodate a wide range of the r

the value of the overcurrent threshold should set at about

180% of the nominal load value. If more accurate current

protection is desired, a current sense resistor placed in

series with the lower MOSFET source may be used. The

inductor current going through the lower MOSFET is sensed

and held at 400ns after the upper MOSFET is turned off;

therefore, the sensed current is very close to its peak value.

The inductor peak current can be written as:

VINVo–()Vo•

peak

--------------------------------------------

2L

oFSWVIN

I

As seen from the equation above, the inductor peak current

changes with the input voltage and the inductor value once

an output voltage is selected.

After overcurrent protection is activated, there are two ways

to bring the offending channel back: (1) Both EN1 and EN2

have to be held low to clear the latch, (2) To recycle the Vcc

of the chip, the POR will clear the latch.

Undervoltage Protection

In the process of operation, if a short circuit occurs, the output

voltage will drop quickly. Before the overcurrent protection

circuit responds, the output voltage will fall out of the required

regulation range. The chip comes with undervoltage protection.

If a load step is strong enough to pull the output voltage lower

than the undervoltage threshold, the offending channel latches

off immediately . The undervoltage threshold is 75% of the

nominal output voltage. Toggling both pins to low, or recycling

Vcc, will clear the latch and bring the chip back to operation.

Overvoltage Protection

Should the output voltage increase over 115% of the normal

value due to the upper MOSFET failure, or for other reasons,

the overvoltage protection comparator will force the

synchronous rectifier gate driver high. This action actively

pulls down the output voltage and eventually attempts to

blow the battery fuse. As soon as the output voltage is within

PGOOD

I

load

8 CLK

SHUTDOWN

M 10.0μsCh1 5.0V

DS(ON)

variation,

(EQ. 16)

IL

VOUT

Ch2 100mV

+=

••

19

FN9094.4

December 21, 2006

ISL6227

regulation, the OVP comparator is disengaged. The

MOSFET driver will restore its normal operation. When the

OVP occurs, the PGOOD will drop to low as well.

This OVP scheme provides a ‘soft’ crowbar function, which

helps clamp the voltage overshoot, and does not invert the

output voltage when otherwise activated with a continuously

high output from lower MOSFET driver - a com mon prob lem

for OVP schemes with a latch.

DDR Application

High throughput Double Data Rate (DDR) memory ICs are

replacing traditional memory ICs in the latest generation of

Notebook PCs and in other computing devices. A novel

feature associated with this type of memory are the

referencing and data bus termination techniques. These

techniques employ a reference voltage, VREF, that tracks

the center point of VDDQ and VSS voltages, and an

additional VTT power source where all terminating resistors

are connected. Despite the additional power source, the

overall memory power consumption is reduced compared to

traditional termination.

The added power source has a cluster of requirements that

should be observed and considered. Due to the reduced

differential thresholds of DDR memory, the termination

power supply voltage, VTT, closely tracks VDDQ/2 voltage.

Another very important feature of the termination power

supply is the capability to operate at equal efficiency in

sourcing and sinking modes. The VTT supply regulates the

output voltage with the same degree of precision when

current is flowing from the supply to the load, and when the

current is diverted back from the load into the power supply.

The ISL6227 dual channel PWM controller possesses

several important enhancements that allow re-configuration

for DDR memory applications, and provides all three

voltages required in a DDR memory compliant computer.

To reconfigure the ISL6227 for a complete DDR solution, the

DDR pin should be set high permanently to the VCC rail.

This activates some functions inside the chip that are

specific to DDR memory power needs.

In the DDR application presented in Figure 32, the first

controller regulates the VDDQ rail to 2.5V. The output

voltage is set by external dividers Rfb1 and Rfb12. The

second controller regulates the VTT rail to VDDQ/2. The

OCSET2 pin function is now different, and serves as an

input that brings VDDQ/2 voltage, created by the Rd1 and

Rd2 divider, inside the chip, effectively providing a tracking

function for the VTT voltage.

The PG2 pin function is also different in DDR mode. This pin

becomes the output of the buffer, whose input is connected

to the center point of the R/R divider from the VDDQ output

by the OCSET2 pin. The buffer output voltage serves as a

1.25V reference for the DDR memory chips. Current

capability of this pin is 10mA (12mA max).

For the VTT channel where output is derived from the VDDQ

output, some control and protective functions have been

significantly simplified. For example, the overcurrent, and

overvoltage, and undervoltage protections for the second

channel controller are disabled when the DDR pin is set

high. The hysteretic mode of operation is also disabled on

the VTT channel to allow sinking capability to be

independent from the load level. As the VTT channel tracks

the VDDQ/2 voltage, the soft-start function is not required,

and the SOFT2 pin may be left open, in the event both

channels are enabled simultaneously. However, if the VTT

channel is enabled later than the VDDQ, the SOFT2 pin

must have a capacitor in place to ensure soft-start. In case of

overcurrent or undervoltage caused by short circuit on VTT,

the fault current will propagate to the first channel and shut

down the converter.

The VREF voltage will be present even if the VTT is

disabled.

Channel Synchronization in DDR Applications

The presence of two PWM controllers on the same die

requires channel synchronization, to reduce inter-channel

interference that may cause the duty factor jitter and

increased output ripple.

The PWM controller is at greatest noise susceptibility when

an error signal on the input of the PWM comparator

approaches the decision making point. False triggering may

occur, causing jitter and affecting the output regulation.

A common approach used to synchronize dual channel

converters is out-of-phase operation. Out-of-phase

operation reduces input current ripple and provides a

minimum interference for channels that control different

voltage levels.

When the DDR pin is connected to GND for dual switcher

applications, the channels operate 180° out-of-phase. When

used in a DDR application with cascaded converters (VTT

generated from VDDQ), several methods of synchronization

are implemented in the ISL6227. In the DDR mode, when

the DDR pin is connected to VCC, the channels operate

either with 0° phase shift, when the VIN pin is connected to

the GND, or with 90° phase shift if the VIN pin is connected

to a voltage higher than 4.2V.

The following table lists the different synchronization

schemes and their usage:

DDR PIN VIN PIN SYNCHRONIZATION

0 Vin pin >4.2V 180° out of phase

1 Vin pin voltage <4.2V 0° phase

1 Vin pin voltage >4.2V 90° phase shift

20

FN9094.4

December 21, 2006

ISL6227

Application Information

Design Procedures

GENERAL

A ceramic decoupling capacitor should be used between the

VCC and GND pin of the chip. There are three major

currents drawn from the decoupling capacitor:

1. the quiescent current, supporting the internal logic and

normal operation of the IC

2. the gate driver current for the lower MOSFETs

3. and the current going through the external diodes to the

bootstrap capacitor for upper MOSFET.

In order to reduce the noisy effect of the bootstrap capacitor

current to the IC, a small resistor, such as 10Ω, can be used

with the decoupling cap to construct a low pass filter for the

IC, as shown in Figure 41. The soft-start capacitor and the

resistor divider setting the output voltage is easy to select as

discussed in the “Block Diagram” on page 13.

TO BOOT

5V

10Ω

FIGURE 41. INPUT FILTERING FOR THE CHIP

Selection of the Current Sense Resistor

The value of the current sense resistor determines the gain

of the current sensing circuit. It affects the current loop gain

and the overcurrent protection setpoint. The voltage drop on

the lower MOSFET is sensed within 400ns after the upper

MOSFET is turned off. The current sense pin has a 140Ω

resistor in series with the external current sensing resistor.

The current sense pin can source up to a 260µA current

while sensing current on the lower MOSFET, in such a way

that the voltage drop on the current sensing path would be

equal to the voltage on the MOSFET.

I

SOURCINGRCS

I

can be assumed to be the inductor peak current. In a

D

worst case scenario, the high temperature r

increase to 150% of the room temperature level. During

overload condition, the MOSFET drain current I

130% higher than the normal inductor peak. If the inductor

has 30% peak-to-peak ripple, I

load current. The design should consider the above factors

so that the maximum I

under worst case conditions. To be safe, I

be less than 100µA in normal operation at room

temperature. The formula in the earlier discussion assumes

a 75µA sourcing current. Users can tune the sourcing

140Ω+()IDr

=

SOURCING

DS ON()

D

VCC

(EQ. 17)

could

DS(ON)

could be

D

would equal to 115% of the

will not saturate to 260µA

SOURCING

should

current of the ISEN pin to meet the overcurrent protection

and the change the current loop gain. The lower the current

sensing resistor, the higher gain of the current loop, which

can damp the output LC filter more.

A higher value current-sensing resistor will decrease the

current sense gain. If the phase node of the converter is very

noisy due to poor layout, the sensed current will be

contaminated, resulting in duty cycle jittering by the current

loop. In such a case, a bigger current sense resistor can be

used to reduce both real and noise current levels. This can

help damp the phase node wave form jittering.

Sometimes, if the phase node is very noisy, a resistor can be

put on the ISEN pin to ground. This resistor together with the

R

can divide the phase node voltage down, seen by the

CS

internal current sense amplifier, and reduce noise coupling.

Sizing the Overcurrent Setpoint Resistor

The internal 0.9V reference is buffered to the OCSET pin

with a voltage follower (refer to the equivalent circuit in

Figure 42). The current going through the external

overcurrent set resistor is sensed from the OCSET pin. This

current, divided by 2.9, sets up the overcurrent threshold and

compares with the scaled ISEN pin current going through

R

with an 8µA offset. Once the sensed current is higher

CS

than the threshold value, an OC signal is generated. The first

OC signal starts a counter and activates a pulse skipping

function. The inductor current will be continuously monitored

through the phase node voltage after the first OC trip. As

long as the sensed current exceeds the OC threshold value,

the following PWM pulse will be skipped. This operation will

be the same for 8 switching cycles. Another OC occurring

between 8 to 16 switching cycles would result in a latch off

with both upper and lower drives low. If there is no OC within

8 to 16 switching cycles, normal operation resumes.

ISEN

ISEN

140 Ω

PHASE

PHASE

R

R

CS

CS

_

_

Rdson

Rdson

+

+

Rset

Rset

FIGURE 42. EQUIV ALENT CIRCUIT F OR OC SIGN AL

140 Ω

OCSET

OCSET

Amplifier

Amplifier

GENERATOR

_

_

+

+

_

_

+

+

0.9 V

0.9 V

Reference

Reference

÷ 2.9

÷ 2.9

+

+

Σ

Σ

÷ 33.1

÷ 33.1

8uA

8uA

+

+

Isense

Isense

+

+

OC

OC

_

_

Comparator

Comparator

21

FN9094.4

December 21, 2006

ISL6227

Based on the above description and functional block

diagram, the OC set resistor can be calculated as:

10.3V

---------------------------------------------------

R

=

set

I

OCrDS ON()

---------------------------------

RCS140+

I

is the inductor peak current and not the load current.

OC

8μ A+

(EQ. 18)

Since inductor peak current changes with input voltage, it is

better to use an oscilloscope when testin g th e overcurrent

setting point to monitor the inductor current, and to

determine when the OC occurs. T o get consistent test results

on different boards, it is best to keep the MOSFET at a fixed

temperature.

The MOSFET will not heat-up when applying a very low

frequency and short load pulses with an electronic load to

the output.

As an example, assume the following:

• The maximum normal operation load current is 1

• The inductor peak current is 1.15-1.3 times higher than

the load current, depending on the inductor value and the

input voltage

•The r

should set at least 1.8 to 2 times higher than the

I

OC

has a 45% increase at higher temperature

DS(ON)

maximum load current to avoid nuisance overcurrent trip.

Selection of the LC Filter

The duty cycle of a buck converter is a function of the input

voltage and output voltage. Once an output voltage is fixed,

it can be written as:

selection. Another factor to consider when choosing the

inductor is its saturation characteristics at elevated

temperature. Saturated inductors could result in nuisance

OC, or OV trip.

Output voltage ripple and the transient voltage deviation are

factors that have to be taken into consideration when

selecting an output capacitor. In addition to high frequency

noise related MOSFET turn-on and turn-off, the output

voltage ripple includes the capacitance voltage drop and

ESR voltage drop caused by the AC peak-to-peak current.

These two voltages can be represented by:

I

pp

----------------------

ΔV

c

ΔV

esrIpp

=

8CoF

sw

ESR=

(EQ. 22)

(EQ. 23)

These two components constitute a large portion of the total

output voltage ripple. Several capacitors have to be

paralleled in order to reduce the ESR and the voltage ripple.

If the output of the converter has to support another load

with high pulsating current, more capacitors are needed in

order to reduce the equivalent ESR and suppress the

voltage ripple to a tolerable level.

To support a load transient that is faster than the switching

frequency, more capacitors have to be used to reduce the

voltage excursion during load step change. Another aspect

of the capacitor selection is that the total AC current going

through the capacitors has to be less than the rated RMS

current specified on the capacitors, to prevent the capacitor

from over-heating.

V

o

IN

---------

=

V

IN

, of ISL6227 is 300kHz. The

sw

(EQ. 19)

()

DV

The switching frequency, F

peak-to-peak ripple current going through the inductor can

be written as:

Vo1DVIN()–()

-----------------------------------------

I

=

pp

F

swLo

(EQ. 20)

As higher ripple current will result in higher switching loss

and higher output voltage ripple, the peak-to-peak current of

the inductor is generally designed with a 20%-40% peak-topeak ripple of the nominal operation current. Based on this

assumption, the inductor value can be selected with the

above equation. In addition to the mechanical dimension, a

shielded ferrite core inductor with a very low DC resistance,

DCR, is preferred for less core loss and copper loss. The DC

copper loss of the inductor can be estimated by:

P

=

copperIload

2

DCR

(EQ. 21)

The inductor copper loss can be significant in the total

system power loss. Attention has to be given to the DCR

22

FN9094.4

December 21, 2006

ISL6227

Selection of the Input Capacitor

When the upper MOSFET is on, the current in the output

inductor will be seen by the input capacitor. Even though this

current has a triangular shape top, its RMS value can be

fairly approximated by:

lin

() DVIN()*I

rmsVIN

=

load

(EQ. 24)

This RMS current includes both DC and AC components.

Since the DC component is the product of duty cycle and

load current, the AC component can be approximated by:

() DVIN()DVIN()–

li

nacVIN

=

()I

2

load

(EQ. 25)

AC components will be provided from the input capacitor.

The input capacitor has to be able to handle this ripple

current without overheating and with tolerable voltage ripple.

In addition to the capacitance, a ceramic capacitor is

generally used between the drain terminal of the upper

MOSFET and the source terminal of the lower MOSFET, in

order to clamp the parasitic voltage ringing at the phase

node in switching.

Choosing MOSFETs

For a notebook battery with a maximum voltage of 24V, at

least a minimum 30V MOSFETs should be used. The design

has to trade off the gate charge with the r

MOSFET:

• For the lower MOSFET, before it is turned on, the body

diode has been conducting. The lower MOSFET driver will

not charge the miller capacitor of this MOSFET.

• In the turning off process of the lower MOSFET, the load

current will shift to the body diode first. The high dv/dt of

the phase node voltage will charge the miller capacitor

through the lower MOSFET driver sinking current path.

This results in much less switching loss of the lower

MOSFETs.

The duty cycle is often very small in high battery voltage

applications, and the lower MOSFET will conduct most of

the switching cycle; therefore, the lower the r

lower MOSFET , the less the power loss. The gate charge for

this MOSFET is usually of secondary consideration.

The upper MOSFET does not have this zero voltage

switching condition, and because it conducts for less time

compared to the lower MOSFET, the switching loss tends to

be dominant. Priority should be given to the MOSFETs with

less gate charge, so that both the gate driver loss, and

switching loss, will be minimized.

DS(ON)

DS(ON)

of the

of the

For the lower MOSFET , it s power loss can be assumed to be

the conduction loss only.

()1DVIN()–()I

P