查询ISL6226EVAL1供应商

®

ISL6226

Data Sheet August 2002

Advanced PWM and Linear Power

Controller for Portable Applications

The ISL6226 provides power control and protection for two

user selected output voltages required in high-performance

notebook PC applications. The IC integrates a fixed,

selectable frequency pulse-width-modulation (PWM)

controller and a 3A LDO linear regulator controller with

monitoring and protection circuitry in a single 24 lead SSOP

package.

The PWM controller regulates the battery input voltage to a

user selected output voltage. Synchronous converter and

hysteretic operation at light loads contribute to a high

efficiency over a wide range of input voltage and load

variation. Efficiency can be further enhanced by using the

lower MOSFET’s r

DS(ON)

voltage feed-forward ramp modulation, current-mode control,

and internal feed-back compensation provide fast and stable

handling of input voltage load transients encountered in

advanced portable computer chip sets.

as the current sense element. Input

FN9078.1

Features

• Provides Two Regulated Voltages

- Linear Regulator, User Selected, Current Limited

- High Efficiency PWM Over Wide Line and Load Range

- Synchronous Buck Converter on PWM Output

- Hysteretic Operation at Light Load

• Dual Mode Operation:

- Directly From Battery Input, V

VCC of 5V

• PWM Output Adjustable From 0.9V to 0.93*V

• Low Drop-Out (LDO) Linear Regulator Operates from

Vout+0.5V to 24V

• LDO Output Adjustable

- From 0.8V to 3.8V at 0A to 3A for NPN Transistor

- From 0.8V to 3.0V at 0A to 3A for N-MOSFET

• 300/600kHz Switching Frequency Selectable

, of 5.6V to 24V or from

IN

IN

The internal linear regulator controller provides a user

selected high current output from an unregulated input with

user selected current limit.

Ordering Information

PART

NUMBER

ISL6226CA -10 to 85 24 Ld SSOP M24.15

ISL6226EVAL1 Evaluation Board

TEMP. RANGE

o

(

C) PACKAGE PKG. NO.

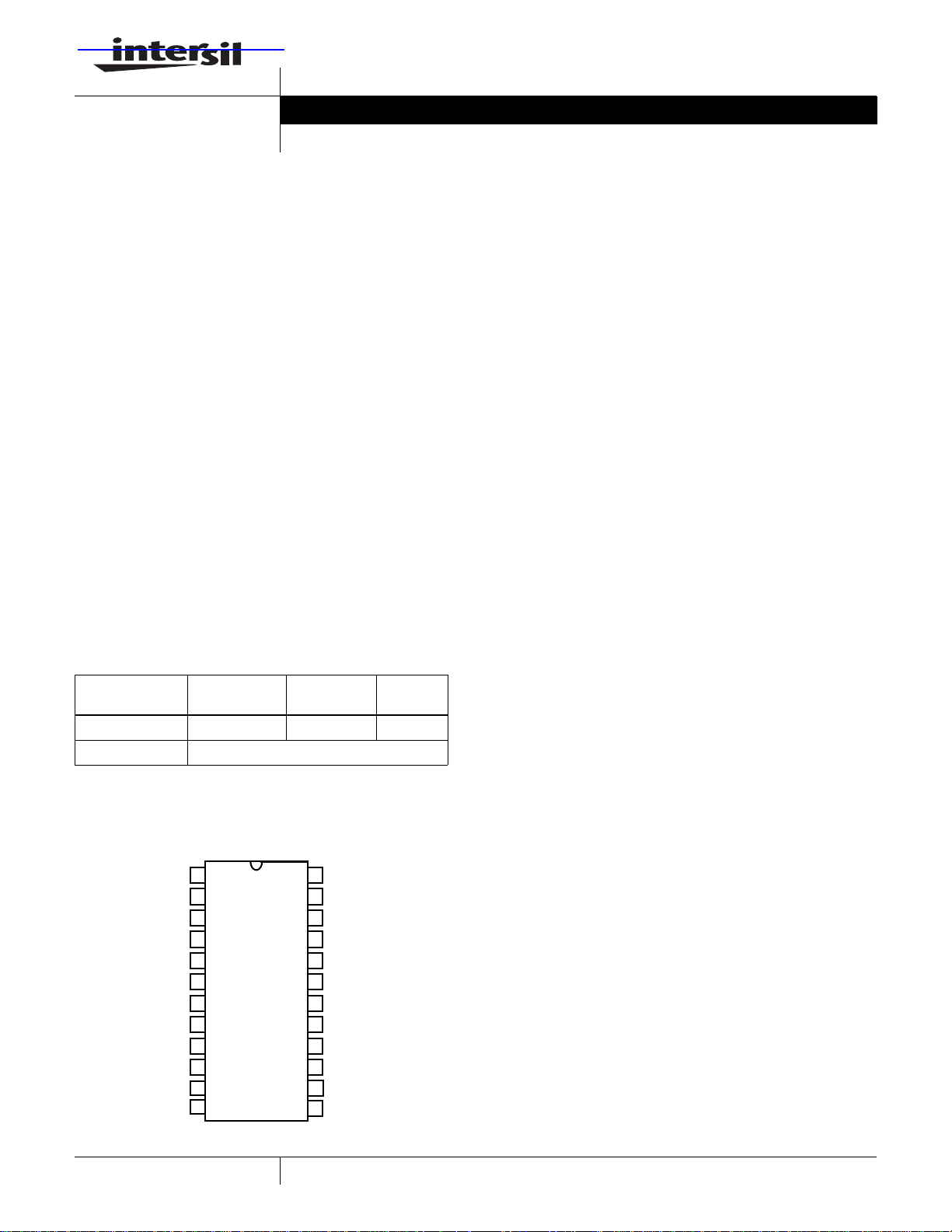

Pinout

ISL6226 (SSOP)

TOP VIEW

24

23

22

21

20

19

18

17

16

15

14

VOUT

VSEN

FPWM

PGOODP

ISEN

BOOT

UGATE

PHASE

SSPWM

PVCC

LGATE

PGND

VIN

PGOODL

PWMEN

OCSET

LINEN

VCC

LINDR

LINCS1

LINCS2

SSLIN

LINVS

GND

1

2

3

4

5

6

7

8

9

10

11

12 13

• Forced PWM Mode Control Option

• No Current-Sense Resistor Required on PWM Output

- Uses MOSFET’s r

DS(ON)

- Optional Current-Sense Resistor for More Precision

• Separate Soft-Start For Both PWM and LDO

• Separate Enable Pins for both PWM and LDO for

Advanced Configuration and Power Interface (ACPI)

Compatibility

• Input Under voltage Lock-Out (UVLO) Protection

• Excellent Dynamic Response

- Input Voltage Feed-Forward and Current-Mode Control

• Monitors Output Voltages and Provides PGOOD Status

• Thermal Shut-Down Protection

Applications

•

Mobile PCs

• Hand-Held Portable Instruments

• Other Devices and Appliances With up to 24V Input

Related Literature

• AN1013

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

ISL6226

Absolute Maximum Ratings Thermal Information

Bias Voltage, Vcc. . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to + 7V

Input Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +30.0V

Phase and Isen Pins . . . . . . . . . . . . . . . . . . . . . GND-0.3V to +30.0V

Boot and Ugate Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 35.0V

BOOT with respect to PHASE . . . . . . . . . . . . . . . . . . . . . . . . . .+ 7.0V

Imax for LINDR Pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70mA

All other pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND -0.3V to 7V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 1

Recommended Operating Conditions

Bias Voltage, Vcc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+ %

Input Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . +5.6V to +24.0V

Ambient Temperature Range. . . . . . . . . . . . . . . . . . . -10

Junction Temperature Range. . . . . . . . . . . . . . . . . . -10

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θ

JA is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

5.0V 5±

o

C to 85oC

o

C to 125oC

Thermal Resistance (Typical, Note 1) θ

SSOP Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Maximum Junction Temperature (Plastic Package) . . 150

Maximum Storage Temperature Range. . . . . . . . . . -65

(oC/W)

JA

o

C

o

C to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . .300

(SSOP - Lead Tips Only)

o

C

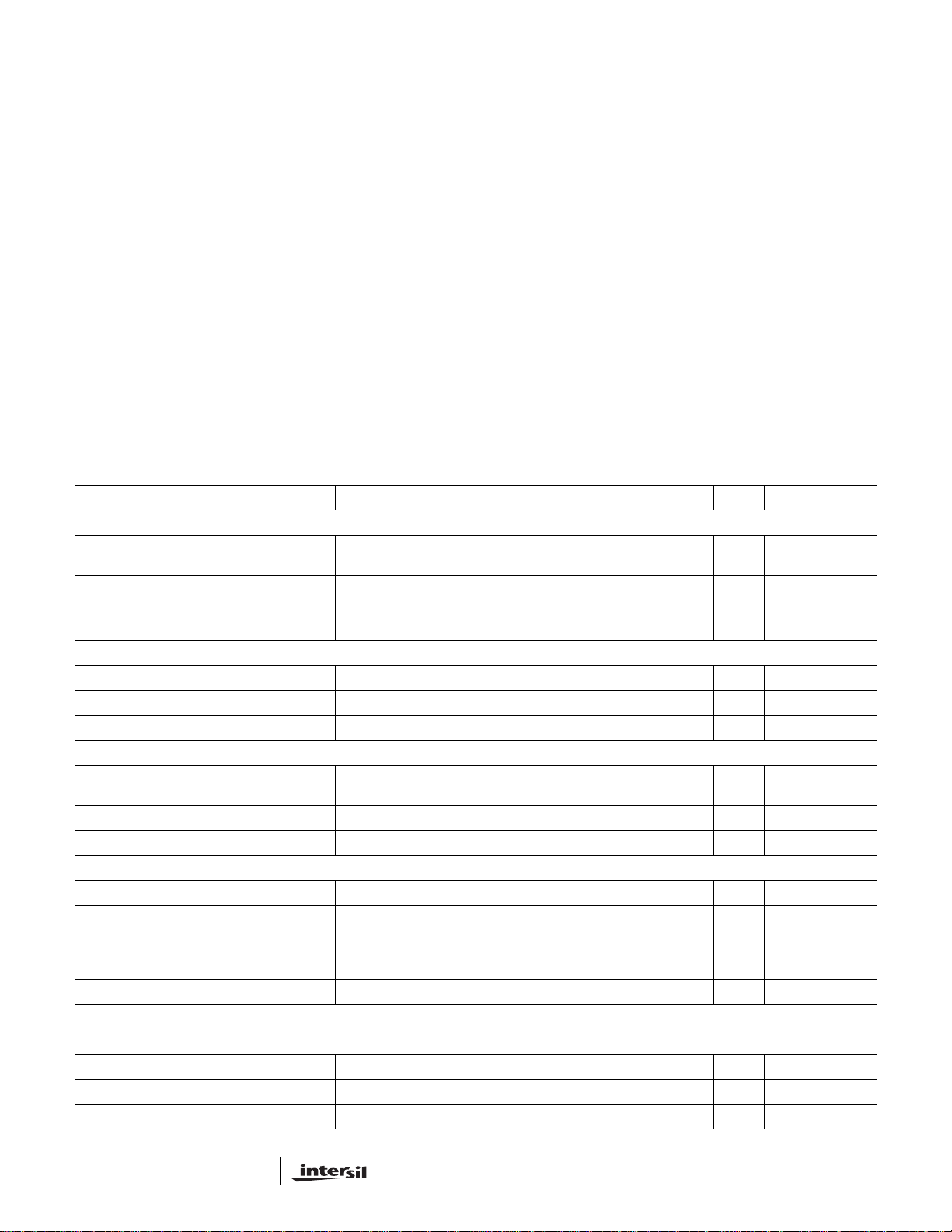

Electrical Specifications Operating Conditions: Vcc = 5V, T

= -10oC to 85oC, Unless Otherwise Noted.

A

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

VCC SUPPLY

Bias Current I

Bias Current I

CC

CC

LGATE, UGATE Open, VSEN forced above

regulation point (Fs = 300K Hz)

LGATE, UGATE Open, VSEN forced above

- 1100 - µA

- 1100 - µA

regulation point (Fs = 600K Hz)

Shut-down Current I

CCSN

-525µA

VCC UVLO

Rising Vcc Threshold 4.30 - 4.65 V

Falling Vcc Threshold 4.1 - 4.45 V

Vcc Hysterises 30 500 mV

VIN

Input Voltage Pin Current (Sink) I

Input Voltage Pin Current (Source) I

Shut-down Current I

VIN

VIN

VIN

VIN pin connected to the input voltage

10 20 30 µA

source

VIN pin connected to ground -7 -12 -17 µA

--1µA

OSCILLATOR

PWM Oscillator Frequency F

PWM Oscillator Frequency F

Ramp Amplitude, pk-pk V

Ramp Amplitude, pk-pk V

Ramp Offset V

ROFF

VIN=3.5V -- 24V 255 300 345 kHz

c1

V

c2

R1

R2

≤0.5V 510 600 690 kHz

IN

VIN= 16V - 2 - V

V

≤5V - 1.25 - V

IN

-0.5- V

PWM CONTROLLER

REFERENCE AND SOFT START

PWM Internal Reference Voltage V

PWM Soft-Start Threshold V

REF

SOFT

-0.9- V

-1.5- V

Reference Voltage Accuracy -2.0 - +2.0 %

2

ISL6226

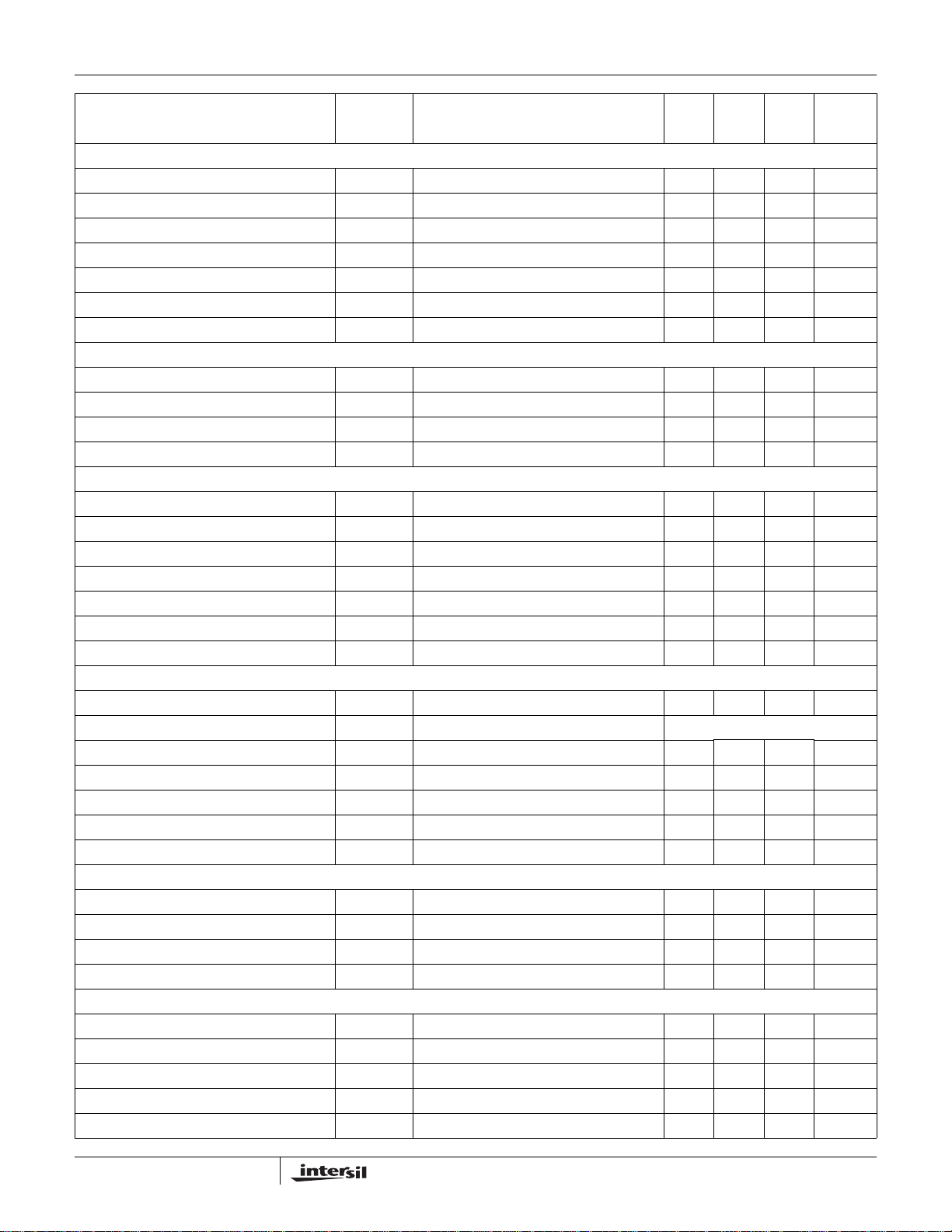

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Soft-Start Current During Start-up I

SOFT

PWM CONVERTER

Load Regulation 0.0mA < I

VSEN pin bias current I

VOUT pin input impedance I

Under-Voltage Shut-Down Level V

VSEN

VOUT

UV1

Fraction of the set point; ~3µs noise filter 70 - 76 %

< 5.0A; 5.0V < VIN < 24.0V -2.0 - +2.0 %

VOUT1

Under Voltage Delay UV_DLY 3 - 5.5 uS

Over-Voltage Protection V

OVP1

Fraction of the set point; ~1µs noise filter 113.5 - 118 %

Over Voltage Delay OVP_DLY 0.5 - 2.7 uS

PWM CONTROLLER GATE DRIVER

Upper Drive Pull-Up Resistance R

Upper Drive Pull-Down Resistance R

Lower Drive Pull-Up Resistance R

Lower Drive Pull-Down Resistance R

2UGPUP

2UGPDN

2LGPUP

2LGPDN

POWER GOOD AND CONTROL FUNCTIONS

Power Good Lower Threshold V

Power Good Higher Threshold V

PGOOD Leakage Current I

PG-

PG+

PGLKG

PGOOD Voltage Low I

Fraction of the set point; ~3µs noise filter -13.5 - -7.5 %

Fraction of the set point; ~3µs noise filter 7.4 - 13.5 %

V

PGOOD

= 5.5V - - 1 µA

PULLUP

= -4mA - - 0.5 V

EN- Low (Off) --0.8V

EN - High (On) 2.0 - - V

FCCM -Hysteretic Operation Enabled -Vcc/2- V

LOW DROP OUT CONTROLLER FUNTIONS

Linear Input Voltage Vin No External Passive Device - Vcc - V

Linear Input Voltage Vin With External Passive Device Device Rating

Linear Output Voltage LDOout No External Passive Device 0.8 - 4.5 V

Output Drive Current for NPN I(DRV) out 50 - - mA

OverCurrent Feedback Voltage V(CS) 100 mV

Under-Voltage Shut-Down Level V

Under-Voltage Delay UV

UV

Fraction of the set point; ~3µs noise filter 71 74 77 %

DLY

REFERENCE AND SOFT START

LDO Internal Reference Voltage V

LDO Soft-Start Threshold V

REF

SOFT

Reference Voltage Accuracy -2.0 - +2.0 %

Soft-Start Current During Start-up I

SOFT

POWER GOOD AND CONTROL FUNTIONS

Power Good Lower Threshold V

Power Good Higher Threshold V

PG-

PG+

Vo<V

Vo>V

REF

REF

PGOOD Leakage Current IPGLKG VPULLUP = 5.5V - - 1.0 uA

PGOOD Voltage Low VPGOOD IPGOOD = -4mA, VCC = 4.75V - - 0.5 V

LINEN-Low (OFF) --0.8V

-5- µA

-80- nA

135 150 198 kOhm

6.2 8.5 13.5 Ω

2.5 3.0 4.7 Ω

6.2 8.5 13.4 Ω

1.3 1.6 2.7 Ω

5.5 - 8 uS

-0.8- V

1.5 V

-5- µA

-15.5 -12 -9 %

10.5 13.5 16.5 %

3

ISL6226

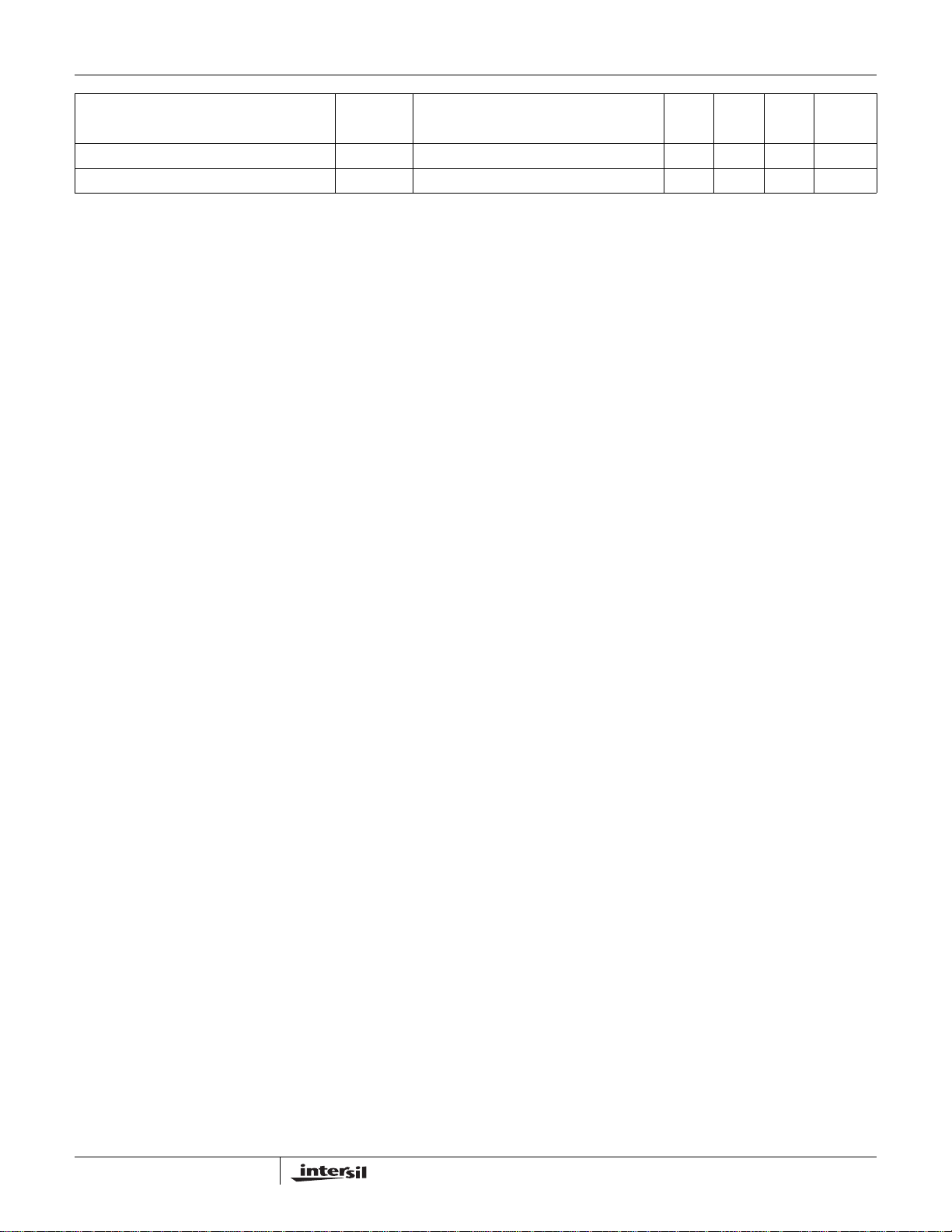

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

LINEN-High (ON) 2.0 - - V

Input Bias Current LINCS1 and LINCS2 Ibias1 Vlincs = 0.8 V - -80 - nA

Input Bias Current LINVS Ibias2 Vlinvs = 0.8 V - -80 - nA

Functional Pin Descriptions

VIN (Pin 1)

Provides battery voltage to the oscillator for feed-forward

rejection of the input voltage variation. Also, this pin programs

frequency of the internal clock and gain of the ramp generator.

PGOODL (Pin 2)

PGOODL is an open drain output used to indicate the status of

the LDO output voltages. This pin is pulled low when the output

voltage is not within of its respective nominal voltage or over

120mV between pin 8 and 9.

PWMEN (Pin 3)

This pin provides enable/disable function the PWM output.

The output is enabled when this pin is high. The PWM output

is held off when this pin is pulled to ground. Intersil

recommends to use hysteresis mode when input voltage

higher than 18V and output voltage is 1.25V or less.

OCSET (Pin 4)

A resistor on this pin to ground sets the over current

threshold for the PWM controller.

LINEN (Pin 5)

This pin provides enable/disable function and soft-start for

the LDO. The output is enabled when this pin is high. The

LDO is held off when this pin is pulled to ground.

VCC (Pin 6)

Input power for the controller and the upper MOSFET gate

drive. The IC starts to operate when the voltage on this pin

exceeds 4.3V and stops operating when the voltage on this

pin drops below approximately 4.45V.

LINDR (Pin 7)

Current output to drive the NPN transistor.

LINCS1 (Pin 8)

High side of current sense resistor.

LINCS2 (Pin 9)

Low side of current sense resistor. Current limit for the linear

regulator is initiated when the voltage difference between

LINCS1 and LINCS2 is 120mV.

SSLIN (Pin 10)

This pin provides soft start of the LDO controller. When the EN

pin is pulled high, the voltage on the capacitor connected to

the soft start pin is rising linearly due to the 5 pull-up

current. The output voltage follows the voltage on the

µA

capacitor till it reaches the value of 0.8V. At this moment the

output voltage starts to regulate and soft start continues to rise

to 1.5V. At this time, the soft start is complete and the

PGOODL will be high to indicate the output voltage within its

respective nominal voltage. The further rise of soft start

capacitor does not affect the output voltage. The soft-start

time can be obtained from the following equation.

Tsslin

1.5VxCss

----------------------------=

5µA

LINVS (Pin 11)

Voltage regulation point (0.8V) for the linear output.

GND (Pin 12)

Signal ground for the IC. All voltage levels are measured

with respect to this pin.

PGND (Pin 13)

This is the lower MOSFET gate drive return connection for

PWM converter. Tie the lower MOSFET source directly to

this pin.

LGATE (Pin 14)

This pin provides the gate drive for the lower MOSFET.

Connect the lower MOSFET gate to this pin.

PVCC (Pin 15)

This pin powers the lower MOSFET gate driver.

SSPWM (Pin 16)

This pin provides soft start of the PWM controller. This pin has

the same function as SSLIN pin. When the EN pin is pulled

high, the voltage on the capacitor connected to the soft start

pin is rising linearly due to the 5

output voltage follows the voltage on the capacitor till it

reaches the value of 0.9V. At this moment the output voltage

starts to regulate and soft start continues to rise to 1.5V. At this

time, the soft start is complete and the PGOODPWM will be

high to indicate the output voltage within its respective

nominal voltage. The further rise of soft start capacitor does

not affect the output voltage. The soft-start time can be

obtained from the following equitation.

Tsspwm

1.5VxCss

----------------------------=

5µA

pull-up current. The

µA

PHASE (Pin17)

The phase node is the junctions of the upper MOSFET

source, output filter inductor, and lower MOSFET drain.

Connect the PHASE pin directly to the PWM converter’s lower

MOSFET drain.

4

ISL6226

UGATE (Pin18)

This pin provides the gate drive for the upper MOSFET.

Connect UGATE pin to the PWM converter’s upper

MOSFET gate.

BOOT (Pin 19)

Power is supplied to the upper MOSFET driver of the PWM

converter via the BOOT pin. Connect this pin to the junction

the bootstrap capacitor with the cathode of the bootstrap

diode. The anode of the bootstrap diode is connected to pin

6, VCC.

ISEN (Pin 20)

This pin is used to monitor the voltage drop across the lower

MOSFET for current feedback control. For more precise

current detection, this input can be connected to optional

current sense resistors placed in series with the source of

the lower MOSFET.

PGOODP (Pin 21)

PGOODP is an open drain output used to indicate the status

of the PWM converter’s output voltages. This pin is pulled

low when the output is not within of their respective nominal

voltage.

FPWM (Pin 22)

This pin when pulled to VCC restrains hysterectic operation

in light loads.

VSEN (Pin 23)

This pin is connected to the PWM voltage divider to provide

the voltage feedback signal for the PWM controller. The

PGOODP, overvoltage protection (OVP) and undervoltage

shutdown circuits use this signal to determine output voltage

status and/or to initiate undervoltage shut down.

VOUT (Pin 24)

The output voltage is sensed on this pin to provide feedback

during the PWM to Hysteretic mode transition.

5

ISL6226

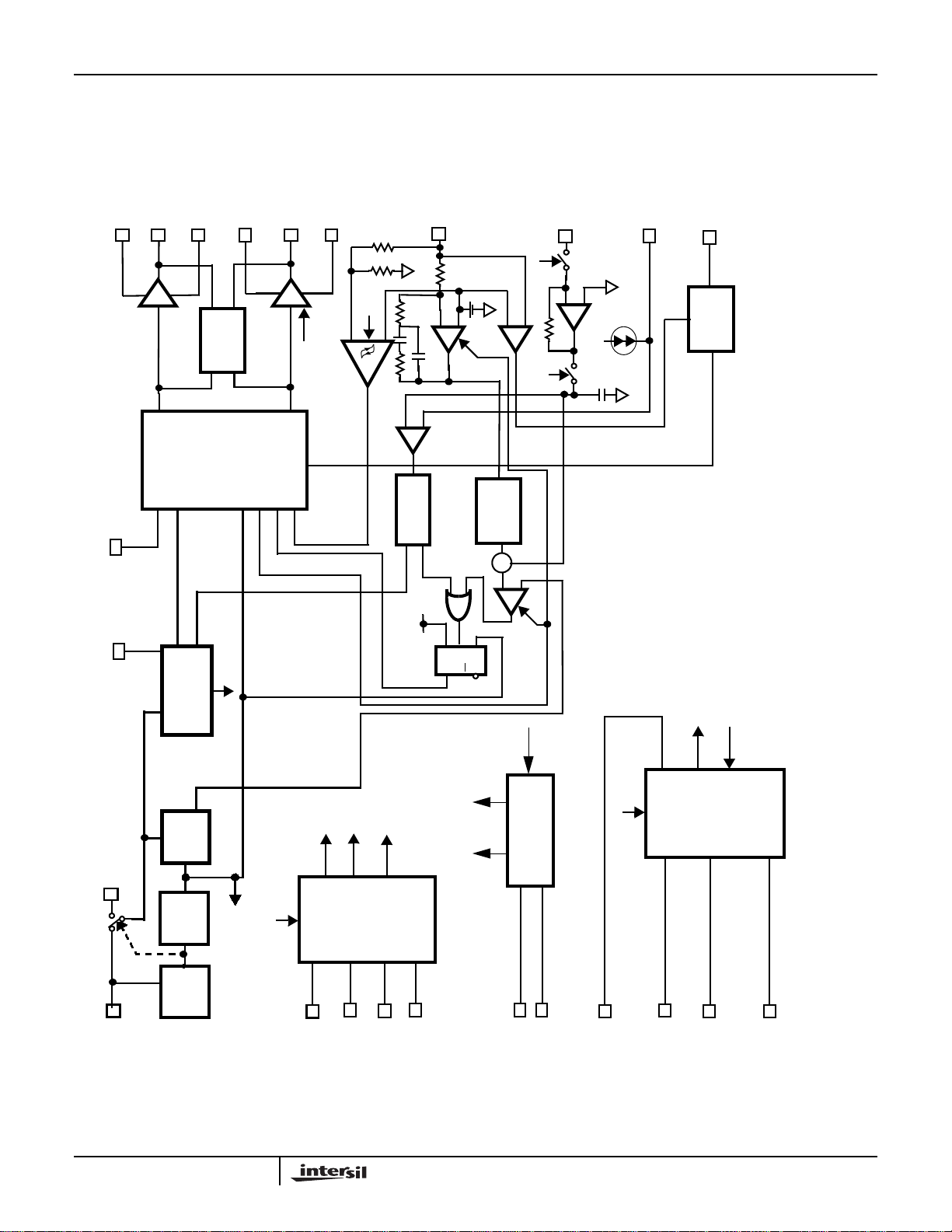

BOOT

FPWM

GND

UGATE

HGDR1

HI

FPWM

PHASE

SHUTOFF

PVCC

GATE

CONTROL

GATE LOGIC

POR

DEADT

PWM/HYST

LGATE

LGDR

LO

PWM ON

PGND

OVP

HYST ON

COMP

-

+

FFBK

CLAMP

S

-

+

ISEN

LGATE

-

+

R1=20K

LGATE1

VSEN

+

-

CLK1

-

+

HYST COMP1

OC COMP1

-

+

OC LOGIC1

VCC

PWM

LATCH 1

EA

-

+

D

Q

MODE CHANGE

REF

VOLTAGE

<

R

Q

OCSET

VOUT

PWM/HYS

LOGIC

POWER-ON

RESET (POR)

VSEN

LINDR

POR

LINCS1

OUTPUT

MONITOR

RAMP

VCC

VIN

CLK

CLK

POR

FSET

PWMEN

SDWN

REFERENCE

LINEN

REF

AND

SOFT START

SSPWM

OVP UVO

SSLIN

VOLTAGE

PGOODP

PGOODL

SDWN

LINEAR

CONTROLLER

LINCS2

REF

LINVS

FIGURE 1. FUNCTIONAL BLOCK DIAGRAM

6

ISL6226

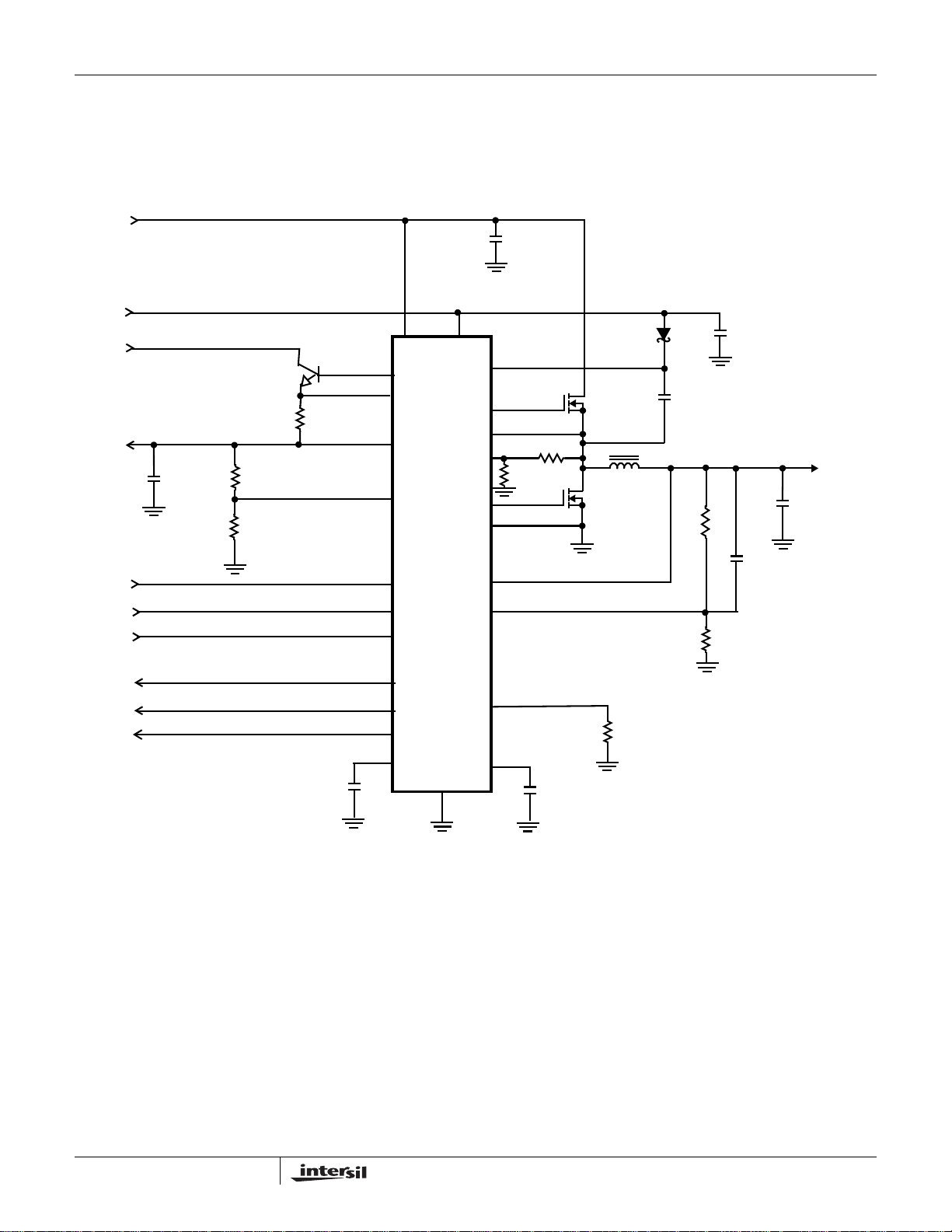

+5.6-24 V

GND

0A to 50mA

IN

5V

Vout = 0.8V - 4.5V

C5

10µF

R2

R3

+

R1

LINDR

LINCS1

LINCS2

LINVS

LINEN

PWMEN

FPWM

VIN

1

7

8

9

ISL6226

11

5

3

22

VCC

6

C2, 3

2x10µF

D1

BAT54WT1

BOOT

19

UGATE

18

PHASE

17

20

14

13

24

23

ISEN

200

LGATE

PGND

VOUT

VSEN

R4

1K

Q2

1/2 FDS6982S

L2

6.4µH

Q3

1/2 FDS6982S

C5

0.15µF

R7

C4

1µF

Vout = 0.9V - 0.93*V

R5

C8

+

(3A)

C6

1x330µF

IN

PVCC

15

PGOODL

PGOODP

C10

SSLIN

2

21

10

12

GND

4

16

OCSET

R8

SSPWM

C11

FIGURE 2. 0A to 50mA OUTPUT CURRENT LDO AND SYNCHORNOUS BUCK CONVERTER (Fs=300KHz)

7

ISL6226

+5.6-24 V

3A

IN

5V

LINEAR INPUT

Vout = 0.8V - 3.0V

+

C5

330µF

R2

R3

Q1

R1

LINDR

LINCS1

LINCS2

LINVS

LINEN

PWMEN

FPWM

7

8

9

11

5

3

22

VIN

1

ISL6226

VCC

6

C2, 3

2x10µF

D1

BAT54WT1

BOOT

19

UGATE

18

PHASE

17

20

14

13

24

23

ISEN

200

PGND

VOUT

VSEN

R4

1K

LGATE

Q2

1/2 FDS6982S

L2

6.4µH

Q3

1/2 FDS6982S

C5

0.15µF

R7

C4

1µF

Vout = 0.9V - 0.93*V

R5

C8

+

IN

(3A)

C6

1x330µF

PVCC

15

PGOODL

PGOODP

C10

Figure 3. LDO WITH EXTERNAL N-MOSFET AND SYNCHORNOUS BUCK CONVERTER (Fs = 300KHz)

SSLIN

2

21

10

12

GND

4

16

OCSET

R8

SSPWM

C11

8

ISL6226

+5.6-24 V

3A

IN

5V

LINEAR INPUT

Vout = 0.8V - 3.8V

+

C5

330µF

R2

R3

Q1

R1

LINDR

LINCS1

LINCS2

LINVS

LINEN

PWMEN

FPWM

8

9

11

3

1

7

5

22

VIN

ISL6226

VCC

6

C2, 3

2x10µF

D1

BAT54WT1

BOOT

19

UGATE

18

PHASE

17

20

14

13

24

23

ISEN

200

PGND

VOUT

VSEN

R4

1K

LGATE

Q2

1/2 FDS6982S

L2

6.4µH

Q3

1/2 FDS6982S

C5

0.15µF

R7

C4

1µF

Vout = 0.9V - 0.93*V

R5

C8

+

(3A)

C6

1x330µF

IN

PVCC

PGOODL

PGOODP

SSLIN

C10

15

OCSET

12

GND

4

16

R8

SSPWM

C11

2

21

10

FIGURE 4. LDO with External NPN and Synchornous Buck Converter (Fs = 300KHz)

9

ISL6226

5V

LINEAR INPUT

Vout = 0.8V - 3.8V

3A

+

C5

330µF

R2

R3

Q1

R1

PWMEN

PGOODL

PGOODP

C10

150K

LINDR

LINCS1

LINCS2

LINVS

LINEN

FPWM

PVCC

SSLIN

R6

VIN

1

7

8

9

11

5

3

22

15

2

21

10

ISL6226

12

GND

VCC

6

19

18

17

20

14

13

24

23

4

16

C2

2 x10µF

BOOT

UGATE

PHASE

ISEN

200

LGATE

PGND

VOUT

VSEN

OCSET

SSPWM

R4

1K

C11

BAT54WT1

Q2

1/2 FDS6982S

L2

6.4µH

Q3

1/2 FDS6982S

R8

D1

C5

0.15µF

R5

R7

Vout = 0.9V - 0.93*V

+

C6

1x330µF

C8

IN

(2A)

FIGURE 5. APPLICATION CIRCUIT FOR TWO STEP 300 kHz CONVERSION (MODE 2)

NOTE: Q1 can be either N-MOSFET, NPN or not use for 50 mA

10

5V

LINEAR INPUT

Vout = 0.8V - 3.8V

3A

+

C5

330µF

R2

R3

Q1

R1

LINDR

LINCS1

LINCS2

LINVS

1

7

8

9

11

VIN

ISL6226

ISL6226

VCC

6

BOOT

19

UGATE

18

PHASE

17

ISEN

20

14

PGND

13

C2

2 x10µF

200

LGATE

R4

1K

BAT54WT1

Q2

1/2 FDS6982S

L2

6.4µH

Q3

1/2 FDS6982S

D1

C5

0.15µF

R5

Vout = 0.9V - 0.93*V

(2A)

+

C6

1x330µF

IN

LINEN

PWMEN

FPWM

PVCC

PGOODL

PGOODP

SSLIN

C10

5

3

22

15

2

21

10

FIGURE 6. APPLICATION CIRCUIT FOR TWO STEP 600 kHz CONVERSION (MODE 3)

NOTE: Q1 can be either N-MOSFET, NPN or not used for 50

mA

12

GND

VOUT

24

VSEN

23

R7

OCSET

4

16

SSPWM

C11

R8

C8

11

ISL6226

Description Of Operation

The ISL6226 is a single channel PWM controller and linear

regulator controller intended for chipset, DRAM, audio or

other low voltage power needs of modern notebook and subnotebook PCs. The IC integrates control circuits for a single

synchronous buck converter whose output voltage is set in

the range of 0.9V to 0.93*Vin by an external resistive divider

and a linear regulator controller which drives an external

NMOSFET or NPN pass transistor whose output is set in the

range of 0.8V to 3.8V by an external resistor divider. The

synchronous buck converter can be operated in several

modes to optimize the application. The 300kHz frequency

operation is recommended when powered from the battery,

which voltage varies from 5.6V to 24V. In this case the V

pin is connected to the battery terminal and the ramp

generator gain is dynamically adjusted according to the input

voltage.

The IC also can be optimized for a two stage power

conversion configuration where the output voltage is derived

from a 5V input in lieu of the raw battery. Two operating

frequencies of 300kHz or 600kHz are available in this mode.

If 300kHz operation is desired while operating from the 5V

system bus, the V

pin should be connected to ground via a

IN

150K ohm resistor. The ramp generator gain is corrected for

the lower input voltage.

When powered from the system 5V rail, the converter can be

configured to operate on increased frequency of 600kHz to

minimize the output filter components. In this case, the V

pin is connected to the ground. Table 1 summarizes the

various modes of operation.

Figure 7 below shows plots of

the ramp speed compensation.

Table 1. Configuration for Modes of Operation

Operation

One stage 300kHz V

Two stage 300kHz 150K-GND 1V<V1<2V

Two stage 600kHz GND V1<0.5V

Pin 1

connection

IN

Pin 1 potential

V1>5.6V

IN

IN

Current Sensing and Current Limit Protection

The PWM converter uses the lower MOSFET on-state

resistance, r

technique eliminates the need for a current sense resistor

and the associated power losses. If more accurate current

protection is desired, current sense resistors may be used in

series with the lower MOSFETs’ source.

A current proportional signal is used to provide average

current mode control and over-current protection. The gain

in the current sense circuit is set by the resistor connected

from ISEN pin to the switching node of buck converter. The

value of this resistor can be estimated by the following

expression:

where Iomax is the maximum inductor current. The value of

Risen should be specified for the expected maximum

MOSFET operating temperature.

The resulting current out of the ISEN pin through Risen, is

used for current feedback and current limit protection. An

over-current protection threshold is set by an external

resistor connected from OCSET (pin 4) to ground. The value

of this resistor can be obtained from the following

expression:

where Ioc is the value of over current. This is compared

with an internal current limit threshold. When a sampled

value of the output current is determined to be above the

current limit threshold, the PWM drive is terminated and a

counter is initiated. This limits the inductor current build-up

and essentially switches the converter into current-limit

mode. If an overcurrent is detected between 26µs to 53µs

later, an overcurrent shutdown is initiated. If during the

26µs to 53µs period, an overcurrent is not detected, the

counter is reset and sampling continues as normal.

, as the current-sensing element. This

DS(ON)

Risen

Rocset

Iomax Rdson•

------------------------------------------- 100–=

75µA

9.6 Ri s en 100–()•

----------------------------------------------------=

Ioc Rdson•

300kHz CLOCK

600kHz CLOCK

Vin

---------

t

---

2

T

Vin

---------

t

---

4

T

Vin

---------

8

Figure 7. Ramp Speed Compensation Vo=2.5V

12

This current limit scheme has proven to be very robust in

applications like portable computers where fast inductor

current build-up is common due to a large difference

between input and output voltages and a low value of the

t

---

T

inductor.

Light-Load (Hysteretic) Operation

In the light-load (hysteretic) mode the output voltage is

regulated by the hysteretic comparator which regulates the

output voltage by maintaining the output voltage ripple as

shown in Figure 8. In Hysteretic mode, the inductor current

flows only when the output voltage reaches the lower limit of

the hysteretic comparator and turns off at the upper limit.

Hysteretic mode saves converter energy at light loads by

supplying energy only at the time when the output voltage

C

ISL6226

requires it. This mode conserves energy by reducing the

power dissipation associated with continuous switching.

During the time between inductor current pulses, both the

upper and lower MOSFETs are turned off. This is referred to

as ‘diode emulation mode’ because the lower MOSFET

performs the function of a diode. This diode emulation mode

prevents the output capacitor from discharging through the

lower MOSFET when the upper MOSFET is not conducting.

NOTE: the FPWM operation can intentionally be forced by tying pin

22, FPWM, to Vcc.

Operation-Mode Control

The mode-control circuit changes the converter’s mode of

operation based on the voltage polarity of the phase node

when the lower MOSFET is conducting and just before the

upper MOSFET turns on. For continuous inductor current,

the phase node is negative when the lower MOSFET is

conducting and the converter operates in fixed-frequency

PWM mode as shown in Figure 9. When the load current

decreases to the point where the inductor current flows

through the lower MOSFET in the ‘reverse’ direction, the

phase node becomes positive, and the mode is changed to

hysteretic.

A phase comparator handles the timing of the phase node

voltage sensing. A low level on the phase comparator output

indicates a negative phase voltage during the conduction

time of the lower MOSFET. A high level on the phase

comparator output indicates a positive phase voltage.

When the phase node is positive (phase comparator high),

at the end of the lower MOSFET conduction time, for eight

consecutive clock cycles, the mode is changed to hysteretic

as shown in Figure 9. The dashed lines indicate when the

phase node goes positive and the phase comparator output

goes high. The solid vertical lines at 1,2,...8 indicate the

sampling time, of the phase comparator, to determine the

polarity (sign) of the phase node. At the transition between

PWM and hysteretic mode both the upper and lower

MOSFETs are turned off. The phase node will ‘ring’ based

on the output inductor and the parasitic capacitance on the

phase node and settle out at the value of the output voltage.

PWM on the next clock cycle. This insures the full power

required by the increase in output current.

Gate Control Logic

The gate control logic translates generated PWM control

signals into the MOSFET gate drive signals providing

necessary amplification, level shifting and shoot-through

protection. Also, it has functions that help optimize the IC

performance over a wide range of operational conditions.

Since MOSFET switching time can vary dramatically from

type to type and with the input voltage, the gate control logic

provides adaptive dead time by monitoring the gate-tosource voltages of both upper and lower MOSFETs. The

lower MOSFET is not turned on until the gate-to-source

voltage of the upper MOSFET has decreased to less than

approximately 1 volt. Similarly, the upper MOSFET is not

turned on until the gate-to-source voltage of the lower

MOSFET has decreased to less than approximately 1 volt.

This allows a wide variety of upper and lower MOSFETs to

be used without a concern for simultaneous conduction, or

shoot-through.

VOUT

I

L

PHASE

COMP

MODE

OF

OPERATION

I

L

1 2 3 4 5 6 7 8

PWM

FIGURE 8. REGULATION IN HYSTERETIC MODE

HYSTERETIC

t

t

t

t

t

The mode change from hysteretic to PWM can be caused by

one of two events. One event is the same mechanism that

causes a PWM to hysteretic transition. But instead of looking

for eight consecutive positive occurrences on the phase

node, it is looking for eight consecutive negative

occurrences on the phase node. The operation mode will be

changed from hysteretic to PWM when these eight

consecutive pulses occur. This transition technique prevents

jitter of the operation mode at load levels close to boundary.

The other mechanism for changing from hysteretic to PWM

is due to a sudden increase in the output current. This step

load causes an instantaneous decrease in the output voltage

due to the voltage drop on the output capacitor ESR and

ESL. If the decrease causes the output voltage to drop

below the hysteretic regulation level, the mode is changed to

13

PHASE

NODE

PHASE

COMP

MODE

OF

OPERATION

1 2 3 4

PWM

FIGURE 9. MODE CONTROL WAVEFORMS

5 6

7 8

HYSTERETI

t

t

t

ISL6226

Feedback Loop Compensation

To reduce the number of external components and remove

the burden of determining compensation components from a

system designer, PWM controller has internally

compensated error amplifiers. To make internal

compensation possible several design measures where

taken.

First, the ramp signal applied to the PWM comparator is

proportional to the input voltage provided via the VIN pin as

shown in Figure 7. Second, the load current proportional

signal is derived from the voltage drop across the lower

MOSFET during on time of lower MOSFET. This signal is

added to the amplifier error signal on the comparator input.

This effectively creates an internal current control loop.

Because of current loop, a compensation network with one

zero and two poles is usually sufficient. One pole is place at

origin which has high DC gain. The zero is place around

9kHz, and another pole is around 137kHz. The zero-pole

pair causes a flat gain region at frequencies in between the

zero and the pole. This region is also make the phase bump

or reduce phase shift. The amount of phase shift reduction

depends on how wide the region of flat gain and has

maximum value of 90

o

.

Low Drop Out Linear Regulator

The linear has separate Enable, Pgood and Soft Start pins

from the PWM. The linear also has over current and under

voltage protection features.

The over current protection will shut down the LDO controller

when the voltage between pin 8 and 9 is more 100mV. The

LDO controller will automatic restart again when the voltage

is less than 100mV. Intersil recommend to use this feature to

protect the ISL6226 IC otherwise the IC will damage when

over current happen.

The under voltage protection will start when the output

voltage is 26% lower than the nominal output voltage.

The ISL6226 has an internal P-channel MOSFET pass

transistor. This provides several advantages over PNP pass

transistor. PNP regulator waste considerable amounts of

current in dropout when the pass transistor saturates. The Pchannel MOSFET requires no base drive current which

reduces quiescent current.

Output Voltage Calculation

Figure 10 describe the output voltage which relative to the

bias voltage. Due to the over current protection circuitry

works properly, the internal P-channel MOSFET has an

approximate 0.5V drop cross it. Therefore, the maximum

voltage at LINDR pin will be.

VLINDR VCC 0.5V–=

The maximum output voltage equals to the voltage at LINDR

pin minus the diode drop voltage of between the base and

emitter of NPN transistor device and minus 100mV across

pin 8 and 9. In the case of using MOSFET instead of NPN

transistor, the maximum output voltage equals to the voltage

at LINDR pin minus the gate threshold voltage of MOSFET

and minus 100mV across pin 8 and 9.

Vou t

External IC

V

IN

C

E

LINDR

B

LINCS1

LINCS2

FIGURE 10. LDO

VCC

Internal IC

PMOS

Output Current

The LDO controller is capable of sourcing 50mA out of

LINDR pin. This amount of current is used to drive the NPN

transistor or as load current up to 50mA. The output current

of the system equals the current out of LINDR pin times the

current gain of NPN transistor ( , Beta).

β

Component Selection Guidelines

LDO Device Considerations

The NPN transistor or MOSFET should be chosen to carry

the load current and power dissipation required by the

conditions of the load current and voltage drop across the

device.

Output Capacitor Selection-LDO

For stable operation, the output current up to 50mA or

without the external device, a minimum output capacitor

value of 4.7µF is recommended. The design simulation

results indicated that the phase margins vary from 70 degree

to 90 degree while the output currents vary from 5µA to

50mA, respectively. The higher output capacitance indicates

the higher phase margin.

For stable operation with the external device, a minimum

output capacitor value of 220µF is recommended. Larger

capacitor values provide better transient response. A

capacitor value of 330µF, such as SANYO POSCAP

6TPB330M, will provide good phase margin and better

transient response.

Output Capacitor Selection-PWM

The output capacitors have unique requirements. In general,

the output capacitors should be selected to meet the

dynamic regulation requirements including ripple voltage

and load transients.

14

ISL6226

Selection of the output capacitors is also dependent on the

output inductor so some inductor analysis is required to

select the output capacitors.

One of the parameters limiting the converter’s response to a

load transient is the time required for the inductor current to

slew to it’s new level. Given a sufficiently fast control loop

design, the ISL6226 will provide either 0% or 93% duty cycle

in response to a load transient. The response time is the

time interval required to slew the inductor current from an

initial current value to the load current level. During this

interval the difference between the inductor current and the

transient current level must be supplied by the output

capacitor(s). Minimizing the response time can minimize the

output capacitance required. Also, if the load transient rise

time is slower than the inductor response time, as in a hard

drive or CD drive, this reduces the requirement on the output

capacitor.

The maximum capacitor value required to provide the full,

rising step, transient load current during the response time of

the inductor is:

C

OUT

Where: C

output inductor, I

is the output capacitor(s) required, LO is the

OUT

TRAN

is the input voltage, V

×

V

–()2×

INVOUT

TRAN

----------------------------------------------

is the transient load current step, V

is output voltage, and DV

OUT

I

TRAN

--------------------×=

DV

OUT

OUT

IN

is

LOI

the drop in output voltage allowed during the load transient.

High frequency capacitors initially supply the transient

current and slow the load rate-of-change seen by the bulk

capacitors. The bulk filter capacitor values are generally

determined by the ESR (Equivalent Series Resistance) and

voltage rating requirements as well as actual capacitance

requirements. The output voltage ripple is due to the inductor

ripple current and the ESR of the output capacitors as

defined by:

V

RIPPLE

where, is calculated in the Inductor Selection section.

∆I

L

∆ILESR×=

High frequency decoupling capacitors should be placed as

close to the power pins of the load as physically possible. Be

careful not to add inductance in the circuit board wiring that

could cancel the usefulness of these low inductance

components. Consult with the manufacturer of the load

circuitry for specific decoupling requirements.

Use only specialized low-ESR capacitors intended for

switching-regulator applications, at 300kHz, for the bulk

capacitors. In most cases, multiple electrolytic capacitors of

small case size perform better than a single large case

capacitor.

The stability requirement on the selection of the output

capacitor is that the ‘ESR zero’, f

, be between 1.8kHz and

Z

45kHz. This range is set by an internal, single compensation

zero at 9kHz. The ESR zero can be a factor of five on either

side of the internal zero and still contribute to increased

phase margin of the control loop. Therefore:

OUT

-------------------------------------------=

2 π ESR f

×××

Z

C

1

In conclusion, the output capacitors must meet three criteria:

1. They must have sufficient bulk capacitance to sustain the

output voltage during a load transient while the output

inductor current is slewing to the value of the load

transient

2. The ESR must be sufficiently low to meet the desired

output voltage ripple due to the output inductor current,

and

3. The ESR zero should be placed, in a rather large range,

to provide additional phase margin.

Output Inductor Selection

The output inductor is selected to meet the output voltage

ripple requirements. The inductor value determines the

converter’s ripple current and the ripple voltage is a function

of the ripple current and output capacitor(s) ESR. The ripple

voltage expression is given in the capacitor selection section

and the ripple current is approximated by the following

equation:

where F

–

V

INVOUT

--------------------------------

∆I

L

F

S

is the switching frequency.

s

V

OUT

----------------×=

L×

V

IN

Input Capacitor Selection

The important parameters for the bulk input capacitor(s) are

the voltage rating and the RMS current rating. For reliable

operation, select bulk input capacitors with voltage and

current ratings above the maximum input voltage and largest

RMS current required by the circuit. The capacitor voltage

rating should be at least 1.25 times greater than the

maximum input voltage and 1.5 times is a conservative

guideline.

The AC RMS input current varies with load. Depending on

the specifics of the input power and it’s impedance, most (or

all) of this current is supplied by the input capacitor(s).

Use a mix of input bypass capacitors to control the voltage

ripple across the MOSFETs. Use ceramic capacitors for the

high frequency decoupling and bulk capacitors to supply the

RMS current. Small ceramic capacitors can be placed very

close to the upper MOSFET to suppress the voltage induced

in the parasitic circuit impedances.

For board designs that allow through-hole components, the

Sanyo OS-CON® series offer low ESR and good

temperature performance.

For surface mount designs, solid tantalum capacitors can be

used, but caution must be exercised with regard to the

15

ISL6226

capacitor surge current rating. These capacitors must be

capable of handling the surge-current at power-up. The TPS

series available from AVX is surge current tested.

MOSFET Considerations

The logic level MOSFETs are chosen for optimum efficiency

given the potentially wide input voltage range and output

power requirements. One dual N-Channel or Two N-channel

MOSFETs are used in each of the synchronous-rectified

buck converters for the outputs. These MOSFETs should be

selected based upon r

DS(ON)

, gate supply requirements,

and thermal management considerations.

The power dissipation includes two loss components;

conduction loss and switching loss. These losses are

distributed between the upper and lower MOSFETs

according to duty cycle (see the following equations). The

conduction losses are the main component of power

dissipation for the lower MOSFETs. Only the upper MOSFET

has significant switching losses, since the lower device turns

on and off into near zero voltage.

2

I

r

P

UPPER

P

LOWER

× V

O

------------------------------------------------------------

2

I

r

× V

O

-------------------------------------------------------------- -------------------=

×

DS ON()

V

IN

DS ON()

V

OUT

INVOUT

IN

–()×

I

OVIN

----------------------------------------------------+=

× tSW× FS×

2

The equations assume linear voltage-current transitions and

do not model power loss due to the reverse-recovery of the

lower MOSFET’s body diode. The gate-charge losses are

dissipated by the ISL6226 and do not heat the MOSFETs.

However, a large gate-charge increases the switching time,

t

which increases the upper MOSFET switching losses.

SW

Ensure that both MOSFETs are within their maximum

junction temperature at high ambient temperature by

calculating the temperature rise according to package

thermal-resistance specifications.

Layout Considerations

MOSFETs switch very fast and efficiently. The speed with

which the current transitions from one device to another

causes voltage spikes across the interconnecting impedances

and parasitic circuit elements. The voltage spikes can

degrade efficiency, radiate noise into the circuit, and lead to

device over voltage stress. Careful component layout and

printed circuit design minimizes the voltage spikes in the

converter. Consider, as an example, the turn-off transition of

one of the upper PWM MOSFETs. Prior to turn-off, the upper

MOSFET is carrying the full load current. During the turn-off,

current stops flowing in the upper MOSFET and is picked up

by the lower MOSFET. Any inductance in the switched current

path generates a voltage spike during the switching interval.

Careful component selection, tight layout of the critical

components, and short, wide circuit traces minimize the

magnitude of voltage spikes. See the Application Note

AN1013 for the evaluation board component placement and

the printed circuit board layout details.

There are two sets of critical components in a DC-DC

converter using an ISL6226 controller. The switching power

components are the most critical because they switch large

amounts of energy, and as such, they tend to generate

equally large amounts of noise. The critical small signal

components are those connected to sensitive nodes or

those supplying critical bias currents.

Power Components Layout Considerations

The power components and the controller IC should be

placed first. Locate the input capacitors, especially the highfrequency ceramic decoupling capacitors, close to the power

MOSFETs. Locate the output inductor and output capacitors

between the MOSFETs and the load. Locate the PWM

controller close to the MOSFETs.

Insure the current paths from the input capacitors to the

MOSFETs, to the output inductors and output capacitors are

as short as possible with maximum allowable trace widths.

A multi-layer printed circuit board is recommended. Dedicate

one solid layer for a ground plane and make all critical

component ground connections with via to this layer. Dedicate

another solid layer as a power plane and break this plane into

smaller islands of common voltage levels. The power plane

should support the input power and output power nodes. Use

copper filled polygons on the top and bottom circuit layers for

the phase nodes, but do not unnecessarily oversize these

particular islands. Since the phase nodes are subjected to

very high dV/dt voltages, the stray capacitor formed between

these islands and the surrounding circuitry will tend to couple

switching noise. Use the remaining printed circuit layers for

small signal wiring. The wiring traces from the control IC to the

MOSFET gate and source should be sized to carry 2A peak

currents.

Small Components Signal Layout Considerations

The Vin pin 1 input should be bypassed with a 1.0uF

capacitor. The bypass capacitors for Vin and the soft-start

capacitor, should be located close to their connecting pins on

the control IC.

Refer to the Application Note AN1013 for a recommended

component placement and interconnections.

16

ISL6226ISL6226

Plastic Packages for Integrated Circuits

Plastic Packages for Integrated Circuits

Shrink Small Outline Plastic Packages (SSOP)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

GAUGE

PLANE

0.25

0.010

h x 45

L

o

α

e

B

0.17(0.007) C AM BS

M

A1

0.10(0.004)

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2

of Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate

burrs. Mold flash, protrusion and gate burrs shall not exceed

0.15mm (0.006 inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch)

per side.

5. The chamfer on the body is optional. If it is not present, a visual index feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. Dimension “B” does not include dambar protrusion. Allowable dambar protrusion shall be 0.10mm (0.004 inch) total in excess of “B”

dimension at maximum material condition.

10. Controlling dimension: INCHES. Converted millimeter dimensions

are not necessarily exact.

A2

C

M24.15

24 LEAD THIN SHRINK NARROW BODY SMALL OUTLINE

PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.053 0.069 1.35 1.75 -

A1 0.004 0.010 0.10 0.25 -

A2 - 0.061 - 1.54 -

B 0.008 0.012 0.20 0.30 9

C 0.007 0.010 0.18 0.25 -

D 0.337 0.344 8.55 8.74 3

E 0.150 0.157 3.81 3.98 4

e 0.025 BSC 0.635 BSC -

H 0.228 0.244 5.80 6.19 -

h 0.0099 0.0196 0.26 0.49 5

L 0.016 0.050 0.41 1.27 6

N24 247

o

α

0

o

8

o

0

o

8

Rev. 0 12/00

NOTESMIN MAX MIN MAX

-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

17

Loading...

Loading...