®

www.BDTIC.com/Intersil

ISL6173

Data Sheet

Dual Low Voltage Hot Swap Controller

This IC targets dual voltage hot swap applications across the

+2.5V to +3.3V (nominal) bias supply voltage range with a

second lower voltage rail down to less than 1V. It features a

charge pump for driving external N-Channel MOSFETs,

regulated current protection and duration, output undervoltage

monitoring and reporting, optional latch-off or retry response,

and adjustable soft-start.

The current regulation level (CR) for each rail is set by two

external resistors and each CR duration is set by an external

capacitor on the TIM pin. After the CR duration has expired

the IC then quickly pulls down the associated GATE(s)

output turning off its external FET(s). The ISL6173 offers a

latched output or indefinite auto retry mode of operation.

Ordering Information

TEMP.

PART NUMBER

(Note)

ISL6173DRZA ISL6173DRZ 0 to +85 28 Ld 5x5 QFN L28.5x5

ISL6173DRZA-T ISL6173DRZ 0 to +85 28 Ld 5x5 QFN

ISL6173EVAL3 Evaluation Platform

NOTE: Intersil Pb-free plus anneal products employ special Pb-free

material sets; molding compounds/die attach materials and 100%

matte tin plate termination finish, which are RoHS compliant and

compatible with both SnPb and Pb-free soldering operations. Intersil

Pb-free products are MSL classified at Pb-free peak reflow

temperatures that meet or exceed the Pb-free requirements of

IPC/JEDEC J STD-020.

PAR T

MARKING

RANGE

(°C)

PACKAGE

(Pb-Free)

Tape & Reel

PKG.

DWG. #

L28.5x5

January 3, 2006

FN9186.3

Features

• Fast Current Regulation amplifier quickly responds to

overcurrent fault conditions

• Less than 1µs response Time to Dead Short

• Programmable Current Regulation Level and Duration

• Two Levels of Overcurrent Detection Provide Fast

Response to Varying Fault Conditions

• Overcurrent Circuit Breaker and Fault Isolation functions

• Adjustable Current Regulation Threshold as low as 20mV

• Selectable Latch-off or Auto Retry Response to Fault

conditions

• Adjustable voltage ramp-up for In-rush Protection During

Turn-On

• Rail Independent Control, Monitoring and Reporting I/O

• Dual Supply Hot Swap Power Distribution Control to <1V

• Charge Pump Allows the use of N-Channel MOSFETs

• QFN Package:

- Compliant to JEDEC PUB95 MO-220

QFN - Quad Flat No Leads - Package Outline

- Near Chip Scale Package footprint, which improves

PCB efficiency and has a thinner profile

• Pb-Free Plus Anneal Available (RoHS Compliant)

Applications

• Power Supply Sequencing, Distribution and Control

• Hot Swap/Electronic Breaker Circuits

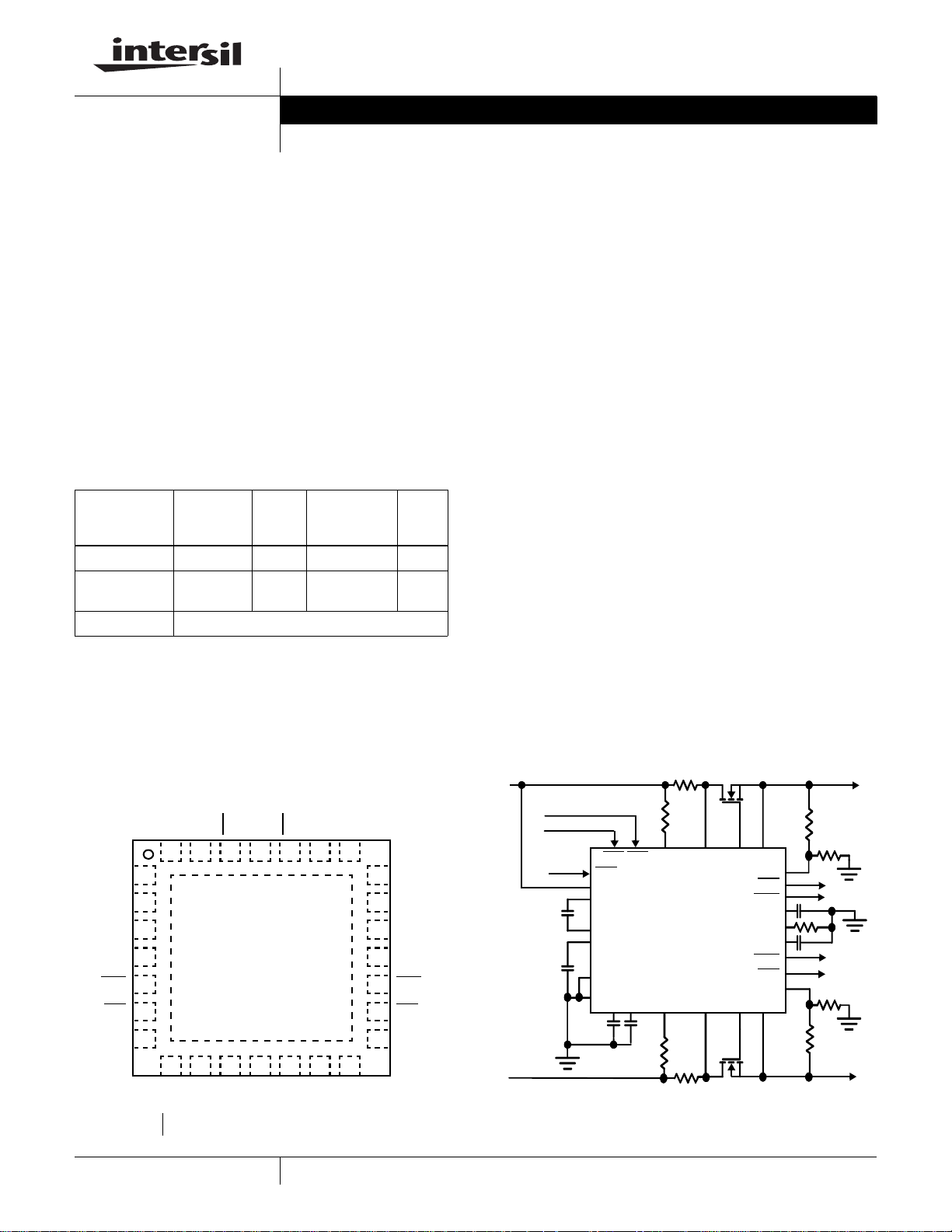

Pinout

SNS1

VO1

SS1

GT1

FLT1

PG1

CT1

ISL6173 (28 LD QFN) TOP VIEW

OCREF

CPQ-

EN2

BIAS

VS1

UV1

EN1

28 27 26 25 24 23 22

1

2

3

4

5

6

7

8 9 10 11 12 13 14

GND

PGND

RTR/LTCH

1

UV2

CPQ+

VS2

CPVDD

21

SNS2

20

VO2

19

SS2

GT2

18

17

FLT2

16

PG2

15

CT2

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

V1(in)

V2(in)

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Rsns1

Rset1

VS1 SNS1

EN2

EN1

RTR/LTCH

BIAS

CPQ+

CPQCPVDD

PGND

GND

CT1 CT2 VS2 SNS2 GT2 VO2

FIGURE 1. TYPICAL APPLICATION

Copyright © Intersil Americas Inc. 2004-2006. All Rights Reserved

ISL6173

Rset2

Rsns2

GT1 VO 1

UV1

PG1

FLT1

SS1

OCREF

SS2

FLT2

PG2

UV2

V1(out)

V2(OUT)

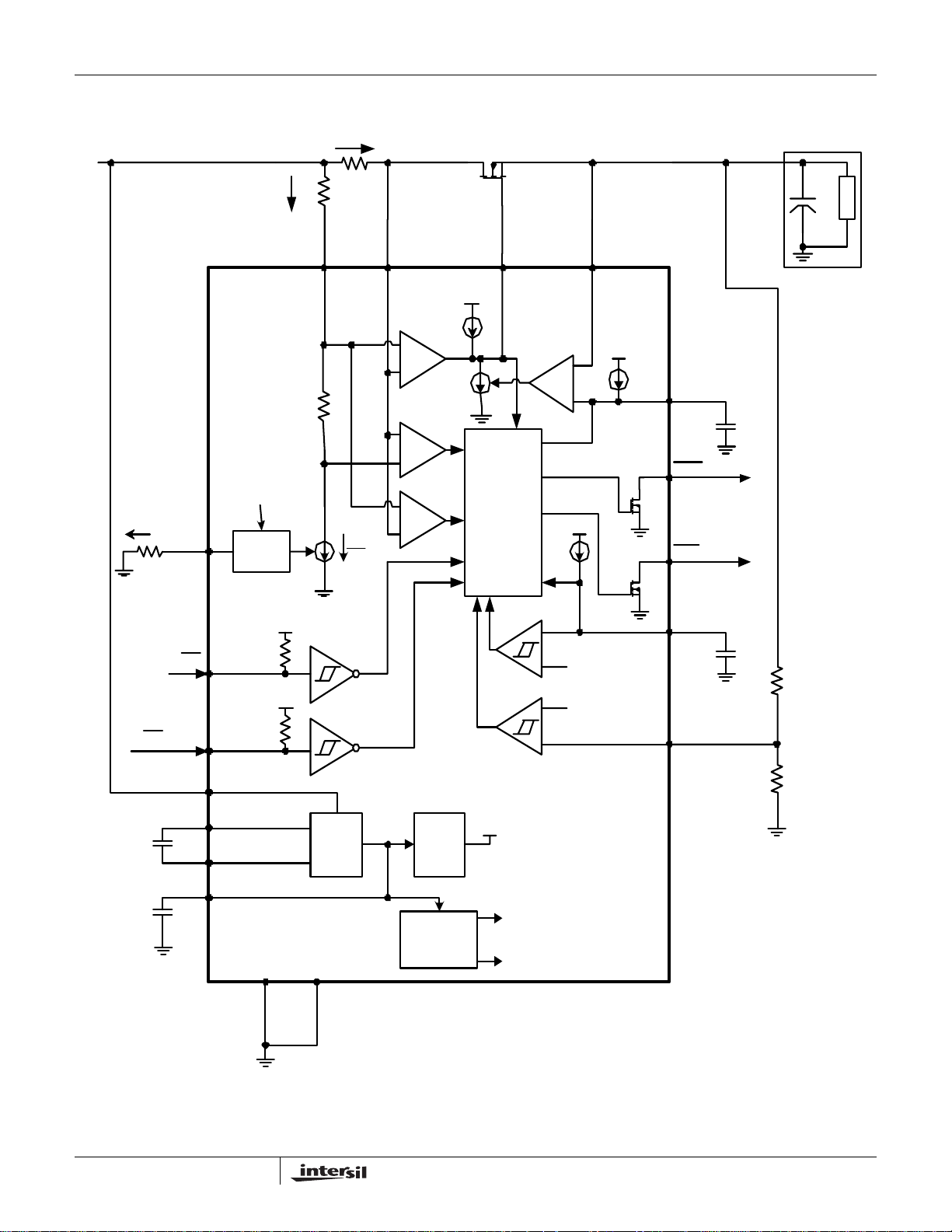

Block Diagram

www.BDTIC.com/Intersil

ISL6173

Io

Vin Vo

Limit

WOC

OC

42µA

QRsn s

10V

GT1

24µA

OC Timer

&

Logic

Soft Start

Amplifier

-

+

CPVDD

10µA

VO1

CPV DD

10µA

SS1

Css

FLT1

PG1

Ire f

Rref

OCREF

1. 178V

Cu rren t

Mi rror

I set

Rset

3K

VS1

Iref

SNS1

Cu rren t

Amplifier

-

+

-

+

Co mpar ato r

+

-

4

Co mpar ato r

LOAD

RT R/ LT CH

Cp

Cv

EN1

BI AS

CPQ +

CPQ -

CPV DD

10K

10K

PGND

BI AS

BI AS

Ch arge

Pump

GND

+

-

Timeout

Co mpar ato r

UV

Co mpar ato r

X2

Ch arg e

Pump

POR and

Bandgap

10V(o u t)

X2

633mV

1. 178V

1. 178V

-

633mV

+

ISL6173

CT 1

Ct

Rs1

UV1

Rs2

FIGURE 2. ISL6173 - INTERNAL BLOCK-DIAGRAM OF THE IC - CHANNEL ONE ONLY

2

FN9186.3

January 3, 2006

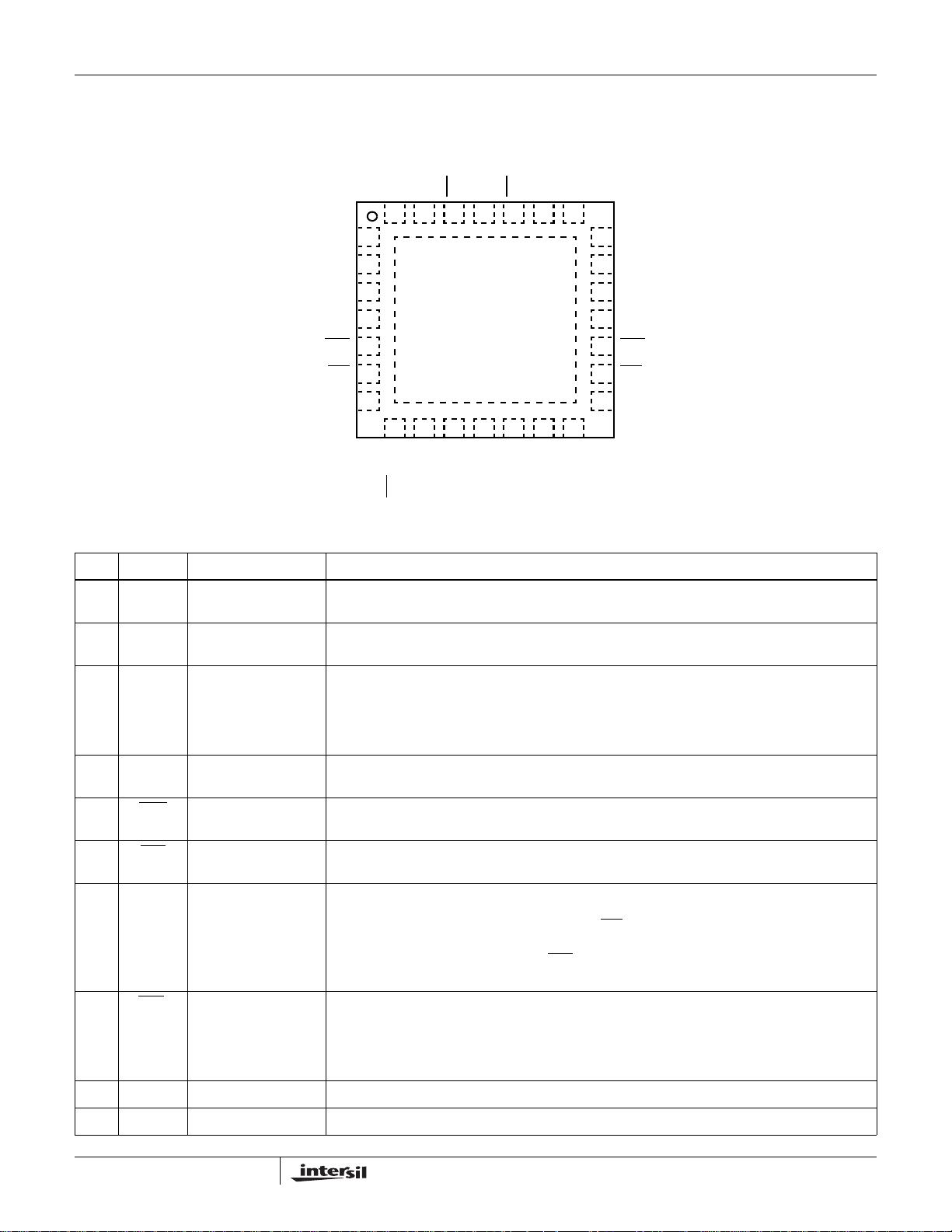

Pinout

www.BDTIC.com/Intersil

SNS1

ISL6173

28 LEAD QFN

TOP VIEW

OCREF

VS1

UV1

EN1

28 27 26 25 24 23 22

1

EN2

UV2

VS2

21

SNS2

CPVDD

20

VO2

19

SS2

GT2

18

17

FLT2

16

PG2

15

CT2

VO1

SS1

GT1

FLT1

PG1

CT1

2

3

4

5

6

7

8 9 10 11 12 13 14

GND

RTR/LTCH

CPQ-

PGND

BIAS

CPQ+

Pin Descriptions

PIN NAME FUNCTION DESCRIPTION

1 SNS1 Current Sense Input This pin is connected to the current sense resistor and control MOSFET Drain node. It provides

2 VO1 Output Voltage 1 This pin is connected to the control MOSFET switch source, which connects to a load. Internally, this

3 SS1 Soft-Start Duration Set

Input

current sense signal to the internal comparator and amplifier in conjunction with VS1 pin.

voltage is used for SS control.

A capacitor from this pin to ground sets the output soft-start ramp slope. This capacitor is charged by

the internal 10µA current source setting the soft-start ramp. The output voltage ramp tracks the SS

ramp by controlled enhancement of FET gate. Once ramp-up is completed, the capacitor continues

to charge to the CPVDD voltage rail. If common capacitor is used (by tying SS1, SS2 together and

the capacitor to GND from the connection) then both the outputs track each other as they ramp up.

4 GT1 Gate Drive Output Direct connection to the gate of the external N-Channel MOSFET. At turn-on the Gate will charge to

4 X Vbias or 10V(max) from the 24µA source.

5FLT1

Fault Output This is an open drain output. It asserts (pulls low) once the current regulation duration (determined

by the CTx timeout cap) has expired. This output is valid for Vbias>1V.

6PG1

Power Good Output This is an active low, open drain output. When asserted (logic zero), it indicates that the voltage on

UV1 pin is more than 643mV (633mV + 10mV hysteresis). This output is valid at VBIAS >1V.

7 CT1 Timer Capacitor A capacitor from this pin to ground controls the current regulation duration from the onset of current

regulation to channel shutdown (current limit time-out). Once the voltage on CTx cap reaches

the GATE output is pulled down and the FLT is asserted.

V

CT_Vth

The duration of current limit time-out = (C

When the OC comparator trips AND the RTR

*1.178)/10µA

TIM

/LTCH pin is pulled low, the IC’s faulty channel remains

shut down for 64 cycles (each cycle length is equal to the current limit time-out duration).

/

8RTR

LTC H

Retry Or Latch Input This input dictates the IC behavior (for either channel) under OC condition. If it is pulled high (or left

floating), the IC will shut down upon OC time-out. If it is pulled low, the IC will go into retry mode after

an interval determined by the capacitor on CTx pin. The faulting channel will remain shut down for

64 cycles and will try to come out of it on the 65th cycle. Each cycle length is determined by the

formula shown in CT pin description.

9 GND Chip Gnd This pin is also internally shorted to the metal tab at the bottom of the IC.

10 PGND Charge pump ground. Both GND and PGND must be tied together externally.

3

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Pin Descriptions (Continued)

PIN NAME FUNCTION DESCRIPTION

11 CPQ- Charge Pump Capacitor

Low Side

12 BIAS Chip Bias Voltage Provides IC Bias. Should be 2V to 4V for IC to function normally. This pin can be powered from a

13 CPQ+ Charge Pump Capacitor

14 CPVDD Charge Pump Output This is the voltage used for some internal pullups and bias. Use of 0.47µF (minimum) is

15 CT2 Timer Capacitor Same function as pin 7

16 PG2

17 FLT2

18 GT2 Gate Drive Output Same as pin 4

19 SS2 Soft-Start Duration Set

20 VO2 Output Voltage 2 Same as pin 2

21 SNS2 Current Sense Input Same as pin 1

22 VS2 Current Sense

23 UV2 Undervoltage Monitor

High Side

Power Good Output Same function as pin 6

Fault Output Same as pin 5

Input

Reference

Input

Flying cap lowside.

supply voltage that is not being controlled. It is preferable to use 3.3V even if the channels being

controlled are 2.5V or lower because more gate drive voltage will be available to the MOSFETs.

Flying cap highside. Use of 0.1µF for 2.5V bias and 0.022µF for 3.3V bias is recommended.

recommended.

Same as pin 3

Voltage input for one of the two voltages. Provides a 20µA current source for the ISET series resistor

which sets the voltage to which the sense resistor IR drop is compared.

This pin is one of the two inputs to the undervoltage comparator. The other input is the 633mV

reference. It is meant to sense the output voltage through a resistor divider. If the output voltage

drops so that the voltage on the UV pin goes below 633mV, PG2

is deasserted.

24 EN2

25 OCREF Ref. Current Adj. Allows adjustment of the reference current through R

26 EN1

27 UV1 Undervoltage Monitor

28 VS1 Current Sense

Enable This is an active low input. When asserted (pulled low), the SS and gate drive are released and the

output voltage gets enabled. When deasserted (pulled high or left floating), the reverse happens.

resistor, thus setting the thresholds for CR, OC and WOC.

Enable Input Same as pin 24

Same as pin 23

Input

Same as pin 22

Reference

and the internal current regulation set

SET

4

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

VBIAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +5.5V

GTx, CPQ+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to +12V

, RTR/LTCH, SNSx, PGx, FLTx, VSx, CTx, UVx,

ENx

SSx, CPQ-, CPVDD. . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 5.5VDC

Output Current . . . . . . . . . . . . . . . . . . . . . . . Short Circuit Protected

ESD Rating

Human Body Model (Per MIL-STD-883 Method 3015.7) . . .1750V

Machine Model (Per EIAJ ED-4701 Method C-111). . . . . . . . 125V

Charged Device Model (Per EOS/ESD DS5.3, 4/14/93) . . .1750V

Operating Conditions

VBIAS/VIN1 Supply Voltage Range. . . . . . . . . . . . +2.25V to +3.63V

Temperature Range (T

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

is measured in free air with the component mounted on a high effective thermal conductivity test board with “direct attach” features. See

1. θ

JA

Tech Brief TB379.

2. All voltages are relative to GND, unless otherwise specified.

3. 1V (min) on the BIAS pin required for FLT

4. For θ

, the “case temp” location is the center of the exposed metal pad on the package underside.

JC

) . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 85°C

A

to be valid.

Thermal Resistance (Typical, Notes 1, 4) θ

5x5 QFN Package . . . . . . . . . . . . . . . . 42 12.5

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . 150°C

Maximum Storage Temperature Range . . . . . . . . . . . -65°C to 150°C

For recommended soldering conditions, see Tech Brief TB389.

(QFN - Leads Only)

(°C/W) θJC (°C/W)

JA

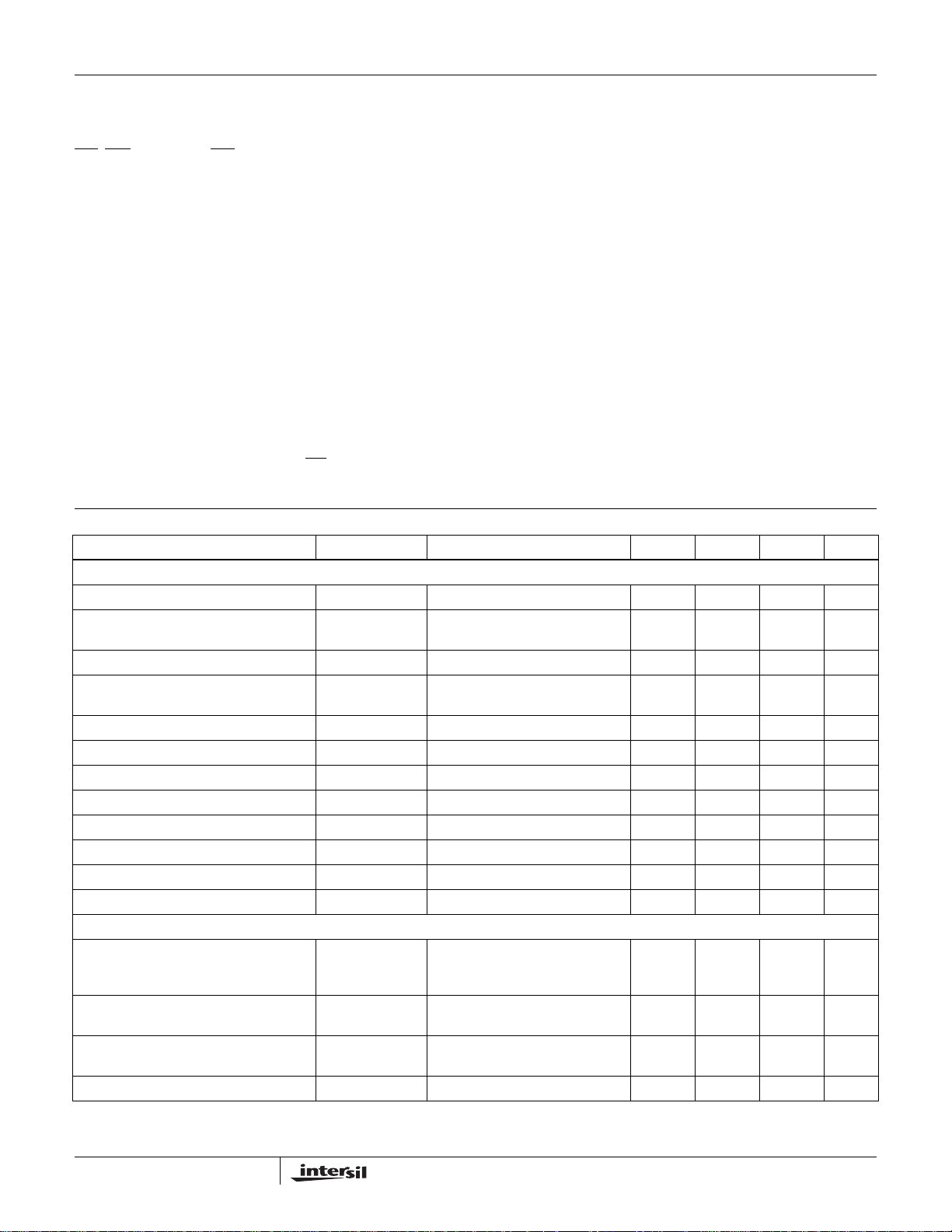

Electrical Specifications V

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

CURRENT REGULATION CONTROL

ISET Current I

Partial Temp Range I

Current Limit Amp Offset Voltage Vio_ft V

Partial Temp. Current Limit Amp Offset

Voltage

Current Regulation Threshold Voltage V

Current Regulation Accuracy V

Current Regulation Threshold Voltage V

Current Regulation Accuracy V

Current Regulation Threshold Voltage V

Current Regulation Accuracy V

CT Threshold Voltage V

CT Charging Current I

GATE DRIVE

GATE Response Time from WOC (Open) pd_woc_open GATE open

GATE Response Time from WOC

(Loaded)

GATE Response Time in Current

Regulation mode (Loaded)

GATE Turn-On Current IGATE GATE = 2V, V

Current I

SET

= 2.5V to +3.3V, VS = 1V ,TA = T

DD

SET_ft

SET_pt

Vio_pt V

CRVTH_1

CRVTH_1

CRVTH_2

CRVTH_2

CRVTH_3

CRVTH_3

CT_Vth

CT

pd_woc_load GATE = 1nF 100 ns

pd_cr_load GATE = 1nF

R

R

TJ = 25oC to 60oC

T

RISET = 1.25K, I

R RISET = 1.25K, I

RISET = 2.50K, I

R RISET = 2.50K, I

RISET = 0.499K, I

R RISET = 0.499K, I

100mV of overdrive on the WOC

comparator

120% Load Current

J

= 14.7kΩ 18.7 20 21.3 µA

OCREF

= 14.7kΩ

OCREF

- V

VS

SNS

- V

VS

SNS

= 25°C to 60°C

J

= 0°C - 85°C, Unless Otherwise Specified.

19 20 21 µA

with I

with I

VS

= 0A -2 2 mV

OUT

= 0A

OUT

= 20µA 23 25 27 mV

SET

= 20µA -8 +8 %

SET

= 20µA 48 50 52 mV

SET

= 20µA -4 +4 %

SET

= 20µA 8 10 12 mV

SET

= 20µA -20 +20 %

SET

= 2V, V

= 2.1V 21 24 27 µA

SNS

-1 1 mV

1.128 1.178 1.202 V

10 µA

3ns

5µs

5

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

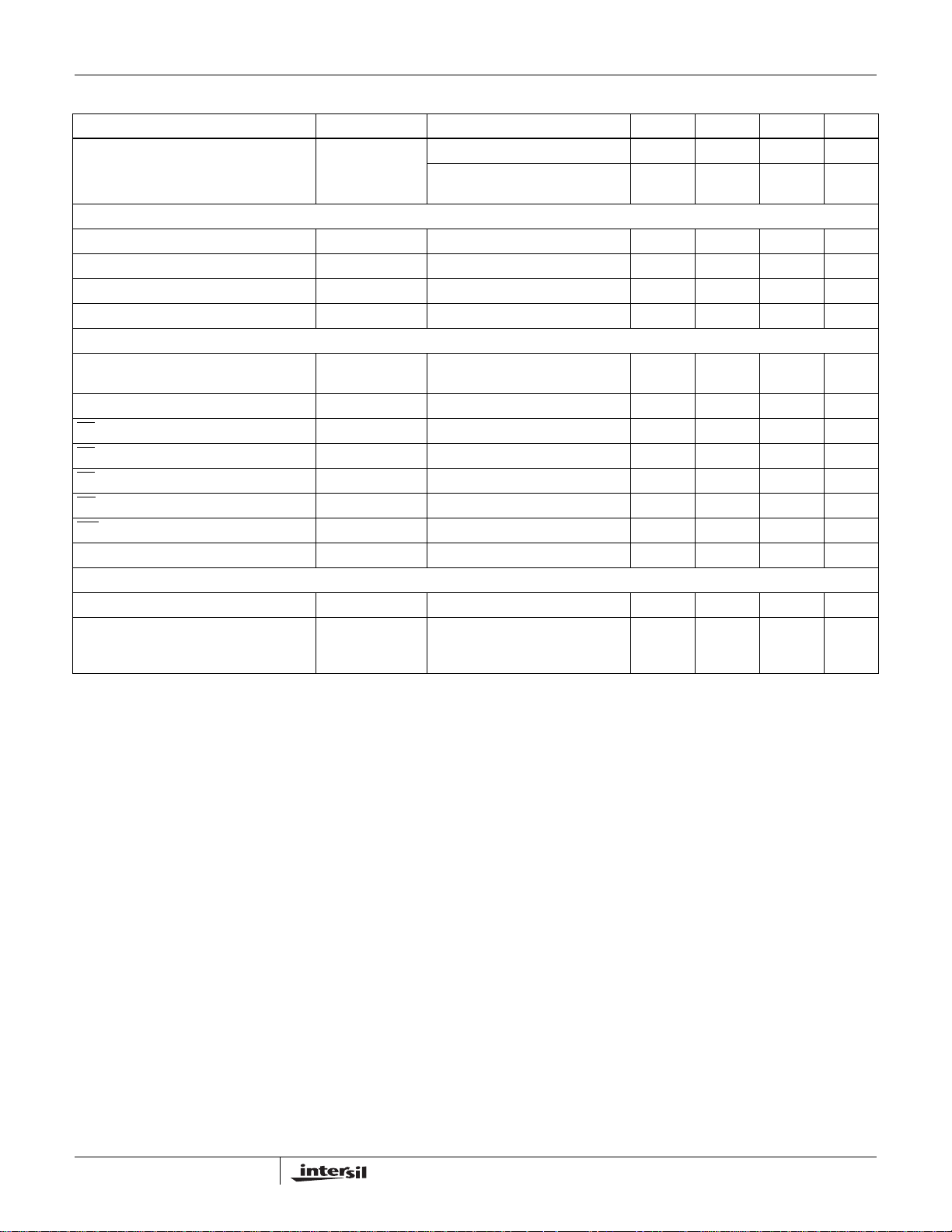

Electrical Specifications V

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNIT

GATE Voltage V

BIAS

Supply Current I

POR Rising Threshold VIN_POR_L2H 2.12 V

POR Falling Threshold VIN_POR_H2L 2.10 V

POR Threshold Hysteresis VIN_POR_HYS 5 mV

I/O

Undervoltage Comparator Falling

Threshold

Undervoltage Comparator Hysteresis V

EN Rising Threshold PWR_Vth_R V

Falling Threshold PWR_Vth_F V

EN

Hysteresis PWR_HYST V

EN

PG Pull-Down Voltage

Pull-Down Voltage (Note 3)

FLT

Soft-Start Charging Current IQ_SS VSS = 1V 10 µA

CHARGE PUMP

CPVDD V_CPVDD V

CPVDD V_CPVDD V

= 2.5V to +3.3V, VS = 1V ,TA = T

DD

GATE

BIAS

V

UV_VTHF

UV_HYST

VOL_PG

VOL_FLT

Bias = 2.5V (see graph on page 7) 7.5 9.0 V

2.1 < Bias < 2.5

(see graph on page 7)

V

I

PG

I

FLT

T = 25°C

External User Load = 6mA

= 0°C - 85°C, Unless Otherwise Specified. (Continued)

J

8V

= 3.3V 9 17 mA

BIAS

620 635 650 mV

71625mV

= 2.5V 1.55 1.95 2.19 V

BIAS

= 2.5V 0.97 1.10 1.30 V

BIAS

= 2.5V 600 850 1100 mV

BIAS

= 8mA 0.047 0.4 V

= 8mA 0.047 0.4 V

= 3.3V 4.9 5.2 5.5 V

BIAS

BIAS

= 3.3V

5.0 V

6

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Typical Performance Curves (at 25°C unless otherwise specified)

12

10

8

6

4

I_BIAS (mA)

2

0

1.0 1.4 1.7 2.0 2.3 2.9 3.2 3.7

CPQ = 22nF, C

V_BIAS(V)

PVDD

= 0.47µF

FIGURE 3. I_BIAS vs V_BIAS FIGURE 4. POR RISING THRESHOLD vs TEMPERATURE

10

9

8

7

6

(V)

5

GATE

4

V

3

2

1

0

2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3 3.1 3.2 3.3 3.5 3.7 3.8 3.9 4

FIGURE 5. V

CPQ = 22nF, C

V_BIAS (V)

vs V_BIAS FIGURE 6. V

GATE

PVDD

= 0.47µF

2.045

2.04

2.035

2.03

2.025

2.02

2.015

POR RISING (V)

2.01

2.005

2

-10 0 25 40 60 85

TEMPERATURE (°C)

10

9

8

7

6

(V)

5

4

GATE

V

3

2

1

0

2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3 3.1 3.2 3.3 3.5 3.7 3.8 3.9 4

CPQ = 0.1µF, C

V_BIAS (v)

vs V_BIAS

GATE

PVDD

= 0.47µF

(µA)

G

I

24.6

24.4

24.2

24

23.8

23.6

23.4

-10 0 25 40 60 85

TEMPERATURE (°C)

0.19

0.18

0.17

0.16

0.15

0.14

PG_VOL

0.13

0.12

0.11

0.1

-10 0 25 40 60 85

FIGURE 7. GATE DRIVE vs TEMPERATURE FIGURE 8. PG_VOL vs TEMPERATURE

7

TEMPERATURE (°C)

IPG = 8mA

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Typical Performance Curves (at 25°C unless otherwise specified) (Continued)

10000

3

1000

(ns)

100

RESPONSE

T

10

1

0 0.1 0.47 1 4 8.7 14 222

C

(nF)

G

2.5

2

1.5

1

RESPONSE TIME (µs)

0.5

0

100 150 200 250 300

OC (% OF LIMIT)

FIGURE 9. WOC RESPONSE vs LOAD CAPACITANCE FIGURE 10. RESPONSE TIME vs IO*R

2.008

2.006

2.004

2.002

2

POR FALLING (V)

1.998

SNS

1.996

-10 0 25 40 60 85

TEMPERATURE (°C)

FIGURE 11. POR FALLING vs TEMPERATURE

8

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Detailed Description of Operation

ISL6173 targets dual voltage hot-swap applications with a

bias of 2.1V to 3.6VDC and the voltages being controlled

down to 0.7VDC. The IC’s main function is to limit and

regulate the inrush current into the loads. This is achieved by

enhancing an external MOSFET in a controlled manner. In

order to fully enhance the MOSFET, the IC must provide

adequate gate to source voltage, which is typically 5V or

greater. Hence, the final steady-state voltage on Gate (GT)

pin must be 5V above the load voltage. Two internal chargepumps allow this to happen.

VIN

Q

1

O

V

CPVDD

-

+

10µA

10V

42µA

1

T

G

24µA

SOFT-

START

AMPLIFIER

FIGURE 12. SOFT-START OPERATION

Controlled Soft-Start

The output voltages are monitored through the Vo pins and

slew up at a rate determined by the capacitors on the Softstart (SS) pin, as illustrated in Figure 12. 24µA of gate

charge current is available. The soft-start amplifier controls

the output voltage by robbing some of the gate charge

current thus slowing down the MOSFET enhancement.

When the load voltage reaches its set level, as sensed by its

respective UV pin through an external resistor divider, the

Power Good (PG

) output goes active.

Current Monitoring and Protection

The IC monitors the load current (Io) by sensing the voltagedrop across the low value current sense resistor (R

which is connected in series with the MOSFET as shown in

the diagram on page 2, through Sense (SNS) and voltage

set (VS) pins. The latter is through a resistor, R

shown. Two levels of overcurrent detection are available to

protect against all possible fault scenarios. These levels are:

1. Current Limit or Current Regulation (CR)

2. Way Overcurrent (WOC)

VO

0

0

SS1

SET

+

-

SNS

, as

VIN

CPVDD

),

Each of these modes is described in detail as follows:

1. Current Limit or Current Regulation (CR) Mode: - When

the load current reaches the current regulation threshold, the

current amplifier loop closes and the circuit behaves like a

current source. The Current Limit Amplifier is a folded

cascode type with source follower output capable of pulling

down the gate very fast in response to fast overload

transients. The current regulation threshold is set by setting a

reference current, I

, through R

SET

by selecting an

SET

appropriate resistor between OCREF and GND, which sets

I

. The relationship between I

REF

4*I

SET

, where I

= Vocref/Rocref = 1.178/Rocref. I

REF

REF

and I

SET

is I

REF

=

REF

would typically be set at 80µA.

Selecting appropriate values for R

when I

Io*R

= ICR,

O

= I

SNS

SET*RSET

Vin Vo

Iset

ISL6173

FIGURE 13. CURRENT REGULATION OPERATION

+

Rset

-

3K

+

VS1

Rsns

Iref

4

-

CURRENT REGULATION

Iset*Rset = Io*Rsns

SNS1

CURRENT

LIMIT

AMPLIFIER

-

+

SET

MODE:

and R

10V

24µA

Q

such that

SNS

GT1

(EQ. 1)

The operating mode is shown in Figure 13. When the circuit

enters this mode, the OC comparator detects it and sets off

the timer. CT begins to charge from an internal 10µA current

source. The amount of time it takes for this cap to charge to

1.178V sets up the current regulation duration. Upon

expiration of this time-out period, the MOSFET gate is pulled

down quickly by the current limit amplifier, unless the load

current level had already dropped back to a level below the

current regulation threshold level prior to that. In that case, the

current regulation mode is no longer active, the MOSFET is

allowed to fully enhance and the IC discharges the C

RTR

/LTCH pin is left open or pulled to BIAS, the output

Cap. If

T

remains latched off after the expiration of the time-out period

determined by C

. If RTR/LTCH pin is pulled to GND, the IC

T

9

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

automatically retries to turn on the MOSFET after a wait

period, during which C

is charged and discharged 64 times

T

and the retry attempt takes place on the 65th time. This wait

period allows the MOSFET junction to cool down.

2. Way Overcurrent (WOC) Mode - This mode is designed

to handle very fast, very low impedance shorts on the load

side, which can result in very high di/dt. Typically, the current

limit set for this mode is 300% of the current regulation limit.

This mode uses a very fast comparator, which directly looks

at the voltage drop across R

and pulls the gate very

SNS

quickly to GND (as shown in Figure 14) and immediately

releases it. If the WOC is still present, the IC enters current

regulation mode and the rest of the current regulation

behavior follows as described earlier in undercurrent

regulation mode.

Vin

Iset

ISL6173

Rset

3K

Io

Rsns

-

SNS1

WOC

COMPARATOR

-

+

Q

GT1

GATE

PULLDOWN

CURRENT

25Ω

+

+

-

VS1

Vo

on this pin reaches 1.178V, the CR duration expires. Fault

(FLT

) pin goes active (pulls low), signaling the load of a fault

condition and the gate (GT) pin gets pulled low.

Retry vs Latched Fault Operational Modes:

RTR/LTCH pin dictates the IC behavior after the gate (GT)

pin pulls down following OC timeout expiration. If the

RTR

/LTCH pin is left floating, the gate pin will remain latched

off. It can only be released by de-asserting and reasserting

the enable (EN

) input. If RTR/LTCH pin is pulled to GND,

then the Retry mode will be activated. In this mode the IC will

automatically attempt to turn-on the MOSFET after a delay,

determined by the capacitor on CT pin. In the Retry mode,

the internal logic charges and discharges the CT cap 64

times during “wait” period. On the 65th time, the FLT output

clears during retry attempt. If the overcurrent condition

persists after the soft-start, the CT pin will again start

charging and the process repeats.

Bias and Charge Pump Voltages:

The BIAS pin feeds the chip bias voltage directly to the first

of the two internal charge pumps, which are cascaded. The

output of the first charge pump, in addition to feeding the

second charge pump, is accessible on the CPVDD pin. The

voltage on the CPVDD pin is approximately 5V. It also

provides power to the POR and band-gap circuitry as shown

in the block diagram. A capacitor connected externally

across CPQ+ and CPQ- pins of the IC is the “flying” cap for

the charge-pump.

The second charge-pump is used exclusively to drive the

gates of the MOSFETs through the 24µA current sources,

one for each channel. The output of this charge pump is

approximately 10V as shown in the block diagram.

FIGURE 14. WOC OPERATION

Additionally, as shown in the block diagram, there is also an

“OC comparator”, which also looks at the Rsense voltage

drop. When this drop exceeds the Current Limit set point, it

triggers the timeout circuit, which starts ticking and CTx is

allowed to charge. If the current limit condition remains in

effect until after the time-out period expires (CTx voltage

exceeding 1.178V), the gate of the MOSFET is pulled down,

the SSx capacitor is discharged, FLT

SS sequence is allowed to begin after ENx

keeping the RTR

/LTCH pin pulled low.

is asserted and a new

recycle or by

The voltage on OCREF pin is the same as the internal bandgap reference voltage, which is 1.178V (nominal). A resistor

to GND from this pin sets the reference current (and hence

the reference voltage) for the current limit amplifier and

OC/WOC comparators. The current regulation (CR) duration

is set by the capacitor on CT pin to GND. Once the voltage

10

Tracking

CH1: VO1, CH2: VO2, T = 2ms/DIV, CSS = 0.066µF

FIGURE 15. TRACKING MODE WAVEFORMS

January 3, 2006

FN9186.3

ISL6173

www.BDTIC.com/Intersil

The two channels can be forced to track each other by

simply tying their SS pins together and using a common SS

capacitor. In addition, their EN

together. Typical Start-up waveforms in this mode are shown

in Figure 15. If one channel goes down for any reason, the

other one will too. One important thing to note here is that

only the overcurrent latch-off mode will work. Auto-retry

feature WILL NOT work. Retry must be controlled manually

through EN

.

pins also must be tied

Typical Hot-plug Power Up Sequence

1. When power is applied to the IC on the BIAS pin, the first

charge pump immediately powers up.

2. If the BIAS voltage is 2.1V or higher, the IC comes out of

POR. Both SS and CT caps remain discharged and the

gate (GT) voltage remains low.

3. ENx

pin, when pulled low (below it’s specified threshold),

enables the respective channel.

4. SSx cap begins to charge up through the internal 10µA

current source, the gate (GT) voltage begins to rise and

the corresponding output voltage begins to rise at the

same rate as the SS cap voltage. This is tightly controlled

by the soft-start amplifier shown in the block diagram.

5. SS cap begins to charge but the corresponding CTx cap

is held discharged.

6. Fault (FLT) remains deasserted (stays high) and the

output voltage continues to rise.

7. If the load current on the output exceeds the set current

limit for greater than the OC timeout period, FLT gets

asserted and the channel shutdown occurs.

8. If the voltage on UV pin exceeds 633mV threshold as a

result of rising Vo, the Power Good (PG) output goes

active.

9. At the end of the SS interval, the SS cap voltage reaches

CPVDD and remains charged as long as EN remains

asserted or there is no other fault condition present that

would attempt to pull down the gate.

State Diagram

This is shown in Figure 16. It provides a quick overview of

the IC operation and can also be used as a troubleshooting

road map.

11

FN9186.3

January 3, 2006

IC Operation State Diagram

www.BDTIC.com/Intersil

ISL6173

No

Po w e r

Apply Power

Bias >1V

PG

&

FLT

Out put s

Valid

Bias>2V

Io> >ICR

(WOC)

Gat e

Pulldow n

Output

Voltage

Available

Vuv >645mVVuv<633mV

PG

Asserted

Io> ICR

FLT

Cleared

EN A s s er t e d

Sof t Star t

(Tss)

Run

OC Timer

(Toc)

EN De - as s e r te d

Io> ICR

Current

Limit

Mo de

Io> =Ic r

AND

t>Toc

FLT

Asserted

Count 64

Pu l s e s

&

Re se t

RTR/LTCH = L

Res et &

Latch

Of f

Stat e

RTR/LTCH = H

FIGURE 16.

12

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Applications Information

Selection of External Components

The typical application circuit of Figure 2 has been used for

this section, which provides guidelines to select the external

component values.

MOSFET (Q1)

This component should be selected on the basis of its

r

voltage) and the effective input gate capacitance (Ciss). One

needs to ensure that the combined voltage drop across the

Rsense and r

(including transients) will still keep the output voltage above

the minimum required level. Power dissipation in the device

under short circuit condition should also be an important

consideration especially in auto-retry mode (RTR

pulled low). Using ISL6173 in latched off mode results in

lower power dissipation in the MOSFET.

Ciss of the MOSFET influences the overcurrent response

time. It is recommended that a MOSFET with Ciss of less

than 10nF be chosen. Ciss will also have an impact on the

SS cap value selection as seen later.

Current Sense Resistor (R

The voltage drop across this resistor, which represents the

load current (Io), is compared against the set threshold of

the current regulation amplifier. The value of this resistor is

determined by how much combined voltage drop is tolerable

between the source and the load. It is recommended that at

least 20mV drop be allowed across this resistor at max load

current. This resistor is expected to carry maximum full load

current indefinitely. Hence, the power rating of this resistor

must be greater than I

This resistor is typically a low value resistor and hence the

voltage signal appearing across it is also small. In order to

maintain high current sense accuracy, current sense trace

routing is critical. It is recommended that either a four wire

resistor or the following routing method be used:

specification at the expected Vgs (gate to source

DS(ON)

at the desired maximum current

DS(ON)

/LTCH pin

)

SNS

2

*R

O(MAX)

LOAD CURRENT CARRYING

FIGURE 17. RECOMMENDED CURRENT SENSE RESISTOR

PCB LAYOUT

TRACES

CURRENT

SENSE

TRACES

SNS

.

R

SNS

Current Set Resistor (R

SET)

This resistor directly sets the threshold for the current

regulation amplifier and indirectly sets the same for the OC

and WOC comparators in conjunction with R

R

has been selected, use Equation 1 (on page 9) to

SNS

calculate R

Reference Current Set Resistor (R

. Use 20µA for I

SET

in a typical application.

SET

REF

SNS

)

. Once

This resistor sets up the current in the internal current

source, I

/4, shown in Figure 2 for the comparators. The

REF

voltage at the OCREF pin is the same as the internal

bandgap reference. The current (I

) flowing through this

REF

resistor is simply:

I

= 1.178/R

REF

This current, I

REF

, should be set at 80µA to force 20µA in the

REF

internal current source as shown in Figure 2, because of the

4:1 current mirror. This equates to the resistor value of

14.7K.

Selection of Rs1 and Rs2

These resistors set the UV detect point. The UV comparator

detects the undervoltage condition when it sees the voltage

at UV pin drop below 0.633V. The resistor divider values

should be selected accordingly.

Charge Pump Capacitor Selection (CP and CV)

CP is the “flying cap” and CV is the smoothing cap of the

charge pump, which operates at 450kHz set internally. The

output resistance of the charge pump, which affects the

regulation, is dependent on the C

value and its ESR,

P

charge-pump switch resistance, and the frequency and ESR

of the smoothing cap, C

.

V

It is recommended that CP be kept within 0.022µF

(minimum) to 0.1µF (maximum) range. Only ceramic

capacitors are recommended. Use 0.1µF cap if CPVDD

output is expected to power an external circuit, in which case

the current draw from CPVDD must be kept below 10mA.

C

should at least be 0.47µF (ceramic only). Higher values

V

may be used if low ripple performance is desired.

Time-out Capacitor Selection (CT)

This capacitor controls the current regulation time-out

period. As shown in Figure 2, when the voltage across this

capacitor exceeds 1.178V, the time-out comparator detects it

and pulls down the gate voltage thus shutting down the

channel. An internal 10µA current source charges this

capacitor. Hence, the value of this capacitor is determined by

the following equation:

C

= (10µA * T

T

Where,

T

= Desired time-out period.

OUT

OUT

)/1.178

13

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Soft-Start Capacitor Selection (CSS)

The rate of change of voltage (dv/dt) on this capacitor, which

is determined by the internal 10µA current source, is the

same as that on the output load capacitance. Hence, the

value of this capacitor directly controls the inrush current

amplitude during hot swap operation.

C

= CO*(10µA/I

SS

Where,

C

= Load Capacitance

O

I

INRUSH

I

INRUSH

the load capacitance charging current. If the dc steady-state

load remains disabled until after the soft-start period expires

(PGx

then only the capacitor charging current should be used as

I

INRUSH

of that of Ciss of the MOSFET to ensure proper soft-start

operation. This is because the Ciss is charged from 24µA

current source whereas the Css gets charged from a 10µA

current source (please refer to Figure 12). In order to make

sure both Vss and Vo track during the soft-start, this

condition is necessary.

= Desired Inrush Current

is the sum of the dc steady-state load current and

could be used as a load enable signal, for example),

. The Css value should always be more than (1/2.4)

INRUSH

)

ISL6173 Evaluation Platform

The ISL6173EVAL1 is the primary evaluation board for this

IC. The board is a standalone evaluation platform and it only

needs input bias and test voltages. The schematic for this

board is shown in Figures 20 and 21. The component

placement diagram is shown in Figure 22.

The evaluation board has been designed with a typical

application and accessibility to all the features in mind to

enable a user to understand and verify these features of the

IC. The circuit is designed for 2A for each input rail but it can

easily be scaled up or down by adjusting some component

values. LED indicators are provided to indicate Fault and

Power Good status. Switches are there to perform Enable

function for each channel, to select auto-retry or latchoff

mode and to check WOC and CR modes.

There are two input voltages, one for each channel plus

there is “+5V” input. The latter is to test the pull-up capability

of FLT

and PG outputs to +5V and also to power the LEDs

and the dynamic load circuitry. ISL6173 does not require 5V.

The outputs are brought out to banana sockets to allow

external loading if desired.

J1 and J3 are wire jumpers. A user can replace them with

wire loops to attach a scope current probe. However, doing

so may reduce the di/dt enough to prevent WOC comparator

from tripping. The internal current regulation amplifier is fast

enough to respond to very fast di/dt. Hence, it is advisable to

use the on board dynamic load circuitry, as will be described,

if a user wants to check the WOC performance.

The dynamic load circuitry, shown in Figure 21, is included

on the board on both channels to ensure minimum

inductance in the current flow path. Two sets of load are

available per output:

1) CR Load: This load is set at 1Ω (approximately 3.3A for

3.3V output), which is higher than the 2.2A of CR limit but

less than WOC limit (6.6A) set on the board.

2) WOC Load: This load is set at 340mΩ, which is roughly

10A for 3.3V supply. This is higher than 6.6A WOC limit set

on the board.

A function/pulse generator is required to activate the

dynamic load circuitry. The function/pulse generator should

have adjustable pulse-width (3ms), single pulse (manual

trigger) and 5V pulse amplitude capability. Agilent model

No: 33220A or equivalent is a good choice. The function

generator needs to be connected through a co-ax cable to

J11 or J12 for channel 1 or channel 2 respectively. WOC or

CR load can be activated by turning SW4 or SW5 (channel

1) and SW6 or SW7 (channel 2) ON followed by applying the

pulse generator to turn on an appropriate load.

The load circuit consists of a MOSFET driver (EL7202),

MOSFET (IRF7821) and surface mount load resistors. The

MOSFET drivers, U2 and U3, respond to a pulse from the

generator to turn on the MOSFET for the duration of the

pulse, which should be set less than the timeout period

described in “Time-out Capacitor Selection”. On this board

the timeout capacitor value is 0.15µF, which corresponds to

a timeout period of 17.67ms.

One way to tell if the WOC mode is active would be by

looking at the Gate waveform of the control MOSFET (M1 or

M2). The WOC comparator when tripped, pulls down the

Gate hard. The following waveform shows WOC operation:

Pins SS1 and SS2 of the IC are available on header J2 as

test points so that they can be tied together to achieve

tracking between Vo1 and Vo2. Both the Enable (EN

switches (SW1 and SW2) must be turned ON to check this

function.

Each channel is preloaded with capacitive load. Extra load

can be externally applied as required.

14

)

FN9186.3

January 3, 2006

FIGURE 18. WOC OPERATION

www.BDTIC.com/Intersil

Channel 1 is Vgate, Channel 2 is the pulse generator output

and Channel 3 is Vout. Note how Vgate gets immediately

pulled down to zero volts up on load application.

ISL6173

In CR mode, however, Vgate always remains above zero

volts because WOC comparator never trips. This can be

seen on the following scope shot:

FIGURE 19. CURRENT REGULATION OPERATION

It is also important to note that in WOC mode, although

Vgate gets pulled down to zero initially, the gate is quickly

released and slowly rises until the CR amplifier takes control.

15

FN9186.3

January 3, 2006

ISL6173

www.BDTIC.com/Intersil

Bill of Materials for ISL6173 Eval 1 Board

ITEM QTY REFERENCE PART PKG MFG P/N MANUFACTURER

1 2 C1, C18 220µF Leaded UPM1E221MPH6 or eq Nichicon

2 2 C2, C17 47µF Leaded UPM1E470MEH or eq Nichicon

3 2 C3, C4 0.1µF 0805 Any

4 2 C5, C6 1000pF 0805 Any

5 2 C9, C10 0.033µF 0805 Any

6 2 C11, C12 0.15µF 0805 Any

7 1 C13 0.47µF 0805 Any

8 1 C14 2.2µF 1206 Any

9 2 C19, C20 0.01µF 0805 Any

10 1 C21 10µF 7343 Any

11 1 C22 0.022µF 0805 Any

12 2 D1, D6 MBR130P SMA MBR130P ON Semi

13 2 D3, D4 LED GRN 1206 PG1101W Stanley

14 2 D2, D5 LED RED 1206 BR1101W Stanley

15 1 J2 2 Pin Header Any

16 2 J1, J3 Jumper Any

17 2 J11, J12 BNC Jack

18 6 M1, M2, M3, M4, M5, M6 IRF7821 SO8 IRF7821 International

19 10 RS1, RS2, R10, R12, R30, R31 1K 0805 Any

R55, R56, R57, R58

20 6 R1, R27, R49, R50, R51, R52 0.01 2512 Any

21 4 R2, R3, R25, R26 390 0805 Any

22 1 R8 3.57K 0805 Any

23 1 R9 2.55K 0805 Any

24 1 R11 14.7K 0805 Any

25 3 R14, R15, R20 0 0805 Any

26 4 R16, R17, R18, R19 10K 0805 Any

27 2 R29, R32 1.1K 0805 Any

28 4 R33, R34, R35, R36 10 0805 Any

29 6 R37, R38, R42, R43, R44, R45 1 2512 Any

30 10 R39, R40, R41, R46, R47, R48 5 2512 Any

R61, R62, R63, R64

31 2 R53, R54 100 1206 Any

32 2 R59, R60 49.9 0805 Any

34 1 U1 ISL6173 QFN28 5x5 ISL6172 Intersil

35 2 U2, U3 EL7202/SO SO8 Intersil

38 7 SW5, SW6, SW7, SW8, SW9,

SW10, SW11

Toggle Switch GT11MCKE C & K

Rectifier

16

FN9186.3

January 3, 2006

Schematic, ISL6173 Eval1

www.BDTIC.com/Intersil

220µF

5V

J4

3.3V

C1

5V

J5

GND_IN

J6

1

Vi_2

J7

1

2.5V

Vi_1

1

1

2

J1

CON2

C4

0.1µF

1

CON2

C18

J3

220µF

1

2

17

Vi_1

Vi_2

0.1µF

SW1

SW2

OPEN = Disable

CLOSE = Enable

C3

TP11

1

TP12

SW3

1

OPEN = Latch

CLOSE = Retry

R20

0

C14

2.2µF

RS2

1K

RS1

1K

C22

0.022µF

C13

0.47µF

TP9

1

TP10

1

TP6

1

C19

0.01µF

0.15µF

8

RTR/LTCH

12

BIAS

13

CPQ+

11

CPQ-

14

CPVDD

10

PGND

9

GND

C11

TP5

1

C20

0.01µF

24

EN126EN2

CT1

VS1

ISL6173

CT215VS222SNS221GT2

7

C12

0.15µF

1000pF

IRF7821

0.01

R29

1.1K

NO STUFF

28

U1

R32

1.1K

C6

R27

0.01

IRF7821

M1

5678123

R1

C5

1000pF

1

SNS1

NO STUFF

M2

5678123

TP1

1

4

GT1

OCREF

18

R14

0

VO1

UV1

PG1

FLT1

SS1

GND1

PG2

FLT2

SS2

UV2

VO2

R15

0

R10

TP16

R3

390

D3

LED55B/TO

D4

PG2

LED55B/TO

R26

390

J8

VO1

1

D1

MBR130P

GND_OUT

J9

1

J10

1

D6

MBR130P

VO1

ISL6173

VO2

VO2

TP2

TP3

1

C2

R53

5V

C17

47µF

TP7

47µF

1

TP17

100

5V

TP18

1

1

R54

100

5V

R2

TP13

1

390

D2

FLT1

LED55B/TO

D5

FLT2

LED55B/TO

R25

390

C21

10µF

R16

R17

10K

10K

1

R18

R19

10K

10K

1

TP14

TP15

1

4

1K

R8

3.57K

2

TP4

1

C10

0.033µF

R11

14.7K

C9

0.033µF

R12

1K

R30

R31

TP8

1

R9

2.55K

1K

1K

1

2

J2

CON2

27

6

5

3

25

29

16

17

19

23

20

1

4

January 3, 2006

FN9186.3

FIGURE 20.

Schematic, ISL6173 Eval1 (Continued)

www.BDTIC.com/Intersil

VO1

TP28

1

R63

R64

5

R37

R38

1

TP31

R35

10

R33

10

M3

IRF7821

4

1

2

3

4

R44

1

M5

IRF7821

4

U2

NC1

IN2

GND

IN2_

EL7202/SO

TP32

R59

49.9

R60

49.9

1

SW4

R55

1K

1

SW6

R57

1K

18

VO2

1

1

1

January 3, 2006

FN9186.3

1

1

2

4

J11

3

1

2

4

J12

3

TP33

TP34

TP35

TP36

1

OUTA

OUTB

R43

1

5

6

7

8

1

2

3

NC8

5

6

7

8

1

2

3

R42

1

TP30

1

SW5

TP26

1

R49

01

5V

8

7

6

V+

5

TP19

1

R45

1

TP20

1

TP21

1

R51

01

1

NC1

2

IN2

3

GND

4

IN2_

SW7

U3

EL7202/SO

NC8

OUTA

OUTB

R56

1K

R58

1K

8

7

6

V+

5

5

R34

10

R61

R62

5

5

M6

IRF7821

R36

4

10

5V

R40

5

M4

IRF7821

4

R47

5

R39

R46

5

TP27

1

R41

5

5

TP29

1

5

6

7

8

1

2

TP25

3

1

R50

01

ISL6173

TP24

1

R48

5

TP23

R52

01

1

1

TP22

5

6

7

8

1

2

3

FIGURE 21.

ISL6173 Eval 1 - Component Layout

www.BDTIC.com/Intersil

19

ISL6173

January 3, 2006

FN9186.3

FIGURE 22.

ISL6173

www.BDTIC.com/Intersil

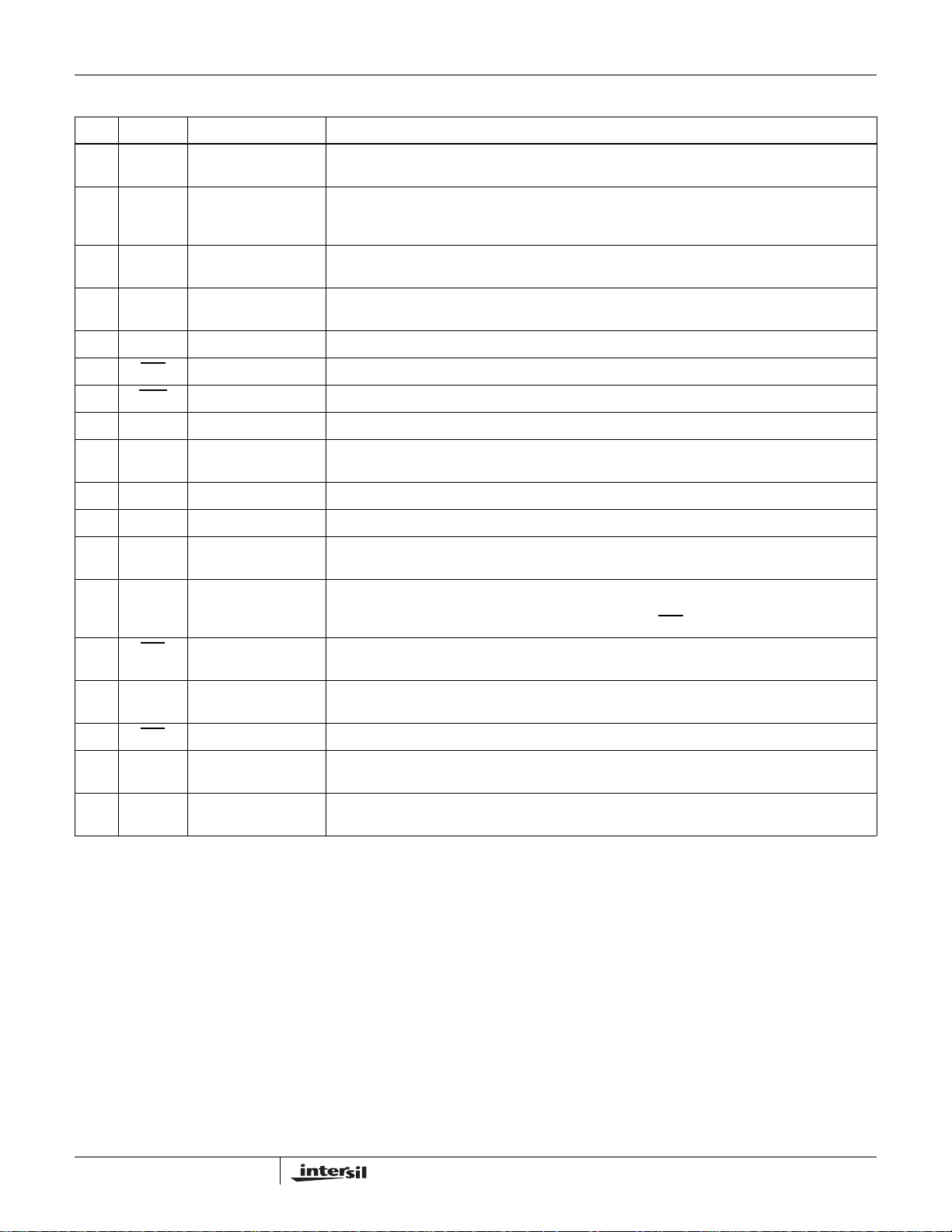

Quad Flat No-Lead Plastic Package (QFN)

Micro Lead Frame Plastic Package (MLFP)

2X

0.15

C

E1/2

E1

A2

A

A1

8

E2

7

8

9

CORNER

OPTION 4X

A1

A

E/2

9

/ /

9

(Ne-1)Xe

REF.

E

B

0.10 C

0.08

0.152XB

C

C

A

6

INDEX

AREA

AREA

2X

2X

SEATING PLANE

(DATUM B)

(DATUM A)

INDEX

AREA

0.15

6

C

4X

C

4X P

4X P

NX L

1

2

3

B

0

8

9

N

TOP VIEW

AC0.15

SIDE VIEW

NX b

N

e

(Nd-1)Xe

BOTTOM VIEW

D

D1

D2

REF.

5

D/2

D1/2

5

D2

2

NX b

0.10 BAMC

7

NX k

N

1

2

3

A3

E2/2

L28.5x5

28 LEAD QUAD FLAT NO-LEAD PLASTIC PACKAGE

(COMPLIANT TO JEDEC MO-220VHHD-1 ISSUE I)

MILLIMETERS

SYMBOL

A 0.80 0.90 1.00 A1 - 0.02 0.05 A2 - 0.65 1.00 9

A3 0.20 REF 9

b 0.18 0.25 0.30 5,8

D 5.00 BSC -

D1 4.75 BSC 9

D2 2.95 3.10 3.25 7,8

E 5.00 BSC E1 4.75 BSC 9

E2 2.95 3.10 3.25 7,8

e 0.50 BSC k0.20 - - L 0.50 0.60 0.75 8

N282

Nd 7 3

Ne 7 3

P- -0.609

θ --129

NOTES:

1. Dimensioning and tolerancing conform to ASME Y14.5-1994.

2. N is the number of terminals.

3. Nd and Ne refer to the number of terminals on each D and E.

4. All dimensions are in millimeters. Angles are in degrees.

5. Dimension b applies to the metallized terminal and is measured

between 0.15mm and 0.30mm from the terminal tip.

6. The configuration of the pin #1 identifier is optional, but must be

located within the zone indicated. The pin #1 identifier may be

either a mold or mark feature.

7. Dimensions D2 and E2 are for the exposed pads which provide

improved electrical and thermal performance.

NOTESMIN NOMINAL MAX

Rev. 1 11/04

8. Nominal dimensions are provided to assist with PCB Land Pattern

C

L

SECTION "C-C"

C

L

Design efforts, see Intersil Technical Brief TB389.

9. Features and dimensions A2, A3, D1, E1, P & θ are present when

Anvil singulation method is used and not present for saw

L

10

L1

e

CC

TERMINAL TIP

FOR ODD TERMINAL/SIDE FOR EVEN TERMINAL/SIDE

e

L1

L

10

singulation.

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

20

FN9186.3

January 3, 2006

Loading...

Loading...