®

www.BDTIC.com/Intersil

ISL6119

Data Sheet March 2004

USB Dual Port Power Supply Controller

The ISL6119 is a USB dual port power controller, fully

independent overcurrent (OC) fault protection IC.

Operational over the +2.5V to +5.5V range, this device

features internal current monitoring, accurate current

limiting, integrated power switches and current limited

delay to latch-off for system protection.

The ISL6119 current sense and limiting circuitry sets the current

limit to a nominal 1A, making this device well suited for the USB

port power management application. The ISL6119 provides OC

fault notification, accurate current limiting and a consistent

timed latch-off thus isolating and protecting the voltage bus in

the presence of an OC event or short circuit. The 12ms time to

latch-off is independent of the adjoining switch’s electrical or

thermal condition and the OC response time is inversely related

to the OC magnitude.

Each ISL6119 incorporates in a single 8 lead SOIC

package two 80mΩ N-channel MOSFET power switches

for power control. Each switch is driven by a constant

current source giving a controlled ramp up of the output

voltage. This provides a soft start turn-on eliminating bus

voltage drooping caused by inrush current while charging

heavy load capacitances. Independent enabling inputs and

fault reporting outputs for each channel are compatible with

3V and 5V logic to allow external control and monitoring.

The ISL6119 undervoltage lockout feature prevents turn-on

of the outputs unless the correct ENABLE state and VIN >

2.5V are present. During initial turn-on the ISL6119

prevents fault reporting by blanking the fault signal. Rising

and falling outputs are current limited voltage ramps so that

both the inrush current and voltage slew rate are limited,

independent of load. This reduces supply droop due to

surge and eliminates the need for external EMI filters.

During operation, once an OC condition is detected the

appropriate output is current limited for 12ms to allow

transient conditions to pass. If still in current limit after the

current limit period has elapsed, the output is then latched

off and the fault is reported by pulling the corresponding

FAULT

low. The FAULT signal is latched low until reset by

the ENABLE signal being de-asserted at which time the

FAULT

signal will clear.

FN9002.3

Features

•80mΩ Integrated Power N-channel MOSFET Switches

• Accurate Current Sensing and 1A Current Limiting

• 12ms Fault Delay to Latch-Off, No Thermal Dependency

• 2.5V to 5.5V Operating Range

• Disabled Output Internally Pulled Low

• Undervoltage Lockout

• Controlled Turn-on Ramp Time

• Channel Independent Fault Output Signals

• Compatible with 3.3V and 5V Logic Families

• Channel Independent Logic Level Enable High Inputs

(ISL6119H) or Enable Low Inputs (ISL6119L)

• Pb-Free Package Options

• Available in Tape & Reel with ‘-T’ Part Number Suffix

Applications

• USB Port Power Management

• Electronic Circuit Limiting and Breaker

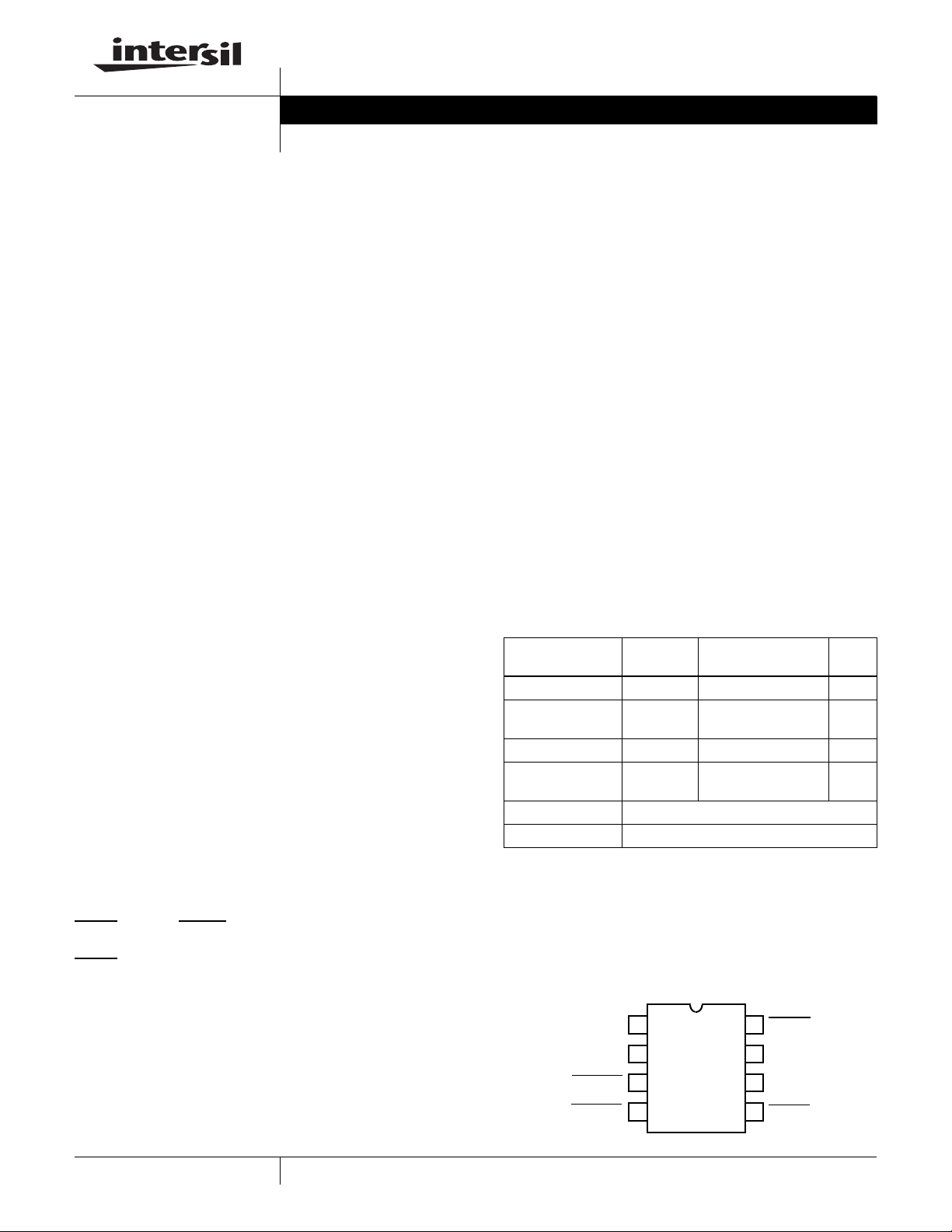

Ordering Information

PART

NUMBER

ISL6119LIB -40 to 85 8 Lead SOIC M8.15

ISL6119LIBZA

(Note)

ISL6119HIB -40 to 85 8 Lead SOIC M8.15

ISL6119HIBZA

(Note)

ISL6119EVAL1 Evaluation Platform

ISL6119USBEVAL1 USB Dual Port Evaluation Platform

NOTE: Intersil Pb-free products employ special Pb-free material

sets; molding compounds/die attach materials and 100% matte tin

plate termination finish, which is compatible with both SnPb and

Pb-free soldering operations. Intersil Pb-free products are MSL

classified at Pb-free peak reflow temperatures that meet or exceed

the Pb-free requirements of IPC/JEDEC J Std-020B.

Pinout

TEMP.

RANGE (°C) PACKAGE

-40 to 85 8 Lead SOIC (Pb-free) M8.15

-40 to 85 8 Lead SOIC (Pb-free) M8.15

ISL6119 (SOIC)

TOP VIEW

DWG. #

PKG.

ENABLE_1

ENABLE_2

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

GND

1

VIN

2

3

4

Copyright © Intersil Americas Inc. 2004. All Rights Reserved

8

7

6

5

FAULT_1

OUT_1

OUT_2

FAULT_2

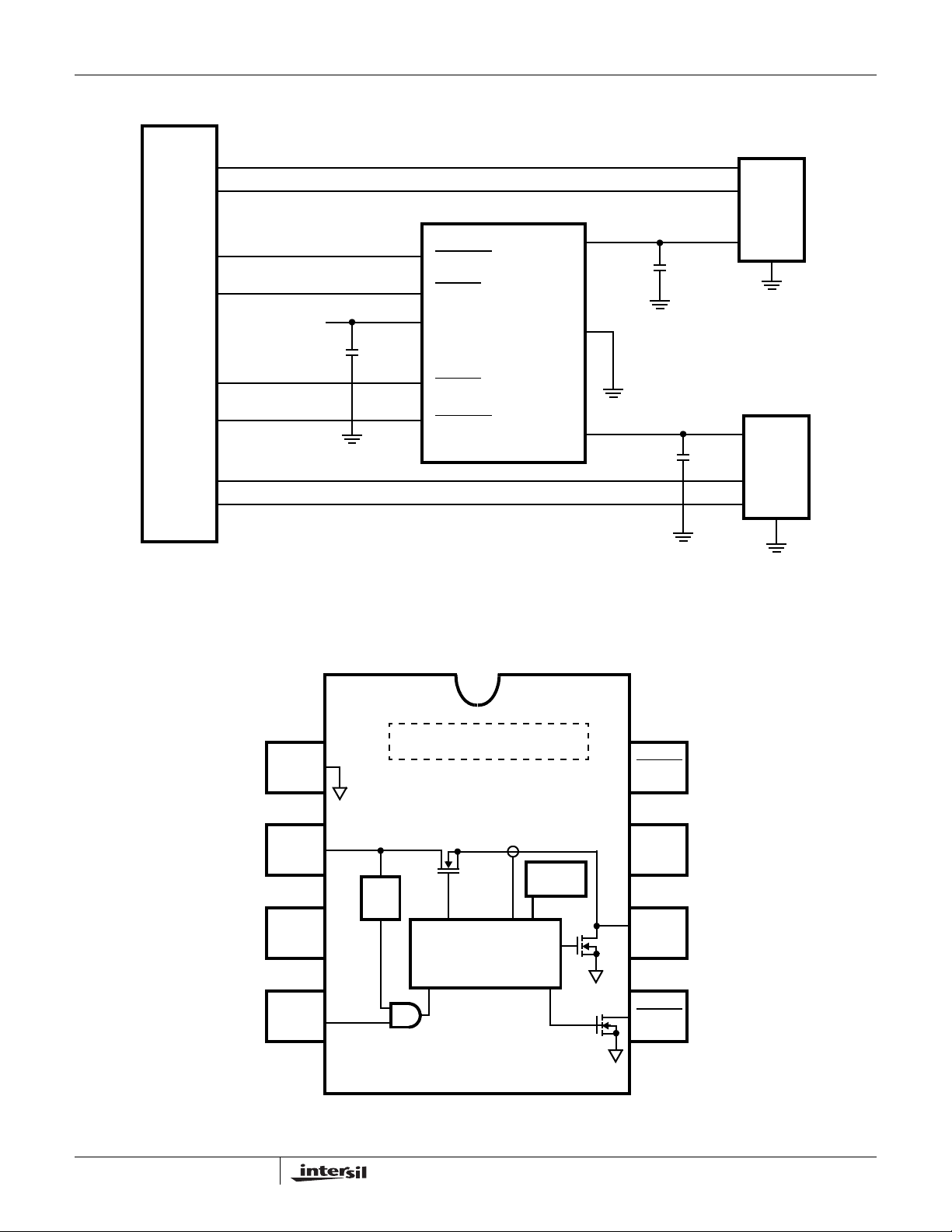

Typical Application: Dual USB Port Power

www.BDTIC.com/Intersil

ISL6119

D+

U

S

B

C

O

N

T

R

O

L

L

E

R

Simplified Block Diagram

+5V

ENABLE_1

FAULT_1

VIN

FAULT_2

ENABLE_2

D-

ISL6119L

D+

D-

OUT_1

GND

OUT_2

USB

PORT 1

V+

V+

USB

PORT_2

CHANNEL 1 LIKE CHANNEL 2

GND

VIN

Q-PUMP

POR

EN_1

EN_2 FAULT_2

CURRENT AND TEMP.

MONITORING, GATE AND

OUTPUT CONTROL

LOGIC

2

FAULT_1

OUT_1

OUT_2

ISL6119

www.BDTIC.com/Intersil

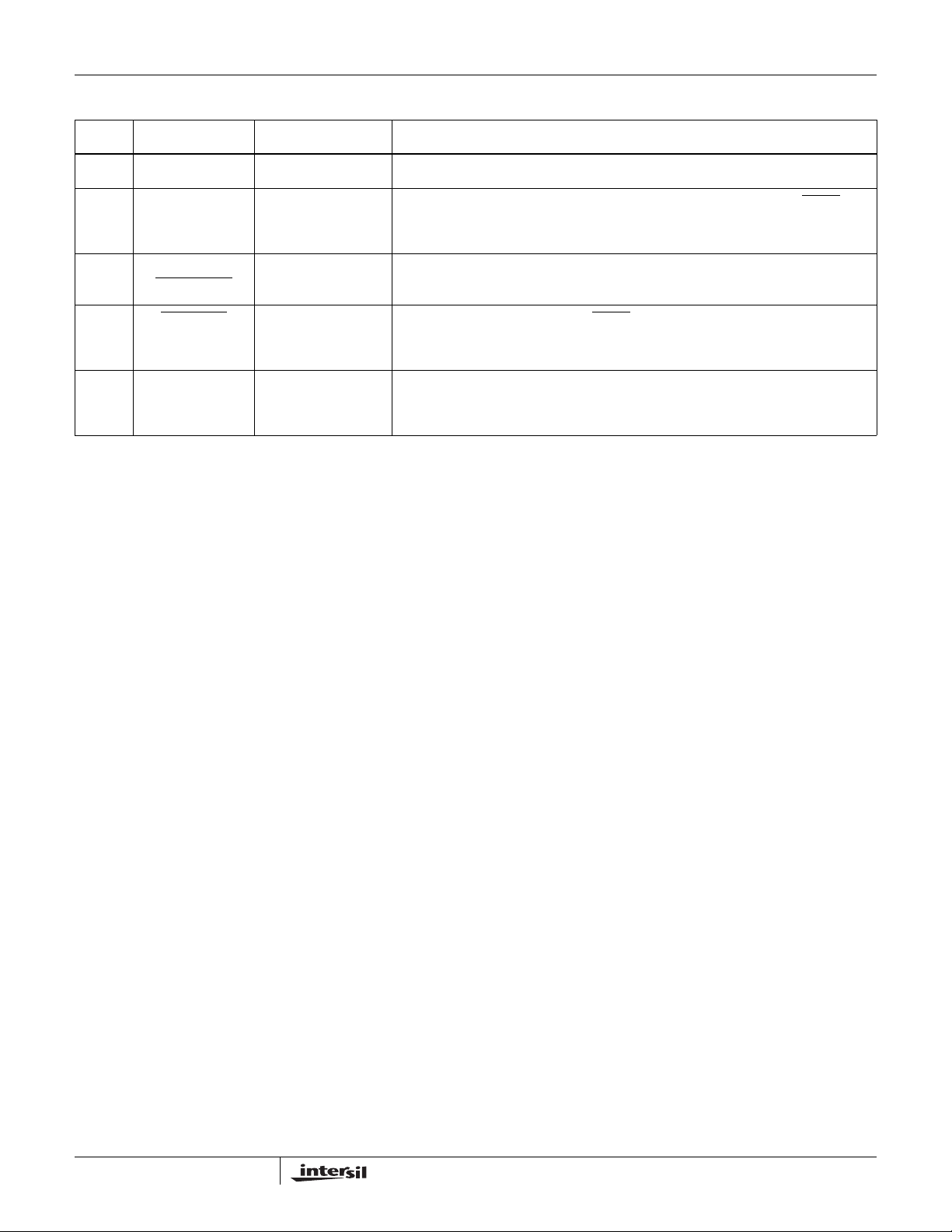

Pin Descriptions

PIN NO. DESIGNATOR FUNCTION DESCRIPTION

1 GND IC Reference

2 VIN Chip bias, Controlled

Supply Input,

Undervoltage lock-out

3, 4 ENABLE_1, 2/

ENABLE_1, 2

5, 8 FAULT_2, 1

6, 7 OUT_2, 1 Channel 2,1 Controlled

Channel Enable/

Enable Not Inputs

Channel 2, 1 Over

Current Fault Not

Indicator

Supply Output

VIN provides chip bias voltage. At VIN < 2.5V chip functionality is disabled, FAULT

is cleared and floating and OUT is held low.

Enables/Disables switch.

Channel overcurrent fault indicator. FAULT floats and is disabled until VIN >2.5V. This

output is pulled low after the OC timeout period has expired and stays latched until

ENABLE is deasserted.

Channel voltage output, connect to load to protect. Upon an OC condition I

current limited to 1A. Current limit response time is within 200µs. This output will remain

in current limit for a nominal 12ms before being latched off.

OUT

latch

is

3

ISL6119

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage (VIN to GND). . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0V

EN, FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to 6V

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND -0.3V to VIN 0.3V

Output Current . . . . . . . . . . . . . . . . . . . . . . . Short Circuit Protected

ESD Rating

Human Body Model (Per MIL-STD-883 Method 3015.7) . . . . 3KV

Thermal Resistance (Typical, Note 1)

8 Lead SOIC Package . . . . . . . . . . . . . . . . . . . . . . . 96

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . 150°C

Maximum Storage Temperature Range . . . . . . . . . . . -65°C to 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

(SOIC - Lead Tips Only)

Operating Conditions

Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . .-40°C to 85°C

Supply Voltage Range (Typical) . . . . . . . . . . . . . . . . . . 2.7V to 5.5V

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

is measured with the component mounted on a high effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

1. θ

JA

2. All voltages are relative to GND, unless otherwise specified.

θ

JA

(°C/W)

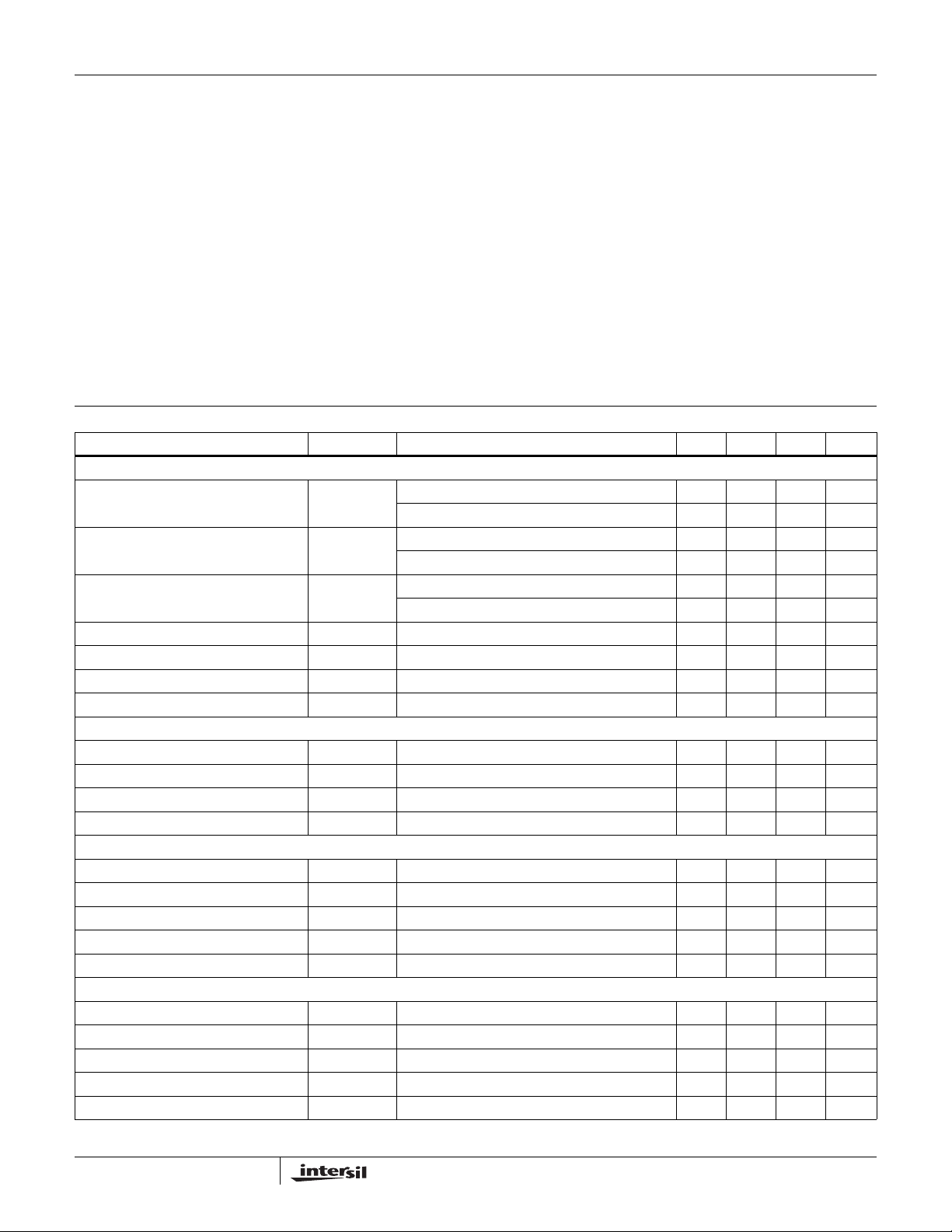

Electrical Specifications Supply Voltages = 5V, T

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

POWER SWITCH

ISL6119 On Resistance at 2.7V r

ISL6119 On Resistance at 3.3V r

ISL6119 On Resistance at 5.0V r

Disabled Output Voltage V

Vout Rising Rate t_vout_rt R

Slow Vout Turn-off Rate t_svout_offt R

Fast Vout Turn-off Rate t_fvout_offt R

CURRENT CONTROL

Current Limit, VIN = 3.3V - 5V Ilim Vout = 0.8V 0.75 1 1.25 A

OC Regulation Settling Time tsett

Severe OC Regulation Settling Time tsett

Over Current Latch-off Time t

I/O PARAMETERS

Fault Output Voltage Vfault_hi Fault I

ENABLE High Threshold Ven_vih VIN = 5.5V 2.0 - - V

ENABLE Low Threshold at 2.7V Ven_vil VIN = 2.7V - - 0.6 V

ENABLE Low Threshold at 5.5V Ven_vil VIN = 5.5V - - 0.8 V

ENABLE Input Current Ien_i ENABLE = 0V to 5V, VIN = 5V, T

BIAS PARAMETERS

Enabled VIN Current I

Disabled VIN Current I

Undervoltage Lockout Threshold V

UV Hysteresis UV

Over Temperature Disable Temp_dis - 150 - °C

DS(ON)_27

DS(ON)_33

DS(ON)_50

OUT_DIS

Ilim

Ilim_sevRL

OC_loff

VDD

VDD

UVLO

HYS

= T

= -40 to 85°C, Unless Otherwise Specified

A

J

VIN = 2.7V I

= TJ = 85°C - 115 130 mΩ

T

A

VIN = 3.3V, I

= TJ = 85°C - 115 130 mΩ

T

A

VIN = 5V, I

T

= TJ = 85°C - 115 130 mΩ

A

VIN = 5V, Switch Disabled, 50µA Load - 300 450 mV

= 10Ω, CL = 0.1µF, 10%-90% - 10 - V/ms

L

= 10Ω, CL = 0.1µF, 90%-10% - 10 - V/ms

L

= 1Ω, CL = 0.1µF, 9 0 % -1 0 % - 4 - V/ µs

L

RL = 5Ω, CL = 0.1µF to Within 10% of CR - 2 - ms

< 1Ω, CL = 0.1µF to Within 10% of CR - 100 - µs

ISL6119X, Tj = +25°C - 10 - ms

OUT

Switches Closed, OUTPUT = OPEN, TJ > 0°C - 120 200 µA

Switches Open, OUTPUT = OPEN - 1 5 µA

VIN Rising, Switch Enabled 1.7 2.25 2.5 V

= 0.7A TA = TJ = 25°C - 90 105 mΩ

OUT

= 0.7A TA = TJ = 25°C - 80 100 mΩ

OUT

= 0.7A TA = TJ = 25°C - 80 95 mΩ

OUT

= 10mA - - 0.4 V

> 25°C -0.5 - 0.5 µA

J

50 100 - mV

4

ISL6119

www.BDTIC.com/Intersil

Introduction

The ISL6119 is a fully independent dual channel overcurrent

(OC) fault protection IC for the +2.5V to +5.5V environment.

Each ISL6119 incorporates in a single 8 lead SOIC package

two 80mW N-channel MOSFET power switches for power

control. Independent enabling inputs and fault reporting

outputs compatible with 3V and 5V logic allows for external

control and monitoring. This device features internal current

monitoring, accurate current limiting, integrated power

switches and current limited timed delay to latch-off for

system protection. See Figure 1 for typical operational

waveforms including both under and overcurrent situations.

Key Feature Description and Operation

UV Lock Out

The ISL6119 undervoltage lockout feature prevents

functionality of the device unless the correct ENABLE state

and VIN > 2.5V are present.

Soft Start

A constant 500nA current source ramps up the switch’s gate

causing a voltage follower effect on the output voltage. This

provides a soft start turn-on eliminating bus voltage drooping

caused by in-rush current charging heavy load capacitances.

Rising and falling outputs are current limited voltage ramps

so that both the inrush current and voltage slew rate are

limited, independent of load. This reduces supply droop due

to surge and also eliminates the need for EMI filters

necessary on other IC products.

Fault Blanking On Start-Up

During initial turn-on the ISL6119 prevents nuisance faults

being reported to the system controller by blanking the fault

signal for 12ms. This blanking eliminates the need for

external RC filters necessary for other vendor products that

assert a fault signal upon initial turn-on into a temporary high

current condition. See Figures 10 through 12 for waveform

examples.

Current Regulation

The ISL6119 has integrated current sensing on the power

MOSFET that allows for rapid control of OC events. Once an

OC is detected the ISL6119 goes into its current regulation

(CR) control mode. The ISL6119 CR level is set to a nominal

1A. This current regulation is ±25% over the full operating

temperature and voltage bias range. See Figures 4 and 5 for

illustrative curves. The speed of this control is inversely

related to the magnitude of the OC fault. Thus a hard

overcurrent is more quickly controlled than a marginal OC

condition. See Figure 6 for waveforms illustrating this and

Figure 7 for an accompanying graph.

Over Temperature Shutdown

Although the ISL6119 has a thermal shutdown feature,

because of the 12ms timed shutdown this will only be

invoked in extremely high ambient temperatures

Latch-Off Time Delay

The primary function of any OC protection device is to

quickly isolate the voltage bus from a faulty load. Unlike

many other IC products that sense the IC thermal condition

(the monitored IC junction temperature depends on a

number of factors the most important of which are power

dissipation of the faulted and adjacent switches and package

temp) to isolate a faulty load, the ISL6119 uses an internal

12ms timer that starts upon OC detection. Once an OC

condition is detected the appropriate output is current limited

for a maximum of 12ms to allow transient conditions to pass

before latch-off. This time to latch-off is independent of

device thermal or adjacent switch condition. See Figure 18

for waveforms illustrating independent latch-off.

If, after the ISL6119 has latched off, and the fault has

asserted and, the enable is not deasserted but the OC

condition still exists, the ISL6119 unlike other IC devices

does not send to the controller a continuous string of fault

pulses. The ISL6119’s single fault signal is sent at the time of

latch-off unlike other devices.

Slow And Fast Shutdown

The ISL6119 has two shutdown modes. When turned off with

a load current less than the current regulation (CR) level the

ISL6119 shuts down in a controlled manner using a 500nA

constant current source controlled ramp. When latched off

due to CR and the timer has expired, the ISL6119 quickly

pulls down the output thereby quickly removing the faulted

load from the voltage bus. See Figures 8 and 9 for

waveforms of each mode.

Active Output Pulldown

Another unique ISL6119 feature is the active pull down on

the outputs to 300mV above GND when the device is

disabled. Competitors’ parts’ switch leakage causes the

output voltage to drift up to VIN voltage even when the part is

supposed to be disabled.

ON

OFF

FAULT

VOUT

IOUT

FIGURE 1. TYPICAL OPERATIONAL WAVEFORMS

LATCH-OFF SET

OVER CURRENT

ENABLE

RESET BY

ENABLE

CURRENT

REGULATION

SETTLING TIME

(1.4ms)

1A CURRENT

LIMIT

12ms CURRENT REGULATION PERIOD

5

Typical Performance Curves

www.BDTIC.com/Intersil

ISL6119

120

110

100

90

80

70

60

50

SWITCH ON RESISTANCE (mΩ)

40

-40-30-20-10 0 102030405060708090

VIN = 2.7V

VIN = 3.3V

TEMPERATURE (°C)

VIN = 5V

100

ENABLE

10µF

CL = 0.1µF

OUTPUT

FIGURE 2. SWITCH ON RESISTANCE AT 0.7A FIGURE 3. VOUT SOFT START vs C

1200

1100

3.1

-40°C

1200

1100

CL = 100µF

-40°C

+25°C

TIME (400µs/DIV)

, Rl = 10Ω

LOAD

1000

IOUT (mA)

900

800

1.25

1.5

1.75

+25°C

+85°C

2.0 2.25 2.5

VOUT (V)

2.75

3.0

1000

IOUT (mA)

900

800

+85°C

1.3 1.5 2.0 2.5 3.0 3.5 4.0 4.5

VOUT (V)

FIGURE 4. CURRENT REGULATION vs Vout (VIN = 3.3V) FIGURE 5. CURRENT REGULATION vs VOUT (VIN = 5.0V)

1.6

1.4

1.2

OUTPUT CURRENT (1A/DIV)

NOMINAL CURRENT

CURRENT REGULATED

LEVEL

TIME (200µs /DIV)

1.0

0.8

0.6

0.4

0.2

TIME TO CURRENT REGULATION (ms)

0

12345678910

FAULT CURRENT (A)

FIGURE 6. OC TO CR SETTLING TIME WAVEFORMS FIGURE 7. CR SETTLING TIME vs FAULT CURRENT

4.8

6

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

ENABLE

ISL6119

CL = 10µF

CL = 100µF

CL = 0.1µF

VOUT VOLTAGE (1V/ DIV) TIME (400µs /DIV)

FIGURE 8. SLOW TURN -OFF vs C

FAULT

VOUT

VOUT

, Rl = 10Ω FIGURE 9. FAST TURN-OFF vs C

LOAD

ENABLE

VOUT

CL = 10µF

CL = 100µF

CL = 0.1µF

VOUT

VOUT VOLTAGE (1V/DIV) TIME (400µs /DIV)

LOAD

ENABLE

FAULT

VOUT

VOUT (1V/ DIV) TIME (2ms /DIV)

FIGURE 10. ISL6119L TURN-ON INTO 1.5A OCS FIGURE 11. ISL6119L TURN-ON INTO 1.5A MOMENTARY OC

ENABLE

FAULT

VOUT

TIME (2ms /DIV)

FIGURE 12. VENDOR IC TURN-ON INTO MOMENTARY OC FIGURE 13. ISL6119 vs PPTC INTO 500mA LOAD

VOLTAGE (2V/ DIV) TIME (2ms /DIV)

VDD = 5.08V

ISL6119 = 5.04 VOUT

PPTC = 4.98 VOUT

VOUT (100mV/ DIV)

7

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

ISL6119

PPTC

ISL6119

0.012S

VOUT (1V/ DIV) TIME (10ms/DIV)

FIGURE 14. ISL6119 vs PPTC PLUGGED ONTO 1.5A LOAD FIGURE 15. ISL6119 vs PPTC WITH EXTENDED 1.5A LOAD

ENABLE

ISL6119

COMP IC

ISL6119

VOUT (1V/ DIV) TIME (1s/DIV)

ENABLE

PPTC

8S

COMP IC

ISL6119

VOUT (1V/ DIV) TIME (1ms /DIV)

FIGURE 16. COMPARATIVE TURN-ON WAVEFORMS, Rl = 10Ω FIGURE 17. I COMPARATIVE TURN-OFF WAVEFORMS

VIN

OUT 2

VOLTAGE (1V/ DIV) TIME (100µs/DIV)

VOUT (1V/ DIV) TIME (2ms/DIV)

OUT 1

VOUT 2 = 3.7V IN CURRENT

REGULATION

FIGURE 18. SWITCH FAULT INDEPENDENCE

8

Using the ISL6119EVAL1 Platform

www.BDTIC.com/Intersil

ISL6119

General and Biasing Information

The ISL6119EVAL1 platform, Figure 19, allows evaluation of

the ISL6119 dual power supply control IC and comparison

against a suitably sized PPTC component.

The evaluation platform is biased and monitored through

numerous test points (TP#). See Table 1 for test point

assignments and descriptions.

TABLE 1. ISL6119EVAL1 TEST POINT ASSIGNMENTS

TP # DESCRIPTION

TP1 Eval Board and IC Gnd

TP2 Eval Bd +5V Bias

TP3 Enable Switch 1

TP4 Enable Switch 2

TP5 Switch 2 Fault

TP6 Switch Out 2

TP7 Switch Out 1

TP8 Switch 1 Fault

TP9 IC VIN Pin

TP10 PPTC Load Side

TP11 Invoke Over Current

FAULT LED, see Figure 10. (Please note: the labeling for

FAULT-1 and FAULT-2 is reversed). The eval board is

designed to only invoke an OC condition on channel 2 (TP4)

so that a channel to channel isolation evaluation in the

presence of an OC condition can be evaluated. See

Figure 18.

The primary function of any OC protection device is to

quickly isolate the voltage bus from a faulty load. Unlike the

PPTC and other vendor available IC products, the ISL6119

internal timer that starts upon OC detection provides

consistent protection that is not temperature dependent. See

Figures 14 and 15 for a comparison of the time to protection

offered by the ISL6119 vs the PPTC. Figure 14 illustrates the

ISL6119 timed latch-off of 12ms with a 1.5A load and

Figure 15 shows the 8 second latch-off of the PPTC at

approximately its trip current rating of 1.5A.

Using the ISL6119USBEVAL1 Platform

General and Biasing Information

The ISL6119USBEVAL1 platform, Figure 20, allows

evaluation of the ISL6119 dual power supply control IC in a

USB environment.

The evaluation platform is biased and monitored through

numerous test points (TP#). See Table 2 for test point

assignments and descriptions.

Upon proper bias the PPTC, F1 has a nominal 500mA load

current passing through it which is the hold current rating for

that particular device. Removal of the PPTC is necessary to

isolate the ISL6119 as the PPTC load current is common to

the ISL6119EVAL1 bias connections.

By enabling either or both of the ISL6119L switches by

signaling TP3 and/or TP4 low (<0.6V) these switches are

also loaded with a nominal 500mA current. See Figures 3

and 8 for typical ISL6119 turn-on and off waveforms.

Provided test points enable the evaluation of voltage loss

across the PPTC (TP9 - TP10) and the ISL6119 enabled

switches (TP9 - TP6 and TP7). Expect to see 50% - 300%

greater voltage loss across typical PPTC devices than the

ISL6119. See Figure 13 for a voltage loss comparison

across ISL6119 and PPTC device.

An overcurrent (OC) condition can be invoked on both the

ISL6119 and the PPTC by driving TP11 to +6V, causing SW1

to close and a nominal 1.5A load is imposed. This

represents a current over load to the ISL6119 and is thus

quickly current regulated to the 1A limit. If the OC duration

extends beyond the nominal 12ms of the internal ISL6119L

timer then the output is latched off and the fault output is

asserted by being pulled low turning on the appropriate

TABLE 2. ISL6119USBEVAL1 TEST POINT ASSIGNMENTS

TP # DESCRIPTION

TP1 Eval Board and IC Gnd

TP2 Eval Bd +5V Bias

TP3 Enable Switch 1

TP4 Enable Switch 2

TP5 Switch 1 Fault

TP8 Switch 2 Fault

Upon proper bias the ISL6119L is held off through pull up

resistors on the enable pins and is enabled by signaling

either or both of the ISL6119L switches TP3, and/or TP4 low

(<0.6V).

The USB connector is provided so that either test loads or

USB peripherals can be powered. In addition, differential

signalling (D+ and D-) access points are provided for each

output port so that I/O activity can also be conducted in a

prototype environment.

9

ISL6119

www.BDTIC.com/Intersil

ISL6119EVAL1

TP2

(VIN)

TP3

TP4

D1

C1

D2

FAULT_OUT1

1

2

VIN OUT1

ISL6119

3

4

EN2 FAULT_OUT2

R7

F1

R6

C2

R1

D3

8

7

6

OUT2EN1

5

D4

R8

C3

R4

R2

R9

SW1

C4

R5

R3

D5

R10

FIGURE 19. ISL6119EVAL1 BOARD SCHEMATIC AND PHOTOGRAPH

TABLE 3. ISL6119EVAL1 BOARD COMPONENT LISTING

COMPONENT

DESIGNATOR COMPONENT FUNCTION COMPONENT DESCRIPTION

DUT1 ISL6119 Intersil, ISL6119LIB 3.3V Aux HotPlug Controller

R1 - R3 500mA Nominal Load Resistors YAGEO, 10Ω, 5%, 5W, 10W-5-ND

R4 - R5 1.5A Current Over Load Resistors YAGEO, 5Ω, 5%, 5W, 5W-5-ND

R6 - R10 LED Current Limiting Resistor 470Ω, 0805

C1 Decoupling Capacitor 0.1µF, 0805

C2 - C4 Load Capacitor 10µF 16V Electrolytic, Radial Lead

D1 - D5 Indicating LEDs 0805, SMD LEDs Red

F1 PPTC (Polymer Positive Temperature Coefficient) Raychem, Poly Switch, RXE075 or Equivalent

SW1 (Q1) Current Over Load Invoking Switch Access TP11 Intersil, ITF86110DK8T, 7.5A, 30V, 0.025Ω, Dual N-channel, Logic

Level Power MOSFET

10

ISL6119USBEVAL1

www.BDTIC.com/Intersil

ISL6119

C1

1

FAULT_OUT

8

VIN

R2

R1

VIN OUT

2

ISL6119

3

4

EN FAULT_OUT

7

OUTEN

6

5

C3

C2

L1 L3

14142 3 2 3

L2

CON1

L4

FIGURE 20. ISL6119USBEVAL BOARD

TAB L E 4 .

COMPONENT

DESIGNATOR COMPONENT NAME COMPONENT DESCRIPTION

ISL6119USBEVAL1

DUT1 ISL6119L Intersil, ISL6119L 5V USB HotPlug Controller

C1 Chip Decoupling Capacitor 0.1µF, 0805

C2 - C3 V+ Decoupling Capacitors 100µF 16V Electrolytic, Radial Lead

L1 - L4 V+ And GND Stability Inductors 220nH, 0805 (OPTIONAL FOR IMPLEMENTATION)

CON1 Dual Stacked USB Type A Connector ASSMANN, AU-Y1008 or Equiv

R1 - R2 Pull-Up Resistors 1.2Ωk, 0805

11

ISL6119

www.BDTIC.com/Intersil

Implementing Autoreset on the ISL6119

Hot Swap Controller

Abstract

In applications where the cost, complexity or requirement for

a system controller is avoided and an autonomous power

control function is desired, a device that can monitor and

protect against excessive current failures is needed. This

tech brief shows how to implement such an autonomous

controller using the ISL6119HIB. This application works only

with the ‘H’ version of this device. The ‘H’ version refers to

the enable function being asserted upon a high input.

Introduction

The ISL6118, ISL6119 and ISL6121 are all 2.5V to 5V power

supply controllers, each having a different level of current

regulation (CR). The ISL6118 and ISL6119 have 2

independent controllers with CR levels of 0.6A and 1.0A

respectively whereas the ISL6121 is a single supply

controller with a 2A CR level. Each of these devices features

integrated power switch(es) for power control. Each switch is

driven by a constant current source giving a controlled ramp

up of the output voltage. This provides a soft start turn-on

eliminating bus voltage drooping caused by in-rush current

while charging heavy load capacitances. The independent

enabling inputs and fault reporting outputs for each channel

are available and necessary for the autonomous autoreset

application.

The undervoltage (UV) feature prevents turn-on of the

outputs unless the ENABLE pin and VIN are > 2.5V. During

initial turn-on the ISL6119 prevents fault reporting by

blanking the fault signal. Rising and falling outputs are

current-limited voltage ramps so that both the inrush current

and voltage slew rate are limited, independent of load. This

reduces supply droop due to surge and eliminates the need

for external EMI filters. During operation, once an OC

condition is detected the appropriate output is current limited

to the appropriate level for 10ms to allow transient conditions

to pass. If still in current limit after the current limit period has

elapsed, the output is latched off and the fault is reported by

pulling the corresponding FAULT

latched low until reset by the ENABLE signal being deasserted at which time the FAULT

low. The FAULT signal is

signal will clear.

Description of Operation

Rpu = 2K

C = 0.1µF

Initially as voltage is applied to VIN, the pull up resistor (Rpu)

provides for pull up to VIN on both the ENABLE pin asserting

the output once VIN > 2.5V and on the FLTn pin. Once

turned on and an overcurrent (OC) condition occurs the IC

provides CR protection for 10ms and then the FLTn pin pulls

low through Rpu and also pulling the ENABLE low thus

resetting the device fault condition. At this time the Rpu

charges the cap and the voltage on the ENABLE/FLTn node

rises until the ENABLE > 2.0 and the output is asserted on

once again. This automatic reset cycle will continue until the

OC fault no longer exists on the output. After several

seconds in this mode of operation the IC thermal protection

invokes adjusting the timing of the on-off cycle to prevent

excessive thermal dissipation in the power switch protecting

itself and surrounding circuitry. See Figure 22 for operation

waveform.

.

0V

0A

FIGURE 22. AUTO RESET OPERATION

VIN

FLTn

ISL6119H

ENABLE

GND

FIGURE 21.

VIN/FLTn 5V/DIV

VOUT 2V/DIV

IOUT 0.5A/DIV

4ms/DIV

It is this described sequence of events that allows for the

autoreset function to be implemented in a cost efficient

manner requiring the addition of only an RC network per

channel to the typical application.

Figure 21 illustrates the RC network needed with suggested

component values and the configuration of the relevant pins

for each autoreset channel.

12

Applications

•USB

• 2.5V to 5V up to 10W power port protection

Small Outline Plastic Packages (SOIC)

www.BDTIC.com/Intersil

ISL6119

N

INDEX

AREA

123

-AD

e

B

0.25(0.010) C AM BS

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerances per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

E

-B-

SEATING PLANE

A

-C-

M

0.25(0.010) BM M

H

α

µ

A1

0.10(0.004)

L

h x 45

o

C

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 -

D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 0 12/93

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

13

Loading...

Loading...