TM

ICL7650S

Data Sheet April 2000

2MHz, Super Chopper-Stabilized

Operational Amplifier

The ICL7650S Super Chopper-Stabilized Amplifier offers

exceptionally low input offset voltage and is extremely stable

with respect to time and temperature. It is a direct

replacement for the industry-standard ICL7650 offering

improved input offset voltage, lower input offset voltage

temperature coefficient, reduced input bias current, and

wider common mode voltage range. All improvements are

highlighted in bold italics in the Electrical Characteristics

section. Critical parameters are guaranteed over the

entire commercial temperature range.

Intersil’s unique CMOS chopper-stabilized amplifier circuitry

is user-transparent, virtually eliminating the traditional

chopper amplifier problems of intermodulation effects,

chopping spikes, and overrange lockup.

The chopper amplifier achieves its low offset by comparing

the inverting and non-inverting input voltages in a nulling

amplifier, nulled by alternate clock phases. Two external

capacitors are required to store the correcting potentials on

the two amplifier nulling inputs; these are the only external

components necessary.

The clock oscillator and all the other control circuitry is

entirely self-contained. Howeverthe14leadversion includes

a provision for the use of an external clock, if required for a

particular application. In addition, the ICL7650S is internally

compensated for unity-gain operation.

File Number 2920.5

Features

• Guaranteed Max Input Offset Voltage for All Temperature

Ranges

• Low Long-Term and Temperature Drifts of Input Offset

Voltage

• Guaranteed Max Input Bias Current. . . . . . . . . . . . . .10pA

• Extremely Wide Common Mode

Voltage Range. . . . . . . . . . . . . . . . . . . . . . . +3.5V to -5V

• Reduced Supply Current . . . . . . . . . . . . . . . . . . . . . . 2mA

• Guaranteed Minimum Output Source/Sink Current

• Extremely High Gain . . . . . . . . . . . . . . . . . . . . . . . .150dB

• Extremely High CMRR and PSRR. . . . . . . . . . . . . .140dB

• High Slew Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5V/µs

• Wide Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2MHz

• Unity-Gain Compensated

• Clamp Circuit to Avoid Overload Recovery Problems and

Allow Comparator Use

• Extremely Low Chopping Spikes at Input and Output

• Improved, Direct Replacement for Industry-Standard

ICL7650 and other Second-Source Parts

Ordering Information

TEMP.

RANGE

PART NUMBER

(oC) PACKAGE

ICL7650SCPA-1 0 to 70 8 Ld PDIP E8.3

ICL7650SCPD 0 to 70 14 Ld PDIP E14.3

ICL7650SCBA-1 0 to 70 8 Ld SOIC M8.15

ICL7650SCTV-1 0 to 70 8 Pin Metal Can T8.C

PKG.

NO.

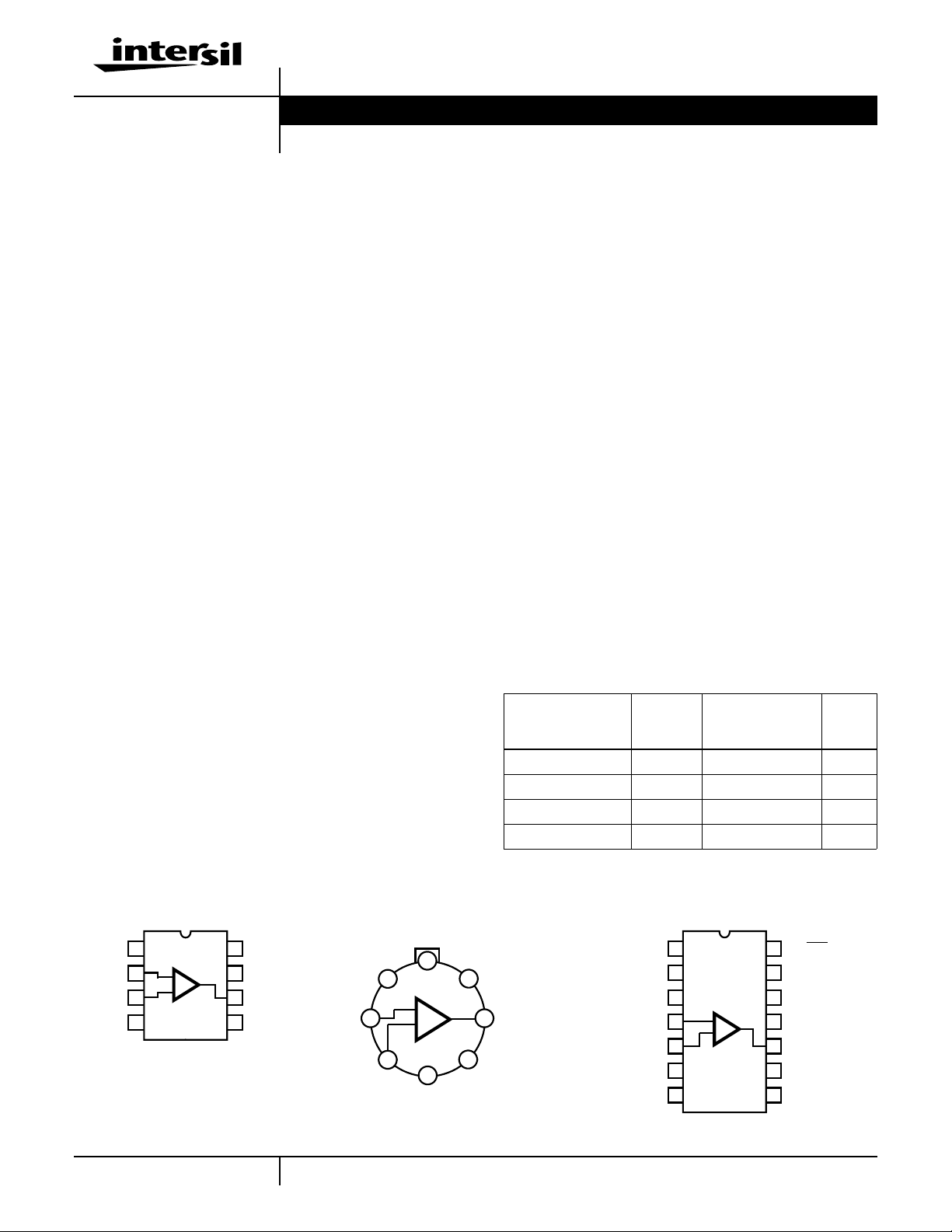

Pinouts

ICL7650S (PDIP, SOIC)

C

EXTA

-IN

+IN

V-

1

2

3

4

TOP VIEW

-

+

8

7

6

5

ICL7650S (METAL CAN)

TOP VIEW

C

C

EXTB

V+

OUTPUT

C

RETN

1

C

EXTA

2

-IN

+IN

1-888-INTERSIL or 321-724-7143 | Intersil and Design is a trademark of Intersil Corporation. | Copyright © Intersil Corporation 2000

EXTB

8

1

3

7

V+/CASE

-

+

4

V-

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

OUTPUT

6

5

C

RETN

C

C

NC (GUARD)

NC (GUARD)

ICL7650S (PDIP)

1

EXTB

2

EXTA

3

-IN

4

+IN

5

6

V-

7

TOP VIEW

-

+

14

13

12

11

10

9

8

EXT

INT/

EXT CLK IN

INT CLK OUT

V+

OUTPUT

OUT CLAMP

C

RETN

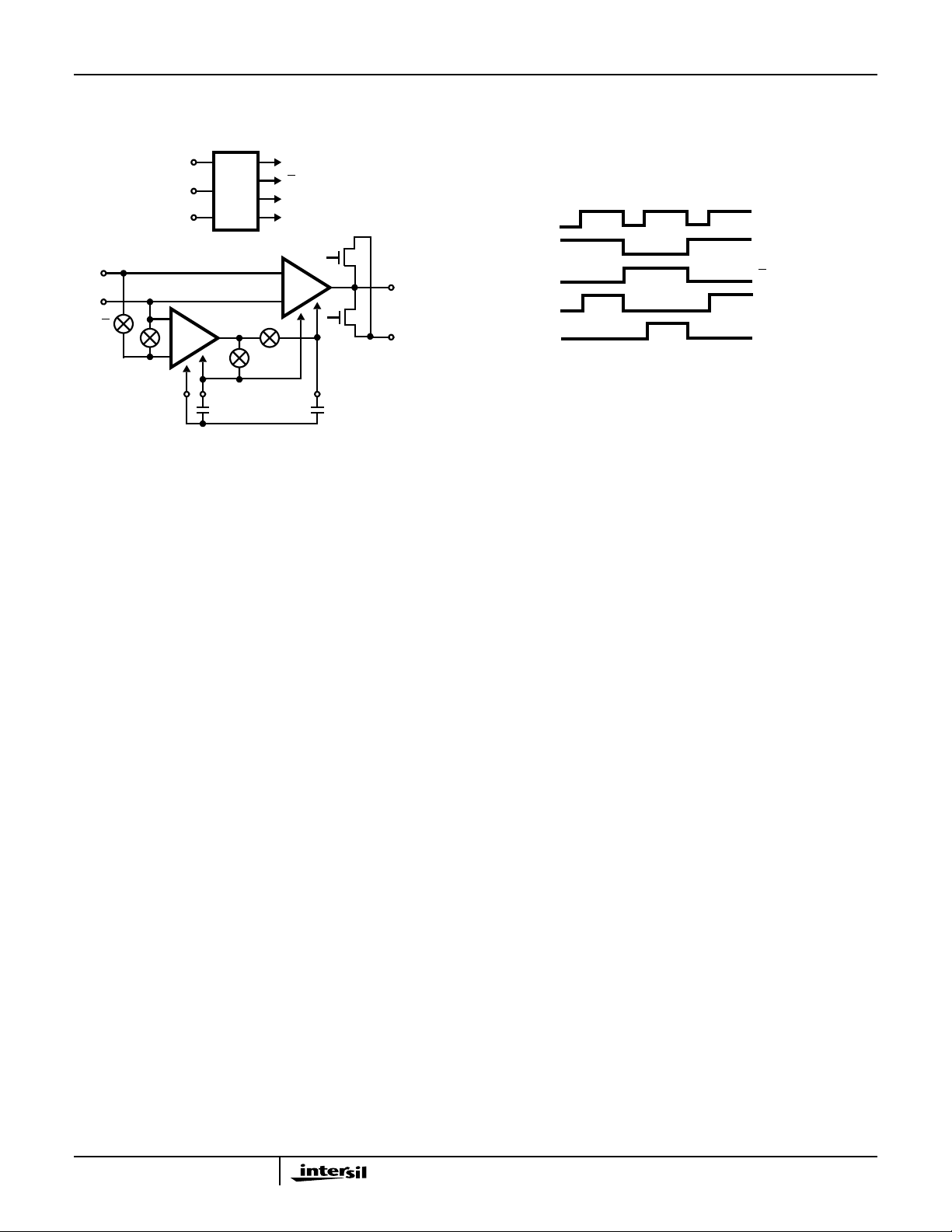

Functional Diagram

ICL7650S

+IN

-IN

A

CAP RETURN

INT/EXT

EXT CLK IN

CLK OUT

A

-

NULL

+

C

OSC.

EXTA

INTERNAL

C

B

A

A

B

C

BIAS

+

MAIN

-

C

EXTB

EXT CLK IN

P

OUTPUT

N

CLAMP

A = CLK OUT

A

B

C

2

ICL7650S

Absolute Maximum Ratings Thermal Information

Supply Voltage (V+ to V-). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18V

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . (V+ +0.3) to (V- -0.3)

Voltage on Oscillator Control Pins. . . . . . . . . . . . . . . . . . . . V+ to V-

Duration of Output Short Circuit. . . . . . . . . . . . . . . . . . . . . Indefinite

Current to Any Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10mA

While Operating (Note 1) . . . . . . . . . . . . . . . . . . . . . . . . . . .100µA

Operating Conditions

Temperature Range

ICL7650SC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0oC to 70oC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Limiting input current to 100µA is recommended to avoid latchup problems. Typically 1mA is safe, however this is not guaranteed.

2. θJA is measured with the component mounted on an evaluation PC board in free air.

Thermal Resistance (Typical, Note 2) θJA (oC/W) θJC (oC/W)

8 Lead PDIP Package . . . . . . . . . . . . . 120 N/A

14 Lead PDIP Package . . . . . . . . . . . . 80 N/A

8 Lead SOIC Package . . . . . . . . . . . . . 160 N/A

Metal Can Package . . . . . . . . . . . . . . . 160 75

Maximum Junction Temperature (Hermetic Package) . . . . . . . .175oC

Maximum Junction Temperature (Plastic Package) . . . . . . . .150oC

Maximum Storage Temperature Range. . . . . . . . . . -55oC to 150oC

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

Electrical Specifications V

= ±5V. See Test Circuit, Unless Otherwise Specified

SUPPLY

TEMP.

PARAMETER SYMBOL TEST CONDITIONS

Input Offset Voltage (Note 3) V

OS

(oC) MIN TYP MAX UNITS

25 - ±0.7 ±5 µV

0 to 70 - ±1 ±8 µV

Average Temperature Coefficient of

∆VOS/∆T 0 to 70 - 0.02 - µV/oC

Input Offset Voltage (Note 3)

Change in Input Offset with Time ∆VOS/∆T 25 - 100 - nV/√month

Input Bias Current |I(+)|, |I(-)| I

BIAS

25 - 4 10 pA

0 to 70 - 520pA

Input Offset Current |I(-), |I(+)| I

OS

25 - 820pA

0 to 70 - 10 40 pA

Input Resistance R

Large Signal Voltage Gain (Note 3) A

IN

VOL

25 - 10

RL = 10kΩ, VO = ±4V 25 135 150 -dB

12

- Ω

0 to 70 130 --dB

Output Voltage Swing (Note 4) V

OUT

RL = 10kΩ 25 ±4.7 ±4.85 - V

RL = 100kΩ 25 - ±4.95 - V

Common Mode Voltage Range (Note 3) CMVR 25 -5 -5.2 to +4 3.5 V

0 to 70 -5 - 3.5 V

Common Mode Rejection Ratio

(Note 3)

CMRR CMVR = -5V to +3.5V 25 120 140 -dB

0 to 70 120 --dB

Power Supply Rejection Ratio PSRR VS = ±3V to ±8V 25 120 140 -dB

Input Noise Voltage e

N

RS = 100Ω,

25 - 2 - µV

P-P

f = DC to 10Hz

Input Noise Current i

N

f = 10Hz 25 - 0.01 - pA/√Hz

Gain Bandwidth Product GBWP 25 - 2 - MHz

Slew Rate SR CL = 50pF, RL = 10kΩ 25 - 2.5 - V/µs

Rise Time t

R

25 - 0.2 - µs

Overshoot OS 25 - 20 - %

Operating Supply Range V+ to V- 25 4.5 - 16 V

Supply Current I

SUPP

No Load 25 - 2 3 mA

0 to 70 - - 3.2 mA

Output Source Current I

O SOURCE

25 2.9 4.5 - mA

0 to 70 2.3 - - mA

3

ICL7650S

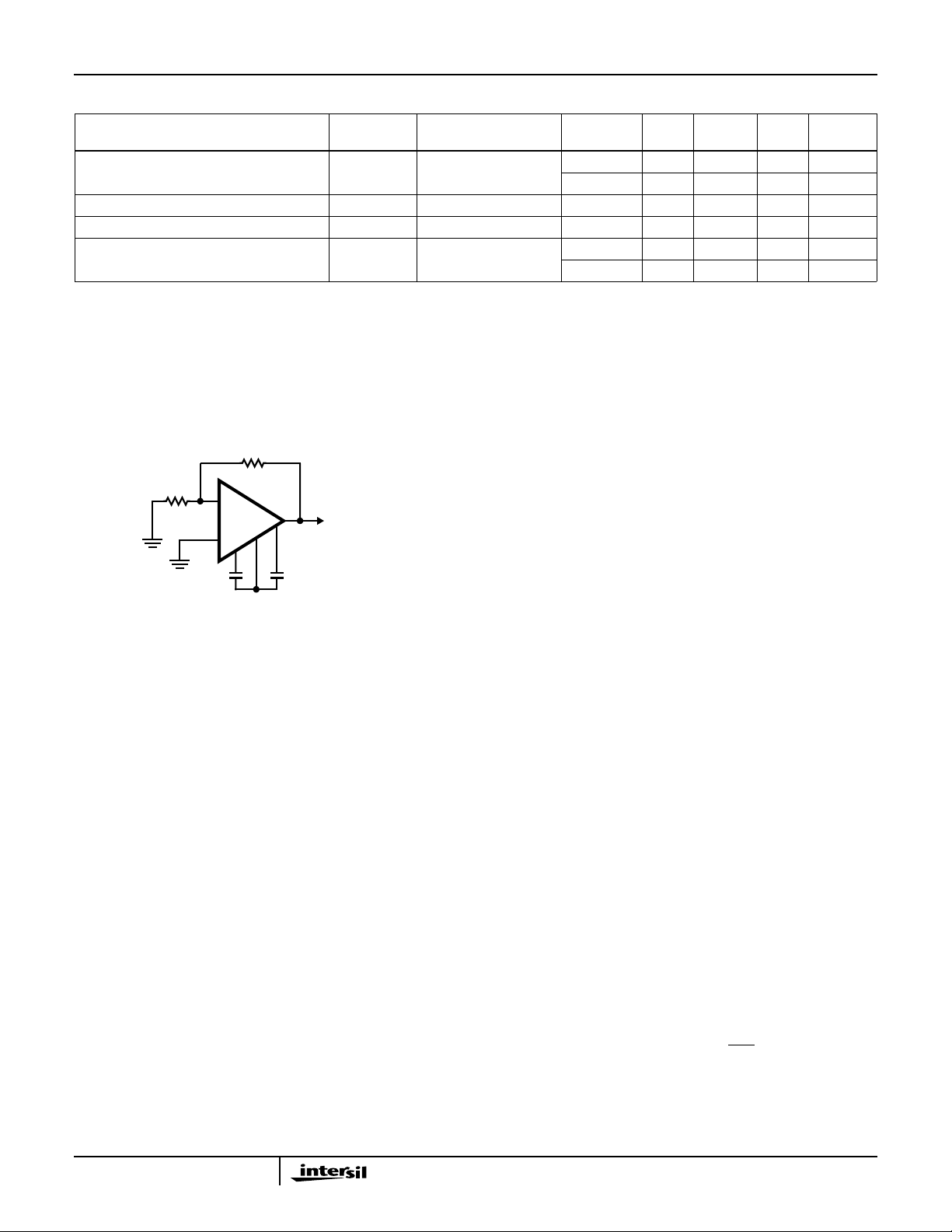

Electrical Specifications V

PARAMETER SYMBOL TEST CONDITIONS

Output Sink Current I

Internal Chopping Frequency f

Clamp ON Current (Note 5) RL = 100kΩ 25 25 70 - µA

Clamp OFF Current (Note 5) -4V ≤ V

NOTES:

3. These parametersare guaranteedbydesign andcharacterization, butnottested attemperature extremesbecausethermocoupleeffectsprevent

precise measurement of these voltages in automatic test equipment.

4. OUTPUT CLAMP not connected. See typical characteristic curves for output swing vs clamp current characteristics.

5. See OUTPUT CLAMP under detailed description.

6. All significant improvements over the industry-standard ICL7650 are highlighted in bold italics.

Test Circuit

R

2

1MΩ

R

1

1MΩ

-

ICL7650S

+

C

R

C

0.1µF 0.1µF

= ±5V. See Test Circuit, Unless Otherwise Specified (Continued)

SUPPLY

TEMP.

(oC) MIN TYP MAX UNITS

O SINK

CH

Pins 13 and 14 Open 25 120 250 375 Hz

≤ +4V 25 - 0.001 5 nA

OUT

25 25 30 - mA

0 to 70 20 - - mA

0 to 70 - - 10 nA

amplifier necessitates a small AC signal at the input. This is

seen by the zeroing circuit as an error signal, which is

chopped and fed back, thus injecting sum and diff erence

frequencies and causing disturbances to the gain and phase

vs frequency characteristics near the chopping frequency.

These effects are substantially reduced in the ICL7650S by

C

OUTPUT

feeding the nulling circuit with a dynamic current,

corresponding to the compensation capacitor current, in such

a way as to cancel that portion of the input signal due to finite

AC gain. Since that is the major error contribution to the

ICL7650S, the intermodulation and gain/phase disturbances

Application Information

Detailed Description

are held to very low values, and can generally be ignored.

CAPACITOR CONNECTION

The null/storage capacitors should be connected to the

AMPLIFIER

The functional diagram shows the major elements of the

ICL7650S.Thereare twoamplifiers,themainamplifier,andthe

nulling amplifier. Both ha v e offset-n ull capability. The main

amplifier is connected continuously from the input to the output,

while the nulling amplifier, under the control of the chopping

oscillator and clock circuit, alternately nulls itself and the main

amplifier. The nulling connections , which are MOSFET gates,

are inherently high impedance, and two external capacitors

provide the required storage of the nulling potentials and the

necessary nulling-looptimeconstants.The nulling arrangement

operatesoverthe full common-mode and power-supplyranges,

and is also independent of the output level, thus giving

exceptionally high CMRR, PSRR, and A

VOL

.

C

and C

EXTA

C

pin. This connection should be made directly by

RETN

pins, with a common connection to the

EXTB

either a separate wire or PC trace to avoid injecting load

current IR drops into the capacitive circuitry. The outside foil,

where available, should be connected to C

RETN

.

OUTPUT CLAMP

The OUTPUT CLAMP pin allows reduction of the overload

recovery time inherent with chopper-stabilized amplifiers.

When tied to the inverting input pin, or summing junction, a

current path between this point and the OUTPUT pin occurs

just before the device output saturates. Thus uncontrolled

input differentials are avoided, together with the consequent

charge buildup on the correction-storage capacitors. The

output swing is slightly reduced.

Careful balancing of the input switches, and the inherent

balance of the input circuit, minimizes chopper frequency

charge injection at the input terminals, and also the feed

forward-type injection into the compensation capacitor, which

is the main cause of output spikes in this type of circuit.

INTERMODULATION

Previous chopper-stabilized amplifiers have suffered from

intermodulation effects between the chopper frequency and

input signals. These arise because the finite AC gain of the

CLOCK

The ICL7650S has an internal oscillator, giving a chopping

frequency of 200Hz, availableat the CLOCK OUT pin on the 14

pin devices. Provision has also been made f or the use of an

external clock in these parts. The INT/

EXT pin has an internal

pull-up and may be left open for normal operation, but to utiliz e

an external clock this pin must be tied to V- to disable the

internal clock. The external clock signal may then be applied to

the EXT CLOCK IN pin. An internal divide-by-two provides the

4

ICL7650S

desired 50% input switching duty cycle. Since the capacitors

are charged only when EXT CLOCK IN is high, a 50% - 80%

positive duty cycle is recommended, especially for higher

frequencies. The external clock can swing betw een V+ and V-.

The logic threshold will be at about 2.5V below V+. Note also

that a signal of about 400 Hz, with a 70% duty cycle, will be

present at the EXT CLOCK IN pin with INT/

This is the internal clock signal before being fed to the divider.

In those applications where a strobe signal is available, an

alternate approach to avoid capacitor misbalancing during

overload can be used. If a strobe signal is connected to EXT

CLK IN so that it is low during the time that the overload

signal is applied to the amplifier, neither capacitor will be

charged. Since the leakage at the capacitor pins is quite low

at room temperature, the typical amplifier will drift less than

10µV/s, and relatively long measurements can be made with

little change in offset.

COMPONENT SELECTION

The two required capacitors, C

optimum values depending on the clock or chopping

frequency. For the preset internal clock, the correct value is

0.1µF, and to maintain the same relationship between the

chopping frequency and the nulling time constant this value

should be scaled approximately in proportion if an external

clock is used. A high quality film type capacitor such as

mylar is preferred, although a ceramic or other lower-grade

capacitor may prove suitable in many applications. For

quickest settling on initial turn-on, low dielectric absorption

capacitors (such as polypropylene) should be used. With

ceramic capacitors, several seconds may be required to

settle to 1µV.

STATIC PROTECTION

All device pins are static-protected by the use of input diodes.

Howev er, strong static fields and discharges should beavoided,

as they can cause degraded diode junction characteristics,

which may result in increased input-leakage currents.

LATCHUP AVOIDANCE

Junction-isolated CMOS circuits inherently include a parasitic

4-layer (PNPN) structure which has characteristics similar to

an SCR. Under certain circumstances this junction may be

triggered into a low-impedance state, resulting in excessive

supply current. To avoid this condition, no voltage greater than

0.3V beyond the supply rails should be applied to any pin. In

general, the amplifier supplies must be established either at

the same time or before any input signals are applied. If this is

not possible, the drive circuits must limit input current flow to

under 1mA to avoid latchup , even under fault conditions.

EXTA

EXT high or open.

and C

EXTB

, have

proportional to load resistance. For example, the open-loop

gain will be 17dB lower with a 1kΩ load than with a 10kΩ

load. If the amplifier is used strictly for DC, this lower gain is

of little consequence, since the DC gain is typically greater

than 120dB even with a 1kΩ load. However, for wideband

applications, the best frequency response will be achieved

with a load resistor of 10kΩ or higher. This will result in a

smooth 6dB/octave response from 0.1Hz to 2MHz, with

phase shifts of less than 10 degrees in the transition region

where the main amplifier takes over from the null amplifier.

THERMO-ELECTRIC EFFECTS

The ultimate limitations to ultra-highprecisionDCamplifiersare

the thermo-electric or Peltier effects arising in thermocouple

junctions of dissimilar metals, alloys, silicon, etc. Unless all

junctions are at the same temperature, thermoelectric voltages

typically around 0.1µV/

materials, will be generated. In order to realize the extremely

low offset voltages that the chopper amplifier can provide, it is

essential to take special precautions to avoid temper ature

gradients. All components should be enclosed to eliminate air

movement, especially that caused by po wer-dissipating

elements in the system. Low thermoelectric-efficient

connections should be used where possible and power supply

voltages and power dissipation should be kept to a minim um.

High-impedance loads are preferable , and good separation

from surrounding heat-dissipating elements is advisable.

GUARDING

Extra care must be taken in the assembly of printed circuit

boards to take full advantage of the low input currents of the

ICL7650S. Boards must be thoroughly cleaned with TCE or

alcohol and blown dry with compressed air. After cleaning,

the boards should be coated with epoxy or silicone rubber to

prevent contamination.

Even with properly cleaned and coated boards, leakage

currents may cause trouble, particularly since the input pins

are adjacent to pins that are at supply potentials. This

leakage can be significantly reduced by using guarding to

lowerthe voltagedifferencebetweentheinputsandadjacent

metal runs. Input guarding of the 8-pin TO-99 package is

accomplished by using a 10-lead pin circle, with the leads of

the device formed so that the holes adjacent to the inputs

are empty when it is inserted in the board. The guard, which

is a conductive ring surrounding the inputs, is connected to a

low impedance point that is at approximately the same

voltage as the inputs. Leakage currents from high-voltage

pins are then absorbed by the guard.

o

C, but up to tens of mV/oC for some

OUTPUT STAGE/LOAD DRIVING

The output circuit is a high-impedance type (approximately

18kΩ), and therefore with loads less than this value, the

chopper amplifier behaves in some ways like a

transconductance amplifier whose open-loop gain is

5

Loading...

Loading...