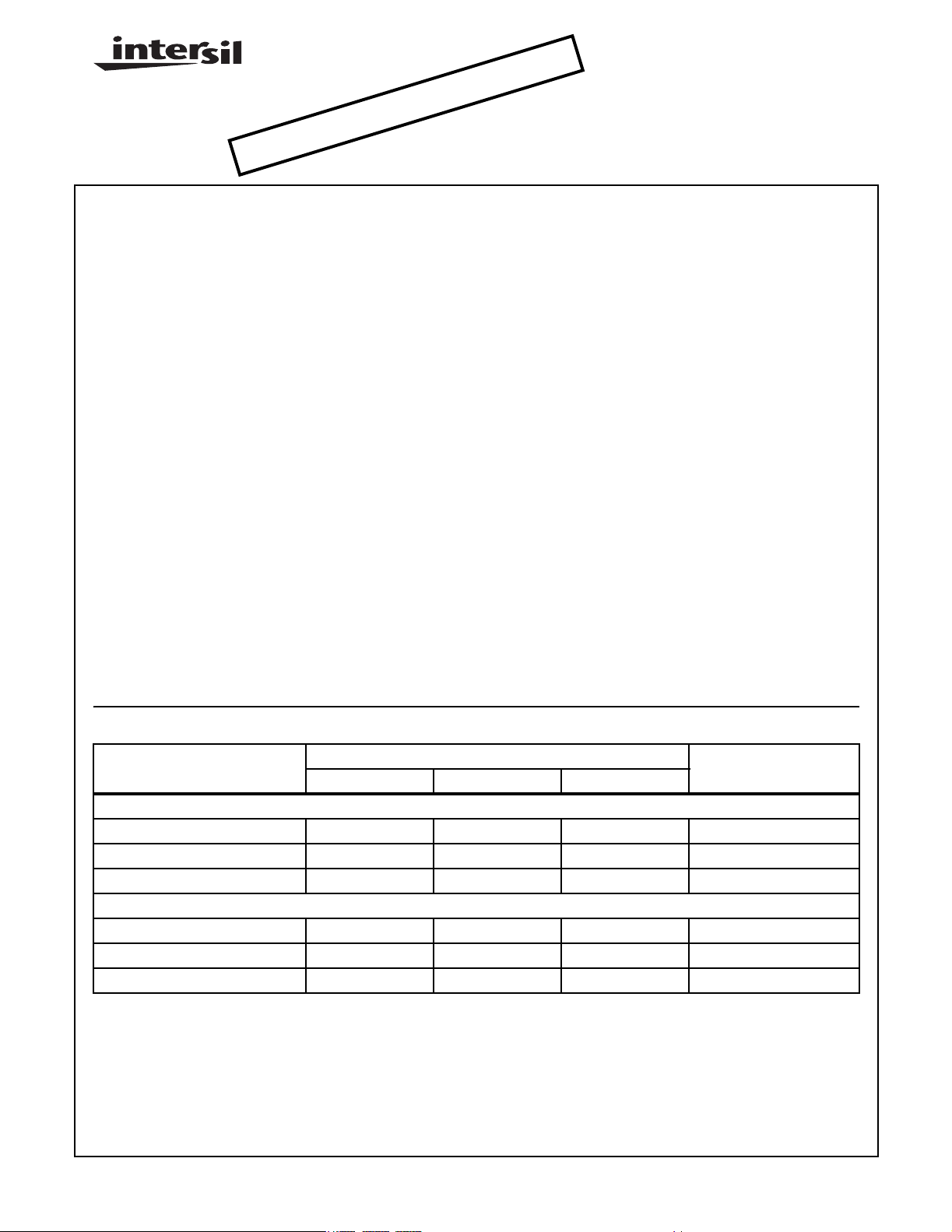

Intersil Corporation ICL7134BJIJI, ICL7134BJMJI, ICL7134BKCJI, ICL7134BKIJI, ICL7134BKMJI Datasheet

...

December 1997

®

D

W

E

N

R

O

F

D

E

D

N

E

M

M

O

C

E

R

T

O

N

S

N

G

I

S

E

ICL7134

14-Bit Multiplying

Microprocessor-Compatible D/A Converter

Features

• 14-Bit Linearity (0.003% FSR)

• No Gain Adjustment Necessary

• Microprocessor-Compatible with Double Buffered

Inputs

• Bipolar Application Requires No Extra Adjustments or

External Resistors

• Low Linearity and Gain Temperature Coefficients

• Low Power Dissipation

• Full Four-Quadrant Multiplication

• 883B Processed Versions Available

Description

The ICL7134 combines a four-quadrant multiplying DAC

using thin film resistor and CMOS circuitry with an on-chip

PROM-controlled correction circuit to achieve true 14-bit

linearity without laser trimming.

Microprocessor bus interfacing is eased using standard

memory WRITE cycle timing and control signal use. Two

input buffer registers are separately loaded with the 8 least

significant bits (LS register) and the 6 most significant bits

(MS register). Their contents are then transferred to the

14-bit DAC register, which controls the current switches. The

DAC register can also be loaded directly from the data

inputs, in which case the MS and LS registers are

transparent.

The ICL7134 is available in two versions. The ICL7134U is

programmed for unipolar operation while the ICL7134B is

programmed for bipolar applications. The V

most significant bit of the DAC is separated from the

reference input to the remainder of the ladder. For unipolar

use, the two reference inputs are tied together, while for

bipolar operation, the polarity of the MSB reference is

reversed, giving the DAC a true 2’s complement input

transfer function. Two resistors which facilitate the reference

inversion are included on the chip, so only an external

op-amp is needed. The PROM is coded to correct for errors

in these resistors as well as the inversion of the MSB.

input to the

REF

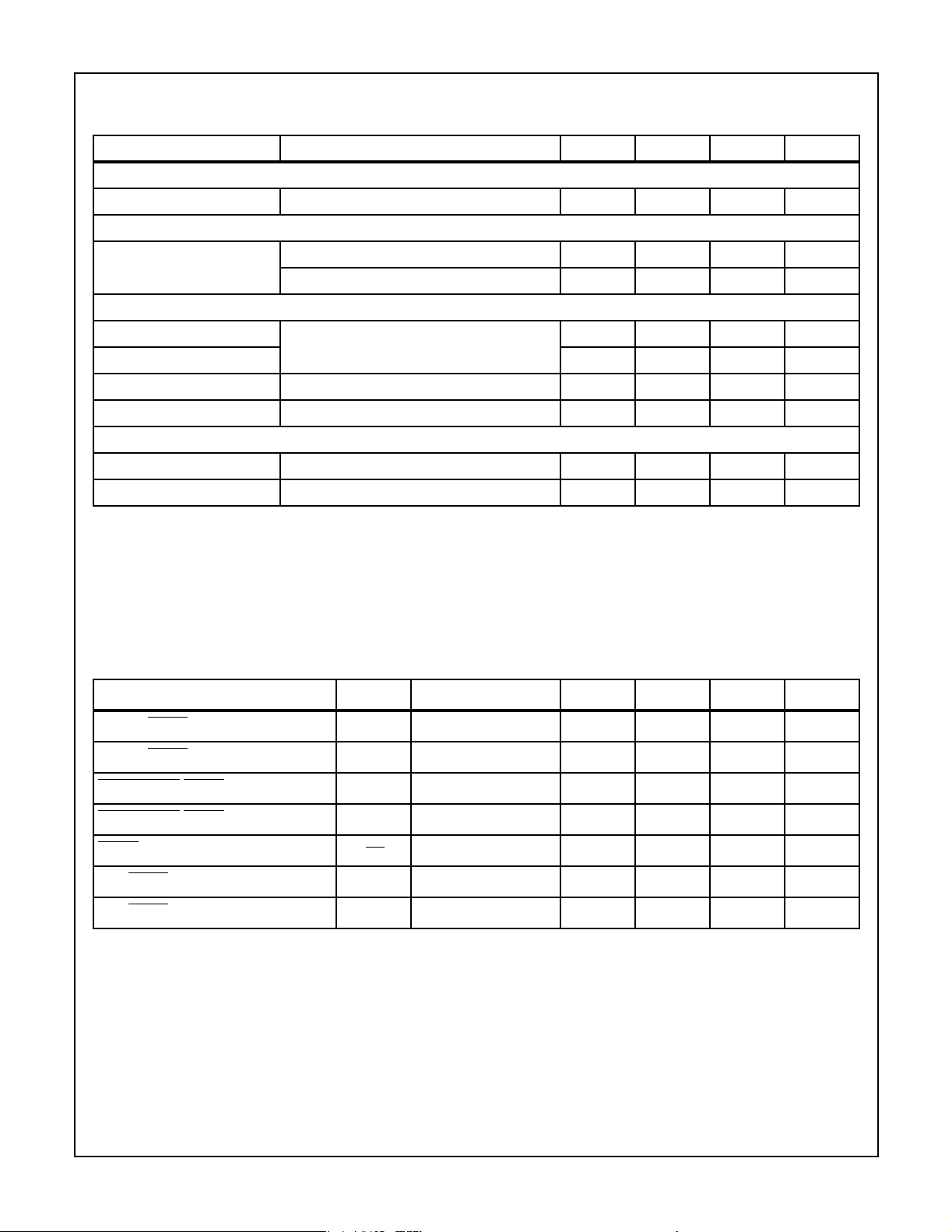

Ordering Information

TEMPERATURE RANGE (oC)

NON-LINEARITY AT 25oC

BIPOLAR VERSIONS

0.01% (12-bit) ICL7134BJCJI ICL7134BJIJI ICL7134BJMJI 28 Ld CERDIP

0.006% (13-bit) ICL7134BKCJI ICL7134BKIJI ICL7134BKMJI 28 Ld CERDIP

0.003% (14-bit) ICL7134BLCJI ICL7134BLIJI ICL7134BLMJI 28 Ld CERDIP

UNIPLAR VERSIONS

0.01% (12-bit) ICL7134UJCJI ICL7134UJIJI ICL7134UJMJI 28 Ld CERDIP

0.006% (13-bit) ICL7134UKCJI ICL7134UKIJI ICL7134UKMJI 28 Ld CERDIP

0.003% (14-bit) ICL7134ULCJI ICL7134ULIJI ICL7134ULMJI 28 Ld CERDIP

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

1

PACKAGE0 to 70 -25 to 85 -55 to 125

File Number 3113.1

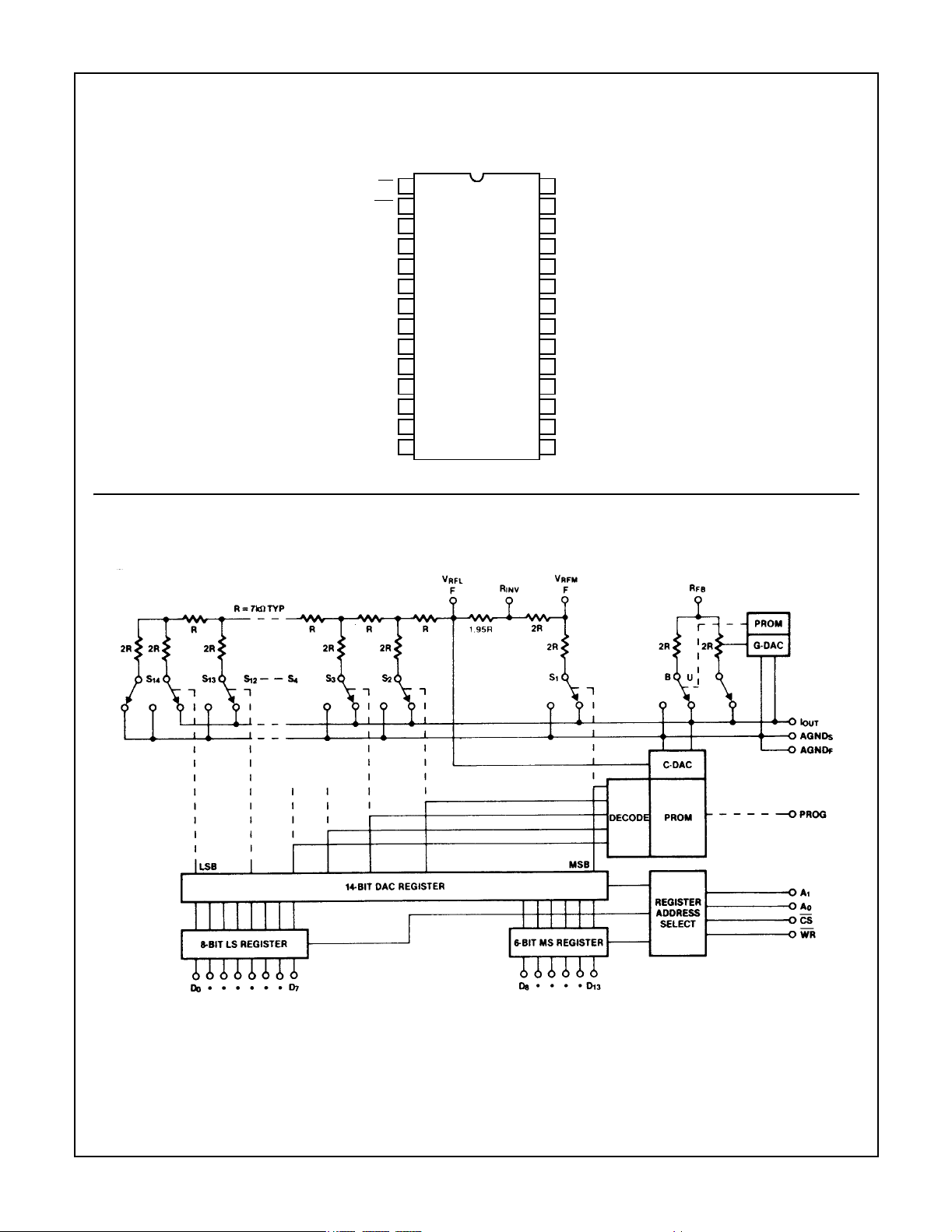

Pinout

ICL7134

ICL7134

(OUTLINE DWG JI)

TOP VIEW

Functional Block Diagram

WR

(LSB) D

D

D

CS

D

D

D

D

D

D

D

D

D

1

2

3

0

4

1

5

2

6

3

7

4

8

5

9

6

10

7

11

8

12

9

13

10

14

11

28

27

26

25

24

23

22

21

20

19

18

17

16

15

A

0

A

1

V+

I

OUT

AGND

AGND

DGND

R

FB

V

RFM

R

INV

V

RFL

PROG

(MSB)

D

13

D

12

S

F

2

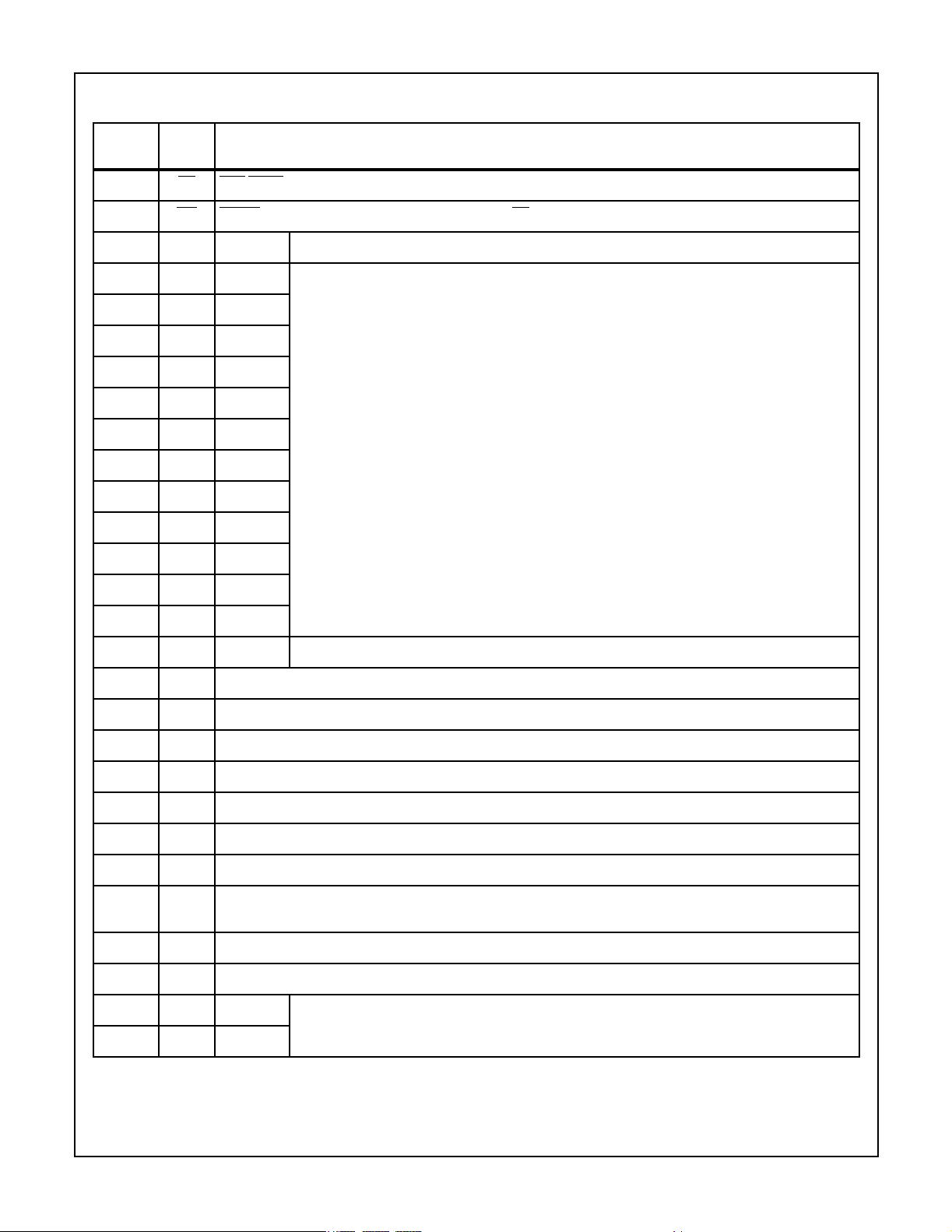

Pin Descriptions

ICL7134

28 LEAD

CERDIP

PIN

NAME PIN DESCRIPTION

1CS

2WR

3D

4D

5D

6D

7D

8D

9D

10 D

11 D

12 D

13 D

14 D

10

11

Chip Select (active low). Enables register write.

WRITE, (active low). Writes in register. Equivalent to CS.

0

1

2

3

4

5

6

7

8

9

Bit 0 Least Significant

Bit1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Bit 8

Bit 9

Bit 10

Bit 11

Input Data Bits (High = True)

15 D

16 D

12

13

Bit 12

Bit 13 Most significant

17 PROG Used for programming only. Tie to +5V for normal operation.

18 V

19 R

20 V

21 R

RFLVREF

INV

RFM

FB

for lower bits.

Summing node for reference inverting amplifier.

FV

for MSB only (bipolar)

REF

Feedback resistor for voltage output applications.

22 DGND Digital Ground Return.

23 AGND

24 AGND

25 I

Analog Ground force lines. Use to carry current from internal Analog GND connections. Tied internally to AGNDS.

F

Analog Ground sense line. Reference point for external circuitry. Pin should carry minimal current; tied internally to

S

AGND

.

F

Current output pin.

OUT

26 V+ Positive Supply.

27 A

28 A

Address 1 Registers Select Lines

1

Address 0

0

3

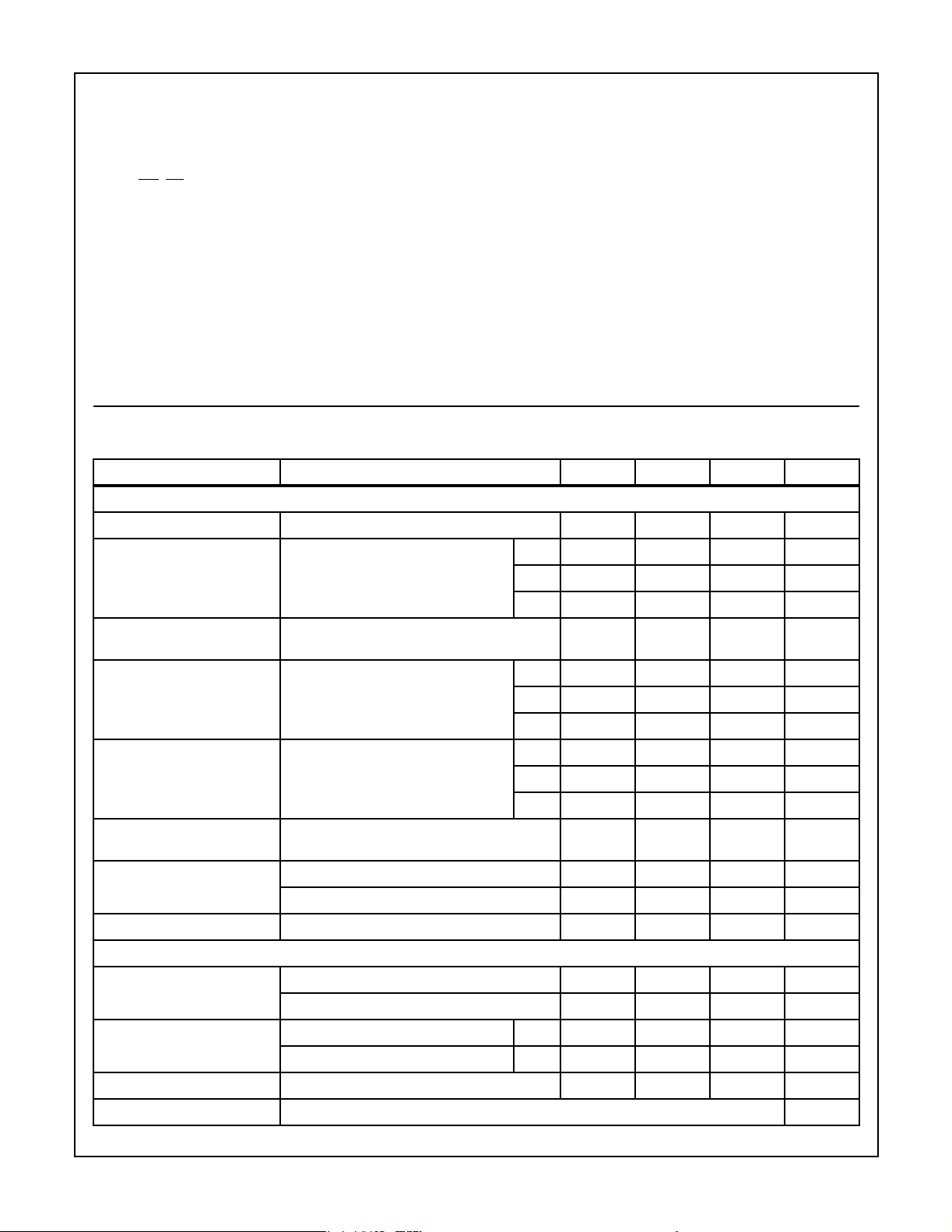

ICL7134

Absolute Maximum Ratings (Note 1) Thermal Information

Supply Voltage (V+ to DGND) . . . . . . . . . . . . . . . . . . . -0.3V to 7.5V

V

, V

, R

RFL

RFM

I

, AGNDF, AGNDS . . . . . . . . . . . . . . . . . . . . . . . . . -0.1V to V+

OUT

Current in AGND

An, Dn, WR

, RFB to DGND . . . . . . . . . . . . . . . . . . . . . . . . ±15V

INV

, AGNDF . . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA

S

, CS, PROG. . . . . . . . . . . . . . . . . . . . -0.3V to V+ +0.3V

Storage Temperature Range . . . . . . . . . . . . . . . . . .-65

Power Dissipation (Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 500mW

Derate Linearly Above 70

o

C @10mW/oC

Lead Temperature (Soldering, 10s) . . . . . . . . . . . . . . . . . . . . 300

Operating Conditions

Temperature Range

ICL7134XXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0

ICL7134XXI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -25

ICL7134XXM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. All voltages with respect to DGND.

2. Assumes all leads soldered or welded to printed circuit board.

o

C to 70oC

o

C to 85oC

o

C to 125oC

o

C to 150oC

o

C

Electrical Specification V+ = +5V, V

= +10V, TA = 25oC, AGND = DGND, I

REF

at Ground Potential,

OUT

Unless Otherwise Specified.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

DC ACCURACY

Resolution 14 - - Bits

Non-Linearity (Notes 3 and 4) Figure 2 J - - ±0.012 %FSR

K- -±0.006 %FSR

L- -±0.003 %FSR

Non-Linearity Temperature

Operating Temperature Range (Note 5) - ±1 ±2 ppm/

Coefficient

Monotonicity (Note 5) J 12 - - Bits

K13 - - Bits

L14 - - Bits

Gain Error (Notes 3 and 4)

Figure 1

J- -±0.024 %FSR

K- -±0.012 %FSR

L- -±0.006 %FSR

Gain Error Temperature

(Note 5) - ±2 ±8 ppm/

Coefficient

Output Leakage Current

(I

Terminal)

OUT

= 25oC--±10 nA

T

A

Operating Temperature Range - ±60 - nA

o

C

o

C

Long Term Stability of I

OUT

1000 Hours, 125oC, (Note 5) - ±10 - ppm/month

AC ACCURACY

Power Supply Rejection ∆V+ = ±10%, Figure 2, T

= 25oC-±10 ±100 ppm/V

A

Operating Temperature Range - - ±150 ppm/V

Feedthrough Error V

REF

= 20V

, 2kHz U - 250 - µV

P-P

Sinewave, Figure 3 B - 500 - µV

Output Current Setting Time To 1/2 LSB, Figure 4 - 1 - µs

Output Noise Equivalent to Johnson Noise of 7kΩ Resistor, Typical

4

P-P

P-P

ICL7134

Electrical Specification V+ = +5V, V

= +10V, TA = 25oC, AGND = DGND, I

REF

at Ground Potential,

OUT

Unless Otherwise Specified. (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

REFERENCE INPUT

Input Resistance V

RFL

= V

RFM

, I

at Ground 4 7 10 kΩ

OUT

ANALOG OUTPUT

Output Capacitance

(I

Terminal)

OUT

DAC Register Outputs All LOW - 160 - pF

DAC Register Outputs All HIGH - 235 - pF

DIGITAL INPUTS

Low State Threshold Operating Temperature Range - - 0.8 V

High State Threshold 2.4 - - V

Input Current Inputs between DGND to V+ - - ±1 µA

Input Capacitance (Note 5) - 15 - pF

POWER SUPPLY

Supply Voltage Range Functional Operation, (Note 6) 3.5 - 6.0 V

Supply Current Excluding Ladder Network (Note 7) - 1.0 2.5 mA

NOTES:

3. Full-Scale Range (FSR) is 10V for unipolar mode, 20V (±10V) for bipolar mode.

4. Using internal feedback and reference inverting resistors.

5. Guaranteed by design, not production tested.

6. Gain error tested to 0.040% FSR, Specifications are not guaranteed.

7. D0 - D13 connected to 2.4V.

Switching Specifications V+ = 5V, T

PARAMETER SYMBOL TEST CONDITIONS MIN TYP MAX UNITS

Address-WRITE

Address-WRITE

CHIP SELECT

CHIP SELECT

Pulse Width Low t

WRITE

Data-WRITE

Data-WRITE

Set-Up Time t

Hold Time t

-WRITE Set-Up Time t

-WRITE Hold Time t

Set-Up Time t

Hold Time t

= 25oC, See Timing Diagram

A

AWs

AWh

CWs

CWh

WR

DWs

DWh

Note 5 0 - - ns

Note 5 0 - - ns

Note 5 0 - - ns

Note 5 0 - - ns

150 - - ns

200 - - ns

200 - - ns

5

Test Circuits

ICL7134

FIGURE 1. NON-LINEARITY TEST CIRCUIT

FIGURE 2. POWER SUPPLY REJECTION TEST CIRCUIT

6

Test Circuits (Continued)

ICL7134

FIGURE 3. FEEDTHROUGH ERROR TEST CIRCUIT

Timing Diagrams

FIGURE 4. OUTPUT CURRENT SETTLING TIME TEST CIRCUIT

FIGURE 5A. USING 14-BIT TRANSPARENT ADDRESSING

7

Timing Diagrams

ICL7134

FIGURE 5B. USING FULL BUFFER 8-BIT ADDRESSING CAPABILITY

8

ICL7134

Definition of Terms

Nonlinearity - Error contributed by deviation of the DAC

transfer function from a straight line through the end points of

the actual plot of transfer function. Normally expressed as a

percentage of full scale range or in (sub)multiples of 1 LSB.

Resolution - It is addressing the smallest distinct analog output change that a D/A converter can produce. It is commonly

expressed as the number of converter bits. A converter with

resolution of n bits can resolve output changes of 2

full-scale range, e.g. 2

-n

V

for a unipolar conversion. Res-

REF

-n

of the

olution by no means implies linearity.

Settling Time - Time required for the output of a DAC to

settle to within specified error band around its final value

(e.g. 1/2 LSB) for a given digital input change, i.e. all digital

inputs LOW to HIGH and HIGH to LOW.

Gain Error - The difference between actual and ideal analog

output values at full-scale range, i.e., all digital inputs at

HIGH state. It is expressed as a percentage of full-scale

range or in (sub)multiples of 1 LSB.

Feedthrough Error - Error caused by capacitive coupling

from V

Output Capacitance - Capacitance from I

REF

to I

with all digital inputs LOW.

OUT

terminal to

OUT

ground.

Output Leakage Current - Current which appears on I

OUT

terminal when all DAC register outputs are LOW.

Detailed Description

The ICL7134 consists of 14-bit primary DAC, two PROM

controlled correction DACs, input buffer registers, and

microprocessor interface logic (See Functional Block

Diagram). The 14-bit primary DAC is an R-2R thin film

resistor ladder with N-channel MOS SPDT current steering

switches. Precise balancing of the switch resistances, and

all other resistances in the ladder, results in excellent

temperature stability.

True 14-bit linearity is achieved by programming a floating polysilicon gate PROM array which controls two correction DAC circuits. A 6-bit gain correction DAC, or G-DAC, diverts up to 2%

of the feedback resistor’s current to Analog GND and reduces

the gain error to less than 1 LSB, or 0.006%. The 5 most

significant outputs of the DAC register address a 31-word

PROM array that controls a 12-bit linearity correction DAC, or

C-DAC. For every combination of the primary DAC’s 5 most

significant bits, a different C-DAC code is selected. This allows

correction of superposition errors, caused by bit interaction on

the primary resistor ladder’s current output bus and by voltage

non-linearity in the feedback resistor. Superposition errors cannot be corrected by any method which corrects individual bits

only, such as laser trimming. Since the PROM programming

occurs in packaged form, it corrects for resistor shifts caused by

the thermal stresses of packaging. These packaging shifts limit

the accuracy that can be achieved using wafer level correction

methods such as laser trimming, which has also been found to

degrade the time stability of thin film resistors at the 14-bit level.

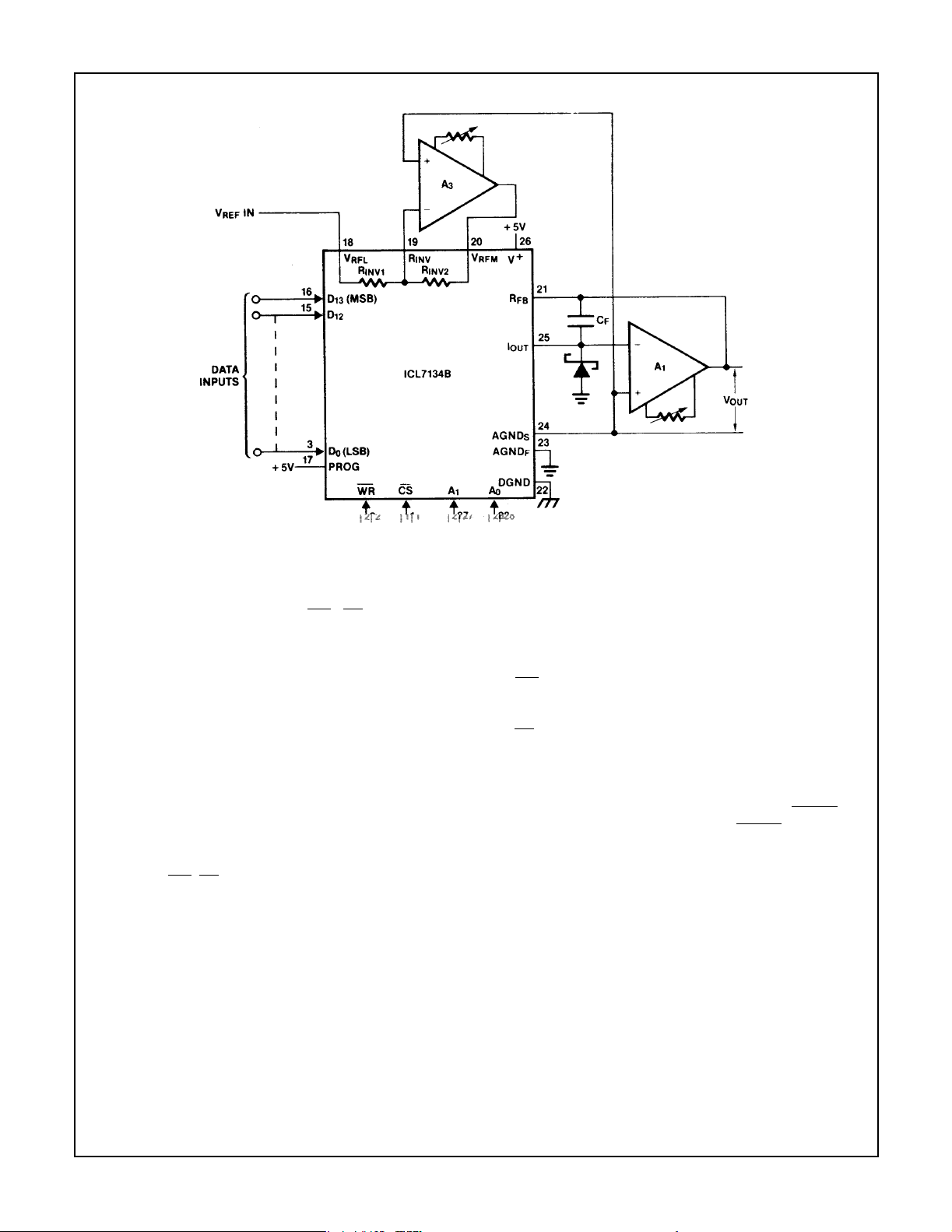

Analog Section

The ICL7134 inherently provides both unipolar and bipolar

operation. The bipolar application circuit (Figure 6) requires

one additional op-amp but no external resistors. The two onchip resistors, R

INV1

and R

, together with the op-amp,

INV2

form a voltage inverter which drives the MSG reference terminal, V

the less significant bits’ reference terminal, V

values of 1.95R and 2R for the R

absolute value is about 2.5% higher than the V

RFM

, to -V

REF

, where V

is the voltage applied at

REF

INV1

and R

RFL

INV2

. The V

RFL

. Notice the

RFM

. This is

necessary so that the gain error can be corrected. This

reverses the weight of the MSG, and gives the DAC a 2’s

complement transfer function. The op-amp and reference

connection to V

RFM

and V

can be reversed, without

RFL

affecting linearity, but a small gain error will be introduced.

For unipolar operation the V

both tied to V

, and the R

REF

and V

RFM

pin is left unconnected.

INV

terminals are

RFL

Since the PROM correction codes required are different for

bipolar and unipolar operation, the ICL7134 is available in

two different versions; the ICL7134U, which is corrected for

unipolar operation, and the ICL7134B, which is programmed

for bipolar application. The feedback resistance is also different in the two versions, and is switched under PROM control

from ‘R’ in the unipolar device to ‘2R’ in the bipolar part.

These feedback resistors have a dummy (always ON) switch

in series to compensate for the effect of the ladder switches.

This greatly improves the gain temperature coefficient and

the power supply rejection of the device.

FIGURE 6. BIPOLAR OPERATION WITH INVERTED V

9

REF

TO MSB

ICL7134

Digital Section

Two levels of input buffer registers allow loading of data from

an 8-bit or 16-bit data bus. The A

and A1, pins select one of

0

four operations: 1) load the LS-buffer register with the data

at inputs D

data at inputs D

to D7; 2) load the MS-buffer register with the

0

to D13; 3) load the DAC register with the

8

contents of the MS and LS-buffer registers and 4) load the

DAC register directly from the data input pins (See Table 1).

The CS

occur. When direct loading is selected (CS

and WR pins must be low to allow data transfers to

, WR, A0 and A

low) the registers are transparent, and the data input pins

control the DAC output directly. The other modes of operation allow double buffered loading of the DAC from an 8-bit

bus.

These input data pins are also used to program the PROM

under control of the PROG pin. This is done in manufacturing, and for normal operation the PROG pin should be tied to

V+ (+5V).

TABLE 1. DATA LOADING CONTROLS

CONTROL I/P

0A1

X X X 1 No Operation, Device Not Selected.

XX1X

0 0 0 0 Load All Registers from Data Bus.

0 1 0 0 Load LS Register from Data Bus.

1 0 0 0 Load MS Register from Data Bus.

1 1 0 0 Load DAC Register from MS and LS

NOTE: Data is latched on LO-HI transition of either WR

CS WR

ICL7134 OPERATIONA

Register.

or CS.

Applications

GENERAL RECOMMENDATIONS

Grounding

Careful consideration must be given to grounding in any

14-bit accuracy system. The current into the analog ground

point inside the chip varies significantly with the input code

value, and the inevitable resistances between this point and

any external connection pint can lead to significant voltage

drop errors. For this reason, two separate leads are brought

out from this point on the IC, the AGND

The varying current should be absorbed through the AGND

pin, and the AGNDS pin will then accurately reflect the

voltage on the internal current summing point, as shown in

Figure 7. Thus output signals should be referenced to the

sense pin AGND

, as shown in the various application

S

circuits.

Operational Amplifier Selection

To maintain static accuracy, the I

exactly equal to the AGND

potential. Thus output amplifier

S

selection is critical, in particular low input bias current (less

than 2nA), low offset voltage (less than 25µV) are advisable

if the highest accuracy is needed. Maintaining a low input

offset over a 0V to 10V range also requires that the output

amplifier has a high open loop gain (A

and AGNDS pins.

F

potential must be

OUT

> 400k for

VOL

effective input offset less than 25µV).

1

FIGURE 7. GROUND CONNECTIONS

The reference inverting amplifier used in the bipolar mode

circuit must also be selected carefully. If 14-bit accuracy is

desired without adjustment, low input bias current (less than

1nA), low offset voltage (less than 50µV), and high gain

(greater than 400k) are recommended. If a fixed reference

voltage is used, the gain requirement can be relaxed. For

highest accuracy (better than 13-bits), and additional

op-amp may be needed to correct for IR drop on the Analog

GROUND line (op-amp A

in Figure 9). This op-amp should

2

be selected for low bias current (less than 2nA) and low

offset voltage (less than 50µV).

The op-amp requirements can be readily met by use of an

ICL7650 chopper stabilized device. For faster setting time,

an HA26XX can be used with an ICL7650 providing

automatic offset null (see A053 applications note for details)

The output amplifier’s non-inverting input should be tied

directly to AGND

. A bias current compensation resistor is of

S

limited use since the output impedance at the summing node

depends on the code being converted in an unpredictable

way. If gain adjustment is required, low tempco (approximately 50ppm/

o

C) resistors or trim-pots should be selected.

Power Supplies

F

The V+ (pin 25) power supply should have a low noise level,

and no transients exceeding 7 volts. Note that the absolute

maximum for digital input voltage is V+ +0.3V, therefore V+

must be applied before digital inputs are allowed to go high.

Unused digital inputs must be connected to GND or V+ for

proper operation.

Unipolar Binary Operation (ICL7134U)

The circuit configuration for unipolar mode operation

(ICL7134U) is shown in Figure 8. With positive and negative

V

values the circuit is capable of two-quadrant

REF

multiplication. The “digital input code/analog output value”

table for unipolar mode is given in Table 2. The Schottky

diode (HP5082-2811 or equivalent) protects I

OUT

from

10

ICL7134

negative excursions which could damage the device, and is

only necessary with certain high spped amplifiers. For

applications where the output reference ground point is

established somewhere other than at the DAC, the circuit of

Figure 9 can be used. Here, op-amp A

removes the slight

2

error due to IR voltage drop between the internal Analog

GrouND node and the external ground connection. For

13-bit or lower accuracy, omit A

AGND

directly to ground through as low a resistance as

S

and connect AGNDF and

2

possible.

FIGURE 8. UNIPOLAR BINARY, TWO-QUADRANT

MULTIPLYING CIRCUIT

TABLE 2. CODE TABLE - UNIPOLAR BINARY OPERATION

DIGITAL INPUT ANALOG OUTPUT

1 1 1 1 1 1 1 1 1 1 1 1 1 1 -V

1 0 0 0 0 0 0 0 0 0 0 0 0 1 -V

1 0 0 0 0 0 0 0 0 0 0 0 0 0 -V

0 1 1 1 1 1 1 1 1 1 1 1 1 1 -V

0 0 0 0 0 0 0 0 0 0 0 0 0 1 -V

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(1 - 1/214)

REF

(1/2 + 1/214)

REF

/2

REF

(1/2 - 1/214)

REF

(1/214)

REF

Zero Offset Adjustment

1. Connect all data inputs and WR

, CS, A0 and A1 to

DGND.

2. Adjust offset zero-adjust trim-pot of the operational amplifier A

, if used, for a maximum of 0V ±50µV at AGNDS.

2

3. Adjust the offset zero-adjust trim-pot of the output

op-amp, A

, for a maximum of 0V ±50µV at V

1

OUT

.

Gain Adjustment (Optional)

1. Connect all data inputs to V+, connect WR

, CS, A0 and A

to DGND.

2. Monitor V

3. To decrease V

between the reference voltage and the V

OUT

for a -V

OUT

(1 - 1/214) reading.

REF

, connect a series resistor of 5Ω or less

RFM

and V

RFL

terminals (pins 20 and 18).

4. To increase V

between A

, connect a series resistor of 5Ω or less

OUT

output and the RFB terminal (pin 21).

1

1

FIGURE 9. UNIPOLAR BINARY OPERATION WITH FORCED

GROUND

Bipolar (2’s Complement) Operation (ICL7134B)

The circuit configuration for bipolar mode operation

(ICL7134B) is shown in Figure 10. Using 2’s complement

digital input codes and positive and negative reference

voltage values, four-quadrant multiplication is obtained. The

“digital input code/analog output value” table for bipolar

mode is given in Table 3. Amplifier A

resistors R

INV1

and R

, forms a simple voltage inverter

INV2

, together with internal

3

circuit. The MSB ladder leg sees a reference input of

approximately -V

, so the MSB’s weight is reversed from

REF

the polarity of the other bits. In addition, the ICL7134B’s

feedback resistance is switched to 2R under PROM control,

so that the bipolar output range is +V

13

1/2

). Again, the grounding arrangement of Figure 9 can be

REF

to -V

REF

(1 -

used if necessary.

TABLE 3. CODE TABLE - BIPOLAR (2’S COMPLEMENT)

0 1 1 1 1 1 1 1 1 1 1 1 1 1 -V

0 0 0 0 0 0 0 0 0 0 0 0 0 1 -V

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 V

1 0 0 0 0 0 0 0 0 0 0 0 0 1 V

1 0 0 0 0 0 0 0 0 0 0 0 0 0 V

OPERATION

DIGITIAL INPUT ANALOG OUTPUT

(1 - 1/213)

REF

(1/213)

REF

(1/213)

REF

(1 - 1/213)

REF

REF

11

ICL7134

FIGURE 10. BIPOLAR (2’S COMPLEMENT), FOUR-QUADRANT MULTIPLYING CIRCUIT

Offset Adjustment

1. Connect all data inputs and WR

, CS, A0 and A1 to

DGND.

2. Adjust the offset zero-adjust trim-pot of the operational

amplifier A

AGND

, if used, for a maximum of 0V ±50µV at

2

.

S

3. Set data to 000000....00. Adjust the offset zero-adjust

trim-pot of any output op-amp A

±50µV at V

4. Connect D

.

OUT

(MSB) data input to V+.

13

5. Adjust the offset zero-adjust trim-pot of op-amp A

maximum of 0V ±50µV at the R

, for a maximum of 0V

1

terminal (pin 19).

INV

for a

3

Gain Adjustment (Optional)

1. Connect WR

2. Connect D

3. Monitor V

4. To increase V

less between the A

5 To decrease V

less between the reference voltage and the V

, CS, A0 and A1 to DGND.

, D1 ... D12 to V+, D13 (MSB) to DGND.

0

OUT

for a -V

OUT

OUT

(1 - 1/213) reading.

REF

, connect a series resistor of 10Ω or

output and the RFB terminal (pin 21).

1

, connect a series resistor of 5Ω or

RFL

termi-

nal (pin 18).

Processor Interfacing

The ease of interfacing to a processor can be seen from

Figure 11, which shows the ICL7134 connected to an 8035

or any other processor such as an 8049. The data bus feeds

into both register inputs; three port lines, in combination with

the WR

line, control the byte-wide loading into these

registers and then the DAC register. A complete DAC set-up

requies 4 write instructions to the port, to set up the address

and CS

lines, and 3 external data transfers, one a dummy

for the final transfer to the DAC register.

A similar arrangement can be used with an 8080A, 8228,

and 8224 chip set. Figure 12 shows the circuit, which can be

arranged as a memory-mapped interface (using MEMW

as an I/O-mapped interface (using I/O WRITE

). See A020

) or

and R005 for discussions of the relative merits of memorymapped versus I/O-mapped interfacing, as well as some

other ideas on interfacing with 8080 processors. The 8085

processor has a very similar interface, except that the control lines available are slightly different, as shown in Figure

13. The decoding of the IO/M line, which controls memorymapped or I/O-mapped operation, is arbitrary, and can be

omitted if not necessary. Neither the MC680X nor R650X

processor families offer specific I/O operations. Figure 14

shows a suitable interface to either of these systems, using a

direct connection. Several other decoding options can be

used, depending on the other control signals generated in

the system. Note that the R650X family does not require

VMA to be decoded with the address lines.

12

ICL7134

FIGURE 11. ICL7134 INTERFACE TO 8048 SYSTEM FIGURE 12. INTERFACE TO 8080 SYSTEM

FIGURE 13. 8085 SYSTEM INTERFACE

13

ICL7134

FIGURE 14. R650X AND MC680X FAMILIES’ INTERFACE TO

ICL7134

FIGURE 16. ICL7134 TO 8048/80/85 INTERFACE WITH LOW FEEDTHROUGH

Digital Feedthrough

All of the direct interfaces shown above can suffer from a

capacitive coupling problem. The 14 data pins, and 4 control

pins, all tied to active lines on a microprocessor bus, and in

close proximity to the sensitive DAC circuitry, can couple

pseudo-random spikes into the analog output. Careful board

layout and shielding can minimize the problems (see PC

layout), and clearly wire-wrap type sockets should never be

used. Nevertheless, the inherent capacitance of the package

alone can lead to unacceptable digital feedthrough in many

cases. The only solution is to keep the digital input lines as

inactive as possible. One easy way to do this is to use the

peripheral interface circuitry available with all the systems

previously discussed. These generally allow only 8 bits to be

updated at any one time, but a little ingenuity will avoid difficulties with DAC steps that would result from partial updates.

The problem can be solved for the 8048 family by tying the

14 port lines to the data input lines, with CS

low, and using only the WR

DAC (as shown in Figure 15). WR

line to enter the data into the

is well separated from the

, A0 and A1 held

analog lines on the ICL7134, and is usually not a very active

line in 8048 systems. Additional “protection” can be achieved

by gating the processor WR

line with another port line. The

same type of technique can be employed in the 8080/85

systems by using an 8255 PIA (peripheral Interface adaptor)

(Figure 16) and in the MC680X and R650X systems by using

FIGURE 15. AVOIDING DIGITAL FEEDTHROUGH IN AN 8048

TO ICL7134 INTERFACE

an MC6820 (R6520) PIA.

Successive Approximation A/D Converters

Figure 17 shows an ICL7134B-based circuit for a bipolar

input high speed A/D converter, using two AM25LO3s to

form a 14-bit successive approximation register. The

comparator is a two-stage circuit with and HA2605 front-end

amplifier, used to reduce setting time problems at the

summing node (see A020). Careful offset-nulling of this

amplifier is needed, and if wide temperature range operation

is desired, and auto-null circuit using an ICL7650 is probably

advisable (see A053). The clock, using two Schmitt trigger

TTL gates, runs at a slower rate for the first 8 bits, where

setting-time is most critical, than for the last 6 bits. The shortcycle line is shown tied to the 15th bit; if fewer bits are

required, it can be moved up accordingly. The circuit will

free-run if the HOLD/RUN

input is held low, but will stop after

completing a conversion if the pin is high at that time. A lowgoing pulse will restart it. The STATUS output indicates

when the device is operating, and the falling edge indicates

the availability of new data. A unipolar version may be constructed by tying the MSB (D

) on an ICL7134U to pin 14

13

on the first AM25L03, deleting the reference inversion

amplifier A

, and tying V

4

RFM

and V

RFL

.

14

ICL7134

FIGURE 17. SUCCESSIVE APPROXIMATION A/D CONVERTER

15

FIGURE 18A. PRONTED CIRCUIT SIDE OF CARD (SINGLE

SIDED BOARD)

FIGURE 18. PRINTED CIRCUIT BOARD LAYOUT (BIPOLAR CIRCUIT, SEE FIGURE 10)

FIGURE 18B. TOP SIDE WITH COMPONENT PLACEMENT

PC Board Layout

Great care should be taken in the board layout to minimize

ground loop and similar “hidden resistor” problems, as well

as to minimize digital signal feedthrough. A suitable layout

for the immediate vicinity of the ICL7134 is shown in Figure

18, and may be used as a guide.

Application Notes

Some applications bulletins that may be found useful are listed here:

A002 “Principles of Data Acquisition and Conversion”

A018 “Do’s and Don’ts of Applying A/D Converters”, by

Peter Bradshaw and Skip Osgood.

A020 “A Cookbook Approach to High Speed Data

Acquisition and Microprocessor Interfacing,”, by Ed

Sliger.

A042 “Interpretation of Data Converters Accuracy

Specifications”

R005 “Interfacing Data Converters & Microprocessor”, by

Peter Bradshaw et al., Electronics, Dec 9, 1976.

Most of these are avilable in the Intersil Data Acquisition Handbook, together with other material.

16

Loading...

Loading...