Intersil Corporation ICL7109CPL, ICL7109IDL, ICL7109IJL, ICL7109IPL, ICL7109MDL-883B Datasheet

1

®

November 2000

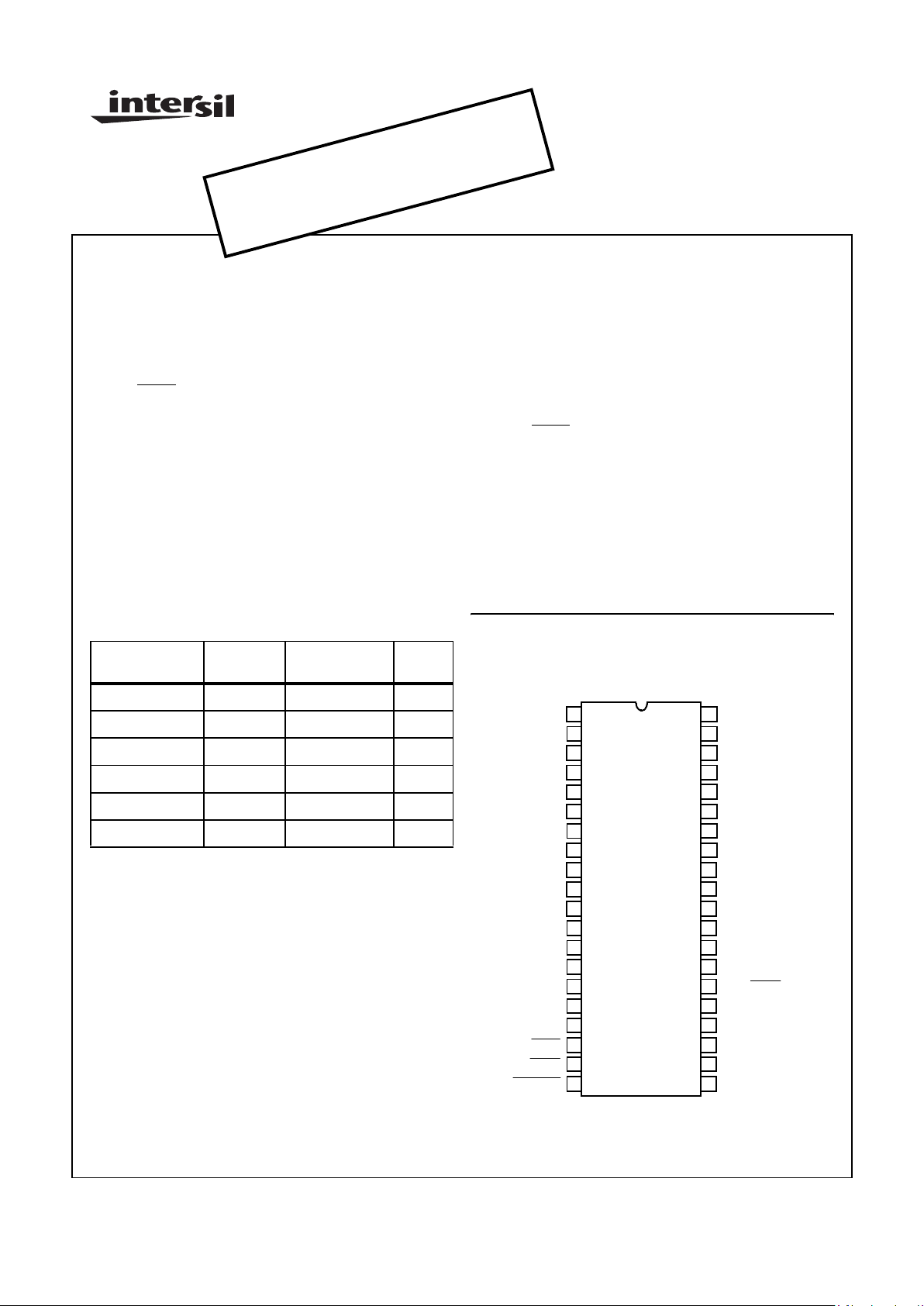

ICL7109

12-Bit, Microprocessor-

Compatible A/D Converter

Features

• 12-Bit Binary (Plus Polarity and Over-Range) Dual

Slope Integrating Analog-to-Digital Converter

• Byte-Organized, TTL Compatible Three-State Outputs

and UART Handshake Mode for Simple Parallel or

Serial Interfacing to Microprocessor Systems

• RUN/HOLD

Input and STATUS Output Can Be Used to

Monitor and Control Conversion Timing

• True Differential Input and Differential Reference

• Low Noise (Typ) . . . . . . . . . . . . . . . . . . . . . . . . 15µV

P-P

• Input Current (Typ) . . . . . . . . . . . . . . . . . . . . . . . . . .1pA

• Operates At Up to 30 Conversions/s

• On-Chip Oscillator Operates with Inexpensive 3.58MHz

TV Crystal Giving 7.5 Conversions/s for 60Hz Rejection. May Also Be Used with An RC Network Oscillator

for Other Clock Frequencies

Description

The ICL7109 is a high performance, CMOS, low power

integrating A/D converter designed to easily interface with

microprocessors.

The output data (12 bits, polarity and over-range) may be

directly accessed under control of two byte enable inputs and a

chip select input for a single parallel bus interface. A UART

handshake mode is provided to allow the ICL7109 to work with

industry-standard UARTs in providing serial data transmission.

The RUN/HOLD

input and STATUS output allow monitoring

and control of conversion timing.

The ICL7109 provides the user with the high accuracy, low

noise, low drift versatility and economy of the dual-slope

integrating A/D converter. Features like true differential input

and reference, drift of less than 1µV/

o

C, maximum input bias

current of 10pA, and typical power consumption of 20mW

make the ICL7109 an attractive per-channel alternative to

analog multiplexing for many data acquisition applications.

Pinout

ICL7109

(CERDIP, PDIP, SBDIP)

TOP VIEW

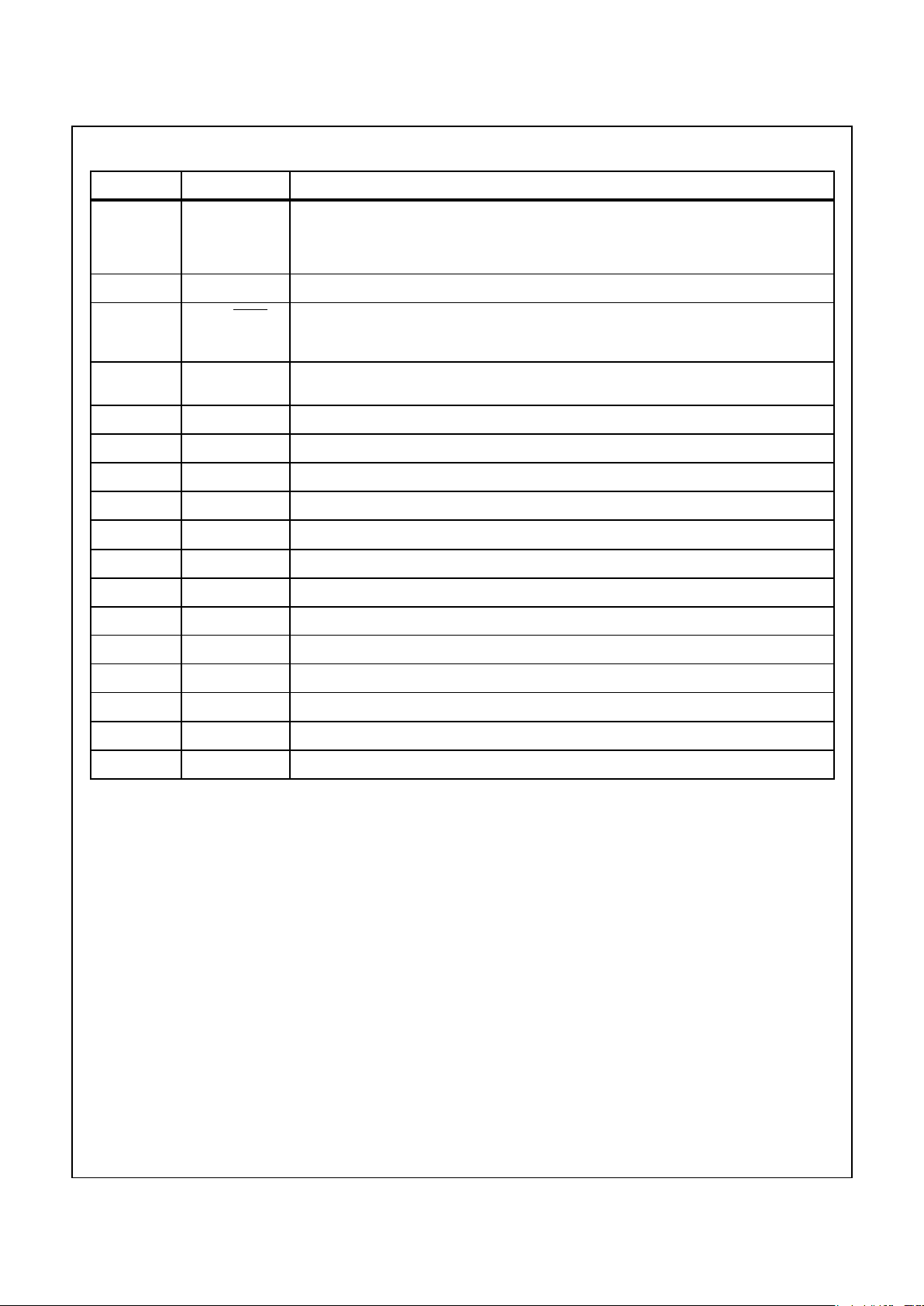

Part Number Information

PART NUMBER

TEMP.

RANGE (oC) PACKAGE

PKG.

NO.

ICL7109MDL -55 to 125 40 Ld SBDIP D40.6

ICL7109IDL -25 to 85 40 Ld SBDIP D40.6

ICL7109IJL -25 to 85 40 Ld CERDIP F40.6

ICL7109CPL 0 to 70 40 Ld PDIP E40.6

ICL7109MDL/883B -55 to 125 40 Ld SBDIP D40.6

ICL7109IPL -25 to 85 40 Ld PDIP E40.6

13

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

GND

STATUS

POL

OR

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

TEST

LBEN

HBEN

CE/LOAD

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

V+

REF IN -

REF CAP-

REF CAP+

REF IN+

IN HI

IN LO

COMMON

INT

AZ

BUF

REF OUT

V-

SEND

RUN/HOLD

BUF OSC OUT

OSC SEL

OSC OUT

OSC IN

MODE

File Number 3092.2

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright © Intersil Americas Inc. 2002. All Rights Reserved

F

O

R

A

P

O

S

S

I

B

L

E

S

U

B

S

T

I

T

U

T

E

P

R

O

D

U

C

T

c

o

n

t

a

c

t

o

u

r

T

e

c

h

n

i

c

a

l

S

u

p

p

o

r

t

C

e

n

t

e

r

a

t

1

-

8

8

8

-

I

N

T

E

R

S

I

L

o

r

w

w

w

.

i

n

t

e

r

s

i

l

.

c

o

m

/

t

s

c

O

B

S

O

L

E

T

E

P

R

O

D

U

C

T

2

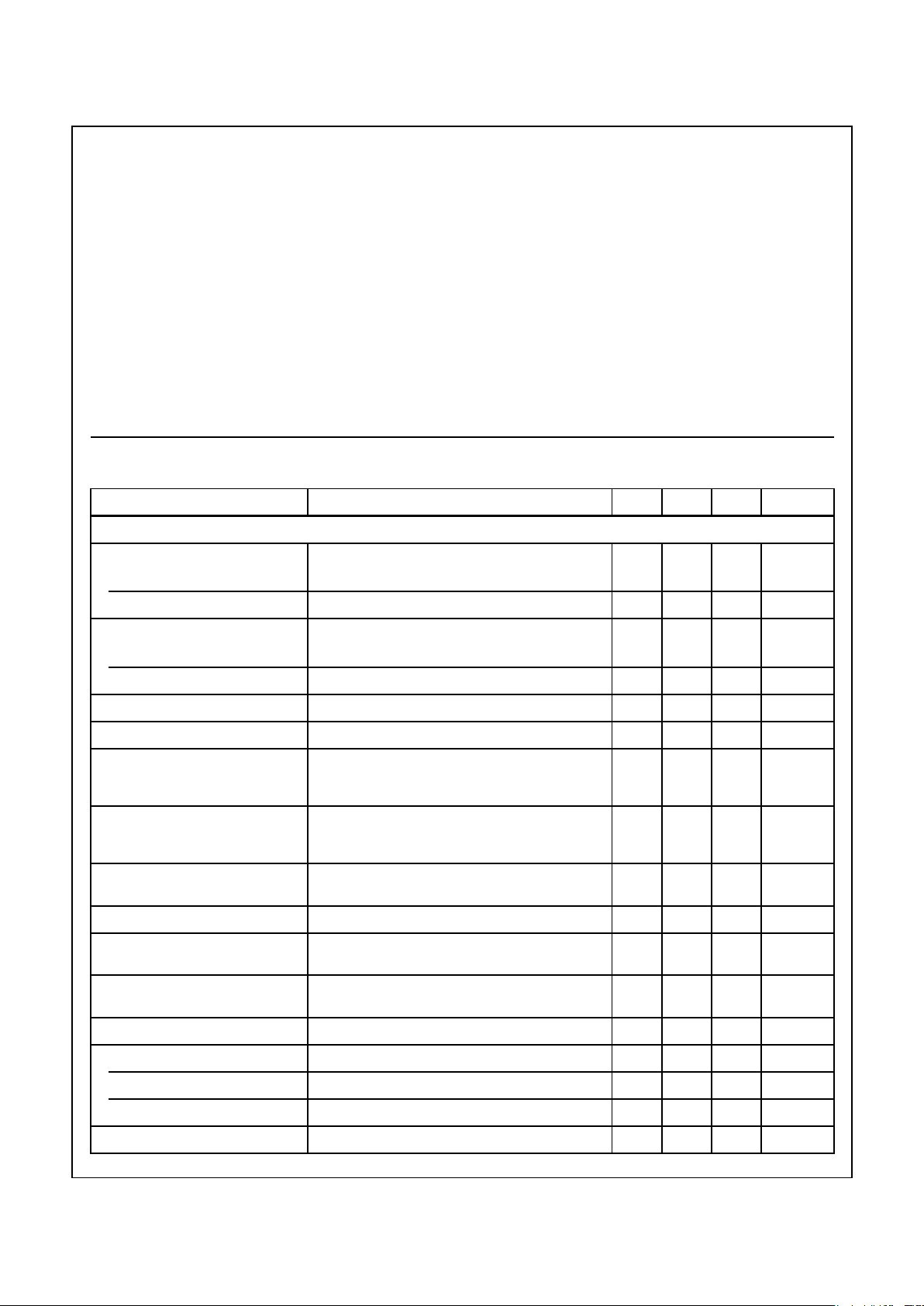

Absolute Maximum Ratings Thermal Information

Positive Supply Voltage (GND to V+). . . . . . . . . . . . . . . . . . . .+6.0V

Negative Supply Voltage (GND to V-) . . . . . . . . . . . . . . . . . . . . .-9V

Analog Input Voltage (Either Input) (Note 1) . . . . . . . . . . . . V+ to V-

Reference Input Voltage (Either Input) (Note 1) . . . . . . . . . . V+ to V-

Digital Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (V+) +0.3V

Pins 2-27 (Note 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND -0.3V

Operating Conditions

Temperature Range

M Suffix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55

o

C to 125oC

I Suffix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -25

o

C to 85oC

C Suffix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0

o

C to 75oC

Thermal Resistance (Typical, Note 1) θ

JA

(oC/W) θJC (oC/W)

SBDIP Package. . . . . . . . . . . . . . . . . . . . 60 20

CERDIP Package . . . . . . . . . . . . . . . . . . 55 18

PDIP Package . . . . . . . . . . . . . . . . . . . . . 50 N/A

Maximum Junction Temperature (PDIP Package) . . . . . . . . . 150

o

C

Maximum Junction Temperature (CERDIP Package). . . . . . . 175

o

C

Maximum Storage Temperature Range . . . . . . . . . . -65

o

C to 150oC

Maximum Lead Temperature (Soldering 10s Max). . . . . . . . . 300

o

C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other condition s above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θ

JA

is measured with the component mounted on an evaluation PC board in free air.

Analog Electrical Specifications V+ = +5V, V- = -5V, GND = 0V, T

A

= 25oC, f

CLK

= 3.58MHz,

Unless Otherwise Specified

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SYSTEM PERFORMANCE

Oscillator Output Current

High, O

OH

V

OUT

= 2.5V - 1 - mA

Low, O

OL

V

OUT

= 2.5V - 1.5 - mA

Buffered Oscillator Output Current

High, BO

OH

V

OUT

= 2.5V - 2 - mA

Low, BO

OL

V

OUT

= 2.5V - 5 - mA

Zero Input Reading V

IN

= 0.0000V, V

REF

= 204.8mV -0000 ±0000 +0000 Counts

Ratiometric Error V

lN

= V

REF

, V

REF

= 204.8mV (Note 7) -3 - 0 Counts

Non-Linearity Full Scale = 409.6mV to 2.048mV

Maximum Deviation from Best Straight Line Fit, Over

Full Operating Temperature Range (Notes 4 and 6)

-1 ±0.2 +1 Counts

Rollover Error Full Scale = 409.6mV to 2.048V

Difference in Reading for Equal Positive and Negative

Inputs Near Full Scale (Notes 5 and 6), R

1

= 0Ω

-1 ±0.2 +1 Counts

Linearity Full-Scale = 200mV or Full Scale = 2V Maximum

Deviation from Best Straight Line Fit (Note 4)

- ±0.2 ±1 Counts

Common Mode Rejection Ratio, CMRR V

CM

= ±1V, VIN = 0V, Full Scale = 409.6mV - 50 - µV/V

Input Common Mode Range, VCMR Input HI, Input LO, Common (Note 4) (V-)

+2.0

-(V+)

-2.0

V

Noise, eN V

IN

= 0V, Full-Scale = 409.6mV

(Peak-to-Peak Value Not Exceeded 95% of Time)

-15- µV

Leakage Current Input, I

ILK

VlN = 0V, All Devices at 25oC (Note 4) - 1 10 pA

ICL7109CPL 0

o

C to 70oC (Note 4) - 20 100 pA

ICL7109IDL -25

o

C to 85oC (Note 4) - 100 250 pA

ICL7109MDL -55

o

C to 125oC-2100nA

Zero Reading Drift V

lN

= 0V, R1 - 0Ω (Note 4) - 0.2 1 µV/oC

ICL7109

3

Scale Factor Temperature Coefficient VIN = 408.9mV = > 77708 Reading Ext. Ref. 0ppm/oC

(Note 4)

- 1 5 ppm/oC

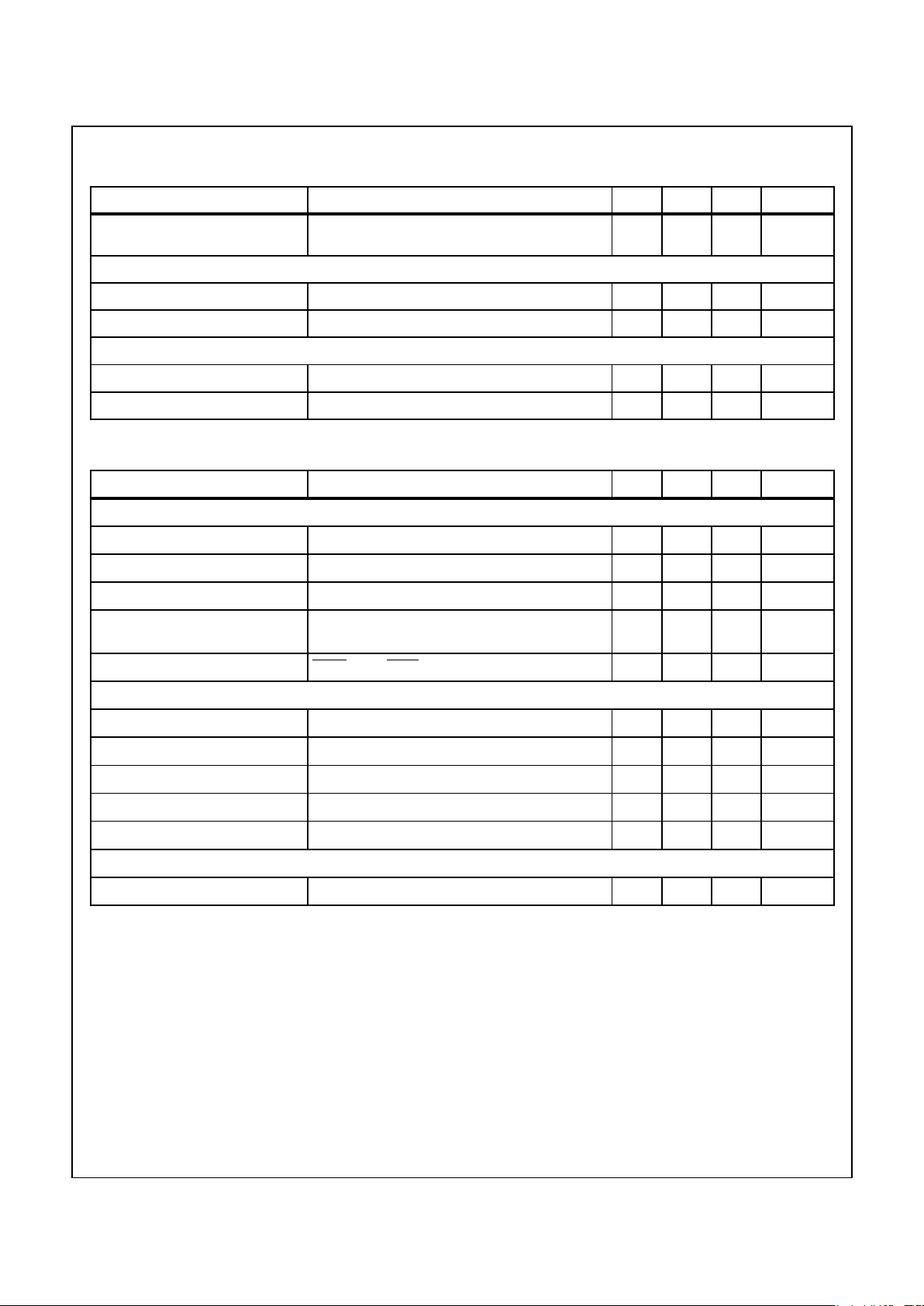

REFERENCE VOLTAGE

Ref Out Voltage, V

REF

Referred to V+, 25kΩ Between V+ and REF OUT -2.4 -2.8 -3.2 V

Ref Out Temperature Coefficient 25kΩ Between V+ and REF OUT (Note 4) - 80 - ppm/

o

C

POWER SUPPLY CHARACTERISTICS

Supply Current V+ to GND, I+ V

IN

= 0V, Crystal Osc 3.58MHz Test Circuit - 700 1500 µA

Supply Current V+ to V-, I

SUPP

Pins 2 - 21, 25, 26, 27, 29; Open - 700 1500 µA

Digital Electrical Specifications V+ = +5V, V- = -5V, GND = 0V, T

A

= 25oC, Unless Otherwise Specified

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DIGITAL OUTPUTS

Output High Voltage, V

OH

I

OUT

= 100µA Pins 2 - 16, 18, 19, 20 3.5 4.3 - V

Output Low Voltage, V

OL

I

OUT

= 1.6mA Pins 2 - 16, 18, 19, 20 - ±0.20 ±0.40 V

Output Leakage Current Pins 3 - 16 High Impedance - ±0.01 ±1 µA

Control I/O Pullup Current Pins 18, 19, 20 V

OUT

= V+ -3V MODE Input at GND

(Note 4)

-5- µA

Control I/O Loading HBEN

Pin 19 LBEN Pin 18 (Note 4) - − 50 pF

DIGITAL INPUTS

Input High Voltage, V

IH

Pins 18 - 21, 26, 27 Referred to GND 3.0 - - V

Input Low Voltage, V

IL

Pins 18 - 21, 26, 27 Referred to GND - - 1 V

Input Pull-Up Current Pins 26, 27 V

OUT

= (V+) -3V - 5 - µA

Input Pull-Up Current Pins 17, 24 V

OUT

= (V+) -3V - 25 - µA

Input Pull-Down Current Pin 21 V

OUT

= GND +3V - 5 - µA

TIMING CHARACTERISTICS

MODE Input Pulse Width, t

W

(Note 4) 50 - - ns

NOTES:

1. Input voltages may exceed the supply voltages provided the input current is limited to ±100µA.

2. Due to the SCR structure inherent in the process used to fabricate these devices, connecting any digital inputs or outputs to voltages

greater than V+ or less than GND may cause destructive device latchup. For this reason it is recommended that no inputs from sources

other than the same power supply be applied to the ICL7109 before its power supply is established, and that in multiple supply systems

the supply to the ICL7109 be activated first.

3. This limit refers to that of the package and will not be obtained during normal operation.

4. This parameter is not production tested, but is guaranteed by design.

5. Roll-over error for T

A

= -55oC to 125oC is ±10 counts (Max).

6. A full scale voltage of 2.048V is used because a full scale voltage of 4.096V exceeds the devices Common Mode Voltage Range.

7. For CERDIP package the Ratiometric error can be -4 (Min).

Analog Electrical Specifications V+ = +5V, V- = -5V, GND = 0V, T

A

= 25oC, f

CLK

= 3.58MHz,

Unless Otherwise Specified (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ICL7109

4

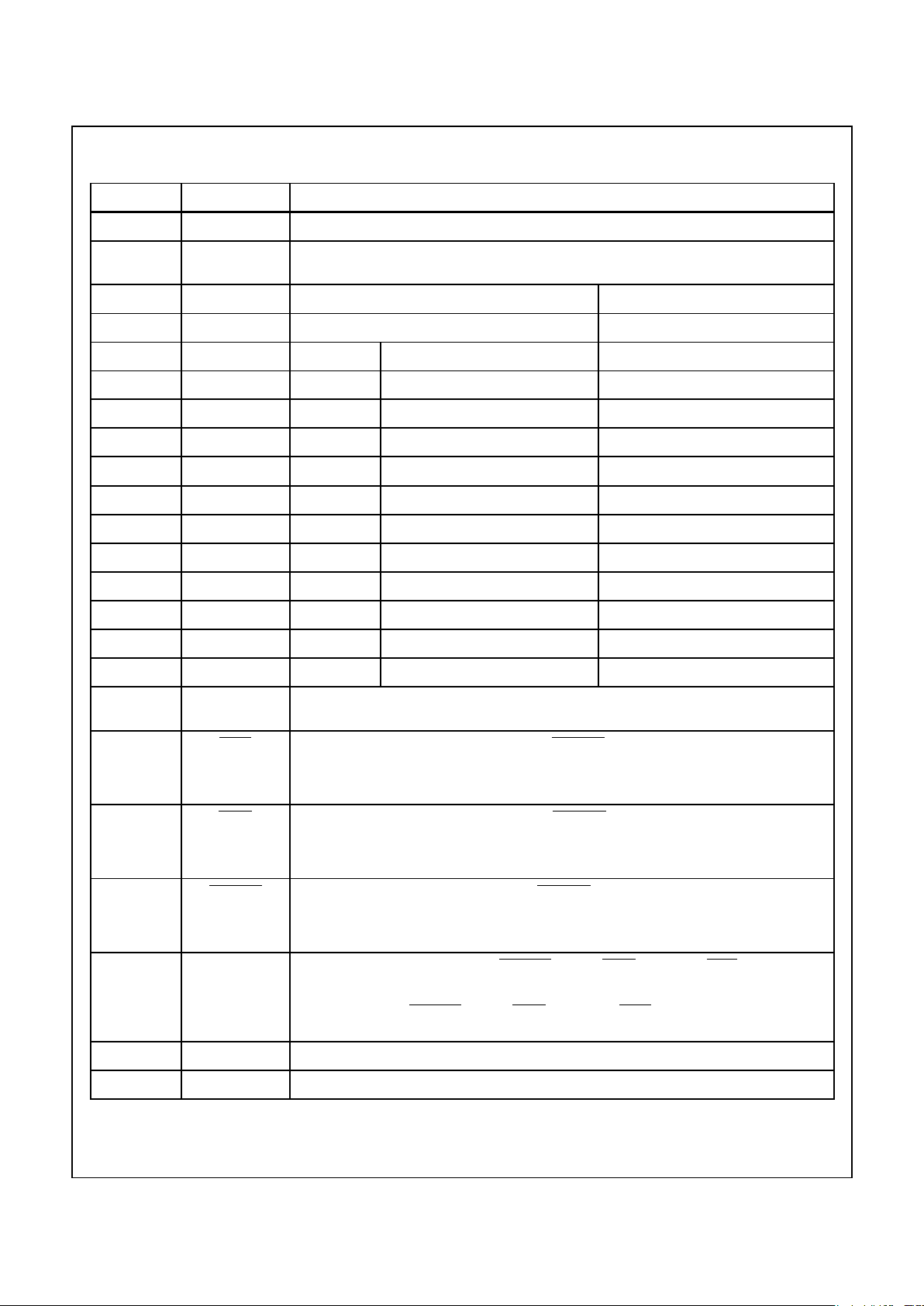

Pin Descriptions

PIN SYMBOL DESCRIPTION

1 GND Digital Ground, 0V. Ground return for all digital logic.

2 STATUS Output High during integrate and deintegrate until data is latched. Output Low when analog section

is in Auto-Zero configuration.

3 POL Polarity - HI for positive input. Three-State Output Data Bits

4 OR Overrange - HI if overranged. Three-State Output Data Bits

5 B12 Bit 12 (Most Significant Bit) Three-State Output Data Bits

6 B11 Bit 11 High = True Three-State Output Data Bits

7 B10 Bit 10 High = True Three-State Output Data Bits

8 B9 Bit 9 High = True Three-State Output Data Bits

9 B8 Bit 8 High = True Three-State Output Data Bits

10 B7 Bit 7 High = True Three-State Output Data Bits

11 B6 Bit 6 High = True Three-State Output Data Bits

12 B5 Bit 5 High = True Three-State Output Data Bits

13 B4 Bit 4 High = True Three-State Output Data Bits

14 B3 Bit 3 High = True Three-State Output Data Bits

15 B2 Bit 2 High = True Three-State Output Data Bits

16 B1 Bit 1 (Least Significant Bit) Three-State Output Data Bits

17 TEST Input High - Normal Operation. Input Low - Forces all bit outputs high. Note: This input is used for

test purposes only. Tie high if not used.

18 LBEN

Low Byte Enable - With Mode (Pin 21) low, and CE/LOAD (Pin 20) low, taking this pin low activates

low order byte outputs B1 through B8.

With Mode (Pin 21) high, this pin serves as a low byte flag output used in handshake mode.

See Figures 7, 8, 9.

19 HBEN

High Byte Enable - With Mode (Pin 21) low, and CE/LOAD (Pin 20) low, taking this pin low activates

high order byte outputs B9 through B12, POL, OR.

With Mode (Pin 21) high, this pin serves as a high byte flag output used in handshake mode.

See Figures 7, 8, 9.

20 CE/LOAD

Chip Enable Load - With Mode (Pin 21) low. CE/LOAD serves as a master output enable. When

high, B1 through B12, POL, OR outputs are disabled.

With Mode (Pin 21) high, this pin serves as a load strobe used in handshake mode.

See Figures 7, 8, 9.

21 MODE Input Low - Direct output mode where CE/LOAD

(Pin 20), HBEN (Pin 19) and LBEN (Pin 18) act as

inputs directly controlling byte outputs.

Input Pulsed High - Causes immediate entry into handshake mode and output of data as in Figure 9.

Input High - Enables CE/LOAD

(Pin 20), HBEN (Pin 19), and LBEN (Pin 18) as outputs, handshake

mode will be entered and data output as in Figures 7 and 8 at conversion completion.

22 OSC IN Oscillator Input

23 OSC OUT Oscillator Output

ICL7109

5

24 OSC SEL Oscillator Select - Input high configures OSC IN, OSC OUT, BUF OSC OUT as RC oscillator - clock

will be same phase and duty cycle as BUF OSC OUT.

Input low configures OSC IN, OSC OUT for crystal oscillator - clock frequency will be 1/58 of

frequency at BUF OSC OUT.

25 BUF OSC OUT Buffered Oscillator Output

26 RUN/HOLD

Input High - Conversions continuously performed every 8192 clock pulses.

Input Low - Conversion in progress completed, converter will stop in Auto-Zero 7 counts before

integrate.

27 SEND Input - Used in handshake mode to indicate ability of an external device to accept data. Connect to

+5V if not used.

28 V- Analog Negative Supply - Nominally -5V with respect to GND (Pin 1).

29 REF OUT Reference Voltage Output - Nominally 2.8V down from V+ (Pin 40).

30 BUFFER Buffer Amplifier Output.

31 AUTO-ZERO Auto-Zero Node - Inside foil of C

AZ

.

32 INTEGRATOR Integrator Output - Outside foil of C

INT

.

33 COMMON Analog Common - System is Auto-Zeroed to COMMON.

34 INPUT LO Differential Input Low Side.

35 INPUT HI Differential Input High Side.

36 REF IN + Differential Reference Input Positive.

37 REF CAP + Reference Capacitor Positive.

38 REF CAP- Reference Capacitor Negative.

39 REF IN- Differential Reference Input Negative.

40 V+ Positive Supply Voltage - Nominally +5V with respect to GND (Pin 1).

NOTE: All digital levels are positive true.

Pin Descriptions (Continued)

PIN SYMBOL DESCRIPTION

ICL7109

6

Design Information Summary Sheet

• OSCILLATOR FREQUENCY

f

OSC

= 0.45/RC

C

OSC

> 50pF; R

OSC

> 50kΩ

f

OSC

(Typ) = 60kHz

or

f

OSC

(Typ) = 3.58MHz Crystal

• OSCILLATOR PERIOD

t

OSC

= RC/0.45

t

OSC

= 1/3.58MHz (Crystal)

• INTEGRATION CLOCK FREQUENCY

f

CLOCK

= f

OSC

(RC Mode)

f

CLOCK

= f

OSC

/58 (Crystal)

t

CLOCK

= 1/f

CLOCK

• INTEGRATION PERIOD

t

INT

= 2048 x t

CLOCK

• 60/50Hz REJECTION CRITERION

t

INT/t60Hz

or t

lNT/t50Hz

= Integer

• OPTIMUM INTEGRATION CURRENT

I

INT

= 20µA

• FULL-SCALE ANALOG INPUT VOLTAGE

V

lNFS

Typically = 200mV or 2V

• INTEGRATE RESISTOR

• INTEGRATE CAPACITOR

• INTEGRATOR OUTPUT VOLTAGE SWING

•V

INT

MAXIMUM SWING

(V- + 0.5V) < V

INT

< (V+ - 0.5V)

V

INT

(Typ) = 2V

• DISPLAY COUNT

• CONVERSION CYCLE

t

CYC

= t

CL0CK

x 8192

(In Free Run Mode, Run/HOLD

= 1)

when f

CLOCK

= 60kHz, t

CYC

= 133ms

• COMMON MODE INPUT VOLTAGE

(V- + 2.0V) < V

lN

< (V+ - 2V)

• AUTO-ZERO CAPACITOR

0.01µF < C

AZ

< 1µF

• REFERENCE CAPACITOR

0.1µF < C

REF

< 1µF

•V

REF

Biased between V+ and VV

REF

≅ V+ - 2.8V

Regulation lost when V+ to V- ≤ 6.4V.

If V

REF

is not used, float output pin.

• POWER SUPPLY: DUAL ±5.0V

V+ = +5V to GND

V- = -5V to GND

• OUTPUT TYPE

Binary Amplitude with Polarity and Overrange Bits

Tips: Always tie TEST pin HIGH.

Don’t leave any inputs floating.

R

INT

V

INFS

I

INT

------ ----- ---- --=

C

INT

t

INT

()I

INT

()

V

INT

--------------------------------=

V

INT

t

INT

()I

INT

()

C

INT

--------------------------------=

COUNT 2048

V

IN

V

REF

-----------------×=

ICL7109

7

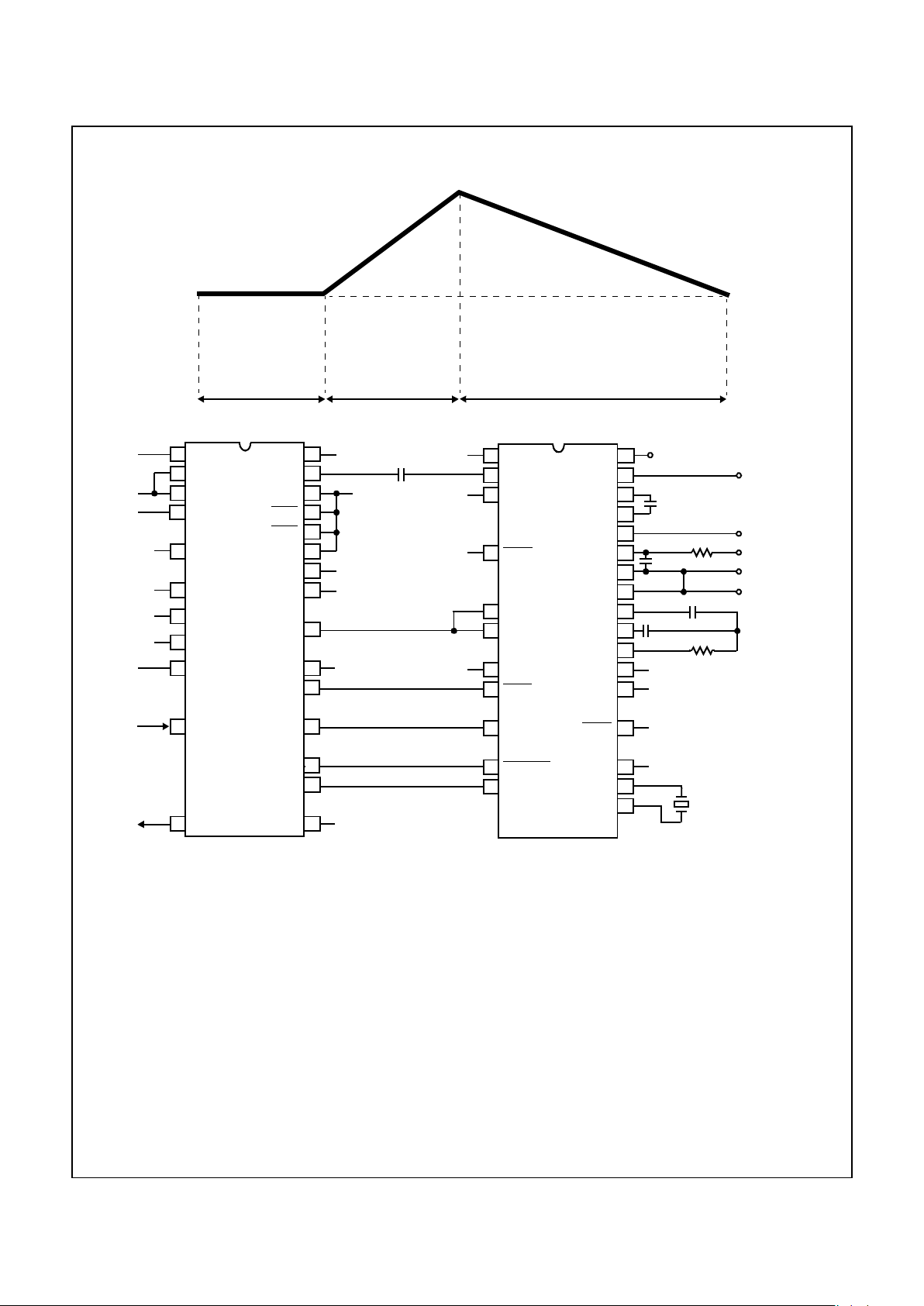

Typical Integrator Amplifier Output Waveform (INT Pin)

AUTO ZERO PHASE

(COUNTS)

6143 - 2048

INTEGRATE

PHASE FIXED

2048 COUNTS

DE-INTEGRATE PHASE

0 - 4095 COUNTS

TOTAL CONVERSION TIME = 8192 x t

CLOCK

(IN FREE-RUN MODE)

FIGURE 1A. TYPICAL CONNECTION DIAGRAM UART INTERFACE-TO TRANSMIT LATEST RESULT, SEND ANY WORD TO UART

18

1

25

2

19

17

21

20

27

GND

BUF OSC

STATUS

HBEN

3 - 8

B9 - B12, POL,OR

9 - 16

TEST

LBEN

MODE

CE/LOAD

SEND

28

40

39

38

37

36

35

34

33

32

31

30

29

26

24

23

22

V+

REF IN -

REF CAP-

REF CAP+

REF IN+

IN HI

IN LO

COMMON

INT

AZ

BUF

REF OUT

V-

RUN/HOLD

OSC SEL

OSC OUT

OSC IN

GND

GND

+5V

1µF

0.01µF

0.33µF

0.15µF

C

AZ

C

INT

R

INT

1MΩ

3.58MHz

CRYSTAL

-

+

+

INPUT

GND

EXTERNAL

REFERENCE

-5V

GND

-

20kΩ 0.2V REF

200kΩ 2V REF

+5V OR OPEN

OUT

/

/

6

8

B1 - B8

1

2

3

4

13

14

15

16

20

25

V+

OSC CONTROL

GND

RRD

5 - 12

PE

FE

OE

SFD

RRI

TRO

18

40

17

39

38

37

36

35

34

31

24

19

23

22

21

XTAL

XTAL

EPE

CLS1

CLS2

SBS

PI

CLR

26 - 33

TRE

DRR

DR

TBRL

TBRE

MR

GND

GND

TBR 1 - 8

+5V

+5V

8

/

GND

1000pF

RBR 1 - 8

SERIAL

OUTPUT

SERIAL

INPUT

+5V

+5V

+5V

IM6403

CMOS UART

ICL7109

CMOS A/D CONVERTER

FOR LOWEST POWER CONSUMPTION

TBR1 - TBR8 INPUTS SHOULD HAVE 100kΩ

PULLUP RESISTORS TO +5V

+5V

ICL7109

8

Detailed Description

Analog Section

Figure 2 shows the equivalent circuit of the Analog Section

for the ICL7109. When the RUN/HOLD

input is left open or

connected to V+, the circuit will perform conversions at a

rate determined by the clock frequency (8192 clock periods

per cycle). Each measurement cycle is divided into three

phases as shown in Figure 3. They are (1) auto-zero (A-Z),

(2) signal integrate (INT) and (3) de-integrate (DE).

Auto-Zero Phase

During auto-zero three things happen. First, input high and

low are disconnected from the pins and internally shorted to

analog COMMON. Second, the reference capacitor is

charged to the reference voltage. Third, a feedback loop is

closed around the system to charge the auto-zero capacitor

C

AZ

to compensate for offset voltages in the buffer amplifier,

integrator, and comparator. Since the comparator is included

in the loop, the A-Z accuracy is limited only by the noise of

the system. In any case, the offset referred to the input is

less than 10µV.

Signal Integrate Phase

During signal integrate, the auto-zero loop is opened, the

internal short is removed, and the internal input high and low

are connected to the external pins. The converter then

integrates the differential voltage between IN HI and IN LO

for a fixed time. This differential voltage can be within a wide

common mode range of the inputs. At the end of this phase,

the polarity of the integrated signal is determined.

FIGURE 1B. TYPICAL CONNECTION DIAGRAM PARALLEL INTERFACE WITH 8048 MICROCOMPUTER

FIGURE 1.

9

25

26

40

39

/

5

20

5

6

17

26

19

18

40

1

2

V+

TEST

3 - 8

B9 - B12,

9 - 16

STATUS

HBEN

CE/LOAD

28

39

38

37

36

35

34

33

32

31

30

29

26

24

23

21

REF IN -

REF CAP-

REF CAP+

REF IN+

IN HI

IN LO

COMMON

INT

AZ

BUF

REF OUT

V-

RUN/HOLD

OSC SEL

OSC OUT

OSC IN

GND

GND

1µF

0.01µF

0.33µF

0.15µF

C

AZ

C

INT

R

INT

1MΩ

3.58MHz

CRYSTAL

-

+

+

INPUT

GND

EXTERNAL

REFERENCE

-5V

GND

-

20kΩ 0.2V REF

200kΩ 2V REF

+5V OR OPEN

GND

/

/

6

8

B1 - B8

1

4

7

8

11

20

XTAL1

TO

RESET

EA

WR

ALE

GND

28

30

29

27

10

XTAL2

P12

P11

P10

RD

P13

+5V

8

/

27

25

22

MODE

SEND

BUFF OSC OUT

+5V

+5V

SS

INT

2

RUN/HOLD

LBEN

POL,OR

12 - 19

DB0 - DB7

31 - 34

P14 - P17

35 - 38

P20 - P27

/

8

21 - 24

OTHER

I/O

GND

PSEN

GND

PROG

V

DD

V

CC

+5V

TL

+5V

+5V

+5V

ICL7109

8748/9048

3

+5V

ICL7109

9

De-Integrate Phase

The final phase is de-integrate, or reference integrate. Input

low is internally connected to analog COMMON and input

high is connected across the previously charged (during

auto-zero) reference capacitor. Circuitry within the chip

ensures that the capacitor will be connected with the correct

polarity to cause the integrator output to return to zero crossing (established in Auto-Zero) with a fixed slope. The time

required for the output to return to zero is proportional to the

input signal.

Differential Input

The input can accept differential voltages anywhere within the

common mode range of the input amplifier, or specifically from

1V below the positive supply to 1.5V above the negative supply. In this range, the system has a CMRR of 86dB typical.

However, care must be exercised to assure the integrator output does not saturate. A worst case condition would be a large

positive common mode voltage with a near full-scale negative

differential input voltage. The negative input signal drives the

integrator positive when most of its swing has been used up

by the positive common mode voltage. For these critical applications the integrator output swing can be reduced to less

than the recommended 4V full scale swing with little loss of

accuracy. The integrator output can swing to within 0.3V of

either supply without loss of linearity.

The ICL7109 has, however, been optimized for operation

with analog common near digital ground. With power supplies of +5V and -5V, this allows a 4V full scale integrator

swing positive or negative thus maximizing the performance

of the analog section.

Differential Reference

The reference voltage can be generated anywhere within the

power supply voltage of the converter. The main source of

common mode error is a roll-over voltage caused by the

reference capacitor losing or gaining charge to stray capacity

on its nodes. If there is a large common mode voltage, the reference capacitor can gain charge (increase voltage) when

called up to deintegrate a positive signal but lose charge

(decrease voltage) when called up to deintegrate a negative

input signal. This difference in reference for positive or

negative input voltage will give a roll-over error. However, by

selecting the reference capacitor large enough in comparison

to the stray capacitance, this error can be held to less than 0.5

count worst case. (See Component Value Selection.)

The roll-over error from these sources is minimized by having

the reference common mode voltage near or at analog

COMMON.

Component Value Selection

For optimum performance of the analog section, care must

be taken in the selection of values for the integrator capacitor and resistor, auto-zero capacitor, reference voltage, and

conversion rate. These values must be chosen to suit the

particular application.

The most important consideration is that the integrator output swing (for full-scale input) be as large as possible. For

example, with ±5V supplies and COMMON connected to

+

-

+

DE-DE+

C

INT

C

AZ

R

INT

BUFFER

A-Z INT

-

+

A-Z

IN HI

COMMON

IN LO

35

33

34

DE- DE+

INT

A-Z

37

C

REF

+

36

REF IN+

C

REF

REF IN-

39

A-Z A-Z

38

C

REF

-

30 31 32

TO ZERO CROSS

DETECTOR

DIGITAL SECTION

A-Z

INTEGRATOR

INT

DE(±)

BUFFER

COMPARATOR

REF OUT

6.2V

29 28 40

10µA

V- V+

AZ

INT

DE+

DE-

FROM CONTROL

LOGIC

DIGITAL SECTION

-

+

FIGURE 2. ANALOG SECTION OF ICL7109

ICL7109

Teflon™ is a trademark of DuPont Corporation

10

GND, the normal integrator output swing at full scale is ±4V.

Since the integrator output can go to 0.3V from either supply

without significantly affecting linearity, a 4V integrator output

swing allows 0.7V for variations in output swing due to component value and oscillator tolerances. With ±5V supplies

and a common mode range of ±1V required, the component

values should be selected to provide ±3V integrator output

swing. Noise and roll-over will be slightly worse than in the

±4V case. For larger common mode voltage ranges, the integrator output swing must be reduced further. This will

increase both noise and roll-over errors. To improve the performance, supplies of ±6V may be used.

Integrating Resistor

Both the buffer amplifier and the integrator have a class A output

stage with 100µA of quiescent current. They supply 20µA of drive

current with negligible nonlinearity. The integrating resistor

should be large enough to remain in this very linear region over

the input voltage range, but small enough that undue leakage

requirements are not placed on the PC board. For 409.6mV fullscale, 200kΩ is near optimum and similarly a 20kΩ for a

409.6mV scale. For other values of full scale voltage, R

INT

should be chosen by the relation :

Integrating Capacitor

The integrating capacitor C

INT

should be selected to give the

maximum voltage swing that ensures tolerance build-up will

not saturate the integrator swing (approximately. 0.3V from

either supply). For the ICL7109 with ±5V supplies and analog

common connected to GND, a ±3.5V to ±4V integrator output

swing is nominal. For 7

1

/2 conversions per second (61.72kHz

clock frequency) as provided by the crystal oscillator, nominal

values for C

INT

and CAZ are 0.15µF and 0.33µF, respectively. If different clock frequencies are used, these values

should be changed to maintain the integrator output swing. In

general, the value C

INT

is given by:

.

An additional requirement of the integrating capacitor is that

it have low dielectric absorption to prevent roll-over errors.

While other types of capacitors are adequate for this application, polypropylene capacitors give undetectable errors at

The integrating capacitor should have a low dielectric

absorption to prevent roll-over errors. While other types may

be adequate for this application, polypropylene capacitors

give undetectable errors at reasonable cost up to 85

o

C.

Teflon™ capacitors are recommended for the military temperature range. While their dielectric absorption characteristics vary somewhat from unit to unit, selected devices should

give less than 0.5 count of error due to dielectric absorption.

Auto-Zero Capacitor

The size of the auto-zero capacitor has some influence on

the noise of the system: a smaller physical size and a larger

capacitance value lower the overall system noise. However,

C

AZ

cannot be increased without limits since it, in parallel

with the integrating capacitor forms an R-C time constant

that determines the speed of recovery from overloads and

the error that exists at the end of an auto-zero cycle. For

409.6mV full scale where noise is very important and the

integrating resistor small, a value of C

AZ

twice C

INT

is optimum. Similarly for 4.096V full scale where recovery is more

important than noise, a value of C

AZ

equal to half of C

INT

is

recommended.

For optimal rejection of stray pickup, the outer foil of C

AZ

should be connected to the R-C summing junction and the

inner foil to pin 31. Similarly the outer foil of C

INT

should be

connected to pin 32 and the inner foil to the R-C summing

junction. Teflon, or equivalent, capacitors are recommended

above 85

o

C for their low leakage characteristics.

Reference Capacitor

A 1µF capacitor gives good results in most applications.

However, where a large reference common mode voltage

exists (i.e., the reference low is not at analog common) and

a 409.6mV scale is used, a large value is required to prevent

roll-over error. Generally 10µF will hold the roll-over error to

0.5 count in this instance. Again, Teflon, or equivalent

capacitors should be used for temperatures above 85

o

C for

their low leakage characteristics.

R

INT

full scale voltage

20µA

--------------------------------------------·.=

C

INT

2048 clock period×()20µA()

integrator output voltage swing

---------------------------------------------------------------------------------=

ICL7109

11

Reference Voltage

The analog input required to generate a full scale output of

4096 counts is V

IN

= 2V

REF

. For normalized scale, a refer-

ence of 2.048V should be used for a 4.096V full scale, and

204.8mV should be used for a 0.4096V full scale. However,

in many applications where the A/D is sensing the output of

a transducer, there will exist a scale factor other than unity

between the absolute output voltage to be measured and a

desired digital output. For instance, in a weighing system,

the designer might like to have a full scale reading when the

voltage from the transducer is 0.682V. Instead of driving the

input down to 409.6mV, the input voltage should be measured directly and a reference voltage of 0.341V should be

used. Suitable values for integrating resistor and capacitor

are 33kΩ and 0.15µF. This avoids a divider on the input.

Another advantage of this system occurs when a zero reading is desired for non-zero input. Temperature and weight

measurements with an offset or tare are examples. The offset may be introduced by connecting the voltage output of

the transducer between common and analog high, and the

offset voltage between common and analog low, observing

polarities carefully. However, in processor-based systems

using the ICL7109, it may be more efficient to perform this

type of scaling or tare subtraction digitally using software.

Reference Sources

The stability of the reference voltage is a major factor in the

overall absolute accuracy of the converter. The resolution of

the ICL7109 at 12 bits is one part in 4096, or 244ppm. Thus

if the reference has a temperature coefficient of 80ppm/

o

C

(onboard reference) a temperature difference of 3

o

C will

introduce a one-bit absolute error.

For this reason, it is recommended that an external highquality reference be used where the ambient temperature is

not controlled or where high-accuracy absolute measure-

ments are being made.

The ICL7109 provides a REFerence OUTput (Pin 29) which

may be used with a resistive divider to generate a suitable

reference voltage. This output will sink up to about 20mA

without significant variation in output voltage, and is provided

with a pullup bias device which sources about 10µA. The

output voltage is nominally 2.8V below V+, and has a temperature coefficient of ±80ppm/

o

C (Typ). When using the

onboard reference, REF OUT (Pin 29) should be connected

to REF- (Pin 39), and REF+ should be connected to the

wiper of a precision potentiometer between REF OUT and

V+. The circuit for a 204.8mV reference is shown in the test

circuit. For a 2.048mV reference, the fixed resistor should be

removed, and a 25kΩ precision potentiometer between REF

OUT and V+ should be used.

Note that if Pins 29 and 39 are tied together and Pins 39 and

40 accidentally shorted (e.g., during testing), the reference

supply will sink enough current to destroy the device. This can

be avoided by placing a 1kΩ resistor in series with Pin 39.

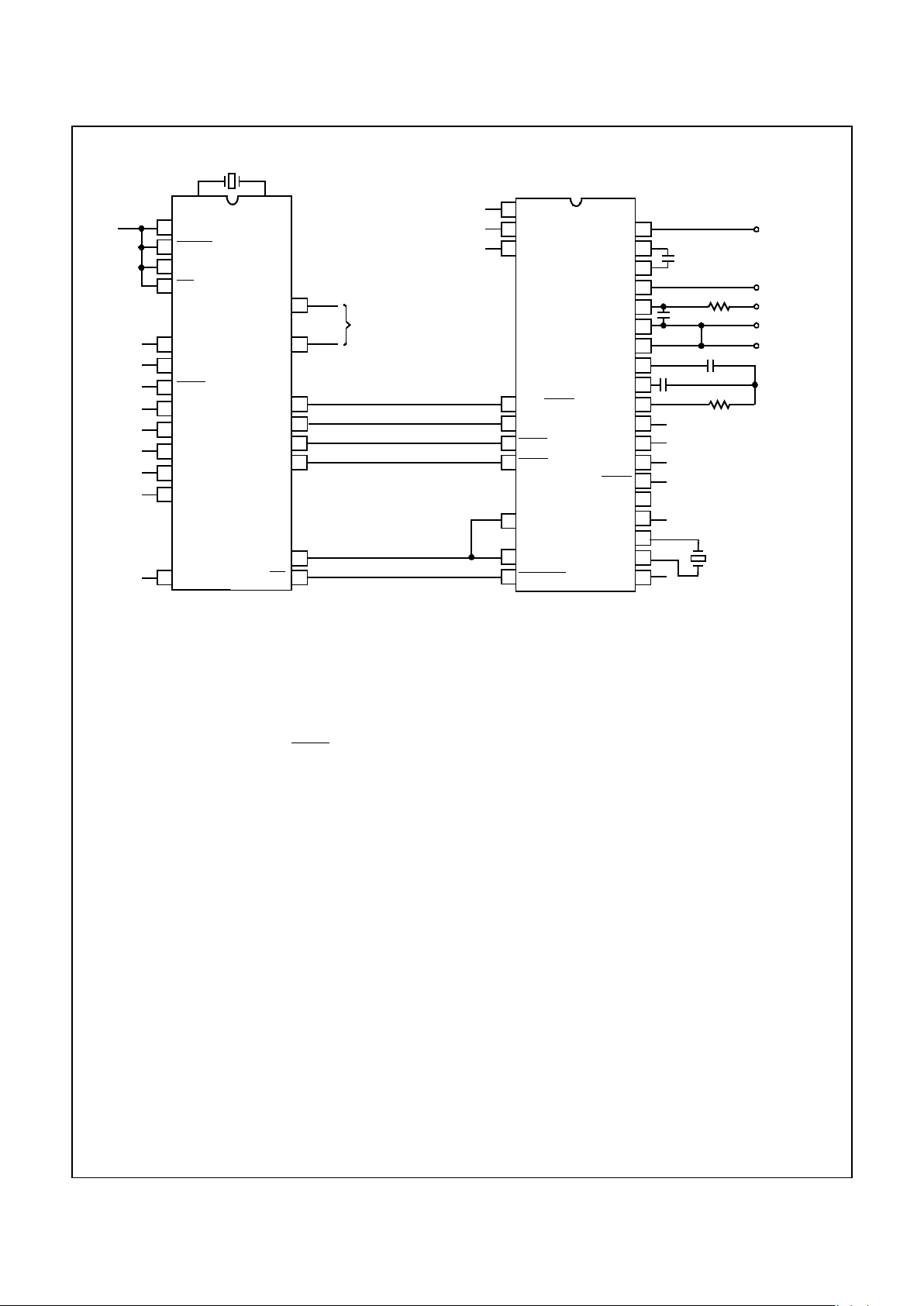

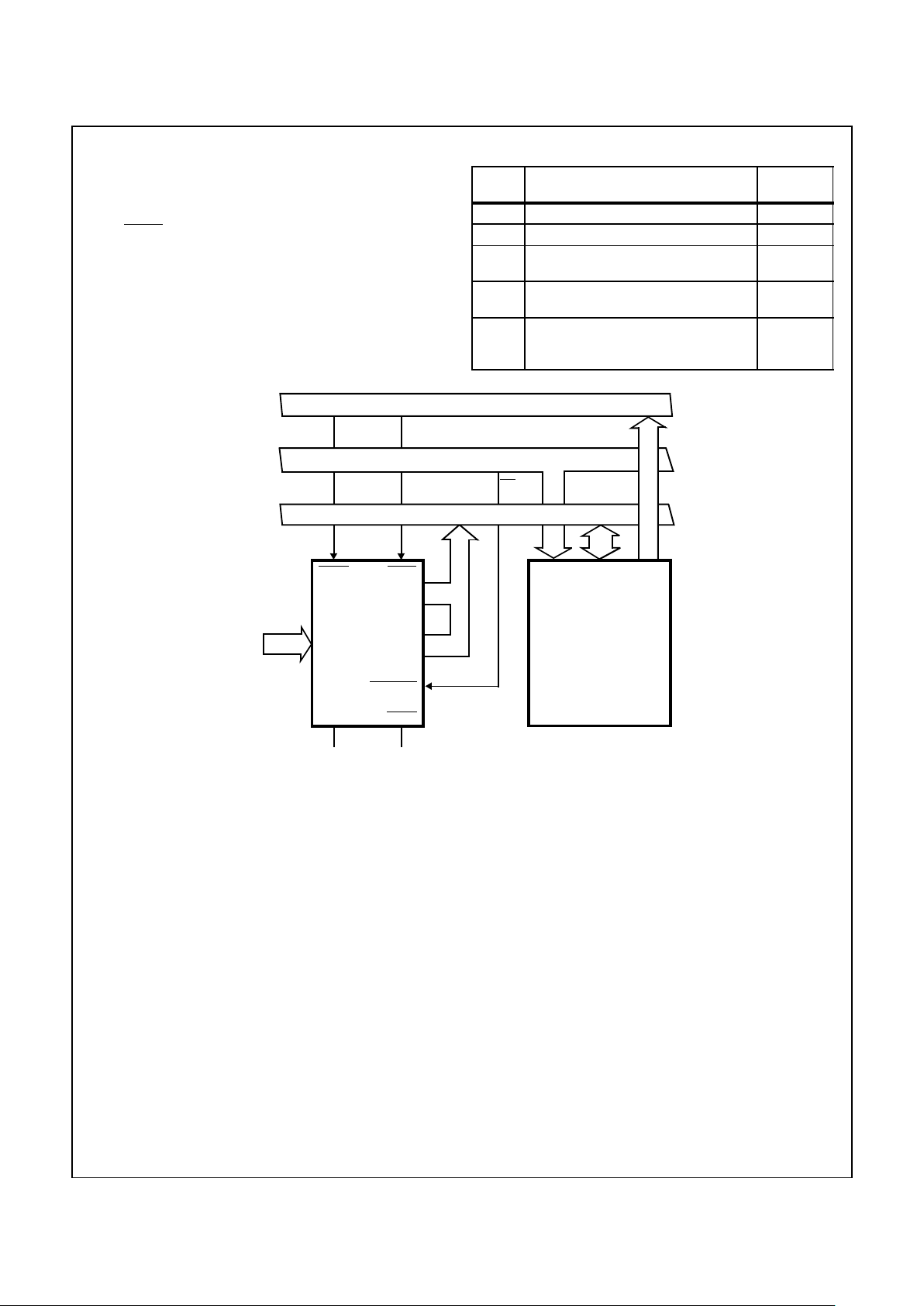

Detailed Description

Digital Section

The digital section includes the clock oscillator and scaling

circuit, a 12-bit binary counter with output latches and TTLcompatible three-state output drivers, polarity, over-range

and control logic, and UART handshake logic, as shown in

Figure 4.

Throughout this description, logic levels will be referred to as

“low” or “high”. The actual logic levels are defined in the Electrical Specifications Table. For minimum power consumption,

all inputs should swing from GND (low) to V+ (high). Inputs

driven from TTL gates should have 3-5kΩ pullup resistors

MODE Input The MODE input is used to control the output mode of the

AZ PHASE I INT PHASE II DEINT PHASE III AZ

INTERNAL CLOCK

INTERNAL LATCH

STATUS OUTPUT

INTEGRATOR

OUTPUT

POLARITY

DETECTED

ZERO CROSSING

OCCURS

ZERO CROSSING

DETECTED

4096 COUNTS

MAX

FIXED 2048

COUNTS

2048 COUNTS

MINIMUM

NUMBER OF COUNTS TO ZERO CROSSING

PROPORTIONAL TO V

IN

AFTER ZERO CROSSING

ANALOG SECTION WILL

BE IN AUTOZERO

CONFIGURATION

FIGURE 3. CONVERSION TIMING (RUN/HOLD PIN HIGH)

ICL7109

12

converter. When the MODE pin is low or left open (this input

is provided with a pulldown resistor to ensure a low level

when the pin is left open), the converter is in its “Direct” output mode, where the output data is directly accessible under

the control of the chip and byte enable inputs. When the

MODE input is pulsed high, the converter enters the UART

handshake mode and outputs the data in two bytes, then

returns to “direct” mode. When the MODE input is left high,

the converter will output data in the handshake mode at the

end of every conversion cycle. (See section entitled “Handshake Mode” for further details).

STATUS Output

During a conversion cycle, the STATUS output goes high at

the beginning of Signal Integrate (Phase II), and goes low

one-half clock period after new data from the conversion has

been stored in the output latches. See Figure 3 for of this timing. This signal may be used as a “data valid” flag (data never

changes while STATUS is low) to drive interrupts, or for

monitoring the status of the converter.

RUN/HOLD

Input

When the RUN/HOLD

input is high, or left open, the circuit will

continuously perform conversion cycles, updating the output

latches after zero crossing during the Deintegrate (Phase III)

portion of the conversion cycle (See Figure 3). In this mode of

operation, the conversion cycle will be performed in 8192

clock periods, regardless of the resulting value.

FIGURE 4. DIGITAL SECTION

TEST

LATCH

CLOCK

POLOR 12111098 7 65432 1

17 3 4 5 6 7 8 9 10 11 12 13 14 15 16

226222324252127

STATUS RUN/ OSC OSC OSC BUF MODE SEND

HOLD

IN OUT SEL OSC

OUT

LOW ORDER

BYTE OUTPUTS

BB BBB B BBBBB B

GND

1

18

19

20

LBEN

HBEN

CE/LOAD

TO

ANALOG

SECTION

COMP OUT

AZ

INT

DEINT (+)

DEINT (-)

CONVERSION

CONTROL LOGIC

OSCILLATOR

AND CLOCK

CIRCUITRY

HIGH ORDER

BYTE OUTPUTS

12-BIT COUNTER

14 LATCHES

14 THREE-STATE OUTPUTS

HANDSHAKE

LOGIC

ICL7109

13

If RUN/HOLD

goes low at any time during Deintegrate (Phase

III) after the zero crossing has occurred, the circuit will immediately terminate Deintegrate and jump to Auto-Zero. This feature can be used to eliminate the time spent in Deintegrate

after the zero-crossing. If RUN/HOLD

stays or goes low, the

converter will ensure minimum Auto-Zero time, and then wait

in Auto-Zero until the RUN/HOLD

input goes high. The converter will begin the Integrate (Phase II) portion of the next

conversion (and the STATUS output will go high) seven clock

periods after the high level is detected at RUN/HOLD

. See

Figure 5 for details.

Using the RUN/HOLD

input in this manner allows an easy

“convert on demand” interface to be used. The converter may

be held at idle in auto-zero with RUN/HOLD

low. When

RUN/HOLD

goes high the conversion is started, and when

the STATUS output goes low the new data is valid (or transferred to the UART; see Handshake Mode). RUN/HOLD

may

now be taken low which terminates deintegrate and ensures a

minimum Auto-Zero time before the next conversion.

Alternately, RUN/HOLD

can be used to minimize conversion

time by ensuring that it goes low during Deintegrate, after zero

crossing, and goes high after the hold point is reached. The

required activity on the RUN/HOLD

input can be provided by

connecting it to the Buffered Oscillator Output. In this mode

the conversion time is dependent on the input value

measured. Also refer to Intersil Application Note AN032 for a

discussion of the effects this will have on Auto-Zero

performance.

If the RUN/HOLD

input goes low and stays low during AutoZero (Phase I), the converter will simply stop at the end of

Auto-Zero and wait for RUN/HOLD

to go high. As above, Integrate (Phase II) begins seven clock periods after the high

level is detected.

Direct Mode

When the MODE pin is left at a low level, the data outputs

(bits 1 through 8 low order byte, bits 9 through 12, polarity and

over-range high order byte) are accessible under control of

the byte and chip enable terminals as inputs. These three

inputs are all active low, and are provided with pullup resistors

to ensure an inactive high level when left open. When the chip

enable input is low, taking a byte enable input low will allow

the outputs of that byte to become active (three-stated on).

This allows a variety of parallel data accessing techniques to

be used, as shown in the section entitled “Interfacing.” The

timing requirements for these outputs are shown in Figure 6

and Table 1.

It should be noted that these control inputs are

asynchronous with respect to the converter clock - the data

may be accessed at any time. Thus it is possible to access

the latches while they are being updated, which could lead to

erroneous data. Synchronizing the access of the latches with

the conversion cycle by monitoring the STATUS output will

prevent this. Data is never updated while STATUS is low.

FIGURE 5. RUN/HOLD OPERATION

INT

PHASE II

STATIC IN

HOLD STATE

7 COUNTS

AUTOZERO

PHASE I

MIN 1790 COUNTS

MAX 2041 COUNTS

DEINT TERMINATED

AT ZERO CROSSING

DETECTION

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

RUN/HOLD

INPUT

INTEGRATOR

OUTPUT

TABLE 1. DIRECT MODE TIMING REQUIREMENTS

(See Note 4 of Electrical Specifications)

DESCRIPTION SYMBOL MIN TYP MAX UNITS

Byte Enable

Width

t

BEA

350 220 - ns

Data Access

Time from Byte

Enable

t

DAB

-210350 ns

Data Hold Time

from Byte

Enable

t

DHB

-150300 ns

Chip Enable

Width

t

CEA

400 260 - ns

Data Access

Time from Chip

Enable

t

DAC

-260400 ns

Data Hold Time

from Chip

Enable

t

DHC

-240400 ns

ICL7109

14

Handshake Mode

The handshake output mode is provided as an alternative

means of interfacing the ICL7109 to digital systems where the

A/D converter becomes active in controlling the flow of data

instead of passively responding to chip and byte enable

inputs. This mode is specifically designed to allow a direct

interface between the ICL7109 and industry-standard UARTs

(such as the Intersil IM6402/3) with no external logic required.

When triggered into the handshake mode, the ICL7109 provides all the control and flag signals necessary to sequentially

transfer two bytes of data into the UART and initiate their

transmission in serial form. This greatly eases the task and

reduces the cost of designing remote data acquisition stations

using serial data transmission.

Entry into the handshake mode is controlled by the MODE pin.

When the MODE terminal is held high, the ICL7109 will enter

the handshake mode after new data has been stored in the output latches at the end of a conversion (See Figures 7 and 8).

The MODE terminal may also be used to trigger entry into the

handshake mode on demand. At any time during the conversion cycle, the low to high transition of a short pulse at the

MODE input will cause immediate entry into the handshake

mode. If this pulse occurs while new data is being stored, the

entry into handshake mode is delayed until the data is stable.

While the converter is in the handshake mode, the MODE input

is ignored, and although conversions will still be performed,

data updating will be inhibited (See Figure 9) until the converter

completes the output cycle and clears the handshake mode.

When the converter enters the handshake mode, or when the

MODE input is high, the chip and byte enable terminals

become TTL-compatible outputs which provide the control

signals for the output cycle (See Figures 7, 8, and 9).

In handshake mode, the SEND input is used by the converter

as an indication of the ability of the receiving device (such as a

UART) to accept data.

Figure 7 shows the sequence of the output cycle with SEND

held high. The handshake mode (Internal MODE high) is

entered after the data latch pulse, and since MODE remains

high the CE/LOAD

, LBEN and HBEN terminals are active as

outputs. The high level at the SEND input is sensed on the

same high to low internal clock edge that terminates the data

latch pulse. On the next low to high internal clock edge the

CE/LOAD

and the HBEN outputs assume a low level, and the

high-order byte (Bits 9 through 12, POL, and OR) outputs are

enabled. The CE/LOAD

output remains low for one full internal

clock period only, the data outputs remain active for 1

1

/2 internal clock periods, and the high byte enable remains low for two

clock periods. Thus the CE/LOAD

output low level or low to

high edge may be used as a synchronizing signal to ensure

valid data, and the byte enable as an output may be used as a

byte identification flag. With SEND remaining high the converter

completes the output cycle using CE/LOAD

and LBEN while

the low order byte outputs (bits 1 through 8) are activated. The

handshake mode is terminated when both bytes are sent.

Figure 8 shows an output sequence where the SEND input is

used to delay portions of the sequence, or handshake to ensure

correct data transfer. This timing diagram shows the relationships that occur using an industry-standard IM6402/3 CMOS

UART to interface to serial data channels. In this interface, the

SEND input to the ICL7109 is driven by the TBRE (Transmitter

Buffer Register Empty) output of the UART, and the CE/LOAD

terminal of the ICL7109 drives the TBRL (Transmitter Buffer

Register Load) input to the UART. The data outputs are paralleled into the eight Transmitter Buffer Register inputs.

FIGURE 6. DIRECT MODE OUTPUT TIMING

TABLE 1. DIRECT MODE TIMING REQUIREMENTS

(See Note 4 of Electrical Specifications)

DESCRIPTION SYMBOL MIN TYP MAX UNITS

DATA

VALID

DATA

VALID

DATA

VALID

t

CEA

t

BEA

t

DAB

t

DHB

t

DAC

t

DHC

CE/LOAD

AS INPUT

HBEN

AS INPUT

LBEN

AS INPUT

HIGH BYTE

DATA

LOW BYTE

DATA

= HIGH IMPEDANCE

ICL7109

15

Assuming the UART Transmitter Buffer Register is empty, the

SEND input will be high when the handshake mode is entered

after new data is stored. The CE/LOAD and HBEN terminals will

go low after SEND is sensed, and the high order byte outputs

become active. When CE/LOAD goes high at the end of one

clock period, the high order byte data is clocked into the UART

Transmitter Buffer Register. The UART TBRE output will now go

low, which halts the output cycle with the HBEN output low, and

the high order byte outputs active. When the UART has transferred that data to the Transmitter Register and cleared the

Transmitter Buffer Register, the TBRE returns high. On the next

ICL7109 internal clock high to low edge, the high order byte outputs are disabled, and one-half internal clock later, the HBEN

output returns high. At the same time, the CE/LOAD and LBEN

outputs go low, and the low order byte outputs become active.

Similarly, when the CE/LOAD returns high at the end of one

clock period, the low order data is clocked into the UART Transmitter Buffer Register, and TBRE again goes low. When TBRE

returns to a high it will be sensed on the next ICL7109 internal

clock high to low edge, disabling the data outputs. One-half

internal clock later, the handshake mode will be cleared, and the

CE/LOAD, HBEN and LBEN terminals return high and stay

inactive (as long as MODE stays high).

With the MODE input remaining high as in these examples,

the converter will output the results of every conversion

except those completed during a handshake operation. By

triggering the converter into handshake mode with a low to

high edge on the MODE input, handshake output

sequences may be performed on demand. Figure 9 shows

a handshake output sequence triggered by such an edge.

In addition, the SEND input is shown as being low when the

converter enters handshake mode. In this case, the whole

output sequence for the first (high order) byte is similar to

the sequence for the second byte. This diagram also shows

the output sequence taking longer than a conversion cycle.

Note that the converter still makes conversions, with the

STATUS output and RUN/HOLD input functioning normally. The only difference is that new data will not be

latched when in handshake mode, and is therefore lost.

Oscillator

The ICL7109 is provided with a versatile three terminal

oscillator to generate the internal clock. The oscillator may be

overdriven, or may be operated with an RC network or crystal.

The OSCILLATOR SELECT input changes the internal configuration of the oscillator to optimize it for RC or crystal operation.

When the OSCILLATOR SELECT input is high or left open

(the input is provided with a pullup resistor), the oscillator is

configured for RC operation, and the internal clock will be of

the same frequency and phase as the signal at the

BUFFERED OSCILLATOR OUTPUT. The resistor and

capacitor should be connected as in Figure 10. The circuit will

oscillate at a frequency given by f = 0.45/RC. A 100kΩ resistor

is recommended for useful ranges of frequency. For optimum

60Hz line rejection, the capacitor value should be chosen

INTEGRATOR

OUTPUT

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

MODE

INTERNAL

MODE

SEND

INPUT

CE/LOAD

HBEN

HIGH BYTE

DATA

LBEN

LOW BYTE

DATA

= DON’T CARE

INPUT

ZERO CROSSING

OCCURS

ZERO CROSSING

DETECTED

MODE HIGH ACTIVATES

CE/LOAD

, HBEN, LBEN

UART

NORM

SEND

SENSED

SEND

SENSED

TERMINATES

UART MODE

= THREE-STATE HIGH IMPEDA NCE = THR EE-STATE WITH PULLUP

MODE LOW, NOT

IN HANDSHAKE MODE

DISABLES OUTPUTS CE/LOAD

, HBEN, LBEN

DATA VALID

DATA VALID

FIGURE 7. HANDSHAKE WITH SEND HELD HIGH

ICL7109

16

such that 2048 clock periods is close to an integral multiple of the 60Hz period (but should not be less than 50pF).

When the OSCILLATOR SELECT input is low a feedback

device and output and input capacitors are added to the oscillator. In this configuration, as shown in Figure 11, the oscillator will operate with most crystals in the 1MHz to 5MHz range

with no external components. Taking the OSCILLATOR

SELECT input low also inserts a fixed ÷58 divider circuit

between the BUFFERED OSCILLATOR OUTPUT and the

internal clock. Using an inexpensive 3.58MHz TV crystal, this

division ratio provides an integration time given by:

t

INT

= (2048 clock periods) x (t

CLOCK

) = 33.18ms where:

This time is very close to two 60Hz periods or 33ms. The

error is less than one percent, which will give better than

40dB 60Hz rejection. The converter will operate reliably at

conversion rates of up to 30 per second, which corresponds

to a clock frequency of 245.8kHz.

If at any time the oscillator is to be overdriven, the overdriving signal should be applied at the OSCILLATOR INPUT,

and the OSCILLATOR OUTPUT should be left open. The

internal clock will be of the same frequency, duty cycle, and

phase as the input signal when OSCILLATOR SELECT is

left open. When OSCILLATOR SELECT is at GND, the clock

will be a factor of 58 below the input frequency.

When using the ICL7109 with the IM6403 UART, it is

possible to use one 3.58MHz crystal for both devices. The

BUFFERED OSCILLATOR OUTPUT of the ICL7109 may be

used to drive the OSCILLATOR INPUT of the UART, saving

the need for a second crystal. However, the BUFFERED

OSCILLATOR OUTPUT does not have a great deal of drive

capability, and when driving more than one slave device

external buffering should be used.

Test Input

When the TEST input is taken to a level halfway between V+

and GND, the counter output latches are enabled, allowing

the counter contents to be examined anytime.

When the RUN/HOLD

is low and the TEST input is

connected to GND, the counter outputs are all forced into the

high state, and the internal clock is disabled. When the

RUN/HOLD

returns high and the TEST input returns to the

1

/2 (V+ - GND) voltage (or to V+) and one clock is applied,

all the counter outputs will be clocked to the low state. This

allows easy testing of the counter and its outputs.

ZERO CROSSING

OCCURS

ZERO CROSSING

DETECTED

INTEGRATOR

OUTPUT

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

MODE

INPUT

INTERNAL

MODE

UART

NORM

SEND INPUT

(UART TBRE)

CE/LOAD

OUTPUT

(UART TBRL)

HBEN

HIGH BYTE

DATA

LBEN

LOW BYTE

DATA

= DON’T CARE = THREE-STATE HIGH IMPEDANCE

SEND

SENSED

SEND

SENSED

TERMINATES

UART MODE

DATA VALID

DATA VALID

FIGURE 8. HANDSHAKE - TYPICAL UART INTERFACE TIMING

t

CLOCK

58

3.58MHZ

--------------------------=

ICL7109

17

FIGURE 10. RC OSCILLATOR FIGURE 11. CRYSTAL OSCILLATOR

ZERO CROSSING

OCCURS

ZERO CROSSING

DETECTED

INTERNAL

CLOCK

INTERNAL

LATCH

STATUS

OUTPUT

MODE

INPUT

INTERNAL

MODE

UART

NORM

SEND INPUT

CE/LOAD

OUTPUT

HBEN

HIGH BYTE

DATA

LBEN

LOW BYTE

DATA

= DON’T CARE = THREE-STATE HIGH IMPEDANCE

SEND

SENSED

SEND

SENSED

TERMINATES

UART MODE

DATA VALID

DATA VALID

= THREE- STATE WITH PULLUP

SEND

SENSED

LATCH PULSE INHIBITED

IN UART MODE

DEINT

PHASE III

STATUS OUTPUT

UNCHANGED IN

UART MODE

POSITVE TRANSITION CAUSES

ENTRY INTO

UART MODE

FIGURE 9. HANDSHAKE TRIGGERED BY MODE

25

OSC

SEL

BUFFERED

OSC

OUT

V+ OR OPEN

R

C

ƒ

OSC

= 0.45/RC

OSC

IN

OSC

OUT

232224

25

OSC

SEL

BUFFERED

OSC

OUT

GND

CRYSTAL

OSC

IN

OSC

OUT

232224

÷58

V+

CLOCK

ICL7109

18

FIGURE 12. DIRECT MODE CHIP AND BYTE ENABLE COMBINATIONS

FIGURE 13. THREE-STATE SEVERAL ICL7109’S TO A SMALL BUS

GND

MODE

LBEN

B9 - B12

POL, OR

B1 - B8

RUN/HOLD

HBEN

CONVERT

ANALOG

IN

CONTROL

6

8

ICL7109

GND

MODE

LBEN

B1 - B12

POL, OR

RUN/HOLD

HBEN

CONVERT

ANALOG

IN

14

ICL7109

GND

MODE

LBEN

B9 - B12

POL, OR

B1 - B8

RUN/HOLD

HBEN

CONVERT

ANALOG

IN

BYTE FLAGS

6

8

ICL7109

CE/LOAD CE/LOADCE/LOAD

CHIP SELECT 1

GND OR

CHIP SELECT 2

CHIP SELECT

FIGURE 12A.

FIGURE 12B.

FIGURE 12C.

GND

CE/LOAD

LBEN

B9 - B12

POL, OR

B1 - B8

HBEN

ANALOG

IN

6

8

MODE

RUN/HOLD

+5V

CONVERTER

SELECT

8-BIT BUS

GND

CE/LOAD

LBEN

B9 - B12

POL, OR

B1 - B8

HBEN

ANALOG

IN

6

8

MODE

RUN/HOLD

+5V

CONVERTER

SELECT

GND

CE/LOAD

LBEN

B9 - B12

POL, OR

B1 - B8

HBEN

ANALOG

IN

6

8

MODE

RUN/HOLD

+5V

CONVERTER

SELECT

ICL7109 ICL7109 ICL7109

BYTE SELECT FLAGS

ICL7109

19

FIGURE 14. FULL-TIME PARALLEL INTERFACE TO 8040/80/85 MICROPROCESSORS

FIGURE 15. FULL-TIME PARALLEL INTERFACE TO 8048/80/85 MICROPROCESSORS WITH INTERRUPT

GND

MODE

LBEN

B9 - B12

POL, OR

B1 - B8

STATUS

HBEN

SEE TEXT

ANALOG

IN

6

8

ICL7109

CE/LOAD

RUN/HOLD +5 V

GND

ADDRESS BUS

CONTROL BUS

RD WR

PA5 - PA

0

PB7 - PB

0

PC

5

D7 - D0 A0 - A1

CS

8255

(MODE 0)

8008, 8080

8085, 8048, ETC.

DATA BUS

GND

MODE

LBEN

B9 - B12

POL, OR

B1 - B8

STATUS

HBEN

+5V

ANALOG

IN

6

8

ICL7109

CE/LOAD

RUN/HOLD

GND

ADDRESS BUS

CONTROL BUS

RD WR

PA5 - PA

0

PB7 - PB

0

PC

4

D7 - D0 A0 - A1

CS

8255

8008, 8080

8085, 8048, ETC.

PC

6

SEE TEXT

STB

A

1µF

10kΩ

PC

6

INTR

A

INTR

DATA BUS

ICL7109

20

Test Circuit

Typical Applications

Direct Mode Interfacing

Figure 12 shows some of the combinations of chip enable

and byte enable control signals which may be used when

interfacing the ICL7109 to parallel data lines. The CE/LOAD

input may be tied low, allowing either byte to be controlled by

its own enable as in Figure 12A. Figure 12B shows a configuration where the two byte enables are connected together.

In this configuration, the CE/LOAD

serves as a chip enable,

and the HBEN

and LBEN may be connected to GND or

serve as a second chip enable. The 14 data outputs will all

be enabled simultaneously. Figure 12C shows the HBEN

and LBEN as flag inputs, and CE/LOAD as a master enable,

which could be the READ strobe available from most microprocessors.

Figure 13 shows an approach to interfacing several

ICL7109s to a bus, connecting the HBEN

and LBEN signals

of several converters together, and using the CE/LOAD

inputs (perhaps decode from an address) to select the

desired converter.

Some practical circuits utilizing the parallel three-state output

capabilities of the ICL7109 are shown in Figures 14 through

19. Figure 14 shows a straightforward application to the Intel

8048/80/85 microprocessors via an 8255PPI, where the

ICL7109 data outputs are active at all times. The I/O ports of

an 8155 may be used in the same way. This interface can be

used in a read-anytime mode, although a read performed

while the data latches are being updated will lead to

scrambled data. This will occur very rarely, in the proportion of

set-up skew times to conversion time. One way to overcome

this is to read the STATUS output as well, and if it is high, read

the data again after a delay of more than

1

/2 converter clock

period. If STATUS is now low, the second reading is correct,

and if it is still high, the first reading is correct. Alternatively,

this timing problem is completely avoided by using a readafter-update sequence, as shown in Figure 15. Here the high

to low transition of the STATUS output drives an interrupt to

the microprocessor causing it to access the data latches. This

application also shows the RUN/HOLD

input being used to ini-

tiate conversions under software control.

A similar interface to Motorola MC6800 or Rockwell R650X

systems is shown in Figure 16. The high to low transition of

the STATUS output generates an interrupt via the Control

Register B CB1 line. Note that CB2 controls the RUN/HOLD

pin through Control Register B, allowing software-controlled

initiation of conversions in this system as well.

The three-state output capability of the ICL7109 allows direct

interfacing to most microprocessor busses. Examples of this

are shown in Figures 17 and 18. It is necessary to carefully

consider the system in this type of interface, to be sure that

requirements for setup and hold times, and minimum pulse

widths are met. Note also the drive limitations on long buses.

Generally this type of interface is only favored if the memory

peripheral address density is low so that simple address

decoding can be used. Interrupt handling can also require

many additional components, and using an interface device

will usually simplify the system in this case.

13

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

17

18

19

20

GND

STATUS

POL

OR

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

TEST

LBEN

HBEN

CE/LOAD

28

40

39

38

37

36

35

34

33

32

31

30

29

27

26

25

24

23

22

21

V+

REF IN -

REF CAP-

REF CAP+

REF IN+

IN HI

IN LO

COMMON

INT

AZ

BUF

REF OUT

V-

SEND

RUN/HOLD

BUF OSC OUT

OSC SEL

OSC OUT

OSC IN

MODE

GND

HIGH

ORDER

BYTE

OUTPUTS

LOW

ORDER

BYTE

OUTPUTS

+5V

BYTE

CONTROL

INPUTS

GND

V+

+5V

1µF

0.01µF

0.33µF

0.15µF

C

AZ

C

INT

R

INT

†

1MΩ R1

1kΩ

24kΩ

3.5795MHz

TV CRYSTAL

†R

INT

= 20kΩ FOR 0.2V REF

= 200kΩ FOR 2.0V REF

REF IN +

REF IN -

-

+

INPUT HIGH

INPU T LOW

GND

DIFFERENTIAL

REFERENCE

-5V

ICL7109

21

Handshake Mode Interfacing

The handshake mode allows ready interface with a wide

variety of external devices. For instance, external latches

may be clocked by the rising edge of CE/LOAD

, and the byte

enables may be used as byte identification flags or as load

enables.

Figure 19 shows a handshake interface to Intel microprocessors again using an 8255PPI. The handshake operation with

the 8255 is controlled by inverting its Input Buffer Full (IBF)

flag to drive the SEND input to the ICL7109, and using the

CE/LOAD

to drive the 8255 strobe. The internal control register of the PPI should be sent in MODE 1 for the port used.

If the ICL7109 is in handshake mode and the 8255 IBF flag

is low, the next word will be strobed into the port. The strobe

will cause IBF to go high (SEND goes low), which will keep

the enable byte outputs active. The PPI will generate an

interrupt which when executed will result in the data being

read. When the byte is read, the IBF will be reset low, which

causes the ICL7109 to sequence into the next byte. This figure shows the MODE input to the ICL7109 connected to a

control line on the PPI. If this output is left high, or tied high

separately, the data from every conversion (provided the

data access takes less time than a conversion) will be

sequenced in two bytes into the system.

If this output is made to go from low to high, the output

sequence can be obtained on demand, and the interrupt

may be used to reset the MODE bit. Note that the

RUN/HOLD

input to the ICL7109 may also be obtained on

command under software control. Note that one port of the

8255 is not used, and can service another peripheral device.

the same arrangement can also be used with the 8155.

Figure 20 shows a similar arrangement with the MC6800 or

MCS650X microprocessors, except that both MODE and

RUN/HOLD

are tied high to save port outputs.

The handshake mode is particularly convenient for directly

interfacing to industry standard UARTs (such as the Intersil

IM6402 or Western Digital TR1602) providing a minimum

component count means of serially transmitting converted

data. A typical UART connection is shown in Figure 1A. In

this circuit, any word received by the UART causes the

UART DR (Data Ready) output to go high. This drives the

MODE input to the ICL7109 high, triggering the ICL7109 into

handshake mode. The high order byte is output to the UART

first, and when the UART has transferred the data to the

Transmitter Register, TBRE (SEND) goes high again, LBEN

will go high, driving the UART DRR (Data Ready Reset)

which will signal the end of the transfer of data from the

ICL7109 to the UART.

Figure 21 shows an extension of the one converter one

UART scheme to several ICL7109s with one UART. In this

circuit, the word received by the UART (available at the RBR

outputs when DR is high) is used to select which converter

will handshake with the UART. With no external components, this scheme will allow up to eight ICL7109s to interface with one UART. Using a few more components to

decode the received word will allow up to 256 converters to

be accessed on one serial line.

MC6820

GND

MODE

ICL7109

B9 - B12

POL, OR

B1 - B8

STATUS

RUN/HOLD

LBENHBENLOAD

CE/

GND

ANALOG

IN

PA0 - 5

PB0 - 7

CB1

CB2

CRB - - 11R-01

MC680X

OR

MCS650X

ADDRESS

BUS

DATA

BUS

CONTROL

BUS

6

8

FIGURE 16. FULL-TIME PARALLEL INTERFACE TO MC680X OR MCS650X MICROPROCESSORS

ICL7109

22

The applications of the ICL7109 are not limited to those

shown here. The purposes of these examples are to provide a starting point for users to develop useful systems

and to show some of the variety of interfaces and uses of

the combination. In particular the uses of the STATUS,

RUN/HOLD

, and MODE signals may be mixed.

The following application notes contain very useful

information on understanding and applying this part and

are available from Intersil Corporation.

Application Notes

NOTE # DESCRIPTION

AnswerFAX

DOC. #

AN016 “Selecting A/D Converters” 9016

AN017 “The Integrating A/D Converter” 9017

AN018 “Do’s and Don’ts of Applying A/D

Converters”

9018

AN030 “The ICL7104 - A Binary Output A/D

Converter for Microprocessors”

9030

AN032 “Understanding the Auto-Zero and

Common Mode Performance of the

ICL7136/7/9 Family”

9032

FIGURE 17. DIRECT INTERFACE - ICL7109 TO 8080/8085

MODE

ICL7109

B9 - B12

B1 - B8

RUN/HOLD

LBENHBEN

GND

ANALOG

IN

+5V

POL, OR

6

8

CE/LOAD

A14 A15

ADDRESS BUS

CONTROL BUS

RD

†

DATA BUS

8008, 8080, 8085

† MEMR OR IOR

FOR 8080/8228 SYSTEM

ICL7109

23

FIGURE 18. DIRECT ICL7109 - MC680X BUS INTERFACE

FIGURE 19. HANDSHAKE INTERFACE - ICL7109 TO 8048, 80/85

74C42

74C30

MC680X

OR

MCS650X

CONTROL

BUS

DATA

BUS

ADDRESS

BUS

A0 - A2

A15 - A10

R/W

, VMA

CE/LOAD

MODE RUN/HOLD

B9 - B12

POL, OR

B1 - B8

HBEN

LBEN

ANALOG

IN

6

8

GND +5V

ANALOG

IN

6

8

STB

A

IBF

A

B9 - B12

POL, OR

ICL7109

B1 - B8

SEND

RUN/HOLD

MODE

CE/LOAD

RD WR D7 - D0 A0 - A1

CS

8255

(MODE 1)

PC

4

PC

5

PC

6

PC

7

PA7 - PA

0

PC

3

ADDRESS BUS

CONTROL BUS

DATA BUS

INTR

8008, 8080,

8085, 8048, ETC.

ICL7109

24

FIGURE 20. HANDSHAKE INTERFACE - ICL7109 TO MC6800, MCS650X

FIGURE 21. MULTIPLEXING CONVERTERS WITH MODE INPUT

ANALOG

IN

HBEN

ICL7109

LBEN

SEND

RUN/HOLD

MODE

CE/LOAD

CRA

MC6820

CA1

CA2

PA

0

- PA

7

- -100 - 01

MC6800

OR

MCS650X

ADDRESS

BUS

DATA

BUS

CONTROL

BUS

+5V

MODE SENDCE/

LOAD

B9 - B12

POL, OR

SEND

RUN/HOLD

HBEN LBEN

ANALOG

IN

+5V

MODE SENDCE/

LOAD

B9 - B12

POL, OR

SEND

RUN/HOLD

HBEN LBEN

ANALOG

IN

+5V

MODE SENDCE/

LOAD

B9 - B12

POL, OR

SEND

HBEN

LBEN

ANALOG

IN

6

8

6

8

6

8

TBRL DRR TBRE RBR1 - RBR8 TBR1 - TBR8

SERIAL INPUT

SERIAL OUTPUT

IM6402 CMOS UART

23

8-BIT DATA BUS

RUN/HOLD +5V

25

Die Characteristics

DIE DIMENSIONS:

(122 mils x 135 mils) x 525µm ±25µm Thick

METALLIZATION:

Type: Al

Thickness: 10k

Å ±1kÅ

PASSIVATION:

Type: Nitride/Silox Sandwich

Thickness: 8k

Å Nitride over 7kÅ Silox

Metallization Mask Layout

ICL7109

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12

OR

POL

STATUS

GND

REF IN-

REF CAP-

REF CAP+

REF IN+

IN HIIN LOCOMMONINTAZBUFREF OUTSEND V-RUN/HOLD

TEST

LBEN

HBEN

CE/LOAD

MODE

OSC IN

OSC OUT

OSC SEL

BUF OSC OUT

V+

Loading...

Loading...