Page 1

®

www.BDTIC.com/Intersil

HA-2539

Data Sheet May 2003 FN2896.5

600MHz, Very High Slew Rate

Operational Amplifier

The Intersil HA-2539 represents the ultimate in high slew

rate, wideband, monolithic operational amplifiers. It has

been designed and constructed with the Intersil High

Frequency Bipolar Dielectric Isolation process and features

dynamic parameters never before available from a truly

differential device.

With a 600V/µs slew rate and a 600MHz gain bandwidth

product, the HA-2539 is ideally suited for use in video and

RF amplifier designs, in closed loop gains of 10 or greater.

Full ±10V swing coupled with outstanding AC parameters

and complemented by high open loop gain makes the

devices useful in high speed data acquisition systems.

For further design assistance please refer to Application Note

AN541 (Using the HA-2539 Very High Slew Rate Wideband

Operational Amplifiers) and Application Note AN556 (Thermal

Safe-Operating-Areas For High Current Operational Amplifiers.

For military grade product information, the HA-2539/883 data

sheet is available upon request.

Part Number Information

Features

• Very High Slew Rate . . . . . . . . . . . . . . . . . . . . . . 600V/µs

• Open Loop Gain. . . . . . . . . . . . . . . . . . . . . . . . . . . 15kV/V

• Wide Gain-Bandwidth (AV ≥ 10). . . . . . . . . . . . . . 600MHz

• Power Bandwidth. . . . . . . . . . . . . . . . . . . . . . . . . 9.5MHz

• Low Offset Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . 8mV

• Input Voltage Noise . . . . . . . . . . . . . . . . . . . . . . 6nV/√Hz

• Output Voltage Swing . . . . . . . . . . . . . . . . . . . . . . . ±10V

• Monolithic Bipolar Dielectric Construction

Applications

• Pulse and Video Amplifiers

• Wideband Amplifiers

• High Speed Sample-Hold Circuits

• RF Oscillators

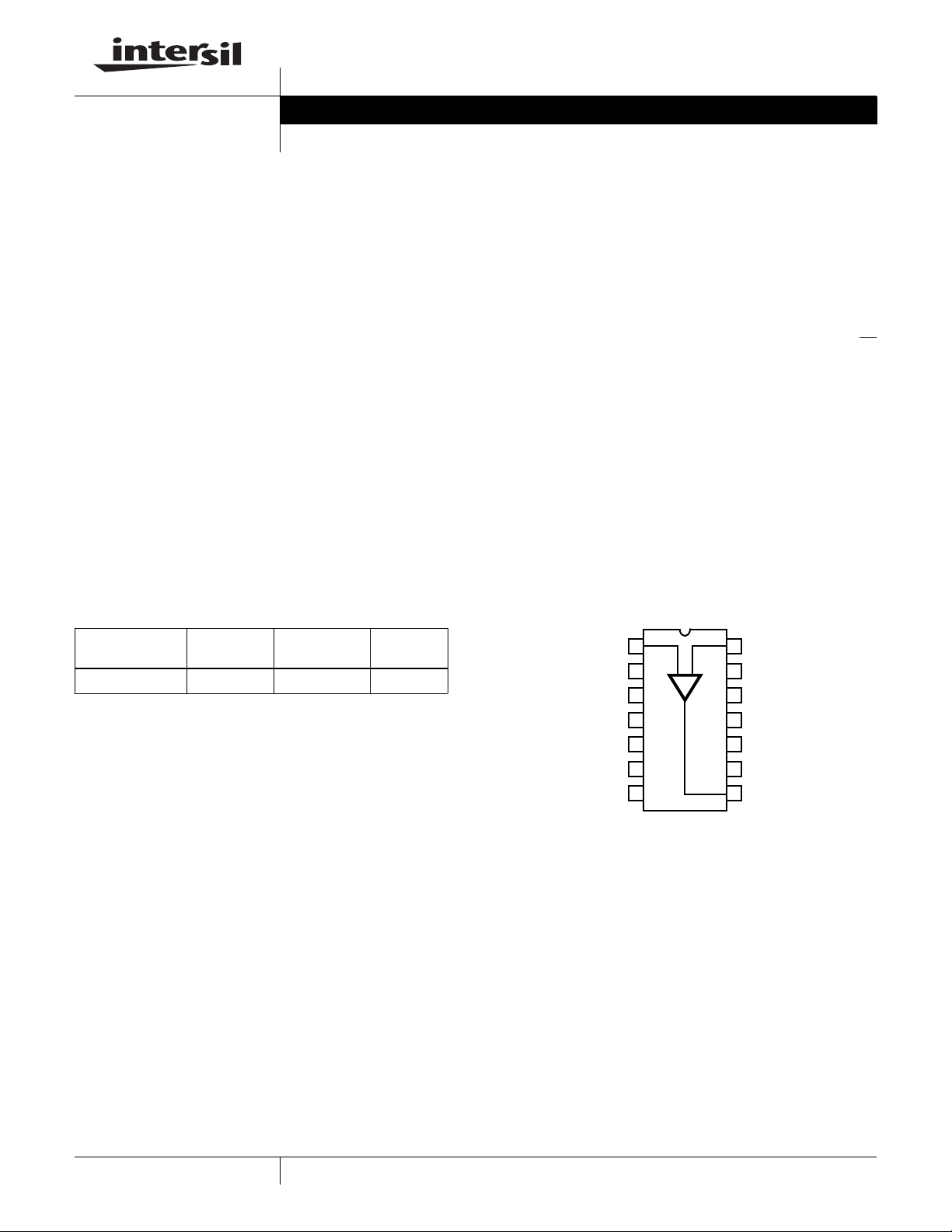

Pinout

HA-2539 (PDIP)

TOP VIEW

PART NUMBER

HA3-2539-5 0 to 75 14 Ld PDIP E14.3

TEMP.

RANGE (oC) PACKAGE PKG. NO.

+IN

1

+

2

NC

3

V-

4

NC

5

NC

6

NC

7

NC

NOTE: No-Connection (NC) leads may be tied to a ground plane

for better isolation and heat dissipation.

14

-IN

-

13

NC

12

NC

11

NC

10

+V

9

NC

8

OUTPUT

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

Copyright © Intersil Americas Inc. 2003. All Rights Reserved

Page 2

HA-2539

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Supply Voltage Between V+ and V- Terminals . . . . . . . . . . . . . 35V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6V

Peak Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

Continuous Output Current . . . . . . . . . . . . . . . . . . . . . . . 33mA

RMS

Operating Conditions

Temperature Range

HA-2539-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Maximum power dissipation with load conditions must be designed to maintain the maximum junction temperature below 150

package. By using Application Note AN556 on Safe Operating Area equations, along with the thermal resistances, proper load conditions can

be determined. Heat sinking is recommended above 75

2. θJA is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief TB379 for details.

o

C to 75oC

o

C.

Thermal Resistance (Typical, Note 2) θ

PDIP Package . . . . . . . . . . . . . . . . . . . 95 N/A

Maximum Internal Quiescent Power Dissipation (Note 1)

Maximum Junction Temperature (Plastic Package) . . . . . . . .150

Maximum Storage Temperature Range . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . 300

(oC/W) θJC (oC/W)

JA

o

C to 150oC

o

C for the plastic

o

o

C

C

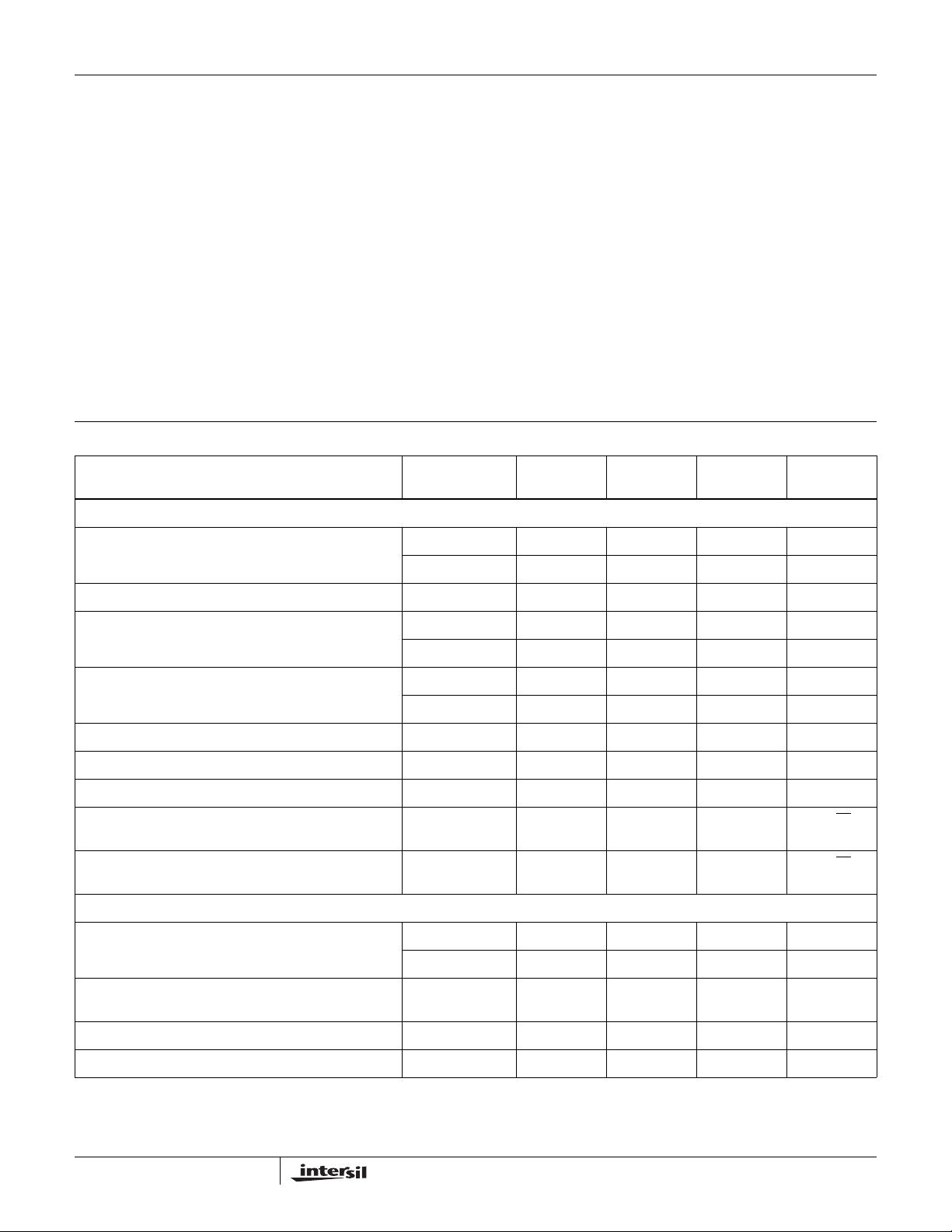

Electrical Specifications V

PARAMETER

INPUT CHARACTERISTICS

Offset Voltage 25 - 8 15 mV

Average Offset Voltage Drift Full - 20 - µV/

Bias Current 25 - 5 20 µA

Offset Current 25 - 1 6 µA

Input Resistance 25 - 10 - kΩ

Input Capacitance 25 - 1 - pF

Common Mode Range Full ±10.0 - - V

Input Current Noise

(f = 1kHz, R

Input Voltage Noise

(f = 1kHz, R

TRANSFER CHARACTERISTICS

SOURCE

SOURCE

= 0Ω)

= 0Ω)

= ±15V, RL = 1kW, CL < 10pF, Unless Otherwise Specified

SUPPLY

TEMP.

o

(

C) MIN TYP MAX UNITS

Full - 13 20 mV

Full - - 25 µA

Full - - 8 µA

25 - 6 - pA/√Hz

25 - 6 - nV/√Hz

o

C

Large Signal Voltage Gain

(Note 3)

Common Mode Rejection Ratio

(Note 4)

Minimum Stable Gain 25 10 - - V/V

Gain Bandwidth (Notes 5, 6) 25 - 600 - MHz

25 10 15 - kV/V

Full 5 - -- kV/V

Full 60 72 - dB

2

Page 3

HA-2539

www.BDTIC.com/Intersil

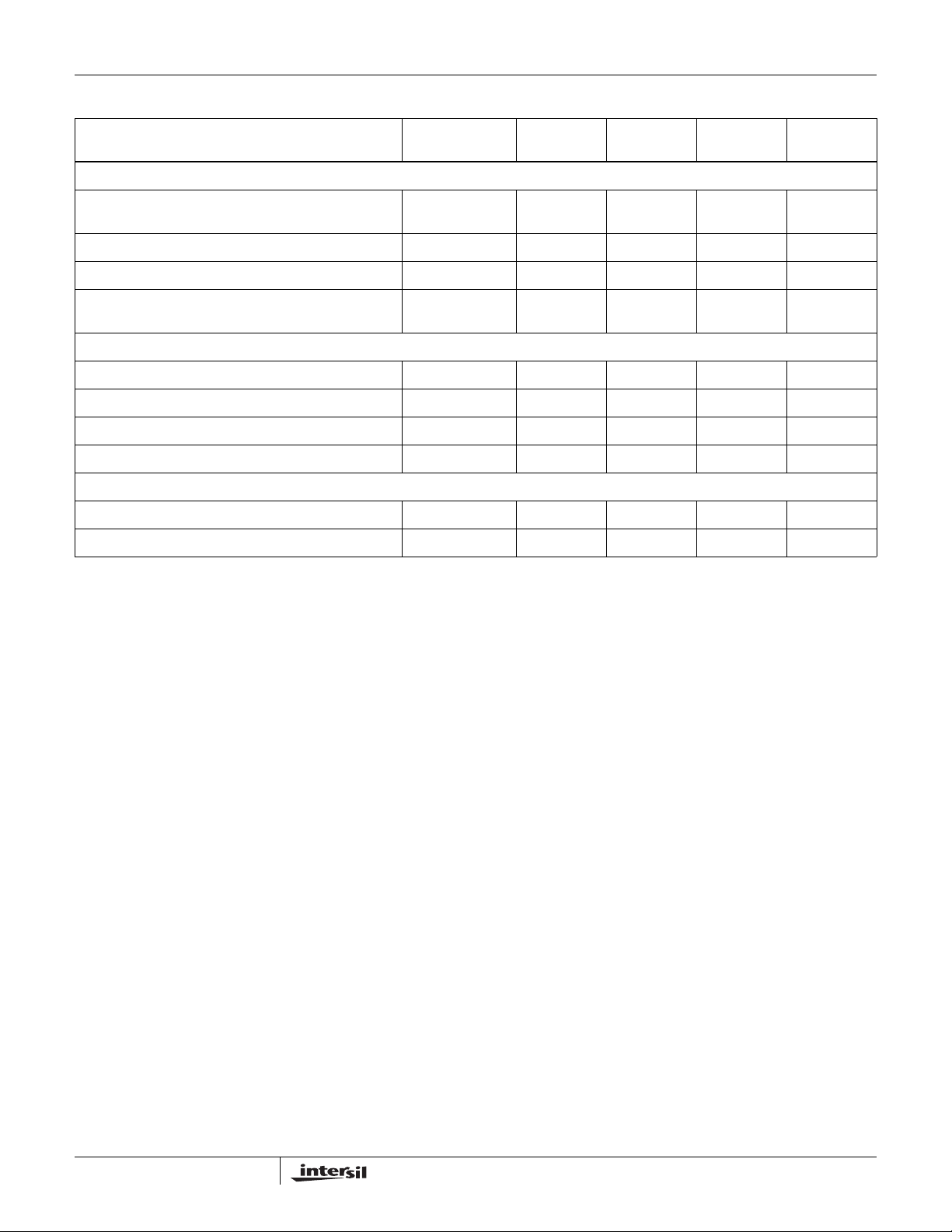

Electrical Specifications V

PARAMETER

OUTPUT CHARACTERISTICS

Output Voltage Swing

(Notes 3, 10)

Output Current (Note 3) 25 ±10 ±20 - mA

Output Resistance 25 - 30 - Ω

Full Power Bandwidth

(Notes 3, 7)

TRANSIENT RESPONSE (Note 8)

Rise Time 25 - 7 - ns

Overshoot 25 - 15 - %

Slew R a t e 25 550 600 - V/µs

Settling Time: 10V Step to 0.1% 25 - 180 - ns

POWER REQUIREMENTS

Supply Current Full - 20 25 mA

Power Supply Rejection Ratio (Note 9) Full 60 70 - dB

= ±15V, RL = 1kW, CL < 10pF, Unless Otherwise Specified (Continued)

SUPPLY

TEMP.

o

(

C) MIN TYP MAX UNITS

Full ±10.0 - - V

25 8.7 9.5 - MHz

NOTES:

= 1kΩ, VO = ±10V.

3. R

L

= ±10.0V.

4. V

CM

= 90mV.

5. V

O

6. A

= 10.

V

7. Full Power Bandwidth guaranteed based on slew rate measurement using: .

8. Refer to Test Circuits section of data sheet.

9. V

10. Guaranteed range for output voltage is ±10V. Functional operation outside of this range is not guaranteed.

= +5V, -15V and +15V, -5V.

SUPPLY

FPBW

Slew Rate

---------------------------- -=

2π V

PEAK

3

Page 4

Test Circuits and Waveforms

www.BDTIC.com/Intersil

HA-2539

IN

A

B

+

900Ω

100Ω

FIGURE 1. TEST CIRCUIT

OUT

NOTES:

11. V

12. A

13. C

= ±15V.

S

= +10.

V

≤ 10pF.

L

Vertical Scale: A = 0.5V/Div., B = 5.0V/Div.

Horizontal Scale: 50ns/Div.

FIGURE 2. LARGE SIGNAL RESPONSE FIGURE 3. SMALL SIGNAL RESPONSE

0.001µF

V+

INPUT

200Ω

500Ω

SETTLE

POINT

1µF

-

+

0.001µF

V-

1µF

2kΩ

5kΩ

Vertical Scale: Input = 10mV/Div., Output = 50mV/Div.

Horizontal Scale: 20ns/Div.

NOTES:

14. A

= -10.

V

15. Load Capacitance should be less than 10pF.

OUTPUT

<10pF

PROBE

MONITOR

FIGURE 4. SETTLING TIME CIRCUIT

16. It is recommended that resistors be carbon composition and that

feedback and summing network ratios be matched to 0.1%.

17. SETTLE POINT (Summing Node) capacitance should be less

than 10pF. For optimum settling time results, it is recommended

that the test circuit be constructed directly onto the device pins.

A Tektronix 568 Sampling Oscilloscope with S-3A sampling

heads is recommended as a settle point monitor.

4

Page 5

Schematic Diagram

www.BDTIC.com/Intersil

R

23

Q

P22

R

R

22

+INPUT

Q

P23

-INPUT

Z

1

R

D

Z1

HA-2539

V+

R

N7

4

Q

P6

Q

N9

Q

P8

Q

N10

Q

N16

R

18

OUTPUT

R

19

Q

P11

R

24

25

Q

N14

R

1

2

Q

P18

Q

V-

Q

N21

R

21

V+

Q

N20

P19

Q

P28

Q

R

13

Q

P25

V-

V+

Q

N25

R

Q

N1

R

6

R

8

Q

P3

10

P17

R

3

R

5

Q

P5

C

Q

N2

R

7

R

9

Q

P4

Q

N15

1

R

Q

Q

N12

R

16

Q

N13

D

Z2

R

R

11

12

Q

N29

R

14

R

15

R

17

V-

5

Page 6

Typical Applications

www.BDTIC.com/Intersil

20 - 100pF

20Ω

+

-

SET A

HA-2539

HA-2539

R

1

= 1+

V

R

1

R

2

= 5

R

2

R

1

-

+

SET AV =

R

2

Z

IN

-R

2

= -3

R

1

FIGURE 5. FREQUENCY COMPENSATION BY OVERDAMPING FIGURE 6. STABILIZATION USING Z

R5 1kΩ R4 10kΩ

INPUT

10kΩ

R

1

3900pF

C

1

-

+

HA-5170

0.039µF

C

2

1kΩ

R

2

R

3

1kΩ

HA-2539

-

+

OUTPUT

IN

FIGURE 7. REDUCING DC ERRORS; COMPOSITE AMPLIFIER FIGURE 8. DIFFERENTIAL GAIN ERROR (3%) HA-2539 20dB

VIDEO GAIN BLOCK

Typical Performance Curves

14

12

10

8

6

4

INPUT BIAS CURRENT (µA)

2

0

-80 -40 0 40 80 120 160

OFFSET VOLTAGE

BIAS CURRENT

TEMPERATURE (

o

C)

FIGURE 9. INPUT OFFSET VOLTAGE AND BIAS CURRENT vs

TEMPERATURE

7

R

6

5

4

3

2

| OFFSET VOLTAGE (mV)

IO

|V

1

0

25

20

15

10

5

NOISE VOLTAGE (nV/√Hz)

VOLTAGE NOISE

0

10 100 1K 10K 100K

= 0Ω

SOURCE

FREQUENCY (Hz)

VS = ±15V

CURRENT NOISE

50

40

30

20

10

0

FIGURE 10. INPUT NOISE VOLTAGE AND NOISE CURRENT vs

FREQUENCY

)

NOISE CURRENT (pA/√Hz

6

Page 7

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

+40µV

+30µV

+20µV

HA-2539

100

+10µV

0µV

-10µV

-20µV

-30µV

-40µV

Vertical Scale: 10mV/Div.

Horizontal Scale: 50ms/Div.

80

60

CMRR (dB)

40

20

0

1K 10K 100K 1M 10M

FREQUENCY (Hz)

FIGURE 11. BROADBAND NOISE (0.1Hz TO 1MHz) FIGURE 12. COMMON MODE REJECTION RATIO vs

FREQUENCY

100

100

80

60

PSRR (dB)

40

20

80

60

40

GAIN (dB)

20

PHASE

0

GAIN

0

45

90

135

180

PHASE (DEGREES)

0

1K 10K 100K 1M 10M

FREQUENCY (Hz)

FIGURE 13. POWER SUPPLY REJECTION RATIO vs

-20

1K 10K 100K 1M 10M100 100M

FREQUENCY (Hz)

FIGURE 14. OPEN LOOP GAIN/PHASE vs FREQUENCY

FREQUENCY

28

100

VS = ±15V

90

80

70

60

50

40

30

20

CLOSED LOOP GAIN (dB)

10

0

-10

1K 10K 100K 1M 10M100 100M

FREQUENCY (Hz)

24

)

P-P

20

16

12

8

OUTPUT VOLTAGE (V

4

0

1K 10K 100K 1M 10M 100M

VS = ±15V

VS = ±10V

VS = ±5V

FREQUENCY (Hz)

FIGURE 15. CLOSED LOOP FREQUENCY RESPONSE FIGURE 16. OUTPUT VOLTAGE SWING vs FREQUENCY

225

7

Page 8

Typical Performance Curves (Continued)

www.BDTIC.com/Intersil

HA-2539

1.4

28

)

24

P-P

20

16

12

8

4

OUTPUT VOLTAGE SWING (V

0

0 200 400 600 800 1K 1.2K

RESISTANCE (Ω)

1.3

C

o

1.2

1.1

1.0

0.9

0.8

NORMALIZED PARAMETERS

REFERRED TO VALUES AT 25

0.7

0.6

-80 -40 0 40 80 120 160

BANDWIDTH

TEMPERATURE (

o

C)

SLEW RATE

FIGURE 17. OUTPUT VOLTAGE SWING vs LOAD RESISTANCE FIGURE 18 . NORMALIZED A C PARAMETE RS vs TEMPE RATUR E

28

10

8

6

4

2

0

-2

-4

-6

-8

OUTPUT VOLTAGE STEP (V)

-10

10mV

10mV

1mV

1mV

24

20

16

12

SUPPLY CURRENT (mA)

VS = ±15V

VS = ±5V

8

4

0 40 80 120 160 200 240

SETTLING TIME (ns)

FIGURE 19. SETTLING TIME FOR VARIOUS OUTPUT STEP

VOLTAGES

0

-80 -40 0 40 80 120 160

TEMPERATURE (

o

C)

FIGURE 20. POWER SUPPLY CURRENT vs TEMPERATURE

8

Page 9

Die Characteristics

www.BDTIC.com/Intersil

HA-2539

DIE DIMENSIONS:

62 mils x 76 mils x 19 mils

1575µm x 1930µm x 483µm

METALLIZATION:

Type: Al, 1% Cu

Thickness: 16kÅ ±2kÅ

PASSIVATION:

Type: Nitride (Si

Silox Thickness: 12k

Nitride Thickness: 3.5kÅ ±1.5kÅ

) over Silox (SiO2, 5% Phos.)

3N4

Å ±2kÅ

Metallization Mask Layout

V-

SUBSTRATE POTENTIAL (POWERED UP):

V-

TRANSISTOR COUNT:

30

PROCESS:

Bipolar Dielectric Isolation

+IN

OUTPUT

V+

-IN

9

Page 10

Dual-In-Line Plastic Packages (PDIP)

www.BDTIC.com/Intersil

HA-2539

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English

and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpendicular to datum .

7. e

strained. e

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 -

1.14mm).

12 3 N/2

-A-

D1

B1

B

e

A

and eC are measured at the lead tips with the leads uncon-

B

D

e

0.010 (0.25) C AM BS

-C-

must be zero or greater.

C

E14.3 (JEDEC MS-001-AA ISSUE D)

14 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8

C 0.008 0.014 0.204 0.355 -

D 0.735 0.775 18.66 19.68 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

L 0.115 0.150 2.93 3.81 4

N14 149

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

NOTESMIN MAX MIN MAX

Rev. 0 12/93

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is ca utioned to verify that data she ets are current before pl acing orders. Information fur nished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or othe rwise under any patent or patent rights of Intersil or its subsidia ries.

For information regarding Intersil Corporation and its products, see www.intersil.com

10

Loading...

Loading...