®

www.BDTIC.com/Intersil

HA-2510/883

Data Sheet FN3697.4January 3, 2006

High Slew Rate Operational Amplifier

The HA-2510/883 is a high performance operational

amplifier which sets the standards for maximum slew rate

and wide bandwidth operation in moderately powered,

internally compensated, monolithic devices. In addition to

excellent dynamic characteristics, this dielectrically isolated

amplifier also offers low offset current and high input

impedance.

The ±50V/µs minimum slew rate and fast settling time of

the HA-2510/883 are ideally suited for high speed D/A,

A/D, and pulse amplification designs. The HA-2510/883’s

superior bandwidth and 750kHz minimum full power

bandwidth are extremely useful in RF and video

applications. To insure compliance with slew rate and

transient response specifications, all devices are 100%

tested for AC performance characteristics over full

temperature limits. To improve signal conditioning accuracy,

the HA-2510/883 provides a maximum offset current of 25nA

and a minimum input impedance of 50MΩ, both at 25

o

C, as

well as offset voltage adjust capability.

Ordering Information

TEMP.

PART

NUMBER

HA2-2510/883 HA2-2510/883 -55 to 125 8 Pin Can T8.C

PAR T

MARKING

RANGE

o

C) PACKAGE

(

PKG.

DWG.

#

Features

• This Circuit is Processed in Accordance to MIL-STD-883

and is Fully Conformant Under the Provisions of

Paragraph 1.2.1.

• High Slew Rate . . . . . . . . . . . . . . . . . . . . . . .50V/µs (Min)

65V/µs (Typ)

• Wide Power Bandwidth . . . . . . . . . . . . . . . . 750kHz (Min)

• Low Offset Current . . . . . . . . . . . . . . . . . . . . . . 25nA (Min)

10nA (Typ)

• High Input Impedance . . . . . . . . . . . . . . . . . . 50MΩ (Min)

100MΩ (Typ)

• Wide Small Signal Bandwidth . . . . . . . . . . . .12MHz (Typ)

• Fast Settling Time (0.1% of 10V Step) . . . . . . 250ns (Typ)

• Low Quiescent Supply Current . . . . . . . . . . . . 6mA (Max)

• Internally Compensated For Unity Gain Stability

Applications

• Data Acquisition Systems

•RF Amplifiers

• Video Amplifiers

• Signal Generators

• Pulse Amplification

HA7-2510/883 HA7-2510/883 -55 to 125 8 Ld CERDIP F8.3A

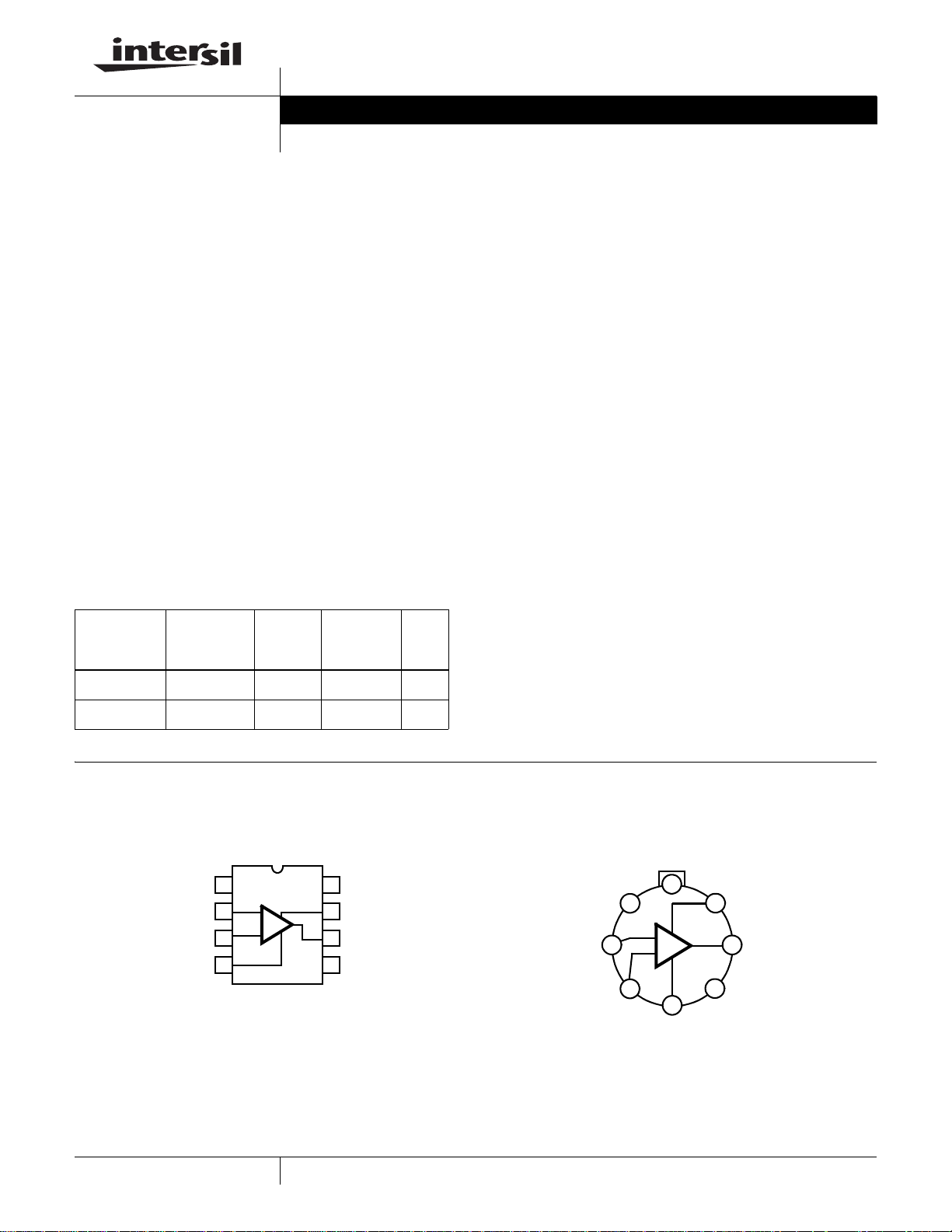

Pinouts

HA-2510/883

(CERDIP)

TOP VIEW

BAL

-IN

+IN

1

2

+

3

V-

4

8

7

6

5

COMP

V+

OUT

BAL

-IN

BAL

2

+IN

HA-2510/883

(METAL CAN)

TOP VIEW

COMP

8

1

-

+

3

4

V-

V+

7

OUT

6

BAL

5

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2002, 2004, 2005, 2006. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

HA-2510/883

www.BDTIC.com/Intersil

Absolute Maximum Ratings Thermal Information

Voltage Between V+ and V- Terminals . . . . . . . . . . . . . . . . . . . .40V

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15V

Voltage at Either Input Terminal . . . . . . . . . . . . . . . . . . . . . V+ to V-

Peak Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50mA

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<2000V

Operating Conditions

Temperature Range. . . . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±15V

≤ 1/2 (V+ - V-)

V

INCM

R

≥ 2kΩ

L

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θ

is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief TB379

JA

for details.

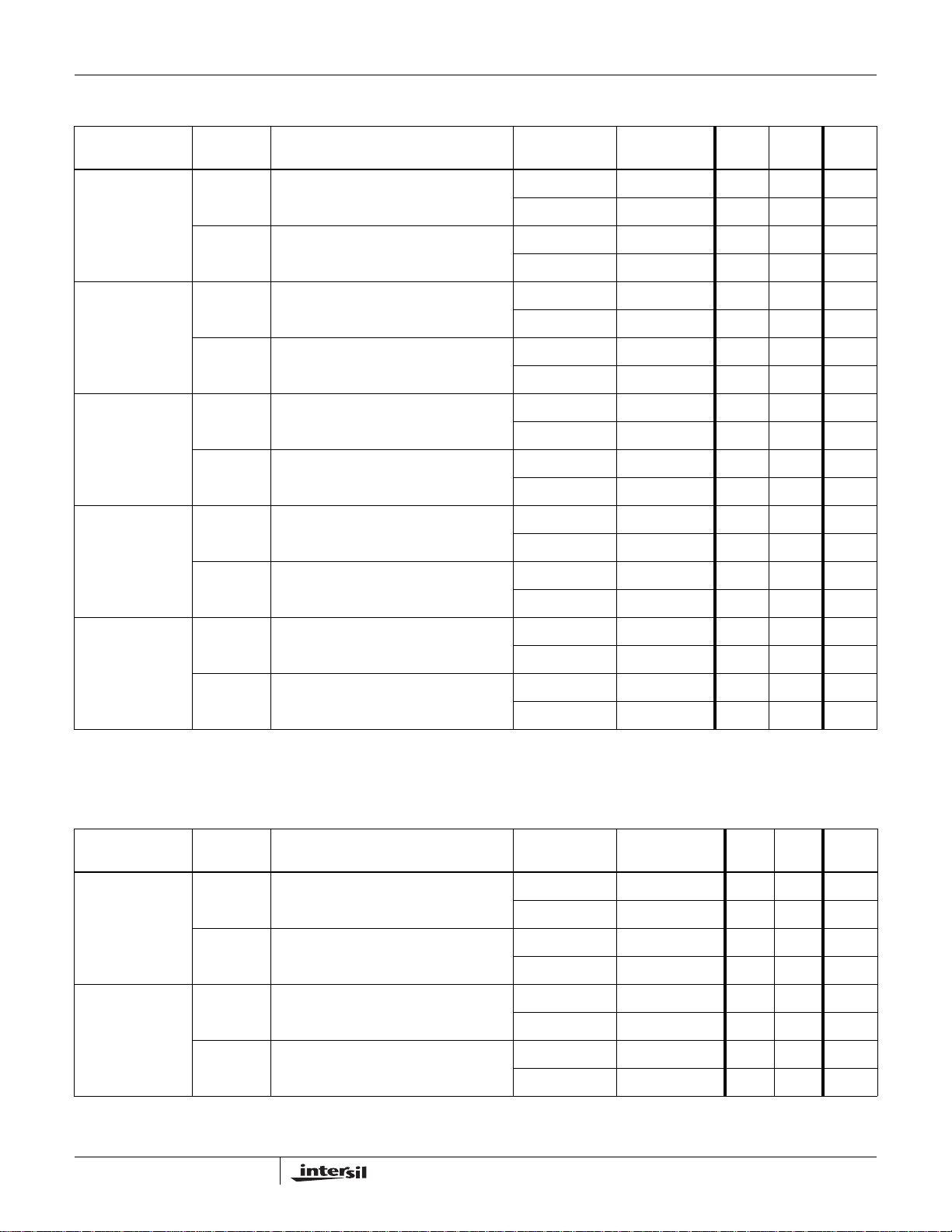

TABLE 1. DC ELECTRICAL PERFORMANCE CHARACTERISTICS

Device Tested at: V

PARAMETER SYMBOL CONDITIONS

SUPPLY

= ±15V, R

SOURCE

= 100Ω, R

LOAD

= 500kΩ, V

Thermal Resistance (Typical, Note 1) θ

Metal Can Package . . . . . . . . . . . . . . . . . 160oC/W 75oC/W

CERDIP Package. . . . . . . . . . . . . . . . . . . 120

Package Power Dissipation Limit at 75

Metal Can Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .625mW

CERDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .870mW

Package Power Dissipation Derating Factor Above 75

Metal Can Package . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3mW/

CERDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.7mW/

Maximum Junction Temperature. . . . . . . . . . . . . . . . . . . . . . .175

Maximum Storage Temperature Range . . . . . . . . . -65

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . .300

= 0V, Unless Otherwise Specified.

OUT

GROUP A

SUBGROUPS TEMP (

o

o

C) MIN MAX UNITS

JA

o

C/W 30oC/W

C for TJ ≤ 175oC

θ

o

C

o

C to 150oC

JC

o

o

o

o

C

C

C

C

Input Offset

Voltage

Input Bias Current +I

Input Offset

Current

Common Mode

Range

Large Signal

Voltage Gain

Common Mode

Rejection Ratio

+CMR V+ = 5V, V- = -25V 1 25 +10 - V

-CMR V+ = 25V, V- = -5V 1 25 - -10 V

+A

-A

+CMRR ∆V

V

-I

I

VOL

IO

B

B

IO

VOL

VCM = 0V 1 25 -8 8 mV

2, 3 125, -55 -18 10 mV

VCM = 0V, +RS = 100kΩ, -RS = 100Ω 1 25 -200 200 nA

2, 3 125, -55 -400 400 nA

VCM = 0V, +RS = 100Ω, -RS = 100kΩ 1 25 -200 200 nA

2, 3 125, -55 -400 400 nA

VCM = 0V, +RS = 100kΩ, -RS = 100kΩ 1 25 -25 25 nA

2, 3 125, -55 -50 50 nA

2, 3 125, -55 +10 - V

2, 3 125, -55 - -10 V

V

= 0V and +10V, RL = 2kΩ 42510-kV/V

OUT

5, 6 125, -55 7.5 - kV/V

V

= 0V and -10V, RL = 2kΩ 42510-kV/V

OUT

5, 6 125, -55 7.5 - kV/V

= +10V, V+ = +5V, V- = -25V, V

CM

= -10V

OUT

12580-dB

2, 3 125, -55 80 - dB

-CMRR ∆V

+10V

= -10V, V+ = +25V, V- = -5V, V

CM

OUT

=

12580-dB

2, 3 125, -55 80 - dB

2

FN3697.4

January 3, 2006

TABLE 1. DC ELECTRICAL PERFORMANCE CHARACTERISTICS (Continued)

www.BDTIC.com/Intersil

Device Tested at: V

PARAMETER SYMBOL CONDITIONS

SUPPLY

= ±15V, R

SOURCE

= 100Ω, R

HA-2510/883

= 500kΩ, V

LOAD

= 0V, Unless Otherwise Specified.

OUT

GROUP A

SUBGROUPS TEMP (

o

C) MIN MAX UNITS

Output Voltage

Swing

Output Current +I

Quiescent Power

Supply Current

Power Supply

Rejection Ratio

Offset Voltage

Adjustment

NOTE:

2. Offset adjustment range is [V

+V

OUT

-V

OUT

OUT

-I

OUT

+I

-I

CC

+PSRR ∆V

-PSRR ∆V

+V

IO

-V

IO

RL = 2kΩ 42510-V

5, 6 125, -55 10 - V

RL = 2kΩ 425--10V

5, 6 125, -55 - -10 V

V

= -10V 4 25 10 - mA

OUT

5, 6 125, -55 7.5 - mA

V

= +10V 4 25 - -10 mA

OUT

5, 6 125, -55 - -7.5 mA

V

CC

Adj Note 2 1 25 VIO-1 - mV

Adj Note 2 1 25 VIO+1 - mV

IO

= 0V,

OUT

I

= 0mA

OUT

V

= 0V,

OUT

I

= 0mA

OUT

= 10V, V+ = +20V, V- = -15V,

SUP

V+ = +10V, V- = -15V

= 10V, V+ = +15V, V- = -20V,

SUP

V+ = +15V, V- = -10V

(Measured) ±1mV] minimum referred to output. This test is for functionality only to assure adjustment through 0V.

125-6mA

2, 3 125, -55 - 6.5 mA

125-6-mA

2, 3 125, -55 -6.5 - mA

12580-dB

2, 3 125, -55 80 - dB

12580-dB

2, 3 125, -55 80 - dB

2, 3 125, -55 V

2, 3 125, -55 V

-1 - mV

IO

+1 - mV

IO

TABLE 2. AC ELECTRICAL PERFORMANCE CHARACTERISTICS

Device Tested at: V

PARAMETER SYMBOL CONDITIONS

Slew Rate +SR V

Rise and Fall Time t

SUPPLY

= ±15V, R

-SR V

r

t

f

SOURCE

OUT

OUT

V

OUT

V

OUT

= 50Ω, R

= -5V to +5V, 25% ≤ +SR ≤ 75% 7 25 50 - V/µs

= +5V to -5V, 75% ≥ -SR ≥ 25% 7 25 50 - V/µs

= 0 to +200mV, 10% ≤ tr ≤ 90% 7 25 - 50 ns

= 0 to -200mV, 10% ≤ tf ≤ 90% 7 25 - 50 ns

LOAD

= 2kΩ, C

LOAD

= 50pF, A

GROUP A

SUBGROUPS TEMP (

= +1V/V, Unless Otherwise Specified.

VCL

8A, 8B 125, -55 45 - V/µs

8A, 8B 125, -55 45 - V/µs

8A, 8B 125, -55 - 60 ns

8A, 8B 125, -55 - 60 ns

3

o

C) MIN MAX UNITS

FN3697.4

January 3, 2006

TABLE 2. AC ELECTRICAL PERFORMANCE CHARACTERISTICS (Continued)

www.BDTIC.com/Intersil

Device Tested at: V

PARAMETER SYMBOL CONDITIONS

SUPPLY

= ±15V, R

SOURCE

= 50Ω, R

HA-2510/883

= 2kΩ, C

LOAD

LOAD

= 50pF, A

GROUP A

SUBGROUPS TEMP (

= +1V/V, Unless Otherwise Specified.

VCL

o

C) MIN MAX UNITS

Overshoot +OS V

-OS V

Device Characterized at: V

PARAMETER SYMBOL CONDITIONS NOTES TEMP (

Differential Input

Resistance

Full Power

Bandwidth

Minimum Closed Loop

Stable Gain

Quiescent Power

Consumption

NOTES:

3. Parameters listed in Table 3 are controlled via design or process parameters and are not directly tested at final production. These parameters

are lab characterized upon initial design release, or upon design changes. These parameters are guaranteed by characterization based upon

data from multiple production runs which reflect lot to lot and within lot variation.

4. Full Power Bandwidth guarantee based on Slew Rate measurement using FPBW = Slew Rate/(2πV

5. Quiescent Power Consumption based upon Quiescent Supply Current test maximum. (No load on outputs.)

SUPPLY

R

IN

FPBW V

CLSG R

PC V

= 0 to +200mV 7 25 - 40 %

OUT

8A, 8B 125, -55 - 50 %

= 0 to -200mV 7 25 - 40 %

OUT

8A, 8B 125, -55 - 50 %

TABLE 3. ELECTRICAL PERFORMANCE CHARACTERISTICS

= ±15V, R

VCM = 0V 3 25 50 - MΩ

PEAK

= 2kΩ, CL = 50pF 3 -55 to 125 1 - V/V

L

OUT

= 2kΩ, C

LOAD

= 10V 3, 4 25 750 - kHz

= 0V, I

= 0mA 3, 5 -55 to 125 - 195 mW

OUT

= 50pF, Unless Otherwise Specified.

LOAD

o

C) MIN MAX UNITS

).

PEAK

TABLE 4. ELECTRICAL TEST REQUIREMENTS

MIL-STD-883 TEST REQUIREMENTS SUBGROUPS (SEE TABLES 1 AND 2)

Interim Electrical Parameters (Pre Burn-In) 1

Final Electrical Test Parameters 1 (Note 6), 2, 3, 4, 5, 6, 7, 8A, 8B

Group A Test Requirements 1, 2, 3, 4, 5, 6, 7, 8A, 8B

Groups C and D Endpoints 1

NOTE:

6. PDA applies to Subgroup 1 only.

4

FN3697.4

January 3, 2006

Die Characteristics

www.BDTIC.com/Intersil

SUBSTRATE POTENTIAL (Powered Up):

Unbiased

TRANSISTOR COUNT:

40

PROCESS: Bipolar Dielectric Isolation

Metallization Mask Layout

HA-2510/883HA-2510/883

HA-2510/883

Burn-In Circuit

+IN

V-

BAL

HA7-2510/883

OUT

BAL-IN

COMP

V+

V-

D

2

= 1MΩ, ±5%, 1/4W (Min)

R

1

= C2 = 0.01µF/Socket (Min) or 0.1µF/Row (Min)

C

1

= 0.01µF/Socket (10%)

C

3

D

= D2 = 1N4002 or Equivalent/Board

1

|(V+) - (V-)| = 30V

1

2

R

1

-

+

3

4

C

2

8

7

C

6

5

3

5

V+

C

D

1

1

FN3697.4

January 3, 2006

Metal Can Packages (Can)

www.BDTIC.com/Intersil

HA-2510/883

REFERENCE PLANE

A

ØD ØD1

F

Q

Øb1

NOTES:

1. (All leads) Øb applies between L1 and L2. Øb1 applies between

L2 and 0.500 from the reference plane. Diameter is uncontrolled

in L1 and beyond 0.500 from the reference plane.

2. Measured from maximum diameter of the product.

α is the basic spacing from the centerline of the tab to terminal 1

3.

and β is the basic spacing of each lead or lead position (N -1

places) from

4. N is the maximum number of terminal positions.

5. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

6. Controlling dimension: INCH.

α, looking at the bottom of the package.

L

L2

L1

A

A

Øe

Øb1

Øb

BASE AND

SEATING PLANE

BASE METAL LEAD FINISH

SECTION A-A

Øb2

e1

ØD2

2

β

N

1

α

k

T8.C MIL-STD-1835 MACY1-X8 (A1)

8 LEAD METAL CAN PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.165 0.185 4.19 4.70 -

Øb 0.016 0.019 0.41 0.48 1

k1

C

L

Øb1 0.016 0.021 0.41 0.53 1

Øb2 0.016 0.024 0.41 0.61 -

ØD 0.335 0.375 8.51 9.40 ØD1 0.305 0.335 7.75 8.51 ØD2 0.110 0.160 2.79 4.06 -

e 0.200 BSC 5.08 BSC -

e1 0.100 BSC 2.54 BSC -

F-0.040 - 1.02 -

k 0.027 0.034 0.69 0.86 -

k1 0.027 0.045 0.69 1.14 2

L 0.500 0.750 12.70 19.05 1

L1 - 0.050 - 1.27 1

L2 0.250 - 6.35 -1

Q 0.010 0.045 0.25 1.14 -

α

β 45

N8 84

45o BSC 45o BSC 3

o

BSC 45o BSC 3

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

6

FN3697.4

January 3, 2006

HA-2510/883

www.BDTIC.com/Intersil

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

c1

LEAD FINISH

-D-

BASE

M

SECTION A-A

METAL

b1

M

(b)

α

E

S

S

D

Q

A

-C-

L

eA

eA/2

M

aaa CA - B

c

S

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc C A - BMD

-A-

-B-

S

D

A

A

e

S

S

NOTES:

1. Index area: A notch or a pin one identification mark shall be

located adjacent to pin one and shall be located within the

shaded area shown. The manufacturer’s identification shall not

be used as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

D

F8.3A MIL-STD-1835 GDIP1-T8 (D-4, CONFIGURATION A)

8 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

(c)

SYMBOL

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c1 0.008 0.015 0.20 0.38 3

S

eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

S1 0.005 - 0.13 -7

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 -

ccc - 0.010 - 0.25 -

INCHES MILLIMETERS

NOTESMIN MAX MIN MAX

A-0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

c 0.008 0.018 0.20 0.46 2

D-0.405 - 10.29 5

E 0.220 0.310 5.59 7.87 5

e 0.100 BSC 2.54 BSC -

L 0.125 0.200 3.18 5.08 Q 0.015 0.060 0.38 1.52 6

o

α

90

105

o

90

o

105

o

-

M-0.0015 - 0.038 2, 3

N8 88

Rev. 0 4/94

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

7

FN3697.4

January 3, 2006

Loading...

Loading...