®

82C55A

Data Sheet August 25, 2005

CMOS Programmable Peripheral Interface

The Intersil 82C55A is a high performance CMOS version of

the industry standard 8255A and is manufactured using a

self-aligned silicon gate CMOS process (Scaled SAJI IV). It

is a general purpose programmable I/O device which may

be used with many different microprocessors. There are 24

I/O pins which may be individually programmed in 2 groups

of 12 and used in 3 major modes of operation. The high

performance and industry standard configuration of the

82C55A make it compatible with the 80C86, 80C88 and

other microprocessors.

Static CMOS circuit design insures low operating power. TTL

compatibility over the full military temperature range and bus

hold circuitry eliminate the need for pull-up resistors. The

Intersil advanced SAJI process results in performance equal

to or greater than existing functionally equivalent products at

a fraction of the power.

Ordering Information

FN2969.8

Features

• Pb-Free Plus Anneal Available (RoHS Compliant)

(See Ordering Info)

• Pin Compatible with NMOS 8255A

• 24 Programmable I/O Pins

• Fully TTL Compatible

• High Speed, No “Wait State” Operation with 5MHz and

8MHz 80C86 and 80C88

• Direct Bit Set/Reset Capability

• Enhanced Control Word Read Capability

• L7 Process

• 2.5mA Drive Capability on All I/O Ports

• Low Standby Power (ICCSB). . . . . . . . . . . . . . . . . . .10µA

PAR T N U MBERS

PAR T

MARKING 8MHz

CP82C55A-5 CP82C55A-5 CP82C55A CP82C55A 0 to 70 40 Ld PDIP E40.6

CP82C55A-5Z (Note) CP82C55A-5Z CP82C55AZ (Note) CP82C55AZ 0 to 70 40 Ld PDIP (Pb-free)

IP82C55A IP82C55A -40 to 85 40 Ld PDIP

IP82C55AZ (Note) IP82C55AZ -40 to 85 40 Ld PDIP (Pb-free)

CS82C55A-5* CS82C55A-5 CS82C55A* CS82C55A* 0 to 70 44 Ld PLCC N44.65

CS82C55AZ* (Note) CS82C55AZ 0 to 70 44 Ld PLCC (Pb-free)

IS82C55A-5 IS82C55A-5 IS82C55A* IS82C55A* -40 to 85 44 Ld PLCC

IS82C55AZ* (Note) IS82C55AZ -40 to 85 44 Ld PLCC (Pb-free)

CQ82C55A* CQ82C55A* 0 to 70 44 Ld MQFP Q44.10x10

CQ82C55AZ (Note) CQ82C55AZ 0 to 70 44 Ld MQFP (Pb-free)

IQ82C55A* IQ82C55A* -40 to 85 44 Ld MQFP

IQ82C55AZ* (Note) IQ82C55AZ -40 to 85 44 Ld MQFP (Pb-free)

ID82C55A ID82C55A -40 to 85 40 Ld CERDIP F40.6

MD82C55A/B MD82C55A/B -55 to 125

8406602QA 8406602QA SMD#

8406602XA 8406602XA SMD# 44 Ld CLCC J44.A

*Add “96” suffix to part number for tape and reel packaging.

PAR T

MARKING

TEMP.

RANGE (°C) PACKAGE PKG. DWG. #5MHz

NOTE: Intersil Pb-free products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate termination

finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are MSL classified at Pbfree peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

Copyright Intersil Americas Inc. 2002, 2005. All Rights Reserved

All other trademarks mentioned are the property of their respective owners.

Pinouts

82C55A (PDIP, CERDIP)

TOP VIEW

PA3

1

PA2

2

PA1

3

PA0

4

RD

5

CS

6

GND

7

A1

8

A0

9

PC7

10

PC6

11

PC5

12

PC4

13

PC0

14

PC1

15

PC2

16

PC3

17

PB0

18

PB1

19

PB2

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

PA4

PA5

PA6

PA7

WR

RESET

D0

D1

D2

D3

D4

D5

D6

D7

V

CC

PB7

PB6

PB5

PB4

PB3

82C55A

82C55A (CLCC)

TOP VIEW

CS

RD

PA0

PA1

PA2

GND

7

NC

8

A1

9

A0

10

PC7

11

PC6

12

PC5

13

PC4

14

PC0

15

PC1

16

PC2

17

18 19 20 21 22 23 24 25 26 27 28

PC3

PB0

PB3

PB1

PB2

PA3

PA4

PA5

PB4

PB5

PB6

WR

PA6

PA7

4065 3 21444342414

NC

39

RESET

38

D0

37

D1

36

D2

35

D3

34

D4

33

D5

32

D6

31

D7

30

NC

29

CC

NC

PB7

V

CS

GND

A1

A0

PC7

NC

PC6

PC5

PC4

PC0

PC1

82C55A (PLCC)

TOP VIEW

RD

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

262524232221201918

PB4

PB5

PB6

2827

WR

PB7

RD

39

RESET

38

D0

D1

37

D2

36

D3

35

NC

34

D4

33

D5

32

D6

31

D7

30

V

29

CC

CS

GND

A1

A0

PC7

PC6

PC5

PC4

PC0

PC1

PC2

44 43 42 41 40

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17

NC

NC

44 43 42 41 40

123456

7

8

9

10

11

12

13

14

15

16

17

PB0

PB1

PB2

NC

PB3

PC2

PC3

82C55A (MQFP)

PA0

PA1

PA2

PC3

PB0

PB1

TOP VIEW

NC

PA4

NC

PA5

PB3

PB4

PA3

39 38 37 36 35 34

PB2

PA6

PA7

WR

33

32

31

30

29

28

27

26

25

24

23

2221201918

NC

PB5

PB6

RESET

D0

D1

D2

D3

D4

D5

D6

D7

V

CC

PB7

2

FN2969.8

August 25, 2005

82C55A

Pin Description

SYMBOL TYPE DESCRIPTION

V

CC

GND GROUND

D0-D7 I/O DATA BUS: The Data Bus lines are bidirectional three-state pins connected to the system data bus.

RESET I RESET: A high on this input clears the control register and all ports (A, B, C) are set to the input mode with the “Bus

CS

RD

WR I WRITE: Write is an active low input control signal used by the CPU to load control words and data into the 82C55A.

A0-A1 I ADDRESS: These input signals, in conjunction with the RD

PA0-PA7 I/O PORT A: 8-bit input and output port. Both bus hold high and bus hold low circuitry are present on this port.

PB0-PB7 I/O PORT B: 8-bit input and output port. Bus hold high circuitry is present on this port.

PC0-PC7 I/O PORT C: 8-bit input and output port. Bus hold circuitry is present on this port.

VCC: The +5V power supply pin. A 0.1µF capacitor between VCC and GND is recommended for decoupling.

Hold” circuitry turned on.

I CHIP SELECT: Chip select is an active low input used to enable the 82C55A onto the Data Bus for CPU

communications.

I READ: Read is an active low input control signal used by the CPU to read status information or data via the data bus.

and WR inputs, control the selection of one of the three

ports or the control word register. A0 and A1 are normally connected to the least significant bits of the Address Bus

A0, A1.

Functional Diagram

POWER

SUPPLIES

BIDIRECTIONAL

DATA BUS

D7-D0

RD

WR

A1

A0

RESET

+5V

GND

DATA BUS

BUFFER

READ

WRITE

CONTROL

LOGIC

GROUP A

CONTROL

GROUP B

CONTROL

8-BIT

INTERNAL

DATA BUS

GROUP A

PORT A

(8)

GROUP A

PORT C

UPPER

(4)

GROUP B

PORT C

LOWER

(4)

GROUP B

PORT B

(8)

I/O

PA7 -PA0

I/O

PC7-PC4

I/O

PC3-PC0

I/O

PB7-PB0

CS

3

FN2969.8

August 25, 2005

82C55A

Functional Description

Data Bus Buffer

This three-state bidirectional 8-bit buffer is used to interface

the 82C55A to the system data bus. Data is transmitted or

received by the buffer upon execution of input or output

instructions by the CPU. Control words and status

information are also transferred through the data bus buffer.

Read/Write and Control Logic

The function of this block is to manage all of the internal and

external transfers of both Data and Control or Status words.

It accepts inputs from the CPU Address and Control busses

and in turn, issues commands to both of the Control Groups.

(CS

) Chip Select. A “low” on this input pin enables the

communication between the 82C55A and the CPU.

(RD

) Read. A “low” on this input pin enables 82C55A to send

the data or status information to the CPU on the data bus. In

essence, it allows the CPU to “read from” the 82C55A.

(WR

) Write. A “low” on this input pin enables the CPU to

write data or control words into the 82C55A.

(A0 and A1) Port Select 0 and Port Select 1. These input

signals, in conjunction with the RD and WR inputs, control

the selection of one of the three ports or the control word

register. They are normally connected to the least significant

bits of the address bus (A0 and A1).

82C55A BASIC OPERATION

INPUT OPERATION

A1 A0 RD

00010Port A → Data Bus

01010Port B → Data Bus

10010Port C → Data Bus

11010Control Word → Data Bus

00100Data Bus → Port A

01100Data Bus → Port B

10100Data Bus → Port C

11100Data Bus → Control

XXXX1Data Bus → Three-State

XX110Data Bus → Three-State

WR CS

(RESET) Reset. A “high” on this input initializes the control

register to 9Bh and all ports (A, B, C) are set to the input

mode. “Bus hold” devices internal to the 82C55A will hold

the I/O port inputs to a logic “1” state with a maximum hold

current of 400µA.

(READ)

OUTPUT OPERATION

(WRITE)

DISABLE FUNCTION

I/O

PA7 -

POWER

SUPPLIES

BIDIRECTIONAL

DATA BUS

D7-D0

RD

WR

A1

A0

RESET

CS

FIGURE 1. 82C55A BLOCK DIAGRAM. DATA BUS BUFFER,

+5V

GND

DATA

BUS

BUFFER

READ

WRITE

CONTROL

LOGIC

READ/WRITE, GROUP A & B CONTROL LOGIC

FUNCTIONS

GROUP A

CONTROL

8-BIT

INTERNAL

DATA BUS

GROUP B

CONTROL

GROUP A

PORT A

(8)

GROUP A

PORT C

UPPER

(4)

GROUP B

PORT C

LOWER

(4)

GROUP B

PORT B

(8)

PA0

I/O

PC7-

PC4

I/O

PC3-

PC0

I/O

PB7-

PB0

Group A and Group B Controls

The functional configuration of each port is programmed by

the systems software. In essence, the CPU “outputs” a

control word to the 82C55A. The control word contains

information such as “mode”, “bit set”, “bit reset”, etc., that

initializes the functional configuration of the 82C55A.

Each of the Control blocks (Group A and Group B) accepts

“commands” from the Read/Write Control logic, receives

“control words” from the internal data bus and issues the

proper commands to its associated ports.

Control Group A - Port A and Port C upper (C7 - C4)

Control Group B - Port B and Port C lower (C3 - C0)

The control word register can be both written and read as

shown in the “Basic Operation” table. Figure 4 shows the

control word format for both Read and Write operations.

When the control word is read, bit D7 will always be a logic

“1”, as this implies control word mode information.

Ports A, B, and C

The 82C55A contains three 8-bit ports (A, B, and C). All can

be configured to a wide variety of functional characteristics

by the system software but each has its own special features

or “personality” to further enhance the power and flexibility of

the 82C55A.

Port A One 8-bit data output latch/buffer and one 8-bit data

input latch. Both “pull-up” and “pull-down” bus-hold devices

are present on Port A. See Figure 2A.

Port B One 8-bit data input/output latch/buffer and one 8-bit

data input buffer. See Figure 2B.

Port C One 8-bit data output latch/buffer and one 8-bit data

input buffer (no latch for input). This port can be divided into

4

FN2969.8

August 25, 2005

82C55A

two 4-bit ports under the mode control. Each 4-bit port

contains a 4-bit latch and it can be used for the control signal

output and status signal inputs in conjunction with ports A

and B. See Figure 2B.

MASTER

RESET

OR MODE

CHANGE

INTERNAL

DATA IN

INTERNAL

DATA OUT

(LATCHED)

FIGURE 2A. PORT A BUS-HOLD CONFIGURATION

RESET

OR MODE

CHANGE

INTERNAL

DATA IN

INTERNAL

DATA OUT

(LATCHED)

FIGURE 2B. PORT B AND C BUS-HOLD CONFIGURATION

FIGURE 2. BUS-HOLD CONFIGURATION

INPUT MODE

OUTPUT MODE

OUTPUT MODE

V

CC

P

EXTERNAL

PORT A PIN

EXTERNAL

PORT B, C

PIN

Operational Description

Mode Selection

There are three basic modes of operation than can be

selected by the system software:

Mode 0 - Basic Input/Output

Mode 1 - Strobed Input/Output

Mode 2 - Bidirectional Bus

When the reset input goes “high”, all ports will be set to the

input mode with all 24 port lines held at a logic “one” level by

internal bus hold devices. After the reset is removed, the

82C55A can remain in the input mode with no additional

initialization required. This eliminates the need to pull-up or

pull-down resistors in all-CMOS designs. The control word

register will contain 9Bh. During the execution of the system

program, any of the other modes may be selected using a

single output instruction. This allows a single 82C55A to

service a variety of peripheral devices with a simple software

maintenance routine. Any port programmed as an output

port is initialized to all zeros when the control word is written.

ADDRESS BUS

CONTROL BUS

DATA BUS

MODE 0

MODE 1

MODE 2

RD, WR

B

8I/O

PB7-PB0

B

8I/O

PB7-PB0 CONTROL

B

8I/O

PB7-PB0

D7-D0 A0-A1

82C55A

C

4I/O

PC3-PC0

OR I/O

PC7-PC4

C

CONTROL

OR I/O

C

CONTROL

4I/O

CS

A

8I/O

PA7 -PA0

A

8I/O

PA7 -PA0

A

PA7 -PA0

BIDIRECTIONAL

FIGURE 3. BASIC MODE DEFINITIONS AND BUS INTERFACE

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

GROUP B

PORT C (LOWER)

1 = INPUT

0 = OUTPUT

PORT B

1 = INPUT

0 = OUTPUT

MODE SELECTION

0 = MODE 0

1 = MODE 1

GROUP A

PORT C (UPPER)

1 = INPUT

0 = OUTPUT

PORT A

1 = INPUT

0 = OUTPUT

MODE SELECTION

00 = MODE 0

01 = MODE 1

1X = MODE 2

MODE SET FLAG

1 = ACTIVE

FIGURE 4. MODE DEFINITION FORMAT

5

FN2969.8

August 25, 2005

82C55A

The modes for Port A and Port B can be separately defined,

while Port C is divided into two portions as required by the

Port A and Port B definitions. All of the output registers,

including the status flip-flops, will be reset whenever the

mode is changed. Modes may be combined so that their

functional definition can be “tailored” to almost any I/O

structure. For instance: Group B can be programmed in

Mode 0 to monitor simple switch closings or display

computational results, Group A could be programmed in

Mode 1 to monitor a keyboard or tape reader on an interruptdriven basis.

The mode definitions and possible mode combinations may

seem confusing at first, but after a cursory review of the

complete device operation a simple, logical I/O approach will

surface. The design of the 82C55A has taken into account

things such as efficient PC board layout, control signal

definition vs. PC layout and complete functional flexibility to

support almost any peripheral device with no external logic.

Such design represents the maximum use of the available

pins.

Single Bit Set/Reset Feature (Figure 5)

Any of the eight bits of Port C can be Set or Reset using a

single Output instruction. This feature reduces software

requirements in control-based applications.

When Port C is being used as status/control for Port A or B,

these bits can be set or reset by using the Bit Set/Reset

operation just as if they were output ports.

CONTROL WORD

D7 D6 D5 D4 D3 D2 D1 D0

XXX

DON’T

CARE

FIGURE 5. BIT SET/RESET FORMAT

BIT SET/RESET

1 = SET

0 = RESET

BIT SELECT

0

1234567

01010101

00110011

00001111

BIT SET/RESET FLAG

0 = ACTIVE

B0

B1

B2

Interrupt Control Functions

When the 82C55A is programmed to operate in mode 1 or

mode 2, control signals are provided that can be used as

interrupt request inputs to the CPU. The interrupt request

signals, generated from port C, can be inhibited or enabled

by setting or resetting the associated INTE flip-flop, using

the bit set/reset function of port C.

This function allows the programmer to enable or disable a

CPU interrupt by a specific I/O device without affecting any

other device in the interrupt structure.

INTE Flip-Flop Definition

(BIT-SET)-INTE is SET - Interrupt Enable

(BIT-RESET)-INTE is Reset - Interrupt Disable

NOTE: All Mask flip-flops are automatically reset during mode

selection and device Reset.

Operating Modes

Mode 0 (Basic Input/Output). This functional configuration

provides simple input and output operations for each of the

three ports. No handshaking is required, data is simply

written to or read from a specific port.

Mode 0 Basic Functional Definitions:

• Two 8-bit ports and two 4-bit ports

• Any Port can be input or output

• Outputs are latched

• Inputs are not latched

• 16 different Input/Output configurations possible

MODE 0 PORT DEFINITION

A B GROUP A

PORT C

D4 D3 D1 D0 PORT A

0 0 0 0 Output Output 0 Output Output

0 0 0 1 Output Output 1 Output Input

0 0 1 0 Output Output 2 Input Output

0 0 1 1 Output Output 3 Input Input

0 1 0 0 Output Input 4 Output Output

0 1 0 1 Output Input 5 Output Input

0 1 1 0 Output Input 6 Input Output

0 1 1 1 Output Input 7 Input Input

1 0 0 0 Input Output 8 Output Output

1 0 0 1 Input Output 9 Output Input

1 0 1 0 Input Output 10 Input Output

1 0 1 1 Input Output 11 Input Input

1 1 0 0 Input Input 12 Output Output

1 1 0 1 Input Input 13 Output Input

1 1 1 0 Input Input 14 Input Output

1 1 1 1 Input Input 15 Input Input

(Upper) PORT B

#

GROUP B

PORT C

(Lower)

6

FN2969.8

August 25, 2005

Mode 0 (Basic Input)

RD

82C55A

tRR

tHR

tRA

CS

tIR

INPUT

tAR

, A1, A0

D7-D0

tRD tDF

Mode 0 (Basic Output)

tWW

tDW

tWD

tWB

CS

, A1, A0

OUTPUT

WR

D7-D0

tAW

Mode 0 Configurations

CONTROL WORD #0 CONTROL WORD #2

D7

1

0D60D50D40D30D20D10

D7 - D0

82C55A

D0

1D70D60D50D40D30D21D10

8

4

4

PA7 - PA0

PC7 - PC4

D7 - D0

PC3 - PC0

A

C

tWA

82C55A

C

D0

8

4

4

PA7 - PA0

PC7 - PC4

PC3 - PC0

A

8

B

PB7 - PB0

CONTROL WORD #1 CONTROL WORD #3

D0

1D70D60D50D40D30D20D11

82C55A

D7 - D0

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

A

C

B

1D70D60D50D40D30D21D11

D7 - D0

7

82C55A

C

D0

8

8

4

4

8

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

August 25, 2005

FN2969.8

B

A

B

82C55A

Mode 0 Configurations (Continued)

CONTROL WORD #4 CONTROL WORD #8

D0

1D70D60D50D41D30D20D10

82C55A

D7 - D0

8

4

4

PA7 - PA0

PC7 - PC4

PC3 - PC0

A

C

1D70D60D51D40D30D20D10

D7 - D0

82C55A

C

D0

8

4

4

PA7 - PA0

PC7 - PC4

PC3 - PC0

A

8

B

PB7 - PB0

CONTROL WORD #5 CONTROL WORD #9

D0

1D70D60D50D41D30D20D11

82C55A

D7 - D0

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

A

C

B

1D70D60D51D40D30D20D11

D7 - D0

CONTROL WORD #6 CONTROL WORD #10

D0

1D70D60D50D41D30D21D10

82C55A

D7 - D0

8

4

4

PA7 - PA0

PC7 - PC4

PC3 - PC0

A

C

1D70D60D51D40D30D21D10

D7 - D0

82C55A

C

82C55A

C

D0

D0

8

8

4

4

8

8

4

4

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

B

A

B

A

8

B

PB7 - PB0

CONTROL WORD #7 CONTROL WORD #11

D0

1D70D60D50D41D30D21D11

82C55A

D7 - D0

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

A

C

B

1D70D60D51D40D30D21D11

D7 - D0

8

82C55A

C

D0

8

8

4

4

8

PB7 - PB0

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

August 25, 2005

FN2969.8

B

A

B

82C55A

Mode 0 Configurations (Continued)

CONTROL WORD #12 CONTROL WORD #14

D0

1D70D60D51D41D30D20D10

82C55A

D7 - D0

8

4

4

PA7 - PA0

PC7 - PC4

PC3 - PC0

A

C

1D70D60D51D41D30D21D10

D7 - D0

82C55A

C

D0

8

4

4

PA7 - PA0

PC7 - PC4

PC3 - PC0

A

8

B

PB7 - PB0

CONTROL WORD #13 CONTROL WORD #15

D0

1D70D60D51D41D30D20D11

82C55A

D7 - D0

8

4

4

8

PA7 - PA0

PC7 - PC4

PC3 - PC0

PB7 - PB0

A

C

B

1D70D60D51D41D30D21D11

D7 - D0

Operating Modes

Mode 1 - (Strobed Input/Output). This functional

configuration provides a means for transferring I/O data to or

from a specified port in conjunction with strobes or “hand

shaking” signals. In mode 1, port A and port B use the lines

on port C to generate or accept these “hand shaking”

signals.

Mode 1 Basic Function Definitions:

• Two Groups (Group A and Group B)

• Each group contains one 8-bit port and one 4-bit

control/data port

• The 8-bit data port can be either input or output. Both

inputs and outputs are latched.

• The 4-bit port is used for control and status of the 8-bit port.

Input Control Signal Definition

(Figures 6 and 7)

CONTROL WORD

1D70D61D51D41/0

CONTROL WORD

D6 D5 D4 D3 D2 D1 D0

D7

1

D3

82C55A

D2 D1 D0

PC6, PC7

1 = INPUT

0 = OUTPUT

RD

11

B

D0

A

C

B

MODE 1 (PORT A)

INTE

A

MODE 1 (PORT B)

INTE

B

8

PB7 - PB0

8

PA7 - PA0

4

PC7 - PC4

4

PC3 - PC0

8

PB7 - PB0

PA7 -PA0

PC4

PC3

PC6, PC7

PB7-PB0

PC2

2

8

STBA

IBFAPC5

INTRA

I/O

8

STBB

IBFBPC1

STB (Strobe Input)

A “low” on this input loads data into the input latch.

IBF (Input Buffer Full F/F)

A “high” on this output indicates that the data has been

loaded into the input latch: in essence, an acknowledgment.

IBF is set by STB

edge of the RD

input being low and is reset by the rising

input.

9

RD

FIGURE 6. MODE 1 INPUT

PC0

August 25, 2005

INTRB

FN2969.8

STB

82C55A

tST

IBF

INTR

RD

INPUT FROM

PERIPHERAL

tSIB

tPS

FIGURE 7. MODE 1 (STROBED INPUT)

INTR (Interrupt Request)

A “high” on this output can be used to interrupt the CPU

when an input device is requesting service. INTR is set by

the condition: STB

“one”. It is reset by the falling edge of RD

is a “one”, IBF is a “one” and INTE is a

. This procedure

allows an input device to request service from the CPU by

simply strobing its data into the port.

INTE A

Controlled by bit set/reset of PC4.

INTE B

Controlled by bit set/reset of PC2.

Output Control Signal Definition

(Figure 8 and 9)

OBF - (Output Buffer Full F/F). The OBF output will go “low”

to indicate that the CPU has written data out to the specified

port. This does not mean valid data is sent out of the port at

this time since OBF

Data is guaranteed valid at the rising edge of OBF

Note 1). The OBF

WR

input and reset by ACK input being low.

can go true before data is available.

, (See

F/F will be set by the rising edge of the

tSIT

tPH

tRIB

tRIT

INTE A

Controlled by Bit Set/Reset of PC6.

INTE B

Controlled by Bit Set/Reset of PC2.

NOTE:

1. To strobe data into the peripheral device, the user must operate

the strobe line in a hand shaking mode. The user needs to send

OBF

to the peripheral device, generates an ACK from the

peripheral device and then latch data into the peripheral device

on the rising edge of OBF

CONTROL WORD

D3

1D70D61D51D41/0

.

D2 D1 D0

PC4, PC5

1 = INPUT

0 = OUTPUT

WR

MODE 1 (PORT A)

PA7 -PA0

PC7

INTE

A

PC3

PC4, PC5

8

OBFA

ACKAPC6

INTRA

2

ACK - (Acknowledge Input). A “low” on this input informs the

82C55A that the data from Port A or Port B is ready to be

accepted. In essence, a response from the peripheral device

indicating that it is ready to accept data, (See Note 1).

INTR - (Interrupt Request). A “high” on this output can be

used to interrupt the CPU when an output device has

accepted data transmitted by the CPU. INTR is set when

ACK

is a “one”, OBF is a “one” and INTE is a “one”. It is reset

by the falling edge of WR

.

10

CONTROL WORD

D7

D6 D5 D4 D3 D2 D1 D0

1

10

FIGURE 8. MODE 1 OUTPUT

WR

MODE 1 (PORT B)

PB7-PB0

PC1

INTE

B

PC0

8

OBFB

ACKBPC2

INTRB

FN2969.8

August 25, 2005

WR

82C55A

tWOB

OBF

INTR

ACK

OUTPUT

tWIT

tWB

tAOB

tAK tAIT

FIGURE 9. MODE 1 (STROBED OUTPUT)

PC7

PC6

PC3

PC2

PC1

PC0

8

2

8

OBFA

ACKA

INTRA

I/O

STBB

IBFB

INTRB

CONTROL WORD

1D70D61D51D41/0

PC4

PC5

PC3

PC1

PC2

PC0

8

2

8

STBA

IIBFA

INTRA

I/O

OBFB

ACKB

INTRB

CONTROL WORD

PA7 -PA0

RD

D3

D2 D1 D0

10 1D70D61D50D41/0

PC6, PC7

1 = INPUT

0 = OUTPUT

WR

PORT A - (STROBED INPUT)

PORT B - (STROBED OUTPUT)

PC6, PC7

PB7, PB0

D3

WR

D2 D1 D0

11

PC4, PC5

1 = INPUT

0 = OUTPUT

RD

PA7 -PA0

PC4, PC5

PB7, PB0

PORT A - (STROBED OUTPUT)

PORT B - (STROBED INPUT)

Combinations of Mode 1: Port A and Port B can be individually defined as input or output in Mode 1 to support a wide variety of strobed I/O applications.

FIGURE 10. COMBINATIONS OF MODE 1

Operating Modes

Mode 2 (Strobed Bidirectional Bus I/O)

This functional configuration provides a means for

communicating with a peripheral device or structure on a

single 8-bit bus for both transmitting and receiving data

(bidirectional bus I/O). “Hand shaking” signals are provided to

maintain proper bus flow discipline similar to Mode 1. Interrupt

generation and enable/disable functions are also available.

Mode 2 Basic Functional Definitions:

• Used in Group A only

• One 8-bit, bidirectional bus Port (Port A) and a 5-bit

control Port (Port C)

• Both inputs and outputs are latched

• The 5-bit control port (Port C) is used for control and

status for the 8-bit, bidirectional bus port (Port A)

Bidirectional Bus I/O Control Signal Definition

(Figures 11, 12, 13, 14)

INTR - (Interrupt Request). A high on this output can be

used to interrupt the CPU for both input or output operations.

11

Output Operations

OBF - (Output Buffer Full). The OBF output will go “low” to

indicate that the CPU has written data out to port A.

ACK

- (Acknowledge). A “low” on this input enables the threestate output buffer of port A to send out the data. Otherwise,

the output buffer will be in the high impedance state.

INTE 1 - (The INTE flip-flop associated with OBF

).

Controlled by bit set/reset of PC4.

Input Operations

STB - (Strobe Input). A “low” on this input loads data into the

input latch.

IBF - (Input Buffer Full F/F). A “high” on this output indicates

that data has been loaded into the input latch.

INTE 2 - (The INTE flip-flop associated with IBF). Controlled

by bit set/reset of PC4.

FN2969.8

August 25, 2005

ONTROL WORD

D7

D6 D5 D4 D3 D2 D1 D0

1

1/0 1/011/0

82C55A

PC3

PA7 -PA0

INTRA

8

PC2-PC0

1 = INPUT

0 = OUTPUT

PORT B

1 = INPUT

0 = OUTPUT

GROUP B MODE

0 = MODE 0

1 = MODE 1

WR

RD

FIGURE 11. MODE CONTROL WORD FIGURE 12. MODE 2

DATA FROM

CPU TO 82C55A

WR

tAOB

OBF

tWOB

INTR

tAK

ACK

INTE

1

INTE

2

PC7

PC6

PC4

PC5

PC2-PC0

3

OBFA

ACKA

STB

IBFA

I/O

A

STB

IBF

PERIPHERAL

BUS

RD

NOTE: Any sequence where WR

• ACK

• WR)

tST

tSIB

tPS

DATA FROM

PERIPHERAL TO 82C55A

tAD

tPH

DATA FROM

82C55A TO PERIPHERAL

tKD

tRIB

DATA FROM

82C55A TO CPU

occurs before ACK and STB occurs before RD is permissible. (INTR = IBF • MASK • STB • RD + OBF • MASK

FIGURE 13. MODE 2 (BIDIRECTIONAL)

12

FN2969.8

August 25, 2005

82C55A

MODE 2 AND MODE 0 (INPUT) MODE 2 AND MODE 0 (OUTPUT)

CONTROL WORD

D6

D5 D4 D3 D2 D1 D0

1D71

01

PC2-PC0

1 = INPUT

0 = OUTPUT

RD

WR

1/0

PC3

PA7 -PA0

PC7

PC6

PC4

PC5

PC2-PC0

PB7-PB0

8

3

8

INTRA

OBFA

ACKA

STBA

IBFA

I/O

CONTROL WORD

D6

D5 D4 D3 D2 D1 D0

1D71

00

PC2-PC0

1 = INPUT

0 = OUTPUT

RD

WR

MODE 2 AND MODE 1 (OUTPUT) MODE 2 AND MODE 1 (INPUT)

CONTROL WORD

D6

D5 D4 D3 D2 D1 D0

1D71

10

PC3

PA7 -PA0

PC7

PC6

PC4

PC5

PB7-PB0

8

8

INTRA

OBFA

ACKA

STBA

IBFA

CONTROL WORD

D6

D5 D4 D3 D2 D1 D0

D7

1

1

11

1/0

PC3

PA7 -PA0

PC7

PC6

PC4

PC5

PC2-PC0

PB7, PB0

PC3

PA7 -PA0

PC7

PC6

PC4

PC5

PB7-PB0

8

3

8

8

8

INTRA

OBFA

ACKA

STBA

IBFA

I/O

INTRA

OBFA

ACKA

STBA

IBFA

RD

WR

PC1

PC2

PC0

OBFB

ACKB

INTRB

FIGURE 14. MODE 2 COMBINATIONS

RD

WR

PC2

PC1

PC0

STBB

IBFB

INTRB

13

FN2969.8

August 25, 2005

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC0

PC1

PC2

PC3

PC4

PC5

PC6

PC7

82C55A

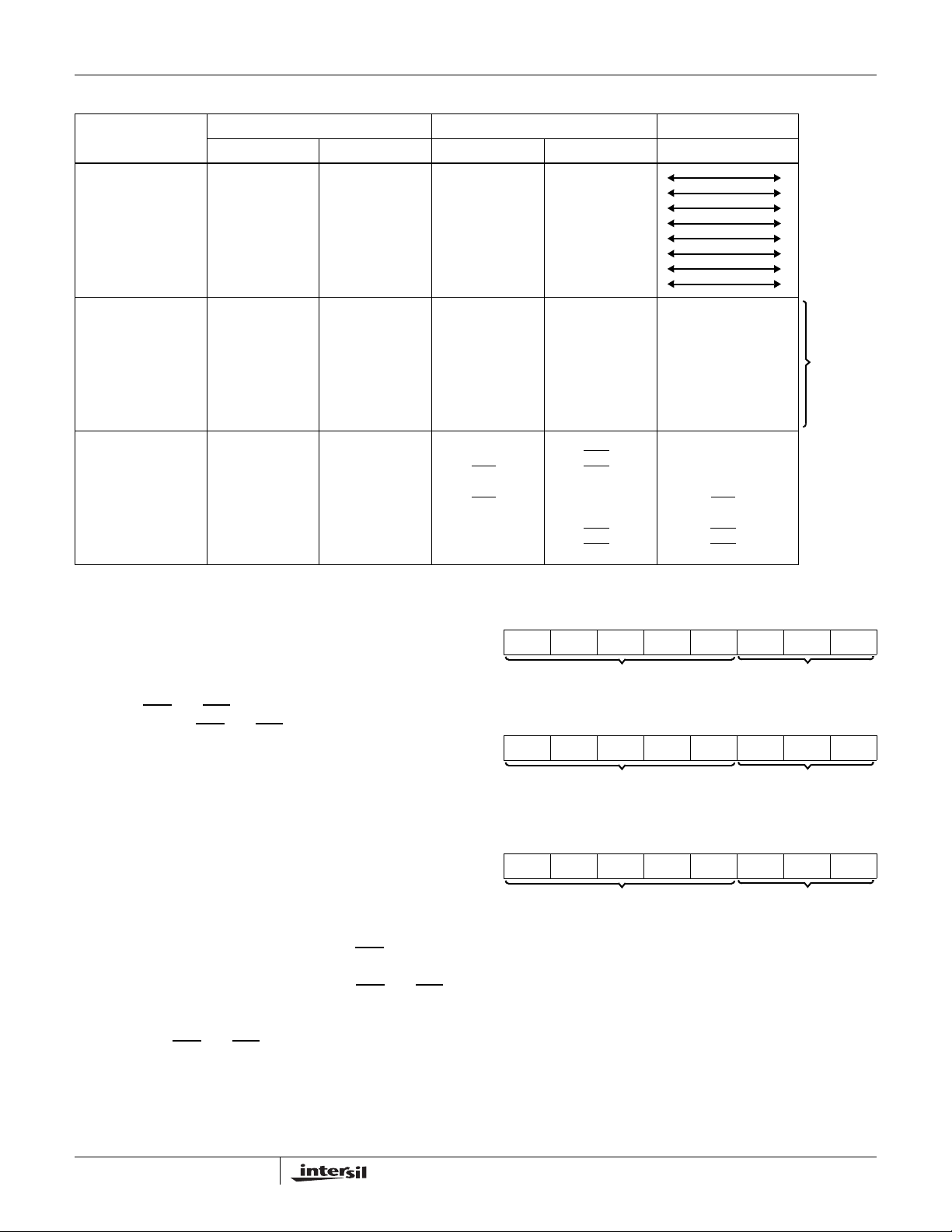

MODE DEFINITION SUMMARY

MODE 0 MODE 1 MODE 2

IN OUT IN OUT GROUP A ONLY

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

In

INTRB

IBFB

STB

INTRA

STB

IBFA

I/O

I/O

B

A

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

Out

INTRB

OBF

ACK

INTRA

I/O

I/O

ACK

OBF

B

B

A

A

I/O

I/O

I/O

INTRA

STB

IBFA

ACK

OBF

A

A

A

Mode 0

or Mode 1

Only

Special Mode Combination Considerations

There are several combinations of modes possible. For any

combination, some or all of Port C lines are used for control

or status. The remaining bits are either inputs or outputs as

defined by a “Set Mode” command.

During a read of Port C, the state of all the Port C lines,

except the ACK

bus. In place of the ACK

appear on the data bus in the PC2, PC4, and PC6 bit

positions as illustrated by Figure 17.

Through a “Write Port C” command, only the Port C pins

programmed as outputs in a Mode 0 group can be written.

No other pins can be affected by a “Write Port C” command,

nor can the interrupt enable flags be accessed. To write to

any Port C output programmed as an output in Mode 1

group or to change an interrupt enable flag, the “Set/Reset

Port C Bit” command must be used.

With a “Set/Reset Port C Bit” command, any Port C line

programmed as an output (including IBF and OBF

written, or an interrupt enable flag can be either set or reset.

Port C lines programmed as inputs, including ACK

lines, associated with Port C are not affected by a “Set/Reset

Port C Bit” command. Writing to the corresponding Port C bit

positions of the ACK

C Bit” command will affect the Group A and Group B

interrupt enable flags, as illustrated in Figure 17.

and STB lines, will be placed on the data

and STB line states, flag status will

) can be

and STB

and STB lines with the “Set Reset Port

INPUT CONFIGURATION

D7 D6 D5 D4 D3 D2 D1 D0

I/O I/O IBFA INTEA INTRA INTEB IBFB INTRB

GROUP A

OUTPUT CONFIGURATION

D7 D6 D5 D4 D3 D2 D1 D0

OBFA INTEA I/O I/O INTRA INTEB OBFB INTRB

GROUP A

FIGURE 15. MODE 1 STATUS WORD FORMAT

D7 D6 D5 D4 D3 D2 D1 D0

OBFA INTE1 IBFA INTE2 INTRA X X X

GROUP A

(Defined by Mode 0 or Mode 1 Selection)

FIGURE 16. MODE 2 STATUS WORD FORMAT

GROUP B

GROUP B

GROUP B

Current Drive Capability

Any output on Port A, B or C can sink or source 2.5mA. This

feature allows the 82C55A to directly drive Darlington type

drivers and high-voltage displays that require such sink or

source current.

Reading Port C Status (Figures 15 and 16)

In Mode 0, Port C transfers data to or from the peripheral

device. When the 82C55A is programmed to function in

14

FN2969.8

August 25, 2005

82C55A

Modes 1 or 2, Port C generates or accepts “hand shaking”

signals with the peripheral device. Reading the contents of

Port C allows the programmer to test or verify the “status” of

each peripheral device and change the program flow

accordingly.

There is not a special instruction to read the status

information from Port C. A normal read operation of Port C is

executed to perform this function.

INTERRUPT

ENABLE FLAG POSITION

INTE B PC2 ACK

INTE A2 PC4 STB

INTE A1 PC6 ACK

FIGURE 17. INTERRUPT ENABLE FLAGS IN MODES 1 AND 2

ALTERNATE PORT C

PIN SIGNAL (MODE)

B (Output Mode 1)

or STB

B (Input Mode 1)

A (Input Mode 1 or Mode

2)

A (Output Mode 1 or

Mode 2)

INTERRUPT

REQUEST

PC3

MODE 1

(OUTPUT)

82C55A

MODE 1

(OUTPUT)

PC0

INTERRUPT

REQUEST

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC7

PC6

PC5

PC4

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC1

PC2

FIGURE 18. PRINTER INTERFACE

Applications of the 82C55A

The 82C55A is a very powerful tool for interfacing peripheral

equipment to the microcomputer system. It represents the

optimum use of available pins and is flexible enough to

interface almost any I/O device without the need for

additional external logic.

Each peripheral device in a microcomputer system usually

has a “service routine” associated with it. The routine

manages the software interface between the device and the

CPU. The functional definition of the 82C55A is programmed

by the I/O service routine and becomes an extension of the

system software. By examining the I/O devices interface

characteristics for both data transfer and timing, and

matching this information to the examples and tables in the

detailed operational description, a control word can easily be

developed to initialize the 82C55A to exactly “fit” the

application. Figures 18 through 24 present a few examples

of typical applications of the 82C55A.

DATA READY

ACK

PAP E R FE E D

FORWARD/REV.

DATA READY

ACK

CONTROL LOGIC

AND DRIVERS

HIGH SPEED

PRINTER

HAMMER

RELAYS

PAP E R FE E D

FORWARD/REV.

RIBBON

CARRIAGE SEN.

15

FN2969.8

August 25, 2005

INTERRUPT

REQUEST

R0

R1

R2

R3

R4

R5

SHIFT

CONTROL

STROBE

ACK

B0

B1

B2

B3

B4

B5

BACKSPACE

CLEAR

DATA READY

ACK

BLANKING

CANCEL WORD

FULLY

DECODED

KEYBOARD

BURROUGHS

SELF-SCAN

DISPLAY

(OUTPUT)

INTERRUPT

REQUEST

PC3

MODE 1

(INPUT)

82C55A

MODE 1

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC4

PC5

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

PC1

PC2

PC6

PC7

FIGURE 19. KEYBOARD AND DISPLAY INTERFACE

82C55A

INTERRUPT

REQUEST

PC3

MODE 1

(INPUT)

82C55A

MODE 0

(INPUT)

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC4

PC5

PC6

PC7

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

R0

R1

R2

R3

R4

KEYBOARD

R5

SHIFT

CONTROL

STROBE

ACK

BUST LT

TEST LT

FULLY

DECODED

TERMINAL

ADDRESS

FIGURE 20. KEYBOARD AND TERMINAL ADDRESS

INTERFACE

MODE 0

(OUTPUT)

82C55A

BIT

SET/RESET

MODE 0

(INPUT)

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC4

PC5

PC6

PC7

PC0

PC1

PC2

PC3

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

LSB

12-BIT

D/A

CONVERTER

(DAC)

MSB

STB DATA

SAMPLE EN

STB

LSB

8-BIT

A/D

CONVERTER

(ADC)

MSB

ANALOG

OUTPUT

ANALOG

INPUT

INTERRUPT

REQUEST

(OUTPUT)

(OUTPUT)

PC3

MODE 1

82C55A

MODE 0

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC7

PC6

PC5

PC4

PC2

PC1

PC0

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

R0

R1

R2

CRT CONTROLLER

R3

² CHARACTER GEN.

² REFRESH BUFFER

R4

² CURSOR CONTROL

R5

SHIFT

CONTROL

DATA READY

ACK

BLANKED

BLACK/WHITE

ROW STB

COLUMN STB

CURSOR H/V STB

CURSOR/ROW/COLUMN

ADDRESS

H&V

FIGURE 21. DIGITAL TO ANALOG, ANALOG TO DIGITAL FIGURE 22. BASIC CRT CONTROLLER INTERFACE

16

August 25, 2005

FN2969.8

82C55A

INTERRUPT

REQUEST

(OUTPUT)

PC3

MODE 2

82C55A

MODE 0

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC4

PC5

PC7

PC6

PC2

PC1

PC0

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

D0

D1

D2

D3

D4

D5

D6

D7

DATA STB

ACK (IN)

DATA READY

ACK (OUT)

TRACK “0” SENSOR

SYNC READY

INDEX

ENGAGE HEAD

FORWARD/REV.

READ ENABLE

WRITE ENABLE

DISC SELECT

ENABLE CRC

TEST

BUSY LT

FLOPPY DISK

CONTROLLER

AND DRIVE

INTERRUPT

REQUEST

(OUTPUT)

PC3

MODE 1

(INPUT)

82C55A

MODE 0

(INPUT)

MODE 0

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PC4

PC5

PC6

PC0

PC1

PC2

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

R0

R1

R2

B LEVEL

R3

PAPER

R4

TAP E

READER

R5

R6

R7

STB

ACK

STOP/GO

MACHINE TOOL

START/STOP

LIMIT SENSOR (H/V)

OUT OF FLUID

CHANGE TOOL

LEFT/RIGHT

UP/DOWN

HOR. STEP STROBE

VERT. STEP STROBE

SLEW/STEP

FLUID ENABLE

EMERGENCY STOP

FIGURE 23. BASIC FLOPPY DISC INTERFACE FIGURE 24. MACHINE TOOL CONTROLLER INTERFACE

17

FN2969.8

August 25, 2005

82C55A

Absolute Maximum Ratings T

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +8.0V

Input, Output or I/O Voltage. . . . . . . . . . . . . GND-0.5V to V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class 1

= 25°C Thermal Information

A

Thermal Resistance (Typical, Note 1) θ

+0.5V

CC

CERDIP Package. . . . . . . . . . . . . . . . . 50 10

CLCC Package . . . . . . . . . . . . . . . . . . 65 14

(°C/W) θJC(°C/W)

JA

PDIP Package . . . . . . . . . . . . . . . . . . . 50 N/A

Operating Conditions

Voltage Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +4.5V to 5.5V

Operating Temperature Range

CX82C55A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to 70°C

IX82C55A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to 85°C

MX82C55A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55°C to 125°C

Die Characteristics

PLCC Package. . . . . . . . . . . . . . . . . . . 55 N/A

MQFP Package . . . . . . . . . . . . . . . . . . 62 N/A

Maximum Storage Temperature Range . . . . . . . . . . .-65°C to 150°C

Maximum Junction Temperature

CDIP Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175°C

PDIP Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . . 300°C

(PLCC and MQFP Lead Tips Only)

Gate Count. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 Gates

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

is measured with the component mounted on an evaluation PC board in free air.

1. θ

JA

Electrical Specifications V

= 5.0V ±10%; TA = Operating Temperature Range

CC

SYMBOL PARAMETER TEST CONDITIONS MIN MAX UNITS

V

Logical One Input Voltage 2.0

IH

-V

2.2

V

V

OH

V

IO I/O Pin Leakage Current VO = V

Logical Zero Input Voltage -0.8V

IL

Logical One Output Voltage IOH = -2.5mA,

I

= -100µA

OH

Logical Zero Output Voltage IOL +2.5mA - 0.4 V

OL

I

Input Leakage Current VIN = VCC or GND, RD, CS, A1, A0, RESET, WR -1.0 +1.0 µA

I

or GND, D0 - D7 -10 +10 µA

CC

3.0

VCC -0.4

-V

IBHH Bus Hold High Current VO = 3.0V. Ports A, B, C -50 -400 µA

IBHL Bus Hold Low Current VO = 1.0V. Port A ONLY 50 400 µA

IDAR Darlington Drive Current Ports A, B, C. Test Condition 3 -2.5 Note 2, 4 mA

ICCSB Standby Power Supply Current V

ICCOP Operating Power Supply Current T

= 5.5V, VIN = VCC or GND. Output Open - 10 µA

CC

= +25°C, VCC = 5.0V, Typical (See Note 3) - 1 mA/MHz

A

NOTES:

2. No internal current limiting exists on Port Outputs. A resistor must be added externally to limit the current.

3. ICCOP = 1mA/MHz of Peripheral Read/Write cycle time. (Example: 1.0µs I/O Read/Write cycle time = 1mA).

4. Tested as V

at -2.5mA.

OH

Capacitance T

= 25°C

A

SYMBOL PARAMETER TYPICAL UNITS TEST CONDITIONS

CIN Input Capacitance 10 pF FREQ = 1MHz, All Measurements are referenced to

CI/O I/O Capacitance 20 pF

device GND

18

FN2969.8

August 25, 2005

82C55A

AC Electrical Specifications V

SYMBOL PARAMETER

READ TIMING

(1) tAR Address Stable Before RD

(2) tRA Address Stable After RD

(3) tRR RD Pulse Width 250 - 150 - ns

(4) tRD Data Valid From RD

(5) tDF Data Float After RD

(6) tRV Time Between RDs and/or WRs 300 - 300 - ns

WRITE TIMING

(7) tAW Address Stable Before WR

(8) tWA Address Stable After WR 20 - 20 - ns

(9) tWW WR

(10) tDW Data Valid to WR

(11) tWD Data Valid After WR High 30 - 30 - ns

OTHER TIMING

(12) tWB WR

(13) tIR Peripheral Data Before RD

(14) tHR Peripheral Data After RD 0-0-ns

(15) tAK ACK Pulse Width 200 - 200 - ns

(16) tST STB Pulse Width 100 - 100 - ns

(17) tPS Peripheral Data Before STB High 20 - 20 - ns

(18) tPH Peripheral Data After STB High 50 - 50 - ns

(19) tAD ACK = 0 to Output - 175 - 175 ns 1

(20) tKD ACK = 1 to Output Float 20 250 20 250 ns 2

(21) tWOB WR

(22) tAOB ACK = 0 to OBF = 1 - 150 - 150 ns 1

(23) tSIB STB = 0 to IBF = 1 - 150 - 150 ns 1

(24) tRIB RD

(25) tRIT RD

(26) tSIT STB = 1 to INTR = 1 - 150 - 150 ns 1

(27) tAIT ACK = 1 to INTR = 1 - 150 - 150 ns 1

(28) tWIT WR

(29) tRES Reset Pulse Width 500 - 500 - ns 1, (Note)

NOTE: Period of initial Reset pulse after power-on must be at least 50µsec. Subsequent Reset pulses may be 500ns minimum.

Pulse Width 100 - 100 - ns

High 100 - 100 - ns

= 1 to Output - 350 - 350 ns 1

= 1 to OBF = 0 - 150 - 150 ns 1

= 1 to IBF = 0 - 150 - 150 ns 1

= 0 to INTR = 0 - 200 - 200 ns 1

= 0 to INTR = 0 - 200 - 200 ns 1

= +5V± 10%, GND = 0V; TA = Operating Temperature Range

CC

82C55A-5 82C55A

0-0-ns

0-0-ns

- 200 - 120 ns 1

10 75 10 75 ns 2

0-0-ns

0-0-ns

UNITS

TEST

CONDITIONSMIN MAX MIN MAX

19

FN2969.8

August 25, 2005

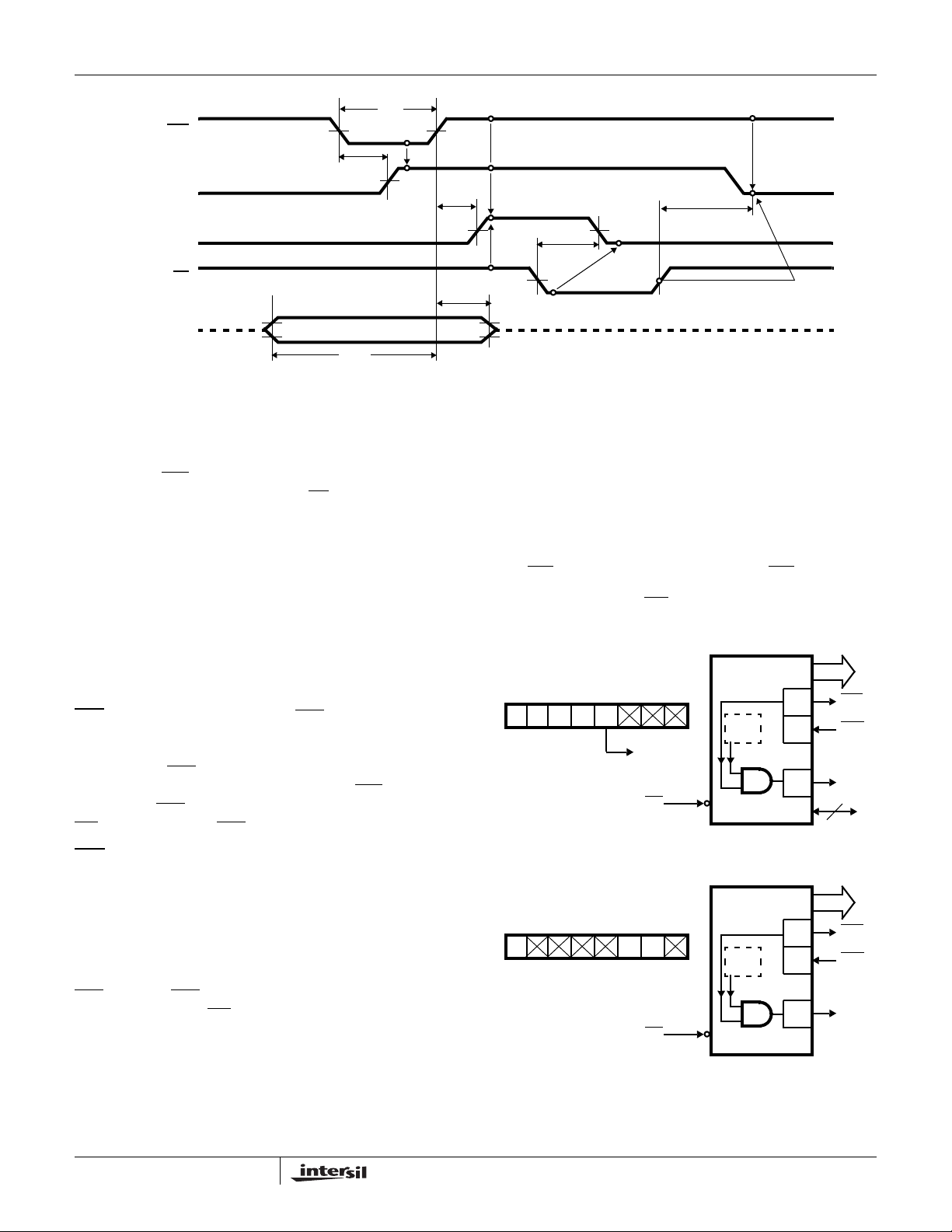

Timing Waveforms

82C55A

CS

CS

RD

INPUT

, A1, A0

D7-D0

WR

D7-D0

, A1, A0

tAW (7)

tRR (3)

tIR (13)

tAR (1)

tRD (4) tDF (5)

FIGURE 25. MODE 0 (BASIC INPUT)

tWW (9)

tDW

(10)

tHR (14)

tRA (2)

tWD (11)

tWA (8)

OUTPUT

STB

IBF

INTR

RD

INPUT FROM

PERIPHERAL

FIGURE 26. MODE 0 (BASIC OUTPUT)

tST (16)

tSIB

(23)

tPS (17)

tSIT

(26)

tPH

(18)

FIGURE 27. MODE 1 (STROBED INPUT)

tRIT

(25)

tWS (12)

tRIB (24)

20

FN2969.8

August 25, 2005

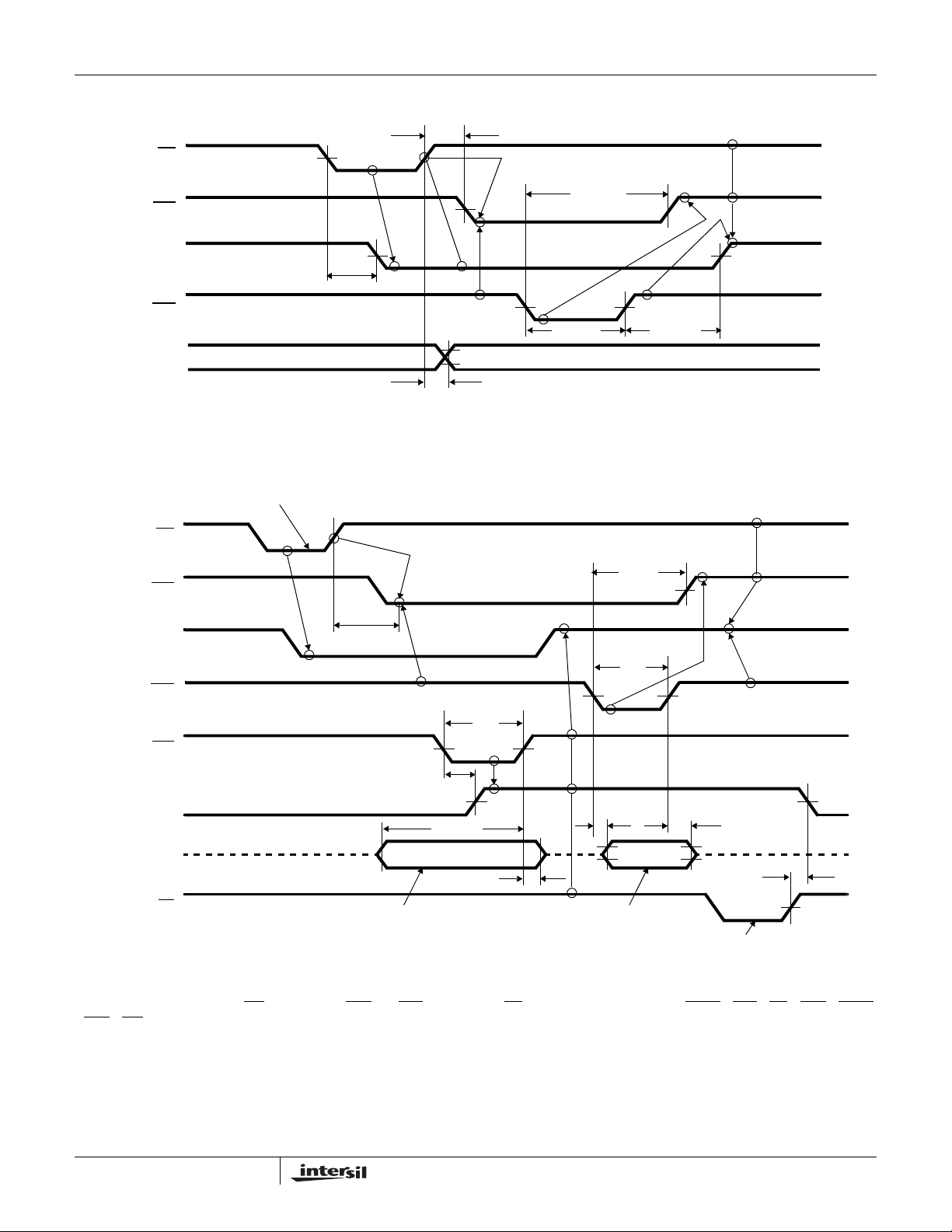

Timing Waveforms (Continued)

WR

OBF

82C55A

tWOB (21)

tAOB (22)

INTR

ACK

OUTPUT

WR

OBF

INTR

ACK

DATA FROM

CPU TO 82C55A

tWIT

(28)

tAK (15) tAIT (27)

tWB (12)

FIGURE 28. MODE 1 (STROBED OUTPUT)

tWOB

(21)

tAOB

(22)

tAK

(15)

(NOTE)

STB

IBF

PERIPHERAL

BUS

RD

NOTE: Any sequence where WR

• ACK

• WR)

21

tST

(16)

(NOTE)

tSIB

(23)

tPS (17)

tPH (18)

DATA FROM

PERIPHERAL TO 82C55A

tAD (19)

DATA FROM

82C55A TO PERIPHERAL

tKD

(20)

tRIB (24)

DATA FROM

82C55A TO CPU

FIGURE 29. MODE 2 (BIDIRECTIONAL)

occurs before ACK and STB occurs before RD is permissible. (INTR = IBF • MASK • STB • RD + OBF • MASK

FN2969.8

August 25, 2005

Timing Waveforms (Continued)

A

82C55A

A0-A1,

CS

DATA

BUS

WR

tAW (7)

tWA (8)

tDW (10) tWD (11)

tWW (9)

A0-A1,

CS

RD

DATA

BUS

tAR (1)

tRR (3)

(4) tRD

VAL ID

HIGH IMPEDANCE

FIGURE 30. WRITE TIMING FIGURE 31. READ TIMING

AC Test Circuit AC Testing Input, Output Waveforms

V1

R1

OUTPUT FROM

DEVICE UNDER

TEST

R2

NOTE: Includes STRAY and JIG Capacitance

C1

(SEE NOTE)

TEST

POINT

INPUT

VIH + 0.4V

1.5V 1.5V

VIL - 0.4V

C Testing: All AC Parameters tested as per test circuits. Input RISE

and FALL times are driven at 1ns/V.

TEST CONDITION DEFINITION TABLE

TEST CONDITION V1 R1 R2 C1

1 1.7V 523Ω Open 150pF

2V

CC

2kΩ 1.7kΩ 50pF

3 1.5V 750Ω Open 50pF

tRA (2)

tDF (5)

OUTPUT

VOH

VOL

22

FN2969.8

August 25, 2005

Burn-In Circuits

F6

F7

F8

F9

F4

F3

GND

F0

F1

F10

F6

F7

F8

F9

F10

F6

F7

F8

F9

F10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CERDIP

82C55A

CLCC

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

F11

F12

F13

F14

F2

F5

F15

F11

F12

F13

F14

F15

F11

F12

F13

F14

F15

F11

F12

F11

F6

46 3

F9

F8

F10

25

F7

F12

F12

F13

F14

F2

44

1

F11

F15

F14

F13

40414243

39

38

37

36

35

34

33

32

31

30

29

2827262524232221201918

C1

CC

V

F5

F15

F11

F12

F13

F14

F15

F11

F12

F3F4F9

GND

F0

F1

F10

F6

F7

F8

F9

V

CC

C1

F10

F6

7

8

9

10

11

12

13

14

15

16

17

F8

F7

NOTES:

= 5.5V ± 0.5V

1. V

CC

2. VIH = 4.5V ± 10%

3. VIL = -0.2V to 0.4V

4. GND = 0V

NOTES:

1. C1 = 0.01µF minimum

2. All resistors are 47kΩ ± 5%

3. f0 = 100kHz ± 10%

4. f1 = f0 ÷ 2; f2 = f1 ÷ 2; . . . ; f15 = f14 ÷ 2

23

FN2969.8

August 25, 2005

82C55A

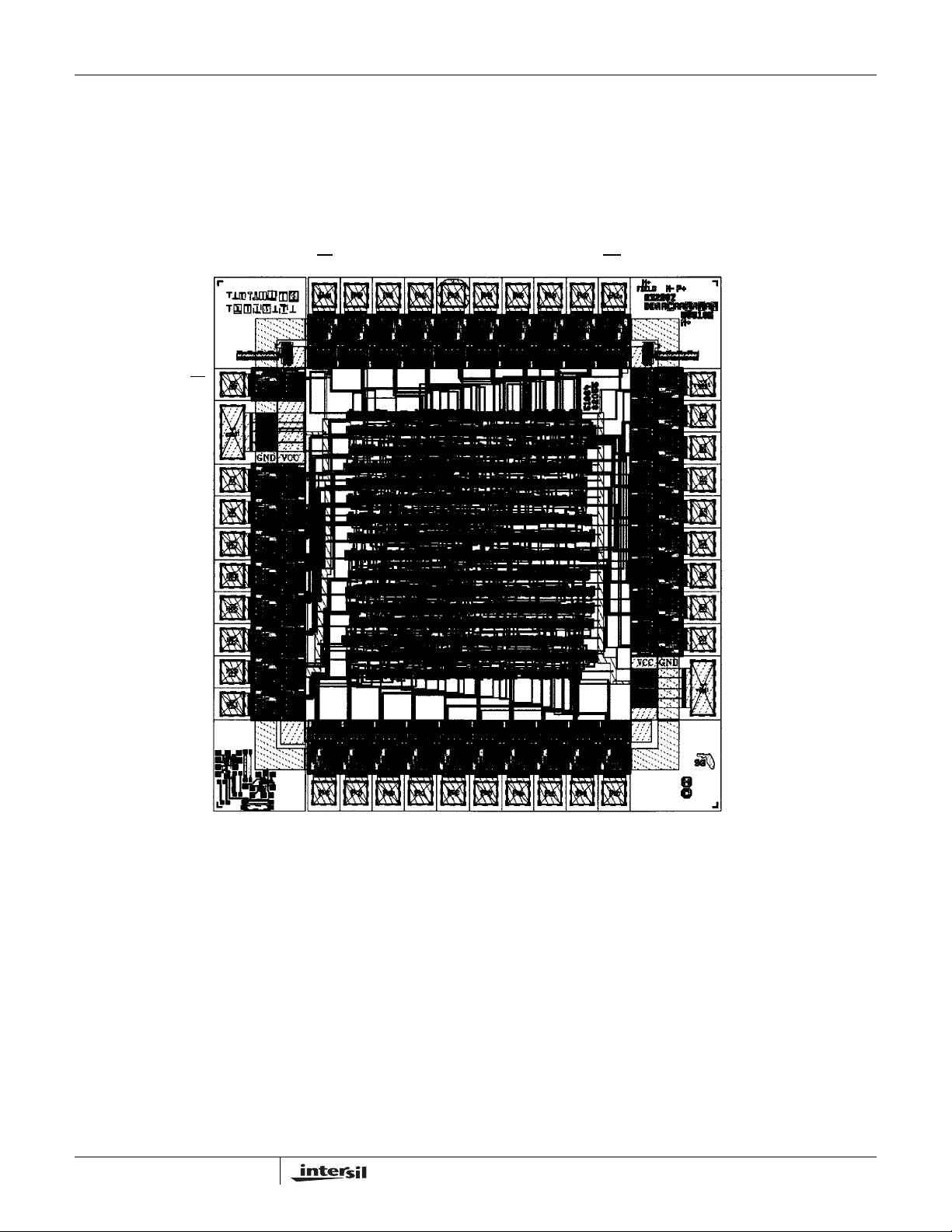

Die Characteristics

METALLIZATION:

Type: Silicon - Aluminum

Thickness: 11kÅ ±1kÅ

Metallization Mask Layout

CS

GND

A1

A0

PC7

GLASSIVATION:

Type: SiO

2

Thickness: 8kÅ ±1kÅ

82C55A

RD PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 WR

RESET

D0

D1

D2

D3

D4

PC6

PC5

PC4

PC0

PC1

PC2 PC3 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7

D5

D6

D7

V

CC

24

FN2969.8

August 25, 2005

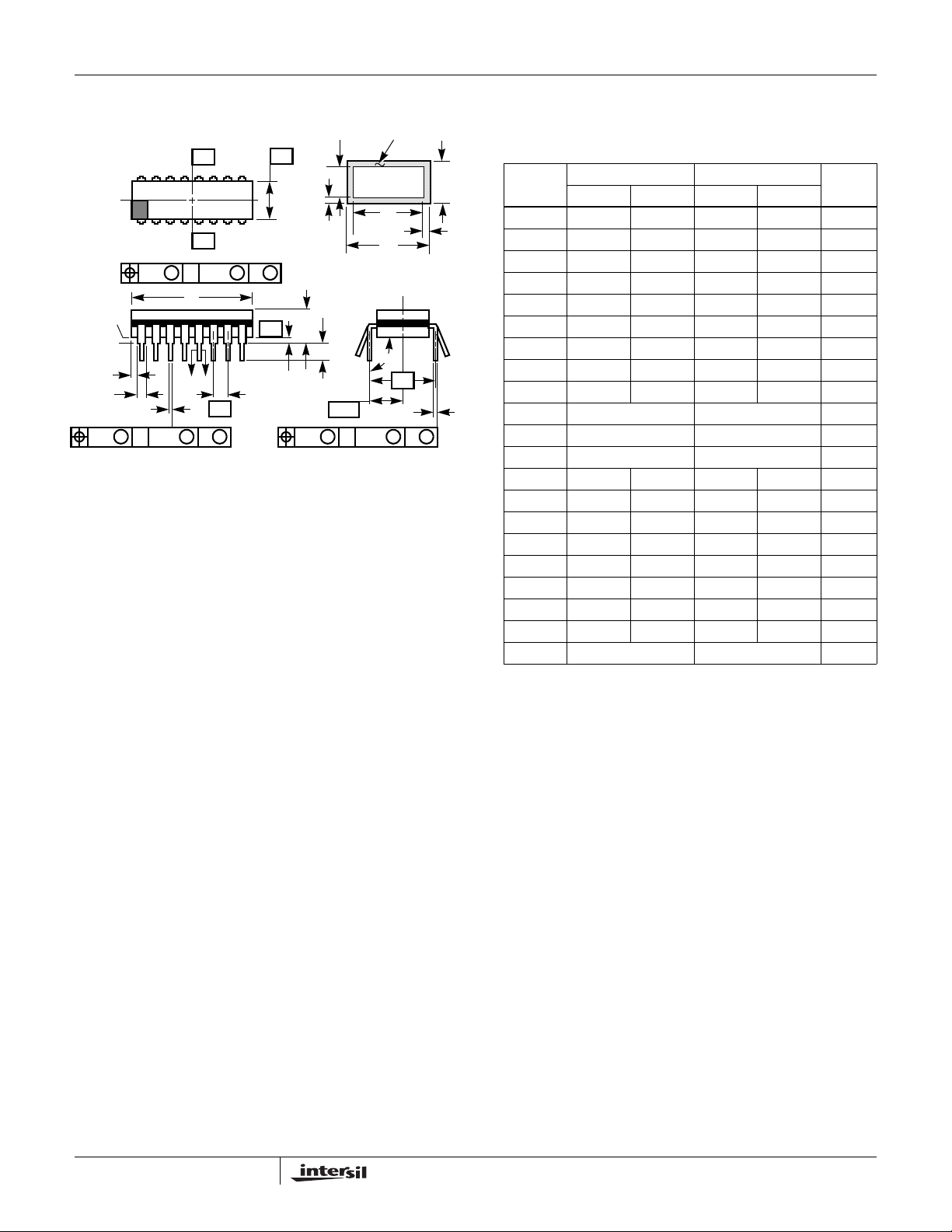

Dual-In-Line Plastic Packages (PDIP)

82C55A

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

12 3 N/2

-AD

e

B

0.010 (0.25) C AM BS

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English

and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2

of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be per-

7. e

e

pendicular to datum .

A

and eC are measured at the lead tips with the leads uncon-

B

strained. e

must be zero or greater.

C

-C-

8. B1 maximum dimensions do not include dambar protrusions. Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 - 1.14mm).

E40.6 (JEDEC MS-011-AC ISSUE B)

40 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.250 - 6.35 4

A1 0.015 - 0.39 - 4

A2 0.125 0.195 3.18 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.030 0.070 0.77 1.77 8

C 0.008 0.015 0.204 0.381 -

D 1.980 2.095 50.3 53.2 5

D1 0.005 - 0.13 - 5

E 0.600 0.625 15.24 15.87 6

E1 0.485 0.580 12.32 14.73 5

e 0.100 BSC 2.54 BSC e

A

e

B

0.600 BSC 15.24 BSC 6

- 0.700 - 17.78 7

L 0.115 0.200 2.93 5.08 4

N40 409

NOTESMIN MAX MIN MAX

Rev. 0 12/93

25

FN2969.8

August 25, 2005

82C55A

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

LEAD FINISH

c1

-A-

-B-

bbb C A - B

S

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc C A - BMD

D

A

A

e

S

S

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

-D-

BASE

E

D

S

S

Q

A

-C-

L

METAL

b1

M

(b)

SECTION A-A

α

(c)

M

eA

eA/2

aaa CA - B

M

c

D

S

S

F40.6 MIL-STD-1835 GDIP1-T40 (D-5, CONFIGURATION A)

40 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.225 - 5.72 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 -

b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 2.096 - 53.24 5

E 0.510 0.620 12.95 15.75 5

e 0.100 BSC 2.54 BSC -

eA 0.600 BSC 15.24 BSC -

eA/2 0.300 BSC 7.62 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.070 0.38 1.78 6

S1 0.005 - 0.13 - 7

o

α

90

105

o

90

o

105

aaa - 0.015 - 0.38 -

bbb - 0.030 - 0.76 -

ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2, 3

N40 408

NOTESMIN MAX MIN MAX

o

Rev. 0 4/94

-

26

FN2969.8

August 25, 2005

82C55A

Ceramic Leadless Chip Carrier Packages (CLCC)

j x 45

E1

o

B

h x 45

-E-

E2

e1

o

A

-F-

0.010 E HS S

L

D

D3

0.007 E FM S HS

B1

L2

D1

-H-

D2

B2

J44.A MIL-STD-1835 CQCC1-N44 (C-5)

44 PAD CERAMIC LEADLESS CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.064 0.120 1.63 3.05 6, 7

A1 0.054 0.088 1.37 2.24 -

B 0.033 0.039 0.84 0.99 4

B1 0.022 0.028 0.56 0.71 2, 4

E3

E

B2 0.072 REF 1.83 REF B3 0.006 0.022 0.15 0.56 -

D 0.640 0.662 16.26 16.81 D1 0.500 BSC 12.70 BSC D2 0.250 BSC 6.35 BSC D3 - 0.662 - 16.81 2

0.010 E FSS

A1

E 0.640 0.662 16.26 16.81 E1 0.500 BSC 12.70 BSC E2 0.250 BSC 6.35 BSC -

PLANE 2

PLANE 1

E3 - 0.662 - 16.81 2

e 0.050 BSC 1.27 BSC -

e1 0.015 - 0.38 - 2

h 0.040 REF 1.02 REF 5

j 0.020 REF 0.51 REF 5

L 0.045 0.055 1.14 1.40 -

e

L3

L1 0.045 0.055 1.14 1.40 L2 0.075 0.095 1.90 2.41 L3 0.003 0.015 0.08 0.38 -

ND 11 11 3

NE 11 11 3

N44 443

B3

NOTES:

1. Metallized castellations shall be connected to plane 1 terminals

and extend toward plane 2 across at least two layers of ceramic

or completely across all of the ceramic layers to make electrical

connection with the optional plane 2 terminals.

2. Unless otherwise specified, a minimum clearance of 0.015 inch

L1

(0.38mm) shall be maintained between all metallized features

(e.g., lid, castellations, terminals, thermal pads, etc.)

3. Symbol “N” is the maximum number of terminals. Symbols “ND”

and “NE” are the number of terminals along the sides of length

“D” and “E”, respectively.

4. The required plane 1 terminals and optional plane 2 terminals (if

used) shall be electrically connected.

5. The corner shape (square, notch, radius, etc.) may vary at the

manufacturer’s option, from that shown on the drawing.

6. Chip carriers shall be constructed of a minimum of two ceramic

layers.

7. Dimension “A” controls the overall package thickness. The maximum “A” dimension is package height before being solder dipped.

8. Dimensioning and tolerancing per ANSI Y14.5M-1982.

9. Controlling dimension: INCH.

NOTESMIN MAX MIN MAX

Rev. 0 5/18/94

27

FN2969.8

August 25, 2005

82C55A

Plastic Leaded Chip Carrier Packages (PLCC)

0.042 (1.07)

0.048 (1.22)

PIN (1) IDENTIFIER

0.020 (0.51) MAX

3 PLCS

C

L

D1

D

0.026 (0.66)

0.032 (0.81)

0.045 (1.14)

MIN

0.042 (1.07)

0.056 (1.42)

0.050 (1.27) TP

VIEW “A” TYP.

C

L

EE1

0.013 (0.33)

0.021 (0.53)

0.025 (0.64)

MIN

0.004 (0.10) C

0.025 (0.64)

0.045 (1.14)

D2/E2

D2/E2

A1

A

-C-

VIEW “A”

0.020 (0.51)

MIN

SEATING

PLANE

N44.65 (JEDEC MS-018AC ISSUE A)

R

44 LEAD PLASTIC LEADED CHIP CARRIER PACKAGE

INCHES MILLIMETERS

SYMBOL

NOTESMIN MAX MIN MAX

A 0.165 0.180 4.20 4.57 -

A1 0.090 0.120 2.29 3.04 -

D 0.685 0.695 17.40 17.65 -

D1 0.650 0.656 16.51 16.66 3

D2 0.291 0.319 7.40 8.10 4, 5

E 0.685 0.695 17.40 17.65 -

E1 0.650 0.656 16.51 16.66 3

E2 0.291 0.319 7.40 8.10 4, 5

N44 446

Rev. 2 11/97

NOTES:

1. Controlling dimension: INCH. Converted millimeter dimensions are

not necessarily exact.

2. Dimensions and tolerancing per ANSI Y14.5M-1982.

3. Dimensions D1 and E1 do not include mold protrusions. Allowable

mold protrusion is 0.010 inch (0.25mm) per side. Dimensions D1

and E1 include mold mismatch and are measured at the extreme

material condition at the body parting line.

4. To be measured at seating plane contact point.

-C-

5. Centerline to be determined where center leads exit plastic body.

6. “N” is the number of terminal positions.

28

FN2969.8

August 25, 2005

82C55A

Metric Plastic Quad Flatpack Packages (MQFP)

D

D1

-D-

E

E1

0.40

0.016

0o MIN

0o-7

-H-

o

-A-

MIN

PIN 1

o

12o-16

0.20

0.008

A2

A1

o

L

12o-16

0.005/0.007

BASE METAL

A-B SD SCM

0.13/0.17

WITH PLATING

-B-

e

SEATING

PLANE

A

0.076

0.003

-C-

b

b1

0.13/0.23

0.005/0.009

Q44.10x10 (JEDEC MS-022AB ISSUE B)

44 LEAD METRIC PLASTIC QUAD FLATPACK PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.096 - 2.45 -

A1 0.004 0.010 0.10 0.25 -

A2 0.077 0.083 1.95 2.10 -

b 0.012 0.018 0.30 0.45 6

b1 0.012 0.016 0.30 0.40 -

D 0.515 0.524 13.08 13.32 3

D1 0.389 0.399 9.88 10.12 4, 5

E 0.516 0.523 13.10 13.30 3

E1 0.390 0.398 9.90 10.10 4, 5

L 0.029 0.040 0.73 1.03 -

N44 447

e 0.032 BSC 0.80 BSC -

NOTES:

1. Controlling dimension: MILLIMETER. Converted inch

dimensions are not necessarily exact.

2. All dimensions and tolerances per ANSI Y14.5M-1982.

3. Dimensions D and E to be determined at seating plane .

4. Dimensions D1 and E1 to be determined at datum plane

.

-H-

5. Dimensions D1 and E1 do not include mold protrusion.

Allowable protrusion is 0.25mm (0.010 inch) per side.

6. Dimension b does not include dambar protrusion. Allowable

dambar protrusion shall be 0.08mm (0.003 inch) total.

7. “N” is the number of terminal positions.

NOTESMIN MAX MIN MAX

Rev. 2 4/99

-C-

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implication or otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

29

FN2969.8

August 25, 2005

Loading...

Loading...