Page 1

User Manual

Interroll

9006 Hybrid Control for RollerDrive

EC100

EC110

EC120 (future)

Page 2

Version 1.1 (11/2011) en

Original language

Manufacturer

Interroll Corporation

3000 Corporate Drive

Wilmington, NC 28405

Tel. 800 830 9680

Fax. 800 830 9679

www.interroll.us

Copyright

The copyright of this manual remains with Interroll Corporation. This manual

includes regulations and technical drawings which may not be copied or

duplicated either in whole or in part. Unauthorized use, publication, or application

of this document is prohibited.

Page 3

1

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Table of contents

Table of contents

Introduction

Handling of the user manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Further symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety

General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unintended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Qualified persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Risks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product information

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ZPA technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Incline and decline applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Peer-to-peer communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Meaning of the LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9006 label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical data. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 17

Speed settings . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Setting options and wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Transport and storage

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Assembly

Warning notices concerning assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Warning notices concerning the electrical installation . . . . . . . . . . . . . . . . 37

Installing the 9006 in a conveyor system . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Initial startup and operation

Initial startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Procedure in case of accident or malfunction . . . . . . . . . . . . . . . . . . . . . . 39

Maintenance and cleaning

Warnings concerning maintenance and cleaning. . . . . . . . . . . . . . . . . . . . 40

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Troubleshooting

Error search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Abandonment and disposal

Abandonment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Manufacturer's declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page 4

2

Version 1.1 (11/2011) en

Original language

Introduction

9006 Hybrid Control for RollerDrive

Introduction

Handling of the user manual

In this manual the 9006 Hybrid Control for RollerDrive for the EC100, EC110,

EC120 is referred to as 9006.

Content of the manual This manual contains important advice, notes, and information about the

9006 in all phases of its lifecycle:

• Transport, assembly, and commissioning

• Safe operation, maintenance, troubleshooting, and disposal

• Accessories

Validity of the manual The manual describes the 9006 as it is delivered by Interroll.

Special application designs require validation from Interroll and additional

technical instructions.

This manual is part of the

product

For trouble-free, safe operation and warranty claims, read this manual and

follow the instructions before handling the 9006.

Keep this manual near to the 9006.

Pass this manual on to any subsequent operator or occupant of the

9006.

Interroll does not accept any liability for malfunctions or defects due to non-

observance of this manual.

If you have any questions after reading this user manual, feel free to contact

our customer service. See the last page for contact information.

Warnings in this manual

The warnings in this document refer to risks which may arise while using the

9006. For relevant warnings, see "Safety", page 4 and the warnings

at the beginning of each chapter.

There are three categories of danger. The following signal words are used in the

document as required:

• Danger

• Warning

• Caution

Structure of warnings

Signal word Meaning

Danger Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Warning Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Caution Indicates a hazardous situation which, if not

avoided, may result in minor or moderate injury.

Nature and source of the hazard

Possible consequence of non-observance

Information about how to avoid the hazard.

DANGER

Page 5

3

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Introduction

Further symbols

This symbol marks the steps that have to be carried out.

This symbol identifies possible material damage.

Information about how to avoid damage.

Important

This symbol displays safety instructions.

Hint

This symbol marks useful and important information.

Page 6

4

Version 1.1 (11/2011) en

Original language

Safety

9006 Hybrid Control for RollerDrive

Safety

General safety instructions

The 9006 is designed according to the technical state of the art and is

reliable in operation, once distributed. However, risks may still arise.

• Risks of physical injury to the user or bystanders.

• Adverse effects of the 9006 and other material.

Always read the entire operating and safety instructions before starting to

work with the 9006 and follow the information contained herein in full.

Only instructed and qualified persons may work with the 9006.

Always keep this user manual at hand when working on the 9006 so

that you can consult it quickly if required.

Always comply with relevant national safety regulations.

If you have any questions after reading this user manual, feel free to contact

our customer service. See the last page for contact information.

Intended use

The 9006 may only be used for industrial applications and in an

industrial environment to control a RollerDrive EC1xx. It must be integrated in a

conveyor module or a conveying system. Any other use is considered

inappropriate.

Use of the 9006 is only allowed in the areas described under product

information.

Any changes that affect the safety of the product are not allowed.

The 9006 may only be used within the given operation limits.

Unintended use

Applications not according to the intended use of the 9006 require

approval from Interroll.

Important

Disregarding the warnings in this manual may lead to serious injury.

Page 7

5

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Safety

Qualified persons

Qualified persons are persons who read and understand the manual and, taking

national regulations into account, can competently execute incidental work.

Only instructed and qualified persons may work with the 9006, taking the

following into account:

• the relevant manuals and diagrams,

• the warning and safety instructions in this manual,

• the system specific regulations and requirements,

• national or local regulations and requirements for safety and accident

prevention.

Risks

Persons Maintenance or repair work must only be executed by authorized and qualified

persons in accordance with the applicable regulations.

Before using the 9006, ensure that no unauthorized persons are near

the conveyor.

Electricity

Only perform installation and maintenance work after you have switched off

the power. Ensure that the power cannot be turned on accidentally.

Working environment

Do not use the 9006 in explosive atmospheres.

Remove equipment or material which is not required from the workspace.

Avoiding malfunctions in

operation

Regularly check the 9006 for visible damage.

In case of fumes, turn off the power at once and ensure that it cannot be

turned on accidentally.

Contact qualified personnel immediately to find the source the malfunction.

Maintenance

As the product is maintenance free, you only need to check regularly for

visible damage and that all leads and screws are still tightened.

Interfaces

By assembling the 9006 in a conveyor module, potential hazards may

occur. These are not described in this manual and have to be analyzed during the

design, installation, and startup of the conveyor module.

After assembling the 9006 in a conveyor module, check the whole

system for any new potential dangerous condition prior to turning on the

conveyor.

Important

The following list informs you about the various types of danger or damage that

may occur while working with the 9006.

Page 8

6

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

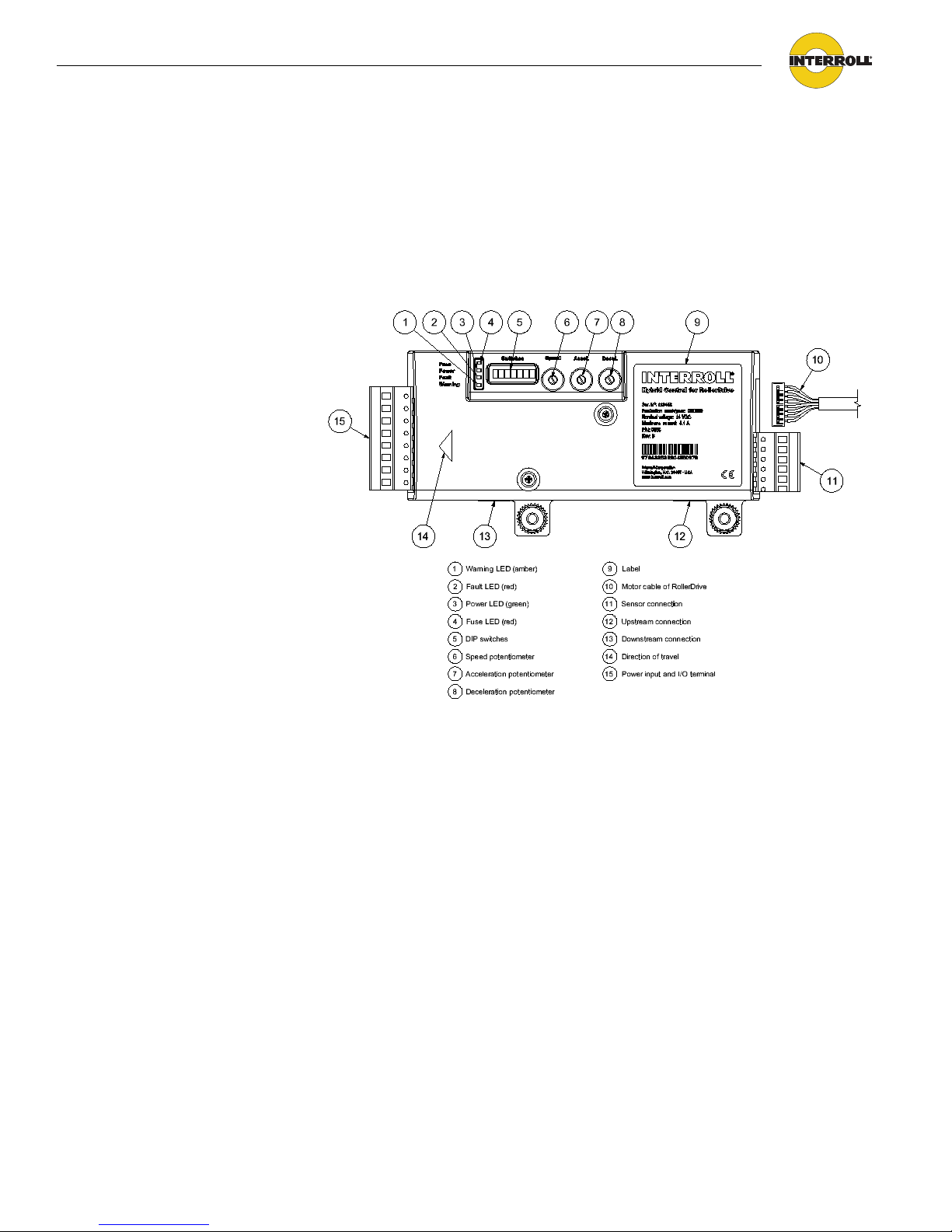

ProdThe ybridControl has ZPA and motor control functionality on board. If no peer-to-peer port is connected and DIP switches 4 and 5 are set to OFF, it switches automatically from ZPA-mode to motor control mode only.uct infor

The 9006 has ZPA and motor control functionality on board. If no

peer-to-peer port is connected and DIP switches 4 and 5 are set to OFF, it

switches automatically from ZPA-mode to motor control mode only.

Components

Page 9

7

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

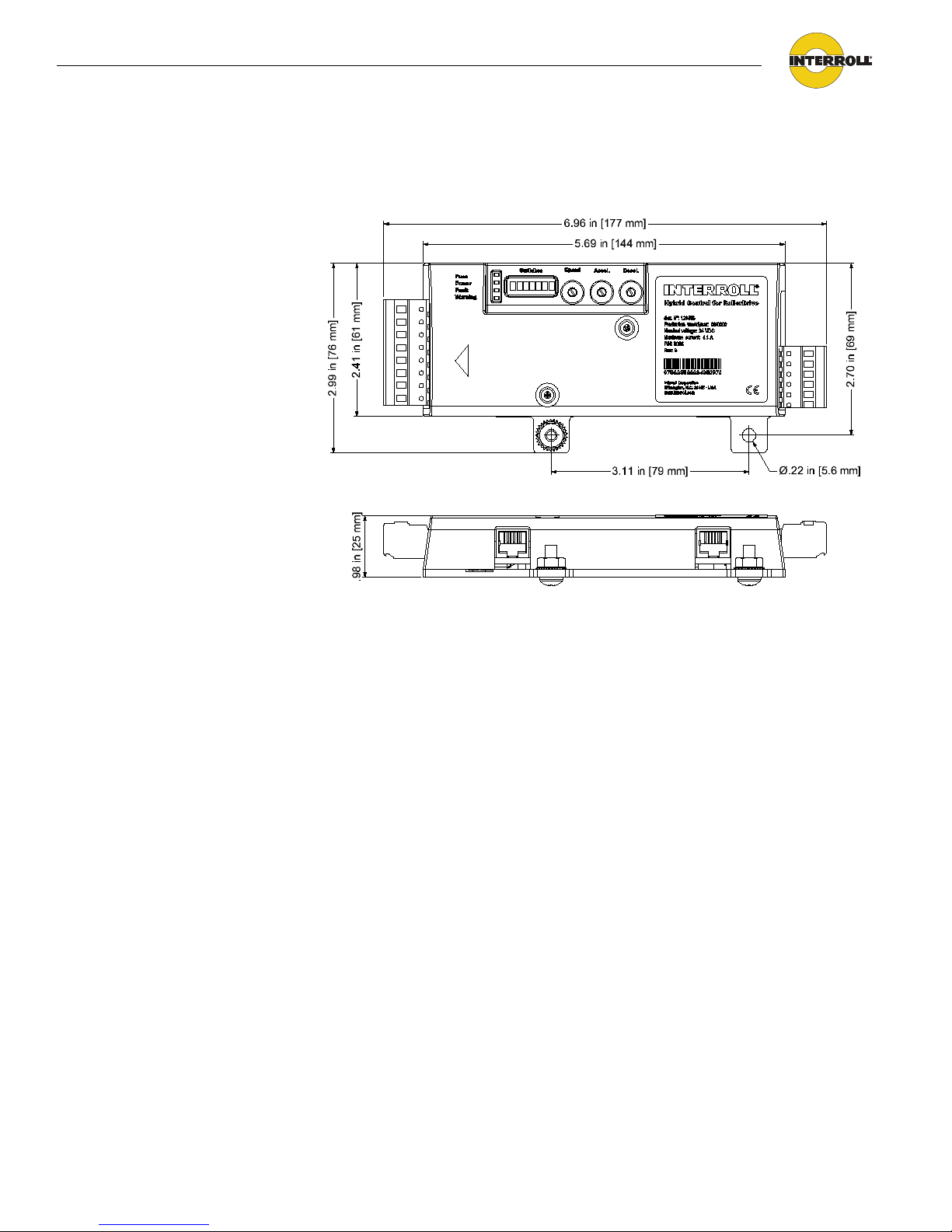

Dimensions

Mounting hardware The following mounting hardware is supplied:

• 2x button head screw 10-32 UNF x 0.5"

• 2x nut with captive star washer 10-32 UNF

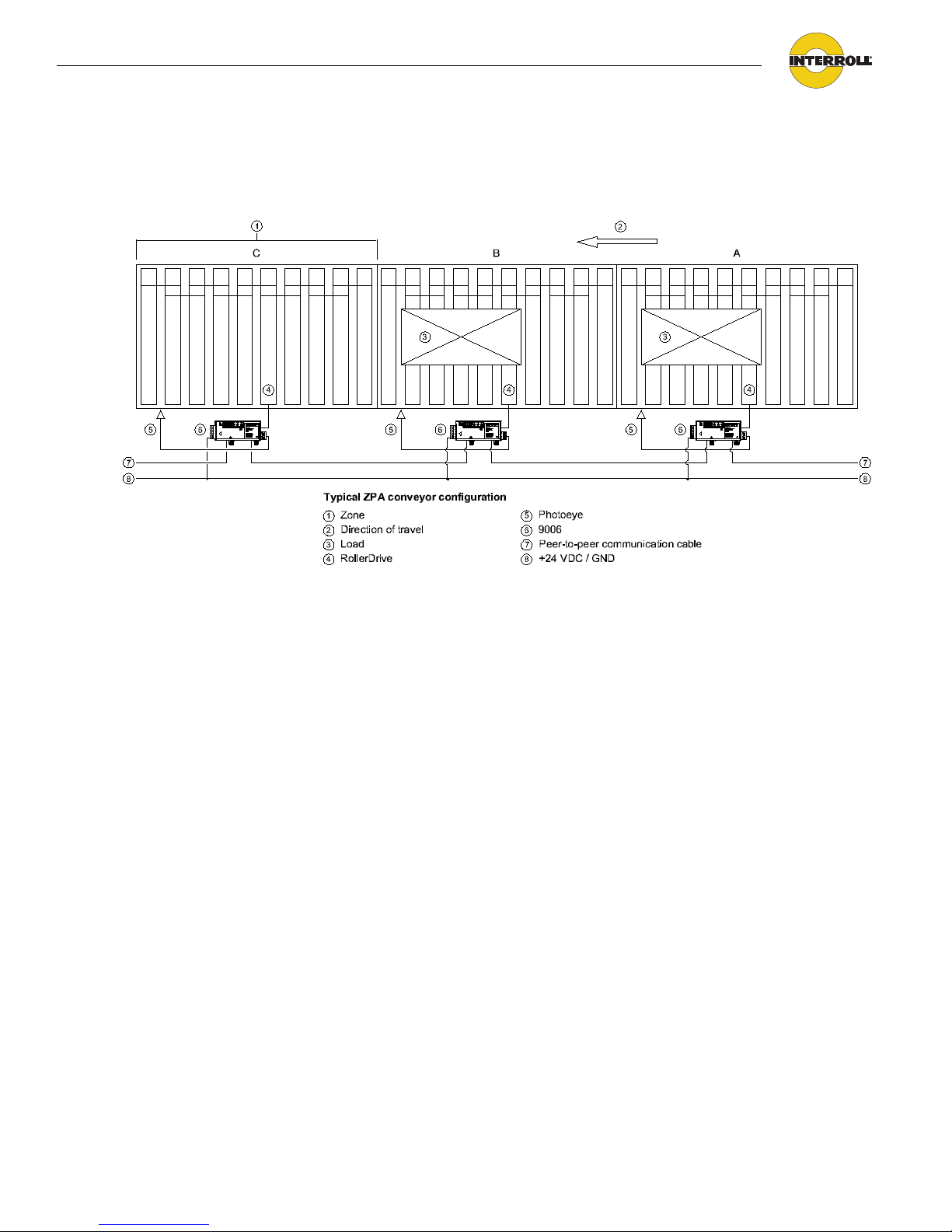

ZPA technology

ZPA is short for zero pressure accumulation. The 9006 provides true

zero pressure accumulation and other control options to a conveyor system.

Each 9006 controls a RollerDrive unit, which in turn drives idler rollers

using O-rings or other belts. The 9006, the RollerDrive, and the idler

rollers (with associated sensors and switches) are assembled into a short

conveyor section – a zone.

Zero pressure accumulation occurs as zones hold packages until the next

downstream zone clears its sensor. When accumulation occurs, a low signal is

passed upstream until each consecutive zone is occupied. Packages never push

each other, and no line pressure occurs.

A logic-controlled, zero pressure conveyor is created when a number of zones

are connected together and a simple six-wire phone cable links each

9006 electronically. The RollerDrives only operate when a package is

detected by a photoeye. If the downstream zone is empty, the package moves

forward.

Page 10

8

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Principle of zones

Zone A has a package at the photoeye. The 9006 of zone A

recognizes its presence, checks zone B for availability and requests permission

to transfer the package to zone B. Since zone B has also a package, its

9006 denies the permission until this package has been transfered to

zone C (singulation mode), or has at least started being transfered (enhanced

singulation mode). The singulation method depends on the setting of DIP switch

SW3.

The 9006 of zone A will only start to operate the RollerDrives in its

zone after it gets permission from the 9006 of zone B.

1 Zone

2 Direction of travel

3 Load

4 RollerDrive

5 Photoeye

6 HC-DriveControl

7 Peer-to-peer communication cable

8 +24 VDC / GND

Page 11

9

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

Product description

Features • Zone-to-zone communication: Activities in upstream and downstream zones

are monitored by photoeyes to permit control in various situations.

• Learn Mode: During system startup, the 9006 will automatically set the zone

length and save it, simply by running an object from the upstream photoeye

to the downstream photoeye.

• Diagnostics: LEDs provide motor, sensor, and jam diagnostics as well as

power, fuse, and temperature status.

• Reverse or jog entire system: Switch settings and connections on the board

allow the user to reverse the zone-to-zone logic, jog the entire system, or

reverse or jog parts of the system, or bypass those functions altogether

(default) without the use of external cards.

• NPN or PNP: All inputs and outputs can be switched, collectively, for NPN or

PNP with one switch. Only "No fault output" is always active high (failsafe

function with 24 VDC in "No fault status").

• Multiple dependent RollerDrives in one zone: Up to three RollerDrives c

an

be run from one 9006 (and two dependent cards) to achieve

multiple RollerDrives in a single zone. This signal can also be used by a PLC

as a "motor running" status input.

• Smart braking: Depending on upstream and downstream zone occupancy,

the RollerDrive will brake if needed, and coast if no braking is required. This

saves on power, heat, and vibration in the RollerDrive and ultimately in the

system. When no photoeyes are blocked in the system, all RollerDrives are in

coast mode.

• Dynamic braking: RollerDrive acts like a generator and the 9006 feeds

back current into the RollerDrive windings.

• Zero motion hold: When the 9006 has no start

signal, the RollerDrive

will be held in place.

• Advanced braking: The combination of dynamic braking followed by zero

motion hold provides superior braking and holding for many applications.

Operation modes The operation modes of a RollerDrive c

onveyor with 9006 Hybrid Controls include:

• Standby: The RollerDrives are turned off if the zone is empty.

• Accept: When a load reaches the sensor at the upstream end of the zone, the

RollerDrives turn on to accept it.

• Transfer: The RollerDrives continue to run to ensure that the load entering

the upstream end of the zone is transferred to the downstream end. This

creates a smooth transition and high throughput.

• Discharge: The RollerDrives in the zone continue running to disc

harge the

load if no accumulation command is received from the downstream zone.

Page 12

10

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Safety and stall functions There are different levels of over-temperature or stall-related functions:

• Jam protection: If the 9006 detects a jam or obstruction at the

downstream end of the zone, it sends an accumulation signal to the upstream

zone, preventing a build-up of accumulation pressure that could cause

product damage or personal injury.

• Motor temperature foldback: At a motor temperature of 80 °C (176 °F) the

9006 will fold back peak current down to continuous current. This is

indicated by the amber LED lighting up constantly. When the RollerDrive cools

down, the amber LED extinguishes, and the maximum peak current is now

possible again. The motor can run at this reduced current limit indefinitely

without harming the 9006 or the motor.

• Motor temperature shutdown: At a motor temperature of 100 °C (212 °F)

the 9006 will shut down the motor and the motor will go into

dynamic braking. This is indicated by the red led flashing five times. When the

RollerDrive cools back down, the red LED stops flashing and motor operation

will resume.

• Motor stall current limiting: When the motor is stalled, the current will fold

back to 1.4 A until the stall is cleared.

• 9006 temperature foldback: At a card temperature of 70 °C (158 °F)

the 9006 will foldback peak current down to continuous current. This is

indicat

ed by the amber LED lighting up constantly. When the 9006

cools down, the amber LED extinguishes, and the maximum peak current is

now possible

again. The 9006 can run at this reduced current limit

indefinitely without harming the 9006 or the motor.

• 9006 temperature shutdown: At a 9006 temperature of

90 °C (194 °F) the 9006 will shutdown the motor and the motor will go

into dynamic braking. This is indicated by the red LED flashing

four times.

When the 9006 cools bac

k down the red LED stops flashing and motor

and 9006 operation will resume.

Incline and decline applications

Due to the zero motion hold and regenerative braking features, the

9006 and RollerDrive EC1xx can be used for incline and decline

applications up to an angle of 15°.

Page 13

11

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

Inputs and outputs

Power input and I/O

connections

8 Speed analog input: External speed control down to approximately 33% of

the maximum speed. When using a 10 kΩ external potentiometer, the wiper

must be connected here. The on-board rotary switch should be set to

maximum (CW) so it will not affect the external speed setting (for the wiring

diagrams see page 19).

7 Sensor out: Mimics the Sensor 1 input signal from pin 4 on the sensor

connection. Unchanged by zone type. (see sensor connections page 12).

6 Smart 1 / FWD input: Has various functions depending on zone type:

• In entry zone: acts as a start signal for the handshake with previous

machines or conveyors.

• In exit zone: acts as a start signal to discharge the conveyor as

handshake to following systems.

• In transport zone: acts as jog signal for the specific zone or the whole

conveyor (depending on the DIP switch settings)

• In dependent zone: acts as jog command to run the motor.

This input is PNP/NPN selectable (with DIP switch 1).

5 REV input: Invokes the system reverse function, causing all interconnected

controls to operate in reverse transport mode while the signal is active.

When in dependent mode, the motor will simply run in reverse while this

signal is active. This input is PNP/NPN selectable (with DIP switch 1).

4 No fault output: Active high (+24 VDC) when either in NPN or PNP mode.

Signal goes low only when system faults occur.

3 Smart 1 output: Has various functions depending on zone type:

• In entry zone: reflects the status of the zone (occupied or free) for

handshake with previous systems.

• In exit zone: reflects the status of the zone (occupied or free) for

handshake with following systems.

• In transport zone: is the connection to control a second RollerDrive in the

zone by interfacing with Smart 1 IN of the dependent zone.

• In dependent zone: reflects the status of the sensor.

This output is PNP/NPN selectable (with DIP switch 1).

2 Common ground input: Must be connect to the main power ground.

1 +24 VDC input: Main power supply 24 VDC (voltage range see "Technical

data", page 17).

Page 14

12

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

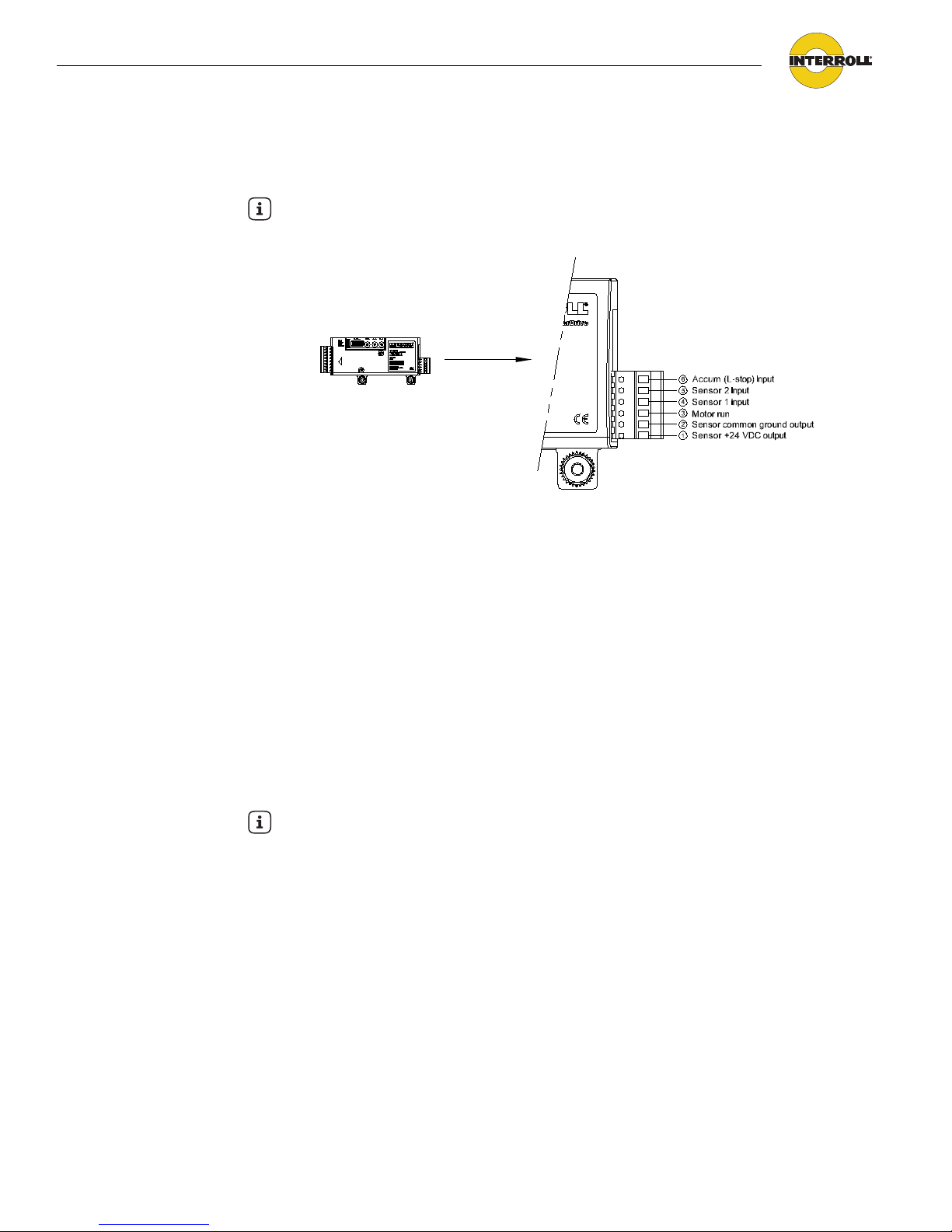

Sensor connection

6 Accum (L-stop) input: An active signal (NPN/PNP switchable) on this

terminal input will cause the 9006 to accumulate in this zone until

the signal is removed. A manual switch or a PLC controller can provide the

signal referenced to a common DC ground (NPN) or +24 VDC (PNP). This

input is PNP/NPN selectable (with DIP switch 1).

5 Sensor 2 input: Used as a start sensor. It is located at the upstream edge of

the zone and tells the first zone in a conveyor to run. This input is PNP/NPN

selectable (with DIP switch 1).

4 Sensor 1 input: Located at the downstream edge of the zone. This input is

PNP/NPN selectable (with DIP switch 1).

3 Motor run output: Output to tell PLC that the motor is running.

Unchanged by zone type. This input is PNP/NPN selectable (with DIP switch 1).

2 Sensor common ground output: Power ground connection for sensor 1 and

sensor 2.

1 Sensor +24 VDC output: +24 VDC power supply for sensor 1 and sensor 2.

Hint

The 9006 is protected against reverse polarity, but the power supply

must provide a short circuit or over current protection and a voltage ripple

tolerance of less than 5%.

Hint

Only the sensors mentioned below may be chosen: (sensor supply current from

the board is 50 mA max)

• NPN retro reflective (reflector required) - dark operate, normally closed (NC)

contact

• NPN diffused (no reflector) - light operate, normally open (NO) contact

• PNP retro reflective (reflector required) - dark operate, normally closed (NC)

contact

• PNP diffused (no reflector) - light operate, normally open (NO) contact

Page 15

13

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

Peer-to-peer communication

Even though all of the external inputs and outputs are NPN and PNP switchable,

the 9006 peer-to-peer communications always use NPN TTL logic.

This means that if a signal passing from board to board is high, it is not in

operation. If it is low (grounded), it is either performing its designated function or

sending the function signal to a nearby board.

All logic operates from a regulated and filtered 5 VDC power supply on the

9006. The 5 VDC power is delivered by a converter on the board

which converts the 24 VDC power that the board receives into 5 VDC for the

internal logic and peer-to-peer board communications (For communication cable

hardware see "Accessories", page 46).

Downstream peer-to-peer

6 Jog (I/O) [left]

5 Reverse (I/O)

4 Accumulation (I/O)

3 B sensor (OUT)

2 Ground

1 NPN (IN) [right]

Upstream peer-to-peer

1 Jog (I/O) [right]

2 Reverse (I/O)

3 Accumulation (I/O)

4 C sensor (IN)

5 NPN (IN)

6 Ground [left]

Hint

While different segments of a system may operate at different input voltages, the

DC ground for each system must be held at the same potential (0 VDC) to ensure

good operation and clean signals. In other words, when multiple power supplies

are used, the DC grounds must always be connected together.

Hint

When a peer-to-peer port is connected to another ZPA product, the NPN (in)

signal is pulled low except for the case where a 9006 is upstream.

Page 16

14

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

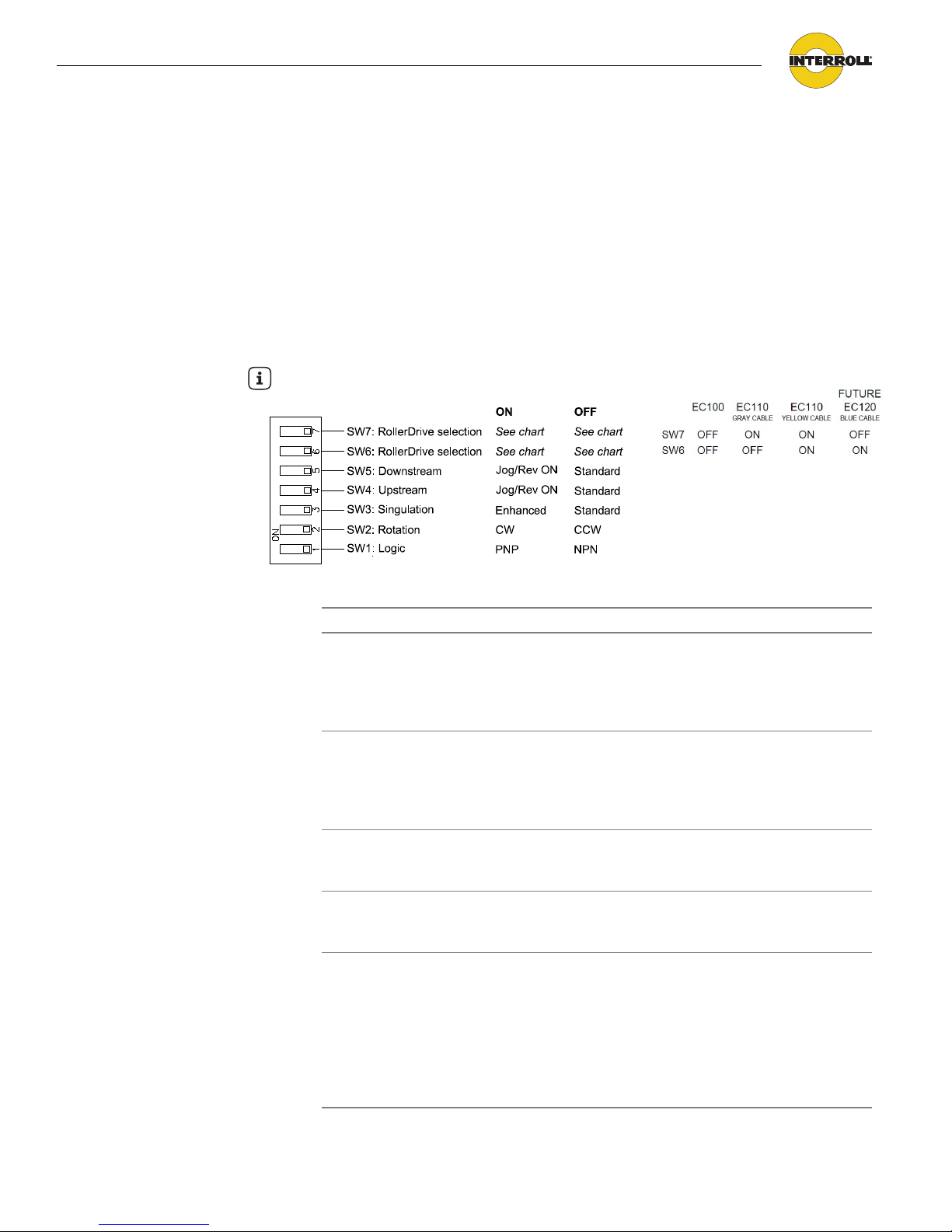

DIP switches

The DIP switches allow the selection of various types of control operations. The

default DIP switch settings are all OFF. This would provide:

• RollerDrive selection of an EC100 (SW6, SW7)

• Standard 9006 connectivity upstream and downstream (SW4, SW5)

• Standard singulate mode (SW3)

• Motor running counter clockwise (SW2)

• All NPN inputs and outputs (SW1)

The following table shows the switch position for different situations:

Hint

DIP switch settings are read at reset (power-up) only.

DIP switch ON (up position OFF (down position)

SW5

Downstream

Jog/Rev ON: the downstream

peer-to-peer cable is connected

to another 9006 and

the jog/reverse signal is

transmitted

Standard: the jog/reverse

signal is not transmitted

SW4

Upstream

Jog/Rev ON: the upstream

peer-to-peer cable is connected

to another 9006 and

the jog/reverse signal is

transmitted

Standard: the jog/reverse

signal is not transmitted

SW3

Singulation

Enhanced: enhanced

singulated release (see

"Glossary", page 47) is needed

Standard: singulated release

(see "Glossary", page 47) is

needed

SW2

Rotation

Clockwise: (rotation of the

RollerDrive seen from the cable

end)

Counter clockwise: (rotation

of the RollerDrive seen from

the cable end)

SW1

Logic

PNP: all external inputs,

photoeye inputs and outputs

are active high (24 VDC)

NPN: all external inputs,

photoeye inputs and outputs

are active low (0 VDC

ground).

This excludes the "No fault

output" which is always active

high (+24 VDC) when in either

NPN or PNP mode.

Page 17

15

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

• Local jog and reverse are always enabled, but upstream and downstream

propagation are controlled by DIP switch 4 and DIP switch 5 respectively.

• It is now simple to use DIP switch 4 and DIP switch 5 to define jog/reverse

groups, or to defeat jog and reverse completely (recommended whenever not

in use).

• If the RollerDrive is mounted with the cable exiting the opposite side of the

conveyor frame, switch SW2 has to be set in the opposite position to maintain

equal direction of travel.

• For special cases see "Setting options and wiring diagrams", page 20

Rotary switches (16 position)

Page 18

16

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Meaning of the LEDs

The LEDs provide motor, sensor, and jam diagnostics as well as power, fuse, and

temperature status. The following table shows the meaning of the LEDs (flashes

are ¼ second on, and ¼ second off, in a fixed 4 second time period):

LED Color Status Meaning

Fuse red on steady (all other

LEDs are off)

Fuse blown

Power green on steady Power ok

Fault red on steady Stalled motor

Jam at or between sensors

flashing once Motor or motor cable open or

disconnected

flashing twice Over-voltage detection

29 VDC ± 0.2 VDC (will cease

normal operation)

flashing three times Under-voltage detection

19 VDC ± 0.2 VDC (will cease

normal operation)

flashing four times 9006 severe temperature

shut-down (will cease normal

operation until cool)

flashing five times Motor severe temperature shut-

down (will cease normal

operation until cool)

flashing six times Low gain or bad sensor (sensor

with fault output connected)

Warning amber on steady Motor current is limited to

maximum continuous current due

to motor over-temperature

flashing four times Motor current is limited to

maximum continuous current due

to card over-temperature

Hint

There is no error output if the amber LED is flashing.

Page 19

17

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

9006 label

The specifications on the 9006 label are used to identify the

9006. This is required to use the 9006 as intended.

Technical data

1

2

3

4

5

6

1

2

3

Page 20

18

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Speed settings

On board speed setting The speed can be continuously adjusted (between 100% and 33% for the

EC100, EC110, and EC120) by the rotary switch marked "speed" on the

9006. Default setting is maximum.

Hint

If more than one 9006 has to run with reduced speed, it is recommended

to set the speed externally (by PLC or external potentiometer; see "External

speed setting", page 19).

Page 21

19

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

External speed setting Apart from the rotary switch on the 9006, there are other ways to set the

speed.

HintF

For the meaning of the settings see "DIP switches", page 14.

Page 22

20

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Setting options and wiring diagrams

This chapter explains the DIP switch settings for different application

9006 is between

two 9006 Cards

Hint

When the DIP switch settings ON / OFF are stated, both settings are possible for

the shown wiring (for the meaning of the settings see "DIP switches", page 14).

Upstream device 9006

Downstream device 9006

DIP switch 4 Off On Off On

DIP switch 5 Off On On Off

Upstream peer-to-peer jog/

reverse

Disabled Functional Disabled Functional

Downstream peer-to-peer

jog/reverse

Disabled Functional Functional Disabled

Zone type ZPA-mode ZPA-mode ZPA-mode ZPA-mode

Smart 1 (in) Jog Jog Jog Jog

Reverse (in) System

reverse

System

reverse

System

reverse

System

reverse

Smart 1 (out) Motor run Motor run Motor run Motor run

Sensor 2 Another

C sensor

Another

C sensor

Another

C sensor

Another

C sensor

Page 23

21

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

DIP switch settings:

• SW1: ON

Page 24

22

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

DIP switch settings:

• SW1: OFF

Page 25

23

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

DIP switch settings:

• If SW5 is ON, direction setting is transferred downstream.

• If SW4 is ON, direction setting is transferred upstream.

• SW1: ON

Start options:

• FWD connected to 24 VDC at PNP mode causes ccw rotation.

• REV connected to 24 VDC at PNP mode causes cw rotation.

• FWD and REV connected to 24 VDC at PNP mode causes coast mode.

Hint

• FWD signal acts like a jog signal, disregarding ZPA functionality and photoeye

signals.

• REV signal reverses motor and logic direction; upstream becomes

downstream and C sensor becomes B sensor.

Page 26

24

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

DIP switch settings:

• If SW5 is ON, direction setting is transferred downstream.

• If SW4 is ON, direction setting is transferred upstream.

• SW1: OFF

Start options:

• FWD connected to GND at NPN mode causes ccw rotation.

• REV connected to GND at NPN mode causes cw rotation.

• FWD and REV connected to GND at NPN mode causes coast mode.

Hin

t

• FWD signal acts like a jog signal, disregarding ZPA functionality and photoeye

signals.

• REV signal reverses motor and logic direction; upstream becomes

downstream and C sensor becomes B sensor.

Page 27

25

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

Works like a standard configuration, only the 9006 is turned upsidedown.

Page 28

26

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Dependent 9006 DIP switch settings:

• SW1: Must have the same switch setting as zone 9006 (logic mode

NPN or PNP).

Hint

A reverse command to the Zone 9006 will not be communicated to the

dependent 9006 cards.

Page 29

27

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

Start options:

• FWD connected to 24 VDC causes ccw rotation.

• REV connected to 24 VDC causes cw rotation.

• FWD and REV connected to 24 VDC causes coast mode.

Page 30

28

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

9006 is entry zone

DIP switch settings:

• SW4: ON / OFF (specifies if this zone is a transport or entry zone; if

sensor 2 IN is used, SW4 must be set to ON)

Sensor 2 IN start signal (by PLC or photoeye):

• Start signal for PNP: 24 VDC

• Start signal for NPN: GND

Upstream device - - - -

Downstream device 9006

DIP switch

4 Off On Off On

DIP switch 5 Off On On Off

Upstream peer-to-peer jog/

reverse

Disabled Functional Disabled Functional

Downstream peer-to-peer

jog/reverse

Disabled Functional Functional Disabled

Zone type Smart I/O

entry

ZPA-mode Smart I/O

entry

ZPA-mode

Smart 1 (in) Request Jog Request Jog

Reverse (in) System

reverse

System

reverse

System

reverse

System

reverse

Smart 1 (out) Perm. Motor run Perm. Motor run

Sensor 2 Not used

(smart I/O)

Another

C sensor

Not used

(smart I/O)

Another

C sensor

Hint

If you are using a photoeye as a starting signal, connect sensor 2 IN with the

photoeye.

Page 31

29

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

9006 is exit zone

DIP switch settings:

• SW5: ON / OFF (specifies if this zone is a transport or exit zone)

Smart 1 IN signal (by PLC or photoeye):

• Start signal for PNP: 24 VDC

• Start signal for NPN: GND

Upstream device 9006

Downstream device---DIP switch 4 Off On Off On

DIP switch 5 Off On On Off

Upstream peer-to-peer jog/

reverse

Disabled Functional Disabled Functional

Downstream peer-to-peer

jog/reverse

Disabled Functional Functional Disabled

Zone type Smart I/O

exit

ZPA-mode ZPA-mode Smart I/O

exit

Smart 1 (in) Perm. Jog Jog Perm.

Reverse (in) System

reverse

System

reverse

System

reverse

System

reverse

Smart 1 (out) Request Motor run Motor run Request

Sensor 2 Another

C sensor

Another

C sensor

Another

C sensor

Another

C sensor

Page 32

30

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

Learn Mode Reset

At startup "Learn Mode" automatically sets the zone length, and saves it, simply

by running an object from the upstream sensor to the downstream sensor. If the

sensor positioning or zone length should change after startup, you must reset

the learn mode. Simply remove the two screws from the cover to reveal the two

pin header shown below. Carefully short these two pins together until you see

the LED's flash. Immediately remove the short. You are now ready to run an

object from the upstream sensor to the downstream sensor to "re-learn" the

zone length.

Page 33

31

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

(this page intentionally left blank)

Page 34

32

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

9006 in

conjunction with PLC-

handshakes

9006 after

PLC-handshake (entry zone)

9006 before

PLC-handshake (exit zone)

9006

between PLChandshakes

Upstream device PLC PLC 9006 9006 PLC

Downstream device

9006 9006 PLC PLC

PLC

DIP switch 4 Off Off Off On Off

DIP switch 5 Off On Off Off Off

Upstream peer-to-peer jog/reverse Disabled Disabled Disabled Functional Disabled

Downstream peer-to-peer jog/

reverse

Disabled Functional Disabled Disabled Disabled

Zone type Smart I/O

entry

Smart I/O

entry

Smart I/O

exit

Smart I/O

exit

Smart I/O

dependent

Smart 1 (in) Request Request Perm. Perm. Run

Reverse (in) System

reverse

System

reverse

System

reverse

System

reverse

System reverse

Smart 1 (out) Perm. Perm. Request Request B sensor

Sensor 2 Not used

(smart I/O)

Not used

(smart I/O)

Another

C sensor

Another

C sensor

Not used

Page 35

33

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

• A smart I/O based handshake is required at the interface

• DIP switch 4 must be OFF to make this zone into an entry zone

• Jog and reverse are enabled only if DIP switch 5 is ON

Page 36

34

Version 1.1 (11/2011) en

Original language

Product information

9006 Hybrid Control for RollerDrive

• A smart I/O based handshake is required at the interface

• DIP switch 5 must be OFF to make this zone into an exit zone

• Jog and reverse are enabled only if DIP switch 4 is ON

Page 37

35

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

• A smart I/O based handshake is required at both interfaces

• DIP switch 4 and DIP switch 5 must both be OFF to make this zone into a

dependent zone.

Page 38

36

Version 1.1 (11/2011) en

Original language

Transport and storage

9006 Hybrid Control for RollerDrive

Transport and storage

Transport

• Each 9006 is packed in its own carton case.

Do not stack more than four carton boxes.

Check the fixation of the 9006 before transport.

Avoid hard shocks during transport.

Check each 9006 visually for damage after transport.

In case of damage, take photos of the damaged parts.

To maintain the warranty, instantly report any damage caused during

transport to the transport company and to Interroll.

Do not transfer the 9006 between warm and cold environments as

this may cause condensing water.

Storage

Check each 9006 for damage after storage.

Risk of injury due to improper transport

Transport may only be carried out by qualified and

authorized persons.

Observe the following notices.

CAUTION

Risk of injury due to improper storage

Do not stack more than four carton boxes.

CAUTION

Page 39

37

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Assembly

Assembly

Warning notices concerning assembly

Do not drop or mishandle the 9006 to avoid internal damage.

Check each 9006 visually for damage before assembly.

Warning notices concerning the electrical installation

The electrical installation may only be executed by qualified and authorized

persons.

Disconnect the power before installing, removing or rewiring the 9006.

Do not apply AC current to the RollerDrive or 9006 device at any time

as this will cause irreparable damage.

Do not apply too much stress to the connector pins. Bending the wires at the

connector can cause damage to the insulation of the wires, which could result

in failure of the 9006 or the RollerDrive.

Ensure that the RollerDrive, the 9006 and the 24 VDC power source

are properly earthed through the frame or supporting structure in which the

RollerDrive and the 9006 are installed. Failure to do so could cause

the buildup of static electricity or ground loops and can cause the motor or

9006 to

malfunction or

fail prematurely.

Do not spin the RollerDrive manually, as this generates an induction voltage

which could damage the 9006.

Risk of damage leading to failure or shortened life

expectancy of the 9006

Observe the following notices.

Risk of damage to the 9006

Observe the following notices.

Page 40

38

Version 1.1 (11/2011) en

Original language

Assembly

9006 Hybrid Control for RollerDrive

Installing the 9006 Hybrid Control in a conveyor system

Use the 9006 as a template and mark the center of the two mounting

holes. For the distance between the holes, see "Dimensions", page 7.

Drill two ø 5.6 - 6 mm (0.22 - 0.24 in) mounting holes at the marked spots.

Insert the button head screws in the holes on the opposite side the

9006 is to be mounted.

Install the 9006 to the frame with the screws protruding through the

mounting holes.

Slip the nuts to the screws and tighten.

Ensure that there is a ground path between the 9006 and the conveyor

frame it is mounted to.

Electrical installation

The connector supplied with the RollerDrive EC1xx mates up with the header on

the 9006.

The connectors "Power input and I/O terminal" and "Sensor connection" are cage

clamp terminals.

To actuate the cage clamp, use the supplied tool or insert a small screwdriver.

Plug in the RollerDrive connector.

Plug in the peer-to-peer connection cable, if applicable.

Hint

The 9006 and conveyor frame should be at the same potential referenced

to earth ground.

Page 41

39

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Initial startup and operation

Initial startup and operation

Initial startup

Inspections before initial

startup

Ensure that all bolts are tightened according to the specifications.

Ensure that no additional dangerous areas arise due to interfaces with other

components.

Ensure that the wiring is in accordance with specifications and legal

guidelines.

Check all protection devices.

Ensure that no bystanders are in dangerous areas around the conveyor.

Operation

Inspections before every

startup

Check the position of the DIP switches (see "DIP switches", page 14).

Check the speed settings at the speed rotary switch. It is recommended to

run the RollerDrive at maximum speed.

Check the 9006 for visible damage.

Check all protection devices.

Ensure that no bystanders are in dangerous areas around the conveyor.

Clearly specify and monitor the way goods are placed on the conveyor.

Changing settings

To reduce the speed manually, turn the rotary switch counterclockwise with a

small screwdriver.

To increase the speed manually, turn the rotary switch clockwise with a small

screwdriver.

To set the DIP switches, carefully use a small screwdriver.

Procedure in case of accident or malfunction

Stop the conveyor at once and ensure that it cannot be started accidentally.

In case of an accident: Provide first aid and call for emergency assistance.

Inform responsible persons.

Have the malfunction repaired by qualified persons.

Start the conveyor only after this has been approved by qualified persons.

Damage to the 9006 or the motor of the

RollerDrive due to induction

Do not push items along the roller conveyor by hand.

Do not spin the RollerDrive manually.

Page 42

40

Version 1.1 (11/2011) en

Original language

Maintenance and cleaning

9006 Hybrid Control for RollerDrive

Maintenance and cleaning

Warnings concerning maintenance and cleaning

Maintenance

Checking the 9006 The 9006 must be checked at regular intervals to avoid malfunctions.

Monthly check the 9006 and its leads for visible damage.

Annually ensure that the screws of the 9006 are still tight and that the

cables are still laid properly and connected to the terminals.

Replacing the 9006 If a 9006 is damaged, it has to be replaced.

Install a new 9006 (see "Abandonment", page 45 and see "Assembly",

page 37).

Replacing fuse

Carefully use tweezers to remove and insert the fuse. Ensure you do not

damage the fuse holder, the circuit board or its devices.

Cleaning

Dust and dirt in combination with humidity may bridge the electric circuit.

Therefore, in a dirty environment, periodic cleaning will help to avoid shortcircuits which could damage the 9006.

Regularly blow off dust and dirt by using low compressed air.

Risk of injury due to improper handling or accidental

motor starts

Maintenance work and cleaning may only be executed

by qualified and authorized persons.

Only perform maintenance work after switching off the

power. Ensure that the 9006 cannot be turned

on accidentally.

Set up signs indicating maintenance work.

CAUTION

Page 43

41

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Troubleshooting

Troubleshooting

Error search

When troubleshooting the conveyor system, keep in mind that each

9006 controls a zone. If a problem exists in a zone or a section of

zones, the symptoms might exist either in the zone or in the neighboring zone.

Hint

Keep in mind that information travels downstream. The cause of most control

problems can be found upstream.

Symptom Possible cause Help

System is not operating No power supply Check whether the output voltage of the

power supply is within the specified

voltage range.

Wrong polarity of the bus line inputs Verify the polarity of the bus line inputs

to the 9006 (see "Inputs and

outputs", page 11).

Wrong position of the DIP switch 1 Verify that the position of the DIP switch

1 Logic (NPN or PNP) matches the

sensor type (see "DIP switches",

page 14).

Fuse is blown Replace the fuse (see "Replacing fuse",

page 40).

Zone runs without package Wrong sensor output Check the type of sensor output (see

"Sensor connection", page 12).

Wrong alignment of sensors Verify the alignment of the sensors.

Align the photoeyes to see the conveyor

field only, no overhead lights, side

frames, etc.

Jog command by an inadvertently

grounded Smart 1 / FWD input

command

Check the connection of Smart 1 / FWD

input

Communication cable is twisted or

defective

Check the communication cable

upstream

Photoeye is not connected properly Check the connection of the photoeye to

9006. Verify the photoeye

pin assignment (see "Sensor

connection", page 12).

Photoeye is damaged Replace the photoeye.

If the zone continues to run without

any communication cables

connected and no photoeye input,

9006 is damaged.

Replace 9006. Assembly of

the 9006 see "Assembly",

page 37.

Page 44

42

Version 1.1 (11/2011) en

Original language

Troubleshooting

9006 Hybrid Control for RollerDrive

Multiple zones run continuously Communication cable is defective,

sending a jog command

Find the farthest zone in the upstream

direction that is running continuously.

Check the communication cables of this

zone.

Different ground of a multiple power

supply

Verify that a common ground is shared

by all supplies.

System reverses or jogs without

prompting

Fuse is blown

If DIP switch 4 and 5 are ON for all

cards, a blown fuse or loss of power

in one 9006 sends a reverse

jog command to all 9006 cards in

the system.

Check the fuses in all 9006 cards of

the system and replace the blown one

(see "Replacing fuse", page 40).

Miswired communication cable Check the communication cables in the

entry zone of the system. Replace the

miswired cables.

Zone stops when package arrives

Zone does not accept package

Zone receives the accumulate signal Check that the zone is not receiving the

accumulate signal from the downstream

zone.

Ensure that there is no jumper installed

from ground to the Accum (L-stop) input

terminal on the 9006 of the

zone where the package stops. If a

switch is used instead of a jumper,

check that the switch is off.

Communication cable to or between

the zones is miswired

Check the communication cables and

replace them if they are miswired.

No power supply of the

9006

Check the power input to

9006

No power supply of the RollerDrive

EC1xx

Verify that the motor wires are

terminated properly.

Communication cable is miswired

between the zone that is operating

and the zone that is not

Replace the cable.

Package stops within a zone Photoeye is not aligned properly Check the alignment of the photoeye.

Speed of the RollerDrive EC1xx is

too slow

Calculate the speed and the distance to

ensure the time limit is not exceeded.

Reset "Learn Mode" (see "Learn Mode

Reset, page 30)

Jammed package Remove jammed packages.

Jammed roller Remove the cause of the jam or replace

the roller.

Symptom Possible cause Help

Page 45

43

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Troubleshooting

Package coasts into the next zone

instead of stopping immediately

Package is heavy or has a low

coefficient of friction

Move the photoeye further back into the

zone.

Apply a coating that increases the

friction between the rollers and the

packages.

Zone does not reverse Communication cable to upstream

zone is miswired

Replace the communication cable.

Signal has not been sent and

received properly

Check the output of the upstream

9006 and the input to the

9006.

Different ground of the zones Check that a common ground exists

between bo

th zones.

Sys

tem turns off when several zones

are in use at the same time

Power supply is not sufficient Ensure that the 24 VDC power supply

has adequate power for the system

requirements.

Check that the AC voltage source and

DC voltage power supply are installed

correctly.

9006 does not recognize the

start sensor

Sensor and reflector are not aligned

properly

Check the alignment of the sensor and

reflector.

Check the settings of DIP switch 4

and 5.

RollerDrive EC1xx is not in braking

mode without any packages on the

conveyor system

This is not an error. It is a powersaving feature. The RollerDrive

EC1xx is in coast mode until it is

commanded to run or accumulate.

Symptom Possible cause Help

Page 46

44

Version 1.1 (11/2011) en

Original language

Troubleshooting

9006 Hybrid Control for RollerDrive

The following errors are reported by illuminated LEDs:

(also see "Meaning of the LEDs", page 16)

Symptom Possible cause Help

Motor is in brake mode, red fault

LED flashes once and error output is

active ("No fault output" is active).

Invalid state of motor hall effect

sensor

• Broken wire

• Failed hall effect sensor

Replace the RollerDrive.

Voltage over or under limits

• Power supply fluctuations, failure

or overload condition

Check the power supply.

On a decline, motor is in brake mode

momentarily. Red fault LED flashes

twice ("No fault output" is active) or

power supply shutdown or fuse

blown on card.

Overvoltage detection (caused by

over speed or excessive back EMF)

• decline angle too high

• package weight too high

• Reduce decline angle

• Use brake roller to keep speed low

Motor overrun, overset speed

• Package enters zone at a higher

than anticipated speed

Reduce the package entry speed.

Red fault LED flashes six times and

error output is active ("No fault

output" is active).

Low gain signal from sensor

• Dirty sensor lens or misaligned

Clean the sensor lens and align the

sensor.

Current folds back to maximum

continuous current, amber fault LED

is on.

Card or motor over temperature

• Excessive load or duty cycle

Reduce the load of packages or

throughput of the zone

Current folds back to approximately

1.5 A while applying consistent

torque. Red fault LED is on and error

output is active ("No fault output" is

active).

Motor stall condition

• Obstruction or load too heavy to

be conveyed

Once the stall condition is removed, the

RollerDrive will resume normal

operation.

Page 47

45

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Abandonment and disposal

Abandonment and disposal

Abandonment

Disconnect all cables from the 9006.

Unscrew the screws attaching the 9006 to the conveyor frame.

Extract the 9006 from the conveyor frame.

Disposal

The operator is responsible for the proper disposal of the 9006. In doing

so, industry-specific and local provisions must be observed for the disposal of the

9006 and its packaging.

Risk of injury due to improper handling

Abandonment may only be executed by qualified and

authorized persons.

Only abandon the 9006 after switching off the

power. Ensure that the 9006 cannot be turned

on accidentally.

CAUTION

Page 48

46

Version 1.1 (11/2011) en

Original language

Appendix

9006 Hybrid Control for RollerDrive

Appendix

Plugs and cables

Accessories

Part Description

Power and I/O plug • 8-pin cage clamp type connector, Wago part #

231-308/026-004

• Wire diameter:

– Minimum 0.08 mm

2

(AGW 28)

– Maximum 2.5 mm

2

(AGW 12)

Sensor plug • 6-pin cage clamp type connector, Wago part #

734-106/000-004

• Wire diameter:

– Minimum 0.08 mm

2

(AGW 28)

– Maximum 1.5 mm

2

(AGW 14)

Peer-to-peer cable • Cable: 6 pos flat cable, Digikey part # A0063R

(parts) • Two plugs: 6 pos modular connector plug,

Digikey part # A9093-ND

• Conductor Size AWG: 26

• Assembly tool: AMP part # 2-231652-8

Peer-to-peer cable • Complete cable: 6 pos flat cable,

(preassembled) with (2) 6 pin modular plugs,

Digikey part # A1663R-03-ND (03 = 3 foot length)

• www.digikey.com

Motor plug • The motor plug for the RollerDrive consists of

a

plug and terminal pins

– Plug: AMP part # 175778-8

– Terminal pins: AMP part # 1-175102-1

• Crimping tool AMP part # 9184381

Page 49

47

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Appendix

Glossary

Back EMF Electromotive force (voltage) generated by a package arriving at high speed at

a powered RollerDrive under no load prior to the package’s arrival. EMF is a

counter-voltage phenomenon that is always present in a motor. Excessive back

EMF can cause a current backlash that may damage the 9006 or power

supply. Care should be taken to minimize excessive back EMF by minimizing

the speed differences between the gravity conveyor and/or different zones of

powered conveyor sections.

B sensor Downstream edge presence sensor of own zone

C sensor Downstream edge presence sensor of upstream zone

Coast mode The RollerDrive is running freely without power or braking.

DIP switch 4 Affects upstream peer-to-peer propagation of speed, jog and reverse signals

for certain scenarios.

DIP switch 5 Affects downstream peer-to-peer propagation of speed, jog and reverse signals

for certain scenarios.

Downstream Normally this is the zone to the left of another given zone. The reference is

always that packages move from upstream to downstream.

Dynamic braking For DC motors, dynamic braking is a method of stopping a motor by applying a

resistive load across the motor

winding leads after disconnection from the DC

supply. The motor operates as a generator. By its nature, dynamic braking has

no holding power by itself, i.e. the motor can still be rotated by outside forces.

Interroll has added zero motion hold to achieve this.

EC1xx Short form for Interroll 24 VDC brushless RollerDrive versions:

• EC100

• EC110

• EC120

Edge full Also referred to as "product waiting". It indicates that an upstream zone has a

product at its downstream edge sensor waiting to be moved into the next

downstream zone. Edge full is a signal transmitted across the peer-to-peer

cable used by the 9006 for zone-to-zone communication.

Enhanced Singulated release Also called wave release. A method of release which allows the upstream

release of a package as soon as the downstream package blocks the photoeye

of the downstream zone with its leading edge. This dramatically increases

throughput over singulated release but can sometimes result in lost packages.

There is also a short delay that is propagated upstream to eliminate all

packages starting at the exact same time.

Foldback current Maximum allowable current is decreased by the 9006.

Page 50

48

Version 1.1 (11/2011) en

Original language

Appendix

9006 Hybrid Control for RollerDrive

Idler rollers Non-powered rollers attached to a RollerDrive typically via O-rings or multi-rip

belts.

Jam protection A method of protecting packages that are possibly jammed in a zone. If the

9006 detects a jam or obstruction at the downstream end of the

zone, it sends an accumulation signal to the upstream zone preventing a

buildup of accumulation pressure.

Jog RollerDrive runs continuously as long as the command is set. If jog mode is

activated, the 9006 disregards ZPA or photoeye signals.

N/C No care; affects nothing

NPN-override DIP switch 4 is for upstream, DIP switch 5 is for downstream.

O-rings O-rings made of materials such as polyurethane that connect RollerDrives to

their associated idler rollers.

Perm Permission: Signal to upstream zone to discharge zone (send load).

Photoeye An ON/OFF sensor that uses light to sense the presence of objects. If the light

beam is broken, an object is present. Usually the light is reflected back to the

sensor via a reflector placed on the opposite side of the conveyor frame from

the sensor itself. The 9006 can use either NPN type or PNP type

photoeyes. NPN sensors indicate an active state by a grounded connection

being made (NPN mode) or a 24 VDC connection being made (PNP mode).

Req Request from upstream zone to discharge zone in downstream direction.

RollerDrive One of several types of DC powered rollers manufactured by Interroll

Corporation.

Singulated release A method of releasing packages where packages are allowed into downstream

zone only after the trailing edge of the package currently occupying that

downstream zone clears the zone's downstream edge sensor.

Si

ngulation DIP switch 3 chooses either standa

rd or enhanced singulation, significant for all

zone types except smart I/O dependent.

Upstream The opposite of "downstream" (see definition). Typically, the zone to the right of

another zone.

Zero motion hold For DC motors, zero motion hold is a method of holding a motor by applying a

small amount of current to the motor winding leads. When the 9006

is commanded to stop and accumulate, the braking action is twofold. First, the

motor/package is stopped using dynamic braking. Second, the motor is held in

place by zero motion hold. In this state the 9006 will resist being

rotated by outside forces.

Zone A segment of conveyor typically comprised of one RollerDrive and multiple idler

rollers interconnected by O-rings or some other device for driving the idlers.

ZPA Zero pressure accumulation: The process of moving packages on a conveyor in

such a manner that they do not touch each other (also see "ZPA technology",

page 7).

Page 51

49

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Appendix

Manufacturer's declaration

in terms of the EC-Machine Directive 98/37/EC and its amendment 98/79/EC,

Annex II B

The manufacturer:

Interroll Corporation

3000 Corporate Drive

Wilmington, NC 28405

USA

hereby declares with sole responsibility that the product range

• 9006 Hybrid Control for RollerDrive

is not a ready-to-use assembly in terms of the EC-Machine Directive and

therefore does not fully comply with the requirements of this directive. It

must not be put into service until the machinery into which it is to be

incorporated has been declared to conform with the provisions of the

Machine Directive.

Applied EC Directives:

Machine Directive 98/37/EC and its amendment 98/79/EC

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

RoHS Directive 2002/95/EC

Applied harmonized norms:

EN ISO 12100 Part1 and Part2

Wilmington, NC, December 20

th

2010

Richard Keely

(Vice President of Manufacturing)

(This declaration can be obtained at www.interroll.com, if needed.)

Page 52

Version 1.1 (11/2011) en

Original language

Interroll Nordic A/S

Hammerholmen 2-6

DK-2650 Hvidovre/Denmark

Tel. +45 36 88 33 33

Fax +45 36 88 33 72

dk-sales@interroll.com

Interroll Service

Islandsvej 5

DK-7900 Nykøbing M.

Tel. +45 97 71 15 55

Fax +45 97 71 16 55

dk-sales@interroll.com

IBH ehf

Dugguvogur 10

104 Reykjavik

Iceland

Tel. +354 562 6858

Fax +354 562 6862

ingi@ibh.ehf.is

Tel. +358 9 54 94 94 00

Fax +358 9 54 94 94 16

Tel. +47 32 88 26 00

Fax +47 32 88 26 10

Tel. +46 35 227077

Fax +46 35 227078

Interroll S.A.S.

ZI de Kerannou

B.P. 34

F-29250 Saint Pol de Léon

Tel. +33 298 24 41 00

Fax +33 298 24 41 02

f-sales@interroll.com

Rulli Rulmeca S.p.A.

Via A. Toscanini, 1

I-24011 Almè (Bg)

Tel. +39 035 4300111

Fax +39 035 545523

i-sales@interroll.com

Rulmeca Interroll de Portugal Lda

Apartado 69, Centro Civico

P-6201-909 Covilhã

Tel. +351 275 330 780

Fax +351 275 990 789

p-sales@interroll.com

Interroll España S.A.

Parc Teconològic del Vallès

C/Dels Argenters, 5

Edificio 1, módulos Bp y Cp

E-08290 Cerdanyola del Vallès

Tel. +34 90 211 0860

Fax +34 93 586 4895

e-sales@interroll.com

Interroll España S.A.

Parc Teconològic del Vallès

C/Dels Argenters, 5

Edificio 1, módulos Bp y Cp

E-08290 Cerdanyola del Vallès

Tel. +34 90 211 0860

Fax +34 93 586 4895

e-sales@interroll.com

Interroll Ltd.

Brunel Road

Earlstrees Industrial Estate

GB-Corby, Northants NN17 4UX

Tel. +44 1536 200 322

Fax +44 1536 748 515

gb-sales@interroll.com

Interroll Fördertechnik GmbH

Höferhof 16

D-42929 Wermelskirchen

Tel. +49 2193 23 0

Fax +49 2193 20 22

d-sales@interroll.com

Tel. +49 2193 23 187

Fax +49 2193 23 164

Tel. +49 2193 23 131

Fax +49 2193 23 164

Tel. +49 2193 23 190

Fax +49 2193 23 164

Tel. +49 2193 23 151

Fax +49 2193 23 164

Tel. +49 2193 23 190

Fax +49 2193 23 164

Interroll CZ, s.r.o.

Na Řádku 7/3172

CZ-69002 Břeclav

Tel. +420 519 330 210

Fax +420 519 330 211

cz-sales@interroll.com

Tel. +36 23 337 891

Fax +36 23 337 892

Interroll Polska Sp. z o.o.

ul. Płochocińska 85

PL-03-044 Warszawa

Tel. +48 22 741 741 0

Fax +48 22 741 741 1

pl-sales@interroll.com

Tel. +421 2 4363 8102

Fax +421 2 4342 7294

Tel. +386 1 56 56 370

Fax +386 1 56 56 372

Rol-er Makina San. Ve. Tic. Ltd. Sti.

Pembegul Sok., Dostlar Apt.

No. 12 D. 10 Suadiye

347 40 Istanbul

Turkiye

Tel. +90 216 386 37 75

Fax +90 216 386 38 22

tr-sales@interroll.com

ComTrans-Tech Ltd.

P.O.B. 17433

Tel-Aviv 61174

Israel

Tel. +972 54 4 27 27 47

Fax +972 3 7 44 08 64

il-sales@interroll.com

Interroll SA

Pty. Ltd.

P.O. Box 327

Isando 1600

37 Director Road, Spartan Ext 2

1619

Tel. +27 11 281 9900

Fax +27 11 252 9083

za-sales@interroll.com

Interroll Corporation

3000 Corporate Drive

USA-Wilmington, NC 28405

Tel. +1 910 799 11 00

Fax +1 910 392 38 22

usa-sales@interroll.com

Interroll Components Canada Ltd.

8900 Keele Street

Unit 2 & 3

Concord, Ontario L4K 2N2

Canada

Tel. +1 905 660 4426

Fax +1 905 660 4159

cdn-sales@interroll.com

Interroll Canada Ltd.

Drives & Rollers Canada

1201 Gorham Street

Newmarket Ontario L3Y 8Y2

Canada

Tel. +1 905 727 3399

Fax +1 905 727 3299

cdn-sales@interroll.com

Interroll Logistica

Elementos para Sistemas

Transportadores Ltda.

Av. Alexandrina das Chagas

Moreira 945

Bairro Distrito Industrial

Pindamonhangaba-SP

Brasil

CEP 12412 - 800

Tel. +55 12 3648 8021

Fax +55 12 3648 8164

sa-sales@interroll.com

Interroll (Suzhou) Co. Ltd.

Unit 10B, Modern Industrial Square

No. 333 Xing Pu Road

Suzhou Industrial Park

Suzhou, Jiangsu Province

People’s Republic of China

Postal Code: 215126

Tel. +86 512 6256 0383

Fax +86 512 6256 0385

cn-sales@interroll.com

Interroll Japan Co. Ltd.

302-1 Shimokuzawa

Sagamihara-shi

Kanagawa 229-1134

Japan

Tel. +81 42 764 2677

Fax +81 42 764 2678

jpn-sales@interroll.com

Interroll Korea Corporation

Room 301, Dongsan Bldg, 333-60

Shindang-Dong, Choong-ku

Seoul

Korea

Tel. +822 2 231 1900

Fax +822 2 254 36 83

kr-sales@interroll.com

Interroll (Asia) Pte. Ltd.

386 Jalan Ibrahim

629156 Singapore

Republic of Singapore

Tel. +65 6266 6322

Fax +65 6266 6849

sgp-sales@interroll.com

Interroll (Thailand) Co. Ltd.

Interroll Drives and Rollers India Private Limited

SF 12, KSSIDC Building 3rd Stage

Peenya, Bangalore

Bangalore - 560058

Kamataka, India

Tel. +91 80 2359 5904

Fax +91 80 2349 5241

in-drummotors@interroll.com

41/6 Moo 6, Bangchalong,

Bangplee

Samutprakarn 10540

Thailand

Tel. +66 2 337 0188 91

Fax +66 2 337 01 92

th-sales@interroll.com

Conveyor Solutions Australia Pty. Ltd.

70 Keon Parade

Thomastown

VIC 3073

Australia

Tel. +61 3 9460 2155

Fax +61 3 9460 2029

aus-sales@interroll.com

South Africa

Automation Equipment (NZ) Ltd.

45 Colombo Street

Frankton

Hamilton

New Zealand

Tel. +64 7847 2082

Fax +64 7847 7160

nz-sales@interroll.com

Europe/Nordic

Denmark

Iceland

Finland

Norway

Sweden

Western/Southern Europe

France

Italy

Portugal

Spain

United Kingdom

Central Europe

Germany

Austria

Belgium

Luxembourg

Netherlands

Switzerland

Eastern Europe

Czech Republic

Hungary

Poland

Slovakia

Slovenia

Turkey

Near East

Israel

Africa

South Africa

North & South America

USA

Canada

Brasil

For other countries in

South America, please contact:

Asia

China

Japan

Korea

Singapore

Thailand

India

Australia & New Zealand

Australia

New Zealand

For other countries please

Loading...

Loading...