IR3721

DATA SHEET

Power Monitor IC with

Analog Output

FEATURES

Accurate TruePower

• 2.5% static accuracy

• Minimizes dynamic errors

Minimizes power dissipation

• 5mV - 150mV full scale current range

Versatile

• Monitors power or current

• Single buck or multiphase converters

• Inductor DCR or resistive shunt sensing

Simple add-on to existing converters

10 pin 3x3 DFN lead free package

RoHS compliant

TM

monitor

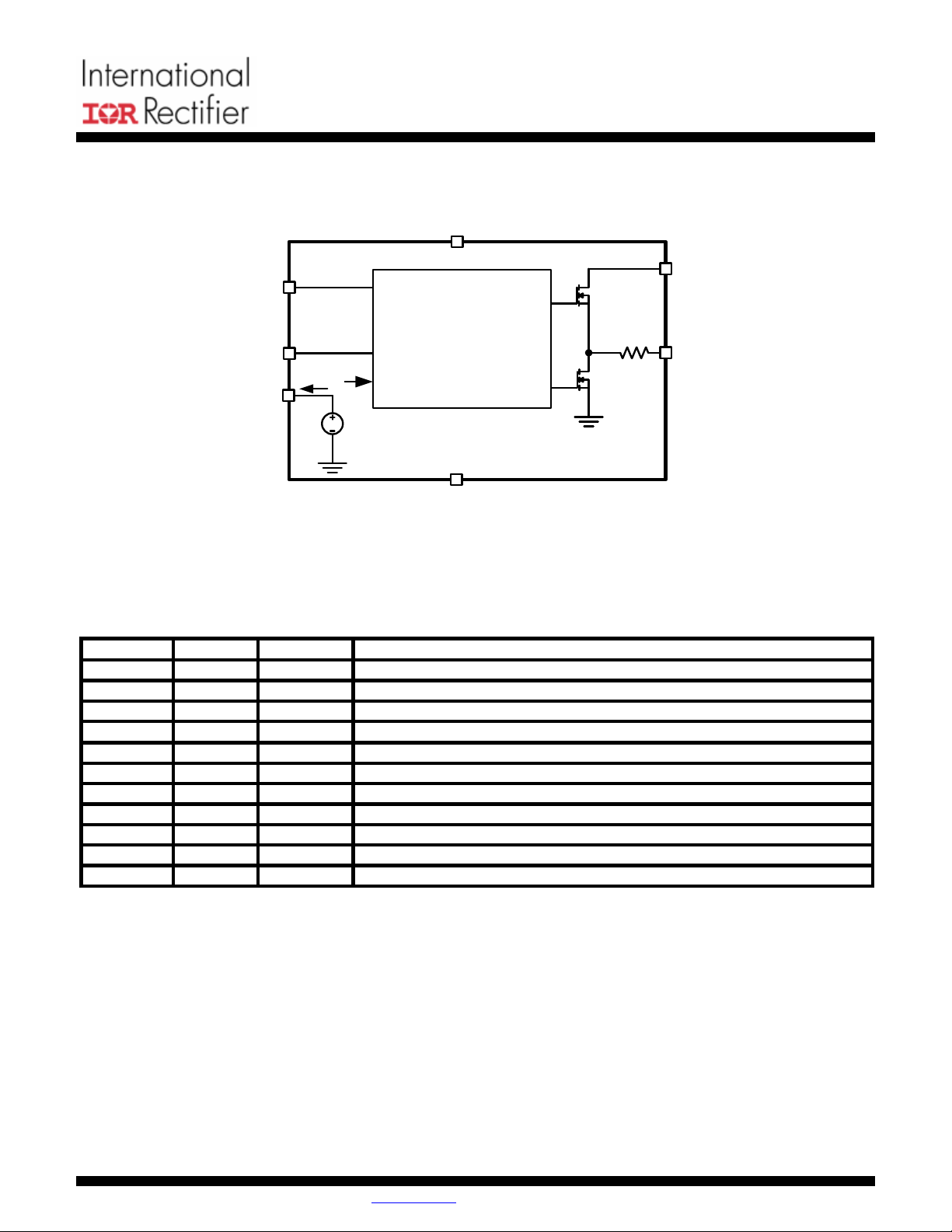

TYPICAL APPLICATION CIRCUIT

DESCRIPTION

The IR3721 is a versatile power or current monitor IC

for low-voltage DC-DC converters. The IR3721

monitors the inductor current in buck or multiphase

converters using either a current sensing resistor or the

inductor’s winding resistance (DCR). The output (DI) is

a pulse code modulated signal whose duty ratio is

proportional to the inductor current. An analog voltage

that is proportional to power is realized by connecting

V

to VO and connecting an RC filter to DI.

K

The IR3721 uses Patent Pending TruePower

technology to accurately capture highly dynamic power

waveforms typical of microprocessor loads.

TM

ORDERING INFORMATION

Device Package Order Quantity

IR3721MTRPBF 10 lead DFN (3x3 mm body) 3000 piece reel

IR3721MPBF 10 lead DFN (3x3 mm body) Sample Quantity

Page 1 of 16 www.irf.com 01/04/08

ABSOLUTE MAXIMUM RATINGS

IR3721

DATA SHEET

Absolute Maximum Ratings (Referenced to GND)

VDD:.................................................................3.9V

All other Analog and Digital pins......................3.9V

Operating Junction Temperature .... -10°C to 150°C

Storage Temperature Range .......... -65°C to 150°C

ESD Rating ............HBM Class 2 JEDEC Standard

MSL Rating ..................................................Level 2

Reflow Temperature ..................................... 260°C

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device.

These are stress ratings only and functional operation of the device at these or any other conditions beyond those

indicated in the operational sections of the specifications are not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

ELECTRICAL SPECIFICATIONS

Unless otherwise specified, these specifications apply: VDD = 3.3V ± 5%, 0oC ≤ TJ ≤ 125oC, 0.5 ≤ Vo ≤ 1.8 V, and

operation in the typical application circuit. See notes following table.

PARAMETER TEST CONDITION MIN TYP MAX UNIT

BIAS SUPPLY

VDD Turn-on Threshold, VDDUP 3.10 V

VDD Turn-off Threshold, VDDDN 2.4 V

VDD UVLO Hysteresis DI output low when off 75 mV

VDD Operating Current, ICC 350 450 μA

VOLTAGE REFERENCE

VRT Voltage RT = 25.5k Ω 1.452 1.493 1.535 V

RT resistance range Note 1 25.5

ΔΣ CONVERTER

Vo common mode range 0.5 1.8 V

Duty Ratio Accuracy V

Duty Ratio Accuracy V

=20 mV, VO=1V,

DCR

R

=25.5kΩ, R

T

T

=65°C, Note 1

j

=20 mV, VO=1V,

DCR

=25.5kΩ, R

R

T

CS1+RCS2

CS1+RCS2

2.5 %

=600 Ω

4 %

=600 Ω,

Note 1

Sampling frequency, f

435 512 589 kHz

CLK

Comparator Offset -0.5 +0.5 mV

CS pin input current, ICS DI output low -250 +250 nA

DIGITAL OUTPUT

VK pin voltage range 0.5 1.8 V

DI source resistance 1250 2000 3000

NOTES:

1. Guaranteed by design

kΩ

Ω

Page 2 of 16 www.irf.com 01/04/08

BLOCK DIAGRAM

IR3721

DATA SHEET

VDD

VK

VO

VCS

V

RT

I

REF

I

REF

VO

TruePower™

VCS

result out

DI

result out/

IR3721

GND

IC PIN DESCRIPTION

NAME NUMBER I/O LEVEL DESCRIPTION

VCS 1 Analog Current sensing input, connect through resistor to sensing node

VO 2 Analog Current sensing reference connect to output voltage

VRT 3 Analog RT thermistor network from this pin to GND programs thermal monitor

GND 4

VDD 5 3.3V IC bias supply

GND 6 Connect to pin 4

GND 7 Connect to pin 4

DI 8 Analog Power Monitor output; connect to output filter

VK 9 1.8V Connect to fixed voltage or VO, multiplied by DI to become analog output

VDD 10 3.3V Connect to pin 5

BASE PAD Connect to pin 4

Bias return and signal reference

Page 3 of 16 www.irf.com 01/04/08

IC PIN FUNCTIONS

VDD PINS

IR3721

DATA SHEET

VRT PIN

These pins provide operational bias current to circuits

internal to the IR3721. Bypass them with a high

quality ceramic capacitor to the GND pins.

GND PINS

These pins return operational bias current to system

ground. VO is measured with respect to GND. The

GND pin sinks reference current established by the

external resistor R

.

T

VO PIN

Since this pin measures DCR voltage drop it is critical

that it be Kelvin connected to the buck inductor

output. Power accuracy may be degraded if the

voltage at this pin is below VO

min

.

VCS PIN

A switched current source internal to the IR3721

maintains the average voltage of this pin equal to the

voltage of the VO pin. The average current into this

pin is therefore proportional to buck inductor current.

A voltage reference internal to the IR3721 drives the

V

pin while the pin current is monitored and used to

RT

set the amplitude of the current monitor switched

current source I

a precision resistor network R

. Connect this pin to GND through

REF

. This network may

T

include provision for canceling the positive

temperature coefficient of the buck inductor’s DC

resistance (DCR).

VK PIN

The voltage of the VK pin is used to modulate the

amplitude of the DI pin. This is one of the terms used

to determine the product of the multiplier output. If VK

is connected to a fixed voltage then the output of the

multiplier is proportional to current. If VK is connected

to the buck converter output voltage then the output

of the DI driven RC filter is proportional to power.

DI PIN

The Dl pin output has a duty ratio proportional to the

current into VCS, and an amplitude equal to the

voltage at the VK pin. The DI pin is intended to drive

an external low pass filter. The output of this filter is

the product of the current and voltage terms.

Page 4 of 16 www.irf.com 01/04/08

FUNCTIONAL DESCRIPTION

Please refer to the Functional Description Diagram

below. Power flow from the buck converter inductor is

the product of output voltage times the current I

L

flowing through the inductor.

Power is measured with the aid of International

Rectifier’s proprietary TruePower™ circuit. Current is

converted to a duty ratio that appears at the DI pin.

The duty ratio of the DI pin is

DI

RATIODUTY

RR

⋅

DCRI

L

=

R

T

⋅

)+(

2CS1CS

V

Τ

R

Equation 1

The full-scale current that can be measured

corresponds to a duty ratio of one.

I

L

Vin

R

L

CS1

DCR

C

CS1

C

CS2

VCS

R

CS2

VO

The amplitude of the DI pin is the voltage appearing

at pin VK. If a fixed voltage is applied to VK then the

output of the RC filter driven by DI will be proportional

to inductor current I

.

L

If VO is applied to V

as shown in the figure then the

K

output of the DI driven RC network will be

proportional to power. The full-scale voltage that can

be measured is established on the chip to be 1.8V.

The full scale power P

that can be measured is the

FS

product of full-scale voltage and full scale current.

Vo

VDD

VK

IR3721

DI

Power

V

RT

R

T

GND

Figure 1 Functional Description Diagram

Page 5 of 16 www.irf.com 01/04/08

THERMAL COMPENSATION FOR INDUCTOR DCR CURRENT

SENSING

The positive temperature coefficient of the inductor

DCR can be compensated if R

varies inversely

T

proportional to the DCR. DCR of a copper coil, as a

function of temperature, is approximated by

TCRTTTDCRTDCR -1

)⋅)(+(⋅)(=)(

CuRR

Equation 2

T

is some reference temperature, usually 25 °C, and

R

TCR

is the resistive temperature coefficient of

Cu

copper, usually assumed to be 0.39 %/°C near room

temperature. Note that equation 2 is linearly

increasing with temperature and has an offset of

DCR(T

If R

) at the reference temperature.

R

incorporates a negative temperature coefficient

T

thermistor then temperature effects of DCR can be

minimized. Consider a circuit of two resistors and a

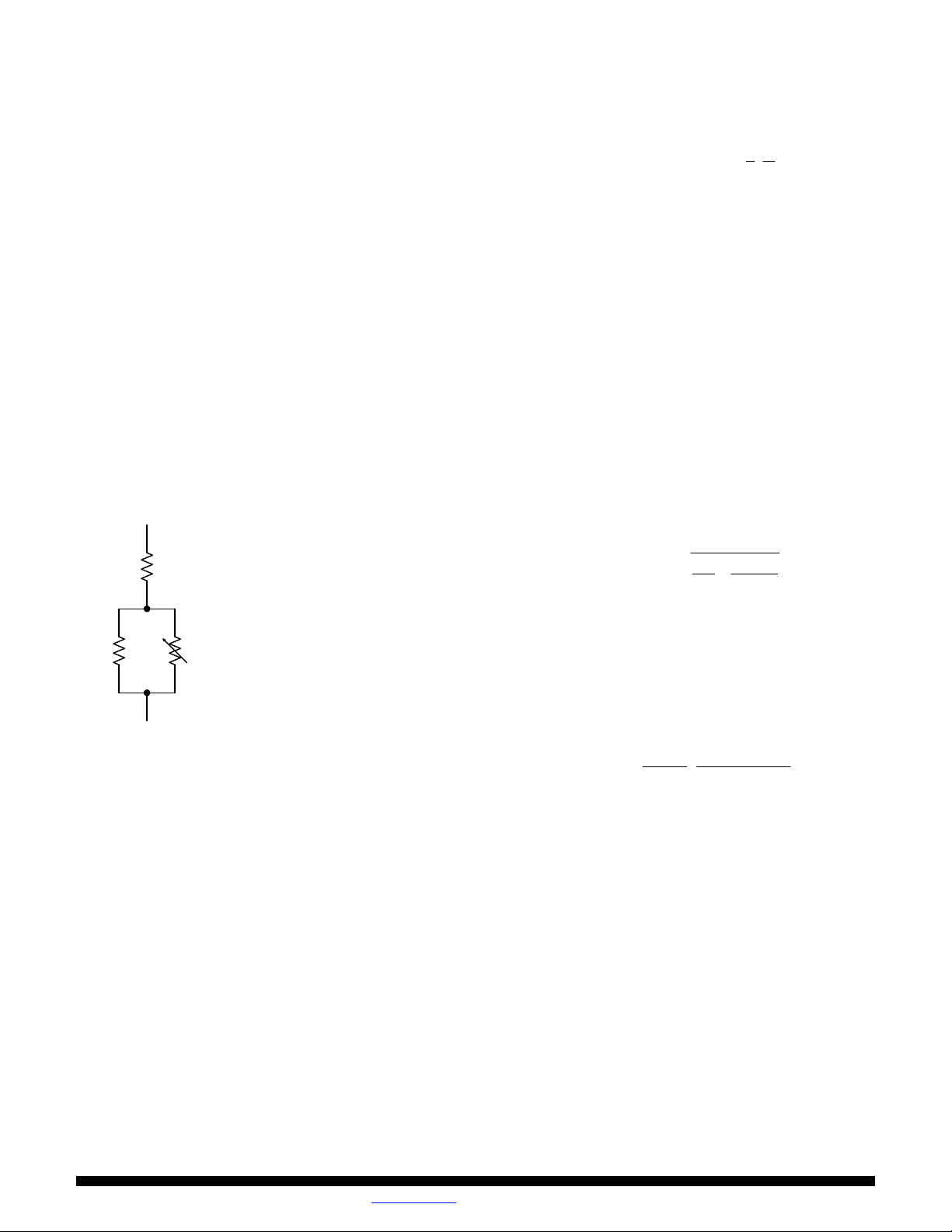

thermistor as shown below.

Rs

⎛

⎜

β

⎜

⎝

⋅)(=)(

eTRTR

0

thth

⎞

⎞

⎛

11

⎟

⎟

⎜

-

⎟

⎜

⎟

TT

0

⎠

⎝

⎠

Equation 3

where R

temperature T, R

the reference temperature T

(T) is the thermistor resistance at some

th

) is the thermistor resistance at

th(T0

, and β is the material

0

constant provided by the thermistor manufacturer.

Kelvin degrees are used in the exponential term of

equation 3. If R

is large and RP is small, the

S

curvature of the equivalent network resistance can be

reduced from the curvature of the thermistor alone.

Although the exponential equation 3 can never

compensate linear equation 2 at all temperatures, a

spreadsheet can be constructed to minimize error

over the temperature interval of interest. The

equivalent resistance R

of the network shown as a

T

function of temperature is

+=)(

RTR

sT

1

+

11

)(

TRR

thp

RthRp

Figure 2 R

If Rth is an NTC thermistor then the value of the

network will decrease as temperature increases.

Unfortunately, most thermistors exhibit far more

variation with temperature than copper wire. One

equation used to model thermistors is

Network

T

Equation 4

using R

(T) from equation 3.

th

Equation 2 may be rewritten as a new function of

temperature using equations 2 and 4 as follows:

()

+

FS

V

Τ

R

=)(

TI

⋅

)(

TR

T

RR

2CS1CS

)(

TDCR

Equation 5

With Rs and Rp as additional free variables, use a

spreadsheet to solve equation 5 for the desired full

scale current while minimizing the I

(T) variation

FS

over temperature.

Page 6 of 16 www.irf.com 01/04/08

TYPICAL 2-PHASE DCR SENSING APPLICATION

The IR3721 is capable of monitoring power in a

multiphase converter. A Two Phase DCR Sensing

Circuit is shown below. The voltage output of any

phase is equal to that of any and every other phase

because they are electrically connected and

monitored at VO as before.

Output current is the sum of the two inductor currents

(I

+ IL2). Superposition is used to derive the transfer

L1

function for multiphase sensing. The voltage on R

due to I

L1

is

)||(

RR

32

⋅⋅

DCRI

L

11

CSCS

)||(+

RRR

321

CSCSCS

CS2

Likewise, the voltage on RCS2 due to IL2 is

)||(

RR

12

⋅⋅

DCRI

L

22

CSCS

)||(+

RRR

123

CSCSCS

The current through R

currents is I

. From the two equations above

CS

I

=

CS

due to both inductor

CS2

+

++

RDCRIRDCRI

122311

CSLCSL

RRRRRR

323121

CSCSCSCSCSCS

The duty ratio of DI is

RI

⋅

DI

DUTYRATIO

=

TCS

V

REF

If DCR1=DCR2, and RCS1=RCS3, then I

can be

CS

simplified to

I

=

CS

DCRII

⋅)+(

LL

2

+

121

RR

21

CSCS

and the DI duty ratio simplifies to

⋅⋅)+(

RDCRII

T2L1L

DI

DUTYRATIO

=

⋅)+(

VR2R

Τ

R2CS1CS

Full scale current occurs when DI duty ratio becomes

one.

Figure 3 Two Phase DCR Sensing Circuit

Page 7 of 16 www.irf.com 01/04/08

RESISTOR SENSING APPLICATION

The Resistor Sensing Circuit shown below is an

example of resistive current sensing. Because the

voltage on the shunt resistor is directly proportional to

the current I

not need to match the L / DCR time constant.

through the inductor, R

L

Phase 1

CS2

and C

I

L

CS2

DCR

do

L

Buck

Converter

R

Power

Return

CS2

VDD

VDD

VDD

Bypass

V

Cap

RT

SHUNT

C

VCS

IR3721

Because the value of the shunt resistance does not

change with temperature as the inductor DCR does,

can be a fixed resistor.

R

T

VO

CS2

VO

VK

DI

Power

R

T

GND

Figure 4 Resistor Sensing Circuit

Page 8 of 16 www.irf.com 01/04/08

COMPONENT SELECTION GUIDELINES

Use a 0.1 μF, 6.3V, X7R ceramic bypass capacitor

from VDD to GND and from VK to GND.

Filter the DI output with an RC filter to give a stable

analog representation of the current or power. Some

of the DI source resistance of this filter is internal to

the IR3721 and specified in the electrical

specifications table. Add twenty thousand to fifty

thousand additional ohms externally to minimize

resistance variation. As the DI source resistance

increases beyond these guidelines, the voltage

measurement error caused by non-ideal voltmeter

conductance will increase.

Select a filter capacitor that limits 512 kHz sampling

frequency ripple to an acceptable value. Sampling

frequency ripple will appear as an error, but can be

reduced 20 dB for each decade that the filter corner

frequency is below 512 kHz. Select a capacitor value

that achieves the desired balance between low

sampling frequency ripple and adequate bandwidth.

Resistor current sensing

For resistor current sensing select a precision resistor

for R

inside the RT resistance range limits specified

T

in the Electrical Specifications table, such as 25.5kΩ

and 1% tolerance.

Next, select a shunt resistor that will provide the most

current sensing voltage while also considering the

allowable power dissipation limitations. The DI output

will saturate to the VK voltage when full scale current

I

flows through this shunt. Recommended

FS

maximum current sensing voltage range is 5 to 150

mV. Maximum sensing voltages less than 5 mV will

cause comparator input offset voltage errors to

dominate, and voltages larger than 150 mV will cause

comparator leakage current, I

Select R

resistor from (R

to be the next higher standard value

CS2

SHUNT·IFS·RT

accommodate full scale current I

Bypass VCS to VO with capacitor C

, errors to dominate.

CS

) / VRT in order to

.

FS

. The value of

CS2

this capacitor limits the bandwidth, but is required

because it is the integrator of the delta sigma

modulator. Consider selecting the value of C

CS2

to

place a filter corner frequency at 5 kHz, which will

reduce sampling ripple by 40 dB.

DCR current sensing

Select an R

45.3kΩ. Consider the R

network resistance between 20kΩ and

T

network of Figure 5 for DCR

T

current sensing.

15.0 kΩ, 1%

Figure 5 R

The resistance of the network above at 25°C, R

is 37.58kΩ. Over temperature R

copper resistance, DCR(25)·(1+(T-25)·0.0039),

divided by (DCR(25)·( R

results, and plotted as nominal error in Figure 6.

5%

4%

3%

2%

1%

0%

-1%

Nominal error

-2%

-3%

-4%

-5%

Figure 6 Nominal error vs. Temperature

Note that the error due to temperature compensation

at 25°C is zero, assuming ideal R

other temperatures the results are over or under

reported by the factor in percent indicated.

Proceed to calculate R

R

plus R

CS1

Again, I

voltage establishing the current in R

Estimate the capacitance C

equation.

26.1 kΩ, 1%

2.00 kΩ, 1%

Murata Thermistor

NCP15WB473F03RC

47 kΩ, 1%

network

T

(25),

(T) is multiplied by

T

(25)) to normalize the

T

020406080100

Temperature [°C]

T

components. At

T

, defined as the sum of

, as follows.

CS2

R

SUM=IFS

SUM

·DCR(25) ·RT(25) / VRT

is full scale current and VRT is the reference

FS

.

T

with the following

CS1

L

⋅

C

>

CS

1

4

25

RDCR

⋅)(

SUM

Page 9 of 16 www.irf.com 01/04/08

Choose a standard capacitor value larger than

indicated by the right hand side of the inequality

above.

Calculate the equivalent resistance R

.

eq

= L / (DCR(25) ·C

R

eq

CS1

)

We now have two equations, R

Req = (R

and R

· R

CS2

) / (R

CS1

using the following two equations.

CS2

CS1

+ R

= R

SUM

CS2

CS1

). Calculate R

+ R

CS2

CS1

and

⎛

⎜

⎜

RR

⎜

⋅=

SUMCS1

⎜

⎜

⎜

⎝

411

⋅+

-

2

⎞

R

eq

⎟

⎟

R

SUM

⎟

and

⎟

⎟

⎟

⎠

⎛

⎜

--

411

⎜

RR

⎜

⋅=

SUM2CS

⎜

⎜

⎜

⎝

⋅

2

⎞

R

eq

⎟

⎟

R

SUM

⎟

⎟

⎟

⎟

⎠

Use the next higher standard 1% value than indicated

in the equations above. This will insure that full scale

current can be measured.

Bypass VCS to VO with capacitor C

. The value of

CS2

this capacitor limits the bandwidth, but is required

because it is the integrator of the delta sigma

modulator. Consider selecting the value of C

CS2

to

place a filter corner frequency at 5 kHz, which will

reduce sampling ripple by 40 dB.

Page 10 of 16 www.irf.com 01/04/08

LAYOUT GUIDELINES

Refer to figures 7 through 11 for guidance laying out

the IR3721. These guidelines also apply to resistive

current sensing. The following guidelines will

minimize sources of noise and error, which is

required because millivolt level signals correspond to

amps of inductor current.

1. Place the capacitor Ccs2 close to the VO and

VCS pins of the IR3721. Treat VO and VCS as a

differential signal pair back to the IC as shown in

the elliptical area designated #1 of figure 8.

2. Sense the inductor (or shunt) Kelvin style at its

terminals. Route the leads back as a differential

pair. Refer to area #2 of figure 8.

3. Route signal VOUT back to the IC VK pin on its

own dedicated trace. Refer to area #3 of figure 8.

4. Place the thermistor near the inductor. Refer to

area #4 of figure 8. Route the thermistor leads

back to the rest of the network using differential

traces. Mount the rest of the thermistor network

consisting of Rs, Rp, and R1 close to the IC.

L1

1 2

Rcs 1

Ccs 1

Rcs 2

Ccs 2

Rs

U1

1

CS

2

VO

3

RT

4

GND_1

VCC5GND_ 4

VCC_ 1

GND_ 3

IR3721

5. Use an isolated dedicated ground plane

connected only to components associated with

the IR3721 that connect to GND as shown in

figure 9. Connect this dedicated ground plane at

one location only to the ground of the monitored

voltage. The thermally relived via in figure eight

illustrates this connection.

6. Bypass IC VDD pin 5 to GND pin 4 with a high

quality 0.1 μF ceramic capacitor. Refer to area #6

of figure 8.

7. Bypass the IC VK pin to GND with a high quality

0.1 μF ceramic capacitor. Refer to area #7 of

figure 8.

VOUT

VOUT

10

9

VK

8

DI

7

6

R_DI_FILT

DI_FILT

VDD

Figure 7 Example schematic

C_VDD

Rth

Rp

0

1 2

R1

0.1uF

C_VK

0.1uF

C_DI_FILT

GND

Page 11 of 16 www.irf.com 01/04/08

2

3

4

1

6

Figure 8 Layer 1

7

Figure 10 Layer 3

Figure 9 Layer 2

Figure 11 Layer 4

Page 12 of 16 www.irf.com 01/04/08

PCB PAD AND COMPONENT PLACEMENT

Figure 12 below shows suggested pad and component placement.

Figure 12 Pad placement

Page 13 of 16 www.irf.com 01/04/08

SOLDER RESIST

Figure 13 below shows suggested solder resist placement.

Figure 13 Solder resist

Page 14 of 16 www.irf.com 01/04/08

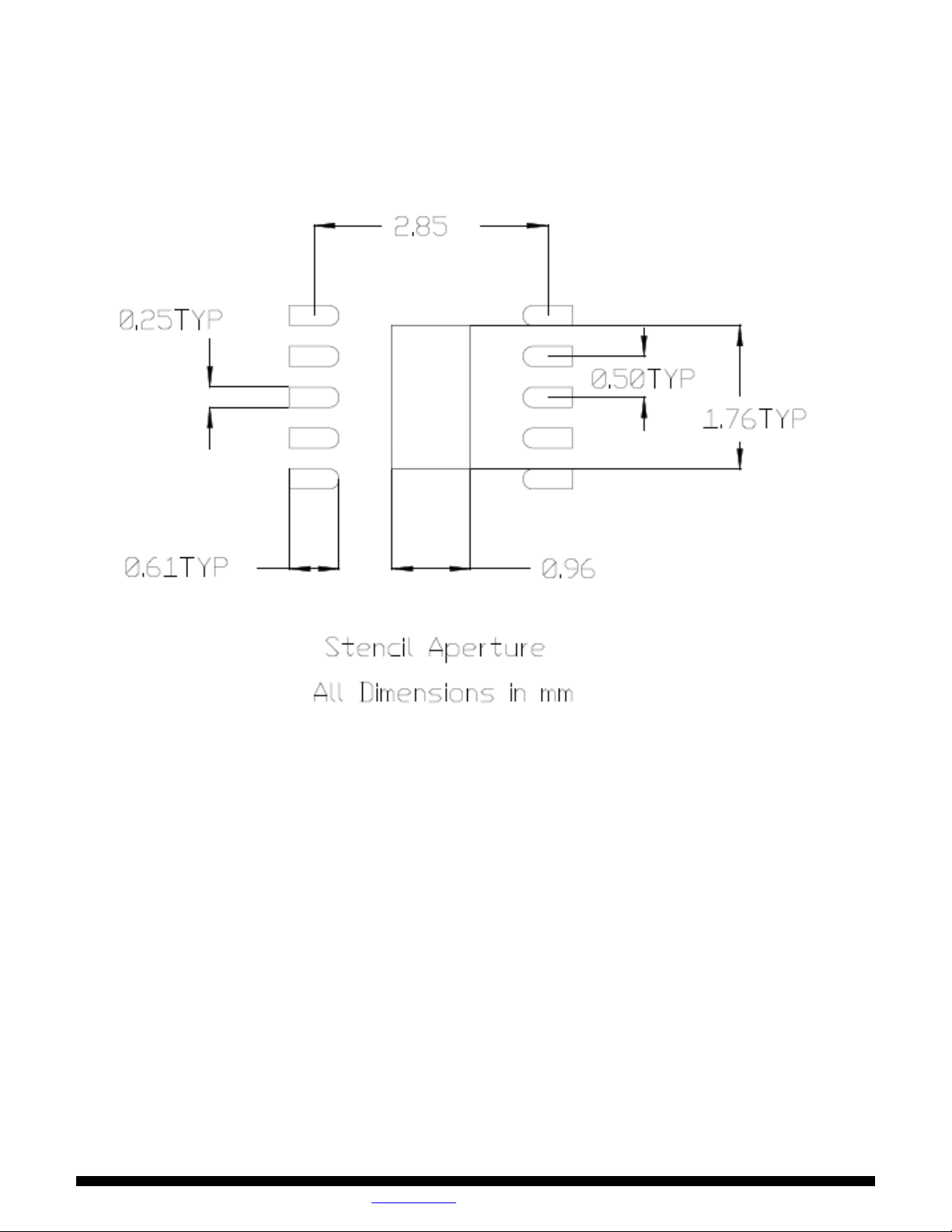

STENCIL DESIGN

Figure 14 below shows a suggested stencil design.

Figure 14 Stencil design

Page 15 of 16 www.irf.com 01/04/08

PACKAGE INFORMATION

3 X 3 MM 10L DFN LEAD FREE

S

Y

M

B

O

L

A 0.80 0.90 1.00 .032 .035 .039

A1 0.00 0.02 0.05 .000 .0008 .0019

A3 0.20REF .008REF

b 0.18 0.25 0.30 .0071 .0098 .0118

D2 2.20 - 2.70 .087 - .106

D 3.00BSC .118BSC

E 3.00BSC .118BSC

E2 1.40 - 1.75 .055 - .068

L 0.30 0.40 0.50 .012 .016 .019

e 0.50 PITCH .020 PITCH

N 10 10

ND 5 5

NE 5 5

aaa 0.15 .0059

bbb 0.10 .0039

ccc 0.10 .0039

ddd 0.05 .0019

MILLIMETERS

MIN NOM MAX MIN NOM MAX

3x3 MLPD

INCHES

Data and specifications subject to change without notice.

This product has been designed and qualified for the Consumer market.

Qualification Standards can be found on IR’s Web site.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

TAC Fax: (310) 252-7903

Visit us at www.irf.com for sales contact information.

Page 16 of 16 www.irf.com 01/04/08

Loading...

Loading...