www.DataSheet4U.com

IR3084U

DESCRIPTION

The IR3084U Control IC combined with an IR XPhase

way to implement a complete VR10, VR11, Opteron, or Athlon64 power solution. The “Control” IC

provides overall system control and interfaces with any number of “Phase” ICs which each drive and

monitor a single phase of a multiphase converter. The XPhase

that is smaller, less expensive, and easier to design while providing higher efficiency than conventional

approaches.

The IR3084U is based on the IR3084 VR10 Control IC, but incorporates the following modifications;

• Supports VR11 7-bit VID, VR10 7-bit extended VID, and Opteron/Athlon64 5-bit VID codes

• Supports both VR11 and legacy Opteron/Athlon64 start-up sequences

• VID Select pin sets the DAC to VR10, VR11, or Opteron/Athlon64

• INTL_MD output pin indicates which DAC is selected – Intel or AMD

• VOSENS float detection protects the CPU in the event that the VOSENS trace is broken

• Enable Input Thresholds set by VID Select pin to either VR10, VR11 or Opteron/Athlon64

• VID Input Thresholds set by VID Select pin to either 0.6V (VR10/VR11) or 1.24V (AMD)

• No-Load Setpoint Current changes polarity based on VID Select to accommodate VR10, VR11

(negative offset from DAC) or Opteron/Athlon64 (positive offset from DAC).

FEATURES

XPHASE

TM

Data Sheet No. PD94719

VR10, VR11 & OPTERON/ATHLON64 CONTROL IC

TM

Phase IC provides a full featured and flexible

TM

architecture results in a power supply

• 1 to X phase operation with matching Phase IC

• 7-bit VR 10/11 compatible VID with 0.5% overall system set point accuracy

• 5-bit Opteron/Athlon64 compatible VID with 1% overall system set point accuracy

• Programmable Dynamic VID Slew Rate

• +/-300mV Differential Remote Sense

• Programmable VID Offset Voltage at the Error Amplifier’s Non-Inverting Input allows Zero Offset

• Programmable 150kHz to 1MHz oscillator

• Programmable VID Offset and Load Line output impedance

• Programmable Hiccup Over-Current Protection with Delay to prevent false triggering

• Simplified VR Ready output provides indication of proper operation and avoids false triggering

• Operates from 12V input with 9.9V Under-Voltage Lockout

• 6.8V/6mA Bias Regulator provides System Reference Voltage

• Phase IC Gate Driver Bias Regulator / VRHOT Comparator

• Reduced Over-Current Detect Delay eliminates and external resistor in typical applications

• Small thermally enhanced 28L MLPQ package

Page 1 of 47 9/14/2005

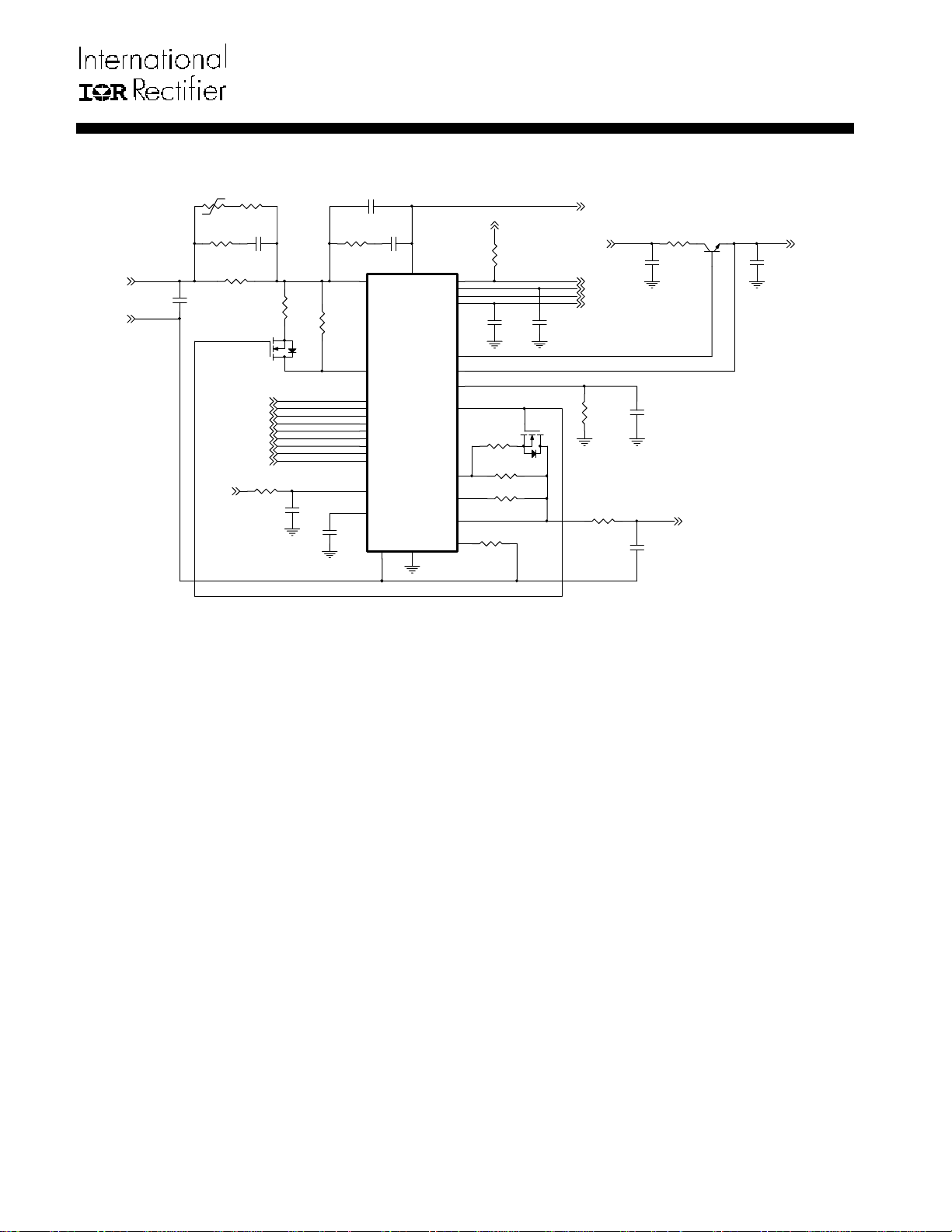

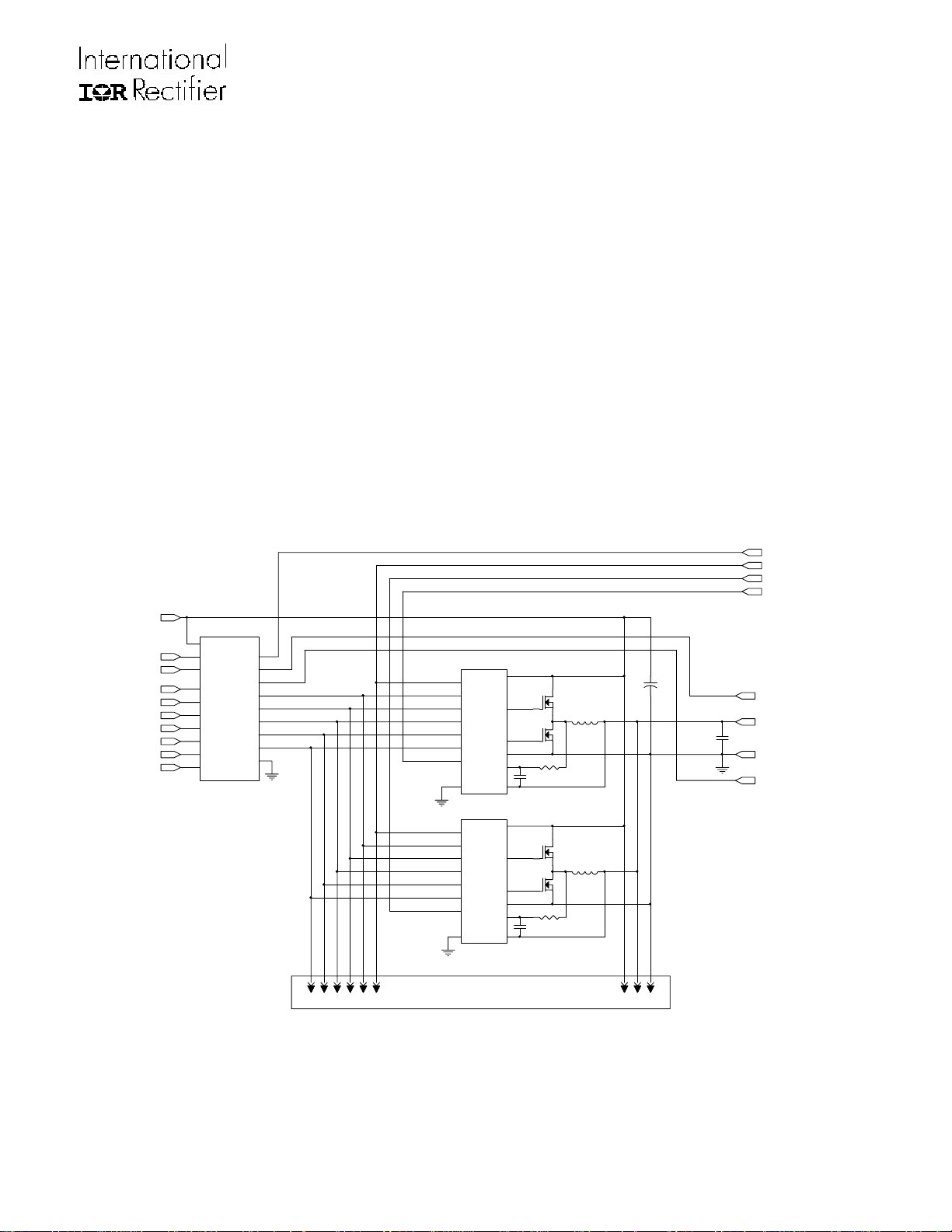

TYPICAL APPLICATION CIRCUIT

CCP1

100pF

R117

RT2

1.21K

VCC_SENSE

VSS_SENSE

4.7K, B=4450

RFB1

162

RFB

348

C1009

1nF

VREG_12V_FI LTERED

CFB

12nF

Q5

OUTEN

VID0

VID1

VID2

VID3

VID4

VID5

VID6

VID_SEL

R30

10

RDRP1

750

C130

0.1uF

RCP

2.49K

RDRP

750

CSS/D EL

0.1uF

17

16

28

9

8

7

6

5

4

3

1

21

26

CCP

56nF

EAOUT

FB

IR3084UMTR

VDRP

ENABLE

VID0

VID1

VID2

VID3

VID4

VID5

VID6

VIDSEL

VCC

SS/DEL

VOSNS--

10

18

LGND

22

VRRDY

RMPOUT

VBIAS

REGDRV

REGFB

REGSET

INTL_MD

VSETPT

OCSET

VDAC

ROSC

U5

IR3084U

VREG_12V_FI LTERED

C89

100pF

Q6

EA

VR_RDY

ISHARE

RMP

VBIAS

RVGDRV

97.6K

RVDAC

3.5

CVGDRV

10nF

CVDAC

33nF

R1331

1

C204

0.1uF

VDAC

Q4

CJD200

C135

1uF

VGDRIVE

+5.0 V

R137

2K

27

15

IIN

19

20

C134

0.1uF

24

23

25

2

RV SETPT1

124

14

RVSETPT

124

13

ROCSET

12.7K

12

11

ROSC

30.1K

Page 2 of 47 9/14/2005

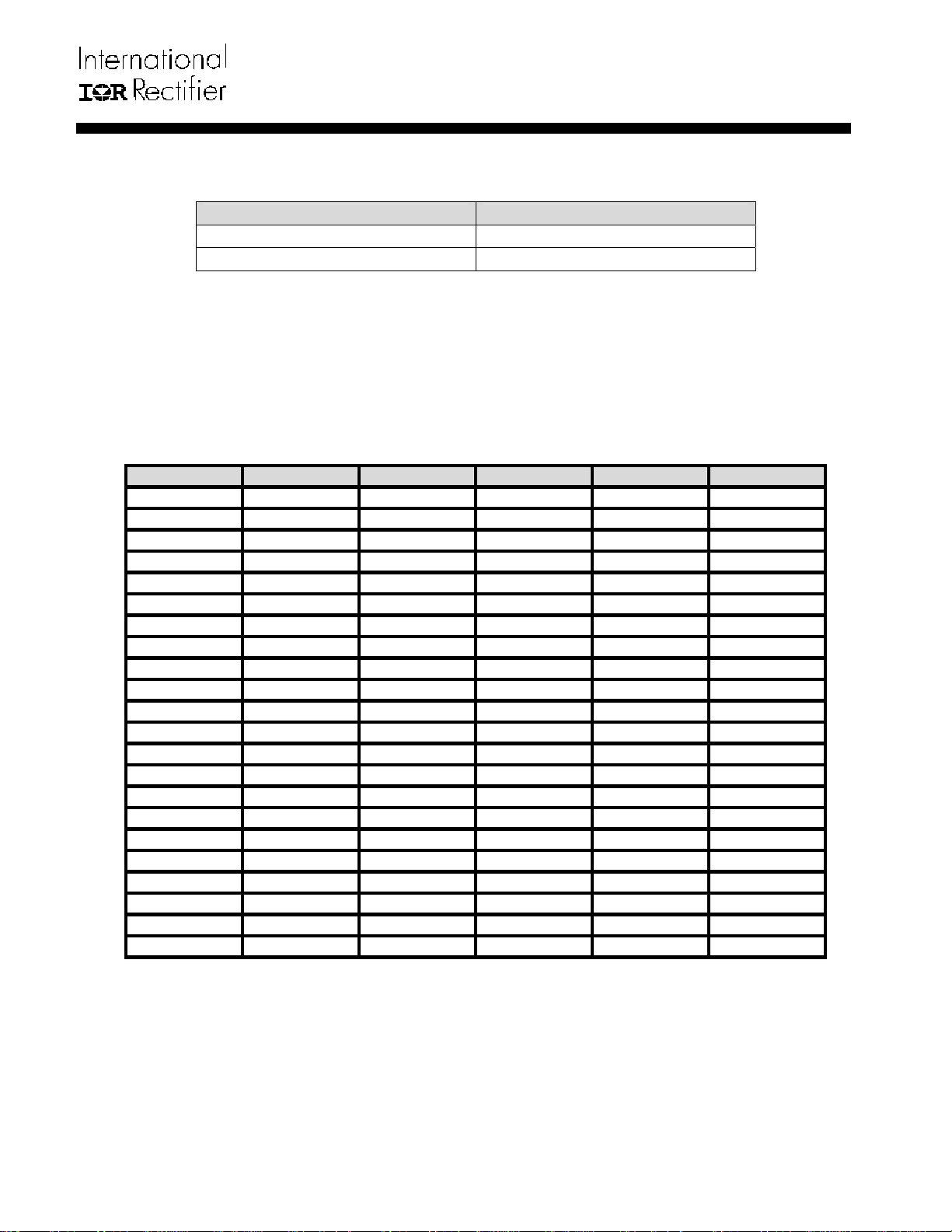

ORDERING INFORAMATION

DEVICE ORDER QUANTITY

IR3084UMTRPBF 3000 Tape and Reel

IR3084UMPBF 100 Piece Strip

ABSOLUTE MAXIMUM RATINGS

IR3084U

Operating Junction Temperature……………..0 to 150oC

Storage Temperature Range………………….65

ESD Rating………………………………………HBM Class 1B JEDEC standard

Moisture Sensitivity Level………………………JEDEC Level 3 @ 260

o

C to 150oC

o

C

PIN # PIN NAME V

V

MAX

I

MIN

SOURCE

I

SINK

1 VIDSEL 20V -0.3V 1mA 1mA

2 INTL_MD 20V -0.3V 1mA 1mA

3-9 VID6VID0 20V -0.3V 1mA 1mA

10 VOSNS- 0.5V -0.5V 10mA 10mA

11 ROSC 20V -0.5V 1mA 1mA

12 VDAC 20V -0.3V 1mA 1mA

13 OCSET 20V -0.3V 1mA 1mA

14 VSETPT 20V -0.3V 1mA 1mA

15 IIN 20V -0.3V 1mA 1mA

16 VDRP 20V -0.3V 5mA 5mA

17 FB 20V -0.3V 1mA 1mA

18 EAOUT 10V -0.3V 20mA 20mA

19 RMPOUT 20V -0.3V 5mA 5mA

20 VBIAS 20V -0.3V 50mA 10mA

21 VCC 20V -0.3V 1mA 50mA

22 LGND n/a n/a 50mA 1mA

23 REGFB 20V -0.3V 1mA 1mA

24 REGDRV 20V -0.3V 10mA 50mA

25 REGSET 20V -0.3V 1mA 1mA

26 SS/DEL 20V -0.3V 1mA 1mA

27 VRRDY 20V -0.3V 1mA 20mA

28 ENABLE 20V -0.3V 1mA 1mA

Page 3 of 47 9/14/2005

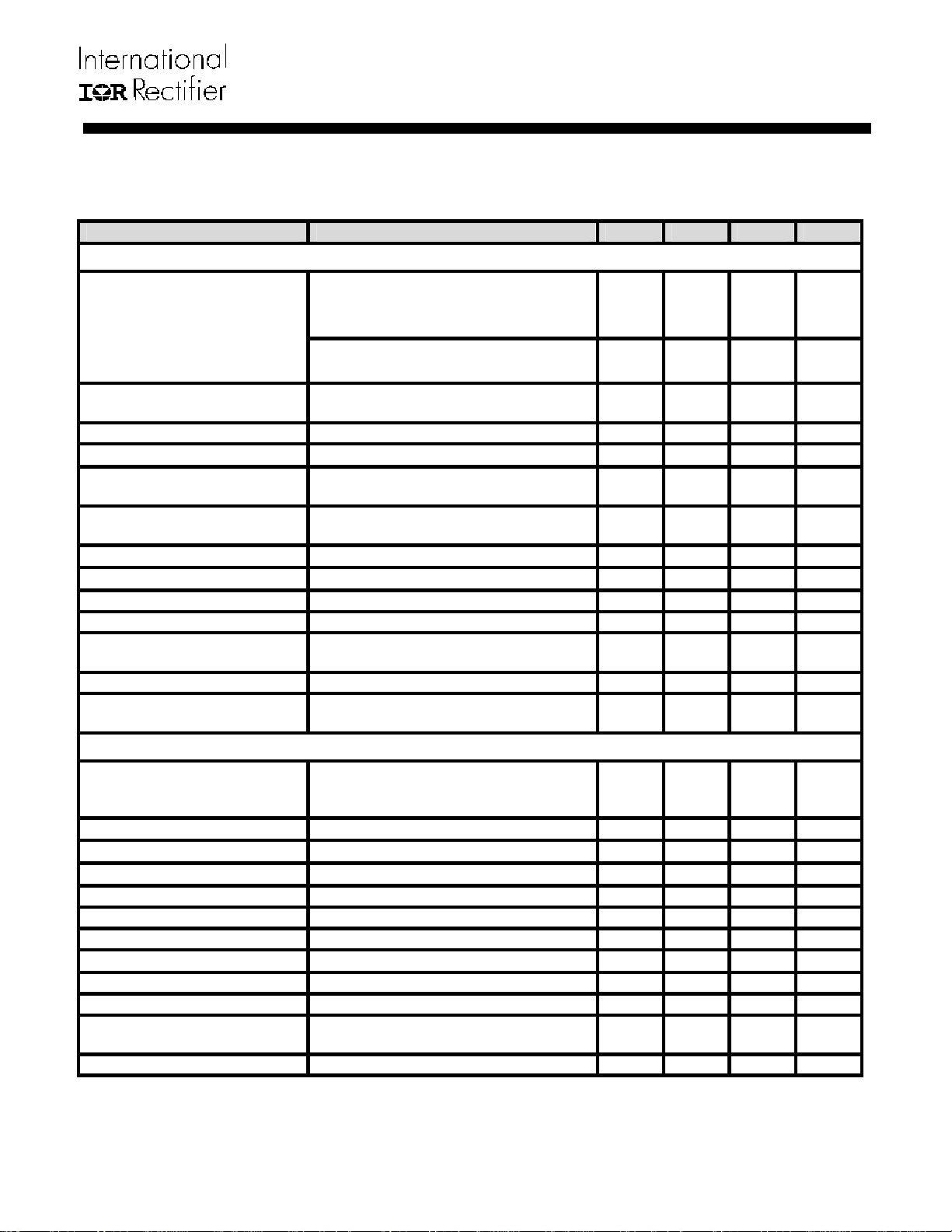

IR3084U

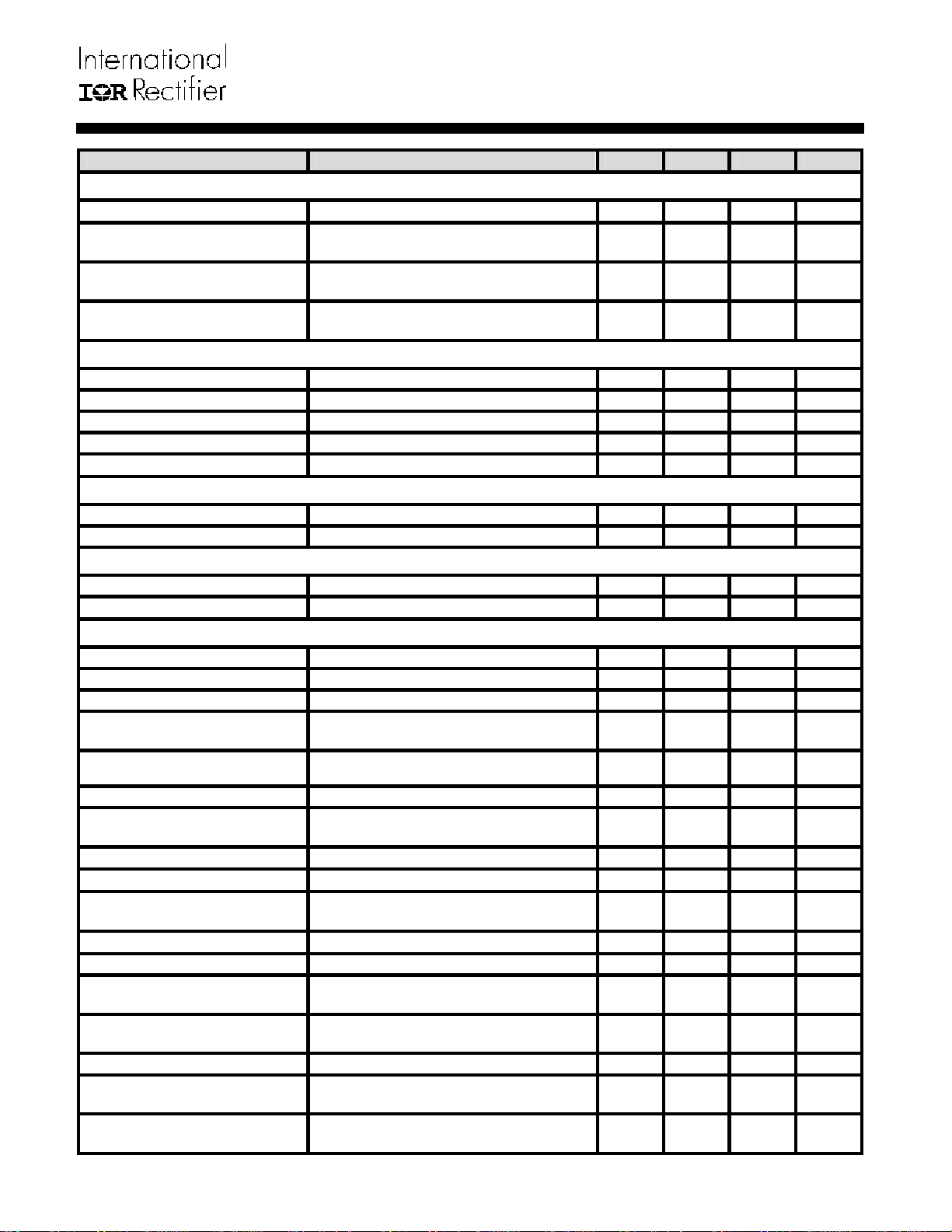

ELECTRICAL SPECIFICATIONS

Unless otherwise specified, these specifications apply over: 9.5V VCC 16V, 0.3V VOSNS- 0.3V,

o

0

C TJ 100 oC, ROSC = 24k, CSS/DEL = 0.1μF ±10%

PARAMETER TEST CONDITION MIN TYP MAX UNIT

VDAC REFERENCE

VR10/VR11 System Set-Point

Accuracy (Deviation from

Tables 1 & 2 per test circuit in

VID 1V, 10kROSC100k,

o

C TJ 100 oC

25

0.5 0.5 %

Figure 1 which emulates in-VR

operation)

Opteron/Athlon64 System SetPoint Accuracy

0.8V VID < 1V, 10kROSC100k,

o

C TJ 100 oC

25

o

C TJ 100 oC 1 1 %

25

5 +5 mV

Source Current Includes OCSET and VSETPT currents 104 113 122 A

Sink Current Includes OCSET and VSETPT currents 92 100 108

VR10/VR11 VIDx Input

Threshold

Opteron/Athlon64 VIDx Input

Threshold

VIDx Input Bias Current

500 600 700 mV

1.04 1.24 1.44 V

0V < VIDx < VCC 5 0 5

VIDx 11111x Blanking Delay Measure Time till VRRDY drives low 0.5 1.3 2.1

μA

μA

μs

VIDSEL Pull up Voltage VIDSEL Floating 1.95 2.4 2.85 V

VIDSEL Pull up Resistor 2.25 4.5 9 K

VIDSEL VR10/Opteron

Threshold

VIDSEL “LOW” 0.5 0.6 0.7 V

VIDSEL Opteron Voltage 6.49K from VIDSEL to GND 0.9 1.3 1.7 V

VIDSEL Opteron/VR11

Threshold

1.8 1.95 2.1 V

ERROR AMPLIFIER

Measure V(FB) – V(VSETPT) per test

Input Offset Voltage

circuit in Figure 1. Applies to all VID

5 0.0 5 mV

codes. Note 2.

FB Bias Current 1 0.1 0.5

VSETPT Bias Current VR10/VR11 Mode 48.5 51 53.5

VSETPT Bias Current Opteron/Athlon64 Mode 54 47 39

μA

μA

μA

DC Gain Note 1 90 100 110 dB

Gain Bandwidth Product Note 1 6 10 MHz

Corner Frequency 45 deg Phase Shift, Note 1 200 400 Hz

Slew Rate Note 1 1.4 3.2 5

V/μs

Source Current 1.2 0.7 0.35 mA

Sink Current 0.5 1.1 1.7 mA

Max Voltage

VBIAS–VEAOUT (referenced to

VBIAS)

150 350 600 mV

Min Voltage Normal operation or Fault mode 30 125 200 mV

Page 4 of 47 9/14/2005

IR3084U

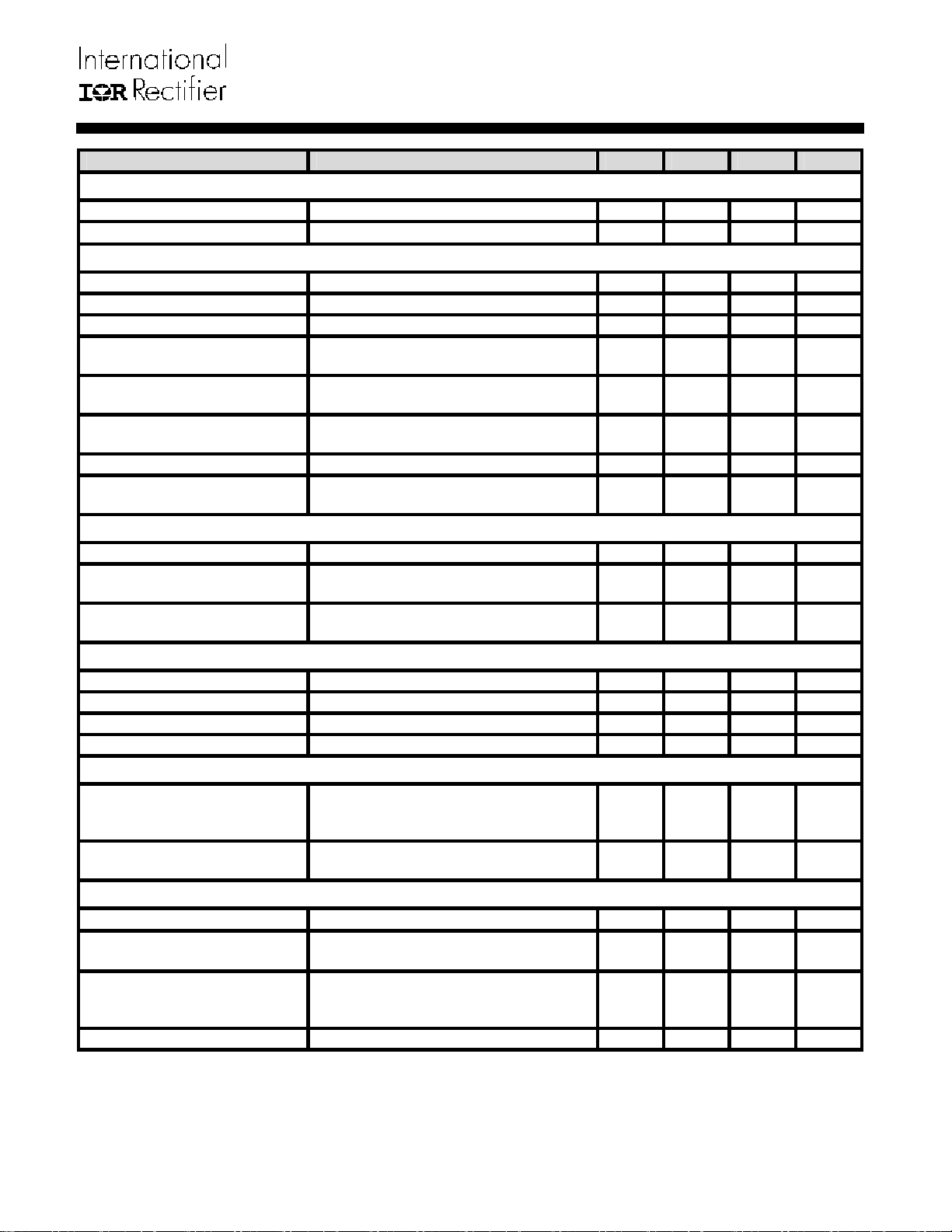

PARAMETER TEST CONDITION MIN TYP MAX UNIT

CURRENT SENSE INPUT

IIN BIAS CURRENT V(SS/DEL) > 0.85V, V(EAOUT) > 0.5V

IIN Preconditioning Pull-Down

Resistance

IIN Preconditioning RESET

Threshold

IIN Preconditioning SET

Threshold

VDRP BUFFER AMPLIFIER

Input Offset Voltage V(VDRP) – V(IIN), 0.5V < V(IIN) < 5V 10 2 6 mV

Source Current 0.5V < V(IIN) < 5V 9.0 6.8 4.0 mA

Sink Current 0.5V < V(IIN) < 5V 0.2 0.85 4.1 mA

Bandwidth (-3dB) Note 1 1 6 MHz

Slew Rate Note 1 5 10

VBIAS REGULATOR

Output Voltage 5mA < I(VBIAS) < 0mA 6.6 6.9 7.2 V

Current Limit 35 20 6 mA

OVER-CURRENT COMPARATOR

Input Offset Voltage 1V < V(OCSET) < 5V 10 0 10 mV

OCSET Bias Current 53.5 51 48.5

SOFT START AND DELAY

Start Delay (TD1) RDRP = 1.2 1.8 2.6 ms

Soft Start Time (TD2) RDRP = , Time to reach 1.1V 0.8 1.8 2.8 ms

VID Sample Delay (TD3) VR10/VR11 mode only 0.2 1.0 2.5 ms

DVID Slew Time & VRRDY

Delay (TD4+TD5)

PowerGood Delay

OC Delay Time 150 250 350 us

SS/DEL to FB Input Offset

Voltage

SS/DEL Charge Current

SS/DEL Discharge Current

Charge/Discharge Current

Ratio

OC Discharge Current Note 1

Charge Voltage 3.6 3.85 4.1 V

OC/VRRDY Delay Comparator

Threshold

OC/VRRDY Delay Comparator

Threshold

Delay Comparator Hysteresis Note 1 20 mV

VID Sample Delay

Comparator Threshold

SS/DEL Discharge

Comparator Threshold

V(SS/DEL) < 0.35V 5.6 12.5 19.4 K

V(EAOUT) 0.20 0.35 0.50 V

V(SS/DEL) 0.35 0.60 0.85 V

VR10/VR11 mode only 0.5 1.3 2.2 ms

Opteron/Athlon64 mode. Measured from

Vcore=1.1V to when VRRDY transitions HI.

With FB = 0V, adjust V(SS/DEL) until

EAOUT drives high

Relative to Charge Voltage, SS/DEL

rising

Relative to Charge Voltage, SS/DEL

falling

VR10/VR11 mode only 3.10 V

215 mV

2.0 0.2 1.0

0.7 2.3 4.7 ms

0.85 1.3 1.5 V

40 70 100

4 6.5 9

9.5 11.2 12.5

20 40 60

80 mV

100 mV

µA

V/μs

μA

μA

μA

μA/μA

μA

Page 5 of 47 9/14/2005

IR3084U

PARAMETER TEST CONDITION MIN TYP MAX UNIT

VRRDY OUTPUT

Output Voltage I(VRRDY) = 4mA 150 300 mV

Leakage Current V(VRRDY) = 5.5V 0 10

ENABLE INPUT

VR10/11 Threshold Voltage ENABLE rising 800 850 900 mV

VR10/11 Threshold Voltage ENABLE falling 700 750 800 mV

VR10/11 Threshold Hysteresis 70 100 130 mV

Opteron/Athlon64 Threshold

Voltage

Opteron/Athlon64 Threshold

Voltage

Opteron/Athlon64 Threshold

Hysteresis

Input Resistance 50 100 200 K

Blanking Time

OSCILLATOR

Switching Frequency ROSC = 24K 450 500 550 kHz

Peak Voltage (4.8V typical,

measured as % of VBIAS)

Valley Voltage (0.9V typical,

measured as % of VBIAS)

INTL_MD OUTPUT

Source Current V(INTL_MD)=2V, VR10 or VR11 mode 100 200 300 µA

Sink Current V(INTL_MD)=2V, Opteron mode 250 750 1500 µA

Max Voltage Pin Floating, V(VBIAS)V(INTL_MD) 50 170 350 mV

Min Voltage Pin Floating, LGND referenced 400 900 mV

VOSNS− FLOAT DETECT

Detect Voltage

Detect Delay

DRIVER BIAS REGULATOR

REGSET Bias Current 1.5V < V(REGSET) < VCC – 1.5V 112 99 85

Input Offset Voltage

Short Circuit Current

Dropout Voltage I(REGDRV) = 10mA, Note 1 0.4 0.87 1.33 V

ENABLE rising 1.11 1.23 1.35 V

ENABLE falling 1.06 1.17 1.29 V

35 60 85 mV

Noise Pulse < 250ns will not register

an ENABLE state change. Note 1

70 71 74 %

10 13 15 %

V(VOSNS) with respect to V(LGND),

Verify V(VRRDY) and V(EAOUT) are

low.

V(VOSNS-) 0V to 2.6V step, measure

time when V(VRRDY) falls. Note 1

1.5V < V(REGSET) < VCC – 1.5V,

100μA < I(REGDRV) < 10mA

V(REGDRV) = 0V,

1.5V < V(REGSET) < VCC – 1.5V,

Note 1

μA

75 250 400 ns

1.2 2 2.6 V

200 350 600 ns

μA

12 0 12 mV

10 20 50 mA

Page 6 of 47 9/14/2005

IR3084U

PARAMETER TEST CONDITION MIN TYP MAX UNIT

VCC UNDER-VOLTAGE LOCKOUT

Start Threshold 9.3 9.9 10.3 V

Stop Threshold 8.5 9.1 9.5 V

Hysteresis Start – Stop 550 800 1000 mV

GENERAL

VCC Supply Current 9 14 18 mA

VOSNS Current

0.3V < VOSNS < 0.3V,

All VID Codes

Note 1: Guaranteed by design, but not tested in production

Note 2: VDAC Output is trimmed to compensate for Error Amp input offsets errors

1.45 1.1 0.75 mA

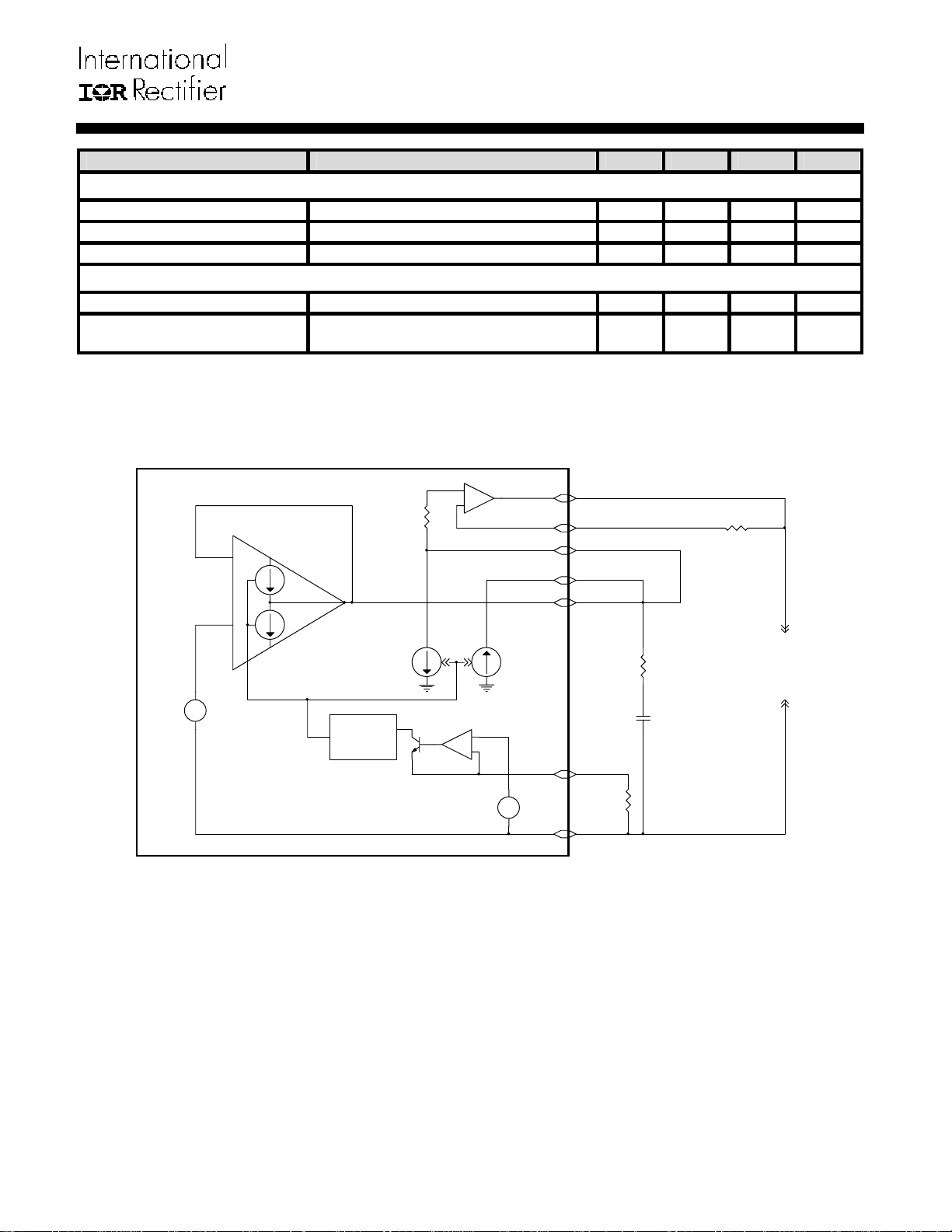

IR3084U

+

"FAST"

VDAC

-

+

200 OHM

VDAC

-

+

BUFFER

AMP

ISOURCE

ISINK

INTEL: +IOFFSET

AMD: --IOFFSET

IROSC IROSC

-

ERROR

AMP

EAOUT

VSETPT

OCSET

IOCSET

FB

VDAC

RVDAC

200 OHM

SYSTEM

SET POINT

VOLTAGE

CVDAC

ROSC

CURRENT

SOURCE

GENERATOR

ROSC

BUFFER

AMP

+

-

ROSC

+

1.2V

-

VOSNS-

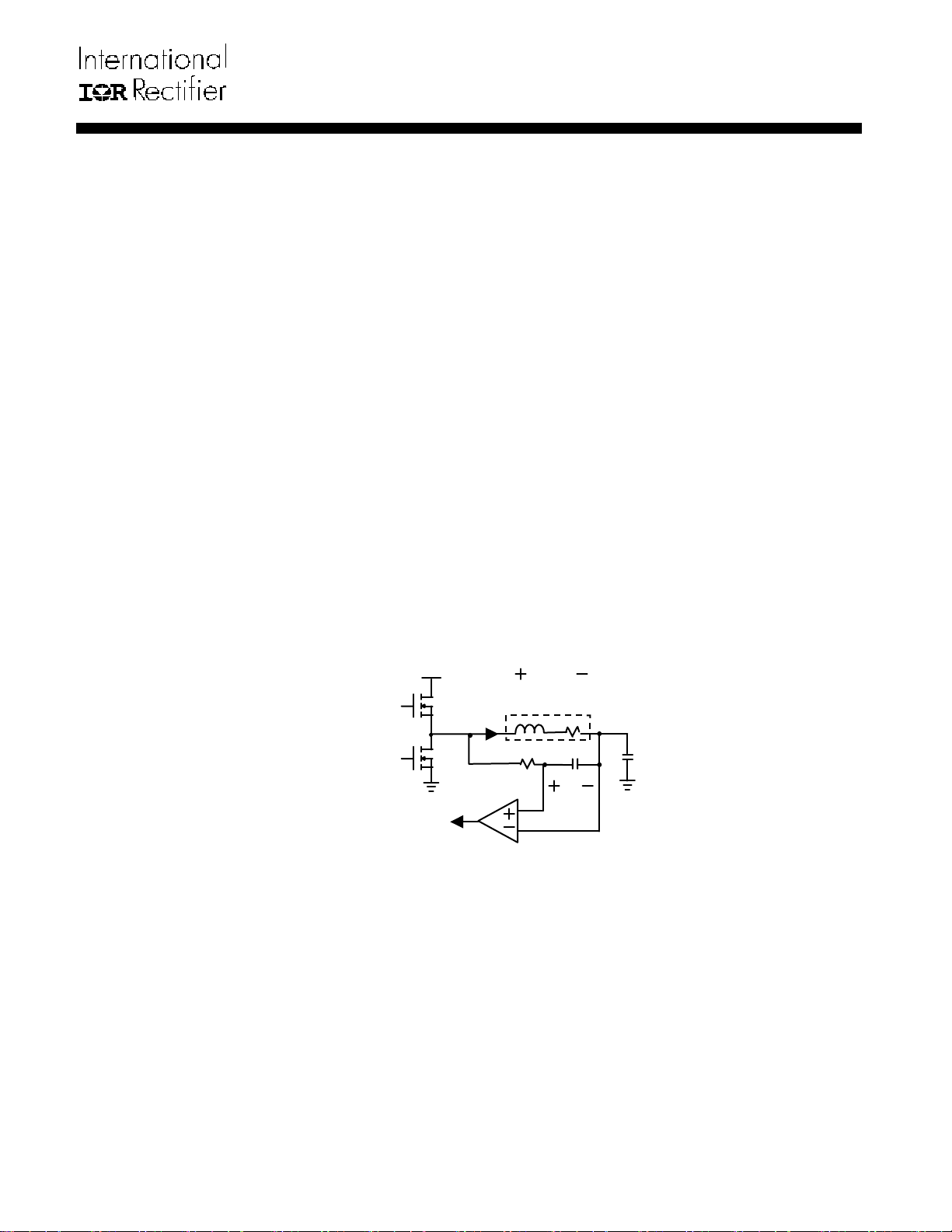

Figure 1 – System Set Point Test Circuit

Page 7 of 47 9/14/2005

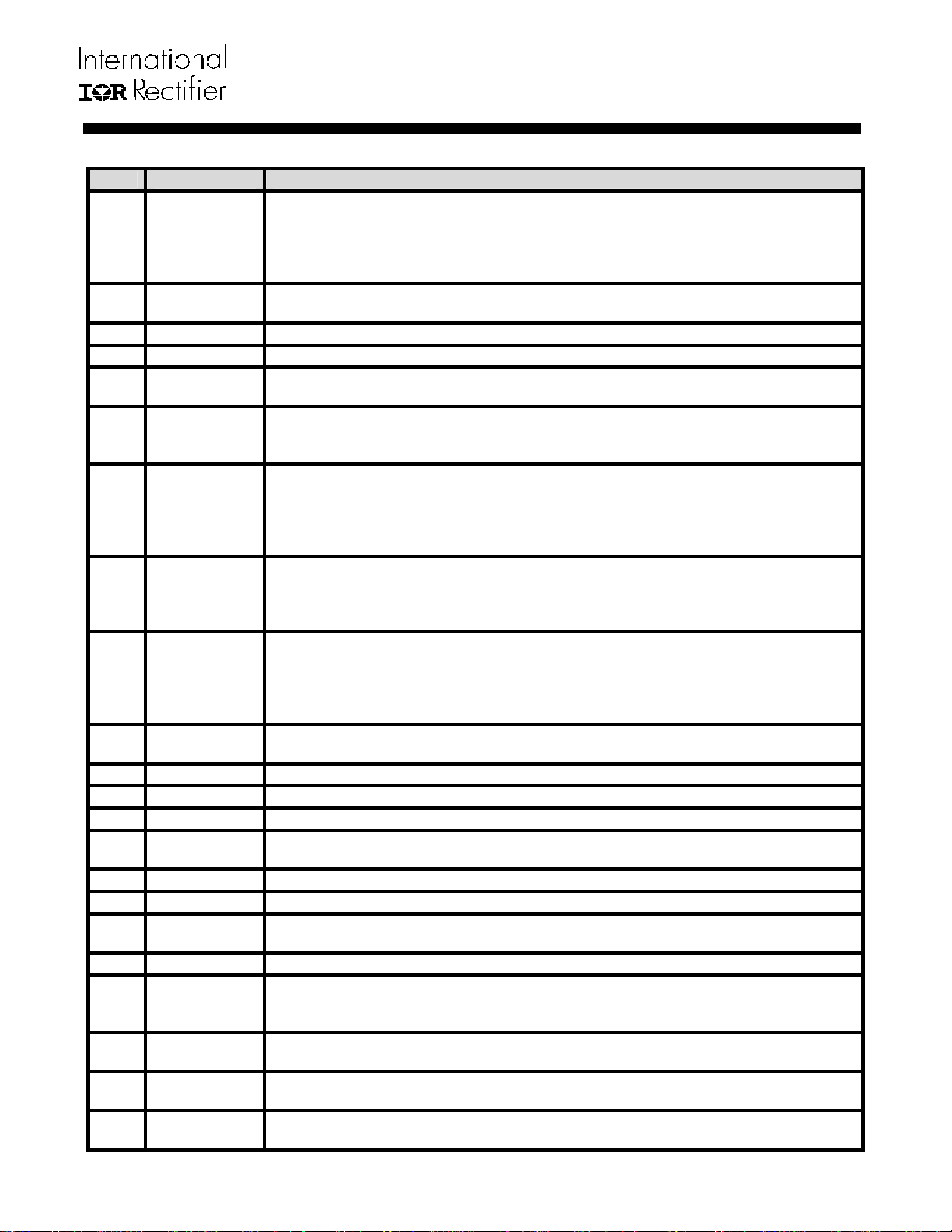

PIN DESCRIPTIONS

PIN# PIN SYMBOL DESCRIPTION

Selects the DAC table and the type of Soft Start. There are 3 possible modes of

operation: (1) GND selects VR10 DAC and VR11 type startup, (2) FLOAT (2.4V)

1 VIDSEL

2 INTL_MD

3-9 VID6VID0

10 VOSNS

11 ROSC

12 VDAC

13 OCSET

14 VSETPT

15 IIN

16 VDRP

17 FB

18 EAOUT

19 RMPOUT

20 VBIAS

21 VCC

22 LGND

23 REGFB

24 REGDRV

25 REGSET

26 SS/DEL

27 VRRDY

28 ENABLE

selects VR11 DAC and VR11 type startup, (3) 6.49K to GND (1.3V) selects

Opteron/Athlon64 DAC and legacy type startup. Additional details are provided in

the Theory of Operation section.

Output that indicates if the controller is in Intel Mode or AMD Mode. This pin will be

Low when in AMD mode and High when in Intel mode.

Inputs to the D to A Converter. Must be connected to an external pull up resistor.

Negative Remote Sense Input. Connect to ground at the Load.

Connect a resistor from this pin to VOSNS to program the oscillator’s frequency,

OCSET, VSETPT, REGSET, and VDAC bias currents.

Regulated output voltage programmed by the VID inputs. Connect an external RC

network to from this pin to VOSNS to program the Dynamic VID slew rate and

provide compensation for the internal Buffer Amplifier.

Programs the hiccup over-current threshold through an external resistor tied to

VDAC and an internal current source. Over-current protection can be disabled by

connecting a resistor from this pin to VDAC to program the threshold higher than the

possible signal into the IIN pin from the Phase ICs but no greater than 5V (do not

float this pin as improper operation will occur).

Error Amp non-inverting input. The converter’s output voltage can be decreased

(Intel) or increased (AMD) from the VDAC voltage with an external resistor

connected between VDAC and an internal current source. Current sensing and

PWM operation are referenced to this pin.

Current Sense input from the Phase IC(s). Prior to startup, when SS/DEL<0.6V, this

pin is pulled low by a 12.5K resistor to disable current balancing in the Phase ICs.

When SS/DEL>0.6V and EAOUT>0.35V, this pin is released and current balancing

is enabled. If AVP or over-current protection is not required, connect this pin to

VDAC. To ensure proper do not float this pin.

Buffered IIN signal. Connect an external resistor from this pin to the FB pin to set the

converter’s output impedance.

Inverting input to the Error Amplifier.

Output of the Error Amplifier. When Low, provides UVL function to the Phase ICs.

Oscillator Output voltage. Used by the Phase ICs to program Phase Delay.

6.9V/6mA Regulated output used as a system reference voltage for internal circuitry

and for phase timing at the Phase ICs.

Power Input for the internal circuitry.

Local Ground for internal circuitry and IC substrate connection

Inverting input of the Bias Regulator Error Amp. Connect this pin to the collector of

the Phase IC Gate Driver Bias transistor.

Output of the Bias Regulator Error Amp.

Non-inverting input of the Bias Regulator Error Amp. The output voltage of the

Phase IC Gate Driver Bias Regulator is set by an internal current source supplying

an external resistor connected from this pin to ground.

Controls converter start-up and over-current timing. Connect an external capacitor

from this pin to LGND to program the soft start and delay times.

Open Collector output that drives low during start-up and when any external fault

occurs. Connect external pull-up resistor.

Enable Input. A logic low applied to this pin puts the IC into Fault mode. This pin

has a 100K pull-down resistor to GND.

IR3084U

Page 8 of 47 9/14/2005

IR3084U

SYSTEM THEORY OF OPERATION

XPhaseTM Architecture

The XPhase

applications requiring small size, design flexibility, low voltage, high current and fast transient response. The

architecture can be used in any multiphase converter ranging from 1 to 16 or more phases where flexibility

facilitates the design trade-off of multiphase converters. The scalable architecture can be applied to other

applications which require high current or multiple output voltages.

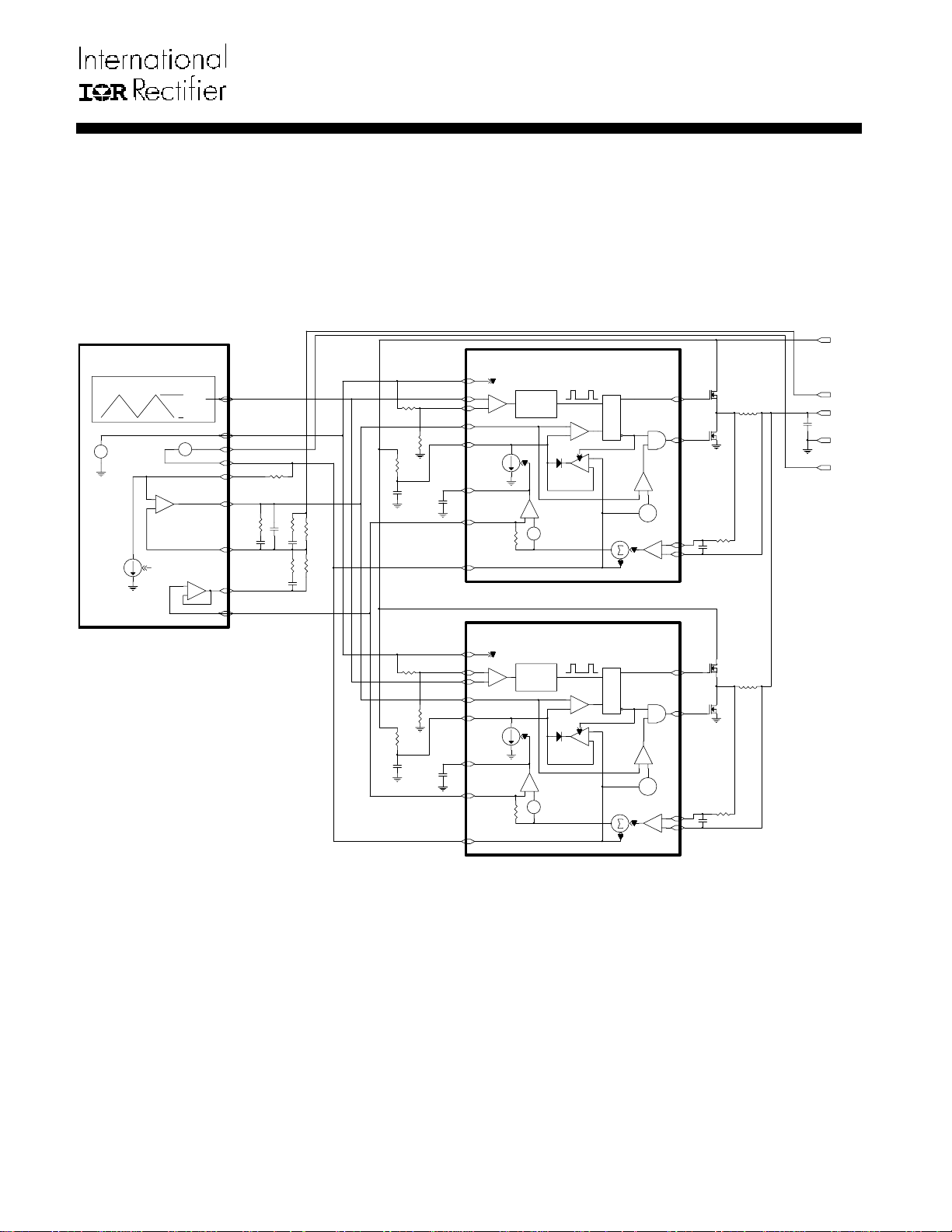

As shown in Figure 2, the XPhase

converters each using a single Phase IC. The Control IC communicates with the Phase ICs through a 5-wire

analog bus, i.e. bias voltage, phase timing, average current, error amplifier output, and VID voltage. The Control

IC incorporates all the system functions, i.e. VID, PWM ramp oscillator, error amplifier, bias voltage, and fault

protections etc. The Phase IC implements the functions required by the converter of each phase, i.e. the gate

drivers, PWM comparator and latch, over-voltage protection, and current sensing and sharing.

There is no unused or redundant silicon with the XPhase

controller that can be configured for 2, 3, or 4 phase operation. PCB Layout is easier since the 5 wire bus

eliminates the need for point-to-point wiring between the Control IC and each Phase. The critical gate drive and

current sense connections are short and local to the Phase ICs. This improves the PCB layout by lowering the

parasitic inductance of the gate drive circuits and reducing the noise of the current sense signal.

TM

architecture is designed for multiphase interleaved buck converters which are used in

TM

architecture consists of a Control IC and a scalable array of phase

TM

architecture compared to others such as a 4 phase

VR READY

PHASE FAULT

VR HOT

VR FAN

12V

ENABLE

VIDSEL

VID6

VID5

VID4

VID3

VID2

VID1

VID0

IR3084

CONTROL

IC

>> BIAS VOLTAGE

>> PHASE TIMING

<< CURRENT SENSE

>> PWM CONTROL

>> VID VOLTAGE

PHASE FAULT

CURRENT SHARE

PHASE FAULT

CURRENT SHARE

IR3086

PHASE

IC

CCS

IR3086

PHASE

IC

ADDITIONAL PHASES

RCS

RCSCCS

Figure 2 – System Block Diagram

CIN

COUT

INPUT/OUTPUTCONTROL BUS

VOUT SENSE+

VOUT+

VOUT-

VOUT SENSE-

Page 9 of 47 9/14/2005

IR3084U

PWM Control Method

The PWM block diagram of the XPhase

with trailing edge modulation is used. A high-gain wide-bandwidth voltage type error amplifier in the Control IC is

used for the voltage control loop. An external RC circuit connected to the input voltage and ground is used to

program the slope of the PWM ramp and to provide the feed-forward control at each phase. The PWM ramp

slope will change with the input voltage and automatically compensate for changes in the input voltage. The input

voltage can change due to variations in the silver box output voltage or due to drops in the PCB related to

changes in load current.

CONTROL IC

50%

RAMP GE NERATOR

DUTY

CYCLE

+

-

IOFFSET

VBIAS

REGULATOR

+

-

IROSC

ERROR

AMP

VPEAK

VVALLEY

VDAC

+

RMPOUT

VBIAS

VOSNS-

-

VDAC

VSETPT

RVSETPT

EAOUT

FB

VDRP

AMP

+

VDRP

-

IIN

TM

architecture is shown in Figure 3. Feed-forward voltage mode control

VIN

CLOCK

PULSE

GENERATOR

+

-

+

-

CLOCK

PULSE

GENERATOR

+

-

+

-

20mV

20mV

RAMP

DISCHARGE

CLAMP

RAMP

DISCHARGE

CLAMP

PHASE IC

PWM

COMPARATOR

-

+

ENABLE

+

-

PHASE IC

PWM

COMPARATOR

-

+

ENABLE

+

-

PWM

LATCH

S

RESET

DOMINANT

R

O% DUTY

CYCLE

COMPARATOR

PWM

LATCH

S

RESET

DOMINANT

R

O% DUTY

CYCLE

COMPARATOR

GATEH

GATELEAIN

+

-

X

0.91

CURRENT

SENSE

AMP

X34

+

CURRENT

SENSE

AMP

X34

CSIN+

+

-

-

X

0.91

+

-

CSIN-

GATEH

GATEL

CSIN+

CSIN-

CCS

CCS RCS

RCS

VOSNS+RAMPIN+

VOUT

COUT

GND

VOSNS-

RAMP

SLOPE

ADJUST

RAMP

SLOPE

ADJUST

SYSTEM

REFERENCE

VOLTAGE

+

-

SHARE

ADJUST

ERROR

AMP

10K

SYSTEM

REFERENCE

VOLTAGE

+

-

SHARE

ADJUST

ERROR

AMP

10K

BIASIN

RRAMP1

RAMPIN-

RRAMP2

PWMRMP

RPWMRMP

SCOMP

CPWMRMP

CSCOMP

RVFB

RDRP

RRAMP1

RRAMP2

RPWMRMP

CPWMRMP

ISHARE

DACIN

BIASIN

RAMPIN+

RAMPIN-

EAIN

PWMRMP

SCOMP

CSCOMP

ISHARE

DACIN

Figure 3 – IR3084U PWM Block Diagram

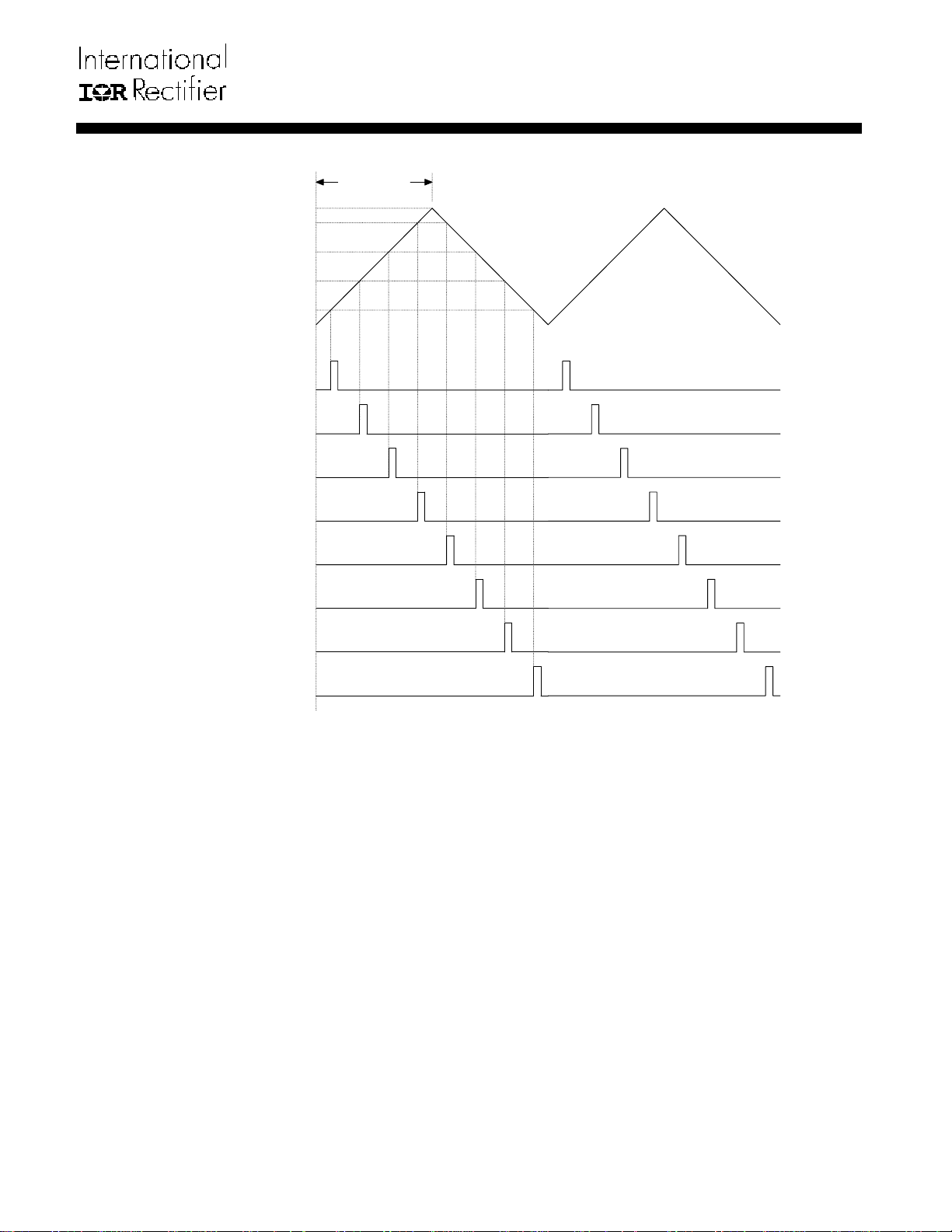

Frequency and Phase Timing Control

The oscillator is located in the Control IC and its frequency is programmable from 150kHz to 1MHZ by an external

resistor. The output of the oscillator is a 50% duty cycle triangle waveform with peak and valley voltages of

approximately 5V and 1V. This signal is used to program both the switching frequency and phase timing of the

Phase ICs. The Phase IC is programmed by resistor divider RRAMP1 and RRAMP2 connected between the

VBIAS reference voltage and the Phase IC LGND pin. A comparator in the Phase ICs detects the crossing of the

oscillator waveform with the voltage generated by the resistor divider and triggers a clock pulse that starts the

PWM cycle. The peak and valley voltages track the VBIAS voltage reducing potential Phase IC timing errors.

Figure 4 shows the Phase timing for an 8 phase converter. Note that both slopes of the triangle waveform can be

used for synchronization by swapping the RAMP + and – pins.

Page 10 of 47 9/14/2005

RAMP (FROM

VPEAK (5.0V)

VPHASE4&5 (4.5V)

VPHASE3&6 (3.5V)

VPHASE2&7 (2.5V)

VPHASE1&8 (1.5V)

VVALLEY (1.00V)

CONTROL IC)

CLK1

CLK2

CLK3

CLK4

50% RAMP

DUTY CYCLE

IR3084U

SLOPE = 80mV / % DC

SLOPE = 1.6mV / ns @ 200kHz

SLOPE = 8.0mV / ns @ 1MHz

CLK5

CLK6

CLK7

PHASE IC CLOCK PULSES

CLK8

Figure 4 – 8 Phase Oscillator Waveforms

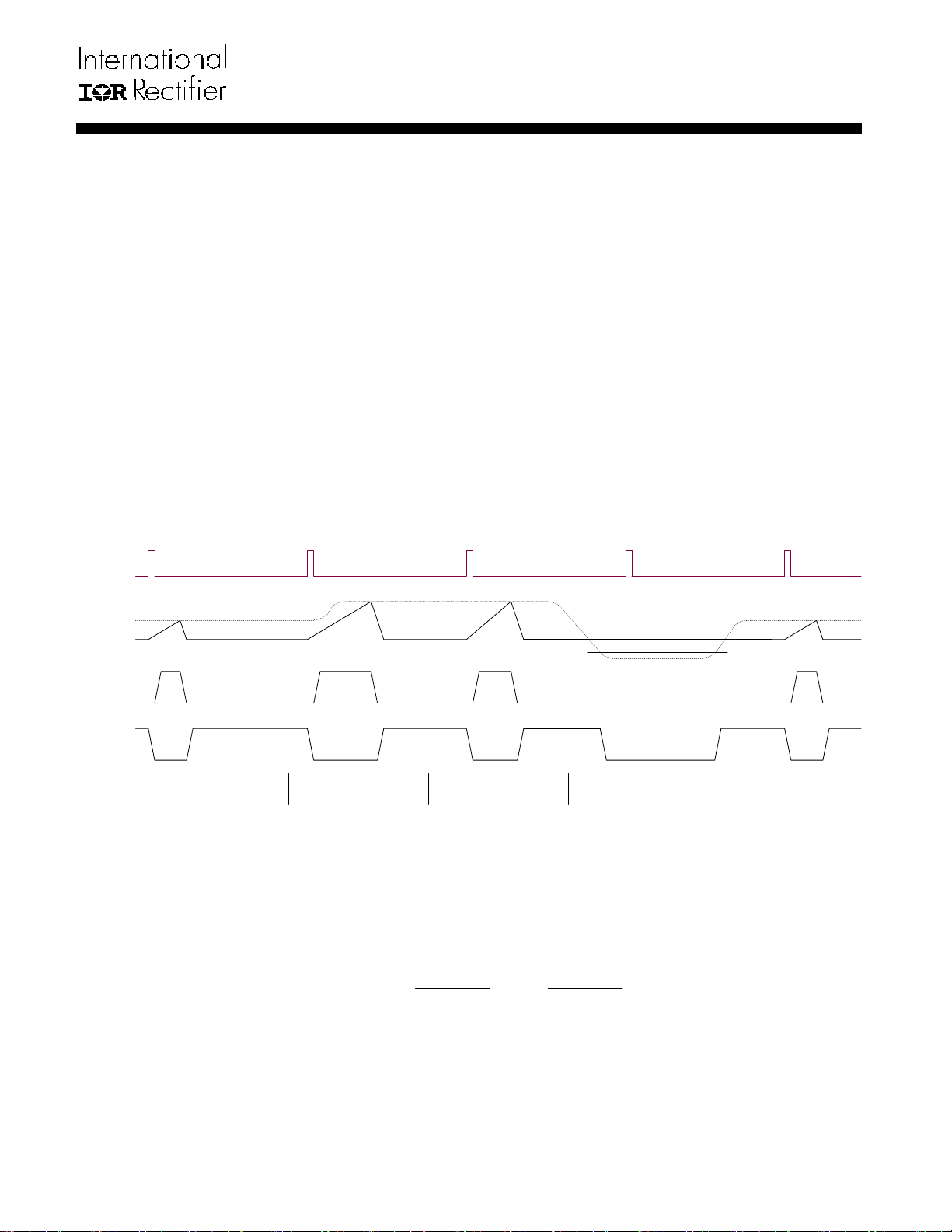

PWM Operation

The PWM comparator is located in the Phase IC. Upon receiving a clock pulse, the PWM latch is set, the

PWMRMP voltage begins to increase, the low side driver is turned off, and the high side driver is then turned on.

When the PWMRMP voltage exceeds the Error Amp’s output voltage the PWM latch is reset. This turns off the

high side driver, turns on the low side driver, and activates the Ramp Discharge Clamp. The clamp quickly

discharges the PWMRMP capacitor to the VDAC voltage of the Control IC until the next clock pulse.

The PWM latch is reset dominant allowing all phases to go to zero duty cycle within a few tens of nanoseconds in

response to a load step decrease. Phases can overlap and go to 100% duty cycle in response to a load step

increase with turn-on gated by the clock pulses. An Error Amp output voltage greater than the common mode

input range of the PWM comparator results in 100% duty cycle regardless of the voltage of the PWM ramp. This

arrangement guarantees the Error Amp is always in control and can demand 0 to 100% duty cycle as required. It

also favors response to a load step decrease which is appropriate given the low output to input voltage ratio of

most systems. The inductor current will increase much more rapidly than decrease in response to load transients.

This control method is designed to provide “single cycle transient response” where the inductor current changes

in response to load transients within a single switching cycle maximizing the effectiveness of the power train and

minimizing the output capacitor requirements. An additional advantage is that differences in ground or input

voltage at the phases have no effect on operation since the PWM ramps are referenced to VDAC.

Page 11 of 47 9/14/2005

IR3084U

Body Braking

In a conventional synchronous buck converter, the minimum time required to reduce the current in the inductor in

response to a load step decrease is;

The slew rate of the inductor current can be significantly increased by turning off the synchronous rectifier in

response to a load step decrease. The switch node voltage is then forced to decrease until conduction of the

synchronous rectifier’s body diode occurs. This increases the voltage across the inductor from Vout to Vout +

V

BODY DIODE

decrease is now;

Since the voltage drop in the body diode is often higher than output voltage, the inductor current slew rate can be

increased by 2X or more. This patent pending technique is referred to as “body braking” and is accomplished

through the “0% Duty Cycle Comparator” located in the Phase IC. If the Error Amp’s output voltage drops below

91% of the VDAC voltage this comparator turns off the low side gate driver.

Figure 5 depicts PWM operating waveforms under various conditions

PHASE IC

CLOCK

PULSE

TM

T

SLEW

= [L x (I

MAX

- I

)] / Vout

MIN

. The minimum time required to reduce the current in the inductor in response to a load transient

T

SLEW

= [L x (I

MAX

- I

MIN

)] / (Vout + V

BODY DIODE

)

EAIN

PWMRMP

GATEH

GATEL

VDAC

STEADY-STATE

OPERATION

DUTY CYCLE INCREASE

DUE TO LOAD

INCREASE

DUTY CYCLE DECREASE

DUE TO VIN INCREASE

(FEED-FORWARD)

BODY BRAKING

THRESHOLD

DUTY CYCLE DECREASE DUE TO LOAD

DECREASE (BODY BRAKING) OR FAULT

(VCC UV, VCCVID UV, OCP, VID=11111X)

STEADY-STATE

OPERATION

Figure 5 – PWM Operating Waveforms

Lossless Average Inductor Current Sensing

Inductor current can be sensed by connecting a series resistor and a capacitor network in parallel with the

inductor and measuring the voltage across the capacitor. The equation of the sensing network is,

sLR

svsv

=

LC

1

)()(

1

CsR

+

SS

si

=

L

+

L

)(

+

1

CsR

SS

Usually the resistor Rcs and capacitor Ccs are chosen so that the time constant of Rcs and Ccs equals the time

constant of the inductor which is the inductance L over the inductor DCR. If the two time constants match, the

voltage across Ccs is proportional to the current through L, and the sense circuit can be treated as if only a sense

resistor with the value of R

L was used. The mismatch of the time constants does not affect the measurement of

inductor DC current, but affects the AC component of the inductor current.

Page 12 of 47 9/14/2005

IR3084U

The advantage of sensing the inductor current versus high side or low side sensing is that actual output current

being delivered to the load is obtained rather than peak or sampled information about the switch currents. The

output voltage can be positioned to meet a load line based on real time information. Except for a sense resistor in

series with the inductor, this is the only sense method that can support a single cycle transient response. Other

methods provide no information during either load increase (low side sensing) or load decrease (high side

sensing).

An additional problem associated with peak or valley current mode control for voltage positioning is that they

suffer from peak-to-average errors. These errors will show in many ways but one example is the effect of

frequency variation. If the frequency of a particular unit is 10% low, the peak to peak inductor current will be 10%

larger and the output impedance of the converter will drop by about 10%. Variations in inductance, current sense

amplifier bandwidth, PWM prop delay, any added slope compensation, input voltage, and output voltage are all

additional sources of peak-to-average errors.

Current Sense Amplifier

A high speed differential current sense amplifier is located in the Phase IC, as shown in Figure 6. Its gain

decreases with increasing temperature and is nominally 34 at 25ºC and 29 at 125ºC (-1470 ppm/ºC). This

reduction of gain tends to compensate the 3850 ppm/ºC increase in inductor DCR. Since in most designs the

Phase IC junction is hotter than the inductor these two effects tend to cancel such that no additional temperature

compensation of the load line is required.

The current sense amplifier can accept positive differential input up to 100mV and negative up to -20mV before

clipping. The output of the current sense amplifier is summed with the DAC voltage and sent to the Control IC

and other Phases through an on-chip 10K resistor connected to the ISHARE pin. The ISHARE pins of all the

phases are tied together and the voltage on the share bus represents the average inductor current through all the

inductors and is used by the Control IC for voltage positioning and current limit protection.

vL

LRL

iL

Rs Cs

CSA

CO

Figure 6 – Inductor Current Sensing and Current Sense Amplifier

Average Current Share Loop

Current sharing between phases of the converter is achieved by the average current share loop in each Phase

IC. The output of the current sense amplifier is compared with the share bus less a 20mV offset. If current in a

phase is smaller than the average current, the share adjust amplifier of the phase will activate a current source

that reduces the slope of its PWM ramp thereby increasing its duty cycle and output current. The crossover

frequency of the current share loop can be programmed with a capacitor at the SCOMP pin so that the share loop

does not interact with the output voltage loop.

vc

Vo

Co

Page 13 of 47 9/14/2005

IR3084U

IR3084U THEORY OF OPERATION

Block Diagram

VCC UVLO

100k

VID INPUT

COMPARATORS

(1 OF 9

SHOWN)

+

-

50%

DUTY

CYCLE

COMPARATOR

-

+

2.0V

-

250ns

BLANKING

IHICCUP

DISCHARGE

6.5uA

+

-

INTEL: 0.6V

AMD: 1.24V

INTEL/AMD

RAMP GENERATOR

+

+

-

VOSNS FLOAT

DETECT

-

+

ENABLE

COMPARATOR

-

+

VCHG

3.85V

ON

ICHG

70uA

DIGITAL TO

IROSC

ANALOG

IROSC

CONVERTER

IROSC

IROSC

IROSC

IROSC

IROSC

IROSC

IROSC

+

80mV

100mV

OFF

"FAST"

VDAC

+

-

1.1V

4.8V

0.9V

-

0.215V

-

-

+

OC

DISCHARGE

CURRENT

40uA

IROSC

+

-

VBIAS

IROSC

DISCHARGE

+

COMPARATOR

+

-

DELAY

COMPARATOR

ON

SS/DEL

DISCHARGE

1.3us

BLANKING

+

1.95V0.6V

-

VID = 1.1V BOOT

-

6.9V

+

CURRENT

SOURCE

GENERATOR

-

+

-

+

-

VBIAS

REGULATOR

NO_CPU

1.2V

ROSC

BUFFER

AMP

UVLO

VOSNS OPEN

DISABLE

OVER CURRENT

NO CPU

NO CPU LATCHED

S

SET

R

OC

COMPARATOR

VID SAMPLE

DELAY COMPARATOR

-

3.1V

+

1.3V

-

ISOURCE

ISINK

VDAC

BUFFER

AMP

IREGSET

+

-

SOFTSTART

CLAMP

INTL_MD

+

-

+

+

-

VCC

IROSC

DOMINANT

VID

FAULT

LATCH

+

IOCSET

S

R

FAULT

LATCH

+

-

IROSC

SET

DOMINANT

0.6V

+

S

-

0.35V

-

R

+

VDRP

-

AMP

+

S

START

LATCH

SET

DOMINANT

R

DISABLE

+

+

-

ERROR

AMP

INTEL: IOFFSET

IROSC

AMD: -IOFFSET

BIAS

REGULATOR

+

ERROR AMP

-

VCC

ENABLE

850mV

750mV

LGND

SS/DEL

VID6

VID5

VID4

VID3

VID2

VID1

VID0

VIDSEL

VOSNS-

VBIAS

RMPOUT

ROSC

AMDINTEL

1.23V

1.17V

4.5K

9.9V

9.1V

2.4V

+

-

+

-

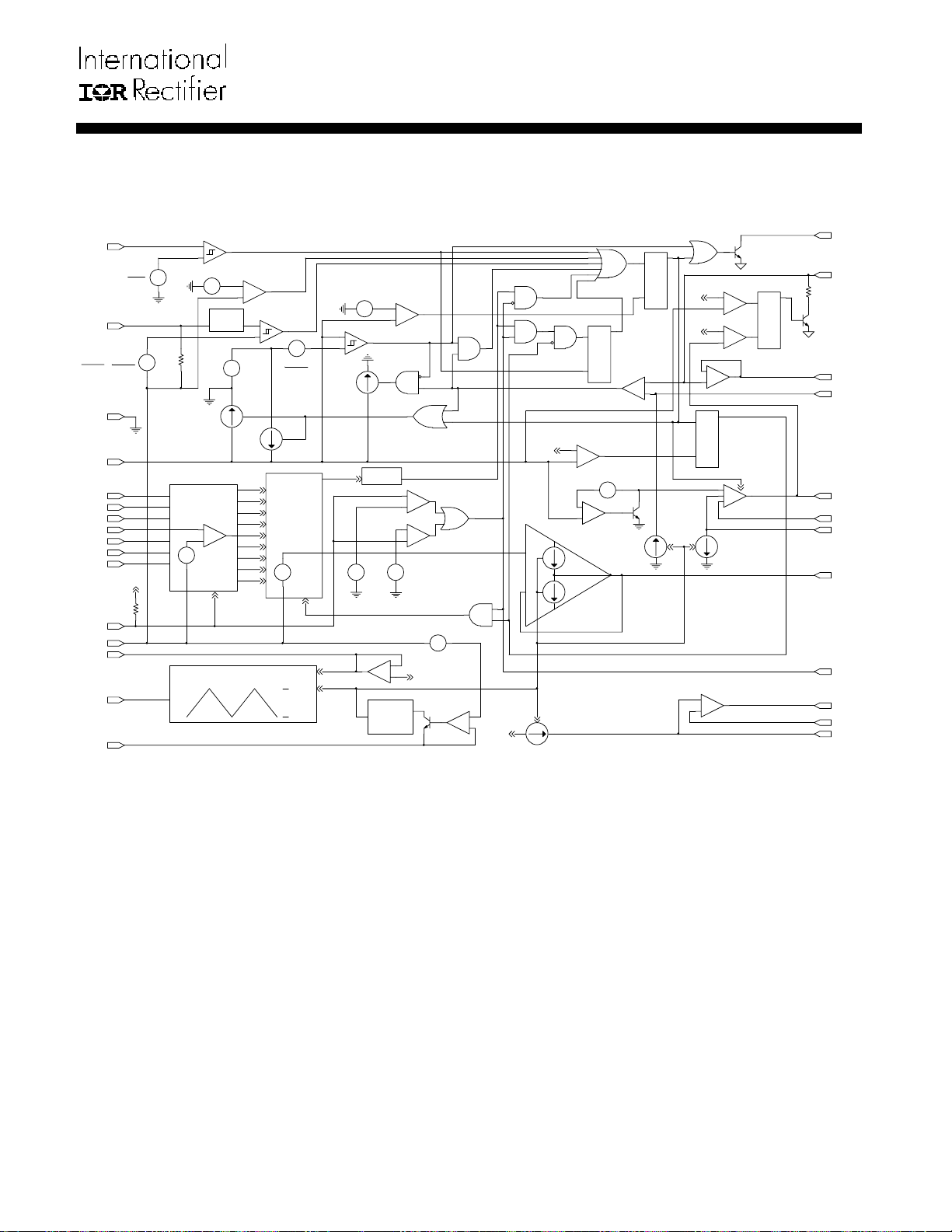

Figure 7 – IR3084U Block Diagram

VID Control

A 7-bit VID voltage compatible with VR10 (see Table 1) and VR11 (see Table 2) and Opteron/Athlon64 (see

Table 3) is available at the VDAC pin. The VIDSEL pin configures the DAC for VR10 if grounded, VR11 if

floating, and Opteron/Athlon64 if connected to GND via a 6.4K resistor. The VIDSEL pin is internally pulled-up to

2.4V through a 4.5Kohm resistor. The VID pins require an external bias voltage and should not be floated. The

VID input comparators, with 0.6V reference for VR10/VR11 and 1.24V for Opteron/Athlon64, monitor the VID

pins and control the 7-bit Digital-to-Analog Converter (DAC) whose output is sent to the VDAC buffer amplifier.

The output of the buffer amp is the VDAC pin. The VDAC voltage is post-package trimmed to compensate for

the input offsets of the Error Amp to provide a 0.5% system accuracy. The actual VDAC voltage does not

represent the system set point and has a wider tolerance.

SET

DOMINANT

IIN

PRECONDITIONING

LATCH

VRRDY

IIN

12.5K

VDRP

OCSET

EAOUT

FB

VSETPT

VDAC

INTL_MD

REGDRV

REGFB

REGSE T

Page 14 of 47 9/14/2005

IR3084U

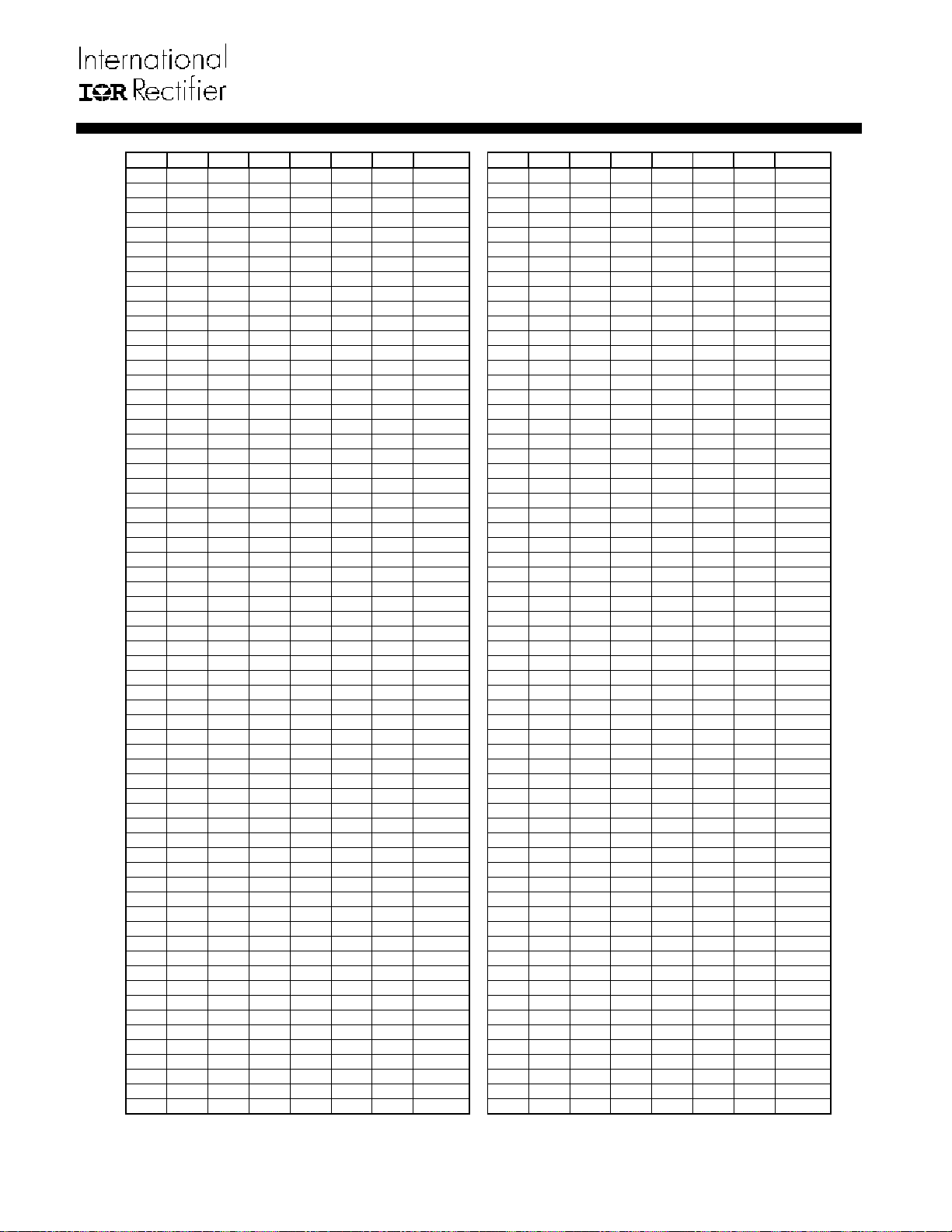

VID4 VID3 VID2 VID1 VID0 VID5 VID6 Voltage VID4 VID3 VID2 VID1 VID0 VID5 VID6 Voltage

0 1 0 1 0 1 1 1.60000 1 1 0 1 0 1 1 1.20000

0 1 0 1 0 1 0 1.59375 1 1 0 1 0 1 0 1.19375

0 1 0 1 1 0 1 1.58750 1 1 0 1 1 0 1 1.18750

0 1 0 1 1 0 0 1.58125 1 1 0 1 1 0 0 1.18125

0 1 0 1 1 1 1 1.57500 1 1 0 1 1 1 1 1.17500

0 1 0 1 1 1 0 1.56875 1 1 0 1 1 1 0 1.16875

0 1 1 0 0 0 1 1.56250 1 1 1 0 0 0 1 1.16250

0 1 1 0 0 0 0 1.55625 1 1 1 0 0 0 0 1.15625

0 1 1 0 0 1 1 1.55000 1 1 1 0 0 1 1 1.15000

0 1 1 0 0 1 0 1.54375 1 1 1 0 0 1 0 1.14375

0 1 1 0 1 0 1 1.53750 1 1 1 0 1 0 1 1.13750

0 1 1 0 1 0 0 1.53125 1 1 1 0 1 0 0 1.13125

0 1 1 0 1 1 1 1.52500 1 1 1 0 1 1 1 1.12500

0 1 1 0 1 1 0 1.51875 1 1 1 0 1 1 0 1.11875

0 1 1 1 0 0 1 1.51250 1 1 1 1 0 0 1 1.11250

0 1 1 1 0 0 0 1.50625 1 1 1 1 0 0 0 1.10625

0 1 1 1 0 1 1 1.50000 1 1 1 1 0 1 1 1.10000

0 1 1 1 0 1 0 1.49375 1 1 1 1 0 1 0 1.09375

0 1 1 1 1 0 1 1.48750 1 1 1 1 1 0 1 FAULT

0 1 1 1 1 0 0 1.48125 1 1 1 1 1 0 0 FAULT

0 1 1 1 1 1 1 1.47500 1 1 1 1 1 1 1 FAULT

0 1 1 1 1 1 0 1.46875 1 1 1 1 1 1 0 FAULT

1 0 0 0 0 0 1 1.46250 0 0 0 0 0 0 1 1.08750

1 0 0 0 0 0 0 1.45625 0 0 0 0 0 0 0 1.08125

1 0 0 0 0 1 1 1.45000 0 0 0 0 0 1 1 1.07500

1 0 0 0 0 1 0 1.44375 0 0 0 0 0 1 0 1.06875

1 0 0 0 1 0 1 1.43750 0 0 0 0 1 0 1 1.06250

1 0 0 0 1 0 0 1.43125 0 0 0 0 1 0 0 1.05625

1 0 0 0 1 1 1 1.42500 0 0 0 0 1 1 1 1.05000

1 0 0 0 1 1 0 1.41875 0 0 0 0 1 1 0 1.04375

1 0 0 1 0 0 1 1.41250 0 0 0 1 0 0 1 1.03750

1 0 0 1 0 0 0 1.40625 0 0 0 1 0 0 0 1.03125

1 0 0 1 0 1 1 1.40000 0 0 0 1 0 1 1 1.02500

1 0 0 1 0 1 0 1.39375 0 0 0 1 0 1 0 1.01875

1 0 0 1 1 0 1 1.38750 0 0 0 1 1 0 1 1.01250

1 0 0 1 1 0 0 1.38125 0 0 0 1 1 0 0 1.00625

1 0 0 1 1 1 1 1.37500 0 0 0 1 1 1 1 1.00000

1 0 0 1 1 1 0 1.36875 0 0 0 1 1 1 0 0.99375

1 0 1 0 0 0 1 1.36250 0 0 1 0 0 0 1 0.98750

1 0 1 0 0 0 0 1.35625 0 0 1 0 0 0 0 0.98125

1 0 1 0 0 1 1 1.35000 0 0 1 0 0 1 1 0.97500

1 0 1 0 0 1 0 1.34375 0 0 1 0 0 1 0 0.96875

1 0 1 0 1 0 1 1.33750 0 0 1 0 1 0 1 0.96250

1 0 1 0 1 0 0 1.33125 0 0 1 0 1 0 0 0.95625

1 0 1 0 1 1 1 1.32500 0 0 1 0 1 1 1 0.95000

1 0 1 0 1 1 0 1.31875 0 0 1 0 1 1 0 0.94375

1 0 1 1 0 0 1 1.31250 0 0 1 1 0 0 1 0.93750

1 0 1 1 0 0 0 1.30625 0 0 1 1 0 0 0 0.93125

1 0 1 1 0 1 1 1.30000 0 0 1 1 0 1 1 0.92500

1 0 1 1 0 1 0 1.29375 0 0 1 1 0 1 0 0.91875

1 0 1 1 1 0 1 1.28750 0 0 1 1 1 0 1 0.91250

1 0 1 1 1 0 0 1.28125 0 0 1 1 1 0 0 0.90625

1 0 1 1 1 1 1 1.27500 0 0 1 1 1 1 1 0.90000

1 0 1 1 1 1 0 1.26875 0 0 1 1 1 1 0 0.89375

1 1 0 0 0 0 1 1.26250 0 1 0 0 0 0 1 0.88750

1 1 0 0 0 0 0 1.25625 0 1 0 0 0 0 0 0.88125

1 1 0 0 0 1 1 1.25000 0 1 0 0 0 1 1 0.87500

1 1 0 0 0 1 0 1.24375 0 1 0 0 0 1 0 0.86875

1 1 0 0 1 0 1 1.23750 0 1 0 0 1 0 1 0.86250

1 1 0 0 1 0 0 1.23125 0 1 0 0 1 0 0 0.85625

1 1 0 0 1 1 1 1.22500 0 1 0 0 1 1 1 0.85000

1 1 0 0 1 1 0 1.21875 0 1 0 0 1 1 0 0.84375

1 1 0 1 0 0 1 1.21250 0 1 0 1 0 0 1 0.83750

1 1 0 1 0 0 0 1.20625 0 1 0 1 0 0 0 0.83125

Table 1 – VR10 7-bit VID Table with 6.25mV Extension

Page 15 of 47 9/14/2005

Loading...

Loading...