International Comfort Products RHS Installation Manual

INSTALLATION INSTRUCTIONS

R−410A Single Package Rooftop Heat Pumps

RHS181 − 243

These instructions must be read and understood completely before attempting installation

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is

only used on product labels to signify an immediate

hazard. The signal words WARNING, CAUTION,

and NOTE will be used on product labels and

throughout this manual and other manual that may

apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING −Hazards or unsafe practices which

could result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which

may result in minor personal injury or product or

property damage.

NOTE − Used to highlight suggestions which will

result in enhanced installation, reliablility, or

operation.

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

!

WARNING

The signal word CAUTION is used throughout

this manual in the following manner:

!

CAUTION

Signal Words on Product Labeling

Signal words are used in combination with

colors and/or pictures or product labels.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 2..................

INSTALLATION 6..............................

Step 1 − Plan for Unit Location 6.................

Step 2 − Plan for Sequence of Unit Installation 7...

Step 3 − Inspect Unit 7.........................

Step 4 − Provide Unit Support 7..................

Step 5 − Field Fabricate Ductwork 10..............

Step 6 − Rig and Place Unit 10...................

Step 7 − Duct Connection 10.....................

Step 8 − Install Outside Air Hood 11...............

Step 9 − Install External condensate Trap &

Piping 12...............................

Step 10 − Make Electrical Connections 13..........

Step 11 − Adjust Factory−Installed Options 19......

Step 12 − Install Accessories 19..................

Unit Wire/Fuse or HACR Breaker Sizing Data 21....

Typical Wiring Diagrams 24......................

!

WARNING

PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified

persons could result in equipment malfunction,

property damage, personal injury and/or death.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped

with proper tools and test instruments.

Installation must conform with local building

codes and with the national Electrical Code

NFPA70 current edition or Canadian Electrical

Code part 1 CSA C.22.1.

516 01 2601 01 01−04−11

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock or other conditions which may cause personal injury or

property damage. Consult a qualified installer, service

agency, or your distributor or branch for information or

assistance. The qualified installer or agency must use

factory−authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloths for brazing operations and

have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions attached to

the unit. Consult local building codes and appropriate

national electrical codes (in USA, ANSI/NFPA70, National

Electrical Code (NEC); in Canada, CSA C22.1) for special

requirements.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury

or death.

Before performing service or maintenance operations on

unit, always turn off main power switch to unit and install

lockout tag. Unit may have more than one power switch.

!

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury,

death and/or equipment damage.

R−410A refrigerant systems operate at higher pressures

than standard R−22 systems. Do not use R−22 service

equipment or components on R−410A refrigerant

equipment.

Recognize safety information. This is the safety−alert

symbol . When you see this symbol in instructions or manuals,

be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety−alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death. WARNING

signifies a hazard which could result in serious injury or death.

CAUTION is used to identify unsafe practices which may result

in minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

These instructions cover minimum requirements and conform

to existing national standards and safety codes. In some

instances, these instructions exceed certain local codes and

ordinances, especially those that may not have kept up with

changing residential construction practices. We require these

instructions as a minimum for a safe installation.

!

!

WARNING

PERSONAL INJURY AND ENVIRONMENTAL HAZARD

Failure to follow this warning could cause personal injury

or death

Relieve pressure and recover all refrigerant before

system repair or final unit disposal.

Ware safety glasses and gloves when handling

refrigerants. Keep torches and other ignition sources

away from refrigerants and oils.

!

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses and gloves when handling parts and servicing

air conditioning units.

CAUTION

2

516 01 2601 01

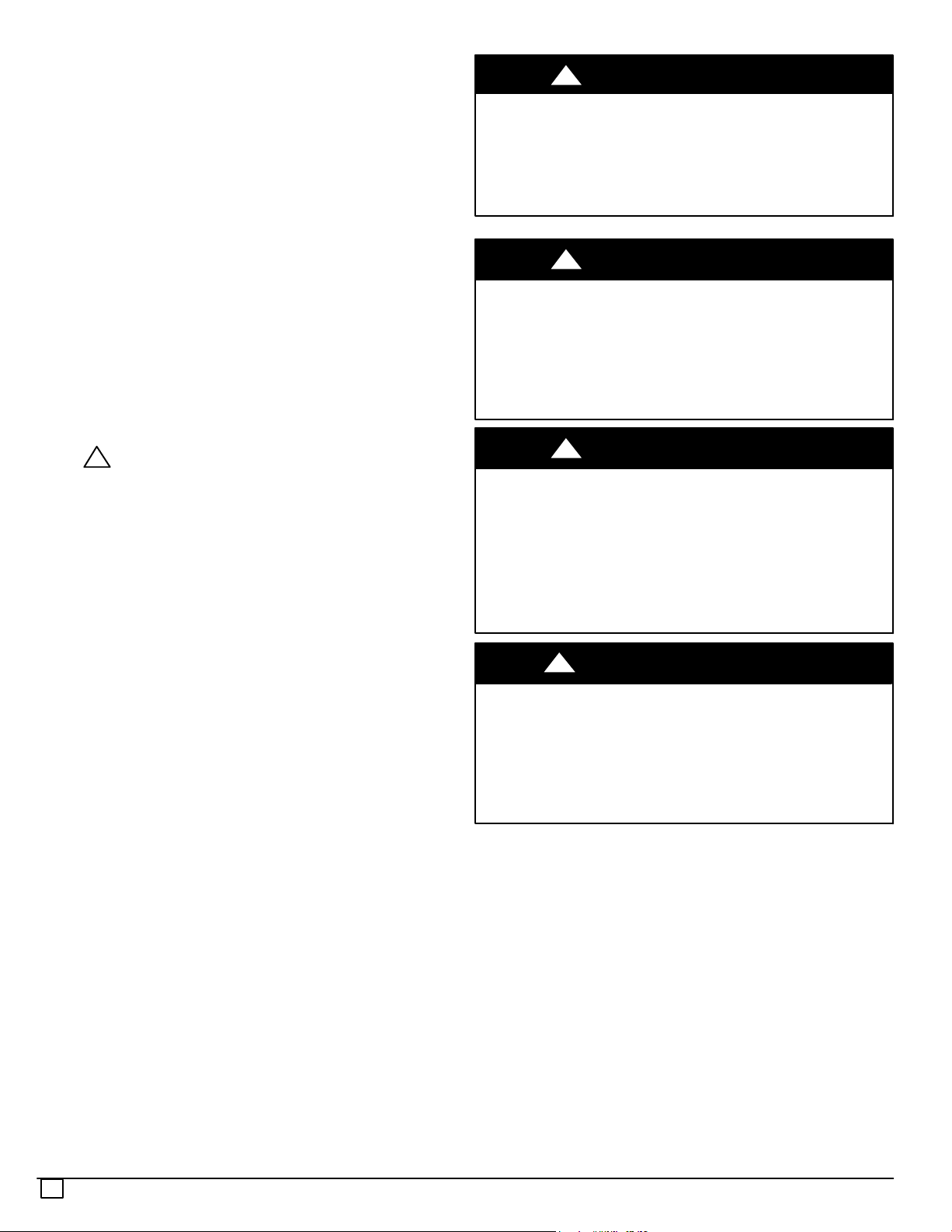

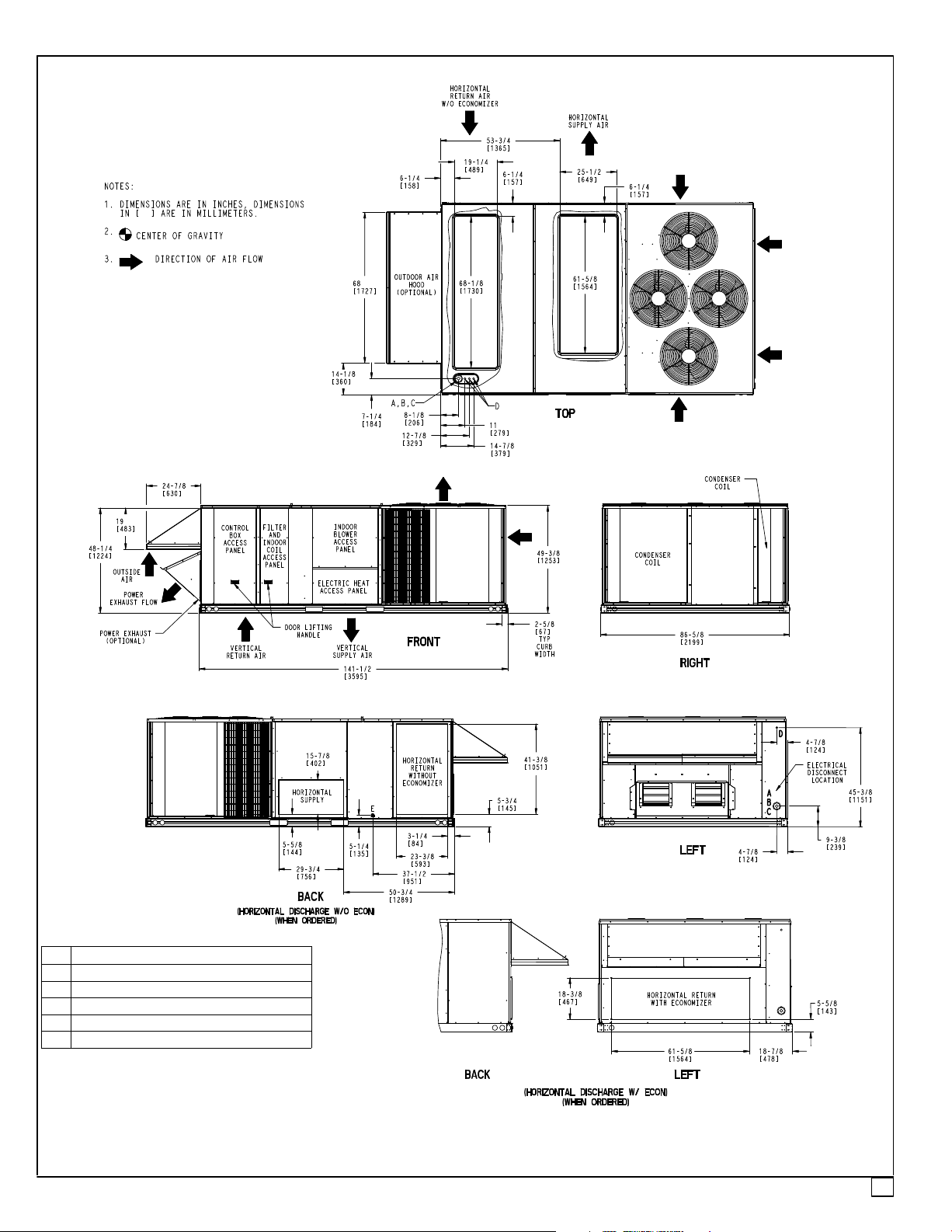

FIGURE 1 RHS Base Unit Dimensions: 15 Ton

Connection Sizes

A 1-3/8” [35] DIA Field Power Supply Hole

B 3” [76] Field Power Supply Knockout

C 3-5/8” [92] Field Power Supply Knockout

D 7/8” [22] Field Control Wiring Hole

E 3/4” 14 NPT Condensate Drain

516 01 2601 01

3

Fig. 1 − Unit Dimensional Drawing − 15 Ton

Unit Size

RHS 15 Ton 2156 980 581 264 442 201 489 222 643 292 45-1/4 [1149] 55-1/2 [1405] 16-1/2 [419]

Base Unit Weight

LBS. KG. LBS. KG. LBS. KG. LBS. KG. LBS. KG. X Y Z

Corner WeightACorner WeightBCorner Weight

C

Corner Weight

D

Center of Gravity

4

516 01 2601 01

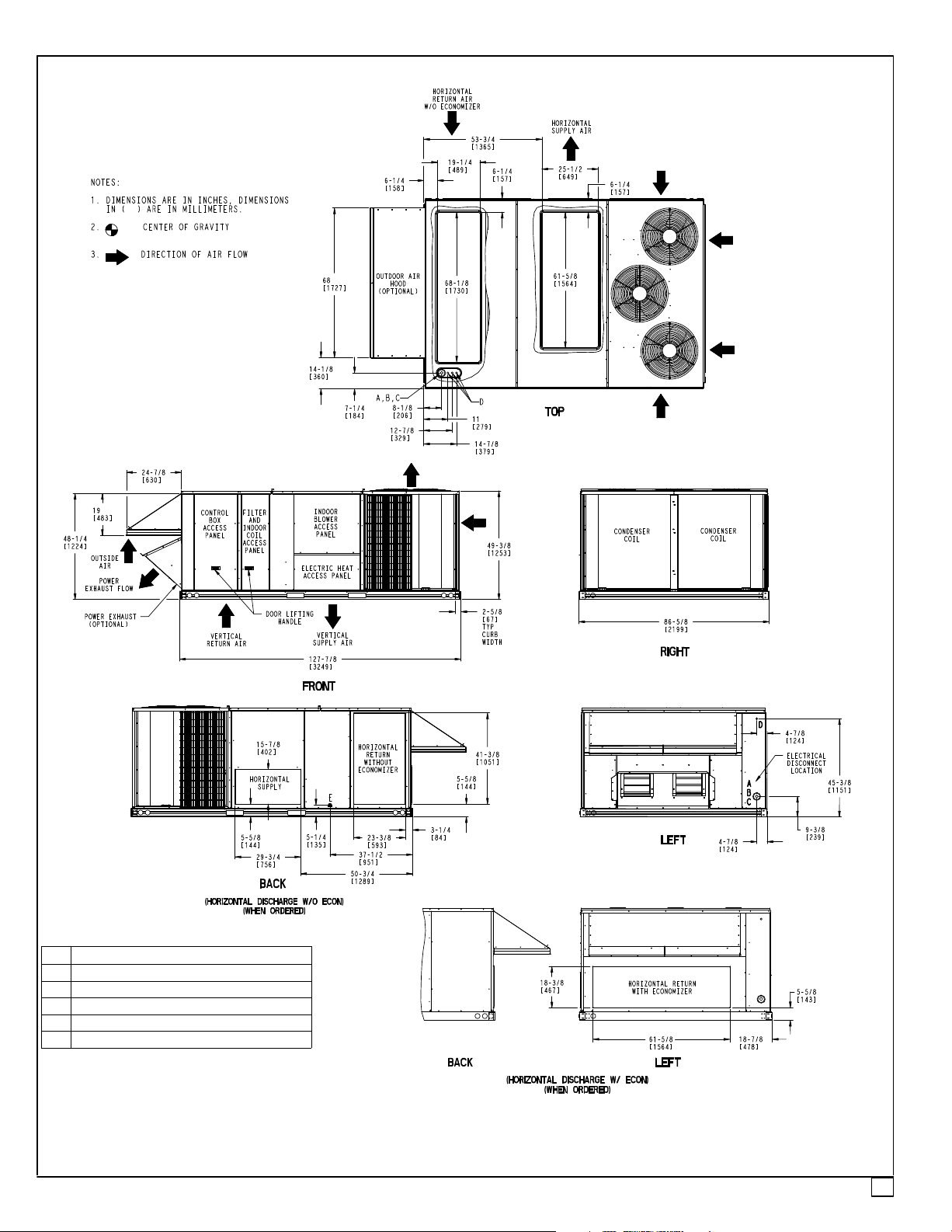

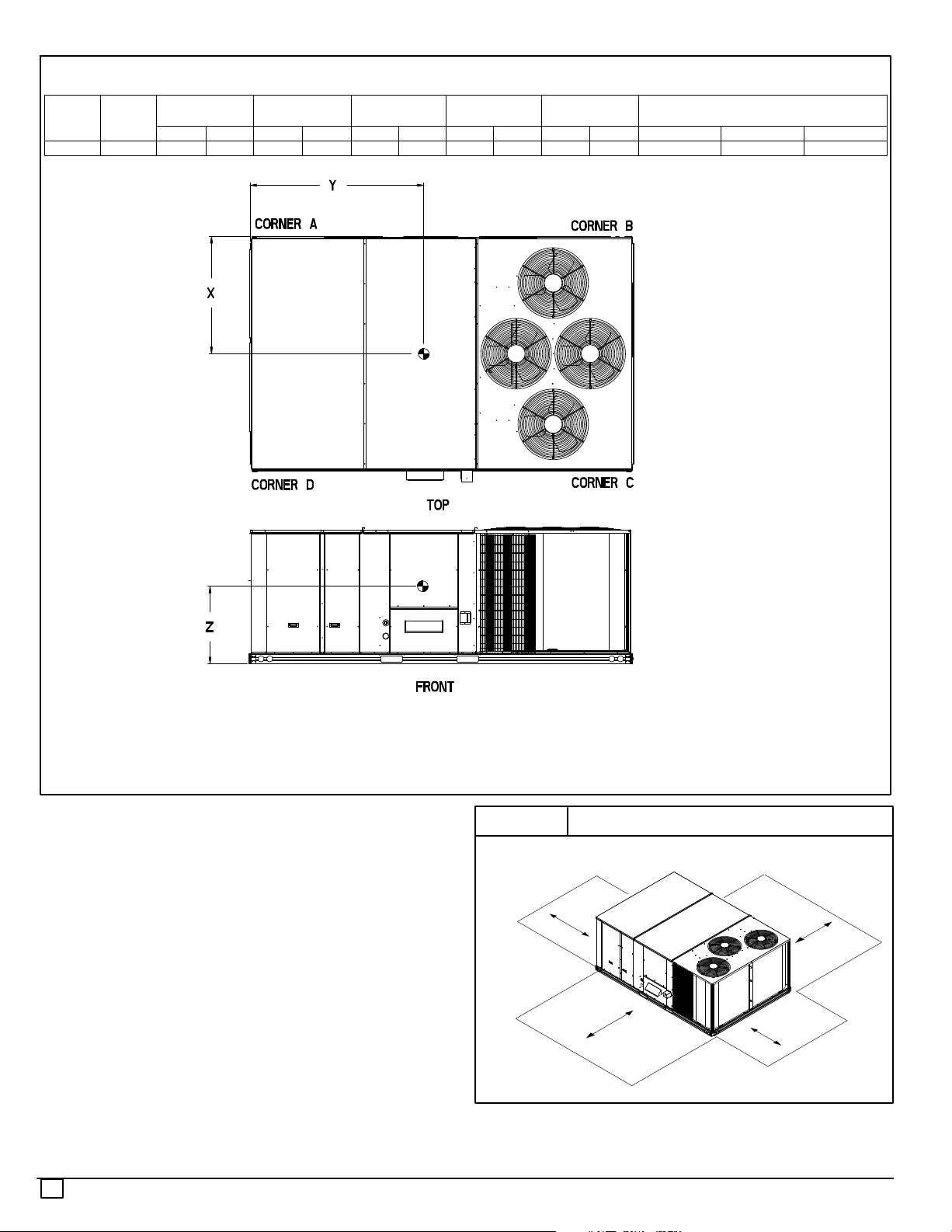

FIGURE 2 RHS Base Unit Dimensions: 20 Ton

Connection Sizes

A 1-3/8” [35] DIA Field Power Supply Hole

B 3” [76] Field Power Supply Knockout

C 3-5/8” [92] Field Power Supply Knockout

D 7/8” [22] Field Control Wiring Hole

E 3/4” 14 NPT Condensate Drain

516 01 2601 01

5

Fig. 2 − Unit Dimensional Drawing − 20 Ton

Unit Size

RHS 20 Ton 2200 998 633 288 609 277 607 276 631 287 43 [1092] 69-1/2 [1765] 16-1/2 [419]

Base Unit Weight

LBS. KG. LBS. KG. LBS. KG. LBS. KG. LBS. KG. X Y Z

Corner WeightACorner WeightBCorner Weight

C

Corner Weight

D

Center of Gravity

INSTALLATION

Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes and the NEC (National

Electrical Code) ANSI/NFPA 70 for special installation

requirements.

2. Determine unit location (from project plans) or select unit

location.

3. Check for possible overhead obstructions which may

interfere with unit lifting or rigging.

Step 1 — Plan for Unit Location

Select a location for the unit and its support system (curb or

other) that provides for the minimum clearances required for

safety. This includes the clearance to combustible surfaces,

unit performance and service access below, around and

above unit as specified in unit drawings. See Fig. 3.

6

FIGURE 3

Service Clearance Dimansional Drawing

36" (914)

42" (1067)

18" (457)

NOTE:Consider also the effect of adjacent units.

516 01 2601 01

42" (1067)

Unit may be installed directly on wood flooring or on Class A,

B, or C roof−covering material when roof curb is used.

Do not install unit in an indoor location. Do not locate air

inlets near exhaust vents or other sources of contaminated

air.

Although unit is weatherproof, avoid locations that permit

water from higher level runoff and overhangs to fall onto the

unit.

Select a unit mounting system that provides adequate height

to allow installation of condensate trap per requirements.

Refer to Step 9 — Install External Trap for Condensate Drain

– for required trap dimensions.

Roof mount —

Check building codes for weight distribution requirements.

Unit operating weight is shown in Table 1.

Step 2 — Plan for Sequence of Unit Installation

The support method used for this unit will dictate different

sequences for the steps of unit installation. For example, on

curb−mounted units, some accessories must be installed on

the unit before the unit is placed on the curb. Review the

following for recommended sequences for installation steps.

Curb−mounted installation —

Install roof curb

Install field−fabricated ductwork inside curb

Install accessory thru−base service connection package, if

used, (affects curb and unit)

Rig and place unit

Remove top skid

Install condensate line trap and piping

Make electrical connections

Install other accessories

Pad−mounted installation —

Prepare pad and unit supports

Rig and place unit

Remove duct covers and top skid

Install field−fabricated ductwork at unit duct openings

Install condensate line trap and piping

Make electrical connections

Install other accessories

Frame−mounted installation —

Frame−mounted applications generally follow the

sequence for a curb installation. Adapt as required to suit

specific installation plan.

Step 3 — Inspect unit

Inspect unit for transportation damage. File any claim with

transportation agency.

Confirm before installation of unit that voltage, amperage

and circuit protection requirements listed on unit data plate

agree with power supply provided.

Step 4 — Provide Unit Support

Roof Curb Mount —

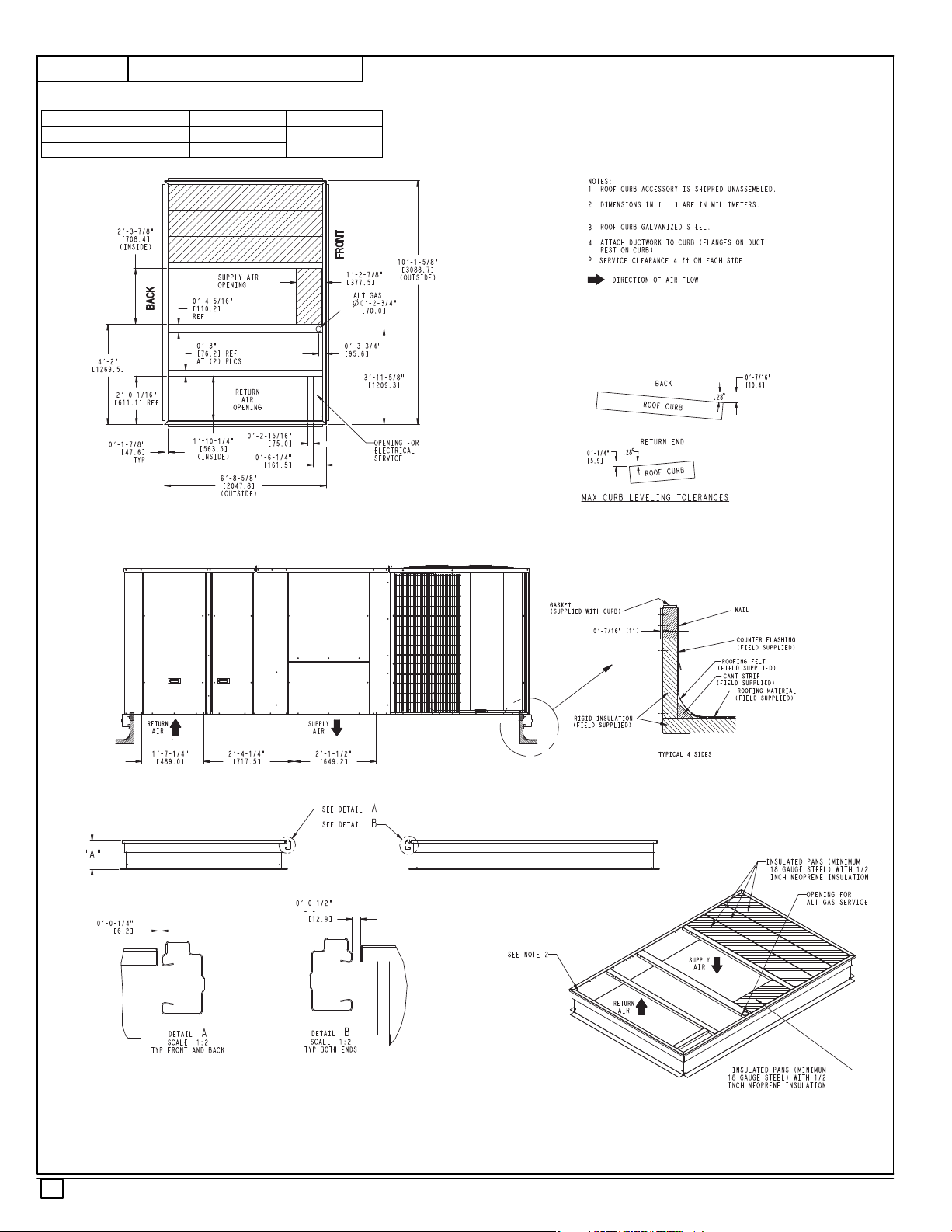

Accessory roof curb details and dimensions are shown in

Fig. 4 (15 ton units) and Fig. 5 (20 ton units). Assemble and

install accessory roof curb in accordance with instructions

shipped with the curb.

NOTE:The gasketing of the unit to the roof curb is critical for

a watertight seal. Install gasket supplied with the roof curb as

shown in Fig. 4 and Fig. 5. Improperly applied gasket can

also result in air leaks and poor unit performance.

Curb should be level. This is necessary for unit drain to

function properly. Unit leveling tolerances are show in Fig. 6.

Refer to Accessory Roof Curb Installation Instructions for

additional information as required.

Install insulation, cant strips, roofing felt, and counter flashing

as shown. Ductwork must be attached to curb and not to the

unit. The accessory thru−the−base power and gas

connection package must be installed before the unit is set

on the roof curb.

If electric and control wiring is to be routed through the

basepan remove knockouts in basepan located in control

box area, see Fig. 7 for location. Attach the service

connections to the basepans.

Slab Mount (Horizontal Units Only) —

Provide a level concrete slab that extends a minimum of 6 in.

(150 mm) beyond unit cabinet. Install a gravel apron in front

of condenser coil air inlet to prevent grass and foliage from

obstructing airflow.

NOTE:Horizontal units may be installed on a roof curb if

required.

Alternate Unit Support (In Lieu of Curb or Slab Mount) —

A non−combustible sleeper rail can be used in the unit curb

support area. If sleeper rails cannot be used, support the

long sides of the unit with a minimum of 4 equally spaced

4−in. x 4−in. (102 mm x 102 mm) pads on each side. Locate

pads so that they support the rails. Make sure to avoid the

fork openings.

Table 1—Operating Weights

UNITS LB (KG)

Component 15 Ton 20 Ton

Base Unit 2035 [923] 2200 [998]

Economizer 245 [111] 245 [111]

Curb

14−in/356 mm 243 [111] 273 [124]

24−in/610 mm 315 [143] 350 [159]

516 01 2601 01

7

FIGURE 4

RoofCurb Accessory A Unit Size

CRRFCURB045A00 1' 2 “ [356]

CRRFCURB046A00 2' 0” [610]

Roof Curb Details RHS

15 Ton

8

516 01 2601 01

Loading...

Loading...