International comfort products PHN524, PHN548, PHN560, PHN536 Installation Instructions Manual

Installation Instructions

PHN5 Series

Single Phase

PACKAGED HEAT PUMP UNITS

TABLE OF CONTENTS

PAG E...............................................

SAFETY CONSIDERATIONS 1.......................

INTRODUCTION 2..................................

RECEIVING AND INSTALLATION 2...................

Check Equipment 2................................

Provide Unit Suppor 2..............................

Ground Level Installation 2.........................

Rooftop Installation 2..............................

Roof Curb 3......................................

Provide Clearances 3..............................

Rig and Place Unit 3...............................

Inspection 3......................................

Use of Rigging Bracket 3..........................

Select and Install Ductwork 7.......................

Converting Horizontal Discharge Units to Downflow

(Vertical) Discharge Units 9........................

Connect Condensate Drain 9.......................

Install Electrical Connections 9......................

High--Voltage Connections 10.....................

Special Procedures for 208--V Operation 10.........

Control Voltage Connections 10....................

Standard Connections 10.........................

Transformer Protection 10........................

Accessory Electric heaters Installation 10...........

Sequence of Operation 11.........................

PRE--START--UP 14.................................

START--UP 14......................................

Checking Cooling & Heating Control Operation 14....

Check for Refrigerant Leaks 14......................

Start--Up Adjustments 15..........................

Checking & Adjusting Refrigerant Charge 15........

Indoor Airflow & Airflow Adjustments 15.............

Continuous Fan Operation 16.....................

Defrost Control 17.................................

Quiet Shift 17...................................

Defrost 17......................................

MAINTENANCE 17.................................

Air Filter 18.......................................

Indoor Blower and Motor 18.........................

Outdoor Coil, Indoor Coil, & Condensate Drain Pan 20.

Outdoor Fan 21...................................

Electrical Controls and Wiring 21....................

Refrigerant Circuit 21..............................

Indoor Airflow 21..................................

Metering Devices-- TXV & Piston 22.................

Pressure Switches 22..............................

Loss of Charge Switch 22..........................

High Pressure Switch 22...........................

Copeland Scroll compressor (R--410A Refrigerant) 22..

Refrigerant System 22.............................

Refrigerant 22...................................

Compressor Oil 23

Servicing on Roofs with Synthetic Materials 23.......

Liquid Line Filter Drier 23.........................

R--410A Refrigerant Charging 23...................

System Information 23.............................

Loss of Charge Switch 23.........................

Check Defrost Thermostat 23.....................

...............................

Printed in U.S.A.

R--410A QUICK REFERENCE GUIDE 24..............

TROUBLESHOOTING 25............................

START--UP CHECKLIST 26..........................

International Comfort Products, LLC

Lewisburg, TN. 37091

518 01 2101 00 04--02--08

SAFE INSTALLATION REQUIREMENTS

We require these instructions as a minimum for a safe

installation.

FIGURE 1

Installation and servicing of this equipment can be

hazardous due to mechanical and electrical components.

Only trained and qualified personnel should install, repair,

or service this equipment.

Untrained personnel can perform basic maintenance

functions such as cleaning and replacing air filters. All other

operations must be performed by trained service

personnel. When working on this equipment, observe

precautions in the literature, ontags, and on labels attached

to or shipped with the unit and other safety precautions that

may apply.

Follow all safety codes. Installation must be in compliance

with local and national building codes. Wear safety glasses,

protective clothing, and work gloves. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions included in literature and attached to

the unit.

Recognize safety information. This is the safety--alert

symbol . When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

These instructions cover minimum requirements and

conform to existing national standards and safety codes. In

some instances, these instructions exceed certain local

codes and ordinances, especially those that may not have

kept up with changing residential construction practices.

!

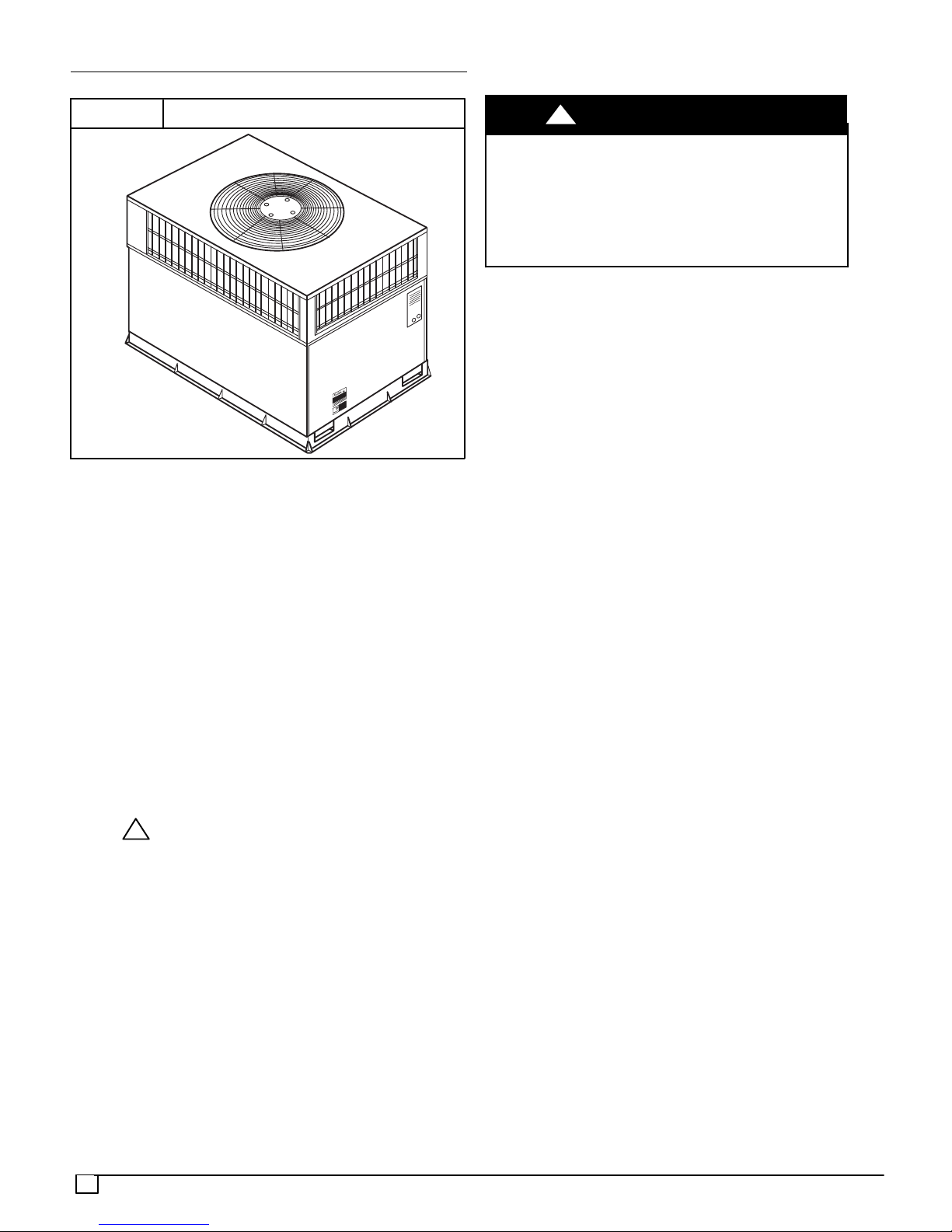

PHN5 HEAT PUMP UNIT

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, turn off power

supply to the unit and install lockout tag. There may be

more than one disconnect switch. Turn off accessory

heater power switch if applicable.

INTRODUCTION

This packaged heat pump unit is fully self--contained and

designed for outdoor installation (see Fig. 1). See Fig. 3 and

4 for unit dimensions. All unit sizes have discharge

openings for both horizontal and downflow configurations

and are factory shipped with all downflow duct openings

covered. The unit may be installed e ither on a rooftop or at

ground level.

Step 1—Check Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped on

the unit information plate. Check this information against

shipping papers.

INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping

pallet. If unit appears to be damaged or is torn loose from

its anchorage, have it examined by transportation

inspectors before removal. Forward claim papers directlyto

transportation company. Manufacturer is not responsible

for any damage incurred in transit. Check all items against

shipping list. Immediately notify the nearest equipment

distribution office if any item is missing. To prevent loss or

damage, leave all parts in original packages until

installation.

Step 2—Provide Unit Support

Ground Level Installation

Ground level platform requirements:

-- The unit MUST be situated to provide safe access for

servicing.

-- The unit must be level and supported above grade by

beams, platform, or a pad. Platform or pad can b e of

open or solid construction but should be of permanent

materials such as concrete, bricks, blocks, steel, or

pressure--treated timbers approved for ground contact.

Soil conditions must be considered so that the platform

or pad does not shift or settle and leave the unit partially

supported.

-- Position platform separate from building foundation.

-- Install in well--drained area, with top surface of platform

above grade level.

-- Platform must be high enough to allow for proper

condensate trap installation and drainage

Rooftop Installation

Rooftop platform requirements:

WARNING

RECEIVING AND INSTALLATION

2

-- The unit MUST be situated to provide safe access for

servicing.

-- The existing roof structure MUST be adequate to

support the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structure if necessary. See Figures 3 and

4 of this manual for unit weights.

-- Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a

platform or a combination of platform and roof beams or

curb.

-- S e e Hoisting section for hoisting instructions.

For hurricane tie downs, contact distributor for details and

PE (Professional Engineering) Certificate if required.

ROOFCURB

Install accessory roof curb in accordance with instructions

shipped with curb. Install insulation,cant strips, roofing, and

flashing. Ductwork must be attached to curb.

equipment, and any other safety precautions that might

apply.

Training for operators of the lifting equipment should

include, but not be limited to, the following:

1. Application of the lifter to the load, and adjustment of

the lifts to adapt to various sizes or kinds of loads.

2. Instruction in any special operation or precaution.

3. Condition of the load as it relates to operation of the

lifting kit, such as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and

work gloves.

INSPECTION

Prior to initial use, and at monthly intervals, all rigging

brackets and straps should be visually inspected for any

damage, evidence of wear, structural deformation, or

cracks. Particular attention should be paid to excessive

wear at hoist hooking points and load support areas.

Brackets or straps showing any kind of wear in these areas

must not be used and should be discarded.

IMPORT ANT: The gasketing of the unit to the roof curb is

critical for a water tight seal. Install gasketing material

supplied with the roof curb. Improperly applied gasketing

also can result in air leaks and poor unit performance.

Curb should be level to within 1/4 in. (6mm). This is

necessary for unit drain to function properly. Refer to

accessory roof curb installation instructions for additional

information as required.

Step 3—Provide Clearances

The required minimumservice clearances areshown in Fig.

3 and 4. Adequate ventilation and outdoor air must be

provided. The outdoorfan draws air through the outdoor coil

and discharges it through the top fan grille. Be sure that the

fan discharge doesnot recirculate tothe outdoor coil.Do not

locate the unit in either a corner or under an overhead

obstruction. The minimum clearance under a partial

overhang (such as a normal house overhang) is 48 in.

(1219mm) above the unit top. The maximum horizontal

extension of a partial overhang must not exceed 48

in.(1219mm).

IMPORT ANT: Do not restrict outdoor airflow. An air

restriction at either the outdoor--air inlet or the fan discharge

may be detrimental to compressor life.

Do not place the unit where water, ice, or snow from an

overhang or roof will damage or flood the unit. Do not install

the unit on carpeting or other combustible materials.

Slab--mounted units should be at least 4 in. (102mm) above

the highest expected water and runoff levels. Do not use

unit if it has been under water.

Step 4—Rig and Place Unit

Rigging and handling of this equipment can be hazardous

for many reasons due to the installation location (roofs,

elevated structures, etc.).

Only trained, qualified crane operators and ground support

staff should handle and install this equipment.

When working with this equipment, observe precautions in

the literature, on tags, stickers, and labels attached to the

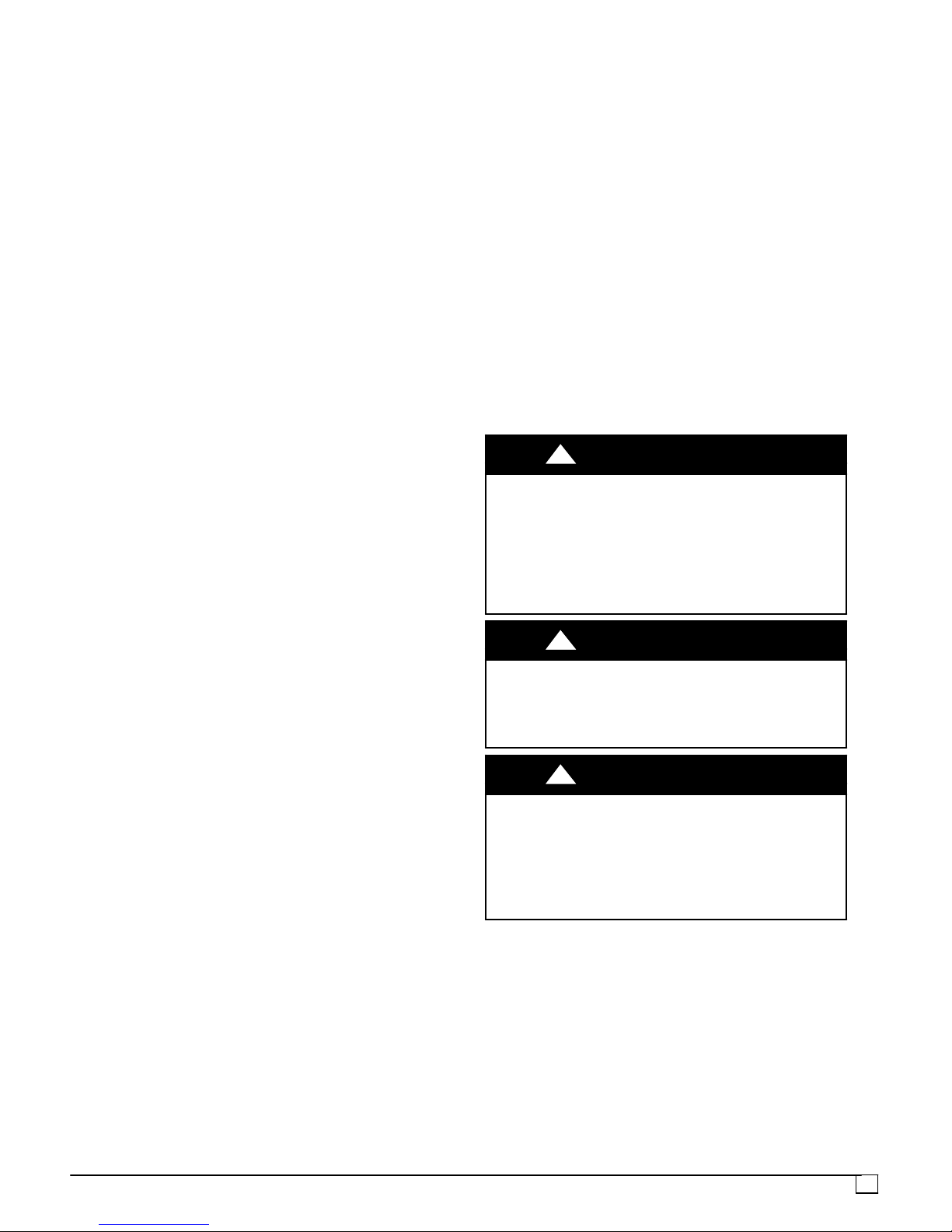

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power

switch if applicable. Tag disconnect switch with a suitable

warning label.

!

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

injury or death.

Never stand beneath rigged units or lift over people.

!

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

Rigging brackets for one unit use only . When

removing a unit at the end of its useful life, use a new set

of brackets.

USE OF RIGGING BRACKET

NOTE: Units may require accessory kit NPLIFTBK003A10.

Field Installation of Rigging Bracket (if not already installed)

1. Remove unit from shipping carton. Leave top shipping

skid on the unit for use as a spreader bar to prevent the

rigging straps from damaging the unit. If the skid is not

available, use a spreader bar of sufficient length to

protect the unit from damage.

2. Remove 4 screws in unit corner posts.

3. Attach each of the 4 metal rigging brackets under the

panel rain lip (See Fig. 2). Use the screws removed in

step 2 above to secure the brackets to the unit.

WARNING

WARNING

WARNING

3

!

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

Rigging bracket MUST be under the rain lip to provide

adequate lifting.

!

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

Do not strip screws when re--securing the unit. If a screw

is stripped, replace the stripped one with a larger diameter

screw (included). When straps are taut, the clevis should

be a minimum of 36 (914mm) inches above the unit top

cover .

WARNING

WARNING

Rigging/Lifting of Unit

1. Bend top of brackets down approximately 30 degrees

from the corner posts.

2. Attach straps of equal length to the rigging brackets at

opposite ends of the unit. Be sure straps are rated to

hold the weight of the unit (See Fig. 2).

3. Attach a clevis of sufficient strength in the middle of the

straps. Adjust the clevis location to ensure unit is lifted

level with the ground.

4. After unit is securely in place detach rigging straps.

Remove corner posts screws, and rigging brackets

then reinstall screws.

After the unit is placed on the roof curb or mounting pad,

remove the top crating.

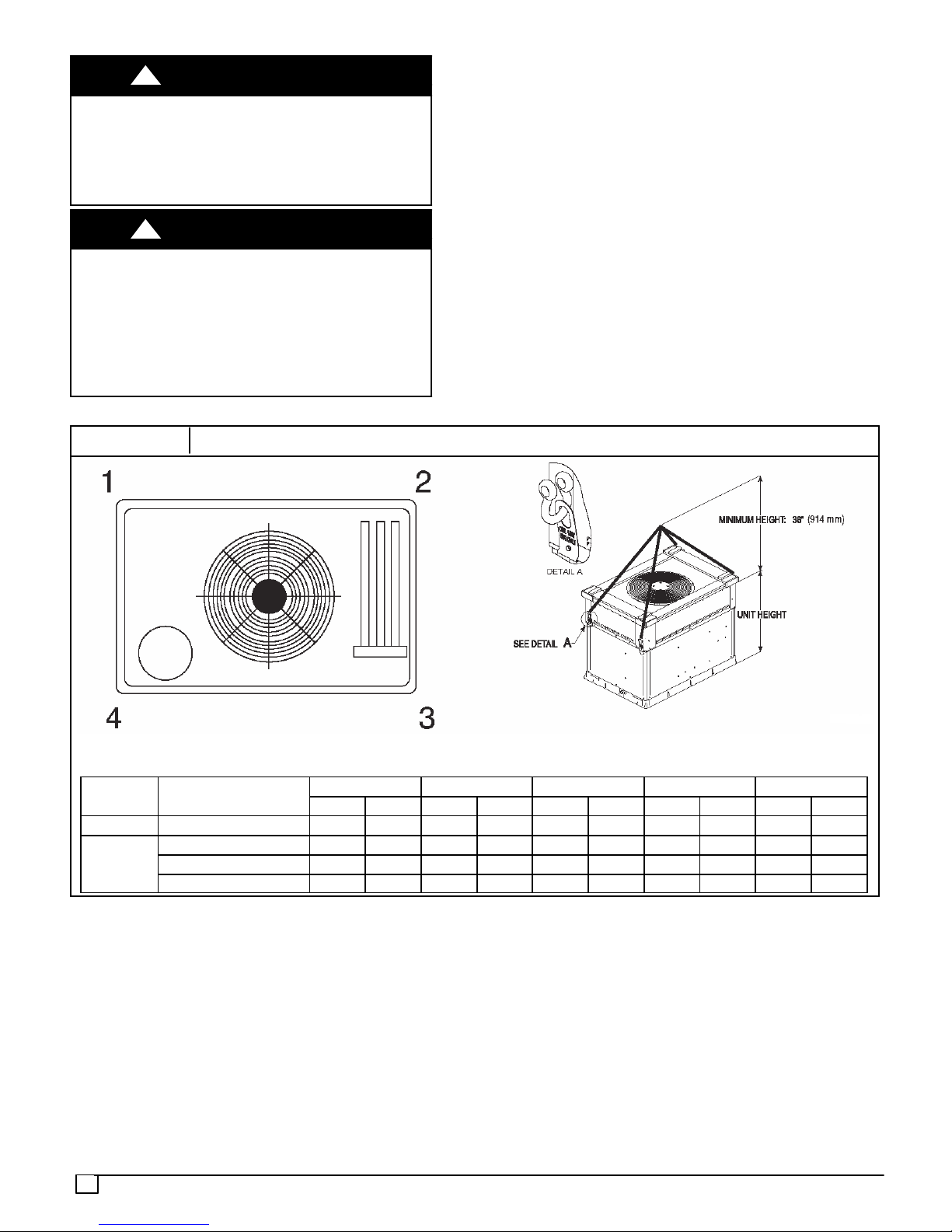

FIGURE 2

Cabinet MODEL NUMBER

Small PHN524 382 173 75 34 57 26 91 41 158 72

PHN536 469 213 93 42 71 32 113 51 192 87

Large

PHN548 497 225 104 47 63 29 136 62 193 88

PHN560 548 249 117 53 75 34 149 68 207 94

Unit Corner Weight (lbs) and Rigging

Rigging Weight 1 2 3 4

lb kg lb kg lb kg lb kg lb kg

4

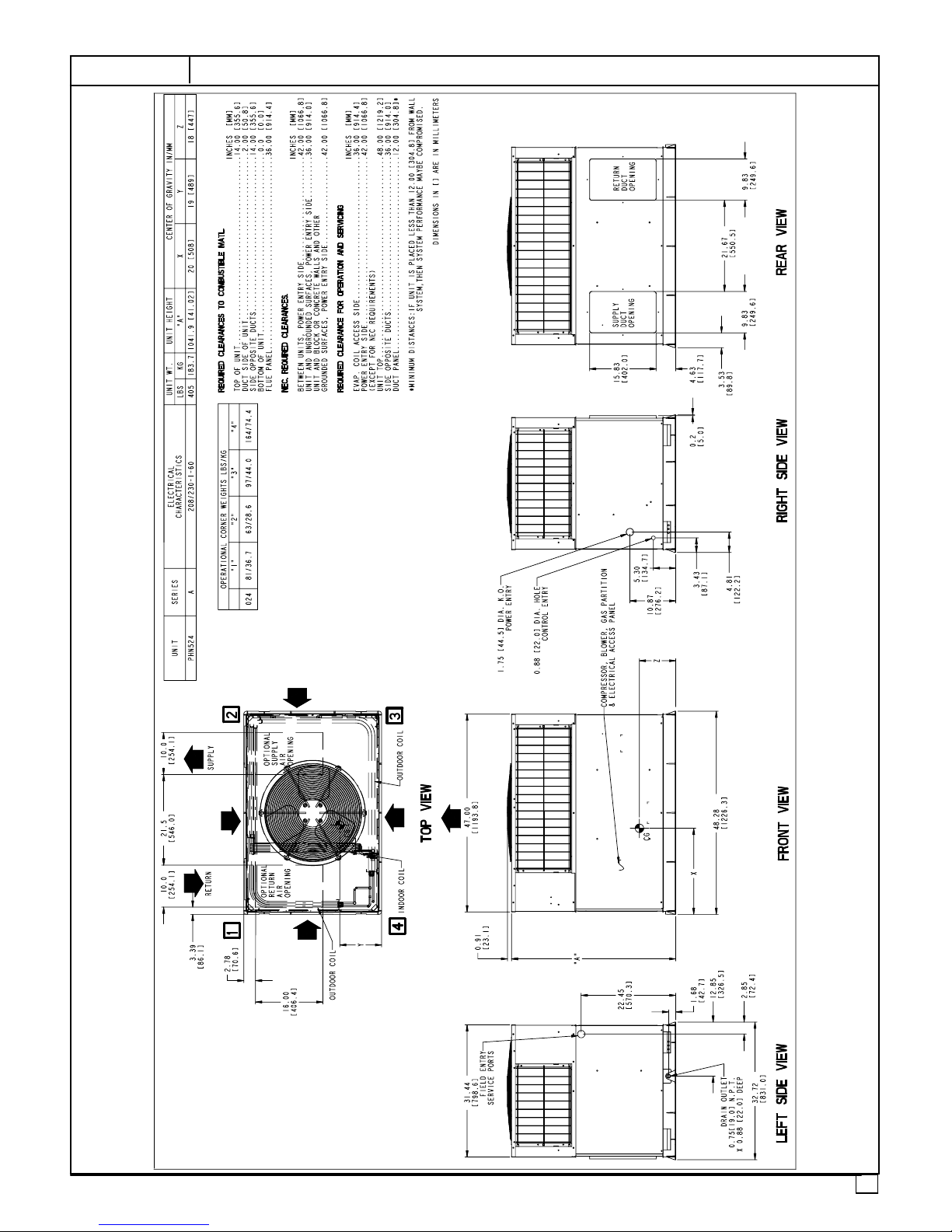

FIGURE 3

PHN524 DIMENSIONS

5

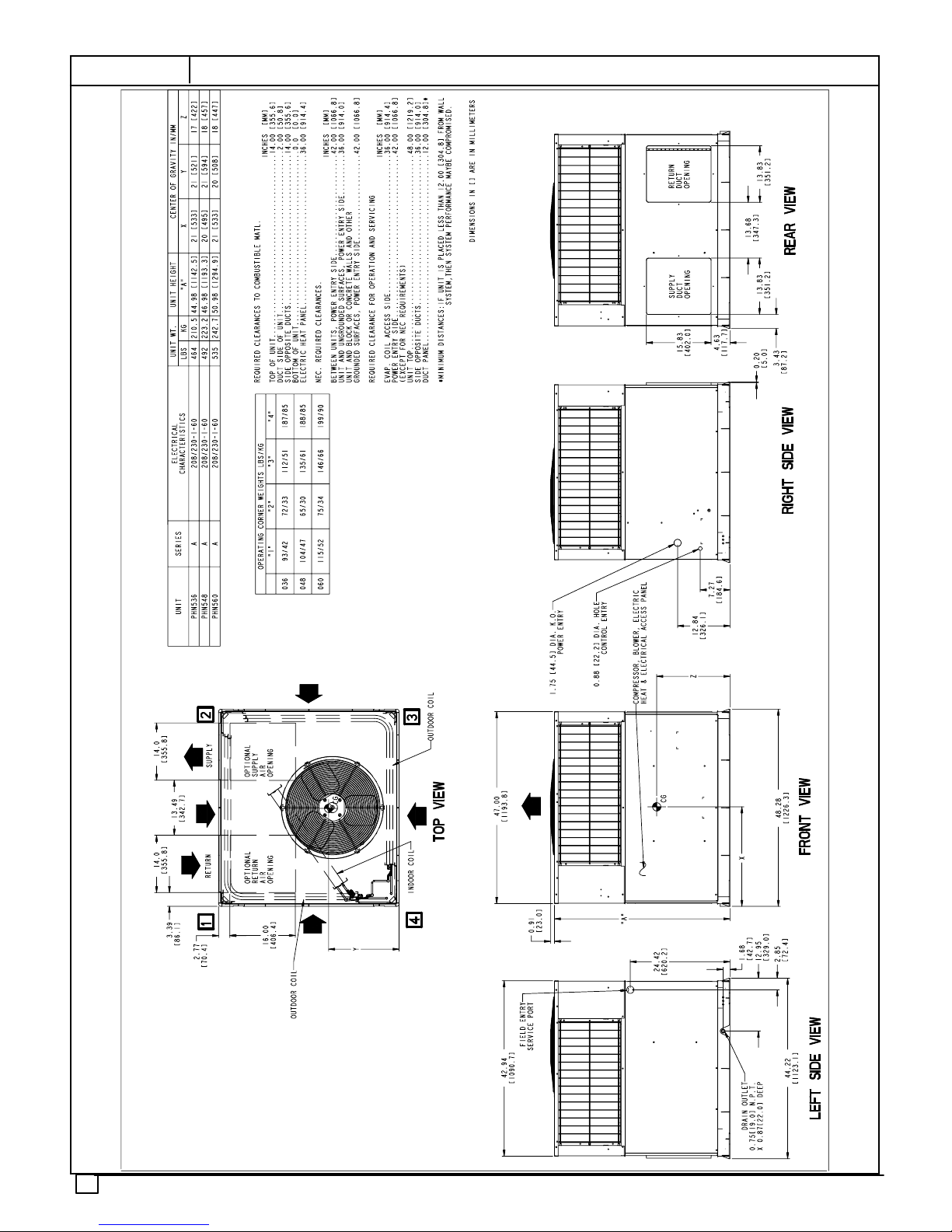

FIGURE 4

PHN536--60 DIMENSIONS

6

Step 5—Select and Install Duct Connections

The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation

of non--residence type air conditioning and ventilating

systems, NFPA 90A or residence type, NFPA 90B and/or

local codes and ordinances.

Select and size ductwork, supply--air registers, and return

air grilles according to ASHRAE (American Society of

Heating, Refrigeration, and Air Conditioning Engineers)

recommendations.

The unit has duct flanges on the supply-- and return--air

openings on the side of the unit.

!

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

For vertical supply and return units, tools or parts could

drop into ductwork. Install a 90 degree turn in the return

ductwork between the unit and the conditioned space. If

a 90 degree elbow cannot be installed, then a grille of

sufficient strength and density should be installed to

prevent objects from falling into the conditioned space.

Units with electric heaters require 90 degree elbow in

supply duct.

WARNING

When designing and installing ductwork, consider the

following:

1. All units should have field--supplied filters or accessory

filter rack installed in the return--air side of the unit.

Recommended sizes for filters are shown in Table 1.

2. Avoid abrupt duct size increases and reductions.

Abrupt change in duct size adversely affects air

performance.

IMPORT ANT: Use flexible transitions between ductwork

and unit to prevent transmission of vibration. Use suitable

gaskets to ensure weather tight and airtight seal. When

electric heat is installed, use fireproof canvas (or similar

heat resistant material) connector between ductwork and

unit discharge connection. If flexible duct is used, insert a

sheet metal sleeve inside duct. Heat resistant duct

connector (or sheet metal sleeve) must extend 24--in.

(610mm) from electric heater element.

3. Size ductwork for cooling air quantity (cfm). The

minimum air quantity for proper electric heater

operation is listed in Table 2. Heater limit switches may

trip at air quantities below those recommended.

4. Seal, insulate, and weatherproof all external ductwork.

Seal, insulate and cover with a vapor barrier all

ductwork passing through conditioned spaces. Follow

latest Sheet Metal and Air Conditioning Contractors

National Association (SMACNA) and Air Conditioning

Contractors Association (ACCA) minimum installation

standards for residential heating and air conditioning

systems.

5. Secure all ducts to building structure. Flash,

weatherproof, and vibration--isolate duct openings in

wall or roof according to good construction practices.

7

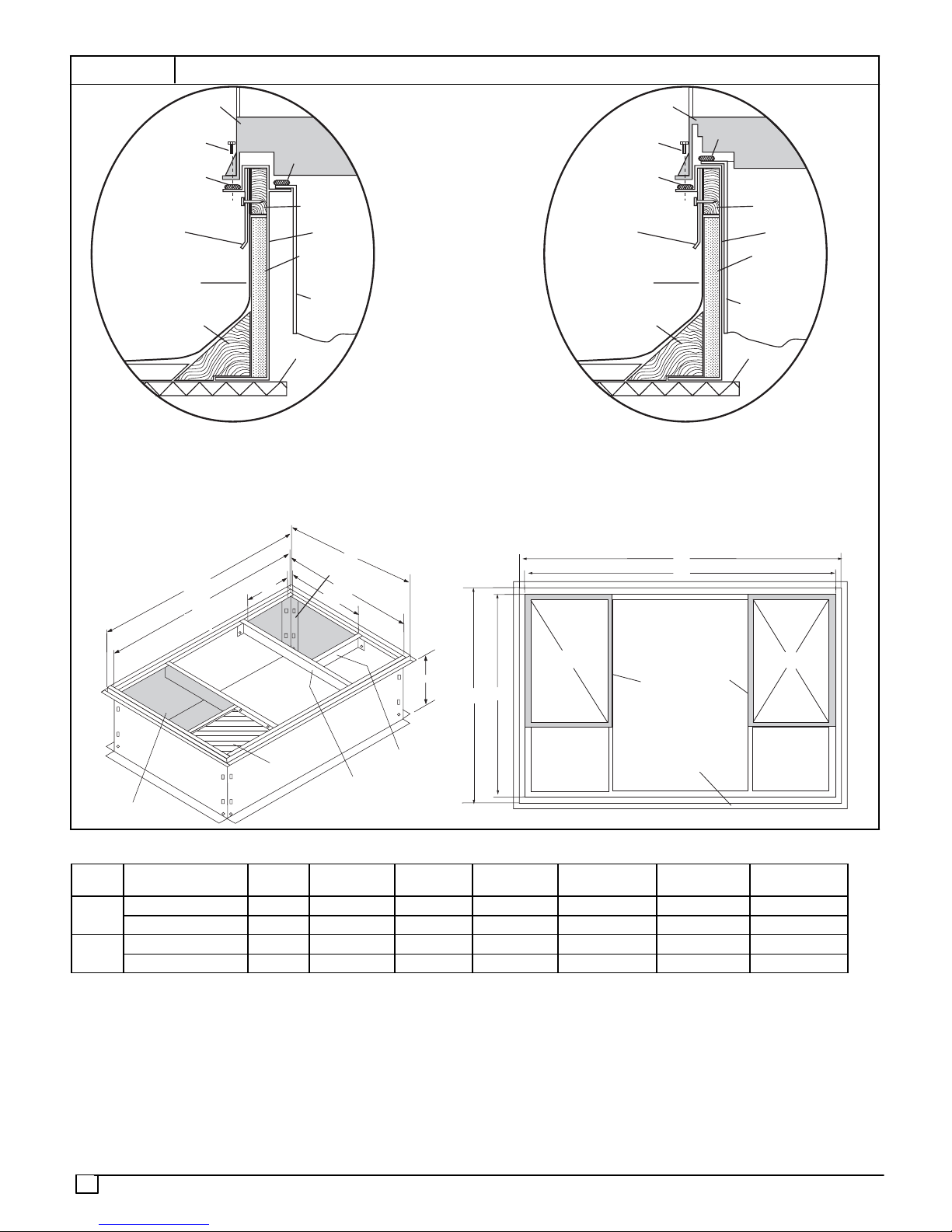

FIGURE 5

Roof Curb Dimensiona

HVAC unit

base

Scre w

(NO TE A)

*Gask eting

outer flange

Flashing field

supplied

Roofing material

field supplied

Cant str ip

field supplied

*Provided with roofcurb

Gask eting

inner flange*

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Duct wo rk

field supplied

Roof

Roof Curb for Small Cabinet

Note A: When unit mounting scre w is used,

retainer bra cke t must also be used.

HVAC unit

Scre w

(NOTE A)

*Gask eting

outer flange

Flashing field

supplied

Roofing material

field supplied

Cant str ip

field supplied

*Provided with roofcurb

base

Gask eting

inner flange*

Duct wo rk

field supplied

Wood nailer*

Roofcurb*

Insulation (field

supplied)

Roof

Roof Curb for Large Cabinet

Note A: When unit mounting scre w is used,

retainer bra cket must also be used.

Model

PHN5

24

36--60

E

Supply opening

G

F

F

B Typ.

C Typ .

(B x C)

D

R/A

A

Short

Long

Support

Support

C

IN. [MM]

Return opening

(B X C)

MODEL NUMBER

Insulated

deck pan

A

IN. [MM]BIN. [MM]

NPRFCURB006A00 8 [203] 11 [279] 16--1/2 [419] 28--3/4 [730] 30--3/8 [771] 44--5/16 [1126] 45 --15/16 [1167]

NPRFCURB007A00 14 [356] 11 [279] 16--1/2 [419] 28-- 3/4 [730] 30-- 3/8 [771] 44-- 5/16 [1126] 45-- 15/16 [1167]

NPRFCURB008A00 8 [203] 16--3/16 [411] 17--3/8 [441] 40--1/4 [1022] 41--15/16 [1065] 44--7/16 [1129] 46--1/16 [1169]

NPRFCURB009A00 14 [356] 16-- 3/16 [411] 17--3/8 [441] 40-- 1/4 [1022] 41--15/16 [1065] 44--7/16 [1129] 46--1/16 [1169]

E

D

D

IN. [MM]

Insulated

deck pan

IN. [MM]

Gask et around

E

G

F

Gask et around

duct

outer edge

IN. [MM]

S/A

F

G

IN. [MM]

Notes:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied as required to unit being installed.

3. Roof curb is made of 16 gauge steel.

4. Attach ductwork to curb (flanges of duct rest on curb).

5. Insulated panels: 1 --- in. (25.4mm) thick fiberglass 1 lb. density.

6. When unit mounting screw is used (see Note A), a retainer bracket must be used as well. This bracket must also be used when required by

code for hurricane or seismic conditions. This bracket is available through Micrometl.

8

Loading...

Loading...