INSTALLATION INSTRUCTIONS

NATURAL GAS to PROPANE GAS CONVERSION KIT

Condensing and Non−Condensing Gas Furnaces

(F/G)9MAC, (F/G)9MAE, (F/G)9MVT, (F/G)9MVE, (F/G)9MXT, (F/G)8MVL, (F/G)8MTL

NAHB01001LP

personnel must perform all other operations. When working on

heating equipment, observe precautions in the literature, on

tags, and on labels attached to or shipped with the unit, and

CERTIFIED

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATION

! WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

This conversion kit shall be installed by a qualified service

agency in accordance with the manufacturer’s instructions

and all applicable codes and requirements of the authority

having jurisdiction. If the information in these instructions is

not followed exactly, a fire, explosion, or production of carbon

monoxide could result causing property damage, personal

injury, or loss of life. The qualified service agency is

responsible for the proper installation of this furnace with this

kit. The installation is not proper and complete until the

operation of the converted appliance is checked as specified

in the manufacturer’s instructions supplied with the kit.

other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety

codes including the current edition of the National Fuel Gas

Code (NFGC) NFPA No. 54/ANSI Z223.1. In Canada, refer to

the current edition of the National Standard of Canada, Natural

Gas and Propane Installation Codes (NSCNGPIC),

CAN/CSA−B149.1 and .2. Wear safety glasses and work

gloves. Have a fire extinguisher available during start−up,

adjustment steps, and service calls.

Recognize safety information. This is the safety−alert symbol

. When you see this symbol on the furnace and in

instructions or manuals, be alert to the potential for personal

injury. Understand the signal words DANGER, WARNING,

CAUTION and NOTE. The words DANGER, WARNING, and

CAUTION are used with the safety alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

INTRODUCTION

!

LE FEU, L’EXPLOSION, CHOC ELECTRIQUE,

ET MONOXYDE DE CARBONE EMPOISONNER

Cette trousse de conversion doit être installée par un servie

d’entretien qualifié, selon les instructions du fabricant et selon

toutes les exigences et tous les codes pertinents de l’autorité

compétente. Assurezvous de bien suivre les instructions

dans cette notice pour réduire au minimum le risque

d’incendie, d’explosion ou la production de monoxyde de

carbone pouvant causer des dommages matériels, de

blessure ou la mort. Le service d’entretien qualifié est

responsable de l’installation de cette trousse. L’installation

n’est pas adéquate ni complète tant que le bon

fonctionnement de l’appereil converti n’a pas été vérfié selon

les instructions du fabricant fornies avec la trousse.

Installing and servicing heating equipment can be hazardous

due to gas and electrical components. Only trained and

qualified personnel should install, repair, or service heating

equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. Trained service

AVERTISSEMENT

! WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow instructions could result in personal injury,

death or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poisoning,

explosion, fire, electrical shock, or other conditions, which

could result in personal injury or death. Consult your

distributor or branch for information or assistance. The

qualified installer or agency must use only factory−authorized

kits or accessories when servicing this product.

! WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Gas supply MUST be shut off before disconnecting electrical

power and proceeding with conversion.

Specifications subject to change without notice.

443 06 1522 00 6/12/14

! WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

CONDENSING FURNACES

MODEL NUMBERS BEGINNING WITH:

(F/G)9MAC (F/G)9MVT

(F/G)9MAE (F/G)9MVE

SECTION 1

(F/G)9MXT

install a lockout tag. There may be more than one disconnect

switch. Lock out and tag switch with a suitable warning label.

Verify proper operation after servicing.

This instruction covers the installation of gas conversion kit Part

No. NAHB01001LP to convert the following furnaces from

natural gas usage to propane gas usage. See appropriate

section for your furnace type.

Section 1—(F/G)9MAC, (F/G)9MAE, (F/G)9MVT, (F/G)9MVE,

& (F/G)9MXT 35−in. (889 mm ) 4-Way Multipoise, Hot Surface

Ignition, Modulating Variable−Speed, Two−Stage

Variable−Speed and Two−Stage ECM Blower Motor

Condensing Furnaces.

Section 2—(F/G)8MVL & (F/G)8MTL, 33.3−in. (846 mm) High,

Induced−Combustion, Hot−Surface Ignition, Two-Stage,

INSTALLATION

1. Set room thermostat to lowest setting or “OFF”.

2. Remove outer doors.

3. Disconnect power at external disconnect, fuse or circuit

breaker.

4. Turn off gas at external shut-off or gas meter.

5. Remove outer doors and set aside.

6. Turn electric switch on gas valve to OFF.

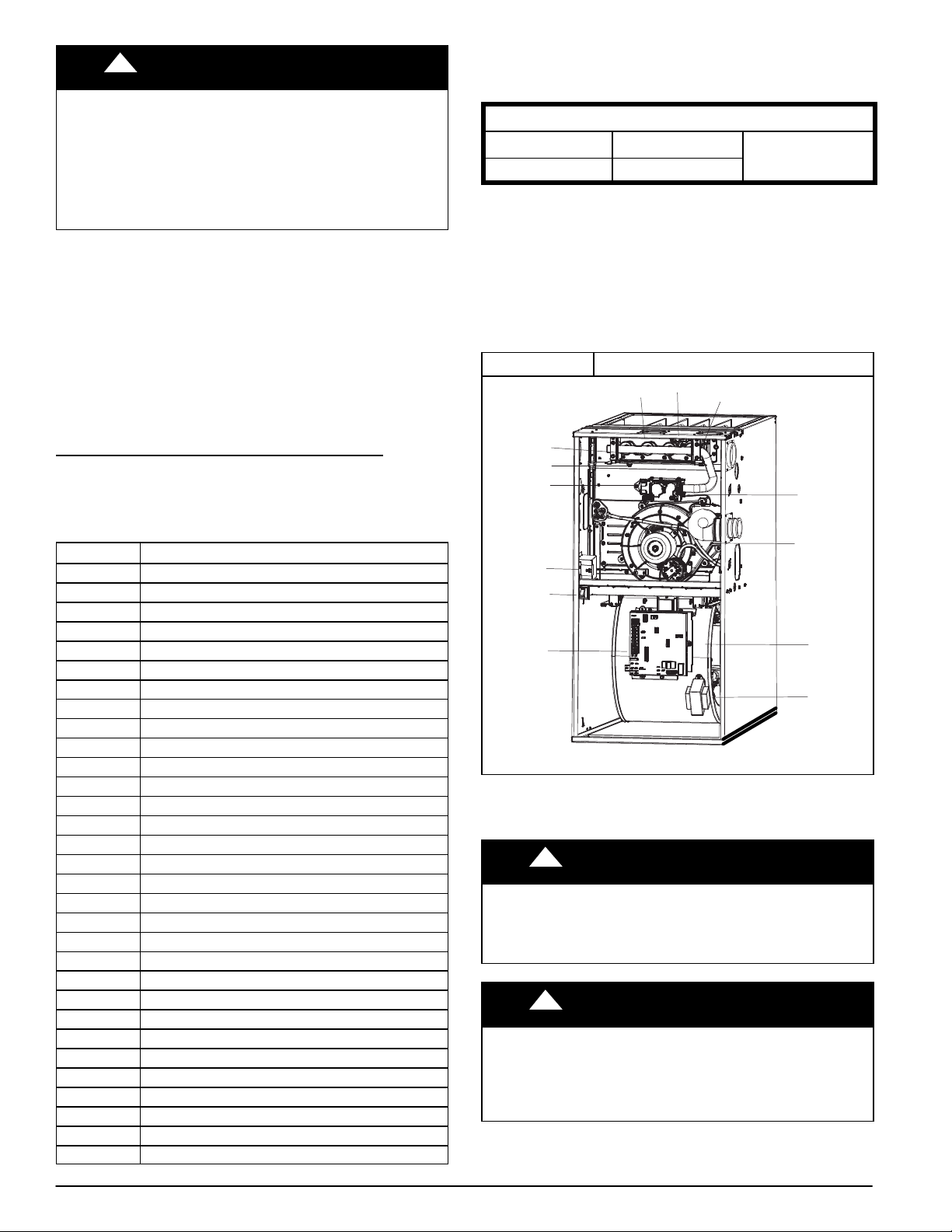

Figure 1

Representative Furnace Drawing

HOT SURFACE

IGNITER

GAS BURNER

MANUAL RESET

ROLLOUT SWITCH

Variable-Speed, Non-Condensing Furnaces.

FLAME

DESCRIPTION AND USAGE

This kit is designed for use in the furnaces listed below. See

Table 1 for kit contents. To accommodate many different

furnace models, more parts are shipped in kit than will be

needed to complete conversion. When installation is complete,

discard extra parts.

Table 1 NAHB01001LP Contents

QUANTITY DESCRIPTION

1 VALVE CVRSN KIT - W/R F92-102100

SENSOR

MANUAL RESET

ROLLOUT SWITCH

GAS VALVE

OPERATING INSTRUCTIONS

NOT SHOWN (LOCATED ON

MAIN FURNACE DOOR, SEE

OPERATING INSTRUCTIONS

INSIDE DOOR FIGURE).

ELECTRICAL JUNCTION

BOX (IF REQUIRED,

LOCATION MAY VARY)

BLOWER DOOR

SAFETY SWITCH

MAIN LIMIT SWITCH

(BEHIND GAS VALVE)

INDUCER MOTOR

ASSEMBLY

2 VALVE CVRSN KIT - W/R SPRING 92-0659

7 ORIFICE - #55

7 ORIFICE - #56

FURNACE

CONTROL

BOARD

BLOWER AND

MOTOR

7 ORIFICE - 1.25mm

7 ORIFICE - 1.30mm

7 SCREW - SPOILER (CONDENSING)

7 SCREW - SPOILER (NON−CONDENSING)

1 CONNECTOR - BRASS 1/8” NPT X2”

1 CONNECTOR,SPLC - 3/16”

1 CONNECTOR-1/4QC ME BOTH ENDS

1 ELBOW, STREET - 150# 1/8” NPT

1 ELBOW, STREET - BRASS 1/8” NPT

RATING PLATE NOT SHOWN

(LOCATED ON BLOWER DOOR)

REPRESENTATIVE DRAWING ONLY, SOME MODELS MAY VARY IN APPEARANCE.

MANIFOLD/ORIFICE/BURNER

REMOVAL

CAPACITOR/

POWER CHOKE

L11F045

1 NIPPLE - HEX (BRASS)

1 SWITCH, PRESSURE

1 TEE - MALE BRANCH (BRASS)

1 TEE, STREET - MALE BRANCH (BRASS)

1 BIT, DRILL 7/64” CONDENSING

1 BIT, DRILL 5/64” NON−CONDENSING

2 WIRE ASSY - ORANGE

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage or

improper operation.

Label all wires prior to disconnection when servicing controls.

! CAUTION

1 LABEL 339268-201

1 LABEL 339268-202

!

PRUDENCE

1 LABEL 339268-203

1 LABEL 339268-204

1 LABEL 339268-205

1 LABEL 339268-206

1 LABEL 339268-209 (FRENCH)

1 LABEL 339268-211 (FRENCH)

1 LABEL 339268-214 (FRENCH)

1 INSTRUCTIONS

D’EQUIPEMENT D’OPERATION

Toute erreur de câblage peut être une source de danger et

de panne.

Lors des opérations d’entretien des commandes, étiqueter

tous les fils avant de les déconnecter.

NOTE: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting

to the burner box.

2 443 06 1522 00

Specifications subject to change without notice.

1. Disconnect the gas pipe from gas valve and remove pipe

from the furnace casing.

2. Disconnect the connector harness from gas valve.

Disconnect wires from Hot Surface Igniter (HSI) and

Flame Sensor.

3. Support the manifold and remove the four (4) screws that

secure the manifold assembly to the burner box and set

aside.

4. Note the location of the green/yellow wire ground wire for

re-assembly later. (See Figure 2)

5. Slide one−piece burner assembly out of slots on sides of

burner box. (See Figure 3)

6. Remove the flame sensor from the burner assembly.

7. Remove the orifices from the manifold and discard.

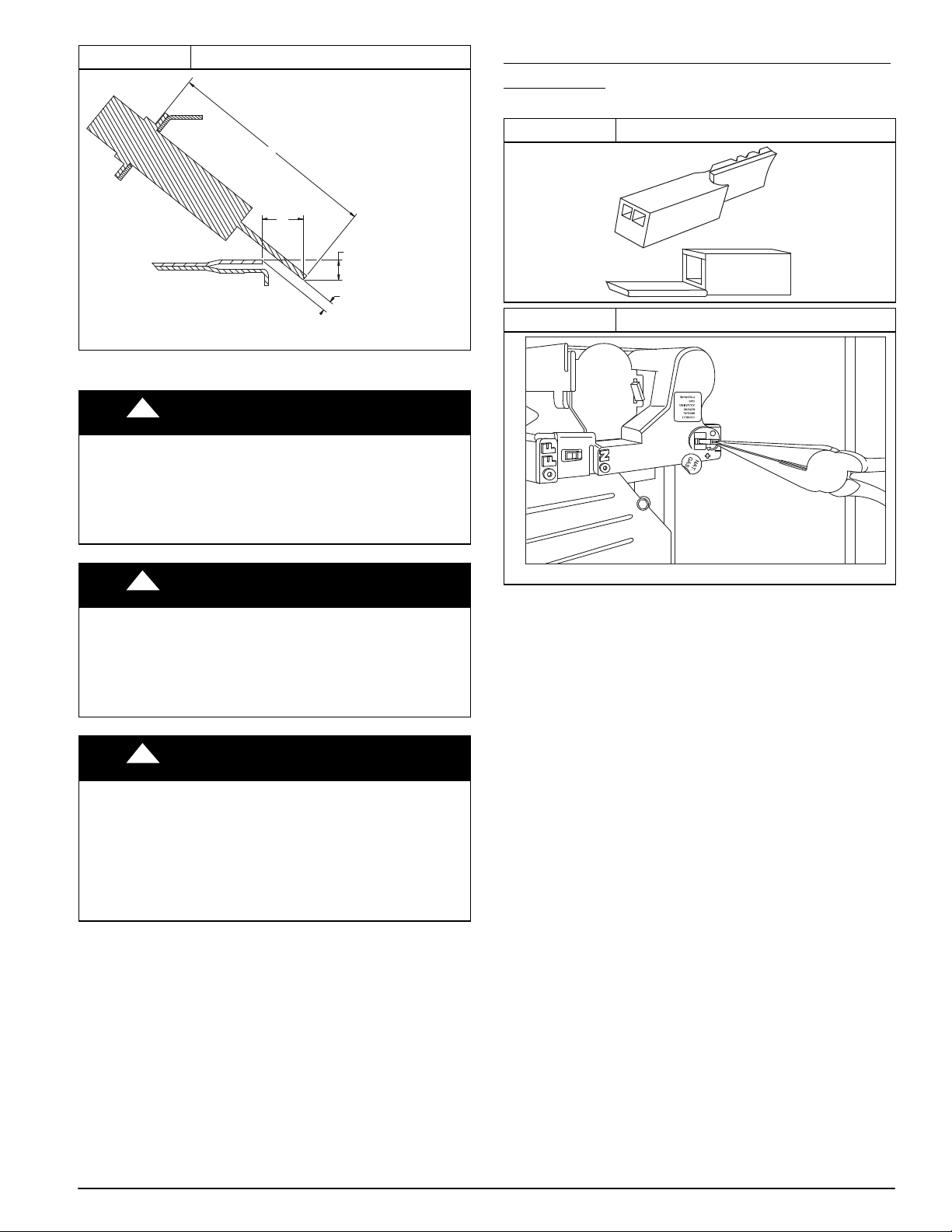

Figure 2

Connect Green/Yellow

ground wire here

Gas valve is parallel to manifold

C

L

within + or - 3˚

Gas valve must be installed on

manifold with minimum engagement of

6 threads. Cross threading is not

acceptable.

REPRESENTATIVE DRAWING ONLY, SOME MODELS MAY VARY IN APPREARANCE.

Gas Valve with Orifices

Orifice

Manifold

Gas Valve

Indicated surfaces

˚+ or -2˚

to be 90

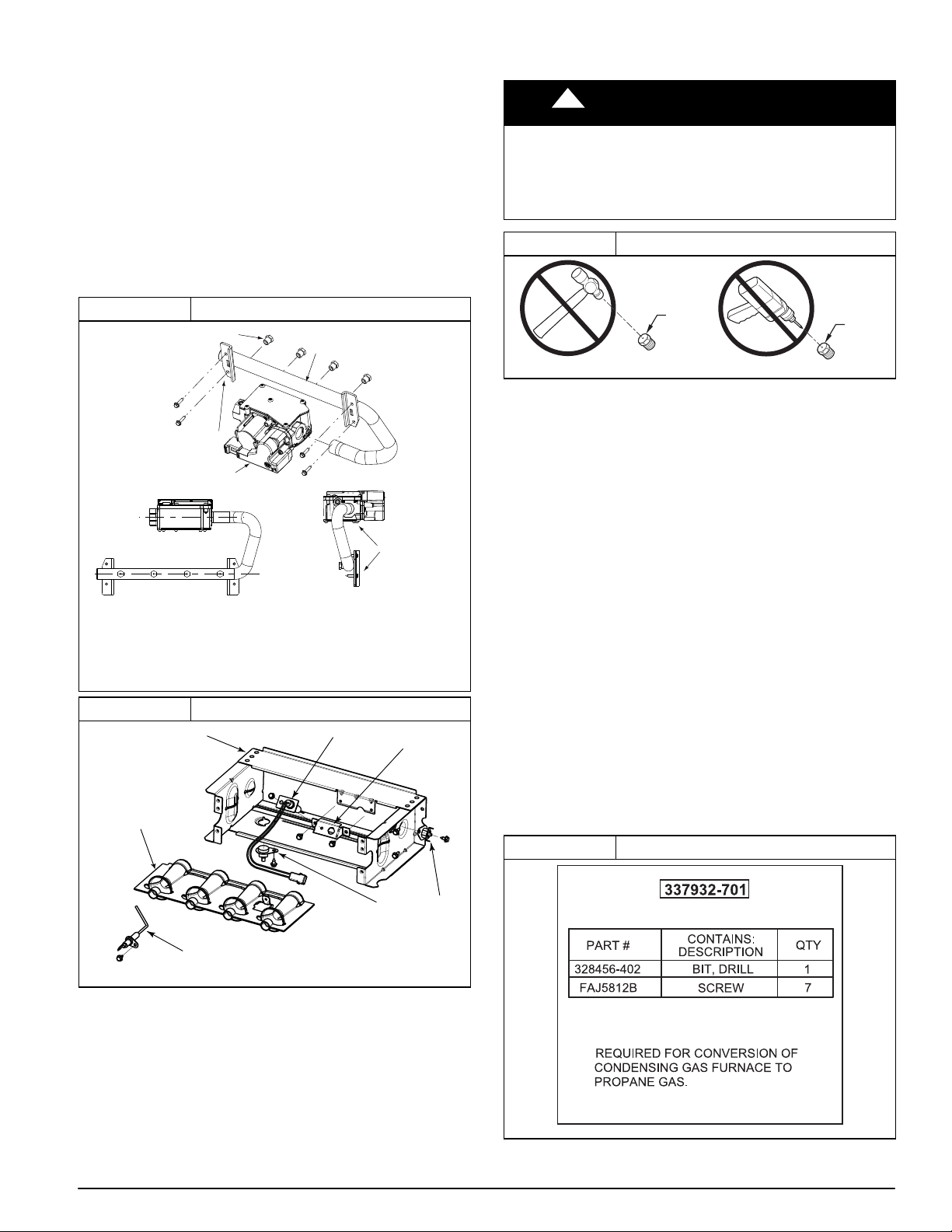

Figure 3 Burner Assembly

BURNER SUPT. ASSY

BURNER ASSY

IGNITER

BRACKET, IGNITER

A11486

ORIFICE SELECTION/DERATE

! CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

DO NOT re−drill burner orifices. Improper drilling may result

in burrs, out−of−round holes, etc. Obtain new orifices if orifice

size must be changed. (See Figure 4)

Figure 4 Burner Orifice

BURNER

ORIFICE

BURNER

ORIFICE

A96249

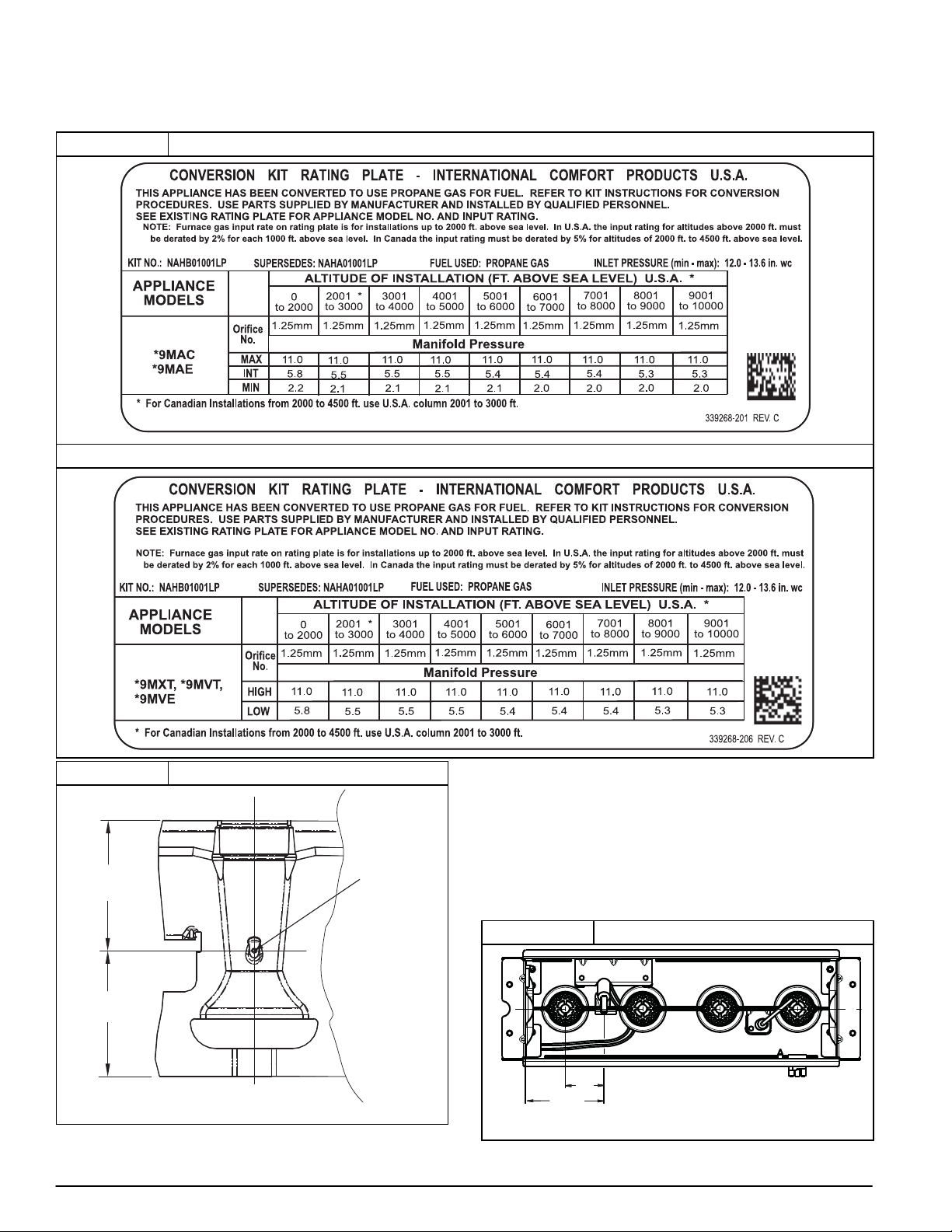

Refer to conversion kit rating plate 339268−201 or 339268−206

to determine main burner orifice size. (See Figure 6)

Furnace gas input rate on furnace rating plate is for installations

at altitudes up to 2000 ft.

In the U.S.A.; the input rating for altitudes above 2000 ft. must

be reduced by 2 percent for each 1000 ft. above sea level.

In Canada, the input rating must be derated by 5 percent for

altitudes of 2000 ft. to 4500 ft. above sea level.

The Conversion Kit Rating Plate accounts for high altitude

derate.

INSTALL ORIFICES

1. Install main burner orifices. Do not use Teflon tape.

Finger−tighten orifices at least one full turn to prevent

cross−threading, then tighten with wrench.

2. There are enough orifices in each kit for largest furnace.

Discard extra orifices.

NOTE: DO NOT reinstall the manifold at this time.

INSTALL MIXER SCREWS

NOTE: There are two sets of mixer screws. One set is for

Condensing gas furnaces, the other set is for Non-condensing

gas furnaces. Use only the parts in the bag marked

“REQUIRED FOR THE CONVERSION OF CONDENSING

GAS FURNACES TO PROPANE GAS”

See Figure 5 to verify you have the correct set of mixer screws.

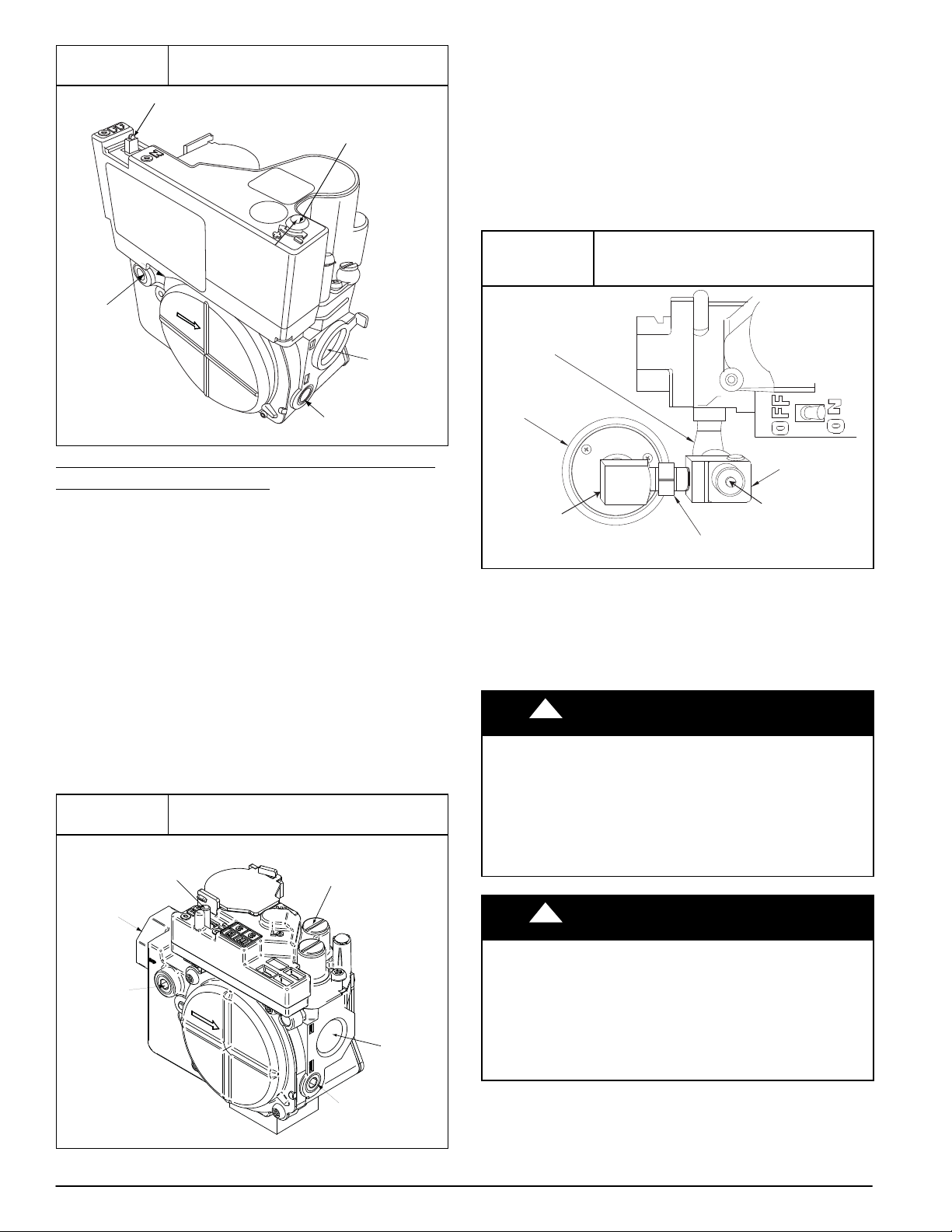

Figure 5

Gas Conversion Kit

FLAME ROLLOUT

SWITCH

FLAME SENSOR

(BELOW BURNER)

443 06 1522 00 3

Specifications subject to change without notice.

A11403

A11294

1. Locate the dimple on each burner venturi tube. If you

cannot locate the dimple, refer to Figure 7 for location of

the mixer screw.

2. Drill a 7/64−in. (2.8 mm) hole (supplied in kit) in each

dimple.

Figure 6

Conversion Kit Rating Plate − (F/G)9MAC & (F/G)9MAE

Conversion Kit Rating Plate − (F/G)9MVT, (F/G)9MVE & (F/G)9MXT

3. Install a mixer screw in each drilled hole drilling as

straight as possible. The screw head should be flush with

the top of the burner venturi.

Figure 7 Mixer Screw Location

REINSTALL BURNER ASSEMBLY

To reinstall burner assembly:

1. Attach flame sensor to burner assembly.

2. Insert one−piece burner in slot on sides of burner box

and slide burner back in place.

1.9”

(48.76 mm)

Drill out with

7/64” drill bit

3. Reattach HSI wires to HSI.

4. Verify igniter to burner alignment. See Figure 8 and

Figure 9.

Figure 8 Igniter Position − Back View

1.8”

(46.96 mm)

1-1/4-in.

(31.8)

2-1/2-in.

A11460

4 443 06 1522 00

Specifications subject to change without notice.

(64.4)

A11405

Figure 9 Igniter Position − Side View

2 − in.

(50 mm)

3/8 − in.

(9.6 mm)

3/16− in.

(4.6 mm)

(F/G)9MAC & (F/G)9MAE − Modulating

Gas Valve

Refer to Figure 10 and Figure 11.

Figure 10

Propane Jumper

3/32− in., +1/32 -3/64-in.

(2.5 mm

, +0.8 -1.5)

A12392

CONVERT GAS VALVES

! CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit damage.

The gas valve must be converted and pre−adjusted before

operating on propane gas. If not converted and pre−adjusted,

sooting and corrosion will occur leading to early heat

exchanger failure.

! WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Gas supply MUST be shut off before disconnecting electrical

power and proceeding with conversion.

! WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag. There may be more than one disconnect

switch. Lock out and tag switch with a suitable warning label.

Verify proper operation after servicing.

A11373

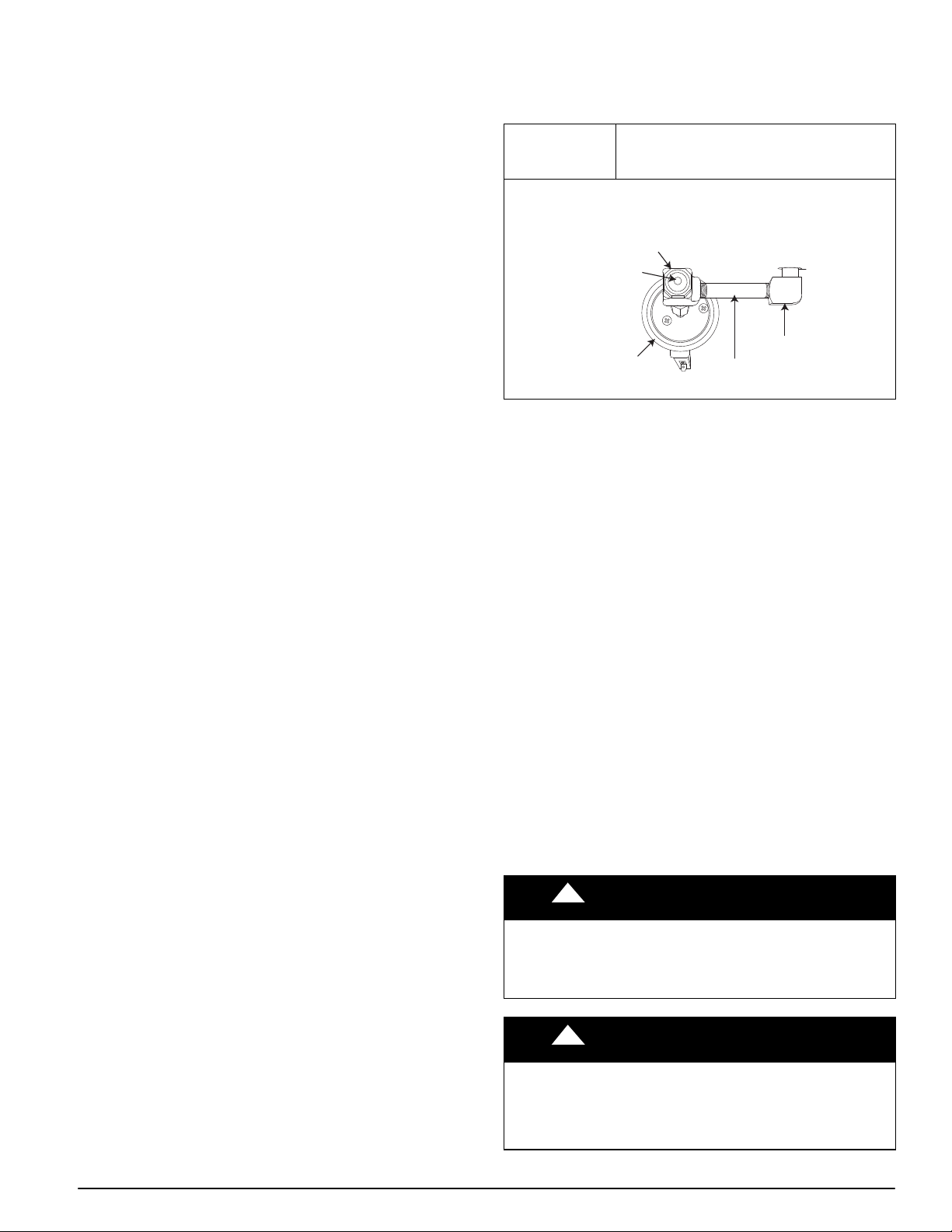

Figure 11 Installing Propane Jumper

A11375

NOTE: The Propane jumper for the modulating gas valve is

very small. Needle-nose pliers are required to insert the jumper

into the valve. If the jumper is not installed, the valve will not

operate properly on propane.

1. Locate the round “NAT GAS” sticker on the top of the

gas valve.

2. Peel the sticker off and discard.

3. Note the small square opening in the top of the gas

valve.

4. Note the two jumper pins inside the modulating gas

valve.

5. Remove the small black plastic propane jumper from the

envelope.

6. Use needle-nosed pliers to hold the jumper by the tab on

the end.

7. Insert the jumper on the pins inside the gas valve.

8. Cover the opening in the gas valve with the label marked

“LP GAS”

443 06 1522 00 5

Specifications subject to change without notice.

Figure 12

Inlet

Pressure Tap

(F/G)9MAC & (F/G)9MAE − Redundant

Automatic Control Valve (Modulating)

ON/OFF Switch

GAS FLOW

MODULATING

Turn screw 1 click per

second to adjust rate.

Clockwise to increase

rate, counter clockwise

to decrease rate.

Min/Max Heat Adust

(Under Cap)

INSTALL LOW GAS PRESSURE

SWITCH

NOTE: Install the Low Gas Pressure Switch before installing

the manifold on the burner assembly.

There are two ways to mount the Low Gas Pressure Switch.

All 14 3/16-in Casings or Vent Passes Between Inducer

Assembly and Burner Assembly

If the vent pipe passes between the inducer and burner

assembly, or the furnace is a 14 3/16-in. wide casing, install the

switch as follows (See Figure 14):

LGPS for 14−3/16 Casing or When Vent

Figure 14

Passes Between Inducer and Burner

Assembly

1/2” NPT Outlet

Manifold

Pressure Tap

A10496

(F/G)9MVT, (F/G)9MVE & (F/G)9MXT −

Two Stage Gas Valve

Refer to Figure 13.

1. Be sure gas and electrical supplies to furnace are off.

2. Remove caps that conceal adjustment screws for high

heat and low heat gas−valve regulators. (See

Figure 13)

3. Remove the high heat and low heat regulator adjustment

screws.

4. Remove the high heat and low heat regulator springs

(silver).

5. Install the high heat and low heat propane gas regulator

springs (white).

6. Install the high heat and low heat regulator adjustment

screws.

7. Turn high heat stage adjusting screw clockwise (in) 13.5

full turns. This will increase the manifold pressure closer

to the propane set point.

8. Turn low heat stage adjusting screw clockwise (in) 9.5

full turns. This will increase the manifold pressure closer

to the propane low heat set point.

9. Do not install regulator seal caps at this time.

Figure 13

1/2” NPT Inlet

(F/G)9MVT, (F/G)9MVE & (F/G)9MXT −

Two −Stage Gas Valve

TWO-STAGE

ON/OFF Switch

Regulator Seal Cap

Regulator Adjustment

Regulator Seal Cap under Cap

Black Iron Street 90 Pointing

Low Gas Pressure Switch

Brass Street Tee

Inlet Pressure Tap with

Brass Street 90

Brass Hex Nipple

A11367

1. Remove the 1/8-in. (3 mm) NPT pipe plug from the gas

valve inlet pressure tap.

NOTE: Use pipe dope approved for use with Propane Gas.

NOTE: Tighten all fittings and the Low Gas Pressure Switch

with a small wrench. Do not over-tighten, check for gas leaks

after gas supply has been turned on.

! WARNING

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in personal injury

and/or death.

NEVER test for gas leaks with an open flame. Use a

commercially available soap solution made specifically for

the detection of leaks to check all connections. A fire or

explosion may result causing property damage, personal

injury or loss of life.

!

AVERTISSEMENT

RISQUE D’EXPLOSION ET D’INCENDIE

Le fait de ne pas suivre cet avertissement pourrait entraîner

1/8” NPT Inlet

Pressure Tap

des dommages corporels et / ou la mort.

Ne jamais examiner pour les fuites de gaz avec une flamme

vive. Utilisez plutôt un savon fait specifiquement pour la

1/2” NPT Outlet

détection des fuites de gaz pour verifier tous les connections.

Un incendie ou une explosion peut entrainer des dommages

matériels, des blessures ou la mort.

1/8” NPT Manifold

Pressure Tap

A11152

6 443 06 1522 00

Specifications subject to change without notice.

2. Apply pipe dope sparingly to the male threads of the

1/8−in. (3 mm) Black iron street elbow. Install the street

elbow into the gas valve inlet pressure tap. Point the

open end of the street elbow toward you.

3. Apply pipe dope sparingly to the male threads of the

1/8−in. (3 mm) brass street tee. Install the male end of

the street tee as shown in Figure 14. One opening on

the street tee should face you. The other opening should

be parallel with the inlet of the gas valve.

4. Apply pipe dope sparingly to the male threads of the

1/8−in. (3 mm) brass hex nipple. Install the hex nipple

into the open end of the brass street tee. See Figure 14.

The hex nipple should be parallel with the boss on the

gas valve.

5. Install the open end of the brass street elbow on the end

of the hex nipple. Tighten the street elbow so the male

threads of the elbow point away from you.

6. Apply pipe dope sparingly to the male threads of the

1/8−in. brass street elbow. Install the Low Gas Pressure

Switch on the male threads of the 1/8−in. (3 mm) street

elbow. Tighten switch at hex fitting at base of switch. Do

not use switch body to tighten switch. Do not over-tighten

switch.

7. The remaining opening on the brass street tee is the new

gas valve inlet pressure tap. Install manometer fitting to

the open end of the brass street tee. Or if installation is to

be completed later, apply pipe dope to inlet pressure

plug from gas valve and install in open end of brass

street tee.

8. Check all fittings for leaks after gas supply has been

turned on.

Casings Wider Than 14 3/16-in./Vent Does Not Pass Between

Inducer and Burner Assembly

1. If the vent pipe does not pass between the inducer and

burner assembly, or the furnace is wider than a 14

3/16-in. wide casing, install the switch as follows (See

Figure 15):

2. Remove the 1/8-in. (3 mm) NPT pipe plug from the gas

valve inlet pressure tap.

NOTE: Use pipe dope approved for use with Propane Gas.

NOTE: Tighten all fittings and the Low Gas Pressure Switch

with a small wrench. Do not overtighten, check for gas leaks

after gas supply has been turned on.

3. Apply pipe dope sparingly to the male threads of the

1/8−in. (3 mm) brass street elbow. Install the street

elbow into the gas valve inlet pressure tap. One end of

the opening of the street elbow should be parallel with

the inlet boss on the gas valve.

4. Apply pipe dope sparingly to the male threads of the

1/8−in. (3 mm) x 2−in. (50.8 mm) brass nipple. Install the

brass nipple into the open end of the brass street elbow.

5. Install the open end of the brass street elbow on the end

of the brass nipple. Tighten the street elbow so the male

threads of the elbow point away from you.

6. Apply pipe dope sparingly to the male threads of the

1/8−in. brass street elbow. Install the Low Gas Pressure

Switch on the male threads of the 1/8−in. (3 mm) brass

street elbow finger tight. Tighten switch at hex fitting at

base of switch. Do not use switch body to tighten switch.

Do not overtighten switch.

7. The remaining opening on the brass street tee is the new

gas valve inlet pressure tap. Install manometer fitting to

the open end of the brass street tee. Or if installation is to

be completed later, apply pipe dope to inlet pressure

plug from gas valve and install in open end of brass

street tee.

8. Check all fittings for leaks after gas supply has been

turned on.

INSTALL LOW GAS PRESSURE

SWITCH WIRES

1. Locate the orange wire in the kit with an insulated

straight female spade terminal and an insulated straight

male terminal on the other end.

2. Connect the female terminal to a terminal on the Low

Gas Pressure Switch.

3. Locate the orange wire in kit with an insulated straight

female spade terminal and an insulated female flag

terminal on the other end.

4. Connect both straight female terminals of the orange

wires to the terminals on the Low Gas Pressure Switch.

LGPS for Casing Wider Than 14−3/16

Figure 15

For larger casing when Vent Pipe does not pass across casing. All Sizes

switch contacts must point toward the Cell Panel. Black Iron Street 90 can be

used at Valve Inlet instead of Brass Street 90.

Inlet Pressure Tap with Plug

Low Gas Pressure Switch

and Vent Does Not Pass Between

Inducer and Burner Assembly

Brass Street Tee

Brass Street

Brass Nipple

A11366

INSTALL MANIFOLD

1. Align the orifices in the manifold assembly with the

support rings on the end of the burner.

2. Insert the orifices in the support rings of the burners.

Manifold mounting tabs should fit flush against the burner

box

NOTE: If manifold does not fit flush against the burner box, the

burners are not fully seated forward. Remove the manifold and

check burner positioning in the burner box assembly.

3. Attach the green/yellow wire and ground terminal to one

of the manifold mounting screws.

4. Install the remaining manifold mounting screws.

5. Connect the wires to the flame sensor and hot surface

igniter.

6. Connect the connector harness to gas valve

NOTE: Use only propane−resistant pipe dope. Do not use

Teflon tape.

7. Insert the gas pipe through the grommet in the casing.

Apply a tin layer of pipe dope to the threads of the pipe

and thread the pipe into the gas valve.

NOTE: Use a back-up wrench on the gas valve to prevent the

valve from rotating on the manifold or damaging the mounting

to the burner box.

8. With a back-up wrench on the inlet boss of the gas valve,

finish tightening the gas pipe to the gas valve.

9. Turn gas on at electric switch on gas valve.

MODIFY PRESSURE SWITCH WIRING

! CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage or

improper operation.

Label all wires prior to disconnection when servicing controls.

! PRUDENCE

D’EQUIPEMENT D’OPERATION

Toute erreur de câblage peut être une source de danger et

de panne.

Lors des opérations d’entretien des commandes, étiqueter

tous les fils avant de les déconnecter.

443 06 1522 00 7

Specifications subject to change without notice.

Loading...

Loading...