INSTALLATION INSTRUCTIONS

CONCENTRIC VENT TERMINATION KITS

NAHA001CV and NAHA002CV

NOTE: These instructions cover the installation of the concentric

vent termination kits, NAHA001CV & NAHA002CV that are

approved for use on International Comfort Products, Category IV,

90% AFUE ratings and above gas furnaces.

Safety Considerations

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory−authorized kits or

accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in literature

and attached to the unit. Consult local building codes, the current

editions of the National Fuel Gas Code (NFCG) NFPA 54/ANSI

Z223.1, National Electrical Code (NEC) NFPA 70.

In Canada refer to the current editions of the National standards of

Canada CAN/CSA−B149.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety−alert symbol

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words; DANGER, WARNING, and CAUTION. These

words are used with the safety−alert symbol. DANGER identifies

the most serious hazards which will result in severe personal

injury or death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

Special Venting Requirements for Installations in Canada

Installation in Canada must conform to the requirements of CSA

B149 code. Vent systems must be composed of pipe, fittings,

cements, and primers listed to ULC S636. The special vent fittings

and accessory concentric vent termination kits and accessory

external drain trap have been certified to ULC S636 for use with

those Royal Pipe and IPEX PVC vent components which have been

certified to this standard. In Canada, the primer and cement must be

of the same manufacturer as the vent system – GVS-65 Primer

(Purple) for Royal Pipe or IPEX System 636, PVC/CPVC Primer,

Purple Violet for Flue Gas Venting and GVS-65 PVC Solvent Cement

for Royal Pipe or IPEX System 636

Venting, rated Class IIA, 65 deg C. must be used with this venting

system - do not mix primers and cements from one manufacturer with

a vent system from a different manufacturer. Follow the

manufacturer’s instructions in the use of primer and cement and

never use primer or cement beyond its expiration date.

The safe operation, as defined by ULC S636, of the vent system is

based on following these installation instructions, the vent system

manufacturer’s installation instructions, and proper use of primer

and cement. All fire stop and roof flashing used with this system must

be UL listed material. Acceptability under Canadian standard CSA

B149 is dependent upon full compliance with all installation

instructions. Under this standard, it is recommended that the vent

system be checked once a year by qualified service personnel.

t, PVC Cement for Flue Gas

(1)

The authority having jurisdiction (gas inspection authority, municipal

building department, fire department, etc) should be consulted

before installation to determine the need to obtain a permit.

(1) System 636 is a trademark of IPEX Inc.

Consignes spéciales pour l’installation de ventillation au

Canada

L’installation faite au Canada doit se conformer aux exigences du

code CSA B149. Ce systême de ventillation doit se composer de

tuyaux, raccords, ciments et apprêts conformes au ULC S636. La

tuyauterie de ventillation des gaz, ses accessoires, le terminal

concentrique mural ainsi que l’ensemble du drain de condensat

extérieur ont été certifiés ULCS 636 pour l’application des

composantes Royal Pipe, IPEX PVC qui sont certifiées à ce

standard. Au Canada, l’apprêt et le ciment doivent être du même

fabricant que le système d’évacuation. L’apprêt GVS-65 (Purple) et

le ciment-solvant GVS-65 doivent être utilisé avec les Royal Pipe.

Système IPEX 636, apprêt PVC/CPVC, Purple pour évacuation des

gaz de combustion et système IPEX 636(1)t, ciment PVC pour

évacuation des gaz de combustion, coté classe IIA, 65 deg C.

doivent être utilisés avec le système d’évacuation IPEX 636 – Ne pas

combiner l’apprêt et le ciment d’un manufacturier avec un système

d’évacuation d’un manufacturier différent.

Bien suivre les indications du manufacturier lors de l’utilisation de

.

l’apprêt et du ciment et ne pas utiliser ceux-ci si la date d’expiration

est atteinte.

L’opération sécuritaire, tel que définit par ULC S636, du système de

ventilation est basé sur les instructions d’installation suivantes, ainsi

que l’usage approprié de l’apprêt et ciment. Tout arrët feu et solin de

toit utilisés avec ce système doivent être des matériaux listés UL.

L’acceptation du standard Canadien CSA B419 est directement relié

à l’installation conforme aux instructions ci- haut mentionnées. Le

standard Canadien recommande l’inspection par un personel

qualifié et ce, une fois par année.

Les autoritées ayant juridiction (inspecteurs de gas, inspecteurs en

bâtiments, département des incendies, etc) devraient être

consultées avant l’installation afin de déterminer si un permis est

requis.

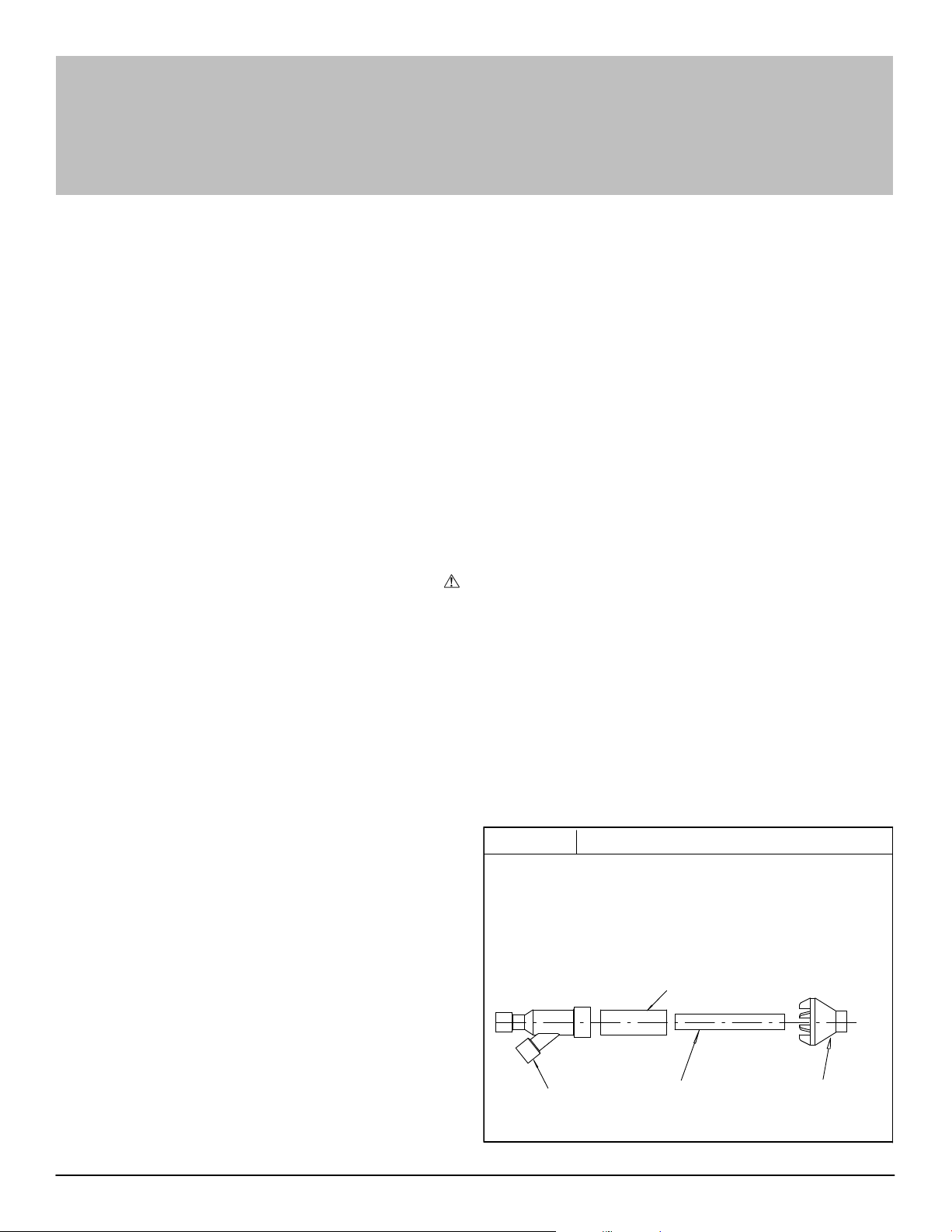

Figure 1

Kit Contents:

3″ (76.2mm) Rain Cap or 2″ (50.8mm) Rain Cap

3″ (76.2mm) Diameter SDR−26 Pipe, 19

4″ (101.6mm) Diameter SDR−26 Pipe, 24″ (609.6mm) Long,

2″ (50.8mm) Diameter SDR−26 Pipe, 31

1

2

/2″ (63.5mm) Diameter SDR−26 Pipe, 371/8″ (943mm) Long,

3″ (76.2mm) Y Concentric Fitting or 2″ (50.8mm) Y Concentric Fitting

2″ (50.8mm) or 3″

(76.2mm) Dia.

Y Concentric Fitting

Kit Components

3″ (76.2mm) or 4″ (101.6mm) Dia.

SDR−26 Pipe

2 (50.8mm) or

1

2

/2″ (63.5mm)

Dia. SDR−26 Pipe

1

/2″ (495.3mm) Long or

5

/8″ (803.3mm) Long or

2″ (50.8mm) or 3″

(76.2mm) Dia.

Rain Cap

25-22-03

Specifications subject to change without notice.

441 06 1018 03 Dec. 2010

CONCENTRIC VENT KIT

These kits are for vertical or horizontal termination of the combustion

air inlet and the exhaust vent pipes on Category IV gas−fired

condensing furnaces. The NAHA001CV kit can be used for 3″

(76.2mm) diameter pipe systems. The NAHA002CV kit can be used

for 2″ (50.8mm) diameter pipe system. Refer to Furnace Installation

Instructions for the correct pipe size for the furnace. Both the

combustion air inlet and the exhaust vent pipes must attach to the

termination kit. The termination kit must terminate outside the

structure and must be installed per the instructions outlined below for

vertical or horizontal termination. Vertical termination is preferred.

Field supplied pipe and fittings are required to complete the

installation.

!

ELECTRIC SHOCK HAZARD/FIRE AND/OR

EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, property damage and/or equipment

damage.

Turn OFF gas supply at manual gas valve before

turning OFF electric power supply and starting

installation.

Turn OFF electric power supply at disconnect switch

or service panel before starting installation. Tag and

lockout shutoff(s) with appropriate device warning labels. There may be more than one disconnect.

!

CARBON MONOXIDE POISONING, AND PROPERTY

DAMAGE HAZARD

Failure to follow this warning could result in

personal injury, death, property damage.

This kit is to be used for terminating condensing

Category IV vent furnaces. DO NOT use kit to

terminate Category I, II, or III vent furnaces.

!

ELECTRIC SHOCK HAZARD/FIRE AND/OR EXPLOSION HAZARD

Failure to carefully read and follow all instructions in

these instructions could result in personal injury,

death, property damage and/or furnace malfunction.

Installation or repairs made by unqualified persons

could result in hazards to you and others.

Installation MUST conform with local codes or, in the

absence of local codes, with codes of the country

having jurisdiction.

The information contained in these instructions is

intended for use by a qualified service technician

familiar with safety procedures and equipped with

the proper tools and test instruments.

Follow the furnace installation instructions for locating the furnace,

clearances, operation and safety procedures. Use these instructions

for installation of the concentric vent termination kit.

Read these instructions completely before attempting installation.

Field supplied pipe and fittings are required to complete installation.

NOTE: All pipe, fittings, solvent cement, primers and procedures

WARNING

MUST conform to American National Standards Institute (ANSI) and

American Society for Testing and Materials (ASTM) Standards:

Pipe and Fittings: − D1785, D2466, D2661, D2665, F−891,

F628, D2665, D2241

PVC Primer & Solvent Cement − D2564 & D2235

Procedure for Cement Joints − D2855

NOTE: In order to create a seal that allows future removal of pipe,

RTV sealant MUST be used on the inlet pipe where it joins to the

furnace. PVC, CPVC, ABS and Cellular Core pipe and cement may

be used on all other joints.

In Canada, refer to Special Venting Requirements for Installations in

Canada.

Vent Termination Clearances

1. The Province of Alberta requires a minimum unobstructed

distance of 4 ft. (1.2m) from the foundation to the property line of

the adjacent lot for vent termination of any appliance with an

input over 35,000 btuh. This means, if there is less than 4 ft.

(1.2m) of unobstructed distance to the property line of the

adjacent lot, no type of vent termination is permitted for

appliances with inputs greater than 35,000 btuh.

The Province of Alberta does not interpret any restrictions on

unobstructed distances greater than 8 ft. (2.4m). This means

that all single, two-pipe and concentric vents may be used,

providing all other Code and manufacturer’s requirements are

adhered to.

The requirement is to re-direct the flue gas plume when the

unobstructed distance from the foundation to the property line of

the adjacent lot is no less than 4 ft. (1.2m) and no greater than 8

ft. (2.4m).

In venting situations where the unobstructed distance from the

foundation to the property line of the adjacent lot is between 4 ft.

(1.2m) and 8 ft. (2.4m), the concentric vent kit cannot be used.

The concentric vent kit cannot be modified to attach a tee or

elbow to the vent portion of the rain cap. A tee or elbow attached

to the rain cap could potentially direct the flue gas plume toward

the intake air stream and contaminate the incoming combustion

air for the furnace.

In a venting situation where the unobstructed distance from the

foundation to the property line of the adjacent lot is between 4 ft.

(1.2m) and 8 ft. (2.4m), a 2-pipe termination (or single pipe when

permitted) must be used.

2. With the exception of The Province of Alberta, Canada,

determine termination locations based on clearances specified

in furnace installation instruction, and following steps as shown

in Figure 2, Figure 5 through Figure 8.

3. The vent termination must be located at least 12″ (304.8mm)

above ground or normally expected snow accumulation levels.

4. Do NOT terminate over public walkways. Avoid areas where

condensate may cause problems such as above planters,

patios, or adjacent to windows where steam may cause fogging.

5. The vent termination shall be located at least 3′ (.9m)

horizontally from any electric meter, gas meter, regulator, and

any relief equipment.

6. The vent termination is to be located at least 3′ (.9m) above any

forced air inlet located within 10′ (3m); and at least 10′ (3m) from

a combustion air intake of another appliance, except another

direct vent furnace intake.

7. In Canada, refer to Special Venting Requirements for

Installations in Canada and the Province of Alberta

requirements and the National Standards of Canada, Natural

Gas, Propane Installation Codes (NSCNGPIC).

2

Specifications subject to change without notice.

441 06 1018 03

CONCENTRIC VENT KIT

Vertical & Horizontal Termination

1. Determine the pipe diameters required for the installation from

Furnace Installation Instructions.

2. Determine the best location for the termination kit. See Figure 2

for vertical termination or Figure 5 for horizontal termination.

Roof termination is preferred since it is less susceptible to

damage, has reduced intake contaminants and less visible vent

vapor. For side wall termination, consideration should be given

to: 1) possible damage from the vapors to plants/shrubs, other

equipment and building materials, 2) possible damage to the

terminal from foreign objects, 3) wind effects that may cause

recirculation of flue products, debris or light snow and 4) visible

vent vapor.

3. Cut one 5″ (127mm) diameter hole through the structure for the

NAHA001CV Kit or one 4″ (101.6mm) diameter hole for the

NAHA002CV Kit .

4. Dimension D may be lengthened to 60″〈1524mm)max. or

shortened by cutting the pipes to 12″(304.8mm) min. Dimension

A will change according to D dimension. (See Figure 3)

Figure 2

Roof Boot/

Flashing

(Field Supplied)

Concentric Vent Roof Installation

Vent

Combustion

Air

Maintain 12″ (304.8mm)

min. clearance above

highest anticipated snow

level. Max. of 24″

(609.6mm) above roof.

Support

(Field Supplied)

Figure 3

1

/2″

1

(38.1mm)

Model A* B C D**

NAHA001CV 387/8(987.4) 3(76.2) 41/2(114.3) 211/8(536.6)

NAHA002CV 333/8(847.7) 2(50.8) 31/2(88.9) 165/8(422.3)

* = Dimension will change accordingly as dimension D is

lengthened or shortened.

** = Dimension D may be lengthened to 60″ (1524mm) may also be

shortened by cutting the pipes provided in the kit to 12″ (304.8mm)

minimum

Concentric Vent Dimensional

Drawing in(mm)

B PVC

Vent/Exhaust

C

B

PVC Intake/Combustion Air

D

A

25−22−03

5. Partially assemble the concentric vent termination kit. Clean and

cement the parts using the procedures for Joining Pipe and

Fittings section of the furnace installation manual. A) Cement

the Y Concentric fitting to the larger diameter kit pipe. (See

Figure 1) B) Cement the rain cap to the smaller diameter kit

part. (See Figure 1) NOTE: A field supplied stainless steel

screw may be used to secure the rain cap to the pipe instead of

cementing when field disassembly is desired for cleaning (See

Figure 4)

45° Elbow

(Field Supplied)

Vent

Combustion

Air

Note:

Support must be field installed to secure termination kit to structure.

25-22-02

!

UNIT OPERATION HAZARD

Failure to follow this caution may result in

intermittent unit operation.

Do not use field supplied couplings to extend the

pipes. Airflow restriction will occur and the furnace

pressure switch may cause intermittent operation.

If assembly needs to be extended to meet height or side wall

thickness requirement, the two pipes supplied in the kit may be

replaced by using the same diameter solid, single (no coupling

connections) field supplied SDR−26 PVC (ASTM D2241) pipes. Do

not extend dimension D more than 60″(1524mm). (See Figure 3)

Figure 4

25-22-02

!

Rain Cap to Vent Pipe Assembly

Drill clearance hole in rain

cap and pilot hole in vent pipe.

Stainless steel screw

(Field supplied)

WARNING

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property damage.

When using the alternate screw assembly method,

drill a clearance hole in the rain cap and a pilot hole

in the vent pipe for the screw size being used.

Failure to drill adequate holes may cause cracking

of the PVC components, allowing flue gases to be

recirculated.

441 06 1018 03

Specifications subject to change without notice.

3

CONCENTRIC VENT KIT

!

WARNING

CARBON MONOXIDE POISONING, FIRE AND

EXPLOSION HAZARD.

Failure to follow this warning could result in

personal injury, death, and/or property damage.

Do not operate the furnace with the rain cap

removed as recirculation of the flue gases may

occur. Water may also collect inside the larger

combustion air pipe and flow to the burner

enclosure.

6. Install the Y concentric fitting and the pipe assembly through the

structure’s hole. For vertical termination, install the parts

through the field supplied roof boot/flashing. NOTE: Do not

allow insulation or other materials to accumulate inside the pipe

assembly when installing through the structure’s hole.

7. Secure the assembly to the structure as shown in Figure 2 or

Figure 6 using field supplied metal strapping or equivalent

material.

NOTE: Ensure the termination height is above the roof surface

or anticipated snow level as shown in Figure 2 for vertical

termination. Ensure the termination location clearance

dimensions are as shown in Figure 5 and Figure 6 for

horizontal termination.

Figure 5

Concentric Vent and Combustion−

Air Side Termination

Roof Overhang

8. Install the rain cap and the small diameter pipe assembly in the Y

concentric fitting and the large pipe assembly. Ensure that the

small diameter pipe is bottomed out and securely cemented in

the Y concentric fitting.

9. Cement the furnace combustion air and vent pipes to the

concentric vent termination assembly. See Figure 2 or Figure 6

for proper pipe attachment.

10.Operate the furnace through one heat cycle to ensure

combustion air and vent pipes are properly connected to the

concentric termination connections.

Multi Vent Termination Clearances

When two (2) or more furnaces are vented near each other, each

furnace must be individually vented.

Two (2) vent terminations may be installed as shown in Figure 7 and

Figure 8, but the next vent termination or pair of vent terminations,

must be at least 36″ (914.4mm) away from first two (2) terminations.

It is important that vent terminations guidelines are followed to avoid

recirculation of flue gases.

Figure 7

12, Min.

(304.8mm)

Grade or

Snow Level

Combustion

Air

Concentric Vent and Combustion−

Air Roof Termination

2” max.

(50.8mm)

36” min.

(914.4mm)

Exhaust

OR

36” min.

(914.4mm)

12″ min.

1″ max.

(25.4mm)

25-22-02

Figure 6

Vent

Combustion

Air

Note:

Securing strap must be field installed to prevent movement of

termination kit in side wall.

Concentric Vent Sidewall Attachment

(304.8mm)

Combustion

Air

Vent

Maintain 12″ (304.8mm) clearance

above highest anticipated snow

level or grade whichever is greater.

Strap

(Field Supplied)

45° Elbow

(Field Supplied)

Combustion

Air

Flush to

1″ max.

(25.4mm)

Vent

25-22-02

Figure 8

Combustion Air

Dimension “A” is touching or 2″ (50.8) maximum separation.

Concentric Vent and Combustion−

Air Sidewall Termination

1, Maximum (TYP.)

(25.4mm)

Vent

“A”

Exhaust

Vent

25-22-02d

International Comfort Product, LLC S PO Box 128 S Lewisburg, TN 37091 USA

4

Specifications subject to change without notice.

441 06 1018 03

Loading...

Loading...