SERVICE MANUAL

R−410A Ductless Split System

Air Conditioner and Heat Pump

MODELS: DLC4(A/H)6−Outdoor, DLF4(A/H)6−Indoor

SIZES: 9K, 12K, 18K, and 24K

INTRODUCTION

This Service Manual provides the necessary information to

service, repair, and maintain the DLF4(A,H), DLC4(A/H)

TABLE OF CONTENTS PAGE

SAFETY CONSIDERATIONS 1........................

MODEL / SERIAL NUMBER NOMENCLATURE 2........

STANDARD FEATURES AND ACCESSORIES 3.........

PHYSICAL DATA 4−7.................................

AHRI CAPACITY RATINGS 8..........................

AIRTHROW DATA 8..................................

SOUND RATINGS 9..................................

DIMENSIONS − INDOOR 10...........................

DIMENSIONS − OUTDOOR 11........................

CLEARANCES 13....................................

SYSTEM OPERATING ENVELOPE 14.................

ELECTRICAL DATA 17...............................

CONNECTION DIAGRAMS 18.........................

WIRING DIAGRAMS 19...............................

REFRIGERATION SYSTEM DIAGRAM 23...............

SYSTEM EVACUATION AND CHARGING 25............

REMOTE CONTROL AND FUNCTIONS 26−27...........

FUNCTION AND CONTROLS 28−31....................

TROUBLESHOOTING 32−59..........................

APPENDIX TABLES 60−62...........................

UNIT REMOVAL PROCEDURES 63....................

Indoor 9k − 12k 115v 64.................................

Outdoor 9k − 12k 115v 75...............................

Indoor 12k − 18k 230v 79................................

Outdoor 12k 230v 85...................................

Outdoor 18k 230v 90...................................

Indoor 24k 230v 96.....................................

Outdoor 24k 230v 102..................................

service agency, or your distributor or branch for information

or assistance. The qualified installer or agency must use

factory−authorized kits or accessories when modifying this

product. Refer to the individual instructions packaged with

the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for brazing

operations. Have fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes and National Electrical Code (NEC) for

special requirements.

Recognize safety information. This is the safety−alert

!

!

symbol

instructions or manuals, be alert to the potential for personal

injury.

Understand these signal words: DANGER, WARNING, and

CAUTION. These words are used with the safety−alert

symbol. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or

death. CAUTION is used to identify unsafe practices which

may result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF

position. There may be more than 1 disconnect switch.

Lock out and tag switch with a suitable warning label.

When you see this symbol on the unit and in

!

WARNING

!

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal

injury, and/or property damage.

Never use air or gases containing

oxygen for leak testing or

operating refrigerant compressors.

Pressurized mixtures of air or

gases containing oxygen can lead

to an explosion.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, or other conditions which may cause death, personal

injury, or property damage. Consult a qualified installer,

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant

pipe in the ground. If any section of pipe is buried, there

must be a 6 in. (152 mm) vertical rise to the valve

connections on the outdoor units. If more than the

recommended length is buried, refrigerant may migrate

to the cooler buried section during extended periods of

system shutdown. This causes refrigerant slugging and

could possibly damage the compressor at start−up.

CAUTION

421 08 9205 00 2/21/14

MODEL NOMENCLATURE

MODEL SERIES

Position Number 1 2 3 4 5 6 7 8 9 10 11

DLC = Outdoor

DLF = Indoor Outdoor/Indoor

4A6 = AC

4H6 = HP

09 = 9k BTU

12 = 12k BTU

18 = 18k BTU

24 = 24k BTU

J = 115−1−60

K = 208/230−1−60

1A Factory Designation

D L C 4 A 6 0 9 J 1 A

Type

Size

Voltage

2 421 01 9204 01

STANDARD FEATURES AND ACCESSORIES

Ease Of Installation

Mounting Brackets S

Low Voltage Controls S

Comfort Features

Microprocessor Controls S

Wireless Remote Control S

Rapid Cooling/Heating S

Automatic Air Sweep S

Cold Blow Prevention S

Continuous Fan * S

Auto Restart Feature S

Memory Function S

Auto Changeover on Heat Pumps S

Dry Function S

Energy Saving Features

Inverter Driven Compressor S

Sleep Mode S

24 Hour Stop/Start Timer S

Safety And Reliability

Indoor Unit Freeze Protection S

3 Minute Compressor Time Delay S

High Compressor Discharge Temperature S

Low Voltage Protection S

Compressor Overload Protection S

Compressor Over current Protection S

IPM Module Protection S

Ease Of Service And Maintenance

Cleanable Filters S

Diagnostic LED’s On Outdoor Board S

Error Messages Displayed Front Panel S

Application Flexibility

Condensate Pump A

Standard Warranty

7 Year Compressor Limited Warranty** S

5 Year Parts Limited Warranty** S

Legend

S Standard

A Accessory

O Optional

F Field Fabricated

* Cooling Only

** For owner occupied residential applications.

For Commercial applications, warranty is 1 year parts and 5 years

compressor.

INDOOR UNITS

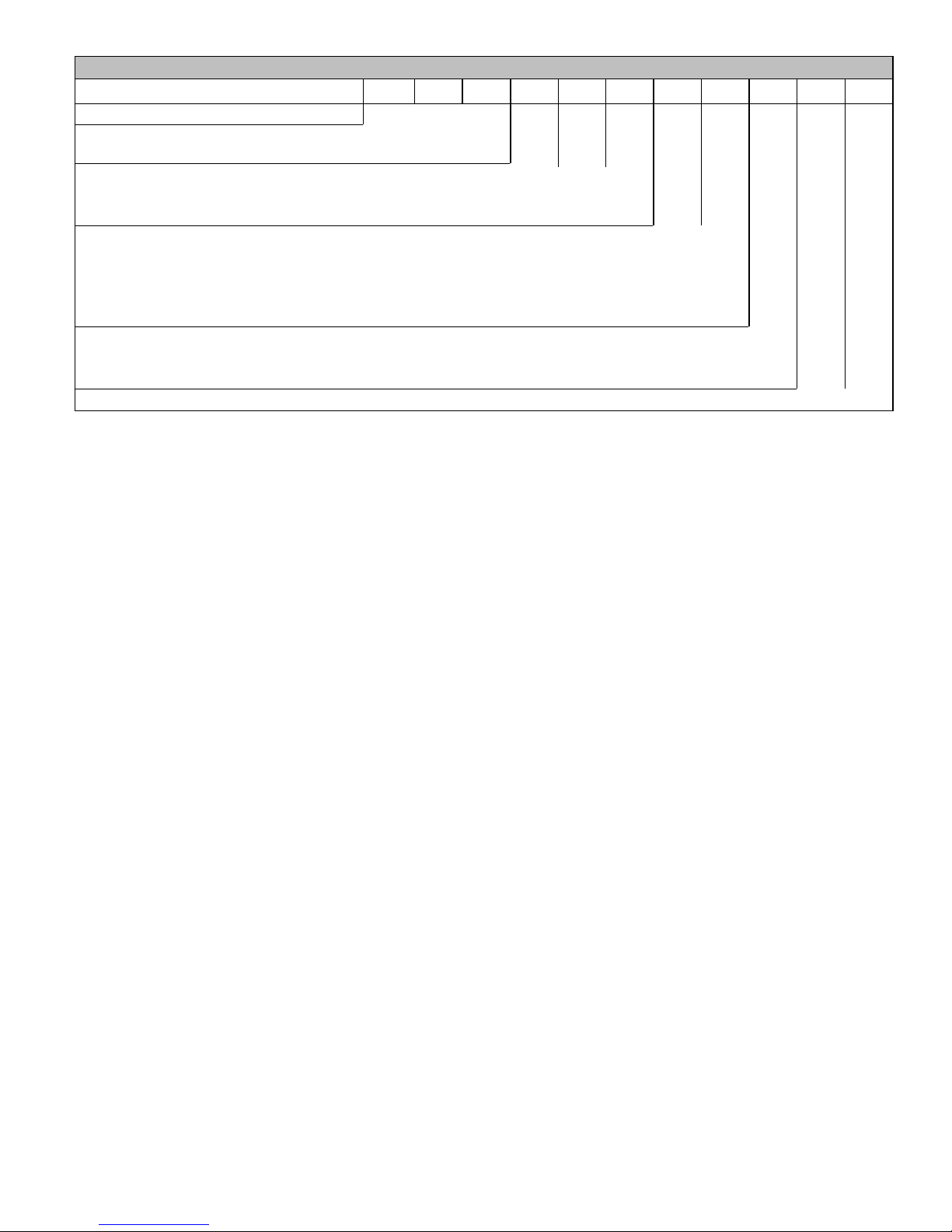

On high wall fan coils, the condensate pump accessory is

recommended when adequate drain line pitch cannot be

provided, or when the condensate must move up to exit.

The pump has a lift capability of 12 ft (3.6 m) on the discharge

side if the pump is mounted in the fan coil or 6 ft (1.8 m) on the

suction side if the pump is remote mounted.

16 ft Transparent Suction/Discharge Tubing 1

Condensate Pump Assembly 1

Low voltage Power Cord 1

Transparent Detection Unit Vent Tubing 1

Power Cable 1

Wire Ties 6

Wall Mount Bracket 1

Adhesive 1

Detection Unit Mounting Bracket 1

⅝-in Rubber Elbow 1

Detection Unit 1

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than one disconnect switch. Lock out

and tag switch with a suitable warning label.

Figure 1 - Condensate Pump Accessory

Table 1—Accessory Condensate Pump Kit Contents

Item Qty.

!

WARNING

A07892

3 421 08 9205 00

PHYSICAL DATA − DLC4A6

Outdoor Unit DLC4A6 09 12 12 18 24

System Voltage 115-1-60 208/230-1-60

Control Voltage Low Voltage Pulse DC

Rated Cooling Capacity (Btuh) 9,000 11,800 12,000 18,000 22,000

Cooling. Capacity Range

Min - Max (Btuh)

Operating Weight lb. (kg) 75 (34) 63.8 (30) 112.2 (51)

Refrigerant Type R-410A

Metering Device @ Outdoor Unit Cap. Tube EXV

Charge lb. (kg) 2.3 (1.05) 2.8 (1.27) 2.2 (1.0) 2.8 (1.27) 3.4 (1.55)

Compressor

Type Twin Rotary Inverter Driven

Model KNB092FHBMC QXA-B096ZC190 SNB130FGYMC C-6RZ146H1A

Outdoor Fan

CFM 1060 942 1880 1880

RPM 850 880 690 690

Diameter (in) 15.7 14.6 20.5 20.5

Watts 30 21 60

Outdoor Coil

Face Area (sq.) 4.4 3.7 5.9 6.1

No. Rows 2

Fins per inch 16 18

Refrigerant Lines

Connection Type Flare

Liquid (Mix Phase) in OD 1/4"

Vapor Line in OD 3/8" 1/2"

Maximum Length ft. 50 65 50 82

Max Lift (Fan Coil Above) ft. 33

Max Drop (Fan Coil Below) ft. 33

External Finish White

3,500-11,000 3,300-12,500 3,300-12,500 4,500-21,000 6,400-24,000

421 08 9205 00 4

PHYSICAL DATA CONTINUED − DLF4A6

Indoor Unit DLF4A6 09 12 12 18 24

System Voltage 115 V 208/230-1-60

Control Voltage Low Voltage Pulse DC

Electrical Connections Indoor Unit Powered From Outdoor Unit

Rated Cooling Capacity (Btuh) 9,000 11,800 12,000 18,000 22,000

Operating Weight lb. (kg) 18.7 (8.5) 19.8 (9.0) 26.5 (12.0) 33.1 (15.0)

Refrigerant Type R-410A

Metering Device @ Outdoor Unit Cap. Tube EXV

Moisture Removal Rate (pints/hr.) 1.7 2.9 2.9 3.8 4.5

Indoor Fan

RPM/CFM (Turbo) - Cooling 1300/330 1350/341 1350/341 1400/471 1350/588

RPM/CFM (High) - Cooling 1100/277 1150/288 1150/288 1150/400 1150/471

RPM/CFM (Medium) - Cooling 900/224 950/235 950/235 1000/330 1000/412

RPM/CFM (Low) - Cooling 700/188 750/200 750/200 850/271 850/353

Motor Watts 15 20 35

Blower Quantity … Size (DxL) in 1 … 3.62 x 23.4 1 … 3.9 x 25.6 1 … 3.9 x 30.1

Indoor Coil

Face Area (sq.) 1.93 2.2 2.8

No. Of Rows 2

Fins Per Inch 18 17

Filters

Quantity 2 2 2 2

Controls Integrated Microprocessor

Wireless Remote Standard

Modes Cool/Heat/Dry/Auto

Fan Mode High/Medium/Low/Auto

Emergency Mode Yes

Defrost Method Demand Defrost

Diagnostics Yes

Air Sweep Yes

Soft Start Yes

Rapid Cooling/Heating Ye s

Cold Blow Prevention Yes

Sleep Mode Yes

24 Hour Timer Yes

Auto Restart Yes

Freeze Protection On Indoor Unit Yes

Refrigerant Lines

Connection Type Flare

Liquid (Mix Phase) in OD 1/4"

Vapor Line in OD 3/8" 1/2"

Maximum Length ft. 50 65 50 82

Max Lift (Fan Coil Above) ft. 33

Max Drop (Fan Coil Below) ft. 33

Condensate Drain

Size in ID = 1/2" OD = 5/8"

External Finish White

5 421 08 9205 00

PHYSICAL DATA CONTINUED − DLC4H6

Outdoor Unit DLC4H6 09 12 12 18 24

System Voltage 115-1-60 208/230-1-60

Control Voltage Low Voltage Pulse DC

Rated Cooling Capacity (Btuh) 9,000 11,800 12,000 18,000 22,000

Cooling. Capacity Range

Min - Max (Btuh)

Rated Heating Capacity (Btuh) 9,800 13,000 12,000 19,200 24,200

Heating. Capacity Range

Min - Max (Btuh)

Operating Weight lb (kg) 75 (34) 63.8 (30) 112.2 (51)

Refrigerant Type R-410A

Metering Device @ OD Unit Cap. Tube EXV

Charge lb (kg) 2.2 (1.0) 2.9 (1.3) 3.4 (1.55)

Compressor

Type Twin Rotary Inverter Driven

Model KNB092FHBMC QXA-B096ZC190 SNB130FGYMC C-6RZ146H1A

Outdoor Fan

CFM 1060 942 1880 1880

RPM 850 880 690 690

Diameter (in) 15.7 14.6 20.5 20.5

Watts watts 30 21 60

Outdoor Coil

Face Area (sq. ft) 4.4 3.7 5.9 6.1

No. Rows 2

Fins per inch 16 18

Refrigerant Lines

Connection Type Flare

Liquid (Mix Phase) in OD 1/4"

Vapor Line in OD 3/8" 1/2"

Maximum Length ft 65 50 82

Max Lift (Fan Coil Above) ft 33

Max Drop (Fan Coil Below) ft 33

External Finish White

3,500 - 11,000 3,300 - 12,500 3,300 - 12,500 4,500 - 21,000 6,400 - 24,000

2,500 - 11,000 3,400 - 13,500 3,400 - 13,500 4,000 - 23,000 4,100 - 24,200

421 08 9205 00 6

PHYSICAL DATA CONTINUED − DLF4H6

Indoor Unit DLF4H6 09 12 12 18 24

System Voltage 115 V 208/230-1-60

Control Voltage Low Voltage Pulse DC

Electrical Connections Indoor Unit Powered From Outdoor Unit

Rated Cooling Capacity (Btuh) 9,000 11,800 12,000 18,000 22,000

Rated Heating Capacity (Btuh) 9,800 13,000 12,000 19,200 24,200

Operating Weight lb (kg) 18.7 (8.5) 19.8 (9.0) 26.5 (12.0) 33.1 (15.0)

Refrigerant Type R-410A

Metering Device @ Outdoor Unit Cap. Tube EXV @ Outdoor Unit

Moisture Removal Rate(pints/hr) 1.7 2.9 3.8 4.2

Indoor Fan

RPM/CFM (Turbo) - Cooling 1300/330 1350/341 1350/341 1400/471 1350/588

RPM/CFM (High) - Cooling 1100/277 1150/288 1150/288 1150/400 1150/471

RPM/CFM (Medium) - Cooling 900/224 950/235 950/235 1000/330 1000/412

RPM/CFM (Low) - Cooling 700/188 750/200 750/200 850/271 850/353

RPM/CFM (Turbo) - Heating 1300/330 1350/341 1350/341 1450/471 1350/588

RPM/CFM (High) - Heating 1150/277 1200/288 1200/288 1250/400 1150/471

RPM/CFM (Medium) - Heating 980/224 1000/235 1000/235 1100/330 1000/412

RPM/CFM (Low) - Heating 820/188 850/200 850/200 950/271 900/353

Motor Watts 15 20 35

Blower Quantity … Size (DxL) in 1 … 3.62 x 23.4 1 … 3.9 x 25.6 1 … 3.9 x 30.1

Indoor Coil

Face Area (sq.ft) 1.93 2.2 4.2

No. Of Rows 2

Fins Per Inch 18 17

Filters

Quantity 2 2 2 2

Controls Integrated Microprocessor

Wireless Remote Standard

Modes Cool/Heat/Dry/Auto

Fan Mode High/Medium/Low/Auto

Emergency Mode Yes

Defrost Method Demand Defrost

Diagnostics Yes

Air Sweep Yes

Soft Start Yes

Rapid Cooling/Heating Yes

Cold Blow Prevention Yes

Sleep Mode Yes

24 Hour Timer Yes

Auto Restart Yes

Freeze Protection On Indoor Unit Yes

Refrigerant Lines

Connection Type Flare

Liquid (Mix Phase) in OD 1/4"

Vapor Line in OD 3/8" 1/2"

Maximum Length ft 65 50 82

Max Lift (Fan Coil Above) ft 33

Max Drop (Fan Coil Below) ft 33

Condensate Drain

Size in ID = 1/2" OD = 5/8"

External Finish White

7 421 08 9205 00

AHRI* CAPACITY RATINGS

Model Numbers Cooling High Heating 47°F Low Heating 17°F

Outdoor Unit Indoor Unit

Capacity

(Btuh)

EER SEER

Capacity

(Btuh)

HSPF Capacity (Btuh)

DLC4A609J1A DLF4A609J1A 9,000 12.0 16.0 - - DLC4A612J1A DLF4A612J1A 11,800 9.4 16.0 - - DLC4A612K1A DLF4A612K1A 12,000 9.8 16.0 - - DLC4A618K1A DLF4A618K1A 18,000 11.1 16.0 - - DLC4A624K1A DLF4A624K1A 22,000 10.0 16.0 - - DLC4H609J1A DLF4H609J1A 9,000 12.0 16.0 9,800 8.6 5,400

DLC4H612J1A DLF4H612J1A 11,800 9.4 16.0 13,000 8.6 8,500

DLC4H612K1A DLF4H612K1A 12,000 9.8 16.0 12,000 8.5 6,800

DLC4H618K1A DLF4H618K1A 18,000 11.1 16.0 19,200 8.0 12,000

DLC4H624K1A DLF4H624K1A 22,000 10.0 16.0 24,200 8.5 18,600

*Air Conditioning, Heating & Refrigeration Institute

- = N/A

Legend

HSPF - Heating Seasonal Performance Factor

SEER - Seasonal Energy Efficiency Ratio

NOTES:

1. Ratings are net values reflecting the effects of circulating fan heat. Ratings are based on: Cooling Standard: 80F (26.67C) db, 67F (19.44C) wb air entering indoor

unit and 95F (35C) db air entering outdoor unit. High Temperature Heating Standard: 70F (21.11C) db air entering indoor unit and 47F (8.33C) db, 43F (6.11C)

wb air entering outdoor unit.

2. Ratings are based on 25 ft. (7.62 m) of interconnecting refrigerant lines.

3. All system ratings are based on fan coil units operating at high fan speed. Consult Physical Data tables for air flows at all available fan speeds.

AIR THROW DATA

Approximate Air Throw ft. (m)

Unit Size

9 K 18 (5.5) 21 (6.4) 23 (7.0) 28 (8.5)

12 K 20 (6.1) 23 (7.0) 25 (7.6) 30 (9.1)

18 K 22 (6.7) 27 (8.2) 33 (10.1) 39 (11.9)

24 K 25 (7.6) 29 (8.8) 34 (10.4) 42 (12.8)

Low Medium High Turbo

421 08 9205 00 8

SOUND RATINGS

Outdoor Units

Model Number Sound Power dBA Sound Pressure dBA

DLC4A609J1A 63 53

DLC4A612J1A 65 55

DLC4A612K1A 62 52

DLC4A618K1A 66 56

DLC4A624K1A 63 53

DLC4H609J1A 63 53

DLC4H612J1A 65 55

DLC4H612K1A 62 52

DLC4H618K1A 66 56

DLC4H624K1A 66 56

Indoor Units

Low Medium High Turbo

Model Number

DLF4A609J1A 42 32 45 35 47 37 50 40

DLF4A612J1A 42 32 45 35 47 37 50 40

DLF4A612K1A 38 28 43 33 49 39 54 44

DLF4A618K1A 44 34 48 38 53 43 58 48

DLF4A624K1A 44 34 49 39 53 43 59 49

DLF4H609J1A (cool/heat) 42/42 32/32 45/45 35/35 47/47 37/37 50/50 40/40

DLF4H612J1A (cool/heat) 42/42 32/32 45/45 35/35 47/47 37/37 50/50 40/40

DLF4H612K1A (cool/heat) 38/38 28/28 43/43 33/33 49/49 39/39 54/54 44/44

DLF4H618K1A (cool/heat) 44/44 34/34 48/48 38/38 53/53 43/43 58/58 48/48

DLF4H624K1A (cool/heat) 44/44 34/34 49/49 39/39 53/53 43/43 59/59 49/49

NOTES:

1. Sound power ratings are per AHRI 270 and AHRI 350

2. Sound pressure ratings are estimated sound pressure, 3 feet (.91 m) from the unit, based on sound power data.

Sound

Power

dBA

Sound

Pressure

dBA

Sound

Power

dBA

Sound

Pressure

dBA

Sound

Power

dBA

Sound

Pressure

dBA

Sound

Power

dBA

Sound

Pressure

dBA

9 421 08 9205 00

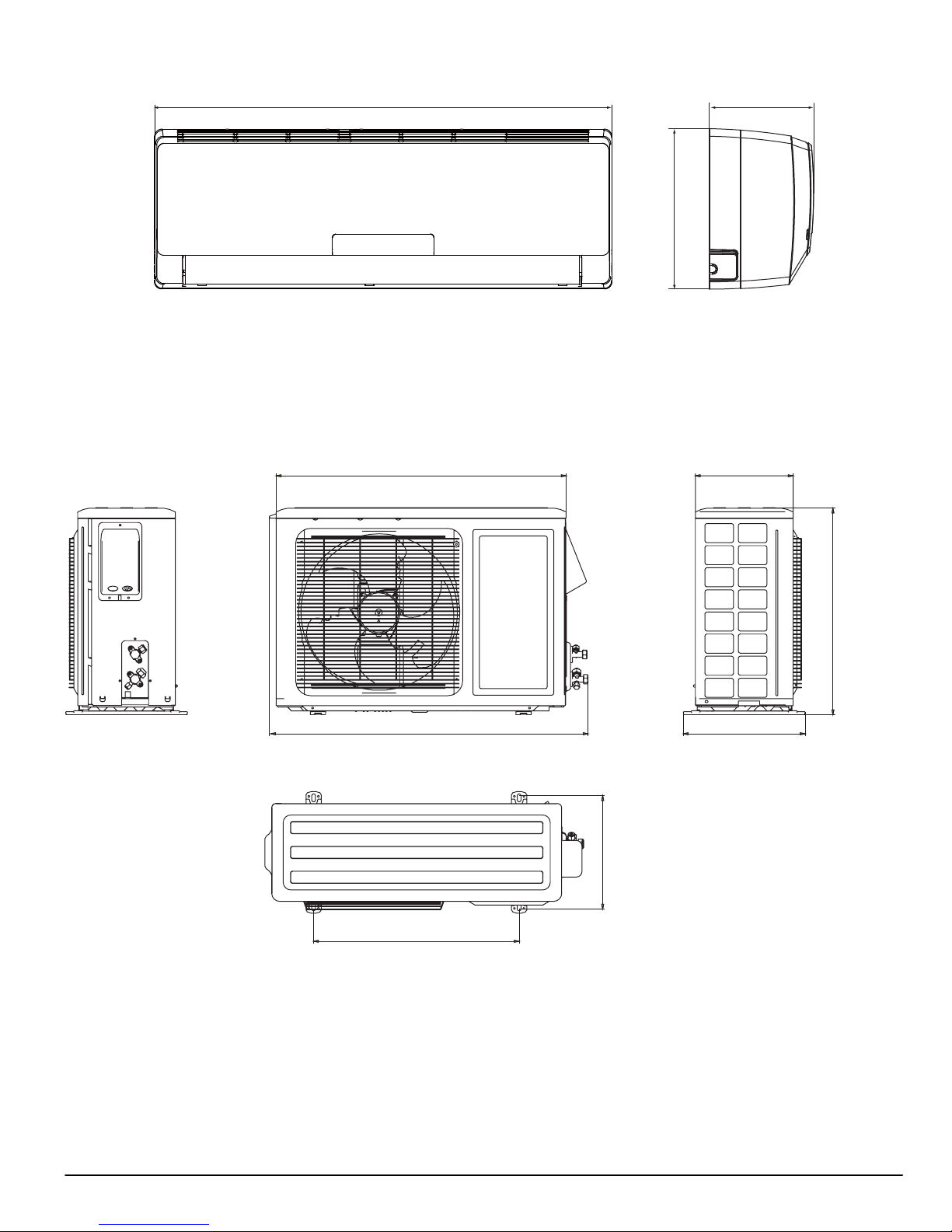

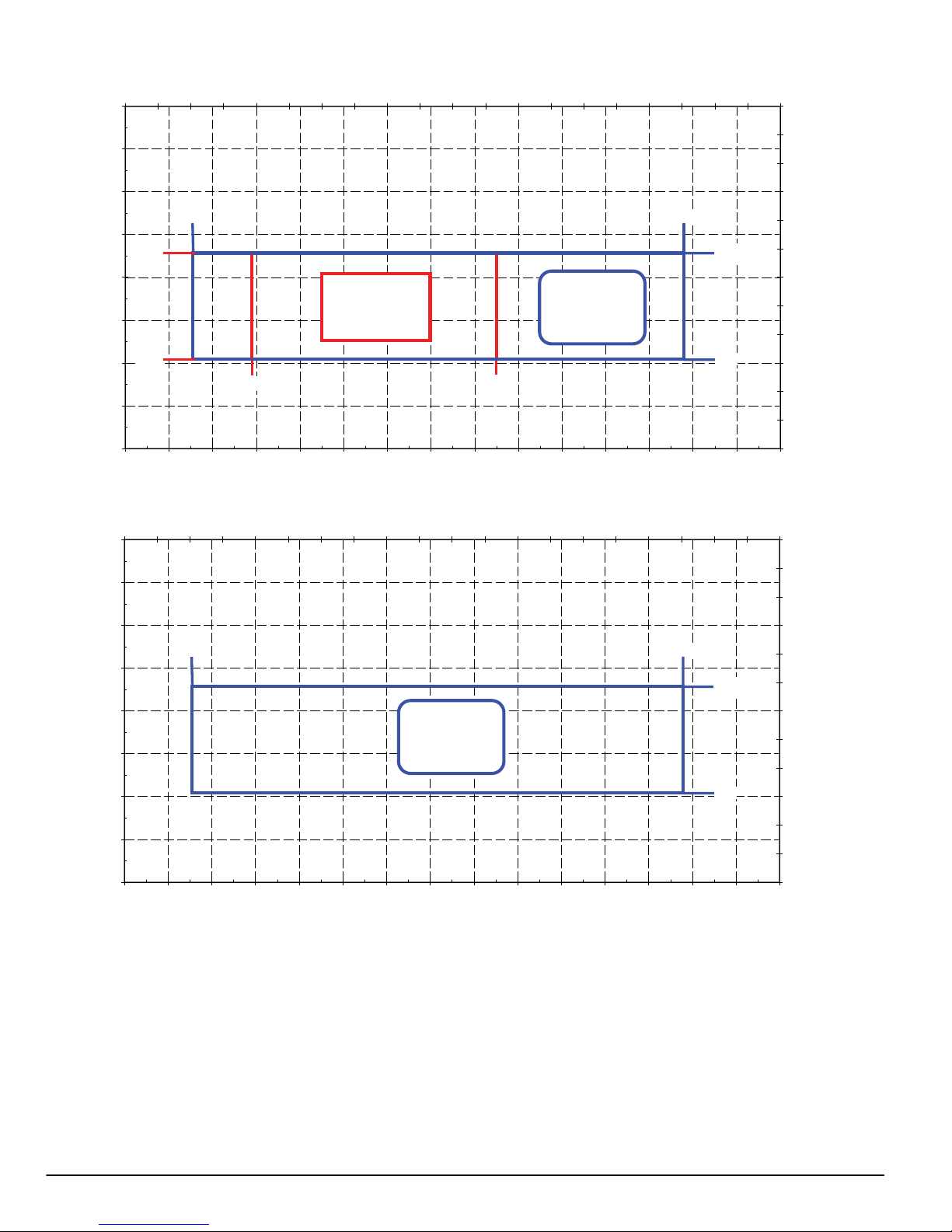

DIMENSIONS − INDOOR

Unit Size

9 K 30.3 (770) 11.1 (283) 7.9 (201) 18.7 (8.5)

12 K 30.3 (770) 11.1 (283) 7.9 (201) 19.8 (9.0)

18 K 34.0 (865) 12.0 (305) 8.5 (215) 26.4 (12)

24 K 39.7 (1008) 12.6 (319) 8.7 (221) 33.1 (15.0)

DIMENSIONS − OUTDOOR

W

In. (mm)

WD

H

A12377

H

In. (mm)

D

In. (mm)

Net Operating Weight

Lbs. (Kg)

Figure 2 - Indoor Unit Dimensions

30.0 (762)

10.1 (257)

Unit: IN. (mm)

33.4 (848)

11.7 (267)

21.3 (540)

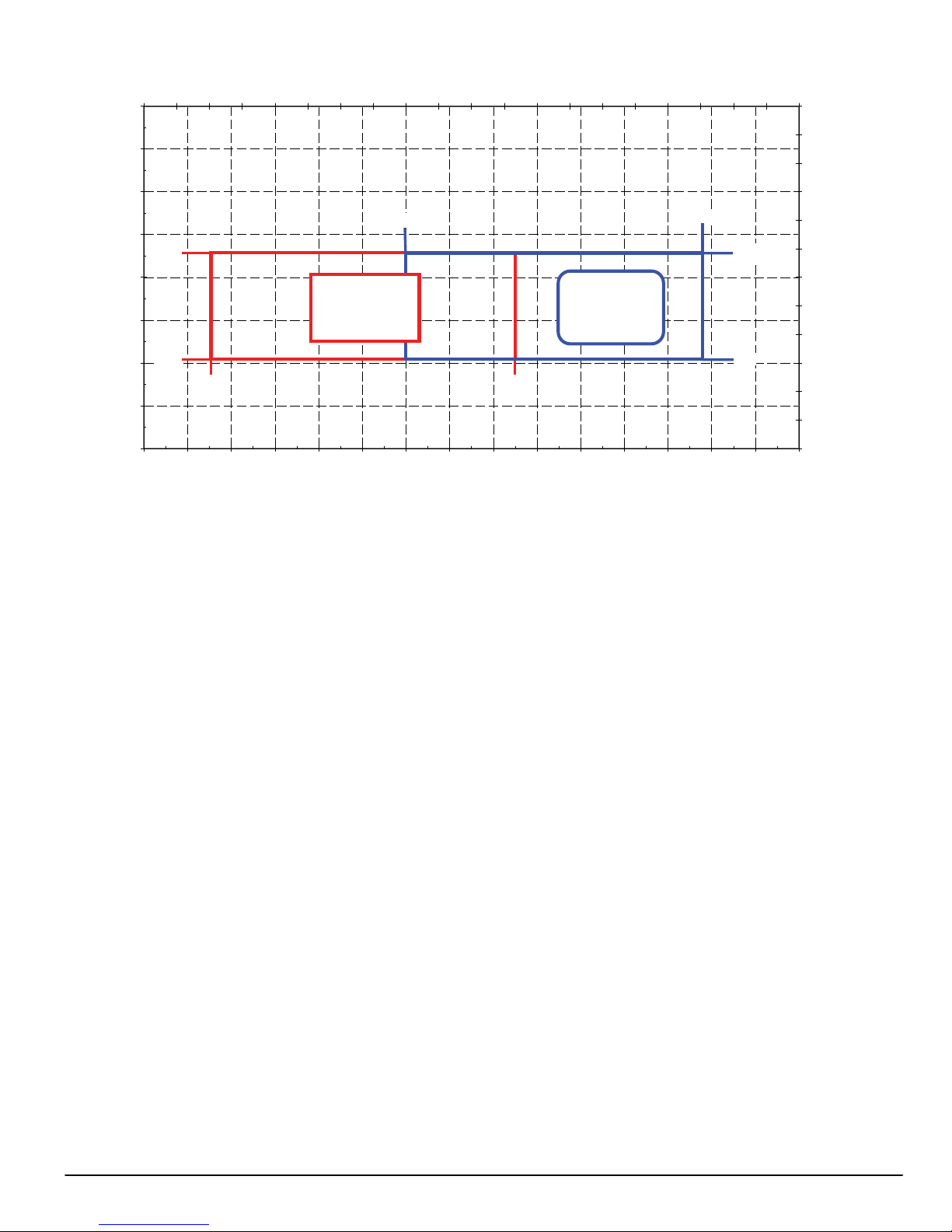

Figure 3 - 9K and 12K 115V (Net Operating Weight: 75 lbs. / 34 kg)

21.3 (540)

12.6 (320)

A12531

421 08 9205 00 10

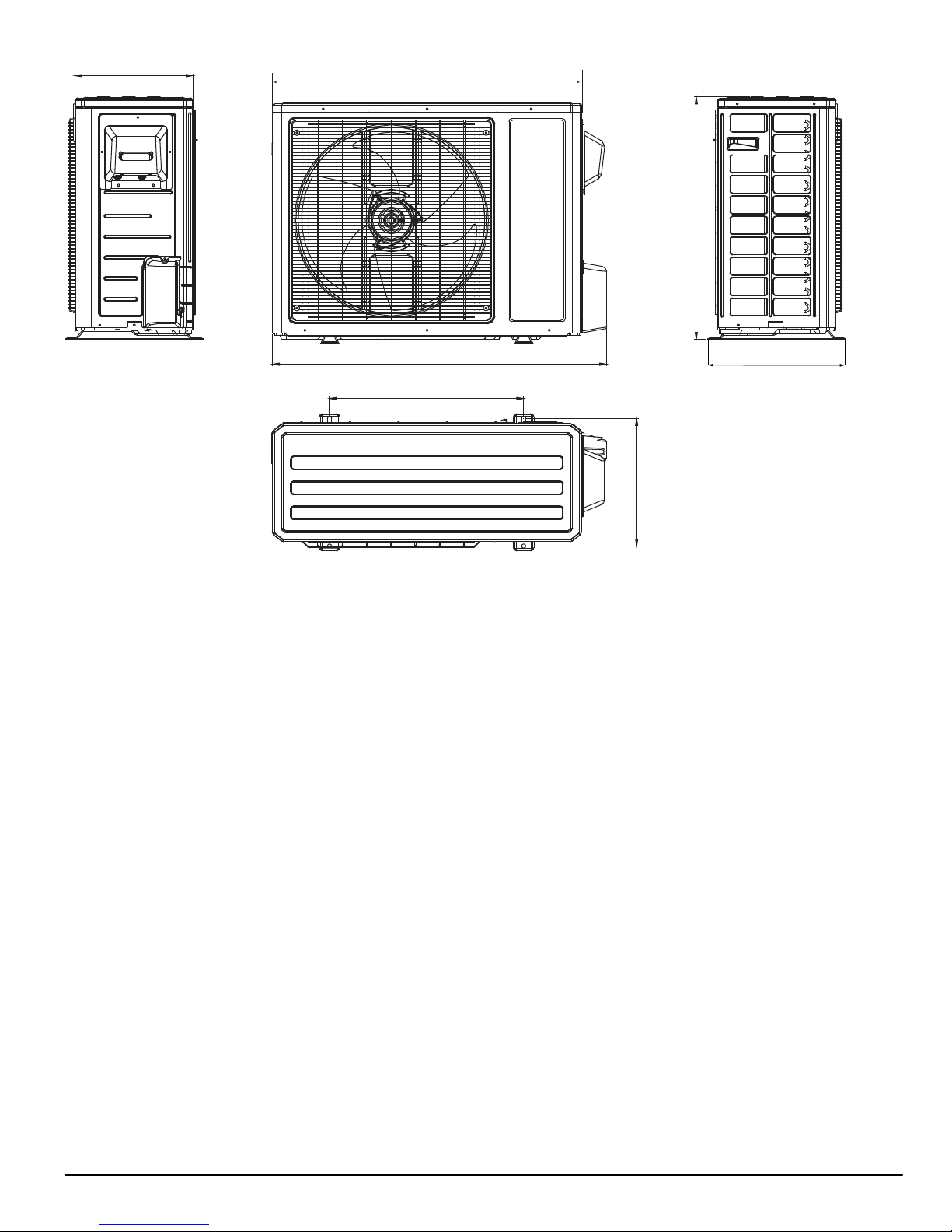

DIMENSIONS − OUTDOOR

10.8 (274)

25.9 (658)

21.7 (551)

Unit: IN. (mm)

28.0 (711)

18.5 (470)

11.8 (300)

Figure 4 - 12K 230V (Net Operating Weight: 63.8 lbs. / 30 kg)

12.5 (318)

Unit: IN. (mm)

A12532

11 421 08 9205 00

13.4 (340)

35.0 (890)

27.6 (700)

Unit: IN. (mm)

37.9 (963)

22.0 (560)

14.3 (364)

Figure 5 - 18K and 24K (Net Operating Weight: 112.2 lbs. / 51 kg)

15.6 (396)

A12533

421 08 9205 00 12

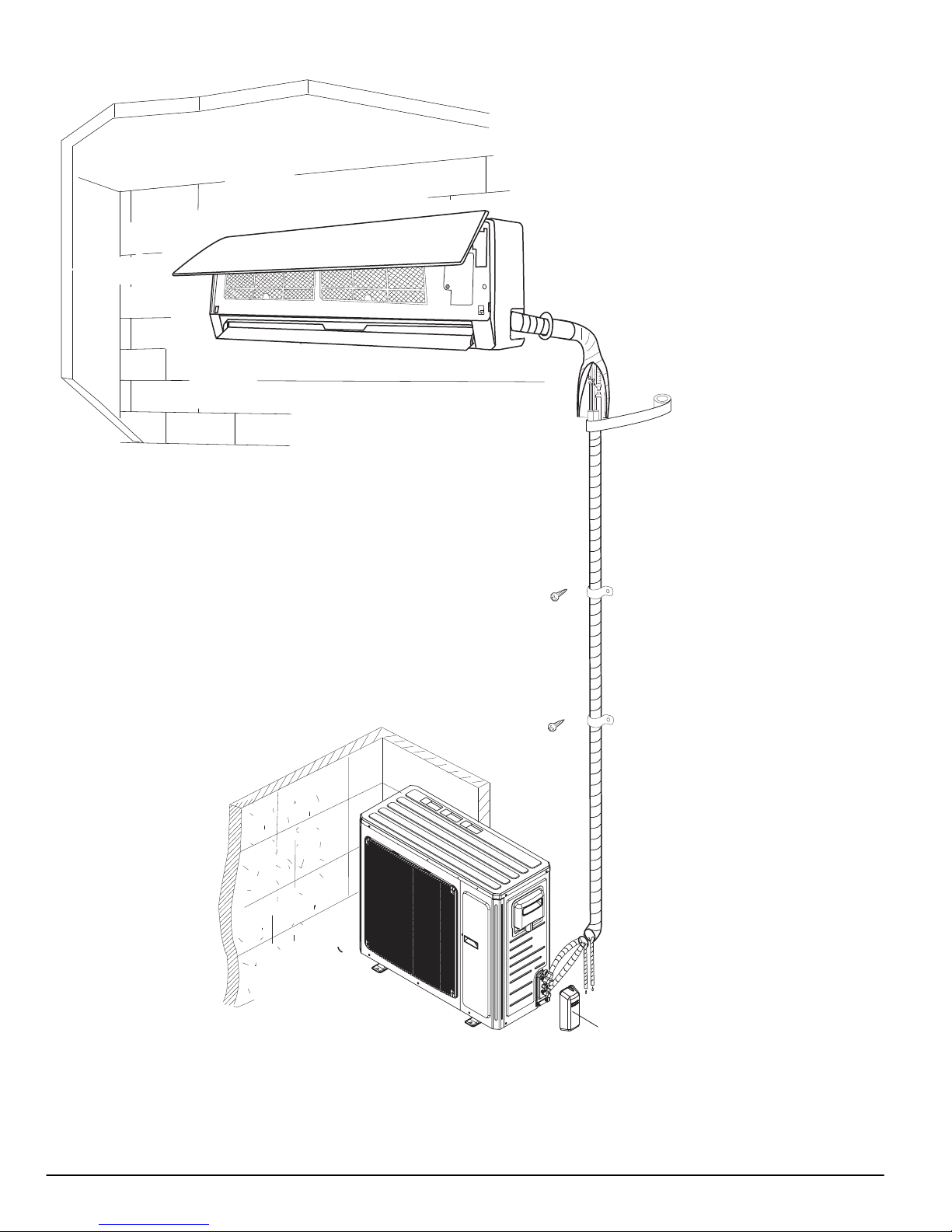

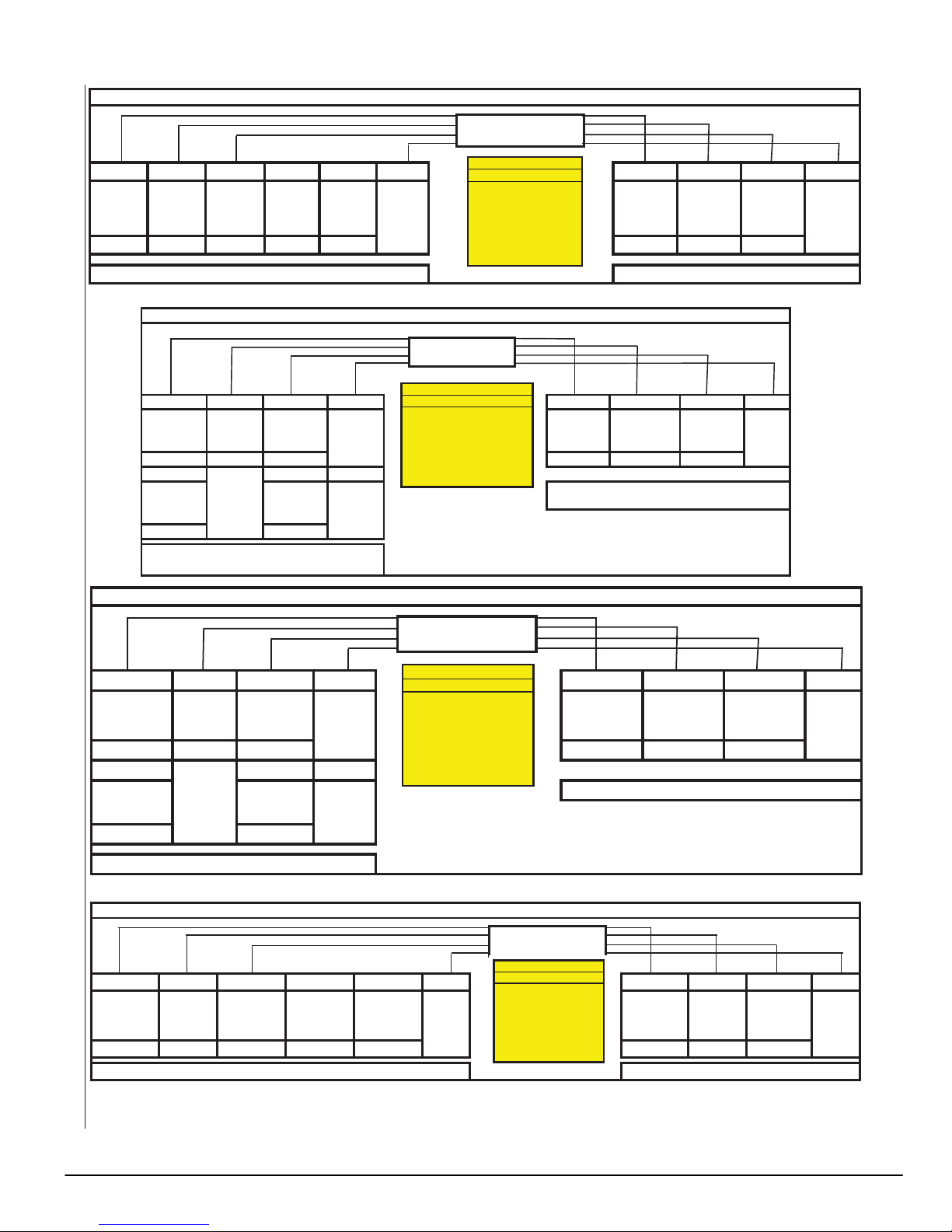

CLEARANCES

Indoor Unit

Distance to Ceiling

6 in (152 mm)

Distance to Wall

6 in (152 mm)

Distance in Front of Unit

118 in (2997 mm)

●

The clearance dimensions are necessary for a correct installation

Distance to Floor

66 in (1676 mm)

and are the minimum permissible distances to adjacent structures.

Outdoor Unit

Distance to Wall

6 in (152 mm)

NOTE: Refrigerant lines

may be routed in any of the

(4) directions, right,

right rear, left, or left rear.

See instructions for details

Distance to

Back Wall

12 in (305 mm)

Air Discharge Side

79 in (2007 mm)

Figure 6 - Indoor and Outdoor Unit Clearances

13 421 08 9205 00

Above Unit

20 in (508 mm)

Air Inlet Side

12 in (305 mm)

Distance to Wall

20 in (508 mm)

valve cover

A12385

SYSTEM OPERATING ENVELOPE

64.4ºF

75ºF

5ºF

113ºF

Heating

5ºF

75ºF

5ºF

86ºF

109ºF

Supply Voltage 115-1-60 AC 208/230-1-60 AC

Model 9k 12k 12k 18k 24k

Indoor Operating Range (A/C and

HP) °F (°C)

Cooling Ambient Operating Range

(A/C) °F (°C)

Cooling Ambient Operating Range

(HP) °F (°C)

Heating Ambient Operating Range

(HP) °F (°C)

64 - 113

(18 - 45)

64 - 113

(18 - 45)

5 - 75

(-15 - 24)

64 - 113

(18 - 45)

64 - 113

(18 - 45)

5 - 75

(-15 - 24)

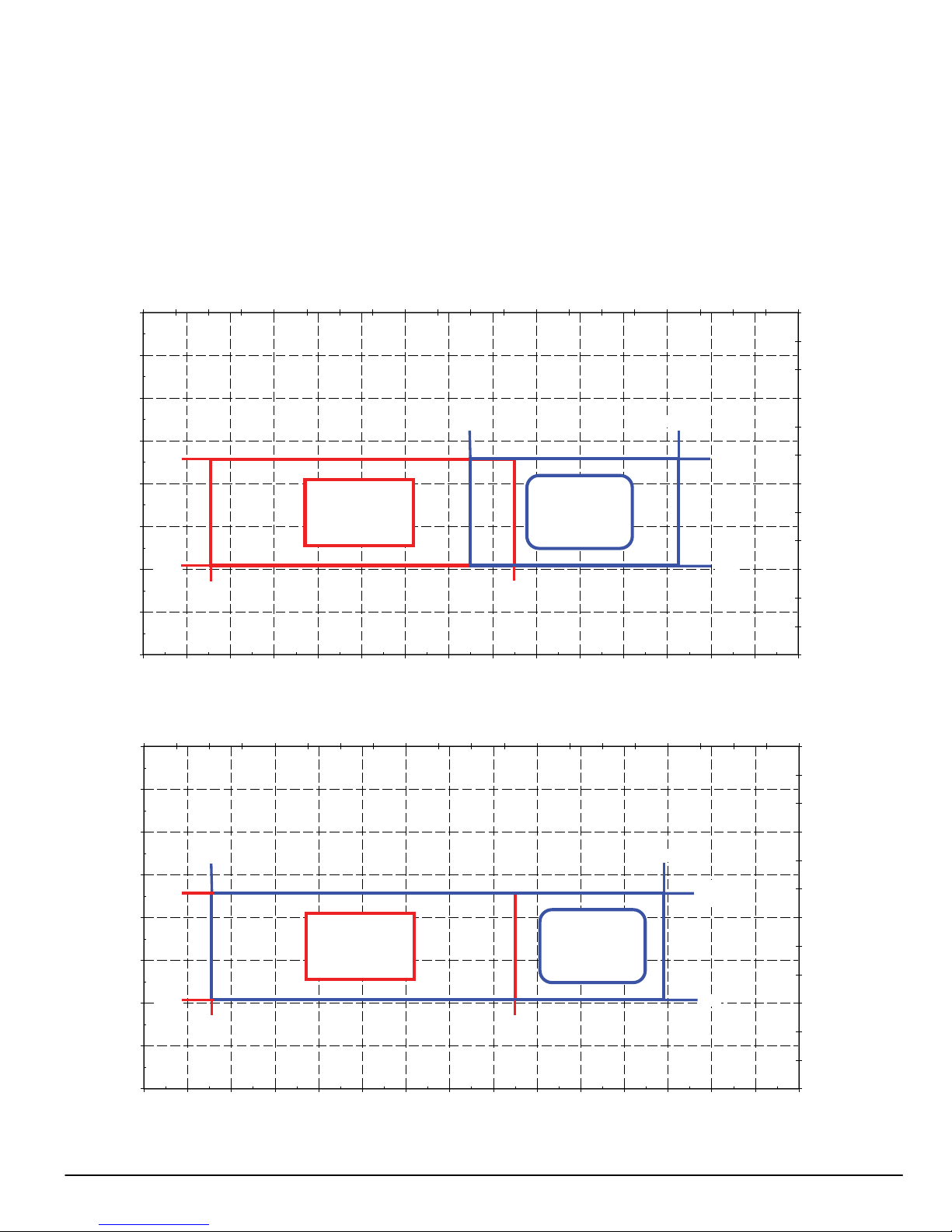

See Figure 7 8 9 10 & 11

120

110

100

90

86ºF

80

Heating

Continuous

Indoor Temperature (°F)

70

Operation

61 - 86 (16 - 30)

5 - 109

(-15 - 43)

5 - 109

(-15 - 43)

5 - 75

(-15 - 24)

Cooling

Continuous

Operation

5 - 118

(-15 - 48)

5 - 118

(-15 - 48)

19 - 75

(-7 - 24)

86ºF

5 - 118

(-15 - 48)

5 - 115

(-15 - 46)

19 - 75

(-7 - 24)

61ºF

60

50

40

-10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Outdoor Temperature (°F)

61ºF

Figure 7 - 9k / 12k 115V System Operating Envelope

120

110

100

90

86ºF

Indoor Temperature (°F)

80

Continuous

70

61ºF

60

Operation

Cooling

Continuous

Operation

61ºF

50

40

-10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

421 08 9205 00 14

Outdoor Temperature (°F)

Figure 8 - 12k 230V System Operating Envelope

SYSTEM OPERATING ENVELOPE CONTINUED

Heating

5ºF

75ºF

19ºF

86ºF

118ºF

Cooling

5ºF

118ºF

120

110

100

90

80

Continuous

Indoor Temperature (°F)

70

Operation

86ºF

Cooling

Continuous

Operation

61ºF

60

50

40

-10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Outdoor Temperature (°F)

61ºF

Figure 9 - 18k 230V System Operating Envelope

120

110

100

F)

°

90

86ºF

80

Continuous

70

Indoor Temperature (

60

Operation

61ºF

50

40

-10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Figure 10 - 24k AC 230V System Operating Envelope

15 421 08 9205 00

Outdoor Temperature (°F)

SYSTEM OPERATING ENVELOPE CONTINUED

Heating

50ºF

75ºF

5ºF

86ºF

118ºF

120

110

100

F)

°

90

80

70

Indoor Temperature (

Continuous

Operation

86ºF

Cooling

Continuous

Operation

61ºF

60

50

40

-10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140

Outdoor Temperature (°F)

61ºF

Figure 11 - 24k HP 230V System Operating Envelope

421 08 9205 00 16

ELECTRICAL DATA

Cooling Only

Operating

System Voltage

Unit

Size

9 K 115 -1 - 60 127/103 9.76 25.00 0.17 30

12 K 115 -1 - 60 127/103 11.20 25.00 0.17 30 15 25

12 K 208/230-1-60 253/187 7.30 16.50 0.25 21 208/230 0.19 15 10 15

18 K 208/230-1-60 253/187 10.86 27.00 0.62 60 208/230 0.32 20 15 25

24 K 208/230-1-60 253/187 11.71 41.00 0.62 60 208/230 0.45 35 16 25

Heat Pump

9 K 115-1-60 127/103 9.76 20.00 0.17 30

12 K 115-1-60 127/103 11.20 20.00 0.17 30 15 25

12 K 208/230-1-60 253/187 7.30 16.50 0.25 21 208/230 0.19 15 10 15

18 K 208/230-1-60 253/187 10.86 27.00 0.62 60 208/230 0.32 20 15 25

24 K 208/230-1-60 253/187 12.50 41.00 0.62 60 208/230 0.45 35 17 25

* Permissible limits of the voltage range at which the unit will operate satisfactorily

Indoor fan powered from outdoor unit.

LEGEND

FLA - Full Load Amps

LRA - Locked Rotor Amps

MCA - Minimum Circuit Amps

RLA - Rated Load Amps

MOCP- Maximum Over Current Protection

Voltage*

MAX /

MIN

Compressor Outdoor Fan Indoor Fan{

RLA LRA FLA W VOLTS FLA W

115 0.38 15

115 0.38 15

MCA

13 20

13 20

WIRING

Power Wiring:

The main power is supplied to the outdoor unit. The field supplied connecting cable from the outdoor unit to indoor unit consists of three

(3) wires and provides the power for the indoor unit. Two wires are high voltage AC power and one is a ground wire.

Consult your local building codes and the NEC (National Electrical Code) or CEC (Canadian Electrical Code) for special requirements.

All wires must be sized per NEC or CEC and local codes. Use Electrical Data table MCA (minimum circuit amps) and MOCP (maximum

over current protection) to correctly size the wires and the disconnect fuse or breakers respectively.

Per caution note, only copper conductors with a minimum 300 volt rating and 2/64−inch thick insulation must be used.

MAX

FUSE/

CB Amp

(MOCP)VOLT-PH-HZ

Control Wiring:

A separate shielded copper conductor only, with a minimum 300 volt rating and 2/64−inch thick insulation, must be used as the

communication wire from from the outdoor unit to the indoor unit.

To minimize voltage drop of the control wire, use the following wire size and maximum lengths shown in the chart below.

Wire Size

18 AWG 50 ft. (15 m)

16 AWG 50 ft (15) to 100 ft. (30 m)

!

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Wires should be sized based on NEC and local codes.

Use copper conductors only with a minimum 300 volt

rating and 2/64 inch thick insulation.

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Be sure to comply with local codes while running wire

from indoor unit to outdoor unit.

Every wire must be connected firmly. Loose wiring may

cause terminal to overheat or result in unit malfunction. A

Length

ft (m)

CAUTION

fire hazard may also exist. Therefore, be sure all wiring is

tightly connected.

No wire should be allowed to touch refrigerant tubing,

compressor or any moving parts.

Disconnecting means must be provided and shall be

located within sight and readily accessible from the air

conditioner.

Connecting cable with conduit shall be routed through

hole in the conduit panel.

17 421 08 9205 00

CONNECTION DIAGRAMS

DLC4 18K~24K Outdoor Unit Terminal Block

Control

from

Outdoor

Unit

DLF4 18K~24K Indoor Unit Terminal Block

DLC4/DLF4 18K~24K 208/230-1-60 Connection Diagram

CONNECTING CABLE

OUTDOOR TO INDOOR

Power from

Outdoor Unit

Power to

Indoor Unit

Main Power

Supply

Main Power

Supply

Power from

Outdoor Unit

Power to

Indoor Unit

Control to

Indoor Unit

CAUTION

Attention

Use Copper Conductors Only

With Minimum 300 Volt, 2/64"

Thick Insulation.

Utilisez seulement des

conducteurs en cuivre d'un

minimum de 300 volt d'une

isol at ion d' èpaisseur de 2/64".

Power from

Outdoor Unit

DLC4/DLF4 12K 208/230-1-60 Connection Diagram

Control to

Indoor Unit

Control from

Outdoor Unit

Power from

Outdoor Unit

CONNECTING CABLE

OUTDOOR TO INDOOR

Power to

Indoor Unit

Power to

Indoor Unit

Main Power

Supply

Main Power

Supply

DLC4 12K Outdoor Unit Terminal Block

DLF4 12K Indoor Unit Terminal Block

CAUTION

Attention

Use Copper Conductors Only

With Minimum 300 Volt, 2/64"

Thick Insulation.

Utilisez seulement des

conducteurs en cuivre d'un

minimum de 300 volt d'une

isolation d' èpaisseur de 2/64".

N S L GND N S L GND

NLGND

DLC4H6 9K-12K Heat Pump Outdoor Unit

Terminal Block

DLF4H6 9K-12K Heat Pump Indoor Unit

Terminal Block

Main Power

Supply

Main Power

Supply

DLC4H6/DLF4H6 9K-12K 115-1-60 Heat Pump Connection Diagram

CONNECTING CABLE

OUTDOOR TO INDOOR

Power to

Indoor Unit

Control to

Indoor Unit

Power to

Indoor Unit

Power from

Outdoor Unit

Control from

Outdoor Unit

Power from

Outdoor Unit

CAUTION

Attention

Use Copper Conductors Only

With Minimum 300 Volt, 2/64"

Thick Insulation.

Utilisez seulement des

conducteurs en cuivre d'un

minimum de 300 volt d'une

isol at ion d' èpaisseur de 2/64".

DLC4A6/DLF4A6 9K~12K 115-1-60 Cooling Only Connection Diagram

DLC4A6 9K~12K Outdoor Unit Terminal Block

CONNECTING CABLE

OUTDOOR TO INDOOR

Power to

Indoor Unit

Power to

Indoor Unit

Power from

Outdoor

Unit

Power from

Outdoor

Unit

Control to

Indoor Unit

Control

from

Outdoor

Unit

Main

Power

Supply

Main

Power

Supply

DLF4A6 9K~12K Indoor Unit Terminal Block

CAUTION

Attention

Use Copper Conductors Only

With Minimum 300 Volt, 2/64"

Thick Insulation.

Utilisez seulement des

conducteurs en cuivre d'un

minimum de 300 volt d'une

isol at ion d' èp aisseur de 2/64".

N S L L N GND N S L GND

Ground Ground

115-1-60 Low V DC 115-1-60 115-1-60 115-1-60 115-1-60 Low V DC 115-1-60

Ground Ground

115-1-60 Low V DC 115-1-60 115-1-60 Low V DC 115-1-60

Ground

115-1-60 115-1-60

L2 S L1 GND L2 S L1 GND

Ground Ground

208/230-1-60 Low V DC 208/230-1-60 208/230-1-60 Low V DC 208/230-1-60

L2 L1 GND

Ground

208/230-1-60 208/230-1-60

L2SL1L1L2GND L2SL1GND

Ground Ground

208/230-1-60 Low V DC 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 Low V DC 208/230-1-60

NOTE: Polarity of power wires muct match original connection on outdoor unit.

Figure 12 - Connection Diagrams

421 08 9205 00 18

A13080

19 421 08 9205 00

CONNECTION DIAGRAMS

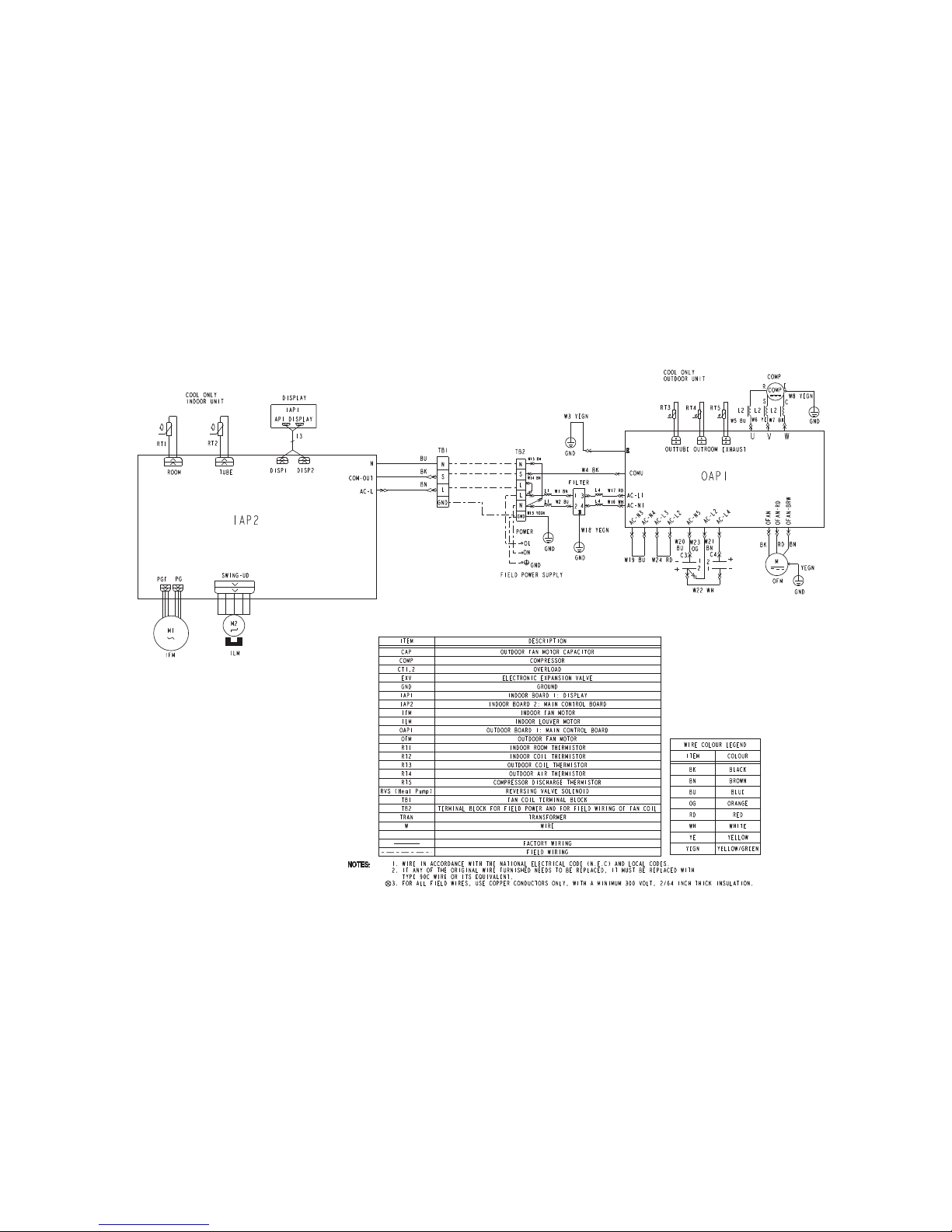

WIRING DIAGRAMS

A13081

DLF4A609/12

DLC4A609/12

Figure 13 - 9K / 12K Cooling Only 115−1−60

20 421 08 9205 00

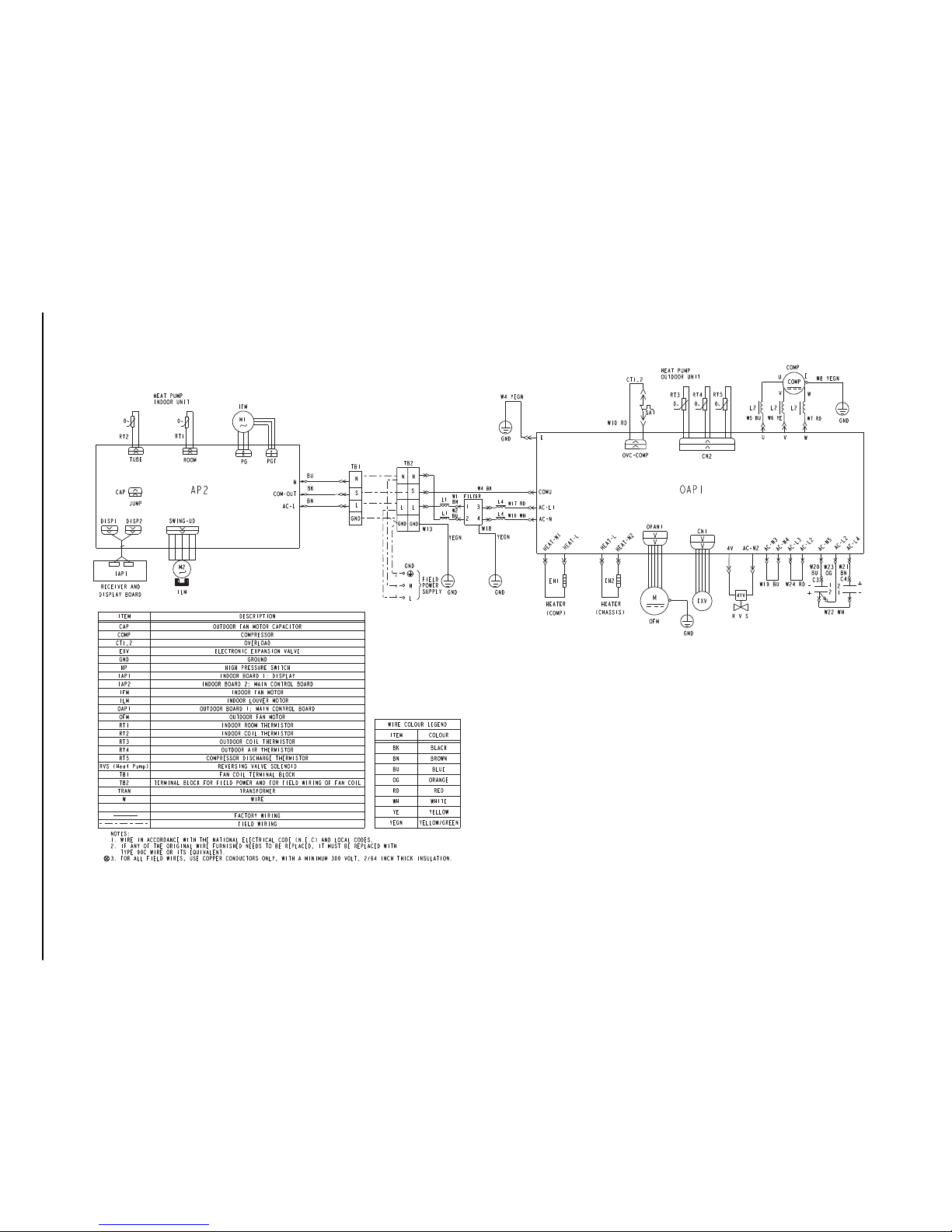

CONNECTION DIAGRAMS

A13082

DLF4H609/12J1

A

DLC4H609/12J1

A

Figure 14 - 9K / 12K Heat Pump Only 115−1−60

421 08 9205 00 21

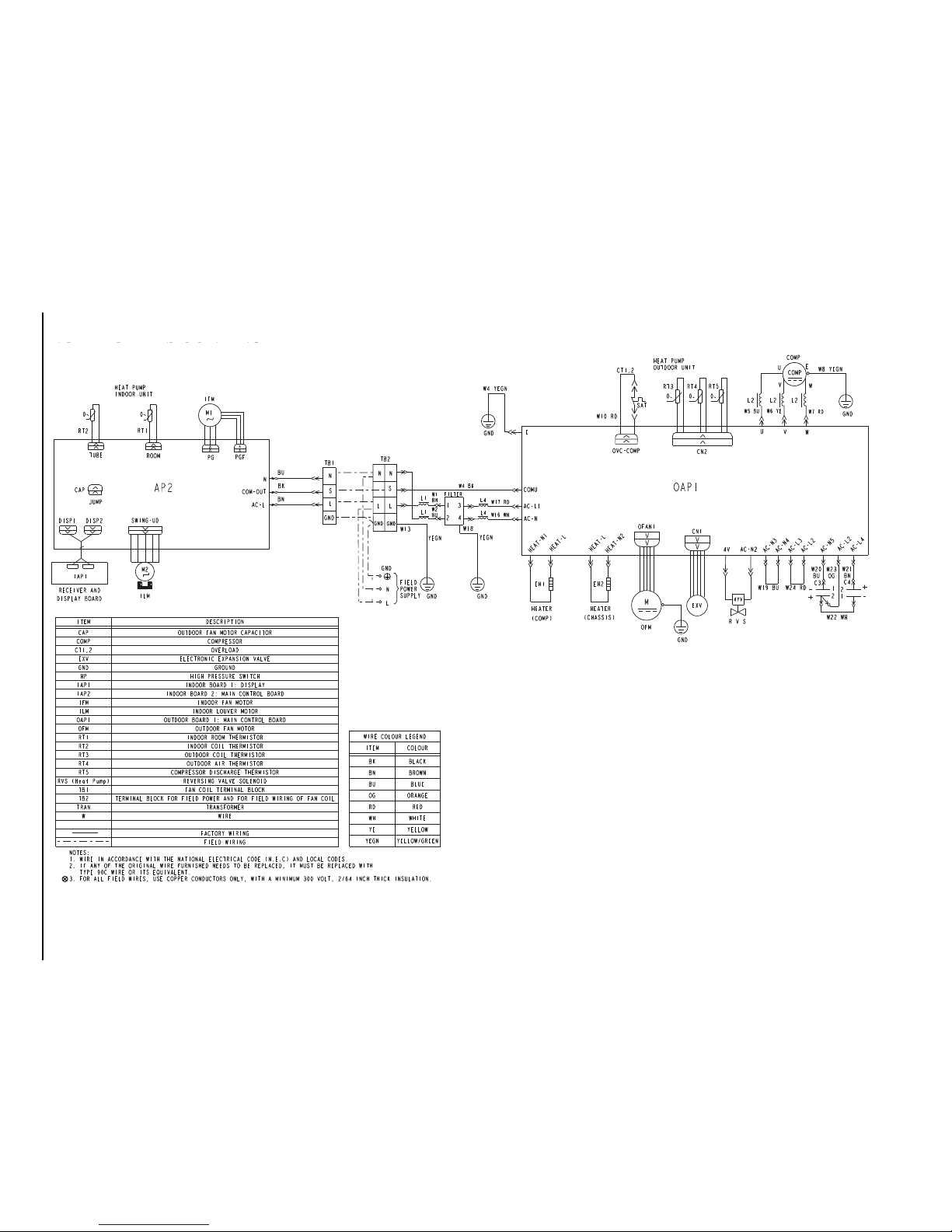

CONNECTION DIAGRAMS

DIAGRAMS CONTINUED

A13083

DLF4H612K1

A

DLC4H612K1

A

Figure 15 - 12k Heat Pump Only 230−1−60

22 421 08 9205 00

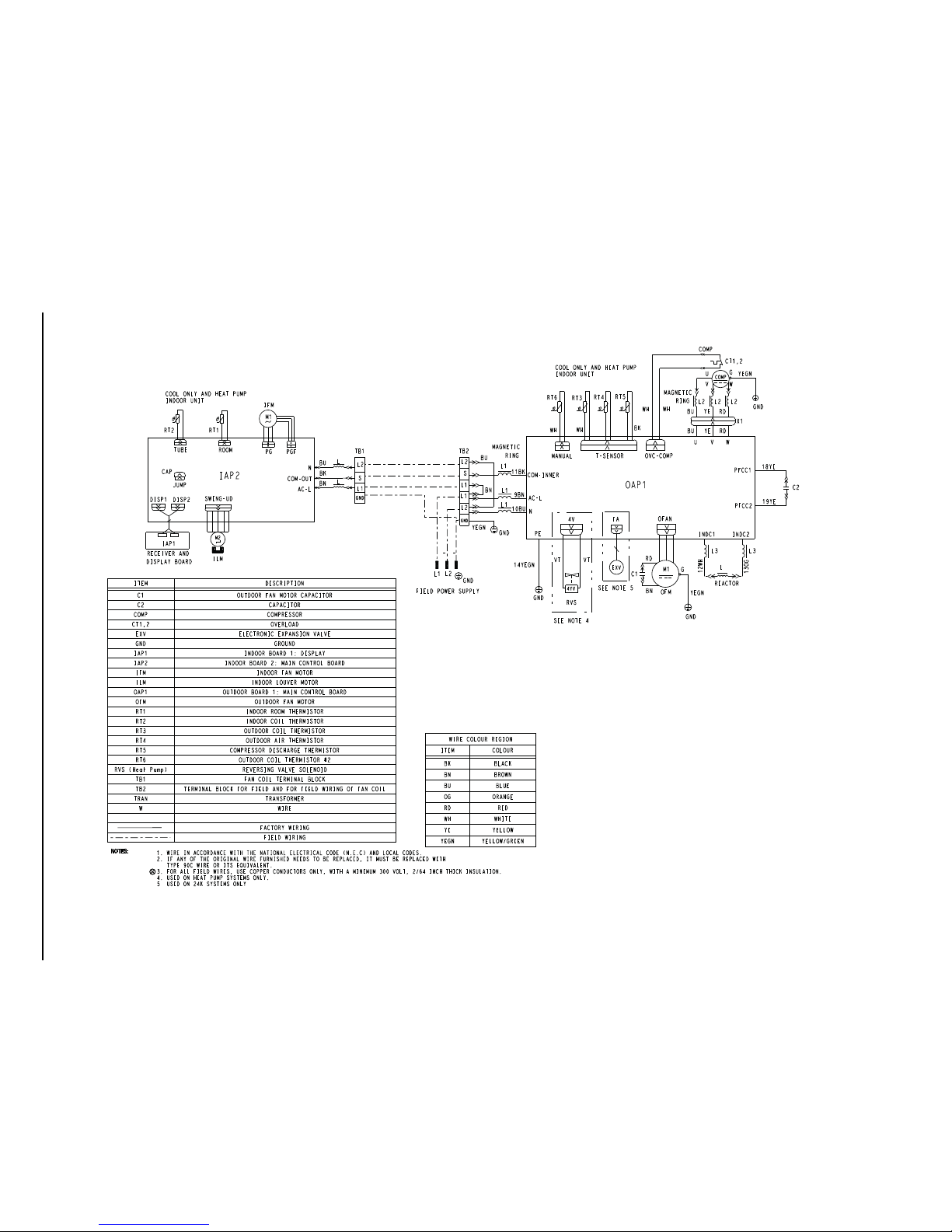

CONNECTION DIAGRAMS

A13084

DLF4A618/24K1

A

DLC4A618/24K1

A

Figure 16 - 18K / 24K 230−1−60

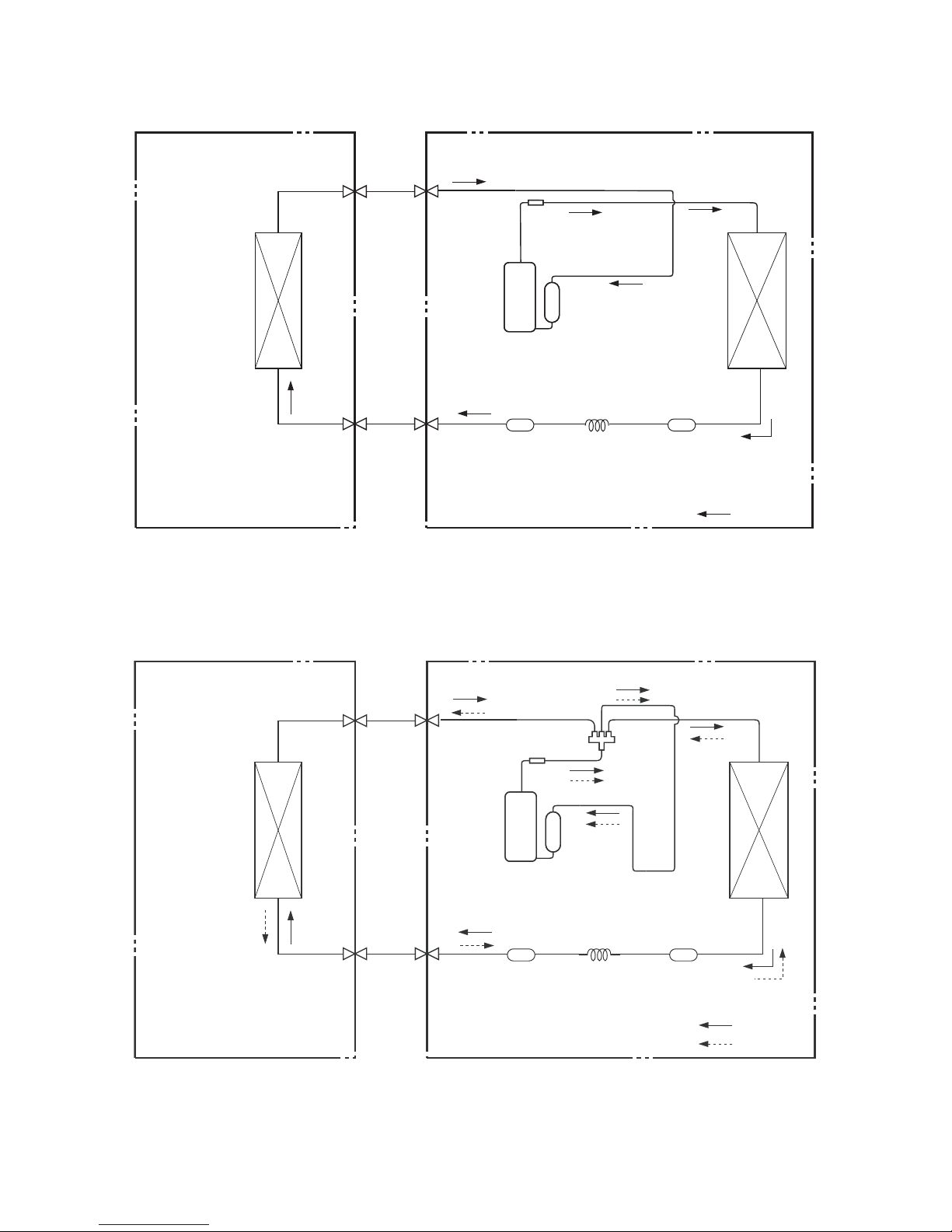

REFRIGERATION SYSTEM DIAGRAMS

GAS SIDE

TINU ROODTUOTINU ROODNI

HEAT

EXCHANGE

(EVAPORATOR)

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

Muffler

Discharge

Suction

COMPRESSOR

Accumlator

HEAT

EXCHANGE

(CONDENSER)

Capillary

Figure 17 - Refrigeration System Diagram DLC/DLF4A6 Cooling Only

9k / 12k − 115v; 12k / 18k − 230v

TINU ROODTUOTINU ROODNI

reniartSreniartS

COOLING

A13086

GAS SIDE

3-WAY VALVE

HEAT

EXCHANGE

(EVAPORATOR)

LIQUID SIDE

2-WAY VALVE

Figure 18 - Refrigeration System Diagram DLC/DLF4H6

Refrigerant Pipe Diameter:

9k / 12k − Liquid: 1/4” (6.4 mm) Gas: 3/8” (9.5 mm)

18k − Liquid: 1/4” (6.4 mm) Gas: 1/2” (12.7 mm)

Discharge

Suction

COMPRESSOR

12k / 18k − 230v

4-Way valve

Muffler

Accumlator

HEAT

EXCHANGE

(CONDENSER)

Capillary reniartSreniartS

COOLING

HEATING

A13087

23 421 08 9205 00

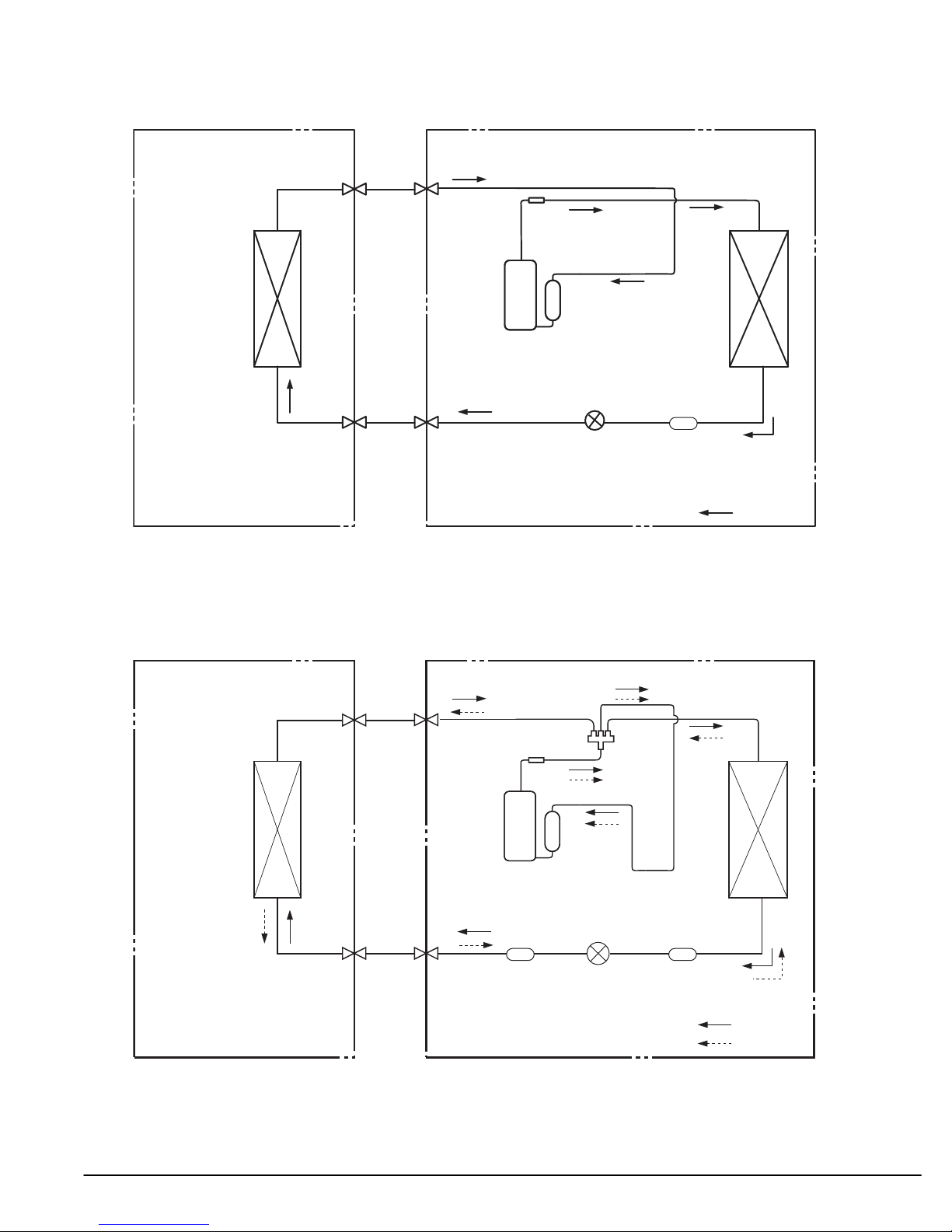

REFRIGERATION SYSTEM DIAGRAMS CONTINUED

INDOOR OUTDOOR

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

Muffler

Discharge

Suction

COMPRESSOR

Accumlator

Electronic Expansion Valve

HEAT

EXCHANGE

(CONDENSER)

Strainer

Figure 19 - Refrigeration System Diagram DLC/DLF4A6 Cooling Only

24k − 230v

TINU ROODTUOTINU ROODNI

COOLING

A13088

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

Muffler

Discharge

Suction

COMPRESSOR

Accumlator

4-Way valve

Expansion valve

HEAT

EXCHANGE

(CONDENSER)

reniartSreniartS

COOLING

HEATING

Figure 20 - Refrigeration System Diagram DLC/DLF4H6

9k / 12k − 115v; 24k − 230v

Refrigerant Pipe Diameter:

9k / 12k − Liquid: 1/4” (6.4 mm) Gas: 3/8” (9.5 mm)

24k − Liquid: 1/4” (6.4 mm) Gas: 1/2” (12.7 mm)

24 421 08 9205 00

A13089

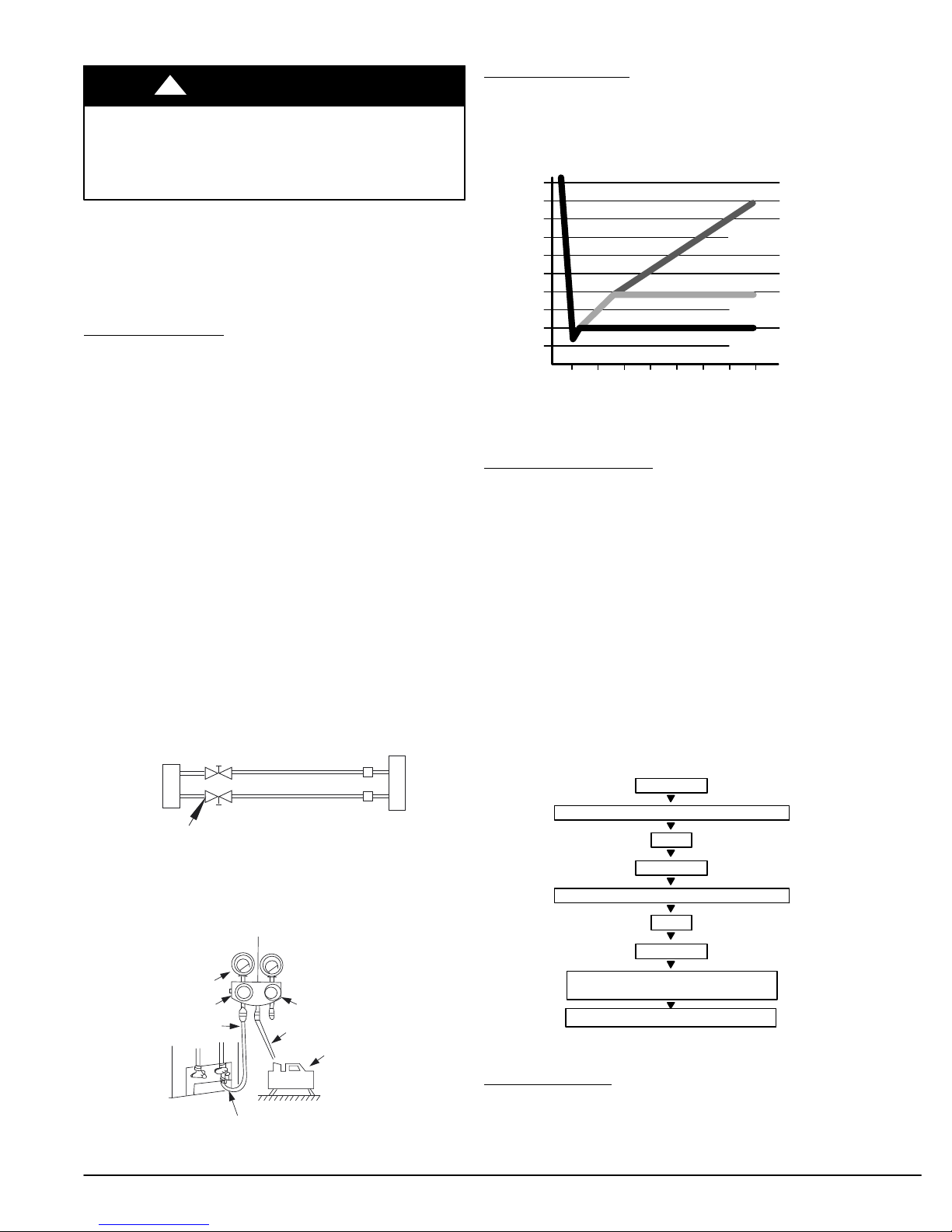

SYSTEM EVACUATION AND CHARGING

t

Deep Vacuum Method

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Never use the system compressor as a vacuum pump.

Refrigerant tubes and indoor coil should be evacuated using

the recommended deep vacuum method of 500 microns. The

alternate triple evacuation method may be used if the

procedure outlined below is followed. Always break a vacuum

with dry nitrogen.

SYSTEM VACUUM AND CHARGE

Using Vacuum Pump

(1.) Completely tighten flare nuts A, B, C, D, connect

manifold gage charge hose to a charge port of the

low side service valve. (See Fig. 21.)

(2.) Connect charge hose to vacuum pump.

(3.) Fully open the low side of manifold gage. (See Fig.

22)

(4.) Start vacuum pump

(5.) Evacuate using either deep vacuum or triple

evacuation method.

(6.) After evacuation is complete, fully close the low side

of manifold gage and stop operation of vacuum

pump.

(7.) The factory charge contained in the outdoor unit is

good for up to 25 ft. (8 m) of line length. For

refrigerant lines longer than 25 ft (8 m), add 0.1 oz.

per foot of extra piping up to allowable maximum

length listed in physical data.

(8.) Disconnect charge hose from charge connection of

the low side service valve.

(9.) Fully open service valves B and A.

(10.) Securely tighten caps of service valves.

Outdoor Unit

Service Valve

CAUTION

Refrigerant

Low Side

A

High Side

B

Figure 21 - Service Valve

The deep vacuum method requires a vacuum pump capable

of pulling a vacuum of 500 microns and a vacuum gage

capable of accurately measuring this vacuum depth. The

deep vacuum method is the most positive way of assuring a

system is free of air and liquid water. (See Fig. 23)

Triple Evacuation Method

The triple evacuation method should only be used when

vacuum pump is only capable of pumping down to 28 in. of

mercury vacuum and system does not contain any liquid

water.

Refer to Fig. 24 and proceed as follows:

Indoor Uni

C

D

A07360

5000

4500

4000

3500

3000

2500

2000

MICRONS

1500

1000

500

01234567

MINUTES

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

A95424

Figure 23 - Deep Vacuum Graph

(1.) Pump system down to 28 in. of mercury and allow

pump to continue operating for an additional 15

minutes.

(2.) Close service valves and shut off vacuum pump.

(3.) Connect a nitrogen cylinder and regulator to system

and open until system pressure is 2 psig.

(4.) Close service valve and allow system to stand for 1

hr. During this time, dry nitrogen will be able to diffuse

throughout the system absorbing moisture.

(5.) Repeat this procedure as indicated in Fig. 24. System

will then be free of any contaminants and water

vapor.

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

WAIT

EVACUATE

BREAK VACUUM WITH DRY NITROGEN

Manifold Gage

500 microns

Low side valve

Charge hose

Low side valve

High side valve

Charge hose

Figure 22 - Manifold

421 08 9205 00 25

Vacuum pump

A07361

WAIT

EVACUATE

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

RELEASE CHARGE INTO SYSTEM

A95425

Figure 24 - Triple Evacuation Method

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both

indoor and outdoor unit has not shifted during shipment.

Ensure tubes are not rubbing against each other or any

sheet metal. Pay close attention to feeder tubes, making

sure wire ties on feeder tubes are secure and tight.

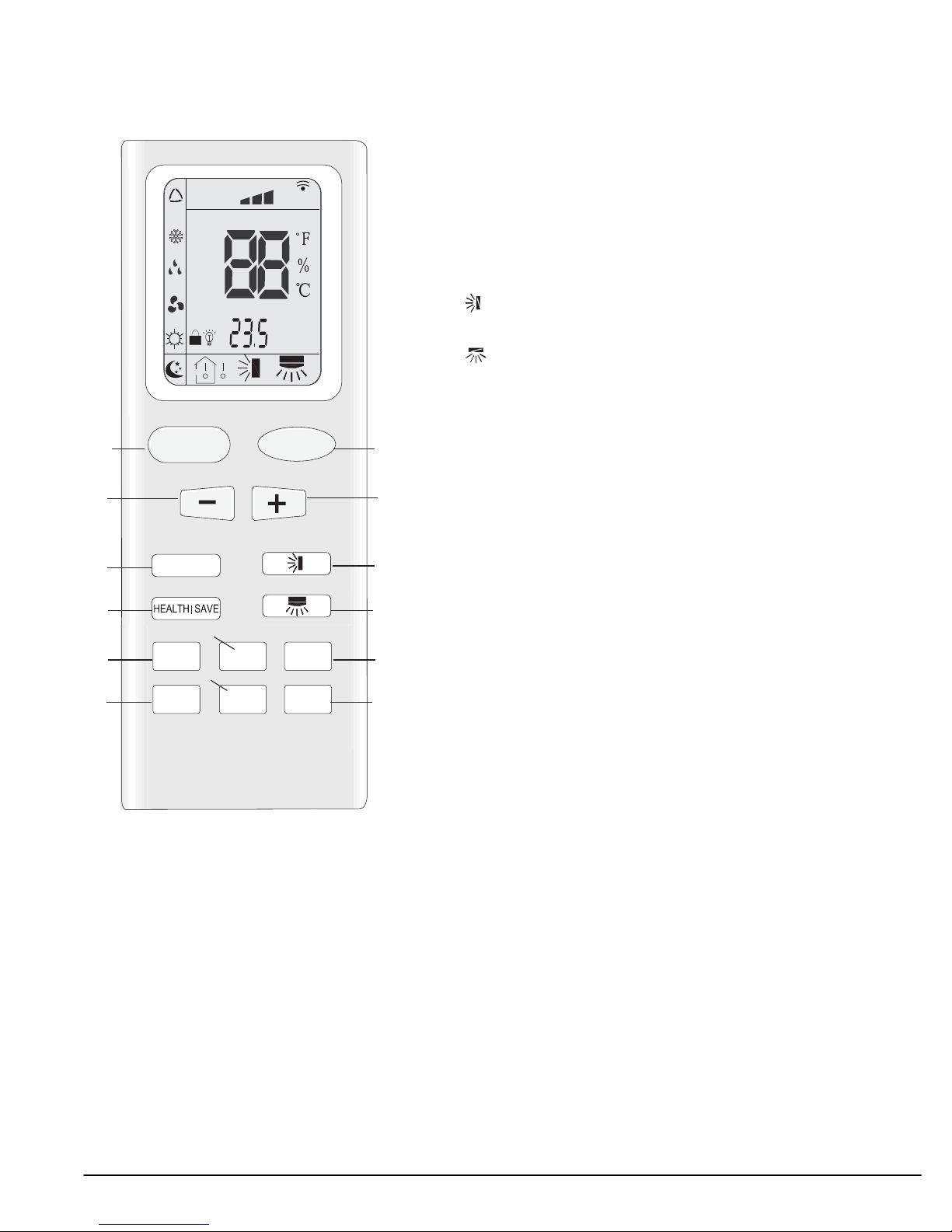

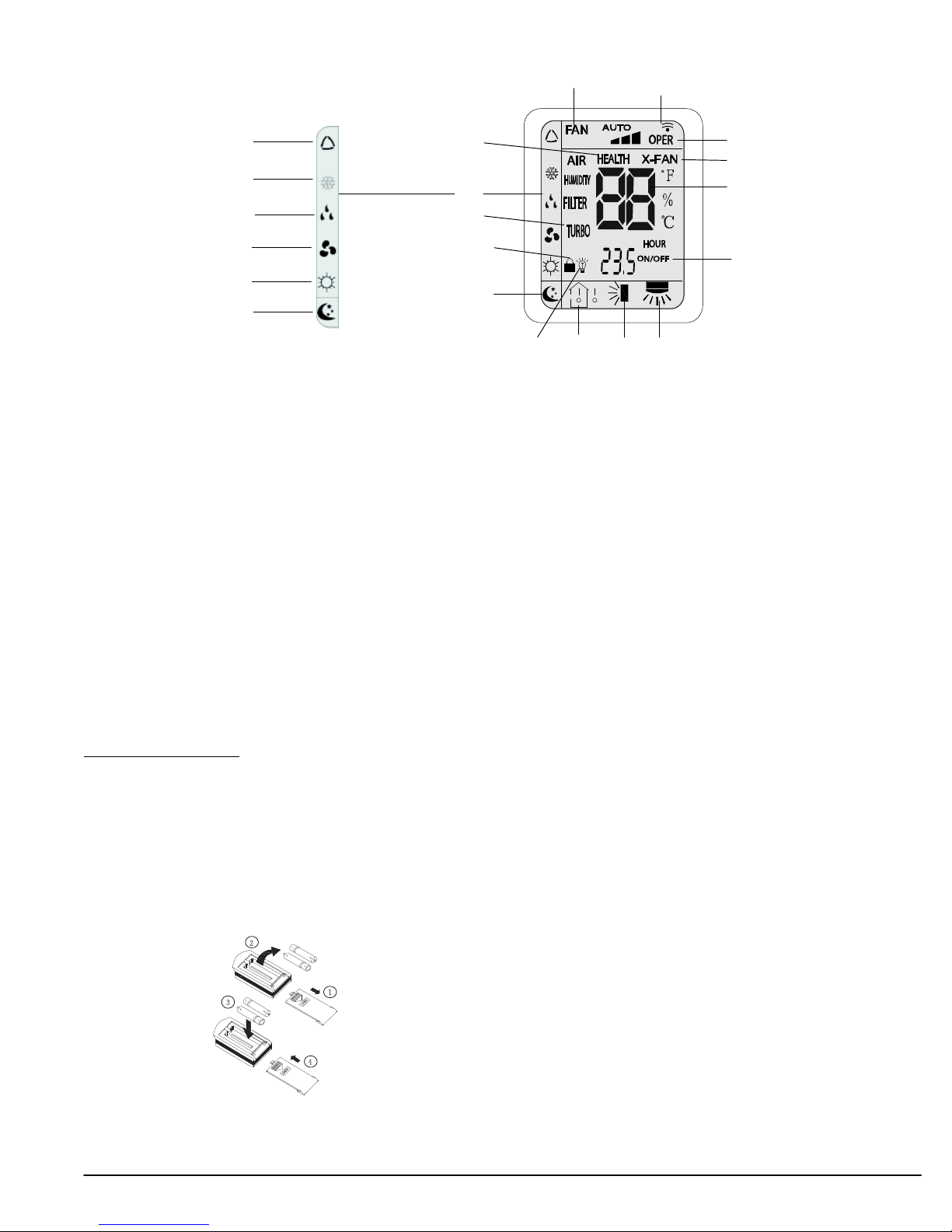

REMOTE CONTROL AND FUNCTIONS

ON/OFF

(1)

Press to start or stop operation

AUTO

FAN

AIR

HEALTH

OPER

X-FAN

HUMIDITY

FILTER

TURBO

(1) (2)

(3)

(5)

ON/OFF

FAN

HOUR

ON/OFF

MODE

(4)

(6)

(2) MODE

Press to select operation mode

(AUTO/COOL/DRY/FAN/HEAT)

(3) - : Press to decrease temperature setting

(4) +: Press to increase temperature setting

(5) FAN

Press to set fan speed

(6) Horizontal Swing

Press to activate horizontal swing or set louver positions

(7) HEALTH|SAVE (Not Available)

(8) Vertical Swing (Not Available)

(9) X-FAN

Press to activate or deactivate DRY function

(10) TEMP

Press to alternate between set point and room temperature display

(11) TIMER

Press to set TIMER ON/ TIMER OFF

(12) TURBO

Press to activate or deactivate TURBO mode

(13) SLEEP

Press to activate or deactivate SLEEP mode

(14) LIGHT

Press to activate or deactivate display panel light

(7)

(9)

(12)

X-FAN

TURBO

(10)

(13)

TEMP

SLEEP

TIMER

LIGHT

(8)

(11)

(14)

A12390

Remote Control

26 421 08 9205 00

Remote Control Display

3

1

MODE DISPLAY

AUTO

COOL

DRY

FAN

HEAT

8

4

10

15

2

11

6

9

5

SLEEP

14 1312

7

A12391

NOTE: Symbols shown in this manual are for the purpose of demonstration. During actual operation, only the

relevant symbols are displayed.

1. TRANSMISSION INDICATOR: Illuminates when re-

mote control transmits signals to the indoor unit.

2. This symbol appears when the unit is turned on by

the remote control, and disappears when the unit is

turned off.

3. FAN SPEED DISPLAY: Indicates the set fan speed.

AUTO is displayed when unit is running in AUTO

mode.

4. MODE DISPLAY: Indicates the current operation

mode “AUTO”, “COOL”, “DRY”, “FAN ONLY”, or

“HEAT”

5. SLEEP DISPLAY: Indicates unit is running in SLEEP

mode.

6. TEMPERATURE DISPLAY: Temperature setting

from 61F (16C) to 86F (30C) will be displayed.

If FAN mode is selected, there will be no temperature

displayed. During DEFROST operation, H1 will be

displayed. During SAVE mode, SE will be displayed.

7. Left/Right Louver Swing: Not available on these

models.

8. HEALTH/SAVE: HEALTH is not available. SAVE is

available on sizes 18k and 24k. SAVE mode can be

applied to cooling mode and when set point is less

than 80F (27C).

9. SETTING ON / OFF TIMES: 0.5 to 24 hours.

10. TURBO DISPLAY: Displayed when unit is running in

TURBO mode.

11. DRY COIL DISPLAY: Indicates unit is running in DRY

COIL mode where the fan continues to run after the

unit is shut off to dry the coil.

12. TEMPERATURE DISPLAY: Displays set point or

room temperature.

13. SWING DISPLAY: Sets louver position or set louvers

to continuously move for better air distribution.

14. LIGHT DISPLAY: Indicates if LED display on the front

panel is illuminated or not.

15. LOCK DISPLAY: Indicates if remote control is locked.

Battery Installation

Two AAA 1.5 v alkaline batteries (included) are required for

operation of the remote control.

To install or replace batteries :

1. Slide the back cover off the control to open the battery

compartment.

2. Remove old batteries if you are replacing the batteries.

3. Insert batteries. Follow the polarity markings inside

the battery compartment.

4. Replace battery compartment cover.

A08299

NOTE:

1. When replacing batteries, do not use old batteries or a

different type battery. This may cause the remote control to

malfunction. 2.If the remote is not going to be used for

several weeks, remove the batteries. Otherwise battery

leakage may damage the remote control.

3. The average battery life under normal use is about 6

months.

4. Replace the batteries when there is no audible beep from

the indoor unit or if the Transmission Indicator fails to light.

421 08 9205 00 27

FUNCTION AND CONTROLS

Description of Each Control Operation

Temperature Parameters

Indoor preset temperature (T

Indoor ambient temperature (T

Basic Functions

Once energized, in no case should the compressor be

restarted within less than 3 minutes. In the situation that

memory function is available, for the first energization, if the

compressor is at stop before de−energization, the compressor

will be started without a 3−minute lag; if the compressor is in

operation before de−energization, the compressor will be

started with a 3−minute lag; and once started, the compressor

will not be stopped within 6 minutes regardless of changes in

room temperature;

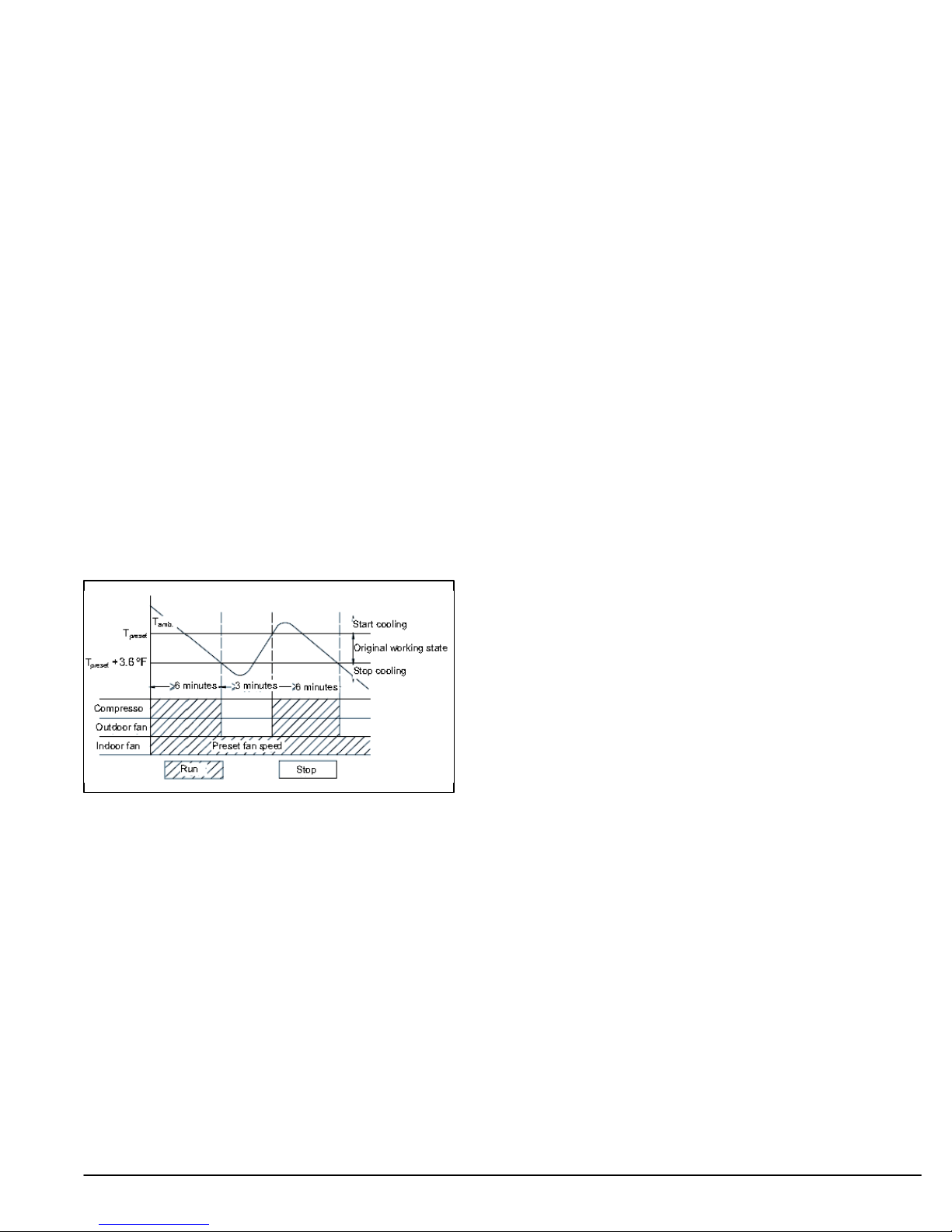

Cooling Mode

Working Conditions and Cooling Process.

When T

amb . Tpreset, the unit will enter cooling operation, in

which case the indoor fan, the outdoor fan and the

compressor will work and the indoor fan will run at preset

speed.

When Tamb v Tpreset −3.6F , the compressor will stop, the

outdoor fan will stop with a time lag of 30 seconds (60

seconds for 30k and 36k units), and the indoor fan will run at

preset speed.

When T

preset −3.6F < Tamb. < Tpreset +1.8F, the unit will

remain at its previous state.

Under this mode, the four−way valve will be de−energized

and temperature can be set within a range from 61F to 86F.

If the compressor is shut down for some reason, the indoor

fan and the swing device will operate at original state.

Figure 25 - Cooling Mode

PROTECTION

Antifreeze Protection

Under cooling and dehumidifying mode, 6 minutes after the

compressor is started:

If Tevap v35.6°F, the compressor will operate at reduced

frequency.

If Tevap v30.2°F is detected for duration of 3 minutes, the

compressor will stop, and after 60 seconds, the outdoor fan

will stop; and under cooling mode, the indoor fan and the

swing motor will remain at the original state.

evap. 42.8°F and the compressor has remained at OFF for

If T

at least 3 minutes, the compressor will resume its original

operation state.

preset)

amb.)

Total current up and frequency down protection

If Itotal vA, frequency rise will be allowed; if Itotal ≥ B,

frequency rise will not be allowed; if I

will run at reduced frequency; and if I

total ≥ C, the compressor

total ≥ D, the compressor

will stop and the outdoor fan will stop with a time lag of 30s.

Lag will be 60s for size 30 and 36 units.

Total Current Table

Unit Size - V

9k115V 10A 12A 14A 16A

12K115V 14A 16A 18A 20A

12K230V 6A 7A 8A 9A

18k230V 8A 9A 10A 11A

24K230V 10A 11A 12A 13A

A B C D

Variables

Heating Mode

Working Conditions and Heating Process

amb. v Tpreset +3.6°F , the unit enters heating mode, in

If T

which case the four−way valve, the compressor and the

outdoor fan will operate simultaneously, and the indoor fan will

run at preset speed in the condition of preset cold air

prevention.

amb. ≥ Tpreset +9°F , the compressor will stop, the outdoor

If T

fan will stop with a time lag of 60s, and the indoor fan will stop

after 60−second blow at low speed

preset +3.6°F < Tamb. < Tpreset +9°F , the unit will maintain

If T

its original operating status.

Under this mode, the four−way valve is energized and

temperature can be set within a range of 61°F − 86°F. The

operating symbol, the heating symbol and preset temperature

are revealed on the display.

Defrost Mode

Condition and Defrost Process

When Toutdoor amb

hour, if Toutdoor tube

. ≥41°F and the compressor has run for 3

< 0°F is continuously detected for 1

minute, the unit will enter defrost. [Note: the accumulated time

is cleared if one of the below condition is met. Toutdoor ambient >

41°F, the compressor starts up after switching to cooling or

dry mode, when defrosting is finished; for other situations

besides above conditions, the accumulated time will not be

cleared (including the unit stops when reaching the

temperature point, the unit stops for protection, switching to

fan mode, et. )]

When duration of successive heating operations is more than

45 minutes, or accumulated heating time IS more than 90

minutes,

and one of the following conditions is reached, the unit will

enter the defrost mode after 3 minutes.

Toutdoor amb. >41°F, Toutdoor tube v28.4°F

a.

b. 28.4°F vToutdoor amb. <41°F, Toutdoor tube v21.2°F

c. 23°F

vToutdoor amb. <28.4°F, Toutdoor tube v17.6°F

d. 14°FvTouter amb. <23°F, Touter tube − Tcompensatorys

v(Toutdoor amb. −5.4°F)

Toutdoor amb.>14°F Touter tube − Tcompensatorys v(Toutdoor amb.

e.

−

5.4°F)

After energization, for the first defrost, T

is not the first defrost, Tcompensation will be determined by

outdoor pipe when defrost ends.

T

outdoor pipe >35.6°F; Tcompensation = 0°F

a. T

b. Toutdoor pipe v35.6°F; Tcompensation = 5.4°F

compensation = 0°F. If it

28 421 08 9205 00

During defrost, if operation time for compressor doesn’t reach

3 minutes, the condenser will not defrost in the next 2 hours.

At the time of defrost the compressor stops operation, and 30

seconds later, the outdoor fan stops operation. In an

additional 30 seconds, the 4−way valve will stop operation. 30

seconds later, compressor will increase it’s frequency to 85

Hz for defrosting. Defrost will last for 450 seconds, or until the

outdoor pipe ≥ 50°F. When defrost is complete the

compressor will decrease its frequency. 30 seconds later the

compressor will stop operation. In 30 seconds the 4−way

valve will be started up. 60 seconds later the compressor and

outdoor fan will operate.

PROTECTION

Cold air prevention

The unit is started under heating mode (the compressor is

ON):

In the case of T

indoor amb. <75.2°F : if Ttube v107.6°F and

the indoor fan is stopped, the indoor fan will begin to run at

low speed with a time lag of 2 minutes. Within 2 minutes, if

T

tube >104°F, the indoor fan also will run at low speed; and

after 1−minute operation at low speed, the indoor fan will be

ramped to operation at a preset speed. Within 1−minute of low

speed operation or 2−minutes of non−operation, if

tube>108°F, the fan will run at preset speed.

T

In the case of Ti

ndoor amb. ≥ 75°F: if Ttube v108°F, the

indoor fan will run at low speed, and after one minute, the

indoor fan will be ramped to preset speed. Within one−minute

low speed operation, if T tube>107.6°F, the indoor fan will be

ramped to preset speed.

Note: T

indoor amb. indicated in and refers to, the

indoor ambient temperature before the command to start the

compressor is performed, or after the unit is withdrawn from

defrost and the defrost symbol is cleared.

Total current up and frequency down protection

If the total current I

I

total ≥X frequency rise will not be allowed; if Itotal ≥Y, the

compressor will run at reduced frequency; and if I

total ≤W, frequency rise will be allowed; if

total ≥Z, the

compressor will stop and the outdoor fan will stop with a time

lag of 30s.

Fan Mode

Under the mode, the indoor fan will run at preset speed and

the compressor, the outdoor fan, the four−way valve and the

electric heater will stop.

Under the mode, temperature can be set within a range of

61°F − 86°F.

AUTO Mode

Working conditions and Auto mode process:

Under AUTO mode, standard cooling temperature T

77°F and standard heating temperature T

Once energized, if T

heating mode; if 68°F < T

amb ≤68°F, the unit will be started under

amb.< 77°F, the unit will run under fan

preset is 64.4°F.

mode and the run indicator will be bright; and if T

preset is

amb ≥77°F,

the unit will be started under cooling mode.

Under AUTO mode, if T

amb.wTpreset is detected, the unit will

select to run under cooling mode, in which case the preset

temperature is 77°F; if T

amb.vTpreset −3.6°F, the compressor

will stop, the outdoor fan will stop with a time lag of 1 minute,

and the indoor fan will run at preset speed. If T

preset

–(−3.6°F)< Tamb.< Tpreset , the unit will remain in its original

state.

Under AUTO mode, if Tamb. vTpreset +3.6°F is detected, the

unit will select to run under heating mode, in which case the

preset temperature is 64.4°F; if T

amb.wTpreset +9°F, the

compressor will stop, the outdoor fan will stop with a time lag

of 1 minute, and the indoor fan will blow residual heat; and if

T

preset +3.6°F < Tamb. < Tpreset +9°F, the unit will remain in its

original state. The cooling−only unit will run under fan mode.

Under AUTO mode, if 68°F

< Tamb. < 77°F, the unit will

remain in its original state.

Protection

In cooling operation, protection is the same as that under the

cooling mode.

In heating operation, protection is the same as that under the

heating mode.

When ambient temperature changes, operation mode will be

converted preferentially. Once started, the compressor will

remain unchanged for at least 6 minutes.

Common Protection Functions and Fault Display under

COOL, HEAT, DRY and AUTO Modes

Overload protection

T tube : measured temperature of outdoor heat exchanger

under cooling mode; and measured temperature of indoor

heat

exchanger under heating mode.

1) Cooling overload

tube v 125.6°F, the unit will return to its original

a. If T

operation state.

b. If T tube w 131°F, frequency rise is not allowed.

c. If T tube w136.4°F, the compressor will run at reduced

frequency.

d. If T

tubew143.6°F, the compressor will stop and the indoor

fan will run at preset speed.

2) Heating overload

a. If T

tubev125.6°F, the unit will return to its original operation

state.

b. If T

tube w131°F, frequency rise is not allowed.

c. If T tube w136.4°F, the compressor will run at reduced

frequency.

d. If

T tubew143.6°F, the compressor will stop and the indoor

fan will blow residual heat and then stop.

Exhaust temperature protection of compressor

If exhaust temperature

w208.4°F, frequency is not allowed to

rise.

If exhaust temperature

w217.4°F, the compressor will run at

reduced frequency.

If exhaust temperature

If exhaust temperature

w230°F, the compressor will stop.

w194°F and the compressor has

stayed at stop for at least 3 minutes, the compressor will

resume its operation.

Communication fault

If the unit fails to receive correct signals for 3 minutes, a

communication fault will be registered and the whole system

will stop.

Module protection

Under module protection mode, the compressor will stop.

When the compressor remains at a stop for at least 3 minutes,

the compressor will resume its operation. If module protection

occurs six times in succession, the compressor will not be

started again.

421 08 9205 00 29

Overload protection

If temperature sensed by the overload sensor is over 239°F,

the compressor will stop and the outdoor fan will stop with a

time lag of 30 seconds. If the temperature drops below 203°F,

the overload protection will be reset.

If voltage on the DC bus is below 150V or over 420V, the

compressor will stop and the outdoor fan will stop with a time

lag of 30 seconds. When voltage on the DC bus returns to its

normal value and the compressor has stayed at a stop for at

least 3 minutes, the compressor will resume its operation.

Faults of temperature sensors

Description of Sensors Faults

Indoor Ambient

Temperature

Indoor Tube Temperature

Outdoor Ambient

Temperature

Outdoor Tube

Temperature

Exhaust

Overload

The sensor is open or short-circuited for 30

consecutive seconds

The sensor is open or short-circuited for 30

consecutive seconds

The sensor is open or short-circuited for 30

consecutive seconds

The sensor is open or short-circuited for 30

consecutive seconds, and no detection is

performed within 10 minutes after defrost begins

After the compressor has run for 3 minutes, the

sensor is open or short-circuited for 30

consecutive seconds

After the compressor has run for 3 minutes, the

sensor is open or short-circuited for 30

consecutive seconds

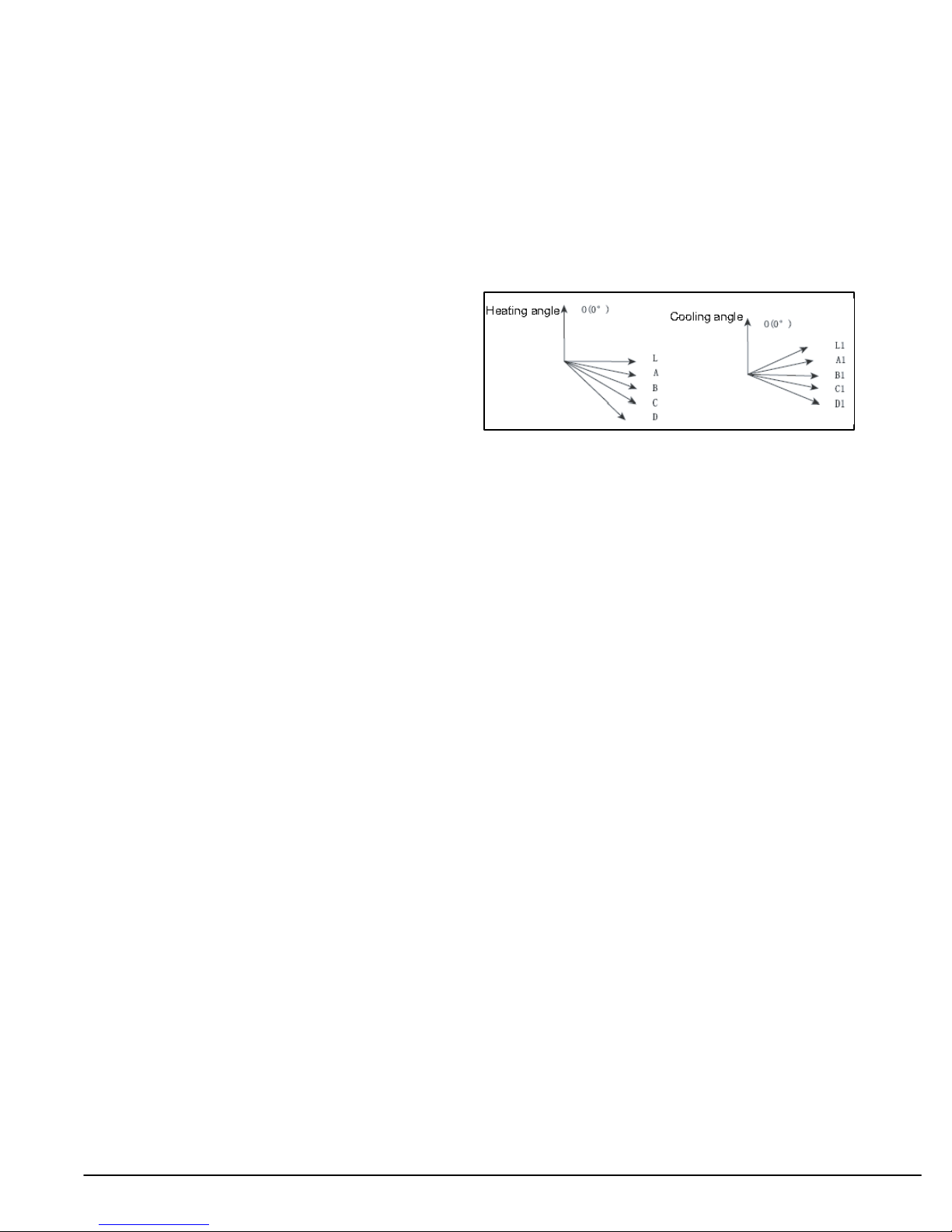

(9) Up−and−Down Swinging Control

When the power is turned on, the up−and−down motor will

first move the air deflector to 0 counter−clockwise. The air

outlet will be closed.

After starting the machine, if you don’t set the swinging

function, heating mode and auto−heating mode, the

up−and−down air deflector will move to D clockwise; under

other modes, the up−and−down air deflector will move to L1. If

you set the swing function when you start the machine, then

the deflector will swing between L and D. The air deflector has

7 swing states: Location L, Location A, Location B, Location

C, Location D, Location L to Location D, stop at any location

between L−D (the included angle between L~D is the same).

The air deflector will be closed at 0 location, and the swing is

function only works if the indoor fan is running.

Figure 26 - Swing Angles for Heating and Cooling

NOTE: Refer to Appendix Tables on pages 60-62 for sensor information.

Other Controls

(1) ON/OFF

Press the remote button ON/OFF: the on−off state will be

changed once each time you press the button.

(2) Mode Selection:

Press the remote button MODE, then select: AUTO, COOL,

DRY, FAN, HEAT, or AUTO.

(3) Temperature Setting Option Button

Each time you press the remote button TEMP+ or TEMP−, the

setting temperature will be up or down by 1°F. Regulating

Range: 61−86°F , the button is useless under the AUTO

mode.

(4) Time Switch

You can start and stop the machine according to the setting

time with the remote controller.

(5) SLEEP State Control

a. When the indoor unit is in the COOL or DRY mode, and the

SLEEP mode has been set, after about 1 hour, the

pre−setting T will raise 1.8°F. It will raise another 1.8°F again

after 2 hours. It will raise 3.6°F in 2 hours, then it will run on at

the setting temperature and fan speed.

b. When the indoor unit is in the HEAT mode, and the Timer

has been set, after about 1 hour, the pre−setting T will reduce

1.8°F, and it will reduce another 1.8°F again after 2 hours. It

will reduce 3.6°F in 2 hours, then it will run on at the setting

temperature and blower speed.

c. The set point stays the same under the FAN mode and

AUTO mode.

(6) Indoor Fan Control

The Indoor Fan can be set to HIGH, MED, LOW by remote

control, and the Indoor Fan will be respectively run at high,

medium, low speed. It can also be set as AUTO.

In moisture removal mode, the Indoor Fan will be set to low

speed.

(7) Buzzer Control

The buzzer will send a “Beep” sound when the indoor unit is

powered up or receives the information sent by the remote

control or there is a button pushed.

(8) Auto button

If the controller is on, it will stop when the button is pressed. If

the controller is off, it will start when the button is pressed. The

swing light will be on, and the main unit will run based on the

remote controls current settings.

(10) Display

a. Operation pattern and mode pattern display

All the display patterns will display for a time when the unit is

powered on, the operation indication icon will display in red

under standby status. When the machine is started by remote

controller, the indication icon will light and display the current

operation mode (the mode light includes: Cooling, Heating

and Dry). If you press the light button, all the display icons will

go dark.

b. Double−8 display

According to the settings of the remote control, the display

may show the current temperature (the temperature scope is

from 61°F to 86°F) on the indoor ambient temperature. The

heating and air supply temperature will display 77°F under

auto−mode, the temperature will display 64°F under the

heating mode, and the temperature will display H1 under the

defrosting mode.(If you set the Celsius temperature display,

the display will show according to Celsius temperature)

(11) Protection function and failure display

E2: Freeze−proofing E4: Exhaust protection E5: Over−current

protection

E6: Communication failure E8: Overload protection

F1: Indoor ambient sensor start and short circuit (continuously

measured failure for 30S)

F2: Indoor evaporator sensor start and short circuit

(continuously measured failure for 30S)

F3: Outdoor ambient sensor start and short circuit

(continuously measured failure for 30S)

F2: Outdoor condenser sensor start and short circuit

(continuously measured failure for 30S, and not measured

within 10 minutes after defrosted)

F5: Outdoor exhaust sensor start and short circuit

(continuously measured failure for 30S after the compressor

has operated 3 minutes)

H3: Overload protection of compressor H5: Module protection

PH: High−voltage protection PL: Low−voltage protection

P1: Nominal cooling and heating P2: Maximum cooling and

heating

P3: Medium cooling and heating P0: Minimum cooling and

heating

(12) Drying Function

You may start or stop the dry function under the cooling and

dry modes. Automatic heating and air modes do not support

the dry function).

30 421 08 9205 00

(13) Memory function when interrupting the power supply

Memory content: mode, swing function, light, set temperature

and blower speed.

After power is interrupted, the machine will start according to

the content of the memory automatically. If the last remote

control command has not set a timed function, the system will

remember the last remote control command and operate

accordingly. If the last remote control command has set a

timed function and the power supply is interrupted before the

time expires, the system will remember the timed function of

the last remote control command, the timed time will be

recounted from power on. If the last remote control command

has set a timed function, the time is up and the system is

started or stopped according to the set time when the power

supply is interrupted, the system will remember the operation

status before the power supply was interrupted, and not carry

out the timed action; The time clock will not be remembered.

Detection of Temperature Sensor Malfunction

Indoor Temperature Sensor

Malfunctions of the temperature sensor can be detected at

any time.

Indoor Pipe Temperature Sensor

During defrost, a temperature sensor malfunction will not be

detected. Five minutes after finishing defrost, the system will

again begin to detect temperature sensor malfunctions. At all

other times, a temperature sensor malfunction will be detected

when:

1. A short−circuit occurs to the temperature sensor for 30

seconds: The temperature sensor overheats. In this case to

protect the system, the entire unit will stop. At the same time,

the temperature protection and temperature sensor

malfunction will be shown.

2. An open circuit of the temperature sensor occurs for 30s:

The unit will stop and the temperature sensor malfunction will

be displayed

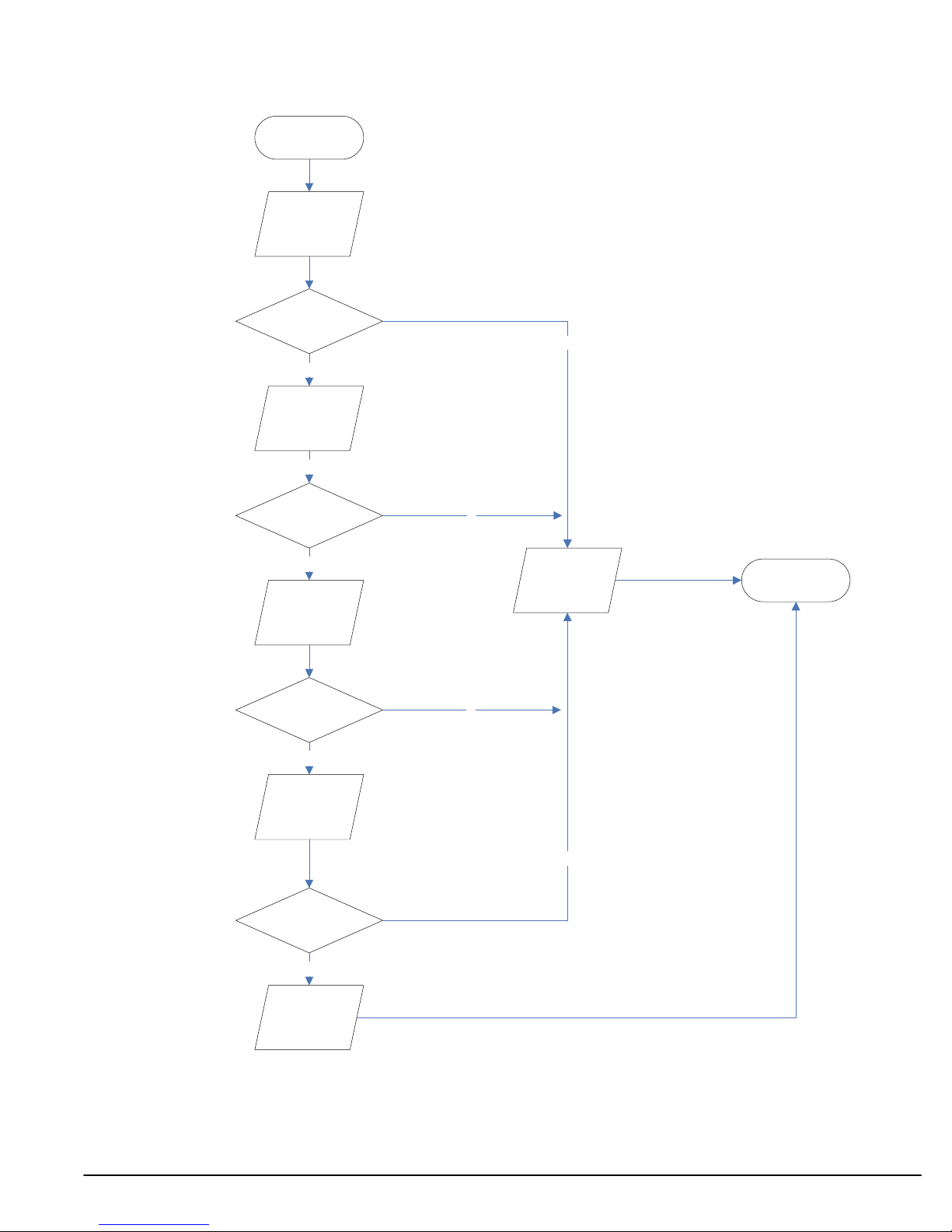

Frequency Control

When starting the compressor, or when conditions have

varied due to the changes in the room, the frequency must be

initialized according to the DD value of the indoor unit and the

Q value of the indoor unit. Q value: Indoor unit output

determined from indoor unit volume, air flow rate and other

factors.

Compressor Protection Function

When turning the compressor from OFF to ON, the system

will ramp the frequency up from a lower starting limit to protect

the compressor.

Figure 27 - Compressor Frequency (When the

compressor is turned off, it cannot be turned back on for

3 minutes, except after defrost.

Discharge Pipe Control

The discharge pipe temperature is used as the compressor’s

internal temperature. If the discharge pipe temperature rises

above a certain level, the operating frequency upper limit is

set to keep this temperature from going up further.

Input Current Control

Detects an input current with the current transformer as the

compressor is running, and sets the upper frequency limit

from the input current.

In the case of a heat pump, this control is the upper limit

control function of the frequency, which takes priority over the

lower limit of four way valves activation compensation.

Freeze−up Protection Control

During cooling operation, the signals being sent from the

indoor unit allow operating frequency limitation and then

prevent freezing of the indoor heat exchanger.

Heating Peak−cut Control: Heat−Pump Only

During heating operation, the signals being sent from the

indoor unit allow operating frequency limitation and prevent

abnormally high pressure.

Defrost Control: Heat Pump Only

Defrosting is carried out by the cooling cycle (reverse cycle).

The defrost time must be complete or the outdoor heat

exchanger temperature must be more than its preset value

when finishing.

Conditions for Starting Defrost

The starting conditions must be determined by the outdoor air

temperature and heat exchanger temperature. When the

system is in heating operation, 6 minutes after the

compressor is started, and more than 44 minutes of

accumulated time has passed since the start of the operation

or end of defrost.

Conditions for Canceling Defrost

The heat exchanger temperature must be between

(39°F−72°F)

Fan Control

Fan control is carried out according to the following

priority.

1. Fan ON control for electric component cooling fan

2. Fan control when defrosting

3. Fan OFF delay when stopped

4. ON/OFF control in cooling operation

5. Speed control when frequency adjustment function is

working

6. Fan control in forced operation

7. Fan control in indoor/outdoor unit silent operation

8. Fan control in powerful mode

9. Fan control in normal operation

Fan OFF Control when Stopped

Fan OFF delay for 60 seconds must be made when the

compressor is stopped.

Speed Control in indoor/outdoor unit silent operation

1. When in Cooling Operation

When the outdoor air temperature is lower than 99°F, the

speed tap must be set to Low.

2. When in Heating Operation

When the outdoor air temperature is higher than 39°F, the

speed tap must be set to Low (only for heat pump model).

421 08 9205 00 31

TROUBLESHOOTING

Precautions for Performing Inspections and Repairs

Be cautious during installation and maintenance. Follow all

rules and regulations to avoid electric shock and to prevent

injury or damage.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position.

There may be more than one disconnect switch. Lock out

and tag switch with a suitable warning label.

Static Maintenance

Static Maintenance is maintenance during de−energization of

the indoor unit.

For static maintenance, make sure that the unit is

de−energized and the plug is disconnected.

Dynamic Maintenance

Dynamic maintenance is the maintenance during energization

of the unit.

Before dynamic maintenance, check the electricity and

ensure that there is a good ground. Check if there is electricity

on the case and copper pipe of the indoor unit with a voltage

tester.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

A large−capacity electrolytic capacitor is used in the

outdoor unit controller (inverter). When the power supply

is turned off, charge (charging voltage DC280V to 380V)

remains and takes a long time to discharge.

Do Not open the outdoor unit for 20 minutes after power

has been turned OFF.

Take sufficient care to avoid directly touching any of the circuit

parts without first turning off the power.

At times, such as when the circuit board is to be replaced,

place the circuit board assembly in a vertical position.

Diagnose troubles according to the trouble diagnosis

procedure as described below.

Also refer to the check points in servicing written on the wiring

diagrams attached to the indoor/outdoor units.

No. Trouble Shooting Procedure

1 Confirmation

2 Code displays interpretation of error codes.

3 Basic System Check

WARNING

Confirmation:

1. Confirmation of Power Supply: Confirm that the

power breaker operates normally and provides power

2. Confirmation Voltage: Confirm that voltage is AC

220−240 ±10%. If voltage is not in this range, the unit

may not operate normally.

32 421 08 9205 00

TROUBLESHOOTING (CONTINUED)

Display and Interpretation of Error Codes:

This unit has on−board diagnostics. Error codes will appear on the LED display on the front panel of the indoor unit in place of

the temperature display. Error codes are also displayed on the outdoor unit microprocessor board with colored LED lights. The

table below explains the error codes for both units.

Diagnostic Codes

DLC/DLF4(A,H)6 9k / 12k, 115v

Malfunction

Indoor PCB Malfunction EE Replace indoor main board

Anti-freeze Protection E2 Outdoor ambient temperature is too low

System overload protection H4 Check for dirty or blocked heat exchangers

Indoor motor malfunction H6 Check motor mounting and wiring

Indoor pipe temperature sensor malfunction F2 Measure the resistance value in the sensor

Return air temperature sensor malfunction F1 Measure the resistance value in the sensor

Indoor board malfunction UF Replace indoor main board

Compressor overload protection H3 Check overload wiring

Compressor start-up failure Lc

Outdoor fan motor failure UH Check outdoor motor

Low voltage protection E5 Check incoming power

4-way valve malfunction U7 Replace 4-way valve

Compressor phase detection error U1 Replace outdoor main board

Compressor speed reduction H7

Current detection malfunction U5 Replace outdoor main board

Outdoor ambient temperature sensor

malfunction

Discharge temperature sensor malfunction

(out of range)

Discharge temperature sensor malfunction

(open or shorted)

Condenser temperature sensor malfunction

(open or shorted)

Heat sink over-temperature P8

DC over-current UU --

Heat sink temperature sensor malfunction P7 Replace outdoor main board

Low charge F0 Check for leaks

DC input voltage is too high PH Check incoming power supply

DC input voltage is too low PL Check incoming power supply

Communication malfunction E6 Check wiring connection

Indoor and outdoor unit mismatched UA Check system combination

Remarks:

Error Code

on indoor unit

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

F3 Measure the resistance value in the sensor

E4 Measure the resistance value in the sensor

F5 Measure the resistance value in the sensor

F4 Measure the resistance value in the sensor

Is outdoor ambient temperature out of system operating range?

Is heat sink blocked or damaged?

4 minutes after the compressor has stopped due to a protection error, an error code will

be displayed. To display other errors, press the LIGHT button six (6) times within four (4)

seconds.

NOTE: Refer to Appendix Tables on pages 60-62 for sensor information.

Repair Method/Cause

421 08 9205 00 33

TROUBLESHOOTING (CONTINUED)

Diagnostic Codes

DLC/DLF4(A,H)6 12K, 230v

Malfunction

Indoor PCB Malfunction EE Replace indoor main board

Anti-freeze Protection E2 Outdoor ambient temperature is too low

System overload protection H4 Check for dirty or blocked heat exchangers

Indoor motor malfunction H6 Check motor mounting and wiring

Indoor pipe temperature sensor malfunction F2 Measure the resistance value in the sensor

Return air temperature sensor malfunction F1 Measure the resistance value in the sensor

Indoor board malfunction UF Replace indoor main board

Compressor overload protection H3 Check overload wiring

Compressor start-up failure Lc

Outdoor fan motor failure UH Check outdoor motor

Low voltage protection E5 Check incoming power

4-way valve malfunction U7 Replace 4-way valve

Compressor phase detection error U1 Replace outdoor main board

Compressor speed reduction H7

Current detection malfunction U5 Replace outdoor main board

Outdoor ambient temperature sensor mal

function

Discharge temperature sensor malfunction

(out of range)

Discharge temperature sensor malfunction

(open or shorted)

Condenser temperature sensor malfunction

(open or shorted)

Heat sink over temperature P8

DC over-current H5 --

Heat sink temperature sensor malfunction P7 Replace outdoor main board

Low charge F0 Check for leaks

DC input voltage is too high PH Check incoming power supply

DC input voltage is too low PL Check incoming power supply

Communication malfunction E6 Check wiring connection

Indoor and outdoor unit mismatched UA Check system combination

Error Code on in

door unit

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

F3 Measure the resistance value in the sensor

E4 Measure the resistance value in the sensor

F5 Measure the resistance value in the sensor

F4 Measure the resistance value in the sensor

Is outdoor ambient temperature out of system operating range?

Is heat sink blocked or damaged?

Repair Method/Cause

NOTE: Refer to Appendix Tables on pages 60-62 for sensor information.

34 421 08 9205 00

TROUBLESHOOTING (CONTINUED)

Diagnostic Codes

DLC/DLF4(A,H)6 18k−24k, 230v

Malfunction

System high pressure protection E1

Anti-freeze Protection E2 Outdoor ambient temperature is too low

Discharge temperature sensor malfunction

(out of range)

Low voltage protection E5 Check incoming power

Communication malfunction E6 Check wiring connection

System overload protection E8 Refer to Service Manual

Indoor board malfunction U8 Replace indoor main board

Indoor motor malfunction H6 Check motor mounting and wiring

Missing jumper from indoor board C5

Return air temperature sensor malfunction F1 Measure the resistance value in the sensor

Indoor pipe temperature sensor malfunction F2 Measure the resistance value in the sensor

Outdoor ambient temperature sensor malfunc

tion

Condenser temperature sensor malfunction

(open or shorted)

Discharge temperature sensor malfunction

(open or shorted)

Overload limit, compressor speed reduction F6 Refer to Service Manual

Over current compressor speed reduction F8 System voltage is too low or system voltage is high

Compressor discharge temperature high,

compressor speed reduction

Over voltage protection PH Check incoming power supply

Current detection malfunction U5 Replace outdoor main board

Compressor current protection P5 Refer to Service Manual. Check inverter board.

Defrosting H1 H1 signal normal operation

Compressor overload protection H3 Check overload wiring

System overload protection H4 Checked for dirty or blocked heat exchangers

IPM protection H5 IPM module over temperature, low voltage, silica grease problem

PFC (power factor correction) board protec

tion

Compressor speed reduction H7

Ambient temperature cut off range H0 Refer to Service Manual (overload, high temperature, cutout)

Compressor start-up failure LC

Compressor phase detection error U1 Replace outdoor main board

Error Code

on indoor unit

Poor heat exchange. Are the coils clogged or blocked? Is the ambi

ent temperature out of system range?

E4 Measure the resistance value in the sensor

No jumper on controller or installed improperly or damaged. Corres

ponding circuit on main board has malfunction.

F3 Measure the resistance value in the sensor

F4 Measure the resistance value in the sensor

F5 Measure the resistance value in the sensor

Load is too great

F9

HC Refer to Service Manual

Ambient temperature too high

Refrigerant is low

Electric expansion valve malfunction

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

Check if the resistance of the compressor and the resistance to

ground is normal. If the resistance is normal, the outdoor main

board may be defective.

Repair Method/Cause

NOTE: Refer to Appendix Tables on pages 60-62 for sensor information.

421 08 9205 00 35

TROUBLESHOOTING (CONTINUED)

Malfunction Analysis

Note: When replacing the controller, make sure to insert the

jumper into the new controller, otherwise the unit will display C5

Tripped breaker

or blown fuse

The air conditioner does not

react after it is

powered (after