International Comfort Products CRHEATER101A00, CRHEATER119A00, CRHEATER125A00, CRHEATER364A00, CRHEATER369A00 Installation Manual

...

CRHEATER101A00 -CRHEATER119A00,

CRHEATER125A00,

CRHEATER364A00 -CRHEATER369A00,

CRSINGLE001A00 -CRSINGLE053A00

SMALL ROOFTOP UNITS

ACCESSORY ELECTRIC HEATER

AND SINGLE POINT BOX

ELECTRIC COOLING AND HEAT PUMP

Installation Instructions

2to12

1

/2TONS

TABLE OF CONTENTS

SAFETY CONSIDERA TIONS 1....................

INSTALLATION 2...............................

IMPORTANT: Read these instructions completely before

attempting to install this accessory.

PACKAGE CONTENTS--

ELECTRIC HEATER

QTY CONTENTS

1 Heater module

4 Screws

1 Wiring label

1 Red wire (10 gauge)*

1 Splice connector*

1 Wire tie*

* Supplied with electric heater packages CRHEATER101A00,

CRHEATER102A00, CRHEATER103A00, and CRHEATER104A00 only.

PACKAGE CONTENTS--

SINGLE POINT KIT*

QTY CONTENTS

1 Single point box

1 Bushing

5 Screws

1 Bracket and conduit drip boot assembly

1

2 Terminal Blocks (TB10A and TB10B)**

2 Screws (for TB10’s)**

* Single point kit not required on standard efficiency, 2 to 6 ton cooling

units with an MOCP of 60 or lower. Heater wires are to be terminated

inside unit control box.

** Supplied with single point boxes C RSINGLE039A00, 045, 049, and 051

only.

Tube clamp (used only on 3 and 4 ton

heat pump units)

SAFETY CONSIDERATIONS

Installation and servicing of air--conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair, or service air-conditioning

equipment.

Untrained personnel can perform the basic maintenance

functions. All other operations should be performed by

trained service personnel. When working on

air-conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves.

Recognize safety information. This is the safety--ale rt

symbol

instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, W ARNING, and

CAUTION. These words are used with the safety--alert

symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify

unsafe practices which may result i n minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Turn off power to unit and install lockout tag.

. When you see this symbol on the unit and in

!

WARNING

INSTALLATION

1. Re move electric heater modules and single point

box from packaging and inspect for damage.

NOTE: If there is a “1” or a “3” in the ninth position of

the heater part number, it indicates that the heater is in a

carton. For exam ple, CRHEATER105A00 is heater

CRHEATER005A00 in a carton, and CRHEATER364A00

is heater CRHEATER264A00 in a carton.

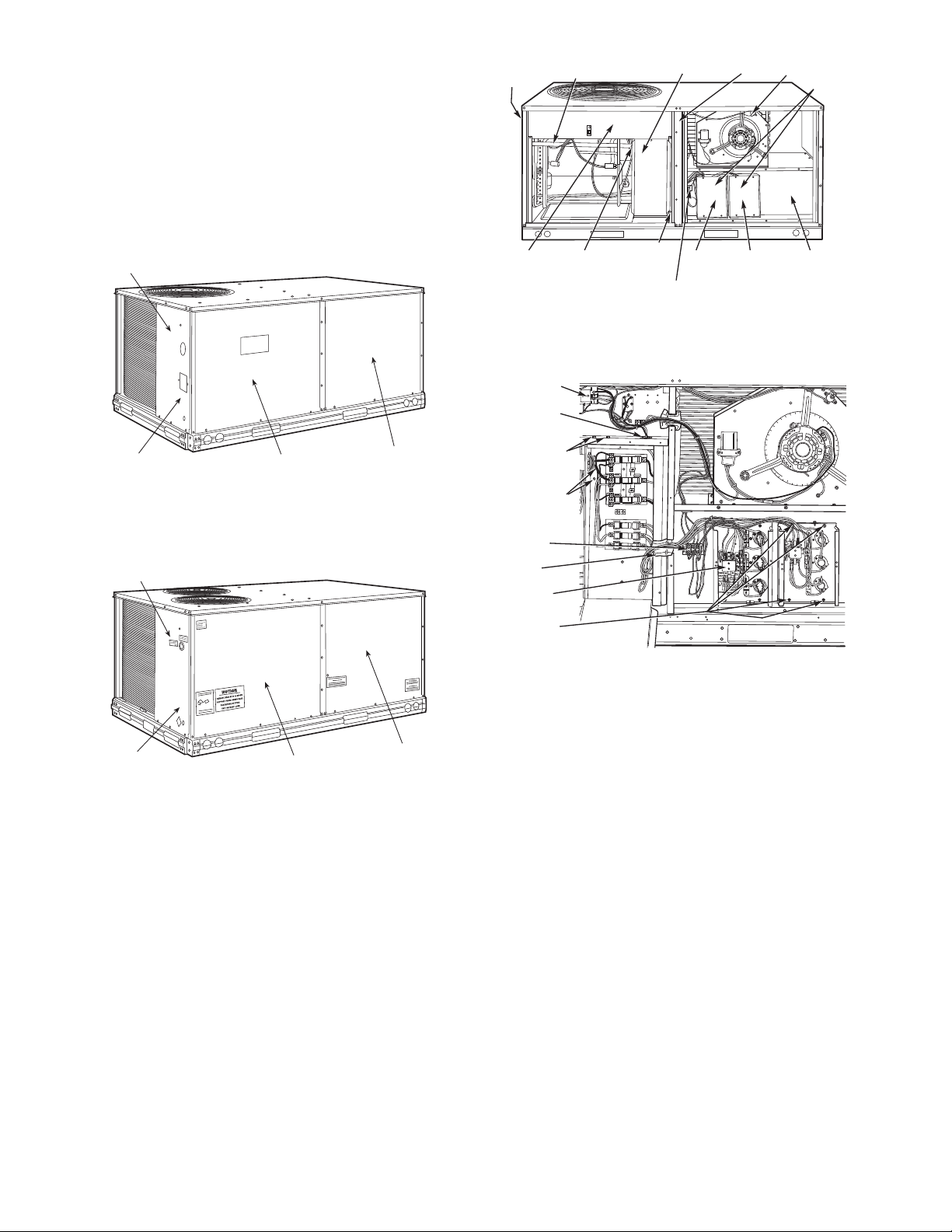

2. Remove indoor and outdoor access panel. (See Fig.

1 and 2.) Save panels and screws.

DISCONNECT MOUNTING

LOCATION

DISCONNECT

MOUNTING

LOCA TION

BRACKET AND

MAIN

CONDUIT

CONTROL

DRIP BOOT

BO X

SINGLE

POINT

EM T OR RIGID CONDUIT

(FIELD-SUPPLIED)

SINGLE POINT

BO X

MOUNTING

SCREW

BO X

(NOT SHIPPED

WITH UNIT)

HEA TER

MODULE

(LOCA TION 1)

MANUAL RESET

CENTER

LIMIT SWITCH

POST

HEA TER

MODULE

(LOCA TION 2)

CONTRO L WIRE TERMINAL BLOCK

Fig. 3 -- Typical Component Location

(2to6TonR--22UnitShown)

HEA TER

COVERS

HEA TER

MOUNTING

BRACKET

C08451

UNIT BLOCK-OFF

PANEL

OUTDOOR

ACCESS PANEL

INDOOR

ACCESS

PANEL

C08133

Fig. 1 -- Typical Access Panel Location

(2 to 6 Ton Units)

DISCONNECT MOUNTING

LOCATION

UNIT

BLOCK-OFF

PANEL

OUTDOOR

ACCESS PANEL

INDOOR

ACCESS

PANEL

C08416

Fig. 2 -- Typical Access Panel Location

1

/2to 121/2Ton U nit s )

(7

3. Re move control box cover and center post. Save

screws.(SeeFig.3)

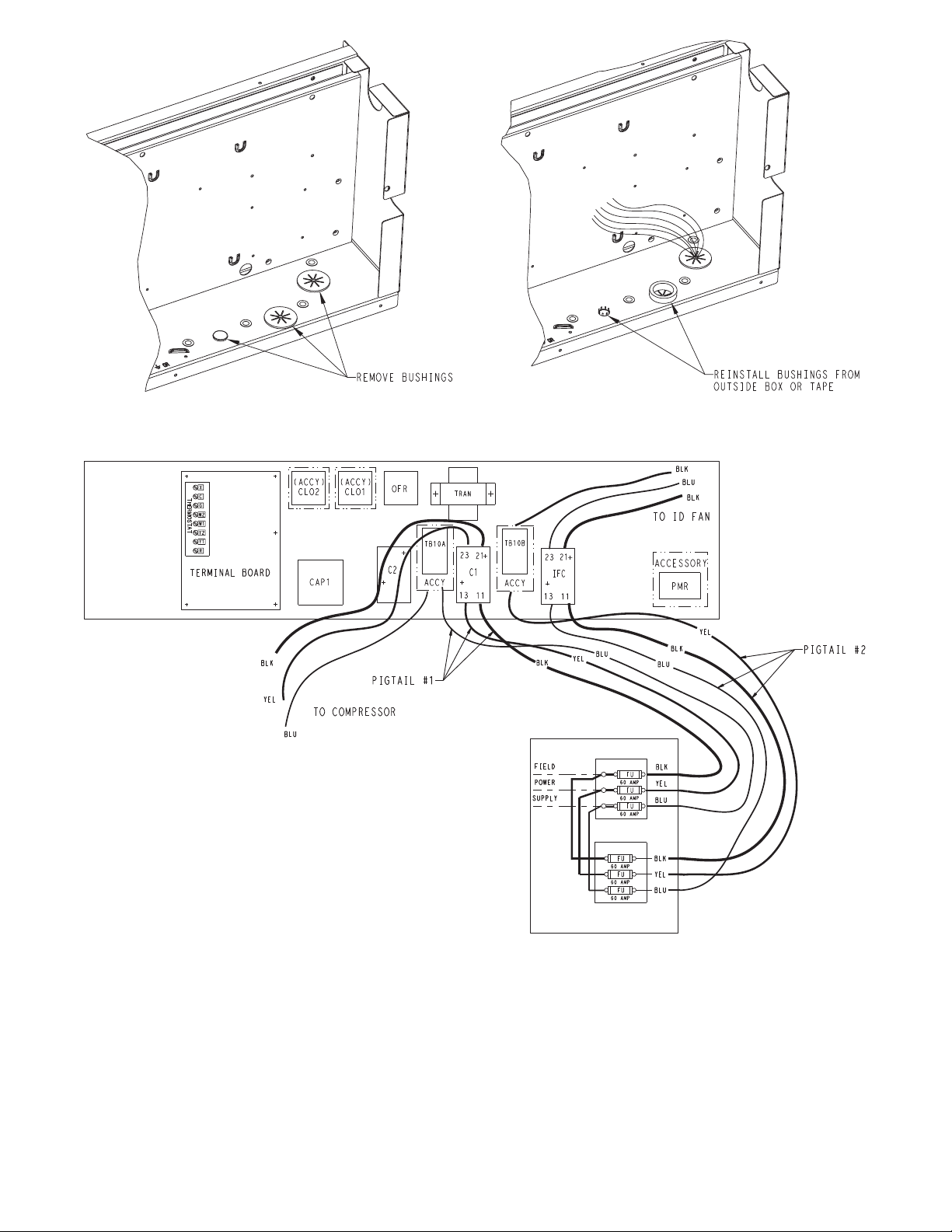

4. Re move the single point box cover. Secure single

point box to the underside of the control box with

the 2 screws provided. (See Fig. 4.)

S On R--410A units, which use single point boxes

CRSINGLE037A00 through CRSINGE053A00,

all bushings in the area of the control box where the

single point box (SPB) mounts must be removed

prior to securing the SPB to the control box (see

Fig. 5). Also, for units installed in the Snow Belt,

all unplugged holes in the bottom of the control box

which are not used must be plugged before

installing the SPB. Use foil tape or reinstall the

bushings from the outside of the control box prior

to securing the SPB (see Fig. 6). Reinstall bushing

on the SPB pigtails (see Fig. 6).

CONTROL

BOX

2

1

1

1

2

13

3

BUSHING

SINGLE

POINT BOX

MOUNTING

SCREWS

DRIP BOOT

BRACKET

MOUNTING

SCREWS

POWER

WIRES

FOAM

BUSHING

HEATER

RELAYS

HEATER

MOUNTING

SCREWS

21

23

11

13

A

L

LIE

D

P

A

C

O

R

P

.

M

O

D

E

L

N

O

.

O

D

ERI

A

L

N

O

.

2

2

.

2

ISTED

AIR

NDITIONING

1

2

3

UIP

ACCESS

346N

.

3

P

/ N

2-

5

6

10

REV

4

Fig. 4 -- Typical Single Point Kit Installation

S On R--410A units with an MOCP > 60, which use

single point boxes CRSINGLE039A00, 045A00,

049A00, and 051A00, two terminal blocks (TB10A

and TB10B) and two attachment screws are

provided. Install the two terminal bl ock into the

control box and terminate the two -- 3 wire power

pigtails as follows (see Fig. 7):

— Pigtail #1 (from top fuse block; long blue

wire with female terminal) — Connect

black wire to C1 --11 screw terminal,

connect yellow wire to C1-- 13 screw

terminal, connect blue wire to TB10A

terminal block and move Compressor 1 blue

wire from IFC--13 to TB10A terminal

block.

— Pigtail #2 (from second fuse block; long

yellow wire with female terminal) —

Connect black wire to IFC--11 screw

terminal, connect blue wire to IFC--13

screw terminal, connect yellow wire to

TB10B terminal block and move ID Fan

yellow wire from C1--13 to TB10B terminal

block.

— Remove black jumper wire from C1-- 11 to

IFC--11.

2

C08136

Fig. 5 -- Control Box -- Bushings to Remove

C09005

C09006

Fig. 6 -- Bushings Replaced from Outside Control Box

Fig. 7 -- Wiring Diagram

5. Sec ure the conduit drip boot bracket assembly to the

back of the single point box with 2 of the screws

provided. (See Fig. 4.) The channel portion of the

bracket assembly extends to the top panel behind

the control box. Secure all wires to bracket with

field--supplied wire tie as shown. (See Fig. 8.)

C09007

NOTE: The conduit drip boot and bracket are not used

on standard efficiency 2 to 6 ton electric cooling units and

R--410A 3--6 ton electric cooling units.

6. Remove heater cover(s) from heater mounting.

bracket. Save screws. Install single module electric

heat option in location 1 (nearest the single point

box). (See Fig. , Fig. 9, and Fig. 10.)

3

Loading...

Loading...