International Comfort Products CRLPELEV001A00, CRLPELEV004A00, CRLPELEV007A00, CRLPELEV009A00 Installation Manual

CRLPELEV001A00-CRLPELEV004A00

CRLPELEV007A00-CRLPELEV009A00

Installation Instructions

TABLE OF CONTENTS

PACKAGE CONTENTS 1.........................

SAFETY CONSIDERATIONS 2....................

GENERAL 2....................................

LP CONVERSION KIT INSTALLATION 3...........

Step 1 -- Remove Burner Section from Base Unit 3..........

Step 2 -- Modify Burner/Valve Assembly 3.................

Step 3 -- Re--install Burner Assembly 5....................

Step 4 -- Check Unit Operation and Make Necessary

Adjustments 6................................

SMALL ROOFTOP UNITS

ACCESSORY LP (LIQUID PROPANE)

HIGH ALTITUDE GAS CONVERSION KIT

GAS HEATING/ELECTRIC COOLING

3to15TON

60,000---350,000 Btu/hr

HIGH ALTITUDE CONVERSION KIT

INSTALLATION 7...............................

Step 1 -- Remove Burner Section from Base Unit 7..........

Step 2 -- Modify Burner/Valve Assembly 7.................

Step 3 -- Re--install Burner Assembly 7....................

Step 4 -- Check Unit Operation and Make Necessary

Adjustments 8................................

IMPORTANT: Read these instructions completely before

attempting to install this accessory.

ACCESSORY

PAR T NO.

CRLPELEV001A00

CRLPELEV002A00

CRLPELEV003A00

CRLPELEV004A00

CRLPELEV007A00

CRLPELEV008A00

CRLPELEV009A00

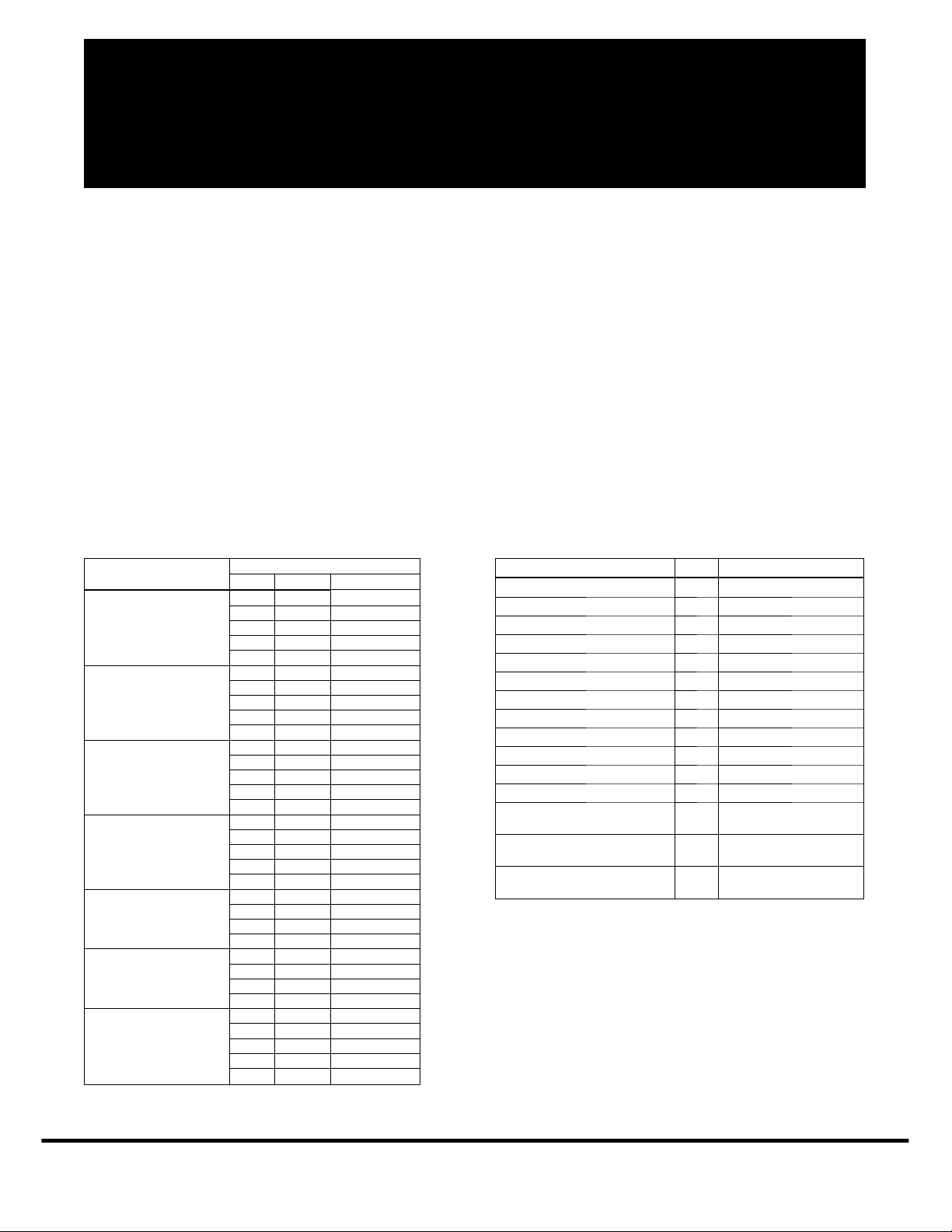

PACKAGE CONTENTS

LP (LIQUID PROPANE) AND HIGH ALTITUDE KIT

SIZE QTY PAR T NU M BE R

ORIFICES

31 5 LH32RF120

32 5 LH32RF116

33 5 LH32RF113

35 5 LH32RF110

36 5 LH32RF105

37 5 LH32RF104

38 5 LH32RF102

39 5 LH32RF103

44 5 LH32RF086

45 5 LH32RF082

46 5 LH32RF080

47 5 LH32RF079

48 5 LH32RF076

49 5 LH32RF073

50 5 LH32RF070

51 5 LH32RF067

52 5 LH32RF065

53 5 LH32RF060

54 5 LH32RF055

55 5 LH32RF052

36 10 LH32RF105

37 10 LH32RF104

38 10 LH32RF102

39 10 LH32RF103

40 10 LH32RF098

41 10 LH32RF096

42 10 LH32RF094

43 10 LH32RF089

51 10 LH32RF067

52 10 LH32RF065

53 10 LH32RF060

54 10 LH32RF055

55 10 LH32RF052

COMMON CONTENTS QTY PA R T N UMB E R

INSTRUCTIONS 1 I I K --- CR L P E L E V 0 1 --- 0 3

ELBOW, 1/8” NPT x 90° 1 CA05RA001 *

ELBOW, STREET1/8” NPT x 90° 1 CA15RA001 *

NIPPLE,1/8”PIPEx3/4” 1 CA01CA001 *

NIPPLE,1/8”PIPEx11/2” 1 CA01CA006 *

NIPPLE,1/8”PIPEx31/2” 1 CA01CA020 *

SWITCH, LP PRESSURE 1 HK02LB008 *

WIRE, BROWN 1 99WG7373XC200918 *

SPRINGS, LP CONVERSION 2 EF39ZW023 *

LABEL, GAS VALVE LP CONV 1 48TM501013 *

LABEL, UNIT WARNING 1 48TM501012

LABEL, LP RESPONSIBILITY 1 48TM501014 *

L A B E L , H I G H --- A LT.

RESPONSIBILITY

LABEL, LP CONVERSION KIT

RATING PLATE

LABEL, NG CONVERSION KIT

RATING PLATE

* Only used in LP applications

1 48TM501015

1 48TM502595 *

1 48TM502594

Copyright 2010 CAC / BDP D 7310 W. Morris St. D Indianapolis, IN 46231 Printed i n U.S.A. Edition Date: 06/10

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

C a t a l o g N o : I I K --- C R L P E L E V 0 1 --- 0 3

R e p l a c e s : I I K --- C R L P E L E V 0 1 --- 0 2

SAFETY CONSIDERATIONS

Installation and servicing of air--conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair, or service air--conditioning

equipment.

Untrained personnel can perform the basic maintenance

functions. All other operations should be performed by

trained service personnel. When working on

air--conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other

safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves.

Recognize safety information. This is the safety--alert

symbol

instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert

CRLPELEV

symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

. When you see this symbol on the unit and in

GENERAL

These models are shipped from the factory equipped to

operate with natural gas at elevations up to 2000 ft

(610 m). The units must be modified if installed at

elevations above 2000 ft (610 m), or if operated with

liquid propane.

For installations in Canada, the input rating must be

derated by 10% for altitudes of 2000 ft (610 m) to 4500 ft

(1372 m) above sea level.

Seven different gas conversion kits are available, as

shown in Package Contents table. Each kit contains a

particular range of orifice sizes plus other hardware and

labels necessary for converting the unit. Refer to Table 1 –

Altitude Compensation to determine the recommended

orifice size based on the nominal heat size, fuel type, and

elevation. Knowing this orifice size, it is possible to select

the proper Kit Accessory Part Number from Package

Contents table.

!

WARNING

FIRE, EXPLOSION, CARBON MONOXIDE

POISONING, PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

This conversion kit shall be installed by a qualified

service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements

of the authority having jurisdiction. The qualified

service agency is responsible for the proper

installation of this kit. The installation is not proper

and complete until the operation of the converted

furnace is checked as specified in the manufacturer’s

instructions supplied in the kit.

!

AVERTISSEMENT

FEU, EXPLOSION, EMPOISONNEMENT PAR

CARBON DE MONOXYDE, RISQUE DE

DOMMAGE ÀLAPROPRIÉTÉ

La négligeance de suivre l’avis suivant, peut causer

des blessures personnelles, la mort ou du dommage à

la propriété.

Cette trousse de conversion doit être installée par un

Entrepreneur qualifié, selon les instructions du

fabricant et doit se conformer à toutes les exigences et

tout les codes pertinents de l’autorité compétente.

L’Entrepreneur qualifié est responsable, et doit

s’assurer de bien suivre les instructions dans cet avis.

L’installation sera considèrèè conforme et rencontrant

les spécifications et instructions du fabriquant qui sont

inclus dans la trousse, seulement aprés vérification de

l’opération de la fournaise convertie.

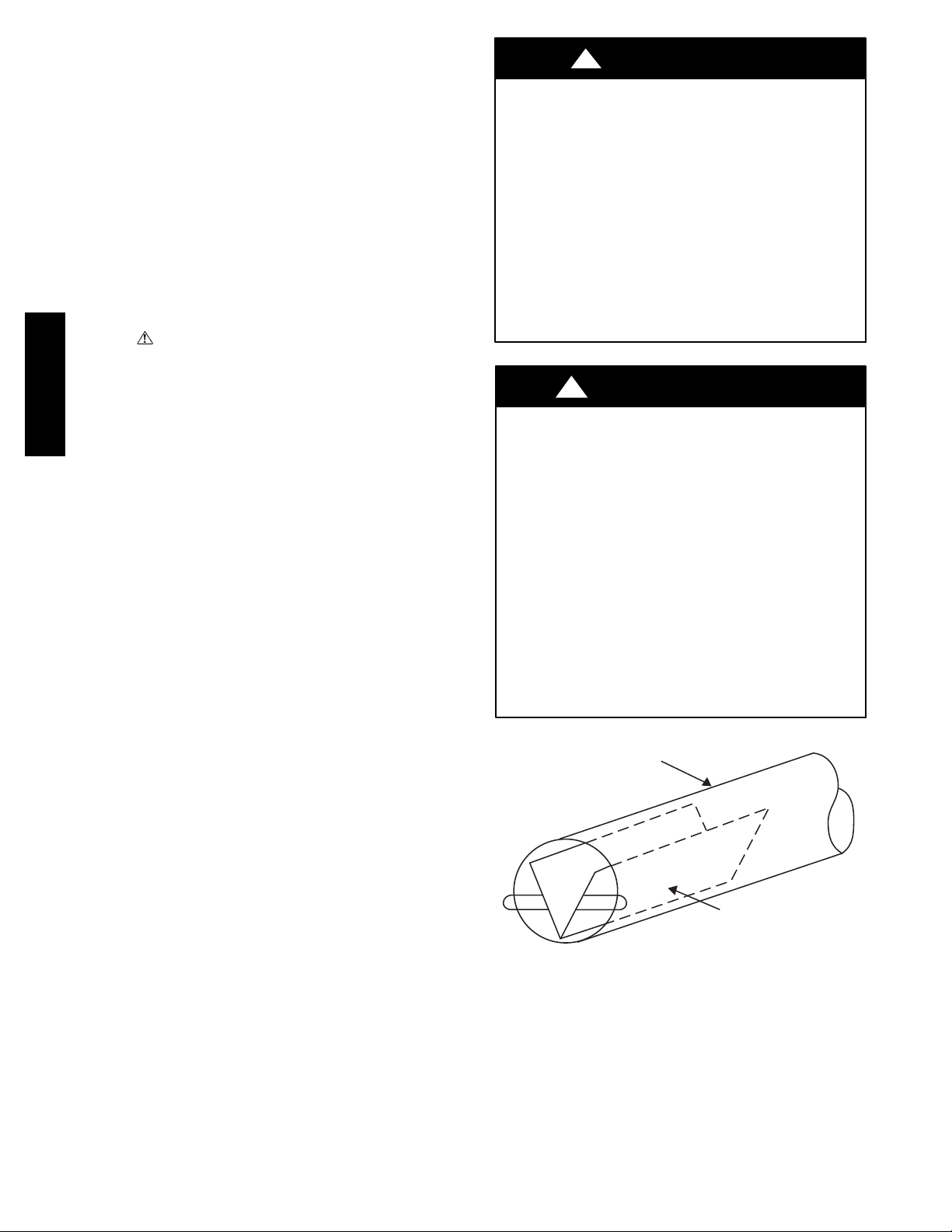

Firing Tube

NOx Baffle

IMPORTANT: The Accessory LP Conversion is not for

use with Low NOx units. If Low NOx units are converted

to LP gas, the Low NOx baffle must be removed. (See

Fig. 1.) The unit will no longer be classified as Low NOx

units. It is suggested that the LP Conversion Kit be used

with standard units only.

C00151

Fig. 1 -- Low NOx Baffle Location

2

!

WARNING

EXPLOSION, PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal

injury or death.

Two--Stage Gas Valve -- Unit is designed to operate at

a 10.0--in. wc of manifold pressure on HIGH stage and

5.0--in. wc on LOW stage with propane gas.

Single--Stage Gas Valve -- Unit is designed to operate

at a 10.0--in. wc of manifold pressure with propane gas.

!

WARNING

FIRE, EXPLOSION, ELECTRICAL HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

Gas supply MUST be shut off before disconnecting

electrical power and proceeding with conversion.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Tag disconnect switch with suitable

warning label.

LP CONVERSION KIT

INSTALLATION

Step 1 — Remove Burner Section from Base

Unit

1. Shut off main gas supply to unit.

2. Shut off power to unit and install lockout tag.

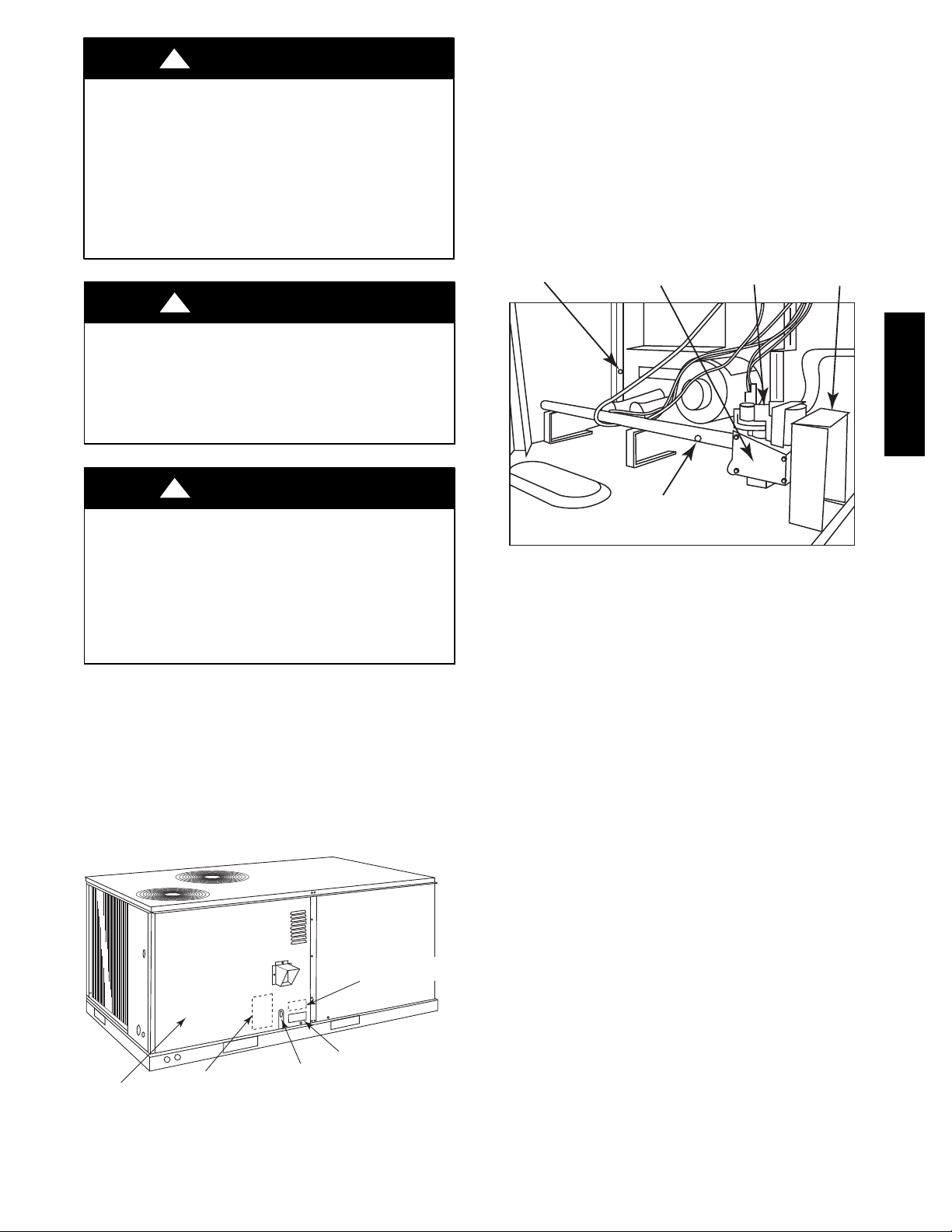

3. Remove burner access panel. (See Fig. 2.)

4. Slide out burner section side panel.

5. Disconnect gas piping at unit gas valve.

6. Remove wires connected to gas valve. Mark each

wire.

7. Remove igniter and sensor wires. Mark each wire.

8. For units with burner sections as shown in Fig. 3,

remove the 2 screws that attach the burner rack to

the vestibule plate. For units with burner sections

as shown in Fig. 5, remove the 4 screws that hold

the manifold to the sheet metal brackets.

Burner Rack

Mounting Screws

(1 of 2 shown)

Fig. 3 -- Gas Section Details (Small Chassis Shown)

Attach Gas Valve

Converstion to LP

Label here

Manifold Pressure Tap

Gas Valve

Manual

Shut-off

Gas

Valve

Bracket

C08237

9. Remove the gas valve bracket.

10. Slide the burner rack or manifold out of the unit.

11. For small chassis units only----inspect the inlet of the

heat exchanger tubes for presence of V--shaped NOx

baffles. (See Fig. 1.) If baffles are present, they must

be removed prior to converting unit for propane gas.

Using needle nose pliers, remove NOx baffles.

Squeeze sides of the baffle, if necessary, to remove

from the heat exchanger tubes.

IMPORTANT: If this unit will be converted back to

natural gas at a later time, these baffles should be retained

for reuse. Otherwise the baffles may be discarded.

CRLPELEV

Burner

Access

Panel

Attach Conversion Kit

Rating Plate Label Here

(Inside Panel)

Fig. 2 -- Typical Base Unit

Gas

Val ve

Attach Responsibility

Label Here

(Inside Panel)

Attach WARNING

Label Here

C09434

Step 2 — Modify Burner/Valve Assembly

1. Separate burners from frame by removing screws.

2. Remove existing gas orifices. Install the new orifices from the gas conversion kit, making sure they

match the recommended size from Table 1.

IMPORTANT: Never use Teflon tape to seal gas orifice

threads because peeling tape can plug the orifice.

3. Remount burners to support frame.

IMPORTANT: The burners should be positioned in the

same order as shipped from the factory. The crossover

flame region of the outermost burners are pinched off to

prevent excessive gas flow from the sides of the burner

assembly. If the pinched crossovers are installed between

two burners, the flame will not ignite properly.

3

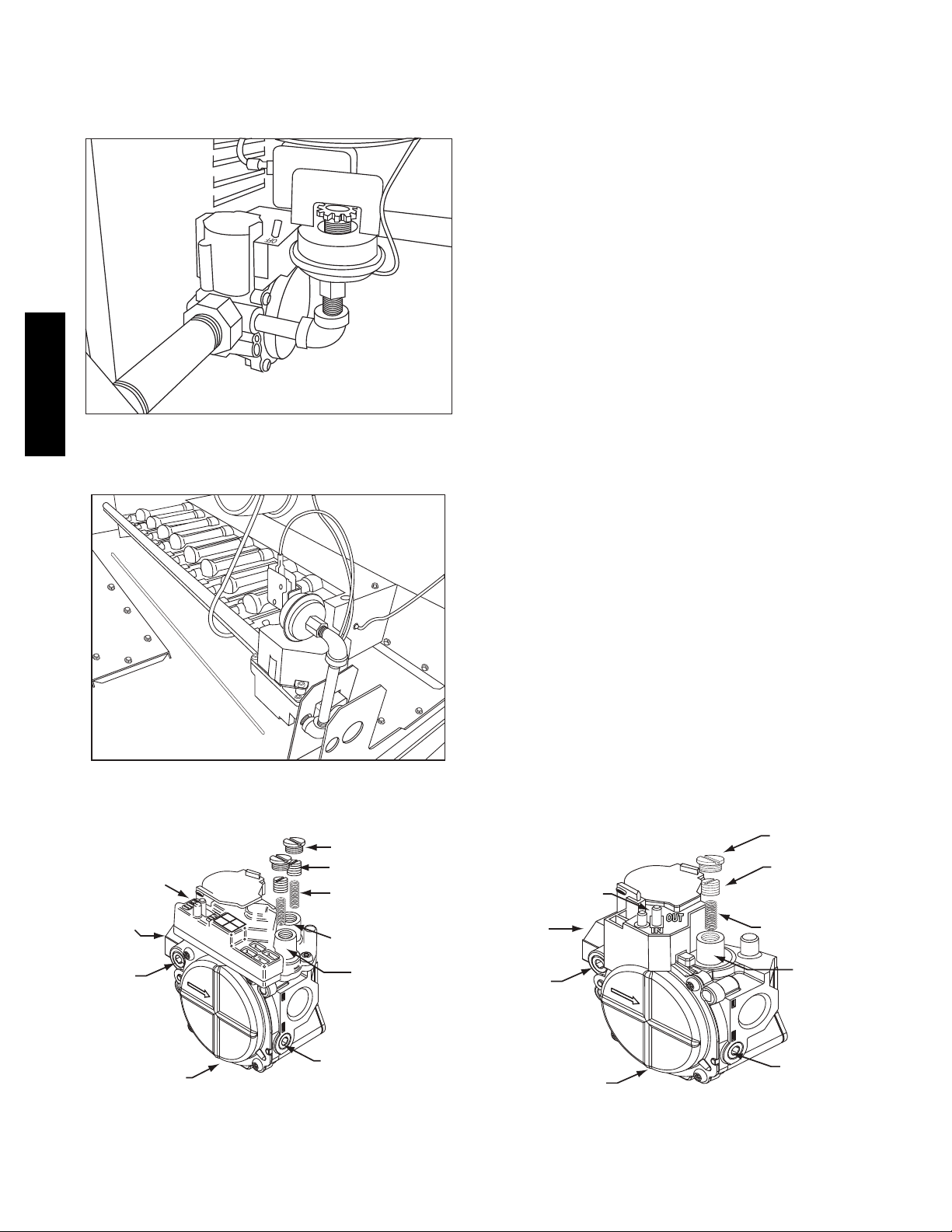

CRLPELEV

4. Remove the plug on the inlet end of the gas valve

3

using a

/16--in. hex wrench. (See Fig. 4 and 6 for

units using White--Rodgers 36G gas valve and Fig.

5 and 7 for units using White--Rodgers 36H gas

valve).

C08238

Fig. 4 -- LP Pressure Switch Piping

(36G Gas Valve Shown)

5. a. For units with 36G valve, install the1/8-- i n . x

1

/2--in. nipple where the plug was removed. (See

1

Fig. 4.) Use pipe thread dope or tape (field--supplied, must be certified for use with propane gas)

for all joints, making sure not to get any excess in

1

the pipe or valve. Next, install the

1

elbow, then

/8-- i n . x3/4--in. nipple, followed by the

/8-- i n . x 9 0 _

LPPressureSwitchasshowninFig.4.

For Single--Stage Gas Valves, connect supplied

brown jumper wire from the “NO” (Normally Open)

terminal on the pressure switch to the terminal

where the gray wire was attached.

NOTE: Terminals are not marked on Gas Valve.

For Two--Stage Gas Valves, connect the supplied

brown jumper wire from the “NO” terminal on the

pressure switch to terminal “M” on the gas valve.

1

b. For units with 36H valve, install the

/8-- i n x

3/4--in nipple where the plug was removed. (See

Fig. 5.) Use pipe thread dope or tape (field supplied,

must be certified for use with propane gas) for all

joints, making sure not to get any excess in the pipe

or valve. Next, install the gas valve bracket over

1

nipple, then the

1

/2--in nipple, then1/8--inx90_ street elbow,

3

/8--inx90_ elbow, then1/8-- i n x

followed by the LP Pressure Switch as shown in

Fig. 5. Connect he supplied brown jumper wire

from the “NO” terminal on the pressure switch to

terminal “MP” on the gas valve.

6. Remove regulator cover screw(s) from gas regulator(s). (See Fig. 6 or 7.) Save regulator cover screws.

7. Using a screwdriver, remove plastic adjust screw(s)

from both regulators. (See Fig. 6 or 7.) Save plastic

adjust screws.

8. Remove regulator spring(s) (silver) from gas regulator(s). (See Fig. 6 or 7.) Discard regulator springs.

9. Install propane gas regulator spring(s) (white)

shipped with the kit into the gas regulator(s). (See

Fig. 6 or 7.)

ON/OFF SWITCH

1/2˝ NPT INLET

INLET

PRESSURE TAP

1/2˝ NPT OUTLET

Fig. 5 -- LP Pressure Switch Piping

(36H Gas Valve Shown)

REGULATOR COVER SCREW

PLASTIC ADJUST SCREW

REGULATOR SPRING

(Propane - White,

Natural - Silver)

HIGH STAGE GAS

PRESSURE REGULATOR

ADJUSTMENT

LOW STAGE

GAS PRESSURE

REGULATOR ADJUSTMENT

MANIFOLD

PRESSURE TAP

Two-Stage 36G Valve

C10520

ON/OFF SWITCH

1/2˝ NPT INLET

INLET

PRESSURE TAP

1/2˝ NPT OUTLET

Fig. 6 -- 36G Valve Spring Installation

4

Single-Stage 36G Valve

REGULATOR

COVER SCREW

PLASTIC

ADJUST

SCREW

REGULATOR SPRING

(PROPANE - WHITE

NATURAL - SILVER)

GAS PRESSURE

REGULATOR

ADJUSTMENT

MANIFOLD

PRESSURE TAP

C10521

Loading...

Loading...