International Comfort Products CRHEATER101A00, CRHEATER112A00, CRHEATER103B00, CRHEATER104B00, CRHEATER113B00 Installation Manual

...

CRHEATER101A00-CRHEATER112A00,

CRHEATER103B00,CRHEATER104B00,

CRHEATER113B00 - CRHEATER116B00

CRHEATER117A00-CRHEATER119A00

CRHEATER264A00-CRHEATER269A00,

CRHEATER288A00-CRHEATER299A00

CRHEATER301A00,CRHEATER308A00

CRHEATER316A00-CRHEATER322A00

CRSINGLE037A00-CRSINGLE054A00

Installation Instructions

SMALL ROOFTOP UNITS

ACCESSORY ELECTRIC HEATER

AND SINGLE POINT BOX

ELECTRIC COOLING

AND HEAT PUMP

SELECT3to15TONS

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 1.........................

PACKAGE USAGE 2..................................

PACKAGE CONTENTS 2..............................

GENERAL 6.........................................

GENERAL INSTALLATION SEQUENCE 9................

SECTION 1 INSTALLATION, SMALL--MEDIUM CABINET 10

Installing Single Point Box (CRSINGLE037A00--

054A00) 10.......................................

Installing Electric Heater (CRHEATER101A00-112A00,

103B00, 104B00, 113B00-116B00, 117A00-119A00,

264A00-269A00, 288A00-299A00, 301A00, 308A00,

A00-322A00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

316

SECTION 2 INSTALLATION, LARGE CABINET (3 OUT-

DOOR FANS) 18.....................................

Installing Single Point Box (CRSINGLE047A00,

049A00--054A00 18................................

Installing Electric Heater (CRHEATER288A00--

296A00) 20.......................................

UNIT POWER SUPPLY WIRING - ALL UNITS ........... 29

APPENDIX A: CONNECTION FIGURES, AC--1, AC--2 31...

APPENDIX B: CONNECTION FIGURES, AC--3 42.........

APPENDIX C: CONNECTION FIGURES, HP--1, HP2 49.....

APPENDIX D: ELECTRIC HEATER DATA ........... 67

IMPORTANT: Read these instructions completely before

attempting to install this accessory.

When working on air-conditioning equipment, observe

precautions in the literature, tags and labels attached to

the unit, and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves.

Recognize safety information. This is the safety--alert

symbol

instructions or manuals, be alert to the potential for

personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety--alert

symbol. DANGER identifies the most serious hazards

which will result in severe personal injury or death.

WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify

unsafe practices which may result i n minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced

installation, reliability, or operation.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Turn off all power to unit and install lockout tag.

Power can come to unit from multiple sources. Verify

power is off with a meter or probe.

. When you see this symbol on the unit and in

!

WARNING

SAFETY CONSIDERATIONS

Installation and servicing of air--conditioning equipment

can be hazardous due to system pressure and electrical

components. Only trained and qualified service personnel

should install, repair, or service air-conditioning

equipment.

Untrained personnel can perform the basic maint enance

functions. All other operations should be performed by

trained service personnel.

!

CUT HAZARD

Failure to follow this caution may result in personal

injury. Sheet metal parts may have sharp edges or

burrs. Use care and wear appropriate protective

clothing, safety glasses and gloves when handling

parts and servicing units.

CAUTION

PACKAGE USAGE

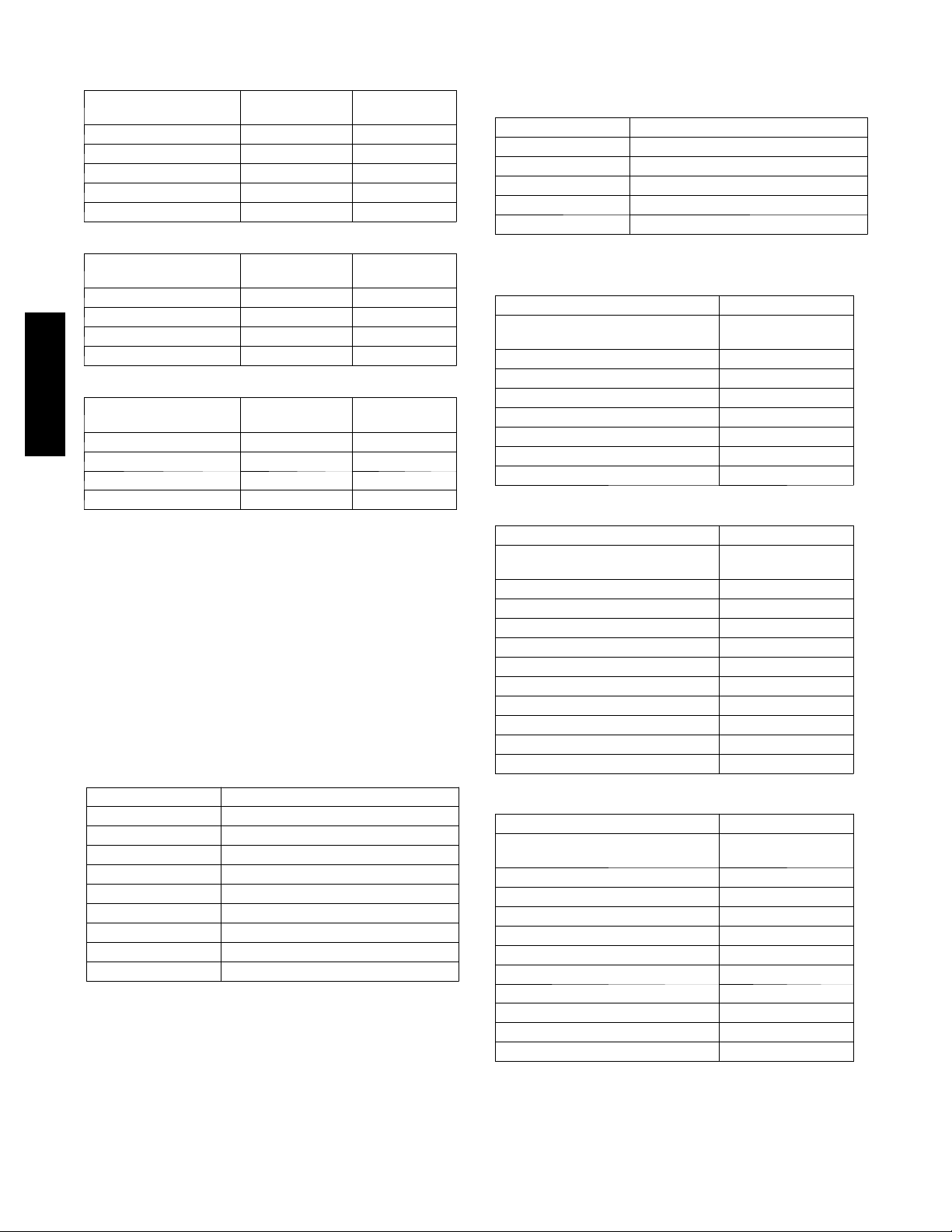

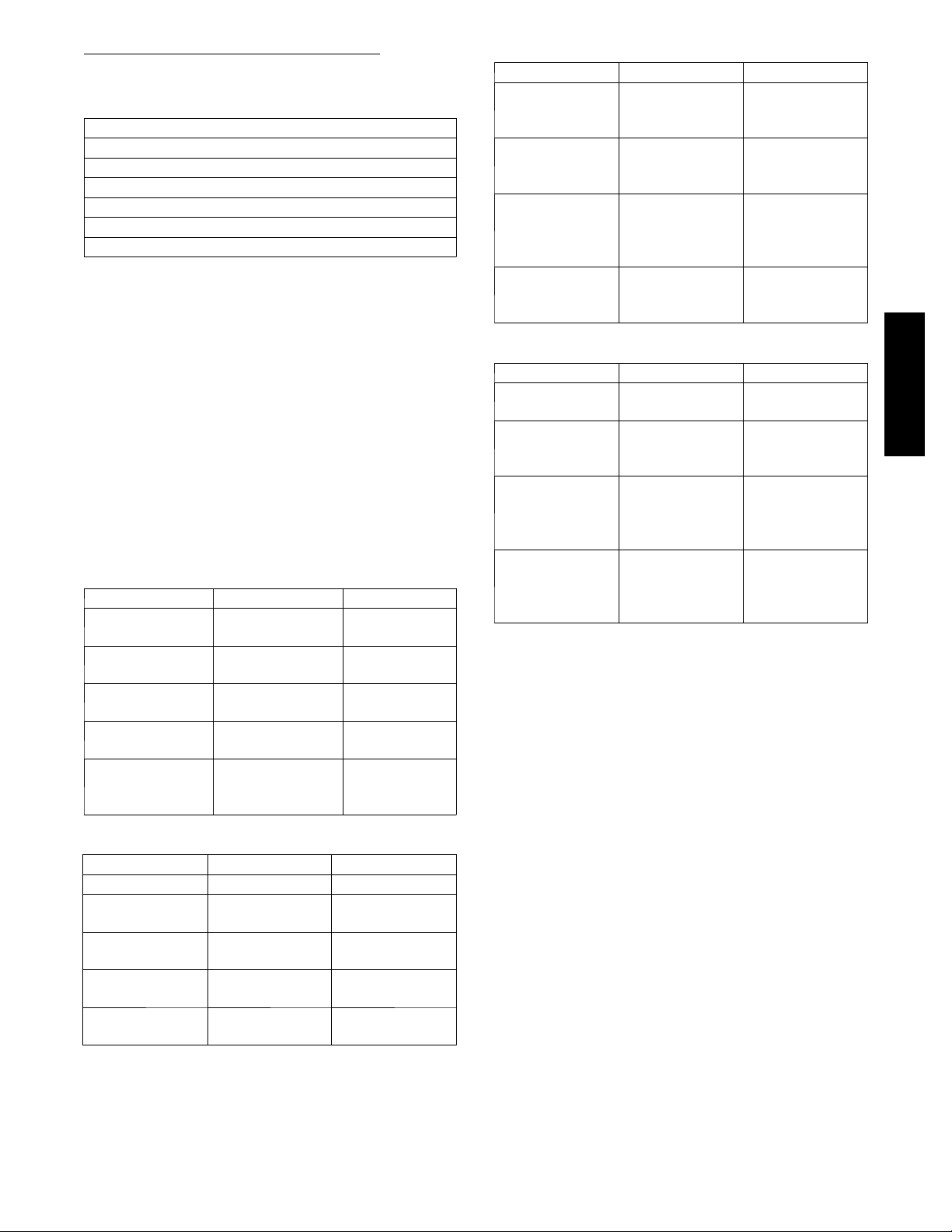

CARRIER MODELS

MODEL NUMBER

50HC A C --- 2 04--- 14

50HCQ H P --- 2 04--- 12

50LC A C --- 3 04--- 12

50TC A C --- 1 04 ---16

50TCQ H P --- 1 04 ---14

CHASSIS

GROUP

BRYANT MODELS

MODEL NUMBER

548J H P --- 1 04 ---14

549J H P --- 2 04 ---12

551J A C --- 2 04 ---14

558J A C --- 1 04 ---16

CHASSIS

GROUP

ICP MODELS

MODEL NUMBER

CRHTR,CRSIN

AC: Cooling Only (air conditioner)

HP: Heat Pump

1 - Standard Efficiency

2 - High Efficiency

3 - Ultra High Efficiency

RAH A C --- 2 036--- 150

RAS A C --- 1 036--- 180

RHH H P --- 2 036---120

RHS H P --- 1 036- --150

CHASSIS

GROUP

PACKAGE CONTENTS--

ELECTRIC HEATERS

CRHEATER101A00-112A00,103B00,

104B00,113B00-116B00,117A00-119A00

CRHEATER264A00-269A00

CRHEATER297A00, 298A00, 301A00,

308A00, CRHEATER316A00-321A00

UNIT SIZES

UNIT SIZES

UNIT SIZES

ELECTRIC HEATERS

CRHEATER288A00--296A00, 299A00,

322A00

QTY CONTENTS

1 Heater module

1 Heater slide track

4 Screws

1 Wiring label

1 Label, Max Temp/Static

CRSINGLE037A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 1 8 --- i n / 4 4 9 m m )

Ter m i na l b lo ck 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 12

Wire ties 7

Tube cl a m p 1

Seal strip 1

1

CRSINGLE038A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 1 8 --- i n / 4 4 9 m m )

Ter m i na l b lo ck / Fu s e ho l d er 1

Fuse block 1

Fuses, 60 ---A class RK5 6

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 12

Wire ties 7

Tube cl a m p 1

Seal strip 1

1

QTY CONTENTS

1 Heater module

1 Heater slider track*

4 Screws*

1 Wiring label

1

1 Splice connector{

1 Wire tie{

1 Label, Max Temp/Static

1 Heater Cover**

*Not included with CRHEATER101A00---109A00, 297A00, 298A00, 301A00

{Supplied with electric heater packages CRHEATER101A00,

CRHEATER102A00, CRHEATER103B00, and CRHEATER104B00 only.

** Supplied with package CRHEATER301A00 only

Red wire (10 gage){

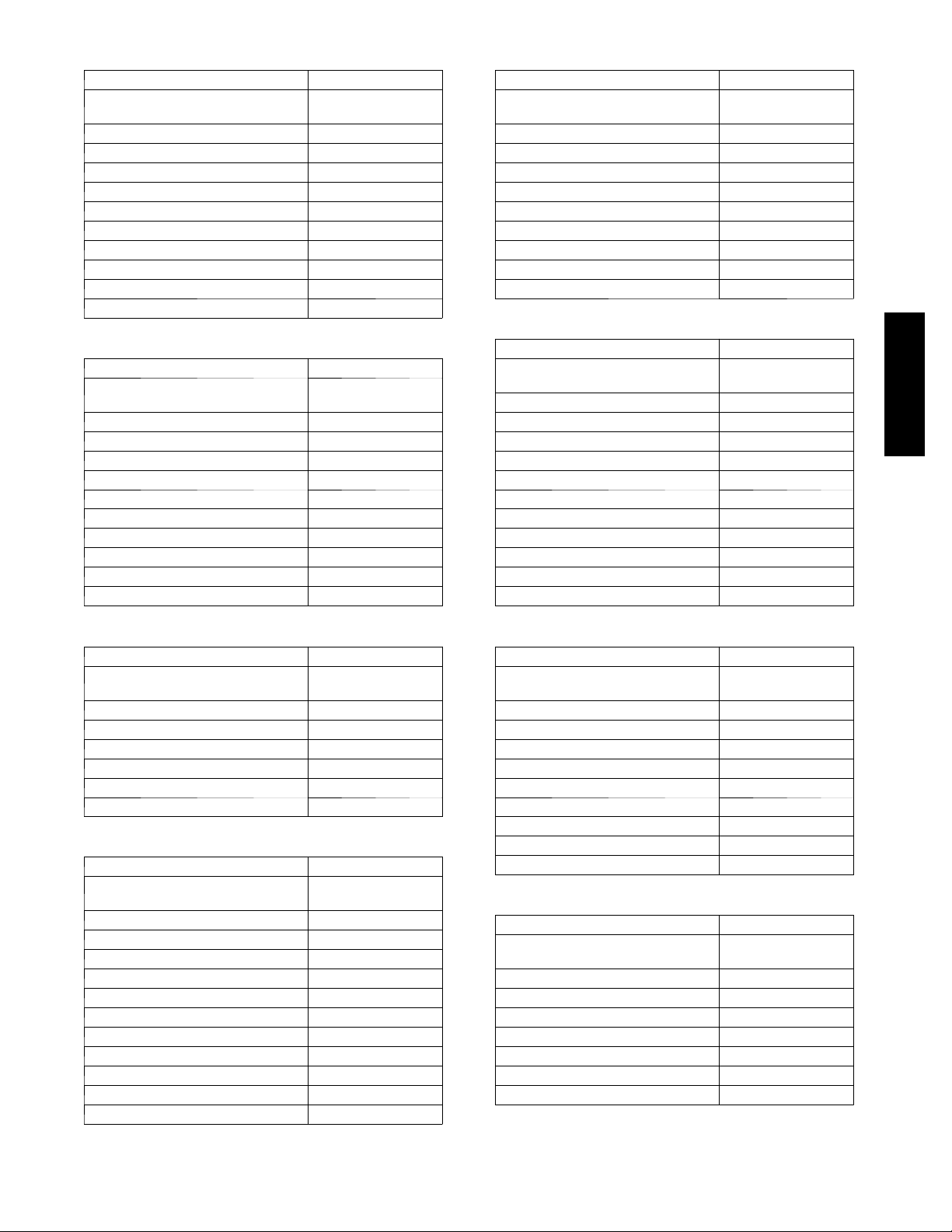

CRSINGLE039A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 1 8 --- i n / 4 4 9 m m )

Ter m i na l b lo ck / Fu s e ho l d er 1

Fuse block 2

Fuses, 60 ---A class RK5 9

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 12

Wire ties 7

Tube cl a m p 1

Seal strip 1

2

1

CRSINGLE040A00

CRSINGLE044A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 1 8 --- i n / 4 4 9 m m )

Ter m i na l b lo ck / Fu s e ho l d er 1

Fuse block 1

Fuses, 60 ---A class RK5 4

Power distribution harness 1

Conductors, Tap, #10 2

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 12

Wire ties 7

Tube cl a m p 1

Seal strip 1

CRSINGLE041A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 1 8 --- i n / 4 4 9 m m )

Ter m i na l b lo ck / Fu s e ho l d er 1

Fuse block 1

Fuses, 60 ---A class RK5 6

Power distribution harness 1

Conductors, Tap, #10 2

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 12

Wire ties 7

Tube cl a m p 1

Seal strip 1

ITEM DESCRIPTION QUANTITY

1

Single Point Box Housing Assembly

( H e i g h t 2 5 --- i n / 6 3 9 m m )

Ter m i na l b lo ck 1

Fuse block 2

Fuses, 60--- A class T (600v) 6

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

1

CRSINGLE045A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

1

( H e i g h t 2 5 --- i n / 6 3 9 m m )

Ter m i na l b lo ck / fu se h ol d er 1

Fuse block 2

Fuses, 60 ---A class RK5 9

Power distribution harness 1

Conductors, Tap, #10 6

Terminal block (TB10) 2

S c r e w s , # 8 x ½ --- i n 2

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

1

CRHTR,CRSIN

CRSINGLE042A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 2 5 --- i n / 6 3 9 m m )

Ter m i na l b lo ck 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

CRSINGLE043A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 2 5 --- i n / 6 3 9 m m )

Ter m i na l b lo ck / Fu s e ho l d er 1

Fuse block 1

Te r m in al b l o ck ( T B --- 1 0 ) 2

Fuses, 60 ---A class RK5 6

Power distribution harness 1

Conductors, Tap, #10 6

S c r e w s , # 8 x ½ --- i n 2

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

CRSINGLE046A00

ITEM DESCRIPTION QUANTITY

1

1

Single Point Box Housing Assembly

( H e i g h t 2 5 --- i n / 6 3 9 m m )

Ter m i na l b lo ck / fu se h ol d er 1

Fuse block 3

Fuses, 60 ---A class RK5 12

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

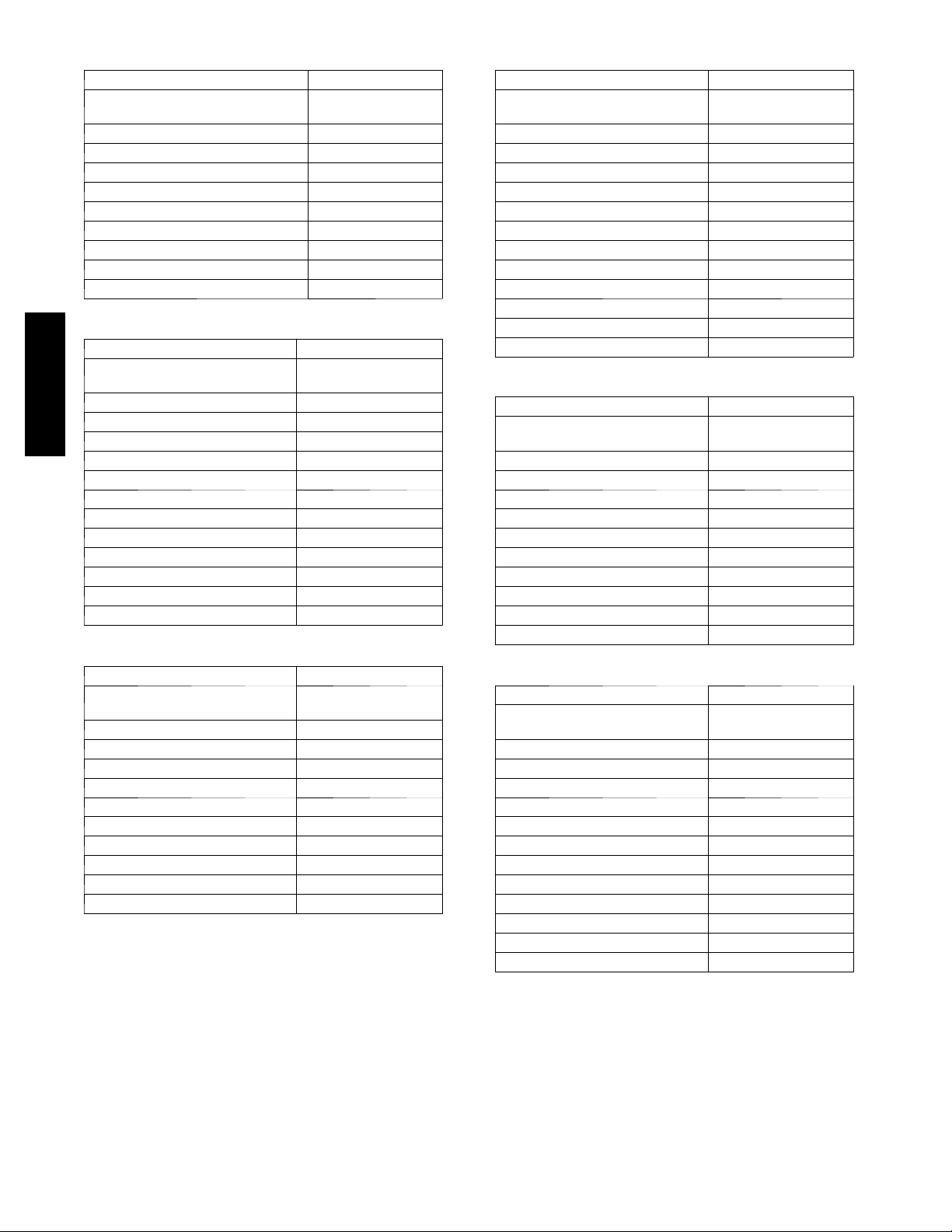

CRSINGLE047A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck 1

Conductors, Tap, #10 3

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

1

1

3

CRSINGLE048A00

CRSINGLE051A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 2 5 --- i n / 6 3 9 m m )

Ter m i na l b lo ck 1

Fuse block 3

Fuses, 60 ---A class RK5 9

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

CRSINGLE049A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck / Fu s e ho l d er 1

Fuse block 1

CRHTR,CRSIN

Fuses, 60 ---A class RK5 6

Power distribution harness 1

Conductors, Tap, #10 8

Terminal block (TB10) 2

S c r e w s , # 8 x ½ --- i n 2

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

CRSINGLE050A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck 1

Fuse block 2

Fuses, 60--- A class T (600v) 6

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

ITEM DESCRIPTION QUANTITY

1

1

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck / fu se h ol d er 1

Fuse block 2

Fuses, 60 ---A class RK5 9

Power distribution harness 1

Conductors, Tap, #10 8

Terminal block (TB10) 2

S c r e w s , # 8 x ½ --- i n 2

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

CRSINGLE052A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck 1

Fuse block 3

Fuses, 60--- A class T (600v) 9

Power distribution harness 1

Conductors, Tap, #10 3

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

1

1

CRSINGLE053A00

1

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck 1

Fuse block 4

Fuses, 60 ---A class RK5 12

Power distribution harness 1

Conductors, Tap, #10 8

Terminal block (TB10) 2

S c r e w s , # 8 x ½ --- i n 2

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

1

4

CRSINGLE054A00

ITEM DESCRIPTION QUANTITY

Single Point Box Housing Assembly

( H e i g h t 3 3 --- i n / 8 4 5 m m )

Ter m i na l b lo ck 1

Fuse block 5

Fuses, 60 ---A class RK5 15

Power distribution harness 1

Conductors, Tap, #10 8

Terminal block (TB10) 2

S c r e w s , # 8 x ½ --- i n 2

Rain shield, small 1

Rain shield with conduit seal 1

S c r e w s , # 1 0 x ½ --- i n 8

Wire ties 7

Seal strip 1

1

CRHTR,CRSIN

5

GENERAL

PuronR Units

This installation instruction manual describes the

installation of electric heaters and associated fuse

block/field power termination kits (single point box or

SPB) on select small rooftop units in nominal cooling

capacities from 3 to 15 tons. These rooftop units use

Puron refrigerant (R-410A). See Package Usage tables on

page 2 for applicable unit models. Unit types include

cooling units (AC) and heat pumps (HP) distributed over

several chassis sizes. Unit types AC--1, AC--2, HP--1,

HP--2 are identified. Unit type AC--3 consists of a single

model — Carrier 50LC.

This information does not include selection data. Refer to

project plans, job submittals and selection programs for

heater and field power termination/SPB kit usage.

Some electric heaters used on these Puron (R-410A) units

may also be installed in earlier R-22 rooftop units. Refer

to Form 50-8SI or IIK-548-36-49 for installation

instructions on heater packages CRHEATER101A00

through 119A00 with ea rlier models. Contact your local

CRHTR,CRSIN

distributor office for a copy of this form.

Electric Heaters

Heaters are shipped with one heater per carton. The carton is

marked with a Sales Package Number. On all heaters except

CRHEATER101A00 through 119A00, 103B00, 104B00, and

113B00 through 116B00, the heater Model Number (as marked

on the heater infoplate) is the same as the Sales Package

number. On heaters CRHEATER101A00 through 119A00,

103B00, 104B00, and 113B00 through 116B00, the value in

position 9 of the part number differs between the sales package

part number (value is 1) and bare heater model number (value is

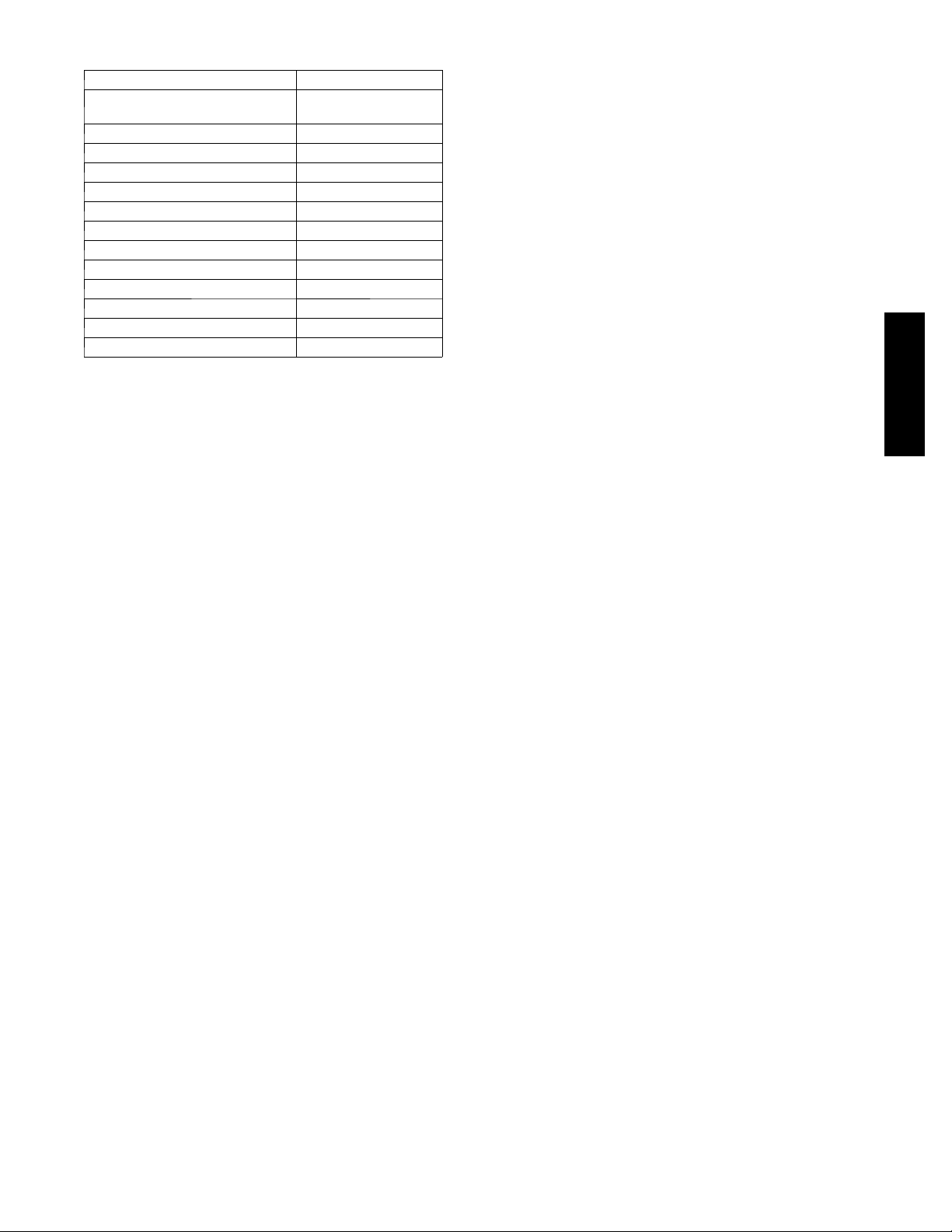

0). (See Table 1.)

The heaters are modular in design, with heater frames

holding open coil resistance wires strung through ceramic

insulators, limit switches and one or two control

contactors. Power conductors are attached. One or two

heater modules may be used in a unit.

Heater modules are installed in the compartment below the

indoor (supply) fan outlet. Access is through the indoor

access panel. Heater modules slide into the compartment on

tracks along the bottom of the heater opening. (See Fig.

15.) Some heaters are "keyed" to be able to go in only one

slot. These keyed heaters have been designed and qualified

to go only into the designated slot. Do not remove the key

for the purpose of putting the heater in the wrong slot.

Placing a keyed heater in the wrong slot could lead to

overheating and unit damage from the heater not operating

properly.

NOTE: The following

CRHEATER101A00-109A00, 297A00, 298A00, 301A00.

Not all available heater modules may be used in every unit.

Use only those heater modules that are UL listed for use in

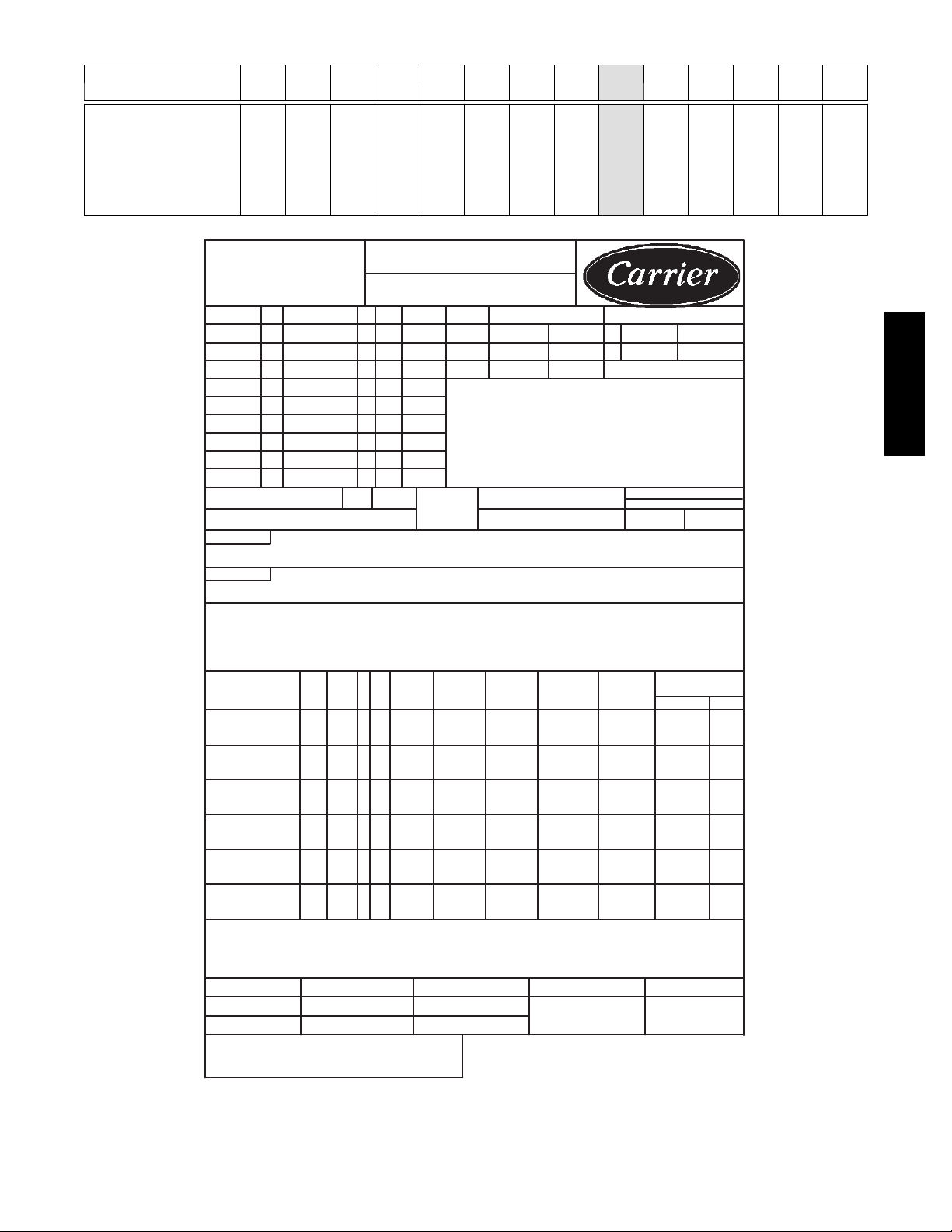

a specific size unit. Refer to the label on the unit cabinet for

the list of approved heaters. (See Fig. 1 and 2.) See

Appendix D for electric heater module data.

heaters do not use the slide track:

Single Point Boxes and Fuses

The Single Point Box (SPB) kits provide a field power

termination location plus an enclosure for heater fuses

when required by code. The SPBs are insta lled under the

unit’s main control box and include a cover plus all

internal wiring. Minimum components of the SPB are a

field power terminal block with tap conductors (to

connect to the unit’s main control box field terminals).

Maximum component population includes up to five fuse

blocks.

Fuses for electric heater circuits are required and provided

when the unit’s MOCP exceeds 60-A or when the total

heater Full Load Amp value exceeds 48-A. When fuses

are required and provided, the cooling circuit is also

provided with fuse protection; some units require minor

wiring changes in the main control box (see section on

TB10 terminal blocks).

No Fuses

If the unit’s MOCP device rating is 60-A or less, then the

MOCP device is recognized as providing the required

overcurrent prote ction to the heater and no internal fusing

is required. If two heater modules are insta lled, a single

point box that contains only a field power terminal block

is required. See tables at the beginning of Appendix A, B

and C for where-used information on the single point

boxes and for connections Figure number.

Units with Factory Installed HACR

The amp rating of the HACR factory installed option is

based on the size, voltage, indoor motor and othe r

electrical options of the unit as shipped from the factory.

When field installed accessory electric heaters are added

or changed in the unit, the HACR may no longer be of the

proper amp rating and therefore will need to be removed

from the unit. See unit nameplate and label on factory

installed HACR for the amp rating of the HACR that was

shipped with the unit from the factory. See unit

nameplates for the proper fuse, HACR or maximum

over--current protection device required on the unit with

field installed electric heat.

Single Point Box Contents

See Package Content tables for a list of components

included in each single point box kit. Note the height

differences and their use in specific size units.

Control Wiring

Heater modules cont ain one or two heater control

contactors. If two heater modules are installed, or a

two-circuit heater module is installed, the cooling unit

(AC type) can be connected for one-stage or two-stage

heating control. On all heat pump units (HP type), all

heater contactors will be connected to provide

second-stage heating control.

6

Table 1 – Heater Model Number

Bare Heater Model

Number

Heater Sales Package

PNO

Includes:

Bare Heater

Carton and packing

materials

Installation sheet

Indianapolis, IN 46231 U.S.A.

COMPR A

COMPR B

COMPR C

FAN MTR QTY VOLTS AC PH HZ FLA

OUTDOOR

INDOOR

PWR.EXH.

ELC.HEAT

OTHER

POWER

SUPPLY PH HZ

PERMISSIBLE

VOLTAGE AT UNIT MINMAX

DOWN SUPPLY

SIDE SUPPLY

C R H E A T E R 0 0 1 A 0 0

A

C R H E A T E R 1 0 1

or

B

MODEL

Carrier

50TC-A06A2A5A0A0A0

Corporation

7310 West Morris Street

QTY VOLTS AC PH HZ RLA LRA REF. SYSTEM R410A TEST PRESSURE GAGE

1 208/230 3 60 15.6 110

10.7 4.9 650 4482

LBS

LBS

LBS kg

kgkgHI

450 3103

LO

PSI kPa

PSI kPa

1 208/230 1 60 1.5

1 208/230 3 60 5.2

CHARGE SYSTEM PER INSTALLATION INSTRUCTIONS

SUITABLE FOR OUTDOOR INSTALLATION

208/230 3 60

VOLT

253 187

MIN. CKT.

AMPS

26.2

MIN CLEARANCE TO COMBUSTIBLE MATERIALS _____INCHES ______mm.

FOR FIRST _____INCHES______mm. OF DUCT WHEN ELECTRIC HEATER IS INSTALLED

12 305

MIN CLEARANCE TO COMBUSTIBLE MATERIALS _____INCHES ______mm.

FOR FIRST _____INCHES______mm. OF DUCT WHEN ELECTRIC HEATER IS INSTALLED

*FOR INSTALLATION ON COMBUSTIBLE FLOORING OR

CLASS A,B, OR C ROOFING MATERIAL

12 305

MAX FUSE OR HACR

BREAKER PER NEC

MAX OVERCURRENT

PROTECTION DEVICE

125

125

40

MINIMUM UNIT DISCONNECT

FLA LRA

26 144-

0 0

CRHTR,CRSIN

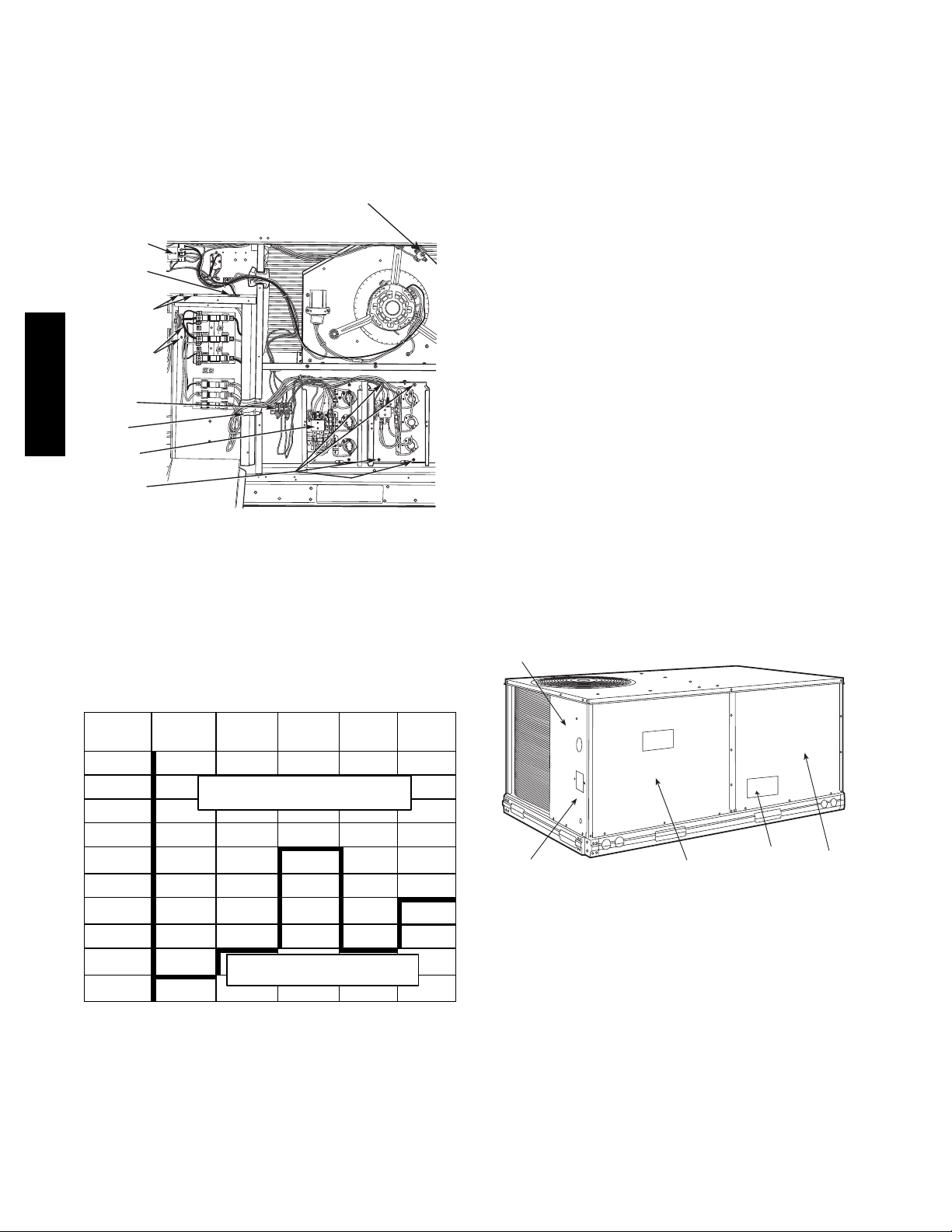

ACCESSORY

HEATER MODEL

NUMBER

102A 208/

104B 208/

105A 208/

104B+104B 208/

104B+105A 208/

INSTALLER NOTE: 1.INSTALL ACCESS HEATER PER INSTALL INSTR ENCLOSED WITH HEATER. MARK

COOLING

HP HEATING

THIS EQUIPMENT COMPLIES WITH THE

2004 REQUIREMENTS OF ASHRAE 90.1

CHECK

VOLTS PH HZ

HERE

240

240

240

240

240

SPACE "CHECK HERE" FOR MODEL USED USE MIN CKT AMPS & MAX OVERCURRENT DEVICE AMPS LISTED FOR HEATER. IF NO HEATER IS USED

MARK SPACE "CHECK HERE" FOR NONE.

2.HEATERS ARE MANUFACTURED BY EMERSON HEATING PRODUCTS OR TUTCO ELECTRIC.

CAPACITY Btu/Hr CAPACITY kW EER COP

HEATER

FLA

3 60 13.6/

15.6

3 60 21.9/

25.3

3 60 33.4/

38.5

3 60 43.8/

50.5

3 60 55.2/

63.8

MIN CKT

AMPS

26.2/

26.2

33.9/

38.1

48.3/

54.6

61.3/

69.6

75.5/

86.3

FUSE OR

HACR

BREAKER

PER NEC

40/40 -/- - 26/26 144/

40/40 -/- - 31/35 144/

50/60 -/- 037 44/50 144/

70/70 -/- 038 56/64 144/

80/90 -/- 038 69/79 144/

17.259000

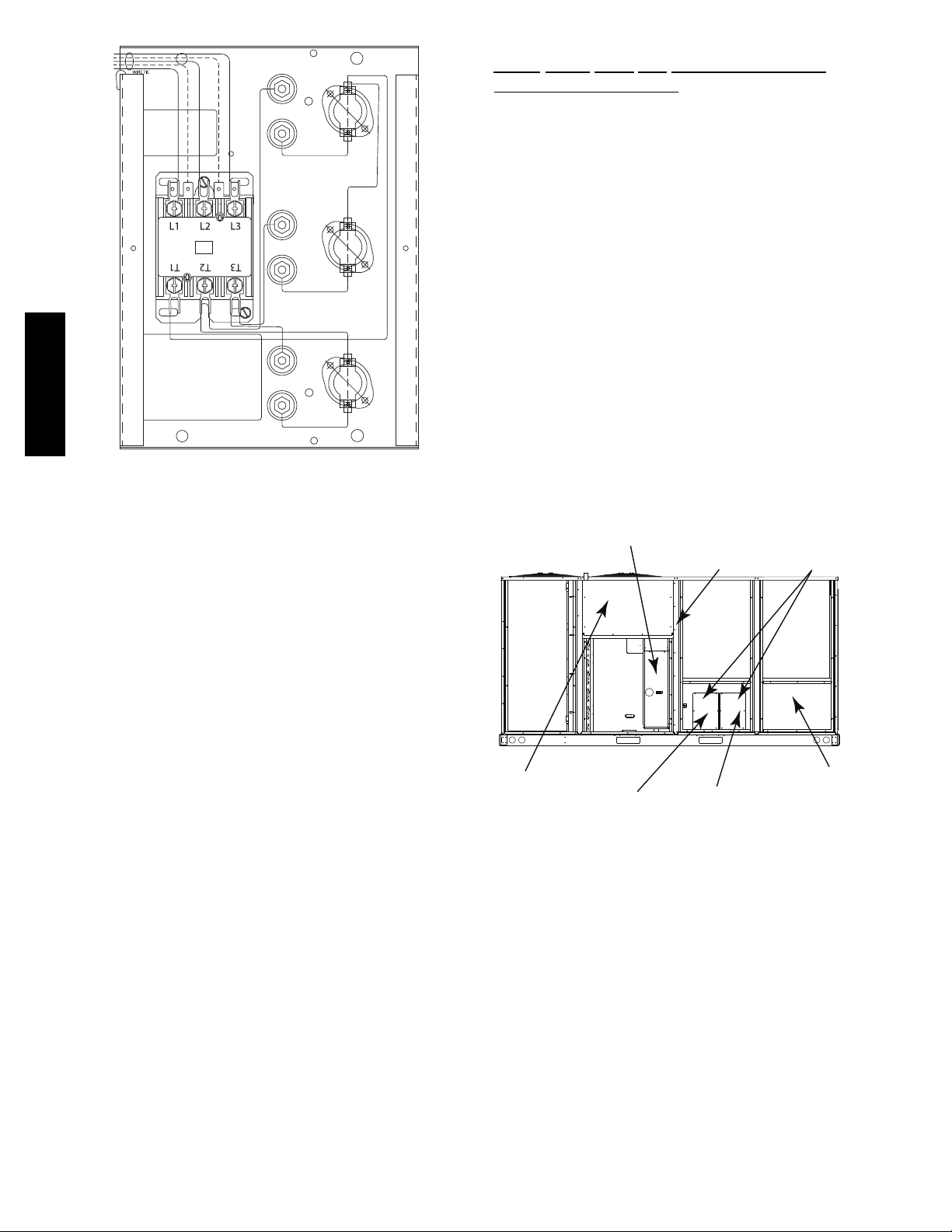

. 1 - Unit Informative Data Label

Fig

MAXIMUM

OVERCURRENT

PROTECTION

DEVICE

13

SINGLE PT.

BOX MODEL

NUMBER

MINIMUM

UNIT

DISCONNECT

FLA LRA

144

144

144

144

144

C10531

7

MODEL

50TC-A06A2A5A0A0A0

REFRIGERANT CHARGE R410A

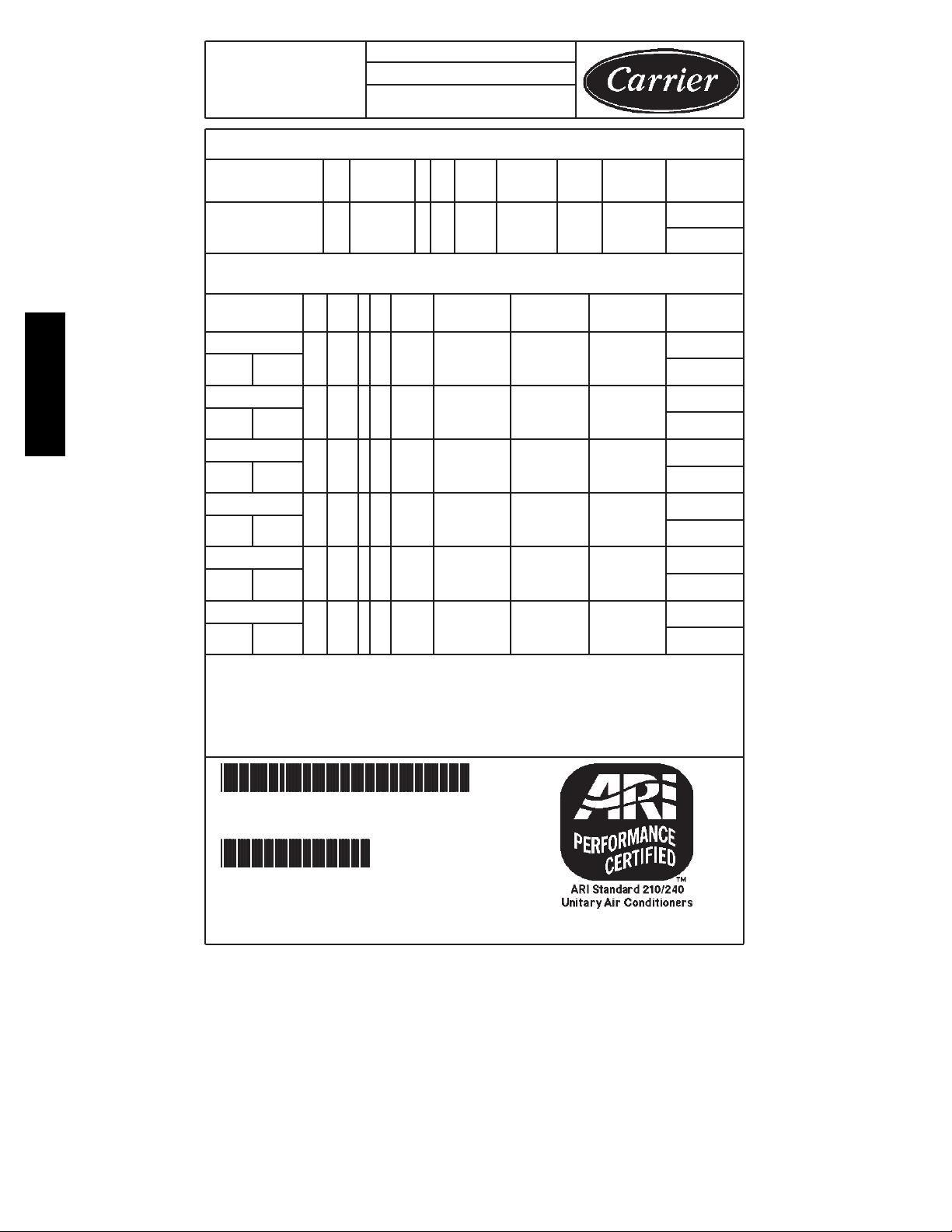

ELECTRICAL DATA FOR ACCESSORY POWER EXHAUST ONLY

ACCESSORY

POWER EXHAUST

MODEL NUMBER

CRPWREXH_

CHECK

HERE

VOLTS PH HZ

POWER

EXHAUST

FLA

MIN CKT

AMPS

28.1

FUSE OR

HACR

BREAKER

PER NEC

40

MAXIMUM

OVERCURRENT

POROTECTION

DEVICE

-/-

MINIMUM

UNIT

DISCONNECT

FLA

28

LRA

146

ELECTRICAL DATA FOR ACCESSORY POWER EXHAUST INSTALLED

IN COMBINATAION WITH ELECTRIC HEATER

ACCESSORY

HEATER MODEL

NUMBER

102A

SINGLE PT

BOX MODEL

NUMBER

104B

SINGLE PT

BOX MODEL

CRHTR,CRSIN

NUMBER

105A

SINGLE PT

BOX MODEL

NUMBER

104B+104B

SINGLE PT

BOX MODEL

NUMBER

104B+105A

SINGLE PT

BOX MODEL

NUMBER

SINGLE PT

BOX MODEL

NUMBER

INSTALLER NOTE:

1.INSTALL ACCESS. HEATER AND/OR POWER EXHAUST PER INSTALL INSTR ENCLOSED

WITH HEATER AND POWER EXHAUST. MARKSPACE "CHECK HERE" FOR MODEL USED.

USE MIN CKT AMPS AND MAX OVER CURRENT DEVICE AMPS LISTED FOR HEATER

AND POWER EXHAUST.

2.HEATERS ARE MANUFACTURED BY EMERSON HEATING PRODUCTS OR TUTCO ELECTRIC.

-

-

037

038

038

CHECK

HERE

VOLTS PH HZ

208/

3 60 13.6/

240

208/

3 60 21.9/

240

208/

3 60 33.4/

240

208/

3 60 43.8/

240

208/

3 60 55.2/

240

HEATER

FLA

15.6

25.3

38.5

50.5

63.8

MIN CKT

AMPS

28.1/28.4

36.3/40.5

50.6/57.0

63.6/72.0

77.9/88.6

FUSE OR

HACR

BREAKER

PER NEC

40/40

40/45

60/60

70/80

80/90

MAXIMUM

OVERCURRENT

POROTECTION

DEVICE

-/-

-/-

-/-

-/-

-/-

MINIMUM

UNIT

DISCONNECT

FLA

28/28

LRA

146/146

FLA

33/37

LRA

146/146

FLA

47/52

LRA

146/146

FLA

59/66

LRA

146/146

FLA

72/82

LRA

146/146

FLA

LRA

*50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0**50TC-A06A2A5A0A0A0*

Fig. 2 - Unit Informative Data Label, Power Exhaust Installed

C10532

8

Terminal Block TB10 (208/230--V Units)

Two small terminal blocks (designated TB10) are

included in these single--point boxes used on select

208/230--3--60 units.

SPB PNO CRSINGLE

043A00

045A00

049A00

051A00

053A00

054A00

TB10 is a small single--pole terminal block, 2-1/2 in. (63

mm) long with seven ¼-in. male quick-connect terminals.

One or two terminal blocks are used to aid in rearranging

the unit’s base cooling power circuit into two circuits, each

under 60-A MOCP. On units using both TB10 blocks, the

indoor fan motor is separated into the second circuit. On

units using only a single TB10 block, Compressor 2 is

separated into the second circuit.

On the largest units and on all AC--3 (50LC) unit s, the

TB10 blocks are not used and may be discarded. The tap

conductors from fuse blocks FU2 and FU3 are connected

in parallel to the main control box’s power terminal block.

See unit--SPB connection figures in the Appendix section.

The following tables indicate TB10 use on AC--1, AC--2,

HP--1 and HP--2 units using these single point boxes:

AC--1

AC--1 SPB TB10 Qty

08 (090,091)

09 (101,102)

12 (120,121)

14 (150)

16 (180)

043A

045A

049A

051A

049A

051A

049A

051A

049A

051A

053A

2

2

2

1

NR

AC--2

AC--2 SPB TB10 Qty

07 (072) 043A 2

08 (090)

09 (102)

12 (120)

14 (150)

049A

051A

049A

051A

049A

051A

049A

051A

2

2

1

NR

HP-- 1

HP--1 SPB TB10 Qty

049A

08 (090)

09 (102)

12 (120)

14 (150)

051A

053A

049A

051A

053A

049A

051A

053A

054A

051A

053A

054A

2

2

1

NR

HP-- 2

HP--2 SPB TB10 Qty

07 (072)

08 (090)

09 (102)

12 (120)

043A

045A

049A

051A

053A

049A

051A

053A

054A

049A

051A

053A

054A

2

2

1

NR

GENERAL INSTALLATION

SEQUENCE

1. Pre--stage heater packages and single point boxes by

placing the required component cartons at each unit.

2. Check the heater sales package number and single

point box part number (if used) against the part

numbers on the unit’s infoplate. See Fig. 1 and 2 for

typical data.

3. Disconnect power wiring into unit control box from

factory--installed disconnect switch or HACR breaker and withdraw wiring from control box.

4. Install the single point box and connect power

wiring tap conductors to field power terminals in

main control box.

5. Install the electric heater module(s) and connect

heater power conductors to single point box or main

unit control box per appropriate connections figure.

(See Appendix A, B and C.)

6. Connect the heater control contactors to unit terminal block TB4.

7. Mark the unit infoplat e to indicate which heater

module(s) have been installed.

CRHTR,CRSIN

9

8. Note the required wire size ampacity for the field

power supply conductors as marked on the unit info

plate as MIN CKT AMPS for accessory heater(s)

plus convenience outlet and power exhaust when

provided. Select and install suitable field power

conductors from external safety disconnect to unit

power connection points, or confirm wiring already

provided is suitable for required MIN CKT AMPS.

MANUAL RESET

LIMIT SWITCH

CONTROL

BOX

2

1

1

1

2

13

3

BUSHING

SINGLE

POINT BOX

MOUNTING

SCREWS

DRIP BOOT

BRACKET

MOUNTING

SCREWS

POWER

WIRES

FOAM

CRHTR,CRSIN

BUSHING

HEATER

RELAY S

HEATER

MOUNTING

SCREWS

21

23

11

13

A

L

LIED

P

A

C

O

RP

.

M

O

DE

L

N

O

.

O

D

E

R

I

A

L

N

O.

2

2

.

2

ISTED

AI

R

NDITIONING

1

2

3

UIP

ACCESS

346

N

.

3

P

/

N

2

56

10

RE

V

4

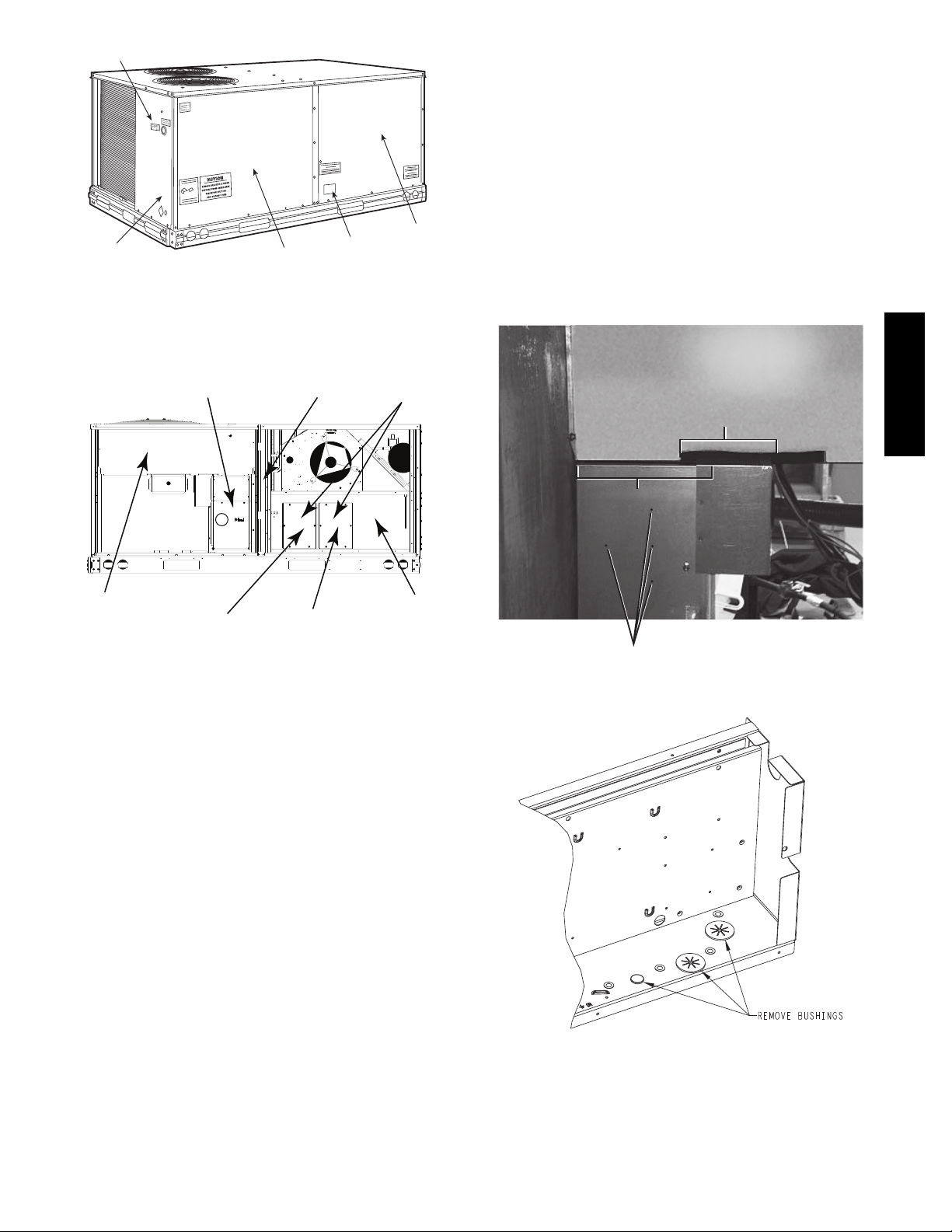

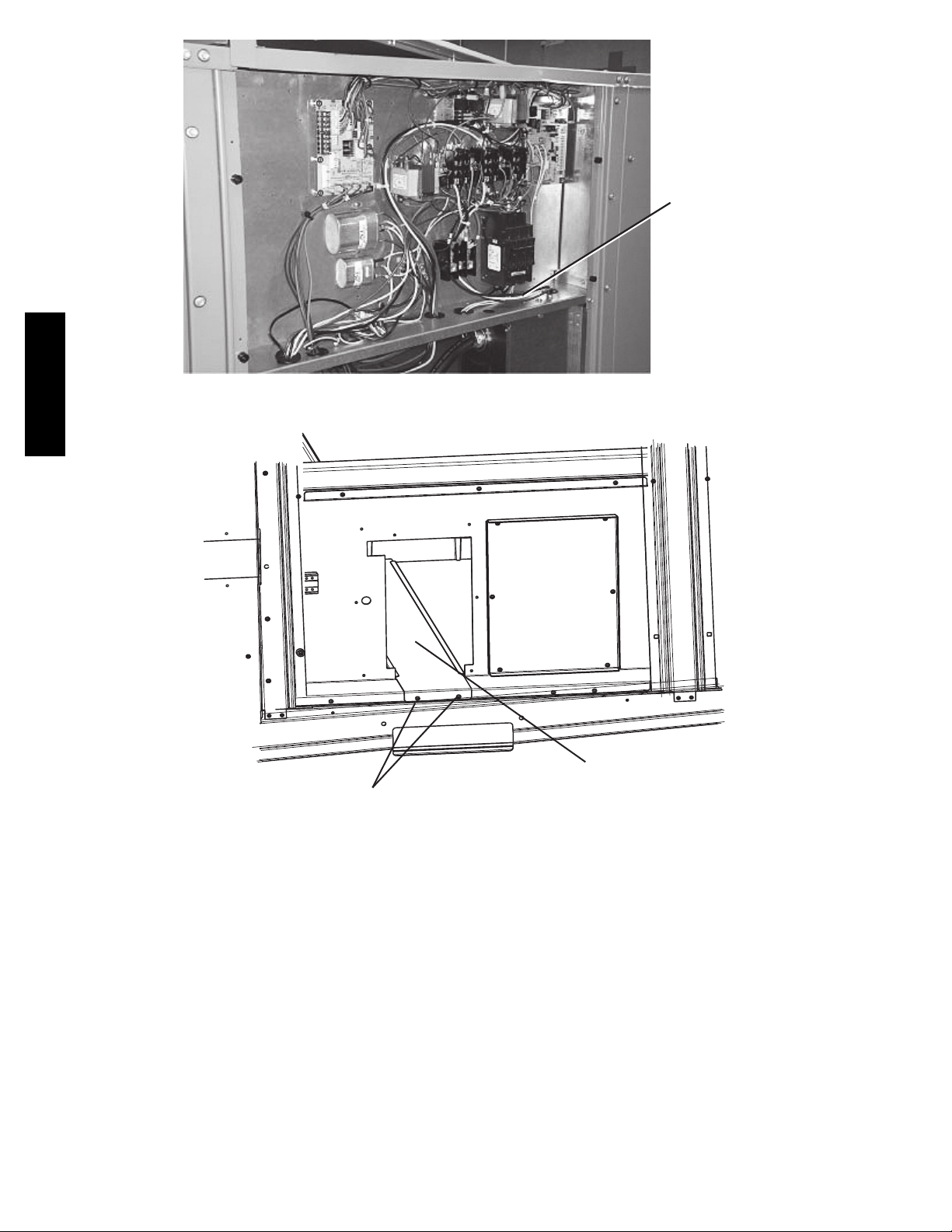

Fig. 3 - Typical Single Point Kit Installation

UNIT SPECIFIC INSTALLATION INSTRUCTIONS

The unit-specific installation instructions are presented in

two sections, grouped by common chassis and control box

design. Section 1 covers smaller chassis models and starts

on page 10. Section 2 covers the large chassis models and

starts on page 18. See table below for section assignment

for specific unit types and sizes.

C13467

SECTION 1

INSTALLATION, SMALL-MEDIUM

CABINET

Product Groups/Sizes included in this section:

AC--1 04--14 (036--150)

AC--2 04--12 (036--120)

AC--3 04--07

HP--1 04--12 (036--120)

HP-2 04-09 (036-102)

Check sales packages – Following the project drawing

schedule tables or submittal documents, select the

scheduled heaters and single point boxes (if used) and

place at each unit.

Compare the sales package number(s) for scheduled

heater modules against the approved usage table on the

unit’s info plate. See Fig. 1 and 2 for typical plate data. If

the scheduled heater usage does not appear on the unit

info plate label, STOP. Contact the project engineer or the

local distributor sales office for clarification.

Open the cartons and inspect for damage.

Disconnect field power supply

1.

Disconnect power to the unit. Lock-out/tag-out on

unit disconnect switch.

2.

Remove the outdoor access panel, control box

cover, and indoor access panels from the unit.

Save screws. See Fig. 4-6.

3. Use a voltmeter to check that no power is present at

unit terminal block.

DISCONNECT MOUNTING

LOCATION

Unit

Size

04, 036

05, 048

06, 060

07, 072

08, 090

09, 102

11

12, 120

14, 150

16, 180

Group

AC--1

AC--2 AC--3 HP--1 HP--2

SECTION 1 UNITS

SECTION 2 UNITS

MAX. TEMP/

UNIT BLOCK-OFF

PAN EL

OUTDOOR

ACCESS PANEL

STATIC LABEL

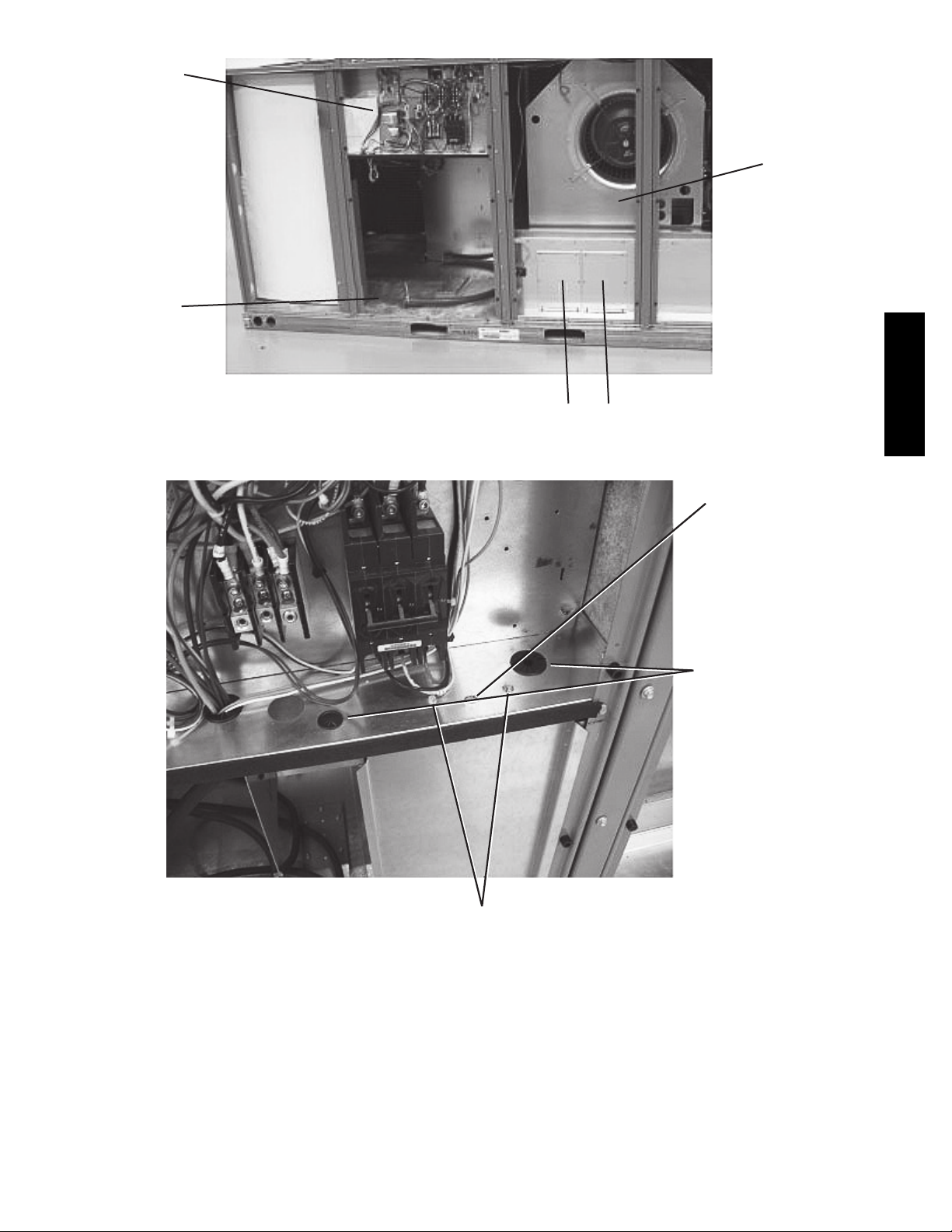

Fig. 4 - Typical Access Panel Location

(AC-1/HP-1 04-07/036-072, HP-2 04-06/036-060,

AC-2,3 04-06/036-060)

INDOOR

ACCESS

PAN EL

C11510

10

DISCONNECT MOUNTING

LOCATION

UNIT

BLOCK-OFF

PAN EL

Fig. 5 - Typical Access Panel Location

(AC-1 08-14/090-150, AC-2 07-12/072-120, AC-3 07,

HP-1 08-12/090-120, HP-2 07-09/072-102)

OUTDOOR

ACCESS PANEL

MAX. TEMP/

STATIC LABEL

INDOOR

ACCESS

PANEL

C11511

trol box which are not used must be plugged before

installing the SPB. Use foil tape or reinstall the

bushings from the outside of the control box prior to

securing the SPB. (See Fig. 9.)

8. Remove the single point box cover. Secure single

point box to the underside of the control box with

the 2 screws provided. (See Fig. 3.) Re--install bushing on the SPB tap conductors. (See Fig. 9.)

9. Secure the rainshield (conduit drip boot bracket) assembly to the back of the single point box with 2 of

the screws provided. (See Fig. 3.) The channel portion of the bracket assembly extends to the top panel behind the control box. Secure all wires to bracket with field --supplied wire tie as shown. (See Fig.

13.)

MAIN

CONTROL

BOX

(All units except large [3 outdoor fan] cabinet)

SINGLE POINT BOX

(NOT SHIPPED WITH

UNIT)

HEATER

MODULE

(LOCATION 1)

Fig. 6

- Typical Component Location

HEATER

MODULE

(LOCATION 2)

CENTER

POST

HEATER

COVERS

HEATER

MOUNTING

BRACKET

4. Remove control box cover and center post. Save

screws.(SeeFig.6.)

5. If unit does not have the factory--installed disconnect or HACR option or has not had field power

wiring connected, skip to Step 6.

When unit is equipped with factory--installed disconnect or HACR or has field power wiring connected, disconnect the power leads at the control box

terminals and withdraw the conductors from the

control box.

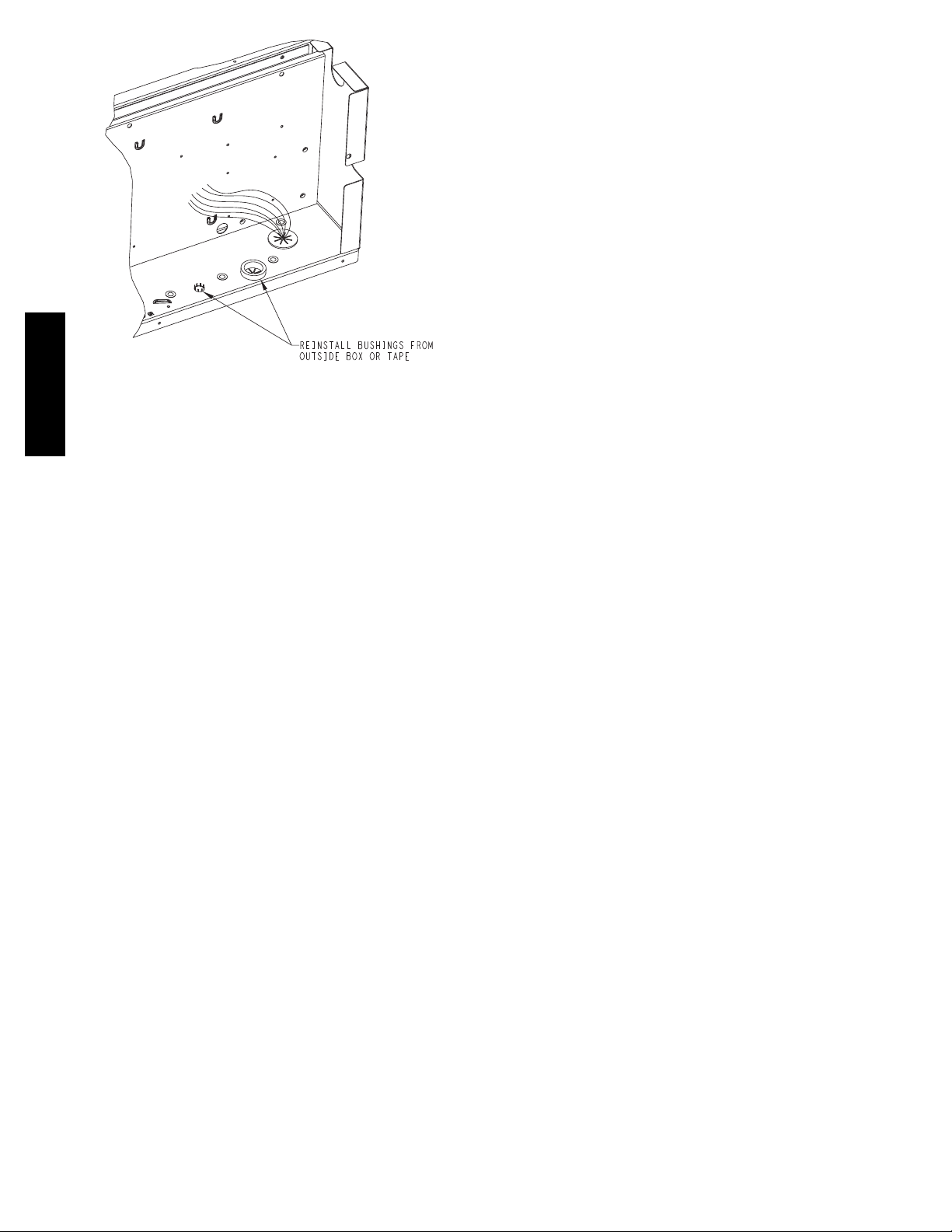

6. Add seal strip to the rear bottom corner of the control panel as shown in Fig. 7. Foil tape open screw

holes on the back of the single point box as shown

in Fig. 7. Different single point boxes will have different screw holes open.

7. All bushings in the area of the control box where

the single point box (SPB) mounts, m ust be removed prior to securing the SPB to the control box.

(See Fig. 8.) Also, for units installed in the snow

belt, all unplugged holes in the bottom of the con-

C11514

Seal Back Corner

CRHTR,CRSIN

Seal Bottom Corner

Foil Tape Locations

C101085

Fig. 7 - Seal Strip and Foil Tape Locations

C09005

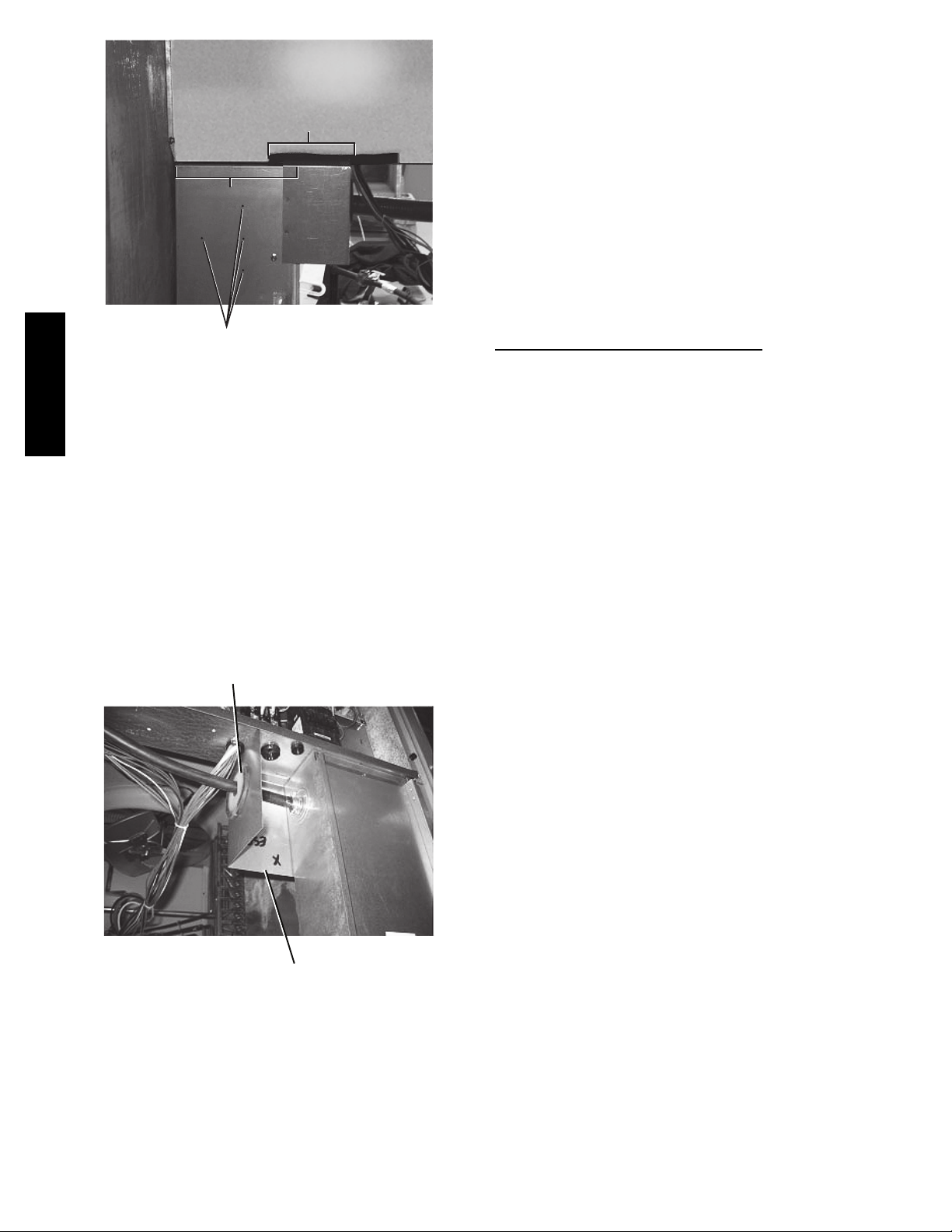

Fig. 8 - Control Box - Bushings to Remove

11

In the unit control box, reloca te these wires:

At IFC terminal 13, disconnect

Compressor 1 BLU and Compressor 2

ORN leads; reconnect at TB10A.

At C1 terminal 13, disconnect ID Fan

YEL lead; reconnect at TB10B.

At C1 terminal 11, disconnect BLK jumper;

reconnect to IFC terminal 11.

Route the first set of tap conductors

(attached at upper fuse block, with

bushing per Step 5) into the main control

box; connect at:

BLK: C1 terminal 11

YEL: C1 terminal 13

BLU (long lead with terminal): TB10A

C09006

Fig. 9 - Bushings Replaced from Outside Control Box

Route the second set of tap conductors

(attached at second fuse block) into the

main control box; connect at:

CRHTR,CRSIN

box.

a. Single point boxes with two or three tap con-

ductors--Route the tap conductors (with bushing

added per Step 5) into the unit main control box.

Connect the power tap conductors to the designated terminal s in the unit’s control box for field

power connections. Refer to the wiring diagram

in the unit, to unit installation instructions for

Field Power Wiring Connections or to Appendix

A, B or C.

b. Single point boxes with six tap conductors

(CRSINGLE043A00, 045A00, 049A00, 051A00,

053A00 and 054A00)

These single point boxes include two sets of

three-lead power tap conductors connected to

10. Connect power tap conductors to unit main control

two separate f

use blocks, at FU2 and FU3.

These kits also include two terminal blocks

(TB10A and TB10B) and attachment screws; the

TB10 block usage will be two, one or none,

basedonbaseunit.

Refer to TB10 usage tables on page 9 to

determine quantity required for this unit.

BLK: IFC terminal 11

YEL (long lead with terminal): TB10B

BLU: IFC terminal 13

(2.) Units requiring ONE TB10 terminal block

Locate t wo 42--in (1067 mm) BLU and YEL

wires with single insulated female terminal

shipped in a bag with this kit.

At the single point box, locate the BLU tap

conductor on fuse block FU3 (second block);

disconnect and discard. Connect the 42-- in

BLU wire to FU3.

Mount one TB10 terminal block in t he unit’s

control box between compressor contacto

C1 and C2. (See Fig. 10.)

S Relocate these wires:

At IFC terminal 13, disconnect Compressor

2 ORN and OFM BLU leads; reconnect

at TB10.

S Remove these leads:

At C1-11, remove BLK jumper to C2-11.

Discard.

At C1-13, remove YEL jumper to C2-13.

rs

Discard.

(1.) Units requiring TWO TB10 terminal blocks

Mount these terminal blocks in the unit’s

control box next to compressor contactor

C1. (See Fig. 10 and Appendix A or C.)

Locate t wo 42--in (1067 mm) BLU and YEL

wires with single insulated female terminal

shipped in a bag with this kit.

At the single point box, locate the BLU tap

conductor on fuse block FU2 (upper block);

disconnect and discard. Connect the 42--in

BLU wire to FU2.

Route the first set of tap conductors

(attached at upper fuse block, with bushing

per Step 5) into the main control box;

connect at:

BLK: C1 terminal 11

YEL: C1 terminal 13

BLU: IFC terminal 13

Route the sec ond set of tap conductors

(attached at second fuse block) into the main

control box; connect at:

BLK: C2 terminal 11

YEL: C2 terminal 13

At the single point box, locate the YEL tap

BLU: TB10

conductor on fuse block FU3 (second block);

disconnect and discard. Connect the 42-- in

YEL wire to FU3.

12

(3.) Units requiring NO TB10 terminal block

Route the first set of tap conductors

(attached at upper fuse block, with bushing

per Step 5) into the main control box.

Route the second set of tap conductors

(attached at second fuse bl ock) into the main

control box.

Connect both sets of tap conductors to unit

terminal block TB1; connect at:

BLK: terminal 11

YEL: terminal 12

BLU: terminal 13

CRHTR,CRSIN

Fig. 10 -- TB10 Locations and Connections

HEATER

012A

CIR#1

CIR#2

HEATER

017A

C101084

13

Installing Electric Heater

CRHEATER101A00-109A00,

CRHEATER110A-112A00, 103B00, 104B00

CRHEATER113B00-116B00, 117A00,

CRHEATER264A00-269A00

CRHEATER297A00-299A00,

CRHEATER301A00,CRHEATER308A00

CRHEATER316A00-322A00

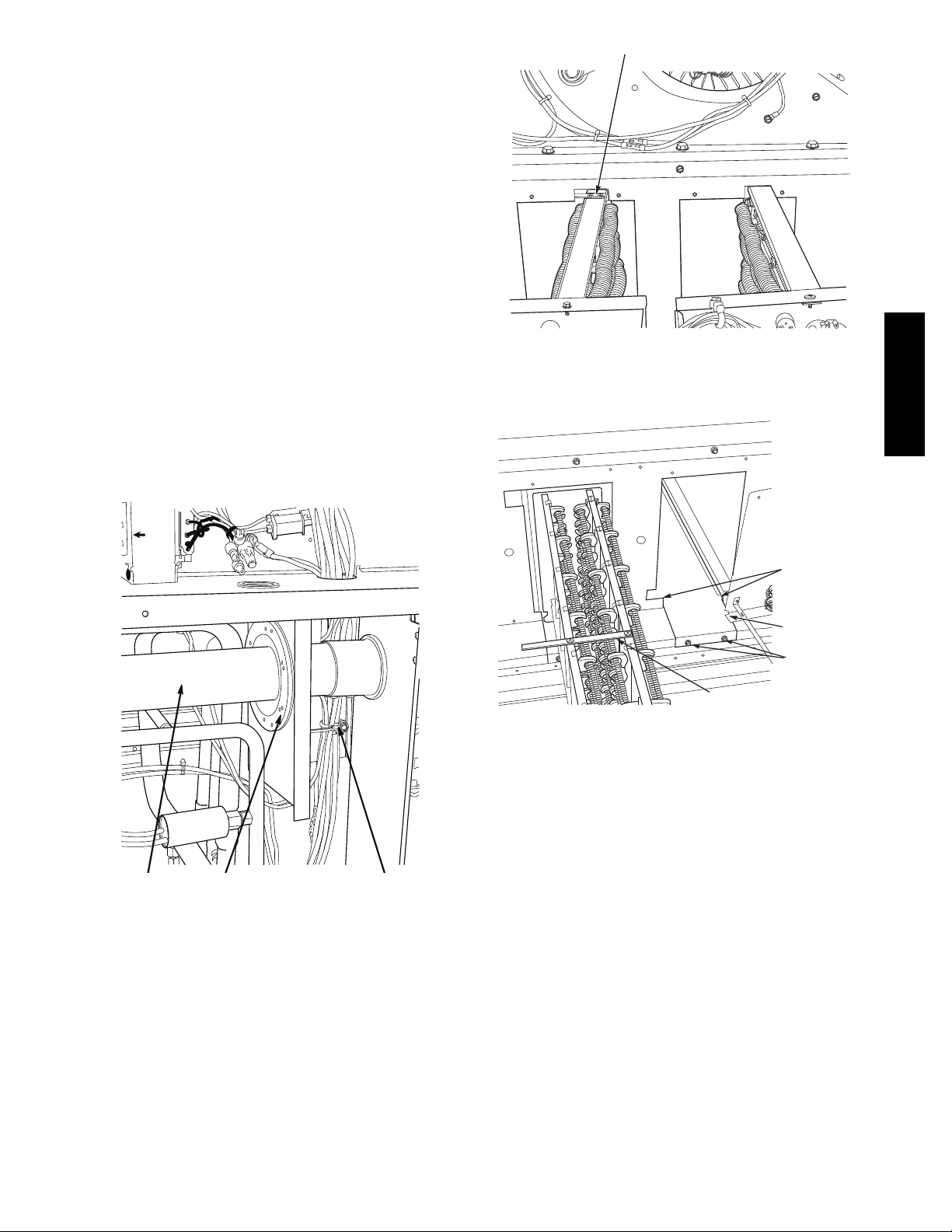

1. Identify heater cover(s) to remove. See Fig. 14 and

15.

a. All two--heater installations: Remove both

heater covers. Save covers and screws.

b.

All single--heater installations EXCEPT

CRHEATER265A00

301A

00:

Remove the heater cove r at Heate r 1 position.

Save cover and screws.

c.

Heater CRHEATER265A00-269A00 ONLY:

Remove the heater cover at Heater 2 position.

CRHTR,CRSIN

Save cover and screws.

d. Heater CRHEATER301A00 ONLY: Remove

both heater covers. Save the screws. Discard

the covers.

2. Open the heater package(s) and remove the heater

module, heater support track (where provided),

screws, wring label, miscell aneous parts.

3. All heaters EXCEPT CRHEATER101A00--109A00,

265A00--269A00 and 301A00: Install heater slide

bracket(s) from the heater kit through the bottom of

the heater mounting hole(s) and fasten each with the

two screws provided. (See Fig. 15.)

4. Install the heater module(s) in the heater support

bracket opening(s). On two--heater installations

where there is no key--forced heater position, install

the heater with the higher kW rating in heater position 1.

a. Heaters CRHEATER101A00--109A00,

265A00--269A00:

To install module, insert heater fram e into location notch in heater bracket opening in unit and

slide heater through the opening. Fasten heater

module to heater mounting bracket with the 4

screws saved from Step 1. (See Fig. 14.)

b. Heater CRHEATER301A00 only: To install

module, insert both heater frames into location

notches in heater bracket opening in unit and

slide heater through the opening. Fasten heater

module to heater mounting bracket with the 4

screws saved from Step 1. (See Fig. 17.)

c. All other heaters: To instal l module, engage

flange on heater with track in uni t and slide

heater through mounting bracket opening. Fasten

heater module to heater mounting bracket with

the 4 screws saved from Step 1. (See Fig. 15.)

5.

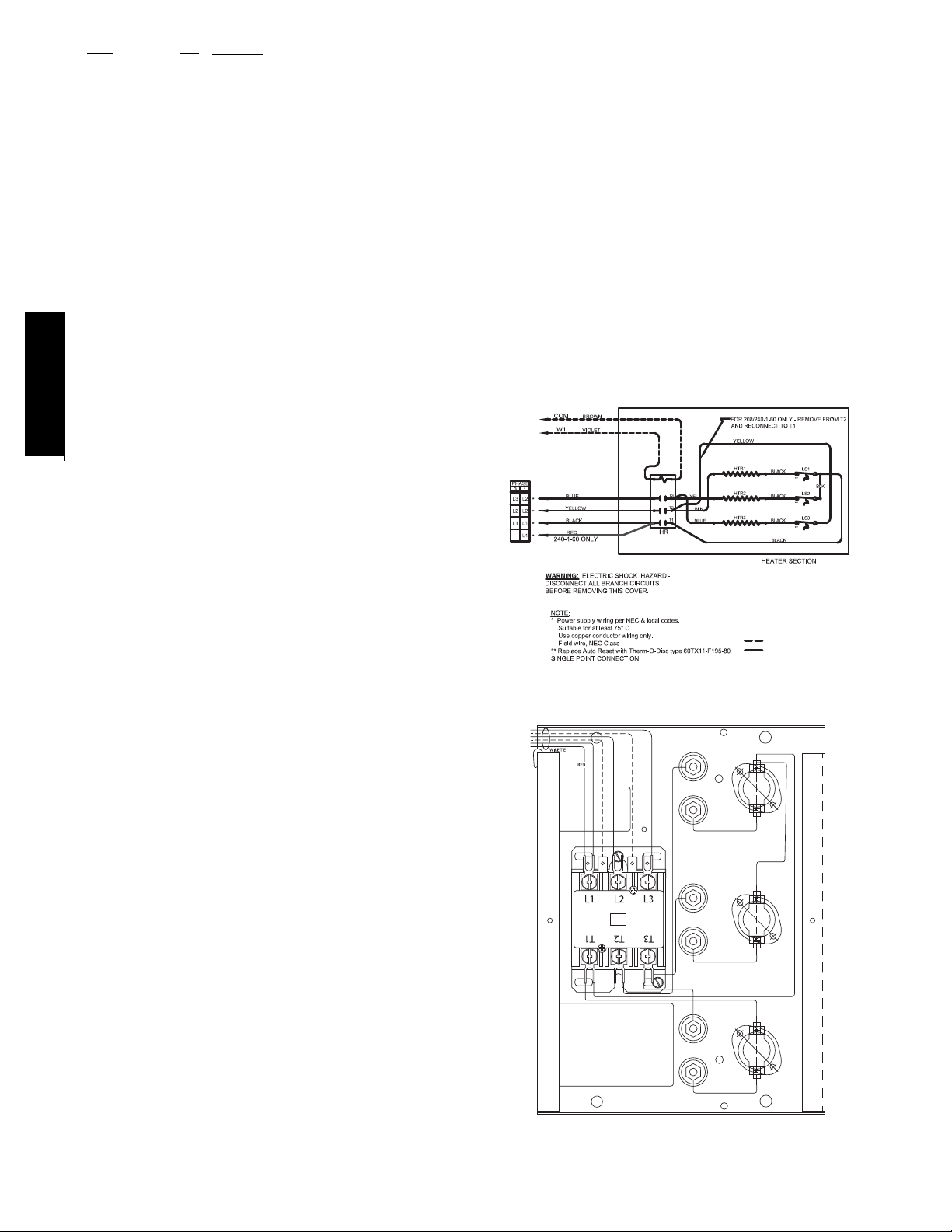

Single-phase heater conversion 208/230-v heaters

CRHEATER101A00 through 104B00 are factorywired for 3-phase applications but can be

converted to single-phase by changing one wire as

described below.

-269A00, 299A00,

Three-phase applications: Skip to Step 6.

For single-phase applications, rewire the heater as

follows (see Fig. 11):

a.

Connect RED wire provided with kit to Heater

Relay (HR) and to L1 as shown.

b.

Disconnect YELLOW wire from HR Terminal

2 and reconnect to HR Terminal 3.

c.

Using the wire tie provided, fasten the RED

wire to heater power wire harness near existing

wire tie on heater module. This provides strain

relief for the RED wire. (See Fig. 12).

Connect the BLACK and RED conductors in the heater

power wire ha rness to the same L1 pole on single point

box TB or fuse block. Connect the BLUE and YELLOW

conductors in the heater power wire harness to the same

L2 pole on single point box TB or fuse block. (See Fig.

11.)

LEGEND

HR - Heater Relay

HTR - Heater

LS - Limit Switch

Control Wiring

Power Wiring

C14214

Fig. 11 - Single--Phase Heater Wiring

C14216

Fig. 12 - Typical Single--Phase Wiring Installed

14

6. Route power wires from heater module(s) through

the foam bushing in the center partition and into the

single point box. (See Fig. 3.) Connect to terminal

block or fuse blocks per schematics in Appendix A

or B. See Tables at beginning of each Appendix to

identify the appropriat e figure.

All heaters are single bank heaters except

CRHEATER111A00, 112A00, 268A00, 269A00,

301A00, 318A00 and 321A00 which are dual bank

heaters. These heaters will be wired as two heaters

(i.e., 6 leads). Fusing is shown pictorially on the

unit wiring schematic label.

If no single point box is required for the unit and

heater combination, run the heater power supply

wiring through the grommet holes to the main unit

control box’s field power connection points or to

optional factory--supplied disconnect.

7. Factory control wiring for heaters runs from unit

control box t o terminal block TB--4, mounted in the

heater compart ment above module 1 location. (See

Fig. 6 and 18.) Connect the heater control wiring at

TB-- 4.

30V—OR 200V—RD OV—YL

N—TRAN 3O—BV2075

E 60 HZ 30-8703

BD236B

D 24V 75VA

KEY FOR MODULE LOCATON 1

C09010

Fig. 14 - Typical Electric Heat Installation

(AC-- 1 Sizes 04 to 07 and 036 to 072, AC--2 Sizes 04--06,

HP-- 1 Sizes 04--07 and 036 to 072, HP--2 Sizes 04--06)

CRHTR,CRSIN

C—COMM

CONDUIT CONDUIT WIRE TIE

DRIP BOOT

3 - Typical Conduit Installation

Fig. 1

C08417

HEATER

SLIDE

TRACK

FLANGE

TRACK SCREWS

KEY FOR MODULE LOCATION 1

C10557

Fig. 15 - Typical Module Installation

(AC-- 1 Sizes 08 to 14 and 090 to 150, AC--2 Sizes 07--12,

HP-- 1 Sizes 08--12 and 090 to 121, HP--2 Sizes 07--09)

15

CRHTR,CRSIN

Fig. 16 - Heater Bracket Keyway

C11513

(AC-2, HP-2 Size 07 and 14 Units Only)

and CRHEATER113B00-116B00

Fig. 17 - Installing CRHEATER301A00

16

C13447

LCTB

CONTL

BOARD

2

3

12

Field

Connections

VIO

ORN

BRN

Elec Htr

VIO

VIO

BRN

BRN

BRN

HR2

HR1

ORN

13

TB4

VIO

VIO

2

VIO

HR1: On Heater 1 in Position #1

HR2: On Heater 2 in Position #2 (if installed)

BRN

BRN

Fig. 18 - Accessory Electric Heater Control

Connections (AC-- 1 Except Size 16 and 180,

AC-- 2 Except Size 14 and 150)

C08331

DEFROST

BOARD

E-HEAT

P3-3

Field

Connections

ORN

BRN

ORN BRN

13

TB4

VIO BRN BRN

VIO

Elec Htr

VIO HR2

HR1

VIO BRN

HR1: On Heater 1 in Position #1

HR2: On Heater 2 in Position #2 (if installed)

Fig. 20 - Accessory Electric Heater Control

Connections (HP--1 Except Size 14 and 150,

HP--2 Except Size 12 and 120)

BRN

C09013

CRHTR,CRSIN

Fig. 19 - Accessory Electric Heater Control Connections

(AC-- 2, Size 06 and 060, 575V only)

C11555

C11554

Fig. 21 - Accessory Electric Heater Control Connections

(HP-- 2, Size 06 and 060, 575V only)

17

CRHTR,CRSIN

Fig. 22 - Typical 3--Phase Wiring Installed

SECTION 2

INSTALLATION, LARGE CABINET

Product Groups/Sizes included in this section:

AC--1 16 (180)

AC--2 14 (150)

AC--3 08--12

HP--1 14 (150)

HP--2 12 (120)

C14217B

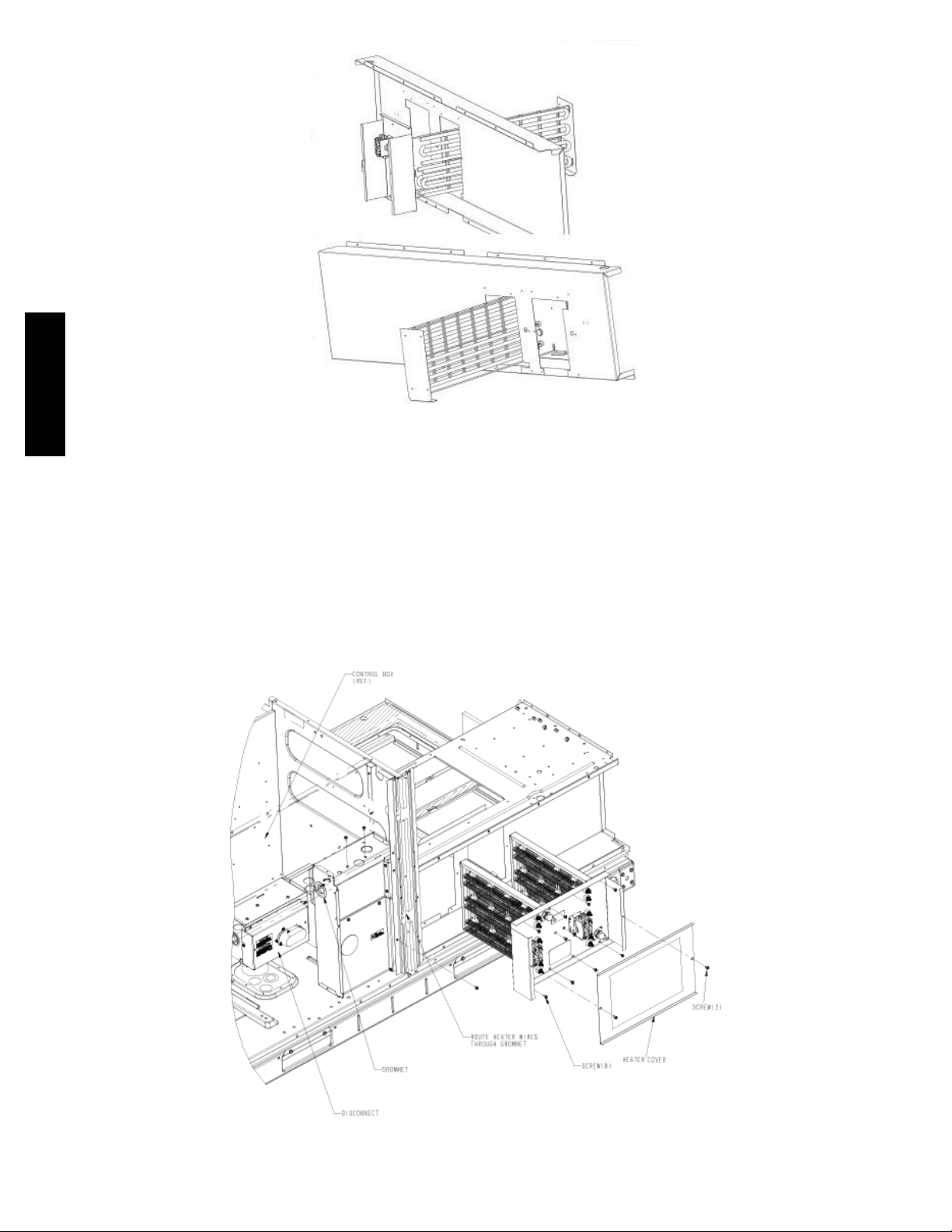

Install Single Point Box (CRSINGLE047A00,

049A00, 050A00-054A00)

1. Remove kits from boxes and verify that all of the

correct parts have arrived undamaged.

2.

If power is already connected to unit, disconnect all power

to the unit per correct lock-out/tag-out procedures.

Disconnect field power wiring or optional factory-installed

disconnect or HACR power leads at TB1 and withdraw the

wiring from the unit control box.

3.

Remove outdoor

access panels from the unit and save screws.

See Fig. 23. Fig. 24 shows the unit with the panels

already removed.

4. Optional – The center post may be removed to facilitate wiring.

5. Remove the bushings and plug from the control

panel per Fig. 25. Save the bushings and discard the

plug.

6. Add seal strip to the rear bottom corner of the control panel as shown in Fig. 26.

7. Foil tape open screw holes on the back of the single

point box as shown in Fig. 26. Different single point

boxes will have different screw holes open.

SINGLE POINT BOX

(NOT SHIPPED WITH

UNIT)

access, control box, and left indoor

CENTER

POST

HEATER

COVERS

Check sales packages – Following the project drawing

schedule tables or submittal documents, select the

scheduled heaters and single point boxes (if used) and

place at each unit.

Compare the sales package number(s) for scheduled

heater modules against the approved usage table on the

unit’s infoplate. See Fig. 1 and 2 for typical plate data. If

the scheduled heater usage does not appear on the unit

infoplate label, STOP. Contact the project engineer or the

local distributor sales office for clarification.

Open the cartons and inspect for damage.

Disconnect field power supply

1.

Disconnect power to the unit. Lock-out/tag-out

on unit disconnect switch.

2. Open and remove the access panel and cover to the

main control box.

3. Use a voltmeter to check that no power is present at

unit terminal block.

MAIN

CONTROL

BOX

(AC-- 1 16/180, AC--2 14--150, AC-- 3 08 --12, HP1 14/150, HP--2

HEATER

MODULE

(LOCATION 1)

Fig. 23 - Typical Component Location

HEATER

MODULE

(LOCATION 2)

12/120)

HEATER

MOUNTING

BRACKET

C11515

18

Control Box

Access

Panel

Outdoor

Access

Panel

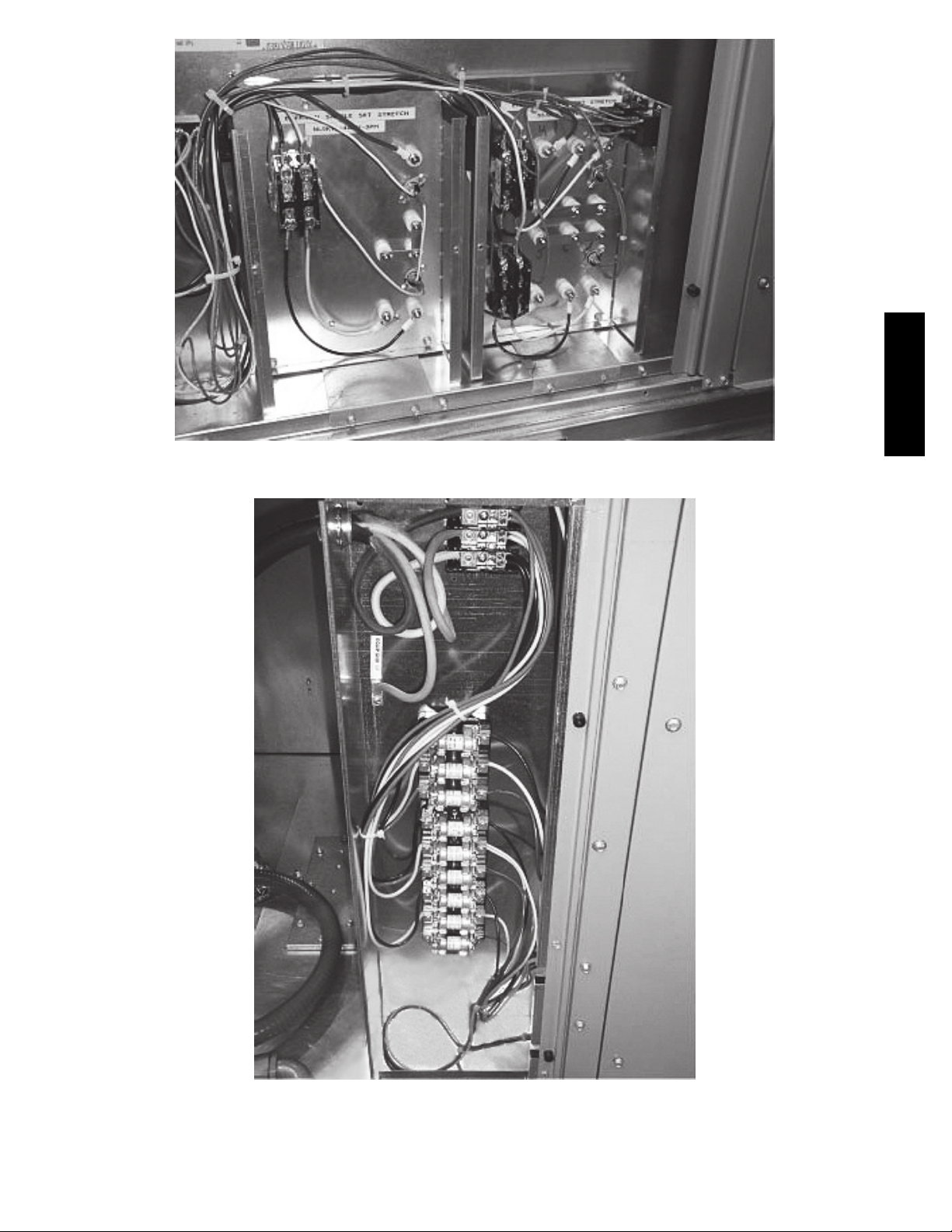

4 - Typical Unit with Access Panels Removed

Fig. 2

Heater Covers

Plug L

Left

Indoor

Access

Panel

ocation

C10170

CRHTR,CRSIN

Single Point Box Mounting Screws

Fig. 2

5 - Single Point Box Installation Details

Bushings

(Re-installed)

C10169

19

conductors (pigtails) from the single point box to

the unit’s powe r t erminal block TB--1 per unit

label wiring schematic and per Appendix A or B

and connection figures. A representative installa-

Seal Back Corner

tion of two 480V heaters and corresponding

single point box is shown in Fig. 28, 29, and 30.

b. CRSINGLE051A00, 053A00 and 054A00

These kits include two sets of tap conductors

Seal Bottom Corner

(blue, yellow and black pigt ails) connected at

fuse blocks 1 and 2. Connect these leads in parallel to the unit’s power terminal block TB--1 per

the unit label wiring schematic and per Appendix A, B or C and connection figures.

(These kits also include two small terminal

blocks (TB10). The TB10 blocks are not used

Foil Tape Locations

Fig

26 - Seal Strip and Foil Tape Locations

.

C101085

Install CRHEATER288A00--296A00

8. Remove the cover from the single point box.

9. Install the single point box under the control panel

CRHTR,CRSIN

with two screws down through the control panel

(Fig. 25) and one screw (not shown) into the center

post. (See Fig. 25.) Holes have been provided.

Foam wire guide s in the center post may have to be

removed. If center post was removed per step 4, the

single point box will have to be screwed into it

later.

10. The single point box kit will contain two rain shield

brackets, a larger bracket with boot seal and a smaller (shorter) bracket without a seal. Remove the

seal from the larger bracket and push the conduit

drip boot seal into the short rain shield bracket. (See

Fig. 27.) Discard the larger bracket.

Conduit Drip Boot

NOTE 1: Heaters with Restrictor Plates

Heater part numbers CRHEATE R288A00, 289A00,

290A00, 294A00, 295A00 and 296A00 have a Restrictor

Plate attached to the heater base plate (see Fig. 33). The

horizontal projection of this plate engages a slot on the

lower left--hand side of Heater Position 2 (right--hand

opening), thus permitting a heater mounting in t he

right--hand heater opening and preventing its inadvertent

with large cabinet units in this section; discard.)

1. Remove and save the heater covers.

2. Install heater slide track(s) from the heater kit

through the bottom of the heater mounting hole(s)

and fasten each with the two screws provided. (See

Fig. 31.)

3.

Install the heater(s) (Fig. 32, 230V shown) into their

mounting location(s) using

the screws provided.

Tables 2 and 3 give the correct heater location as a

function of heater size, voltage, and supply air flow

direction and unit supply air opening size.

mounting in the left--hand heater opening.

On certain heater applications in Tables 2 and 3,

designated by dagger ({) symbol, a heater with a

Restrictor Plate must be installed in the left--hand heater

opening. On these installations ONLY, remove the two

screws at the Restrictor Plate, remove the plate and

discard the plate and screws. Apply foil tape over the

open screw holes.

NOTE 2: Heater CRHEATER295A00, Vertical Unit,

Table 3.

The mounting location for heater CRHEATER295A00

differs based on unit type. When this heater is installed in

a unit type AC--1, AC--2 or AC--3 with vertical supply

duct (unit base opening size is approximately 36 x 28

Rain Shield Bracket

Fig. 2

7 - Rain Shield Installation

C10167

inches), the heater is located in Heater Position 2

(right--hand opening), with Restrictor Plate intact.

When this heater is installed in a unit type HP--1 or HP--2

with vertical supply duct (unit base ope ning size is

11. Install the rain shield bracket to the left and behind

the single point box using the two screws and holes

provided.

12. Re--install the bushings removed in Step 5.

13. Connect the tap conductors.

approximately 30 x 16 inches), the heater is located in

Heater Position 1 (left --hand opening) and Restrictor Plate

must be removed. On these installations ONLY, remove

the two screws at the Restrictor Plate, remove the plate

and discard the plate and screws. Apply foil tape over the

open screw holes.

a. CRSINGLE047A00, 050A00 and 052A00

Connect the blue, yellow, and black power tap

20

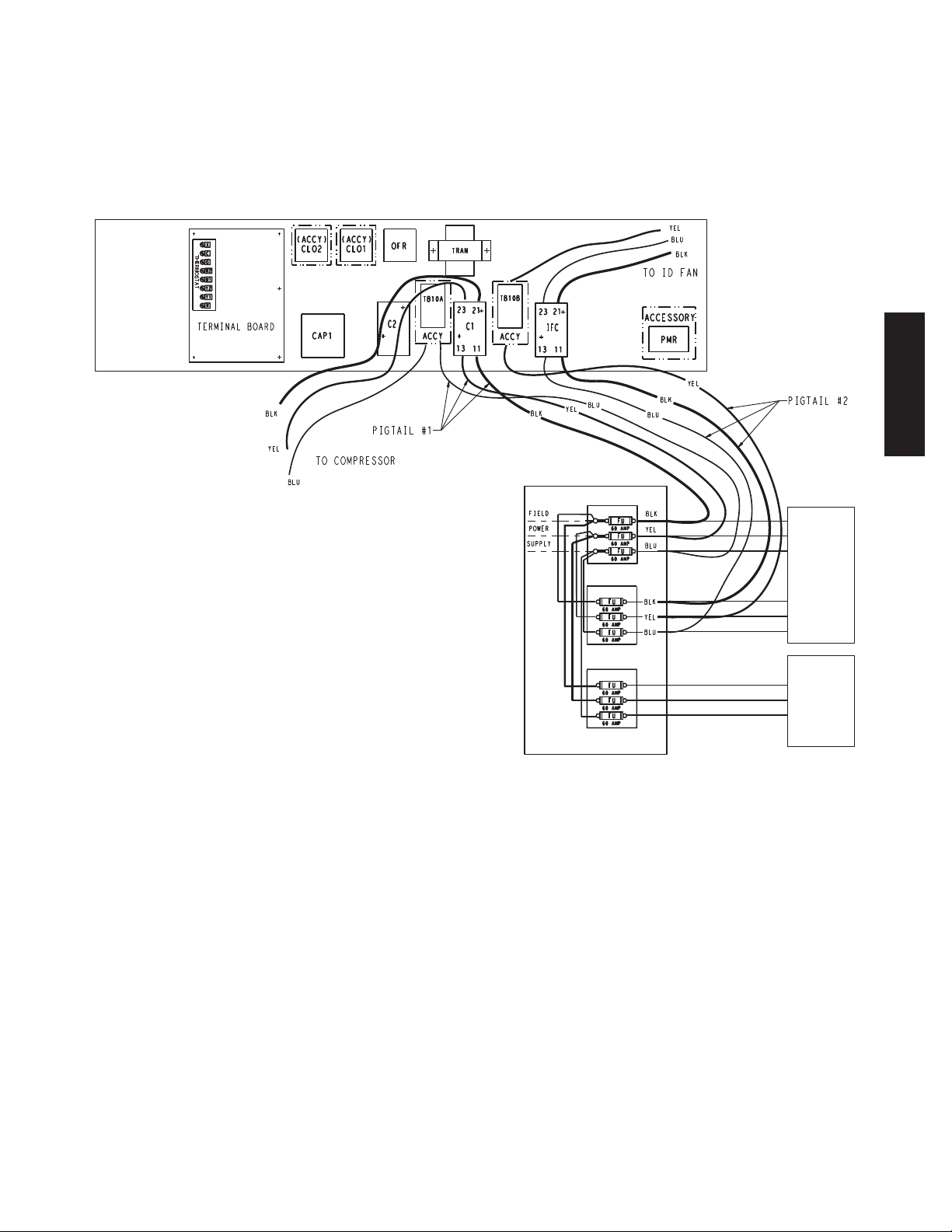

Fig. 28 - Heater Wiring (2-pole contactor shown, has been replaced with 3-pole contactor.)

C10174

CRHTR,CRSIN

Fig. 29 - Typical Single Point Box Wiring

21

C10172

Single Point Box

Power Wires

C10175

Fig. 30 - Typical Control Panel Wiring

CRHTR,CRSIN

Mounting Screws

1 - Heater Slide Track Installation

Fig. 3

Heater Slide Track

C10198

22

Loading...

Loading...