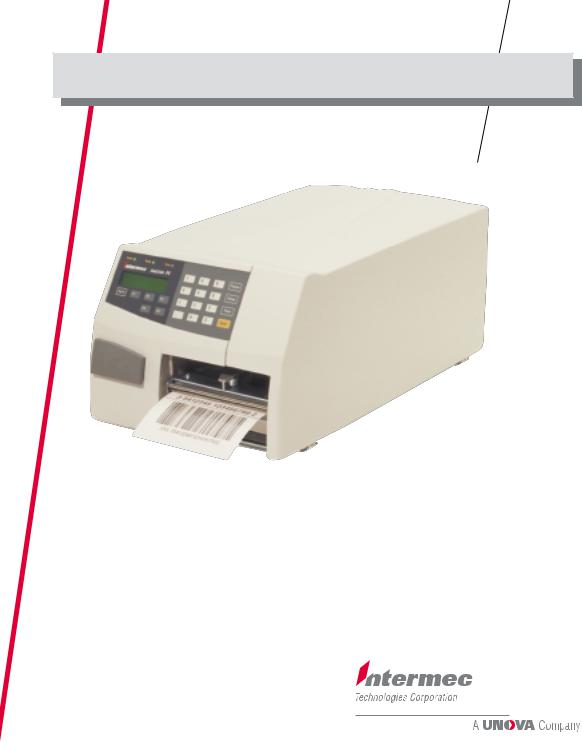

Intermec F4 User Manual

Installation & Operation, IPL Version

P/N 1-960490-02

Edition 3

August 2001

EasyCoder F4

Bar Code Label Printer

Preface

Contents

Preface

1.Introduction

2.Installation

3.Starting Up

4.Media Load

5.Thermal Transfer Printing

6.Setting Up the Printer

EasyCoder F4

Installation & Operation

IPL Version

Edition 3, August 2001

Part No. 1-960490-02

Table of Contents................................................................................. |

1 |

|

Copyright Information ........................................................................ |

3 |

|

Trademarks .......................................................................................... |

3 |

|

FCC Notice (U.S.A.) ........................................................................... |

4 |

|

DOC Notice (Canada)......................................................................... |

4 |

|

GS Notice (Germany) ......................................................................... |

4 |

|

EU Standard EN 55022 (The European Union) ............................... |

4 |

|

Declaration of Conformity (CE) ........................................................ |

5 |

|

Description........................................................................................... |

6 |

|

Safety Precautions ............................................................................... |

7 |

|

Product Labeling ................................................................................. |

7 |

|

Unpacking ............................................................................................ |

8 |

|

Front View ........................................................................................... |

9 |

|

Rear View .......................................................................................... |

10 |

|

Media Compartment ......................................................................... |

11 |

|

Print Mechanism ............................................................................... |

14 |

|

Connections ....................................................................................... |

15 |

|

• |

Power............................................................................................. |

15 |

• |

Computer....................................................................................... |

15 |

Controls and Indicators ..................................................................... |

16 |

|

• |

Control Lamps .............................................................................. |

16 |

• |

Display........................................................................................... |

16 |

• |

Keyboard....................................................................................... |

17 |

• |

Beeper ........................................................................................... |

17 |

Switching On ..................................................................................... |

18 |

|

Tear-Off (Straight-through) .............................................................. |

19 |

|

Tear-Off (Straight-through) with Quick-Load................................. |

23 |

|

Peel-Off (Self-strip)........................................................................... |

25 |

|

External Supply (fanfold).................................................................. |

29 |

|

Ribbon Load ...................................................................................... |

30 |

|

Description......................................................................................... |

34 |

|

Default Setup ..................................................................................... |

34 |

|

Setup Parameters:.............................................................................. |

35 |

|

• |

Serial Communication: ................................................................ |

35 |

|

- Baud Rate ................................................................................... |

35 |

|

- Data Bits...................................................................................... |

35 |

|

- Parity........................................................................................... |

35 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

1 |

Preface |

|

|

|

Contents, cont. |

|

|

|

6. Setting Up the Printer, cont. |

|

- Stop Bits...................................................................................... |

35 |

|

|

- Protocol....................................................................................... |

36 |

|

• |

Test/Service: ................................................................................. |

38 |

|

|

- Testprint ...................................................................................... |

38 |

|

|

- Data Dump ................................................................................. |

39 |

|

|

- Memory Reset ............................................................................ |

39 |

|

|

- Label Rest Dots .......................................................................... |

39 |

|

|

- Form Adj Dots X........................................................................ |

39 |

|

|

- Form Adj Dots Y........................................................................ |

39 |

|

• |

Media: .......................................................................................... |

40 |

|

|

- Media Type................................................................................ |

40 |

|

|

- Paper Type ................................................................................. |

40 |

|

|

- Label Length ............................................................................. |

40 |

|

|

- Sensitivity .................................................................................. |

40 |

|

|

- Darkness ..................................................................................... |

41 |

7. Setup Mode |

Entering the Setup Mode .................................................................. |

42 |

|

|

Navigating in Setup Mode ................................................................ |

42 |

|

|

Setup Mode Overviews..................................................................... |

43 |

|

8. Options |

Introduction....................................................................................... |

46 |

|

|

DTP Model ........................................................................................ |

47 |

|

|

Side Doors and Megatop................................................................... |

47 |

|

|

Integral Liner Takeup Unit ............................................................... |

47 |

|

|

Media Supply Hub............................................................................. |

47 |

|

|

3-inch Adapter ................................................................................... |

47 |

|

|

Quick-Load Guides ........................................................................... |

48 |

|

|

Label Taken Sensor ........................................................................... |

48 |

|

|

Interface Boards ................................................................................ |

48 |

|

9. Troubleshooting |

Troubleshooting List.......................................................................... |

49 |

|

10. Maintenance |

Printhead Cleaning............................................................................ |

50 |

|

|

External Cleaning.............................................................................. |

53 |

|

|

Cleaning the Media Guides .............................................................. |

54 |

|

|

Printhead Replacement ..................................................................... |

55 |

|

11. Adjustments |

Narrow Media Adjustment ............................................................... |

58 |

|

|

Label Stop Sensor Position ............................................................... |

59 |

|

|

Printhead Pressure............................................................................ |

60 |

|

|

Ribbon Break Shaft Adjustment ...................................................... |

61 |

|

2 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

|

|

|

Preface |

Contents, cont. |

|

|

|

Appendix 1 |

Technical Data ................................................................................... |

62 |

|

Appendix 2 |

Media Specifications ........................................................................ |

64 |

|

|

• |

Direct Thermal Media ................................................................ |

64 |

|

• |

Thermal Transfer Media............................................................. |

64 |

|

• |

Media Roll Size ............................................................................ |

65 |

|

• |

Media............................................................................................. |

66 |

|

|

- Non-Adhesive Strip.................................................................... |

66 |

|

|

- Self-Adhesive Strip .................................................................... |

67 |

|

|

- Self-Adhesive Labels ................................................................. |

68 |

|

|

- Tickets with Gap ........................................................................ |

69 |

|

|

- Tickets with Black Mark............................................................ |

70 |

|

• |

Transfer Ribbons .......................................................................... |

71 |

|

• Setting the Media Sensitivity Number........................................ |

72 |

|

Appendix 3 |

Interfaces............................................................................................ |

75 |

|

|

• |

RS-232 Interface........................................................................... |

75 |

|

• IEEE 1284 Parallel Interface Board (option) ............................. |

76 |

|

|

• EasyLAN 100i Interface Board (option) .................................... |

77 |

|

Appendix 4 |

Supported IPL-3 commands............................................................. |

78 |

|

Information in this manual is subject to change without prior notice and does not represent a commitment on the part of Intermec Printer AB.

© Copyright Intermec Printer AB, 2001. All rights reserved. Published in Sweden.

EasyCoder, EasyLAN, Fingerprint, and LabelShop are registered trademarks of Intermec Technologies Corp. The word Intermec, the Intermec logo, PrintSet, and Duratherm are trademarks of Intermec Technologies Corp.

Kimdura is a registered trademark of Kimberly Clark. Centronics is a registered trademark of Genicom Corporation Microsoft is a registered trademark of Microsoft Corporation. Torx is a registered trademark of Camcar Division of Textron Inc. TrueDoc is a registered trademark of Bitstream, Inc.

TrueType is a trademark of Apple Computer Inc. Unicode is a trademark of Unicode Inc.

Valeron is a registered trademark of Van Leer Worldwide

Windows is a trademark of Microsoft Corporation.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

3 |

Preface

FCC Notice (United States of America)

WARNING

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in accordance with the instructions manual, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference in which case the user at his own expense will be required to take whatever measures may be required to correct the interference.

DOC Notice (Canada)

Canadian Dept. of Communication

REGULATIONS COMPLIANCE (DOC-A)

This digital apparatus does not exceed the class A limits for radio noise emissions from a digital apparatus as set out in the radio interference regulations of the Canadian Department of Communication.

Ministère des Communications du Canada CONFORMITE DE REGLEMENTS (DOC-A)

Le présent appareil numérique n’émet pas de bruits radio-électriques dépassant les limites applicables aux appareils numériques de classe A prescrites dans le règlement sur brouillage radioélectrique édicté par le Ministère des Communications du Canada.

GS Notice (Germany)

ALLGEMEINE VORSCHRIFT

Reparaturen oder sonstige Eingriffe, die sich nicht auf normale Bedienung der Maschine beziehen, dü rfen ausschließlich nur von einem ausgebildeten, zuständigen Fachmann vorgenommen werden.

EU Standard EN 55022 (The European Union)

WARNING

This is a Class A ITE product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

4 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Preface

Declaration of Conformity

We,

Intermec Printer AB

Idrottsvä gen 10

Box 123

S-431 22 Mö lndal

Sweden

declare under our sole responsibility1 that the product

EasyCoder F4

to which this declaration relates

is in conformity with the following standards

EMC:

EN 50 081-1:1992

EN 55 022:1994

EN 61 000-3-2:1995, class A

EN 50 082-2:1995

EN 61 000-4-2:1995

EN 61 000-4-3:1996

ENV 50 204:1995

EN 61 000-4-4:1995

EN 61 000-4-6:1996

Electrical Safety:

EN 60 950

following the provisions of Directives

89/336/EEC and 73/23/EEC

Mö lndal 1999-09-01

President

1 /. Intermec assumes no responsibility regarding the CE Directive if the printer is handled, modified, or installed in other manners than those described in

Intermec’s manuals.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

5 |

Chapter 1

Introduction

Description

The EasyCoder F4 is a sturdy medium-duty direct thermal/thermal transfer printer with a printhead resolution of 8 dots per mm (203.2 dots per inch) and a maximum print width of 104 mm (4.095 inches).

The EasyCoder F4 is delivered with the Intermec Programming Language (IPL-3) installed. There is also a version of the EasyCoder F4 that uses the Intermec Fingerprint Programming Language. Mechanically, the IPL version is identical to the Intermec Fingerprint version, but a few options are not supported by IPL-3, for example:

•Optional double serial and industrial interface boards

•Electronic keys

•Memory cards (except for firmware upgrading)

•EasySet Bar Code Wand

•Real Time Clock Circuit

In most respects, the EasyCoder F4 IPL version is compatible with other IPL printers from Intermec. Please refer to Appendix 4 for a list of supported IPL-3 commands.

6 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Chapter 1 Introduction

Safety

Precautions

Intermec assumes no responsibility regarding the CE Directive if the printer is handled, modified, or installed in any way other than described in Intermec’s manuals.

Caution

•Read this manual carefully before connecting the printer.

•Moving parts are exposed when the side door is open, so ensure that the door is closed before you operate the printer.

•Do not open the front/left-hand cover. Dangerous voltage!

•Do not remove the bottom plate. Dangerous voltage!

•Do not put your fingers inside the print mechanism when the power is on.

•Place the printer on an even surface which can support its weight of approximately 7 kg (15.5 lb) plus supplies.

•Do not spray the printer with water. If you are using a hose to clean the premises in an industrial environment, remove the printer or protect it carefully from spray and moisture.

•Carefully read the warning text on the envelope before using a cleaning card.

Product Labeling |

The machine label is attached to the printer’s rear plate and contains |

information on type, model, and serial number as well as AC input |

|

|

voltage range. It also contains various signs of approval. |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

7 |

Chapter 2

Installation

Unpacking

1/. Type and quantity may vary, or labels/ribbon may be omitted completely, depending on area of distribution.

Before you install the printer, examine the package for possible damage or missing parts:

•Open the box and lift the printer out.

•Check that the printer has not been visibly damaged during transportation. Keep the packing materials in case you need to move or reship the printer.

•Check the label on the printer’s rear plate, which gives the voltage, the part number, and the serial number.

•Check that any options you ordered are included.

•Check that all accessories are included. As standard, the box contains:

-Intermec EasyCoder F4 printer

-Two sets of Quick-Load guides (wide and narrow)

-Power cord (at least one depending on model)

-Quality check card

-Cleaning card

-Short strip of labels1

-Adapter for 3-inch media roll core (only in models fitted with a rotating media supply hub)

-Starter pack of thermal transfer ribbon (thermal transfer models only)1

-User’s Guide (multilingual)

-Installation & Operation manual

-Supporting software and product information on CD.

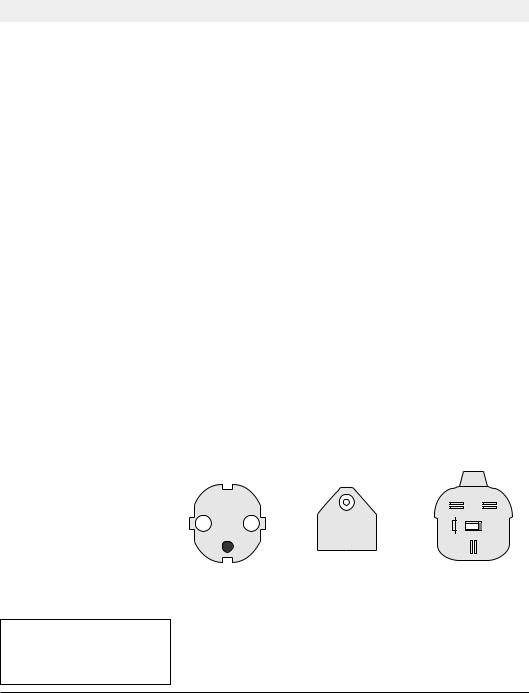

•Check that the power cord is appropriate for the local standard. The printer works within 100 to 240 VAC, 50 to 60Hz.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

European-type |

US/Canadian-type |

|

|

GB-type |

||||||||||

230V mains plug |

115V mains plug |

230V mains plug |

||||||||||||

If the printer has been damaged in any way during transportation, complain to the carrier immediately.

If the delivery is incorrect or any parts are missing, report it immediately to the distributor.

8 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Chapter 2 Installation

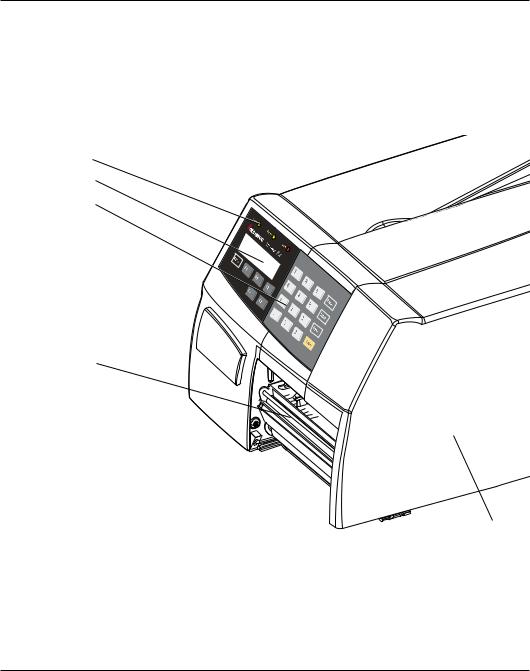

Front View

Control Lamps

Display Window

Keyboard

Print Mechanism

At the front of the printer are the display window, the control lamps, and the keyboard. These features allow the operator to control and set up the printer manually.

The printed labels, tickets, or tags are presented at the front of the print mechanism.

Side Door

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

9 |

Chapter 2 Installation

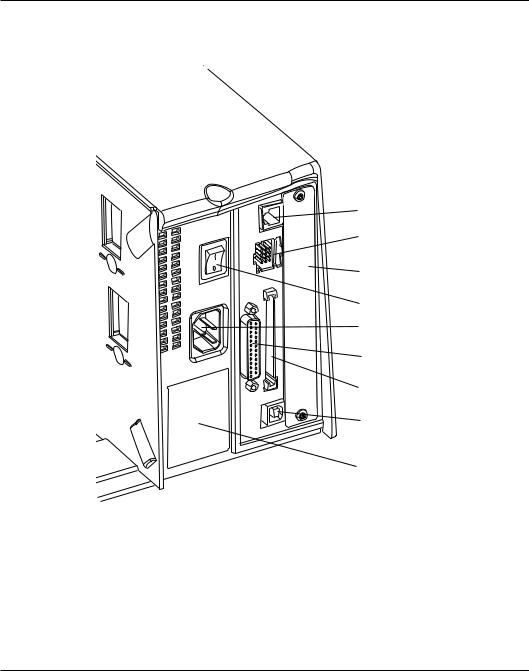

Rear View

The rear plate contains the On/Off switch, the AC power cord receptacle, and various interface connectors and slots.

(not used) (not used)

Provision for one Interface Board

On/Off Switch

AC Power Cord Receptacle

RS-232 Serial Interface Socket

Memory Card Slot (for firmware upgrade)

(not used)

Machine Label

10 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Chapter 2 Installation

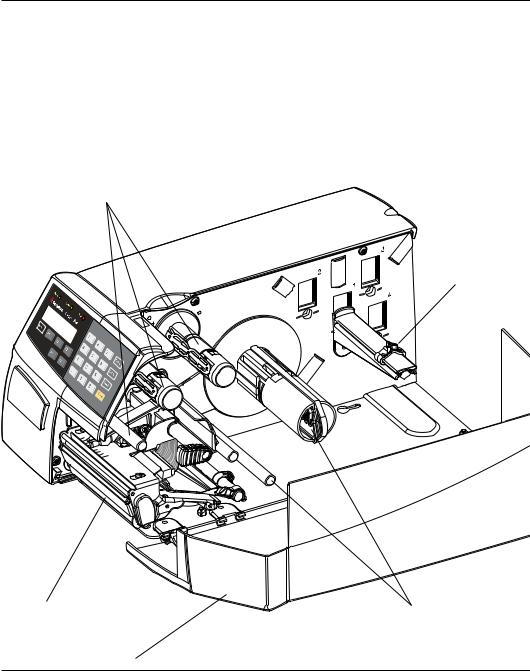

Media

Compartment

The media compartment is either covered by a long side door that completely encloses the print mechanism and media compartment, an 8-inch Megatop for extra large media rolls, or a short side door that only covers the print mechanism and gives easy access to the media stock. The door is held by a magnetic lock. It can be opened 180° so to provide full access to the media compartment.

The media supply can be from a supply post, or from an external supply of fan folds behind the printer. There is also an optional rotating media supply hub, see Chapter 8 “Options.”

Thermal Transfer Mechanism

(optional)

Media Supply

Roll Post with Edge Guide

Print Mechanism |

Optional Integral Liner |

|

Takeup with Guide Shaft |

Long Side Door |

|

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

11 |

Chapter 2 Installation

Media Compartment, cont.

Since the EasyCoder F4 has a modular design, it uses a media supply roll post that can be fitted in three different positions inside the media compartment. The position depends on the type of side door (long, short, or Megatop) and whether or not the printer is fitted with an integral liner takeup. Alternatively, an external media supply (for example a box of fan folded tickets) behind the printer can be used. A rotating media supply hub is also available as an option, see Chapter 8, “Options.”

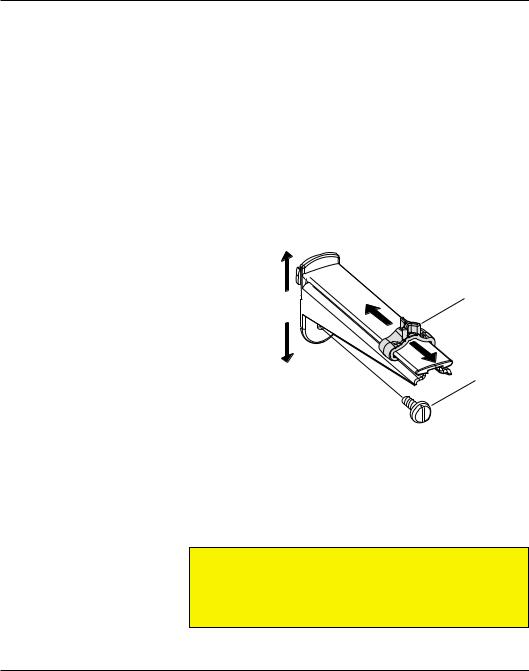

Media Supply Roll Post

The media supply roll post fits both 38-40 mm (1.5 inches) and 76 mm (3.0-inches) cores, since it can be moved vertically in the slot in the center section. The bottom position is intended for small cores and the top position for large cores only. The post is locked by a straight-slot screw and has a moveable edge guide to fit various media widths.

|

|

76 |

mm |

|

||

(3 |

|

inches) |

Edge Guide |

|||

|

|

|

|

|

||

|

|

CORE |

|

|||

38 |

- 40 |

mm |

|

|||

|

|

|||||

|

inches) |

|

||||

(1 |

.5 |

|

||||

|

|

|

|

|||

|

|

|

|

|

|

|

Screw

To move the post to a different slot; remove the screw, twist the post a quarter of a turn, and pull it out.

To fit the post; rotate it a quarter of a turn, insert it into the appropriate slot in the center section (see next page), and twist back so the lips engage the cutouts in the sides of the slot. Move it up (large core) or down (small core) as far as it goes and secure it with the screw.

Caution!

Make sure to adjust the position of the post according to the size of the media roll core. When the post is fitted in the top position, the head of the screw will interfere with small (38 mm/1.5 inches) cores, causing media misalignment.

12 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Chapter 2 Installation

Media Compartment, cont.

Media Supply Positions

There are four sets of slots and threaded holes in the printer’s center section for the media supply roll post or rotating hub (optional). These slots allow the largest possible roll size to fit, given the limitations of any liner takeup unit and/or the full enclosure provided by the long side door or Megatop. The positions are indicated by numbers engraved in the center section.

•Position 1 is used when the media compartment is fully enclosed by a long side door, regardless of the existence of any integral liner takeup unit. Maximum roll size is 152 mm (6 inches).

•Position 2 is used when the printer has a short side door that only encloses the print mechanism, but does not have an integral liner takeup unit. Maximum roll size is 213 mm (8.38 inches).

•Position 3 is used when the printer has a short side door and an integral liner takeup unit. This position is also used with the optional 8-inch Megatop, see Chapter 8, “Options.” Maximum roll size is 213 mm (8.38 inches).

•Position 4 is reserved for possible future development.

The printer can also use an external media supply located behind the printer, unless it has an optional 8-inch Megatop.

3

Pos. 3

2

1 |

Pos. 2 |

|

|

|

4 |

|

Pos. 1 |

(Pos. 4)

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

13 |

Chapter 2 Installation

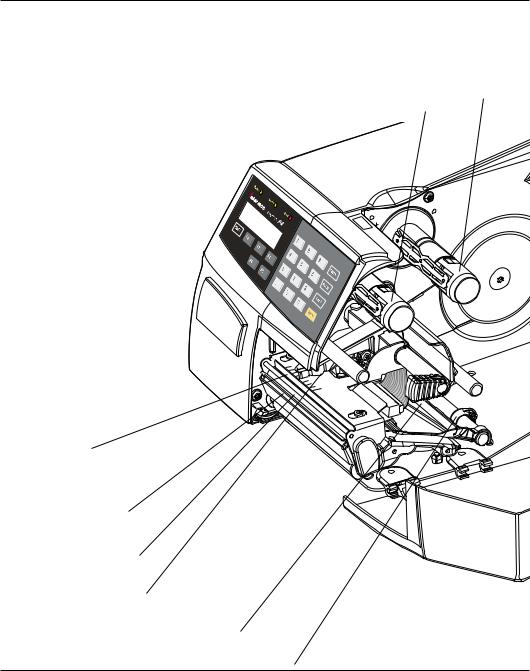

Print Mechanism |

The print mechanism features a high-performance 8 dots-per-mm |

|

|

|

(203.2 dots-per-inch) thermal printhead with quick-mount fittings |

|

to facilitate replacement. The thermal transfer ribbon mechanism is |

|

omitted in dedicated direct thermal printing models. |

|

Ribbon Supply Hub |

|

Ribbon Rewind Hub |

Thermal Printhead

Tear Bar

Platen Roller

Pressure Arm

Printhead Lift Lever

Edge Guide

14 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

|

Chapter 2 Installation |

Connections |

|

Power |

1 Place the printer on a level surface near an AC outlet. You should |

|

be able to easily access the printer to load media, to load ribbon, |

|

and to remove the printout |

|

2 Check that the printer is switched off. |

|

3 Connect the power cord between the receptacle on the rear plate |

|

and an electrical outlet (>90 to <264 VAC). |

Computer |

The EasyCoder F4 is fitted with one 25pin D-style subminiature |

|

(DB25) socket for the RS-232 serial interface port (see Appendix |

|

3). The printer is also prepared for one optional interface board |

|

(auto-sensing). |

|

• RS-232 Serial Interface |

|

Use the serial interface when you need a two-way communication |

|

between printer and host computer. Before you can use the |

|

serial interface, you may need to set up the communication |

|

parameters, such as baud rate, parity, etc. as described in Chapter |

|

6, “Setting Up the Printer.” |

|

• Parallel Interface Board |

|

Optional. Refer to Appendix 3 and the separate documentation |

|

delivered with the board for connection and setup instructions. |

|

• EasyLAN 100i Interface Board |

|

Optional. Refer to Appendix 3 and the separate documentation |

|

delivered with the board for connection and setup instructions. |

|

Switch off both the PC and the printer before connecting them |

|

together. |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

15 |

Chapter 2 Installation

Controls and

Indicators

Control Lamps

Display

The EasyCoder F4 has several ways of communicating directly with its operator: three control lamps, a display window, a membraneswitch keyboard with 22 keys, a big “Feed” button on the printer’s front, and a beeper. Only some of the keys are used with IPL.

The control lamps are colored LEDs (Light Emitting Diodes) and indicate the following conditions:

• |

Power (green): |

|

|

On |

Power on |

|

Off |

Power off |

• |

Ready (green): |

|

|

On |

Media fault detected |

|

Flashing |

Printer offline |

|

Off |

Printer online |

• |

Error (red): |

|

|

On |

System fault detected |

|

Flashing |

Printer overtemperature |

|

Off |

OK |

The display window contains an LCD (Liquid Crystal Display) with background illumination and two lines of text, each with 16 characters. It guides the operator through upgrading, startup, and setup.

16 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

|

|

|

|

Chapter 2 Installation |

|

Controls and Indicators, cont. |

|

|

|

||

Keyboard |

The keyboard is of membrane-switch type and has 22 keys. The |

||||

|

keyboard is supplemented by a large “Feed” button on the printer’s |

||||

|

front. Only four of these keys plus the “Feed” button are working |

||||

|

with IPL (except in the Setup Mode where the keyboard works |

||||

|

differently, see Chapter 7, “Setup Mode”). |

|

|||

|

|

|

|

|

|

|

Condition |

<Feed> |

<C> |

<Pause> |

<Setup> |

|

|

|

|

|

|

|

Idle |

Feed/Reload |

– |

Toggle offl ine/online |

Enter Setup Mode |

|

Printing |

– |

– |

Hold printing |

– |

|

Paused |

Feed/Reload |

Cancel print job |

Resume printing |

Enter Setup Mode |

|

|

|

|

|

|

|

“Feed” means advancing the media one form, whereas “Reload” |

||||

|

means notifying the hardware when certain configuration commands |

||||

|

have been entered. |

|

|

|

|

Beeper |

The beeper notifies the operator that a key has been pressed. |

||||

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

17 |

Chapter 3

Starting Up

Switching On

Before switching on the printer, make the necessary connections and check that the printhead is engaged.

Switch on the power using the On/Off switch on the rear plate. The “Power” control lamp on the front panel lights up when the power is on. Wait for a few moments, while the printer loads the program and runs some self-diagnostic tests.

While the printer is initialized, the progress of the initialization is indicated by an increasing number of colons on the lower line in the display:

Initializing

:::

When the initialization is completed, a label is fed out. Then the following message appears, indicating that the printer is ready for operation:

IPL Ver 1.3

9600-8-N-1-X/X

The upper line indicates the IPL version number and lower line shows the either the present serial communication setup or an error message:

-Paused

-Printhead Up

-Press Feed

-Paper Out

-Ribbon Out

-Printhead Hot

18 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Chapter 4

Media Load

Tear-Off

(Straight-through)

Important!

Save the label indicating the sensitivity number attached to the media roll. You will need this number to set the media sensitivity, see Appendix 2.

The EasyCoder F4 can print on labels, tickets, tags, and continuous stock in various forms. This chapter describes the case when the media is to be torn off manually against the printer’s tear bar. This method is also known as “straight-through printing”.

Tear-off can be used for:

•Non-adhesive continuous stock

•Self-adhesive continuous stock with liner

•Self-adhesive labels with liner

•Tickets with gaps, with or without perforations

•Tickets with black marks, with or without perforations

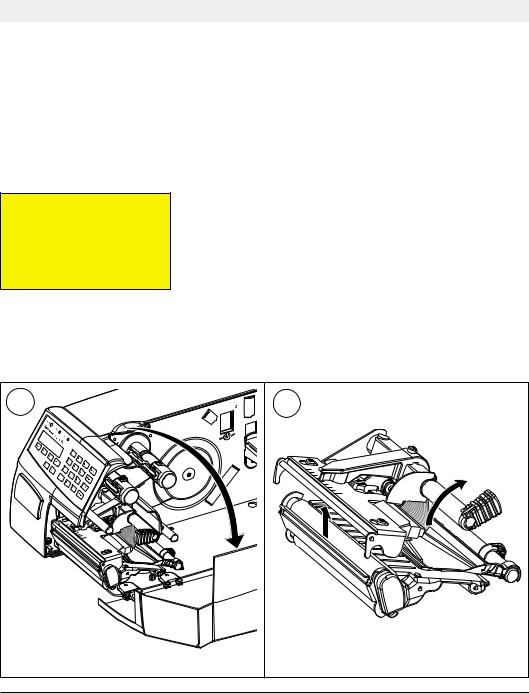

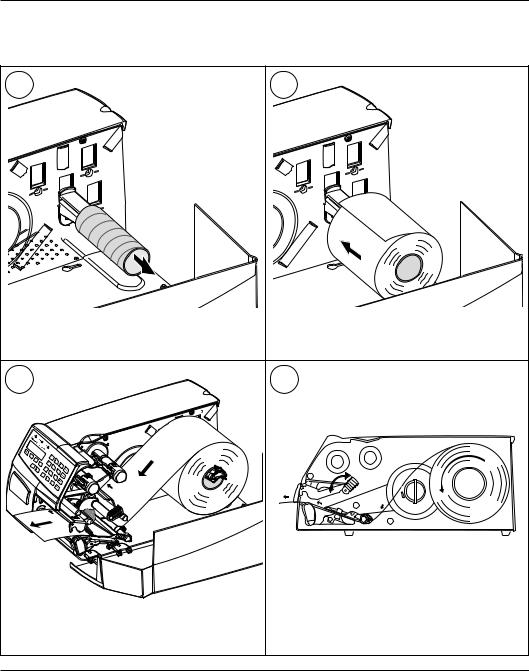

1 |

2 |

|

Turn the printhead lift lever clockwise to raise |

Open the side door. |

the printhead. |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

19 |

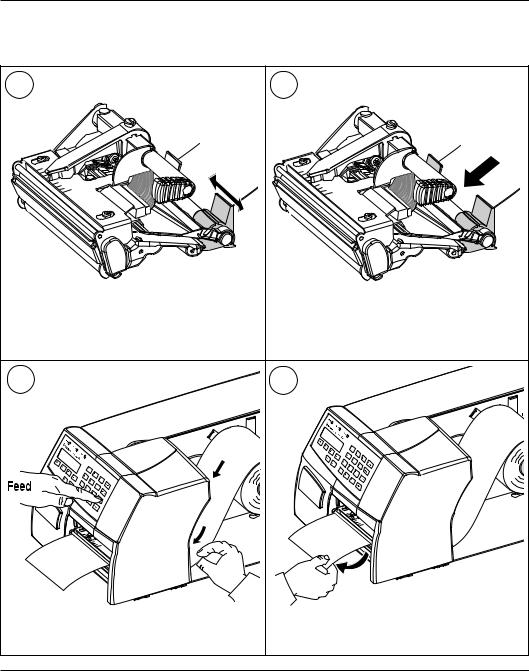

Chapter 5 Ribbon Load

Tear-Off, cont.

3 |

4 |

|

3 |

|

2 |

|

1 |

|

4 |

Remove any empty core from the media supply |

Fit a new roll of media on the supply post and |

adjust the edge guide so the roll becomes flush |

|

roll post. |

with the center section. |

|

6 |

Route the media through the print mechanism. Then push it inwards as far as it will go.

This diagram shows the media path.

20 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Chapter 4 Media Load

Tear-Off, cont.

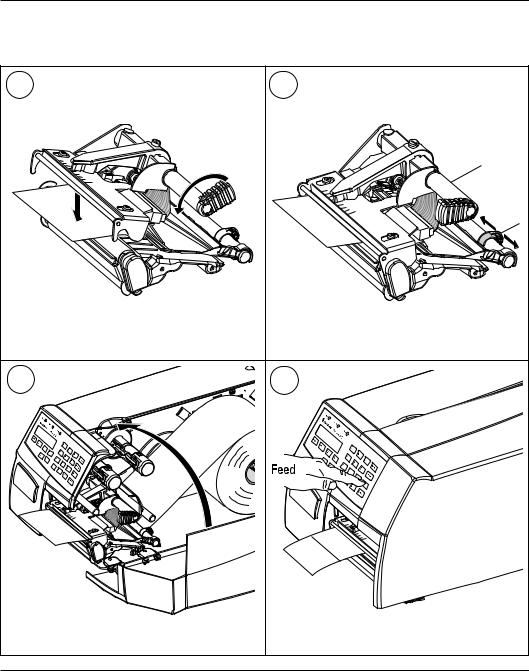

7 |

8 |

Turn the printhead lift lever counterclockwise to engage the printhead.

Adjust the position of the green edge guide so the media is guided with a minimum of play.

Close the side door. |

Press the Feed key to advance the media and |

adjust the media feed. |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

21 |

Chapter 4 Media Load

Tear-Off, cont.

11

To tear off the media, grab the outer edge and pull downwards.

22 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

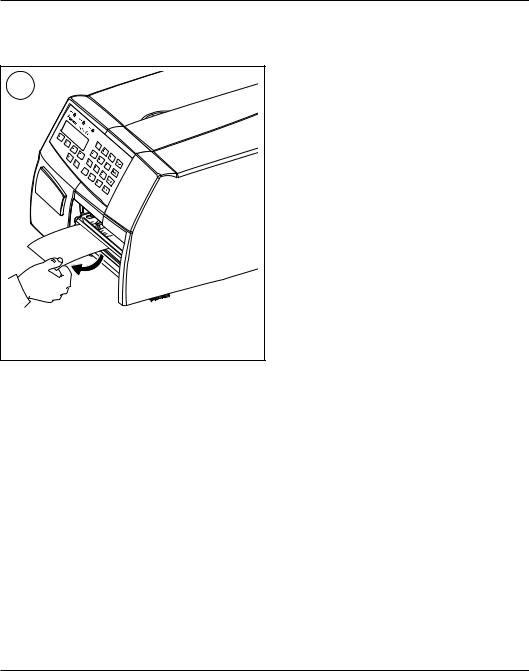

Chapter 4 Media Load

Tear-Off with Quick-Load

(Straight-through)

Important!

Save the label indicating the sensitivity number attached to the media roll. You will need this number to set the media sensitivity, see Appendix 2.

In addition to the media load procedure for tear-off (straight-through) operation described earlier in this chapter, the EasyCoder F4 can optionally be fitted with a set of Quick-Load guides that makes media load much easier and quicker, especially if the printer has a short side door. See Chapter 8, “Options” for installation instructions.

The printer is normally delivered with two sets of Quick-Load guides: wide and narrow. The wide type generally guides the media better, but the media must be at least of 80 mm (3.15 inches) wide. The narrow type allows a media width as narrow as 40 mm (1.57 inches), but may be less suited for wide and thin media. Illustrations in this chapter show the narrow type of guides.

Quick-Load cannot be combined with peel-off (self-strip) operation.

1

|

Fit a new roll of media on the supply post and |

Remove any empty core from the media supply |

adjust the edge guide so the roll becomes flush |

roll post. |

with the center section. |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

23 |

Chapter 4 Media Load

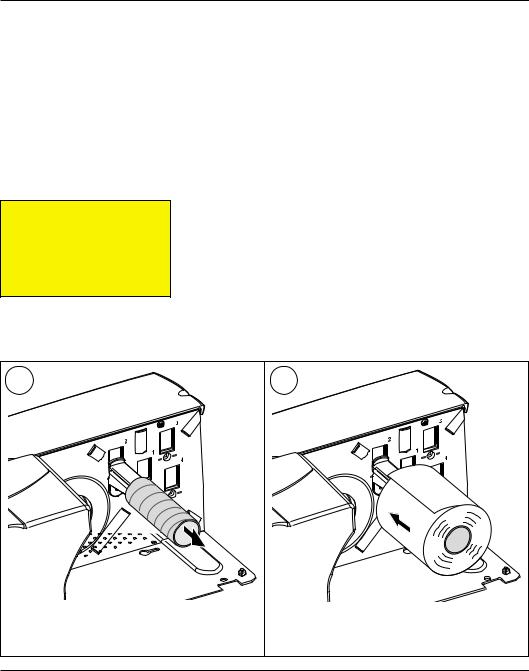

Tear-Off with Quick-Load, cont.

3 |

4 |

|

Insert the media between the guides and feed |

If necessary, adjust the outer Quick-Load |

it forward until the media reaches the platen |

guide to fit the width of the media. |

roller and cannot be inserted any further. |

5 |

6 |

Keep pushing the media forward while pressing the Feed key.

To tear off the media, grab the outer edge and pull downwards.

24 |

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 |

Loading...

Loading...