Page 1

Installation & Operation, IPL Version

P/N 1-960490-02

Edition 3

August 2001

EasyCoder F4

Bar Code Label Printer

Page 2

Preface

Contents

Preface

Tab le o f Contents.................................................................................1

Copyright Information........................................................................3

Trademarks ..........................................................................................3

FCC Notice (U.S.A.)...........................................................................4

DOC Notice (Canada).........................................................................4

GS Notice (Germany).........................................................................4

EU Standard EN 55022 (The European Union)...............................4

Declaration of Conformity (CE)........................................................5

1. Introduction

Safety Precautions...............................................................................7

Product Labeling.................................................................................7

2. In s ta l l a t i o n

Front View...........................................................................................9

Rear View ..........................................................................................10

Media Compartment.........................................................................1 1

Print Mechanism...............................................................................14

Connections .......................................................................................15

• Power.............................................................................................15

• Computer.......................................................................................15

Controls and Indicators .....................................................................16

• Control Lamps..............................................................................16

• Display...........................................................................................1 6

• Keyboard.......................................................................................1 7

• Beeper ...........................................................................................17

3. Starting Up

4. Media Load

T ear-Off (Straight-through) with Quick-Load.................................23

Peel-Off (Self-strip)...........................................................................25

External Supply (fanfold)..................................................................29

5. Thermal Transfer Printing

6. Setting Up the Printer

Default Setup .....................................................................................34

Setup Parameters:..............................................................................35

• Serial Communication:................................................................35

EasyCode r F4

- Baud Rate ...................................................................................35

Installation & Operation

- Data Bits......................................................................................35

IPL Ve rsion

- Parity...........................................................................................35

Edition 3, August 2001

Part No. 1-960490-02

Description...........................................................................................6

Unpacking............................................................................................8

Switching On.....................................................................................18

T ear -Off (Straight-through) ..............................................................19

Ribbon Load ......................................................................................30

Description.........................................................................................34

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 1

Page 3

Preface

Contents, cont.

6. Setting Up the Printer, cont.

- Protocol.......................................................................................36

• T est/Service: .................................................................................38

- T estprint......................................................................................38

- Data Dump .................................................................................39

- Memory Reset............................................................................39

- Label Rest Dots..........................................................................39

- Form Adj Dots X........................................................................39

- Form Adj Dots Y........................................................................39

• Media: .......................................................................................... 40

- Media T ype................................................................................ 40

- Paper T ype................................................................................. 40

- Label Length ............................................................................. 40

- Sensitivity .................................................................................. 40

- Darkness .....................................................................................4 1

7 . Setup Mode

Navigating in Setup Mode................................................................42

Setup Mode Overviews.....................................................................43

8. Options

DTP Model ........................................................................................47

Side Doors and Megatop...................................................................47

Integral Liner T akeup U nit...............................................................47

Media Supply Hub.............................................................................47

3-inch Adapter...................................................................................47

Quick-Load Guides...........................................................................48

Label Taken Sensor...........................................................................48

Interface Boards ................................................................................48

9. T roubleshooting

10. Maintenance

External Cleaning..............................................................................53

Cleaning the Media Guides..............................................................54

Printhead Replacement.....................................................................55

11. Adjustments

Label Stop Sensor Position...............................................................59

Printhead Pressure............................................................................ 60

Ribbon Break Shaft Adjustment ......................................................61

Entering the Setup Mode..................................................................42

Introduction....................................................................................... 46

Troubl eshooting List..........................................................................49

Printhead Cleaning............................................................................50

Narrow Media Adjustment...............................................................58

- Stop Bits......................................................................................35

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 32

Page 4

Contents, cont.

Preface

Appendix 1

Appendix 2

• Direct Thermal Media................................................................ 64

• Thermal Transfer Media............................................................. 64

• Media Roll Size ............................................................................65

• Media.............................................................................................66

- Non-Adhesive Strip....................................................................66

- Self-A dhesiv e S trip ....................................................................67

- Self-A dhesiv e Labels.................................................................68

- Tickets with Gap........................................................................69

- Tickets with Black Mark............................................................70

• Transfer Ribbons ..........................................................................71

• Setting the Media Sensitivity Number........................................72

Appendix 3

• RS-232 Interface...........................................................................75

• IEEE 1284 Parallel Interface Board (option).............................76

• EasyLAN 100i Interface Board (option)....................................77

Appendix 4

Information in this manual is subject to change without prior notice and does not represent a commitment

on the part of Intermec Printer AB.

© Copyright Intermec Printer AB, 2001 . All rig hts reserved. Published in Sweden.

EasyCoder, EasyLAN, Finge rprint, and LabelShop are registered trademarks of Intermec Technologies

Corp. T he word Interm ec, the Inter mec logo, Prin tSet, a nd Durather m are tradem arks of Inter mec

Technologies Corp.

Kimdura is a registered trademark of Kimberly Clark.

Centronics is a registered trademark of Genicom Corporation

Microsoft is a registered trademark of Microsoft Corporation.

To rx is a reg ister ed trademark of Camcar Division of T extron Inc.

T rueDoc is a registered trademark of Bitstream, Inc.

T rueType is a trademark of Apple Computer Inc.

Unicode is a trademark of Unicode Inc.

Valeron is a re g istered tr ademark of Van Leer Worldwide

Windows is a trademark of Microsoft Corporation.

T echnical Data...................................................................................62

Media Specifi cations........................................................................ 64

Interfaces............................................................................................75

Supported IPL- 3 commands.............................................................78

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 3

Page 5

Preface

FCC Notice (United States of America)

WARNING

This equ ipment generates, uses, and ca n rad iate ra dio f requency energy a nd i f not insta l led a nd used i n

accordance with the i nstr uctions manual, may cause inter ference to radio communications. It has been

tested and found to comply with the limits for a Class A computing device pursuant to Subpart J of Part

15 of FCC Rules, which are designed to provide reasonable protection against such interference when

operated i n a commercial environm ent. Operation of this e quipment in a residential ar ea is likely to

cause interference in which case the user at his own expense will be required to ta ke whatever measures

may be required to correct the interference.

DOC Notice (Canada)

Canadian Dept. of Communication

REGULATIONS COMPLIANCE (DOC-A)

This digital apparatus does not exceed the class A limits for radio noise emissions from a digital apparatus

as set out in the radio interference regulations of the Canadian Department of Communication.

Ministère des Communications du Canada

CONFORMITE DE REGLEMENTS (DOC-A)

Le présen t appareil numériq ue n ’émet pas de bruits radio-électriques dépassant les limites applicables aux

appareils numériques de classe A prescrites dans le règlemen t sur brouillage radioélectrique édicté par le

Ministère des Communications du Canada.

GS Notice (Germany)

ALLGEMEINE VORSCHRIFT

Reparaturen oder sonstige Eingriffe, die sich nicht auf normale Bedienung der Maschine beziehen, dürfen

ausschließlich nur von einem ausgeb ildeten, zuständigen F achmann vorgenommen werden.

EU Standard EN 55022 (The European Union)

WARNING

This is a Class A I TE pro duct. In a domestic environment t his product may cause rad io inter ference in

which case the user may be required to take adequate measures.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 34

Page 6

Declaration of Conformity

We,

Intermec Printer AB

Idrottsvägen 10

Box 123

S-431 22 Mölndal

Sweden

declare under our sole responsibility1 that the product

EasyCoder F4

to which this declaration relates

is in conformity with the following standards

EMC:

EN 50 081-1:1992

EN 55 022:1994

EN 61 000-3-2:1995, class A

EN 50 082-2:1995

EN 61 000-4-2:1995

EN 61 000-4-3:1996

ENV 50 204:1995

EN 61 000-4-4:1995

EN 61 000-4-6:1996

Electrical Safety:

EN 60 950

following the provisions of Directives

89/336/EEC and 73/23/EEC

Mölndal 1999-09-01

Preface

...................................................................

Mats Gunnarsson

President

1

/. Intermec assumes no responsibility regarding the CE Directive if the

printer is handled, modifi ed, or installed in other manners than those described in

Intermec’s manuals.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 5

Page 7

Chapter 1

Introduction

Description

The EasyCoder F4 is a sturdy medium-duty direct thermal/thermal

tr ans fer pr inte r with a p rin the ad res oluti on of 8 dot s per m m

(20 3.2 dots p er inch ) and a ma xim um pri nt widt h of 104 mm

(4.095 inches).

The Easy Coder F4 is delivered with the I ntermec P rogramm ing

Language (IPL- 3) installed. There is also a version of the EasyCoder

F4 tha t uses the I nterme c Finger print P rogra mmin g Langua ge.

Mechanically, the IPL version is iden tical to the Intermec Fingerprint

version, but a f ew options are not supported by IPL-3, f or ex ample:

• Optional double serial and industrial interface boards

• Electronic keys

• Memory cards (except for fi rmware upgrading)

• EasySet Bar Code Wand

• Real Time Clock Circuit

In most respects, the EasyCoder F4 IPL version is compatible with

other IPL pri nters f rom Inter me c. Please refer to Appendix 4 for a

list of supported IPL- 3 commands.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 36

Page 8

Chapter 1 Introduction

Safety

Precautions

Product Labeling

Intermec a ssumes no responsibility regarding the CE Dire ctive if

the printer is handled, modifi ed, or installed in a ny way other than

described in Intermec’s manuals.

Caution

• Read this manual carefully before connecting the printer.

• Moving parts are exposed when the side door is open, so ensure

that the door is closed before you operate the printer.

• Do not open the front/left-hand cover. Dangerous v o ltage!

• Do not remove the bottom plate. Dangerous vol tage!

• Do not put your fi ngers inside the print mechanism when

the powe r i s o n .

• Place the printer on an even surface which can support its wei ght

of approximately 7 kg ( 1 5 .5 lb ) pl us supp lies.

• Do not spray the printer with water. If you are using a hose to clean

the premises in an industrial environment, remove the printer or

protect it carefully from spray and moisture.

• Carefully read the war ning text on the envelope before using

a cleaning card.

The machine label is attached to the printer’s rear plate and contains

information on type, model, and serial number a s well as AC input

voltage range. I t also contains various signs of approval.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 7

Page 9

Chapter 2

Installation

Unpacking

Before you inst all the p rinter, exam ine the p ackage for possible

damage or missing parts:

• Open the box and lift the printer out.

• Check that the printer has not been visibly damaged during

transpor tat ion. Keep the packing mat erials i n case you need to

move or reship the printer.

• Check the label on the printer’s rear plate, which giv es the voltage,

the part number, and the serial number.

• Check that any options you ordered are included.

• Check that all accessories are included. As standard, the

box contains:

- Intermec EasyCoder F4 printer

- Two sets of Quick-Load guides (wide and narrow)

- Power cord (at least one depending on model)

- Quality check card

- Cleaning card

- Short strip of labels

- Adapter for 3-inch media roll core (only in models fi tted

with a rotating media supply hub)

- Starter pack of thermal transfer ribbon (thermal transfer

models only)

- User’s Guide (multilingual)

- Installation & Operation manual

- Supporting software and product information on CD.

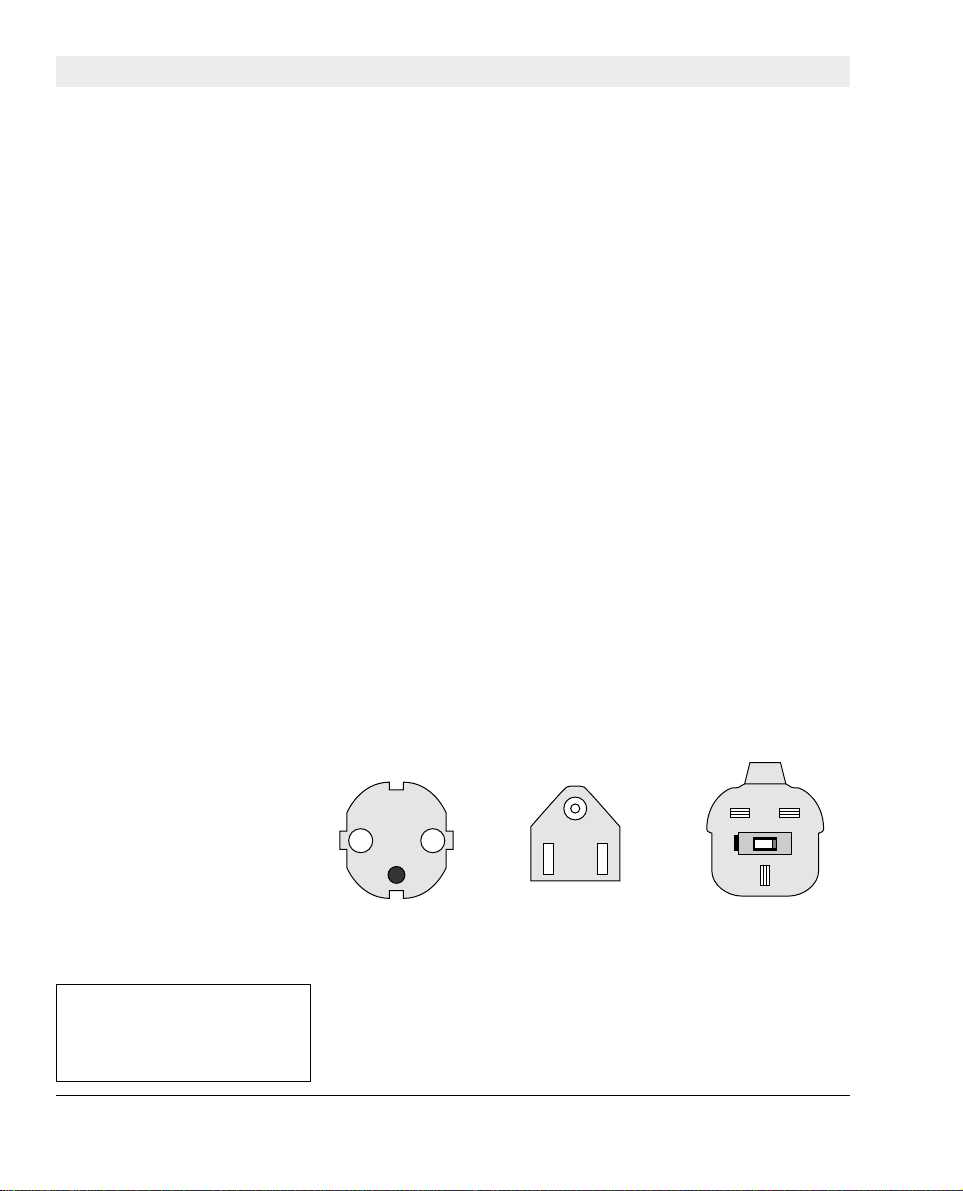

• Check that the power cord is appropriate for the local standard. The

printer works within 100 to 240 VAC, 50 to 60Hz.

1

1

1

/. T ype and quantity may vary,

or labels/ribbon may be omitted completely, dependi ng on

area of distribution.

European-type US/Canadian-type GB-type

230V mains plug 115V mains plug 230V mains plug

If the pr inter has b een da maged in a ny way during tra nspor tat ion,

complain to the carrier immediately.

If t he del iver y is inc orr ect or a ny par ts a re mi ssing , repo rt it

immediate ly to the di s trib u t o r.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 38

Page 10

Chapter 2 Installation

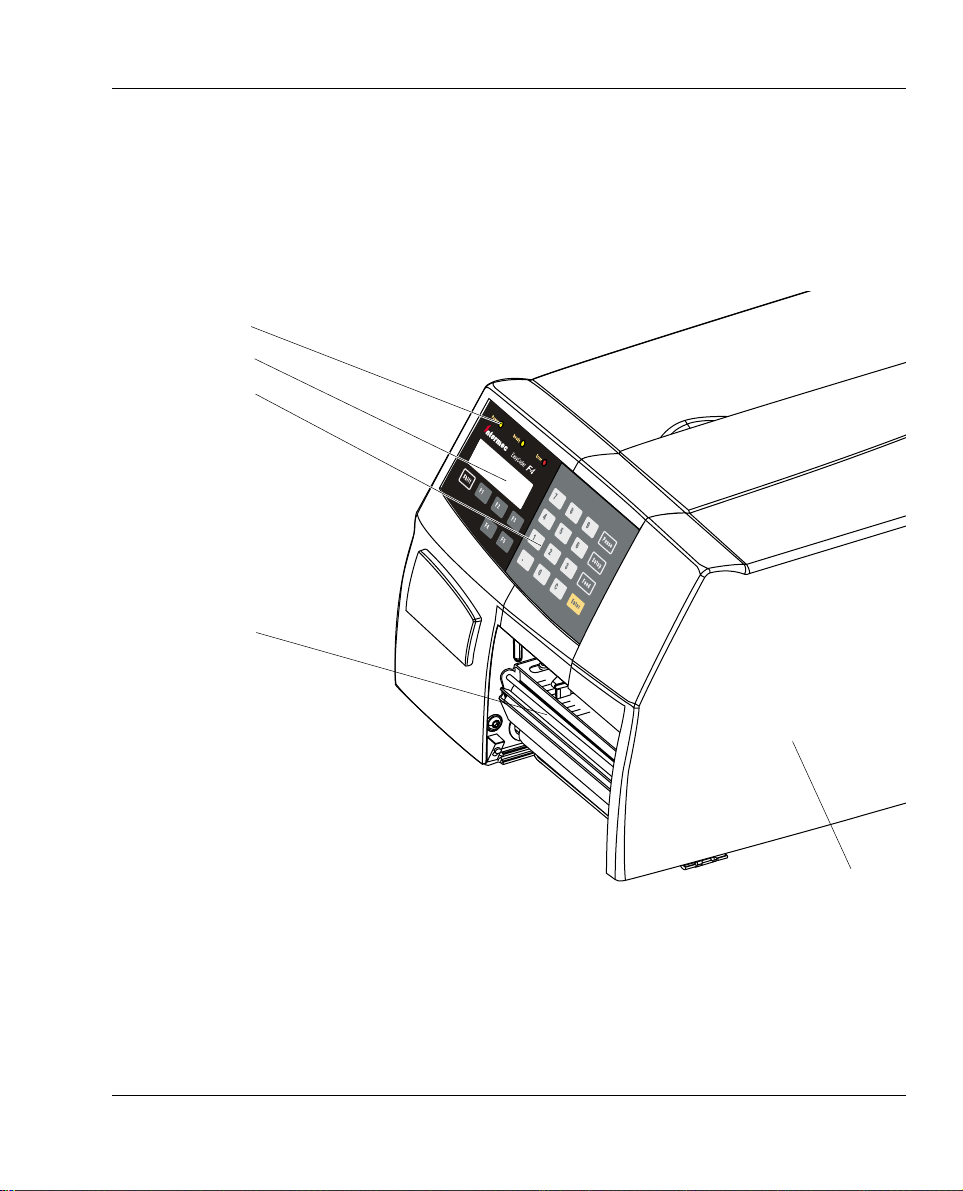

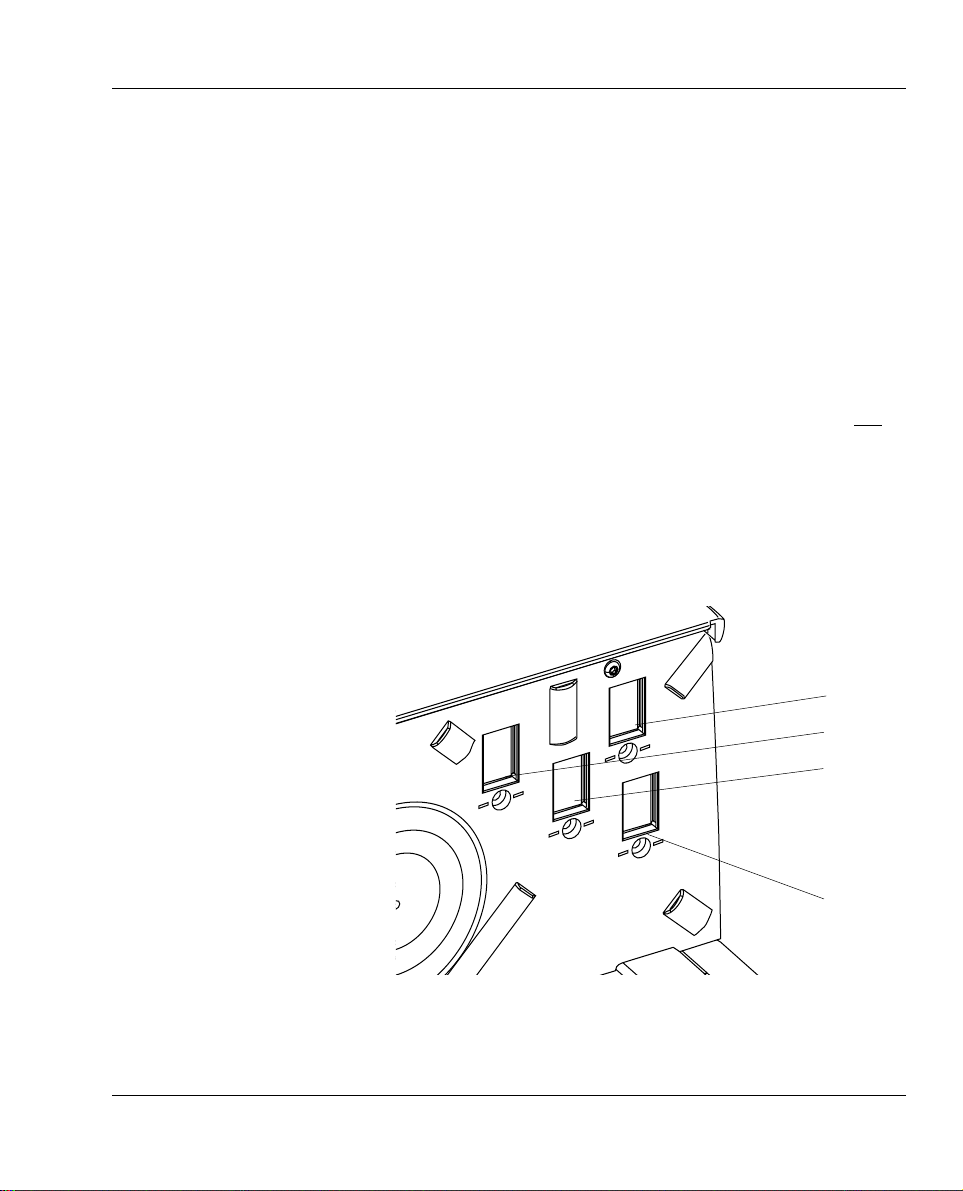

Front View

Control Lamps

Display Window

Keyboard

Print Mechanism

At the front of the printer are the display window, the control lamps,

and the keyboard. These featu res a l low the operator to cont rol and

set up the printer manually .

The p rinte d labels, t ickets, or t ags are pr esente d at the fr ont of

the print mechanism.

Side Door

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 9

Page 11

Chapter 2 Installation

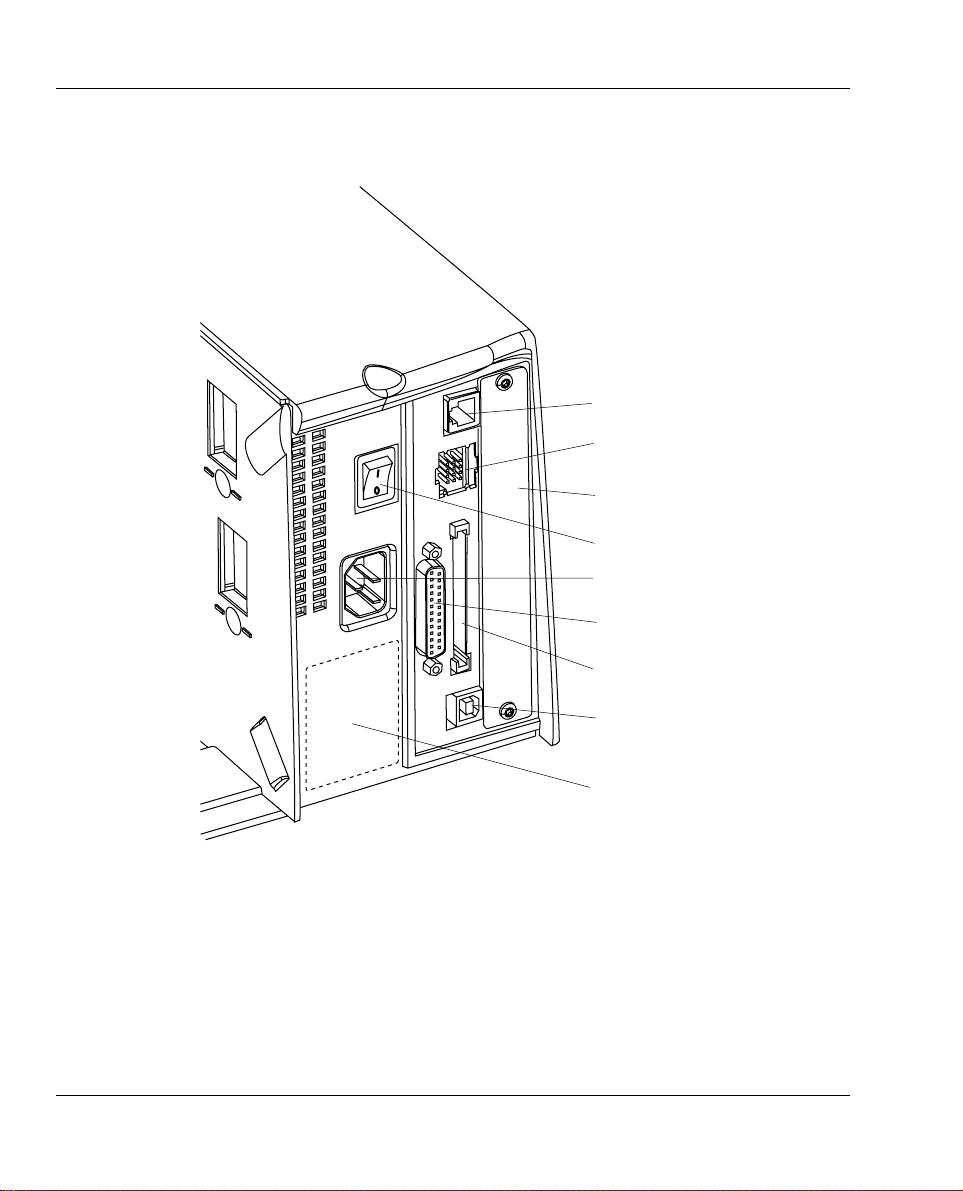

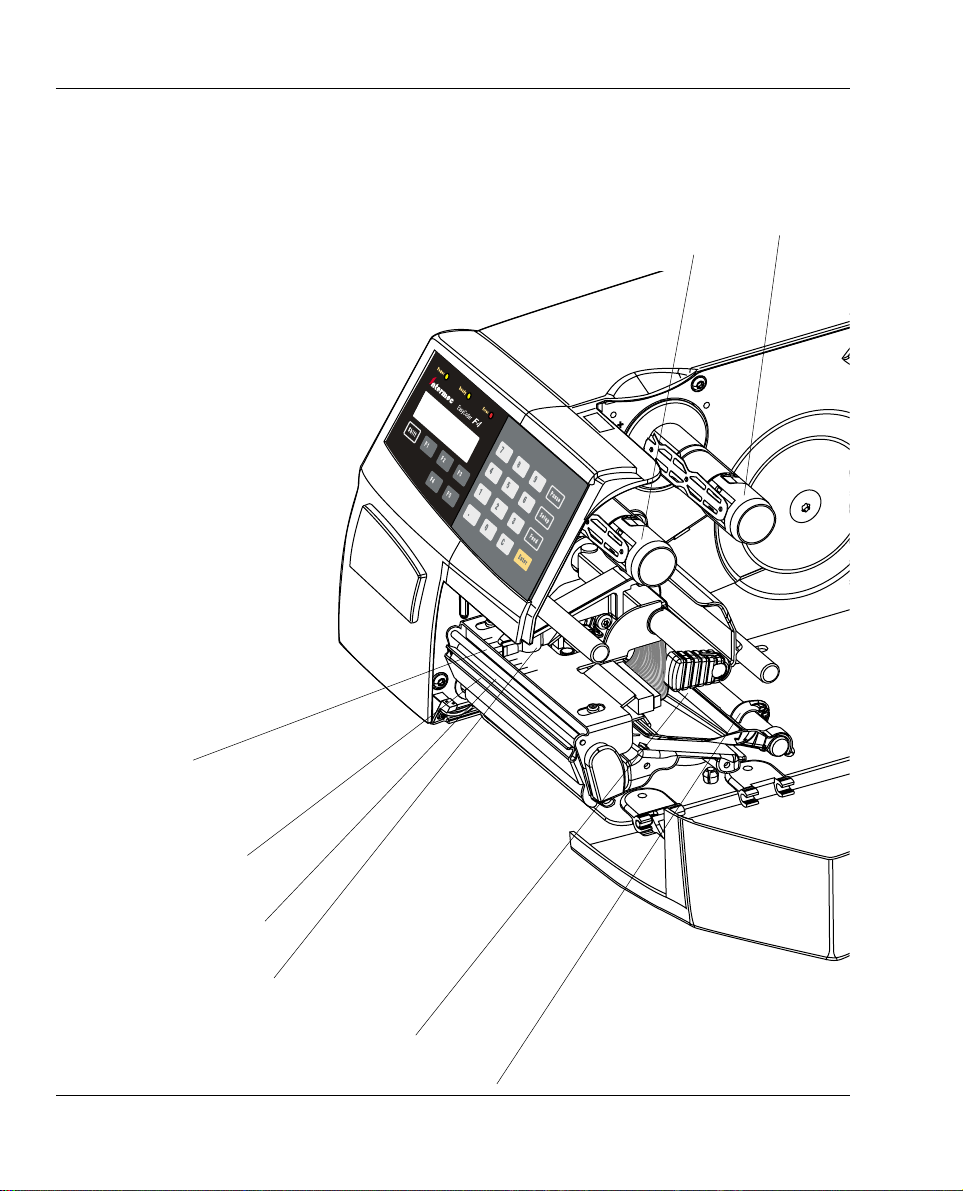

Rear View

The r ear plat e conta ins th e On/ Off sw itch, the AC power c ord

receptacle, and various interface connectors and slots.

(not used)

(not used)

Provision for one Interface Board

On/Off Switch

AC Power Cord Receptacle

RS-232 Serial Interface Socket

Memory Card Slot (for fi rmware upgrade)

(not used)

Machine Label

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 310

Page 12

Chapter 2 Installation

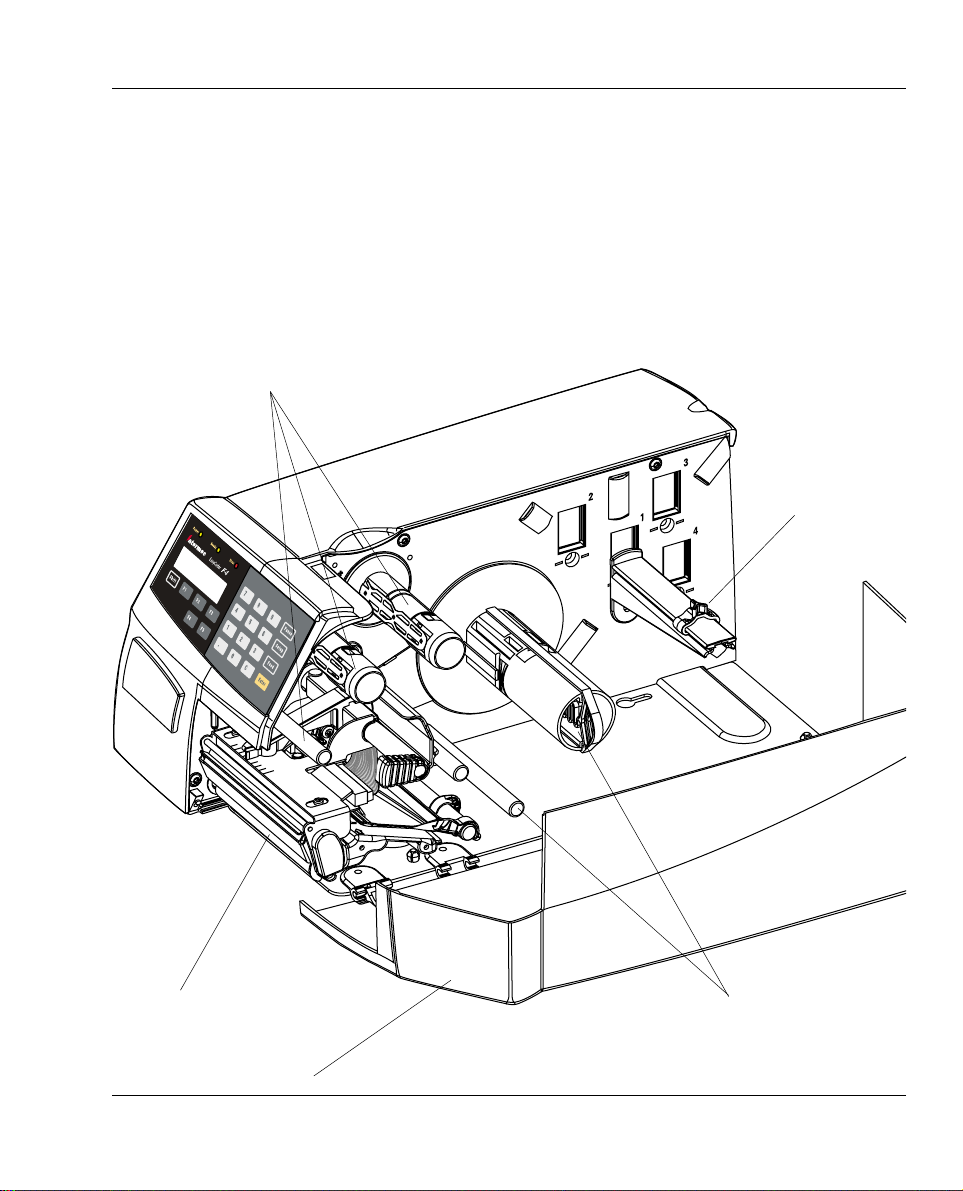

Media Compartment

Thermal Transf er Mechanism

(optional)

The media compa rt ment is either covered by a long side door that

completely encloses the print mechanism and media compartment,

an 8-inch Megatop for extra large media rolls, or a short side door that

only covers the print mechanism and giv es easy access to the media

stock. The door is held by a magnetic lock. It can be opened 180° so

to provide full access to the media compartment.

The media supply can be from a supply post, or from an exter nal

supply of fan folds beh ind the pri nter. There is a lso an optiona l

rotating media supply hub, see Chapter 8 “Options.”

Media Supply

Roll Post

with Edge Guide

Print Mechanism

Long Side Door

Optional Integral Liner

Takeup with Guide Shaft

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 11

Page 13

Chapter 2 Installation

Media Compartment, cont.

Since the EasyCoder F4 has a modular design, it uses a media supply

roll post that can be fi tted in three different positions inside the

media compartment. The position depends on the type of side door

(long, short, or Megatop) and whether or not the printer is fi tted with

an integral liner takeup. Alternatively, an external media supply

(for example a box of fan folded tickets) behind the printer ca n be

used. A rotating med ia supply hub is also available as an option,

see Chapter 8, “Option s.”

Media Supply Roll Post

The media supply roll post fi ts b oth 38-40 m m (1.5 inches) an d

76 mm (3.0-inches) cores, since it can be moved vertically in the

slot i n the ce nter s ectio n. The b otto m posit ion is int ende d for

small cores and t he top position for large cores only. The post is

locked by a straight-slot screw and has a moveable edge guide to

fi t various media widths.

76 mm

(3 inches)

Edge Guide

CORE

38 - 40 mm

(1.5 inches)

Screw

T o mo v e the post to a different slot; remov e the screw, twist the post

a quarter of a turn, and pull it out.

To fi t the post; rotate it a quarter of a turn, insert it into the approp-

riate slot in the c enter section (see next page), and twist back so

the l ips enga ge the cut outs in t he sides of t he slot. M ove it up

(large core) or down (small core) as far as it goes and secure it

with the screw .

Caution!

Make sure to adjust the posit ion o f the p ost a ccording to the size

of the media roll core. W he n th e pos t is fi tted in the top position ,

the head of the screw will interfere with small (38 mm/1.5 inches)

cores, causing media misalignment.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 312

Page 14

Chapter 2 Installation

Media Compartment, cont.

Media Supply Positions

There are four sets of slots and threaded holes in the printer’s center

section for th e media supply roll post or rot ating hub (optional) .

The se slots a llow th e large st possib le roll si ze to fit, given t he

limitati ons o f any liner take up uni t and/or the fu ll enc los ure pro vide d

by the long side door or Megatop. The positions are indicate d by

numbers engraved in the center section.

• Position 1 is used when the media compartment is fully enclosed

by a long si de door, regardless of the existence of any integral liner

takeup unit. Maximum roll size is 152 mm (6 inches).

• Position 2 is used when the printer has a short side door that only

encloses the print mechanism, but does not hav e an integral liner

takeup unit. Maximum roll size is 213 mm (8.38 inches).

• Position 3 is used when the printer has a short side door a nd an

integral liner takeup unit. This position is also used with the

optional 8-inch Megatop, see Chapter 8, “Optio ns.” Maximum

roll size is 21 3 mm (8.38 inches).

• Position 4 is reserved for possib le future devel opment.

The printer can also use an external media supply located behind the

printer, unless it has an optional 8-inch Megatop .

3

2

1

4

Pos. 3

Pos. 2

Pos. 1

(Pos. 4)

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 13

Page 15

Chapter 2 Installation

Print Mechanism

The print me chanism features a h igh-performa nce 8 dots-per-mm

(203.2 dots-per-inch) thermal printhead with quick-mount fi ttings

to facilitate replacemen t. The thermal transfer ribbon mechanism is

omitted in dedicated direct thermal printing models.

Ribbon Supply Hub

Ribbon Rewind Hub

Thermal Printhead

Tear Bar

Platen Roller

Pressure Arm

Printhead Lift Lever

Edge Guide

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 314

Page 16

Connections

Chapter 2 Installation

Power

Computer

1 Place the printer on a lev el surface near an AC outlet. Y ou should

be able to easily access the printer to load media, to load ribbon,

and to remove the printout

2 Check that the printer is switched off.

3 Connect the power cord between the receptacle on the rear plate

and an electrical outlet (>90 to <264 VAC).

The EasyCoder F4 is fi tted with one 25pin D-style submi niature

(DB25) socket for the RS-232 serial interface port (see Appendix

3). The p rinter is a lso prepared for one opt ional inter face board

(auto-sensing).

• RS-232 Serial Interface

Use the serial interface when you need a two-w ay communication

between printer and host computer. Before you can use the

serial interface, you may need to set up the communication

parameters, such as baud rate, parity, etc. as described in Chapter

6, “Setting Up the Printer.”

• Parallel Interf ac e Board

Optional. Refer to Appendix 3 a nd the separ ate documentat ion

delivered with the board for connection and setup instructions.

• EasyLAN 100i Interface Board

Optional. Refer to Appendix 3 and t he separat e documentat ion

delivered with the board for connection and setup instructions.

Switch of f both t he PC and t he prin ter before c onnect ing them

together.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 15

Page 17

Chapter 2 Installation

Controls and

Indicators

Control Lamps

The EasyCoder F4 has several ways of communicating directly with

its operator: thre e control lamps, a display window, a membraneswitc h k eyboard wi th 2 2 k e ys, a bi g “Feed” button on the printer’s

front, and a beeper. Only some of the key s are used with IPL.

The control lamps a re colored LEDs (Light Emitt ing Diodes) and

indicate the following conditions:

• Power (green):

On Power on

Off Power off

• Ready (green):

On Media fault detected

Flashing Printer offl ine

Off Printer online

• Error (red):

On System fault detected

Flashing Printer overtemperature

Off OK

Display

The d isplay window con tain s an LCD ( Liquid Cryst al Displ ay)

with background illumination and two lines of text, each with

16 characte rs. It guides t he operator t hrough upg rading, st art up,

and se tup.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 316

Page 18

Controls and Indicators, cont.

Chapter 2 Installation

Keyboard

Beeper

The keyboard is of membra ne-switch type and has 22 keys. The

keyboard is supplemented by a large “Feed” button on the printer’s

front. Only four of these keys plus the “Feed” button are work ing

with I PL (except in the Set up Mode where t he keyboard work s

differently, see Chapter 7, “Setup Mode”).

Condition <Feed> <C> <Pause> <Setup>

Idle Feed/Reload – Toggle offl ine/online Enter Setup Mode

Printing – – Hold printing –

Paused Feed/Reload Cancel print job Resume printing Enter Setup Mode

“Feed” means advanci ng the media one form, whereas “Reload”

means notifying the hardware when certain confi guration commands

have been entered.

The be ep e r n o ti fi es the operator that a key has been pressed.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 17

Page 19

Chapter 3

Starting Up

Switching On

Before switching on the pri nter, make the necessa ry connect ions

and c he c k tha t the p rin the ad i s engag e d.

Switch on the power us ing the On/Off switch on the rear plate. The

“Power” control lamp on the front pa nel lights up when the power

is on. Wait for a few moments, while the printer loads the program

and runs some self-diagnostic tests.

Whi le the pri nter is init ialize d, the progre ss of the initia lizat ion

is indicated by an increasing number of colons on the lower line

in the display:

Initializing

:::

When the in itialization is completed, a label is fed out. Then t he

follow ing mess age appe ars, i ndica ting t hat the p rint er is rea dy

for operation:

IPL Ver 1.3

9600-8-N-1-X/X

The uppe r line ind icates the I PL version number and lower line

shows t he eithe r the pr esent s eria l commu nica tion set up or a n

error message:

- Paused

- Printhead Up

- Press Feed

- Paper Out

- Ribbon Out

- Printhead Hot

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 318

Page 20

Media Load

Chapter 4

Tear-Off

(Straight-through)

Important!

Sa ve the l abe l ind ica ting t he

sensitivity num ber attached to

th e medi a roll . You will n eed

th is nu mber t o set t he me dia

sensitivity, see Appendix 2.

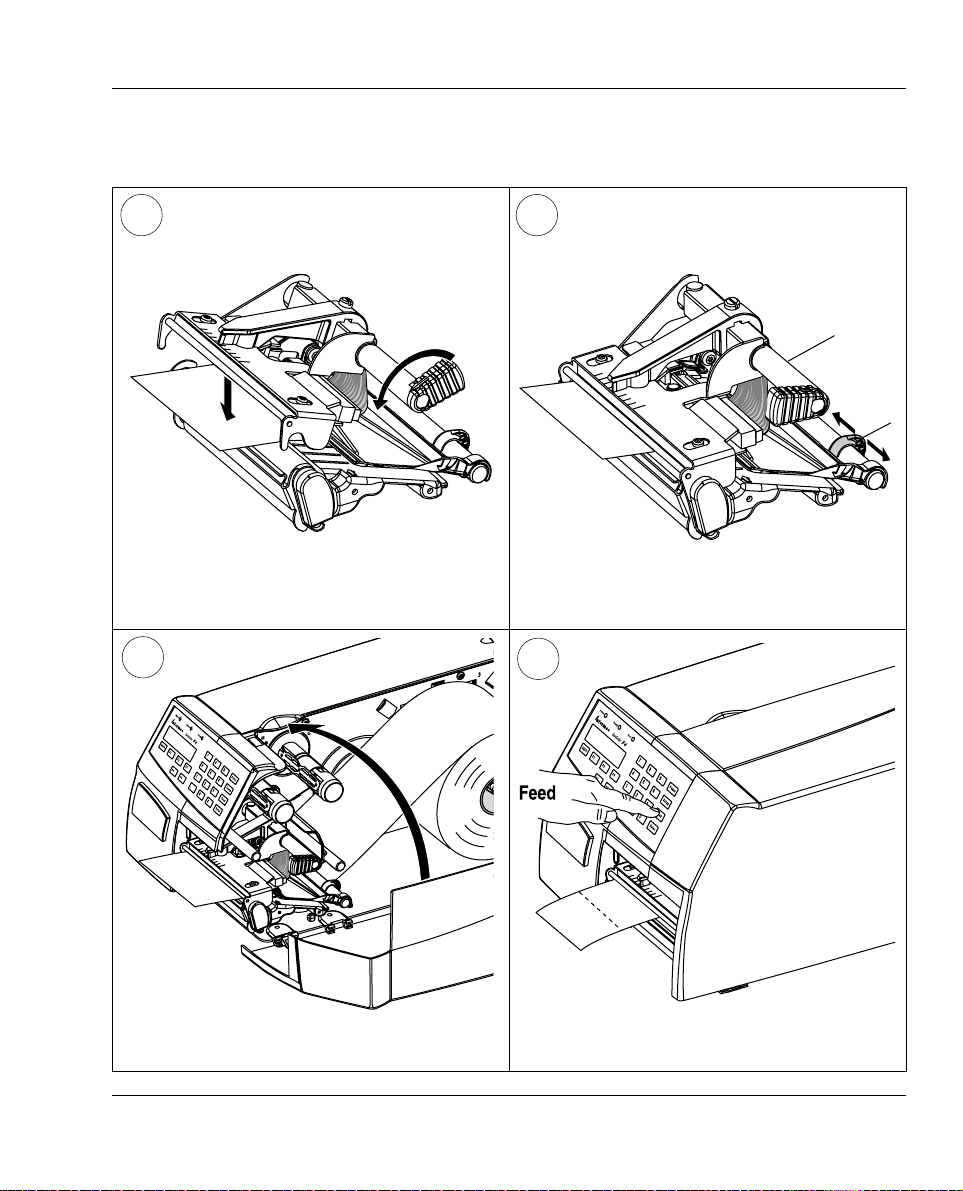

1

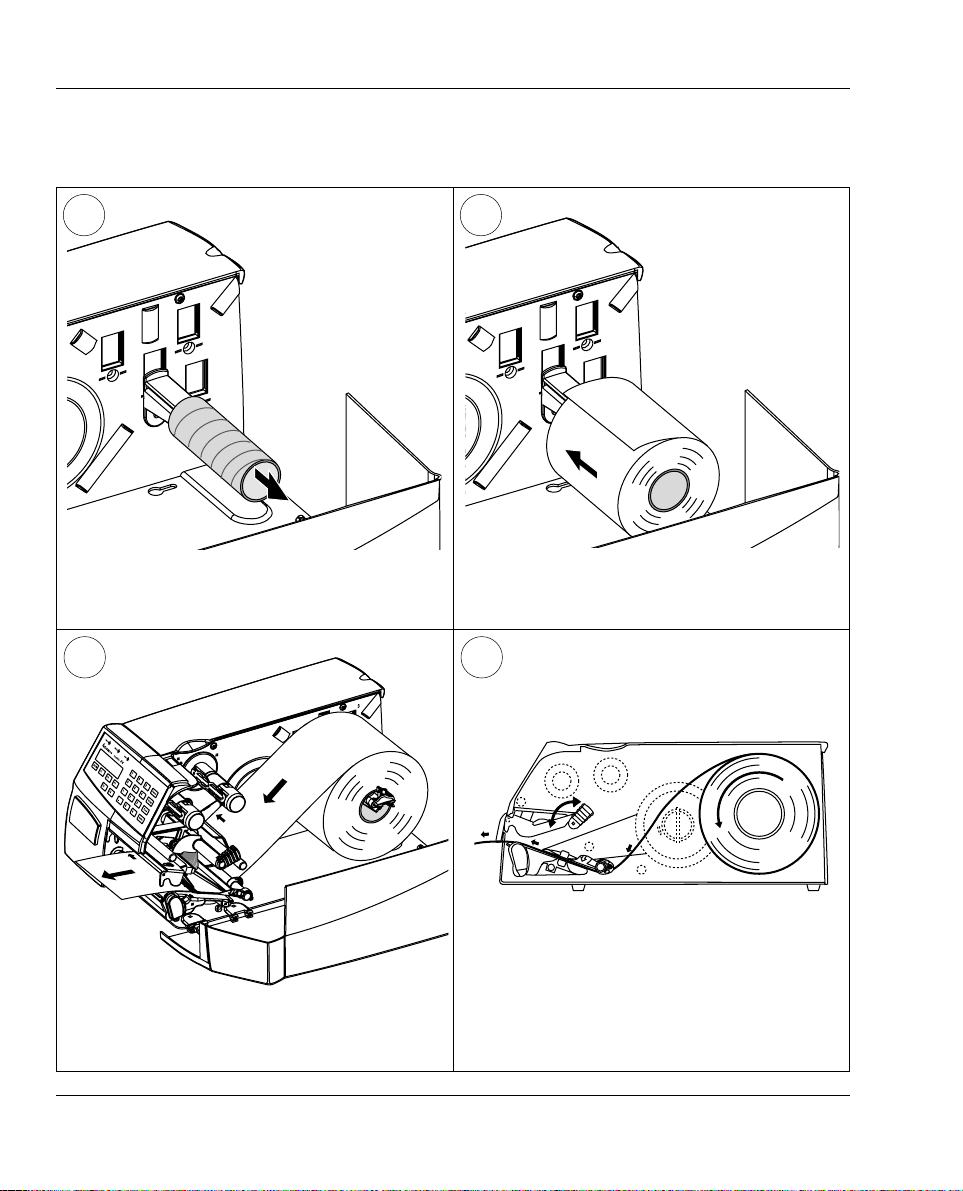

The EasyCoder F4 can print on labels, tickets, tags, and continuous

stock in various forms. Th is chapter describes the case when the

media is to be torn off manually against the pr i nter’s tear bar. This

method is also known as “straight-through printing”.

T ear-off can be used for:

• Non-adhesive continuous stock

• Self-adhesive continuous stock wi th liner

• Self-adhesive labels with liner

• Tickets with gaps, with or without perforations

• Tickets with black marks, with or without perforations

2

Turn the printhead lift lever clockwise to raise

Open the side door.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 19

the printhead.

Page 21

Chapter 5 Ribbon Load

Tear-Off, cont.

43

3

2

1

4

Remove any empty core from the media supply

roll post.

5

3

2

1

4

Fit a new roll of media on the supply post and

adjust the edge guide so the roll becomes fl ush

with the center section.

6

Route the media through the print mechanism.

Then push it inwards as far as it will go. This diagram shows the media path.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 320

Page 22

Tear-Off, cont.

7 8

Chapter 4 Media Load

Turn the printhead lift lever counterclockwise

to engage the printhead.

9

Close the side door.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 21

Adjust the position of the green edge guide so

the media is guided with a minimum of play.

10

Press the Feed key to advance the media and

adjust the media feed.

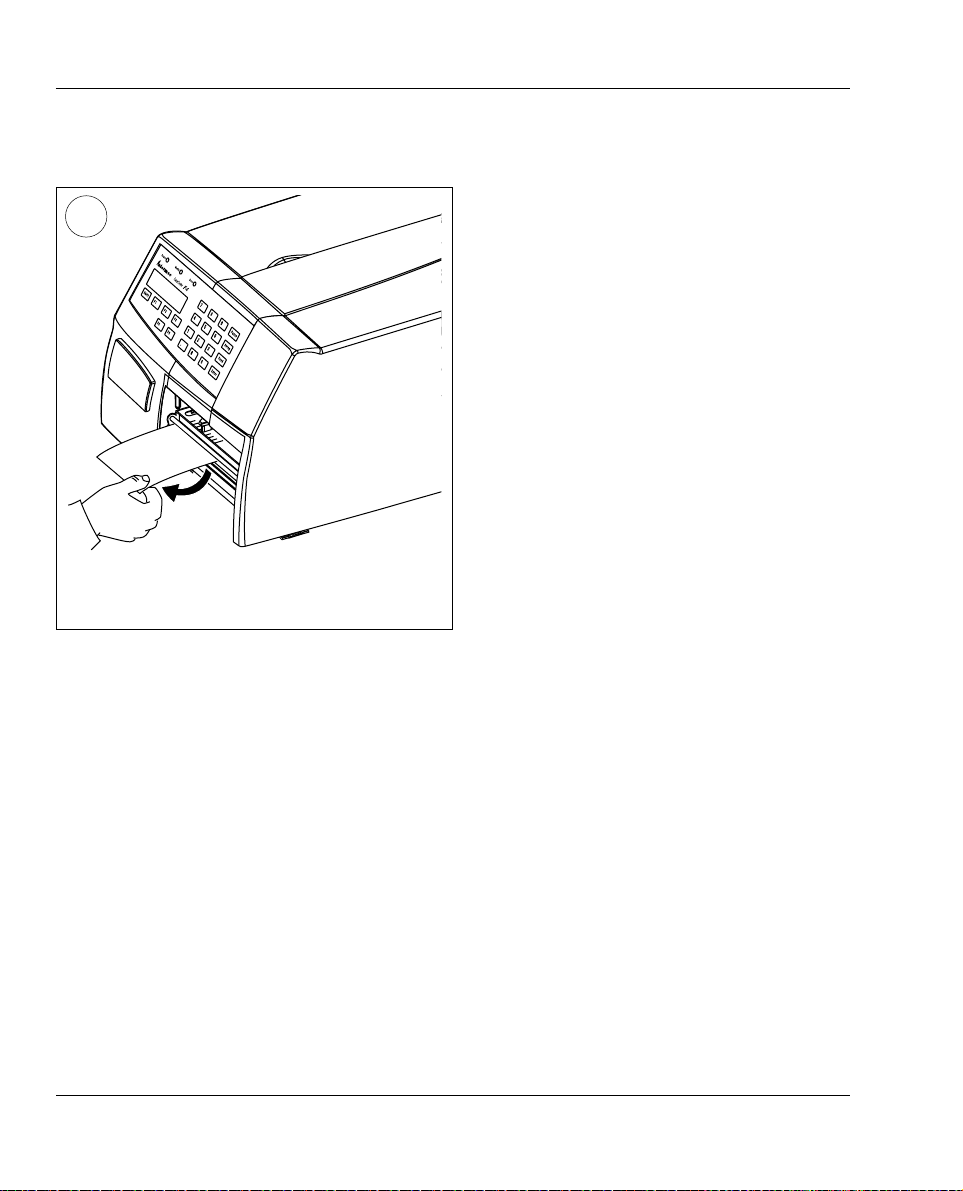

Page 23

Chapter 4 Media Load

Tear-Off, cont.

11

To tear off the media, grab the outer edge and

pull downwards.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 322

Page 24

Chapter 4 Media Load

Tear-Off with Quick-Load

(Straight-through)

Important!

Sa ve the l abe l ind ica ting t he

sensitivity num ber attached to

th e medi a roll . You will n eed

th is nu mber t o set t he me dia

sensitivity, see Appendix 2.

1

In addition to the media load procedure for tear-off (s traight-through)

operation described e arlier in this chapter, the Ea syCoder F4 can

optionally be fi tted with a set of Quick-Load guides that makes media

load much easier and quicker , especially if the printer has a short side

door. See Chapter 8, “Options” for installation instructions.

The p rint er is nor mally de livered wit h two set s of Quick-Loa d

guides: wide and narrow . The wide type generally guides the media

better, but the media must be at least of 80 mm (3.15 inches) wide.

The nar row type a llows a media width as nar row as 40 mm (1.57

inches), but may be less suited for wide and thin media. Illustrations

in this chapter show the narrow type of guides.

Quick-Load cannot be combined with peel-off (self-strip) operation .

2

Fit a new roll of media on the supply post and

Remove any empty core from the media supply

roll post.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 23

adjust the edge guide so the roll becomes fl ush

with the center section.

Page 25

Chapter 4 Media Load

Tear-Off with Quick-Load, cont.

3 4

Insert the media between the guides and feed

If necessary, adjust the outer Quick-Load

guide to fi t the width of the media.

it forward until the media reaches the platen

roller and cannot be inserted any further.

5

Keep pushing the media forward while

pressing the Feed key.

6

To tear off the media, grab the outer edge and

pull downwards.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 324

Page 26

Chapter 4 Media Load

Peel-Off

(Self-strip)

Important!

Sa ve the l abe l ind ica ting t he

sensitivity num ber attached to

th e medi a roll . You will n eed

th is nu mber t o set t he me dia

sensitivity, see Appendix 2.

The EasyCoder F4 can print on labels, tickets, tags, and continuous

sto ck in va rio us form s. Th is cha pter d escr ibe s the ca se whe n

self-adhesive labels are separated from t he liner i mme diately af ter

printing. The liner is then wound up on an integral liner takeup hub.

This is also known as “Self-strip” operation.

Peel-off operation cannot be p erformed when Quick-Load guides

are fi tted.

Peel-off can only be used for:

• Self-adhesive labels with liner

An optional label ta ken sensor can hold the pri nting of next label

in a batch unti l the present label has been removed, see Ch apter

8, “Opti ons.”

1 2

Turn the printhead lift lever clockwise to raise

Open the side door.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 25

the printhead.

Page 27

Chapter 4 Media Load

Peel-Off, cont.

3

Pull out the handle to collapse the takeup hub,

then remove any liner.

5

2

3

1

4

4

3

2

1

4

Remove any empty core from the media supply

roll post. Remove the edge guide if necessary.

6

Fit a new roll of labels on the supply post and

adjust the edge guide so the roll becomes fl ush

with the center section.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 326

Remove labels from the fi rst 50 cm (20 inches)

of the liner. Route the liner through the print

mechanism and push it inwards.

Page 28

Peel-Off, cont.

Chapter 5 Ribbon Load

7

Route the liner around the tear bar and the

liner drive roller and back under the print

mechanism and guide shaft.

8

Insert the start of the liner under the lip of the

takeup hub, then rotate the hub counterclock-

wise a few turns to wind up some of the liner.

9 10

Turn the printhead lift lever counterclockwise

This diagram shows the media and liner paths.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 27

to engage the printhead

Page 29

Chapter 5 Ribbon Load

Peel-Off, cont.

11

Adjust the position of the green edge guide so

the media is guided with a minimum of play.

13

12

Close the side door.

Press the Feed key to advance the media and

adjust the media feed.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 328

Page 30

Chapter 4 Media Load

External Supply

1

The EasyCoder F4 can print on labels, tickets, tags, and continuous

stock in various forms. Th is chapter describes the case when the

media supply is placed behind the pr inter, usually in the form of

fan folded tickets or tags. External supply can be used with tear-off

(straight-through) printing–preferably with Quick -Load.

External supply can be used with both short and long side doors and

there is no need to remove the media supply roll post.

When using an external media supply , take care to protect the media

from dust, dirt, or other foreign particles, that can impair the printout

quality or cause unnecessary wear to the printhead.

Depending on brand and quality, all direct thermal media are more

or less sensitiv e to heat, direct sunlight, moisture, oil, plasticizers, fat,

and other substances. You should protect them accordingly.

This diagram shows the media path from an external supply. In case of the standard edge guide

(as opposed to Quick-Load guides), turn it to vertical position.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 29

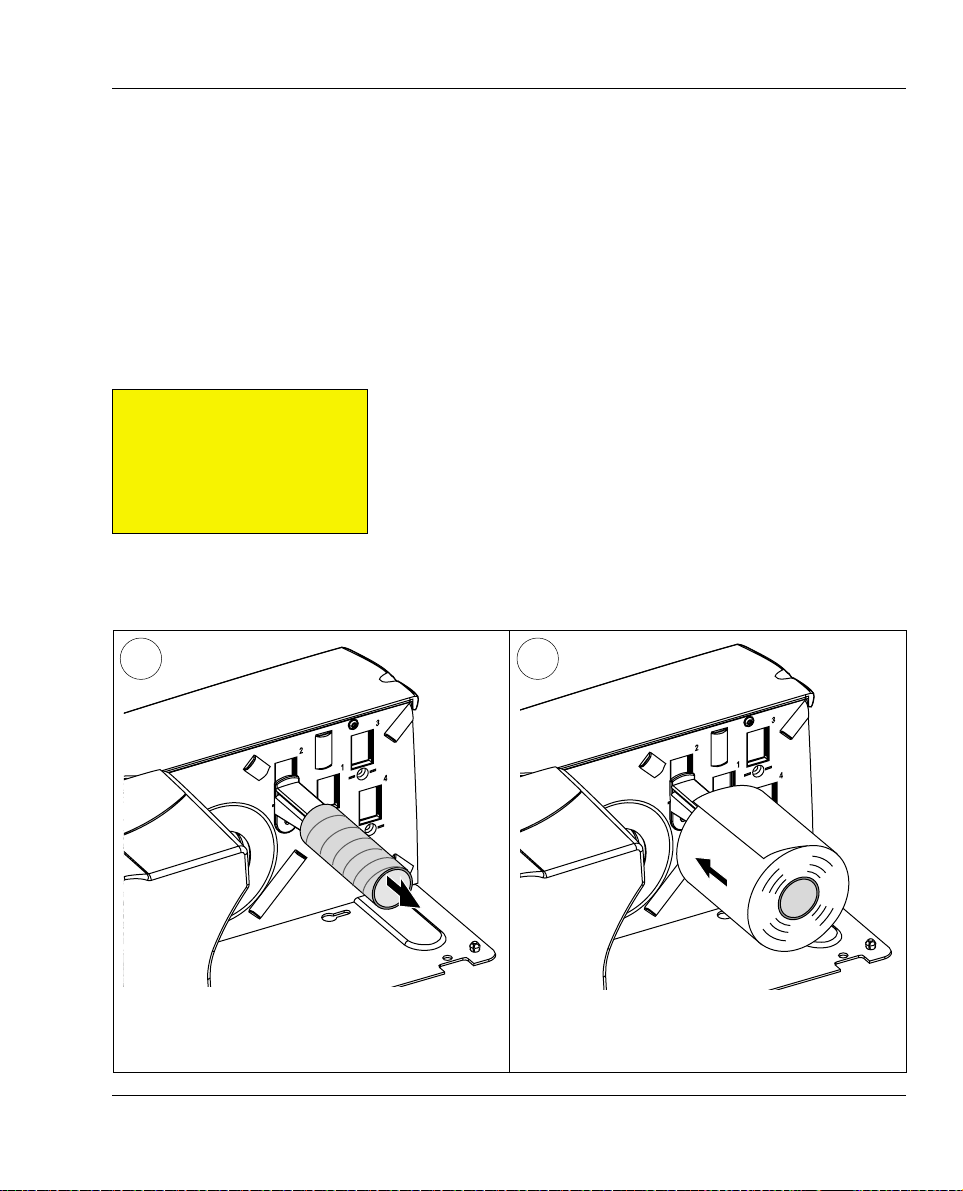

Page 31

Chapter 5

Thermal Transfer Printing

Ribbon Load

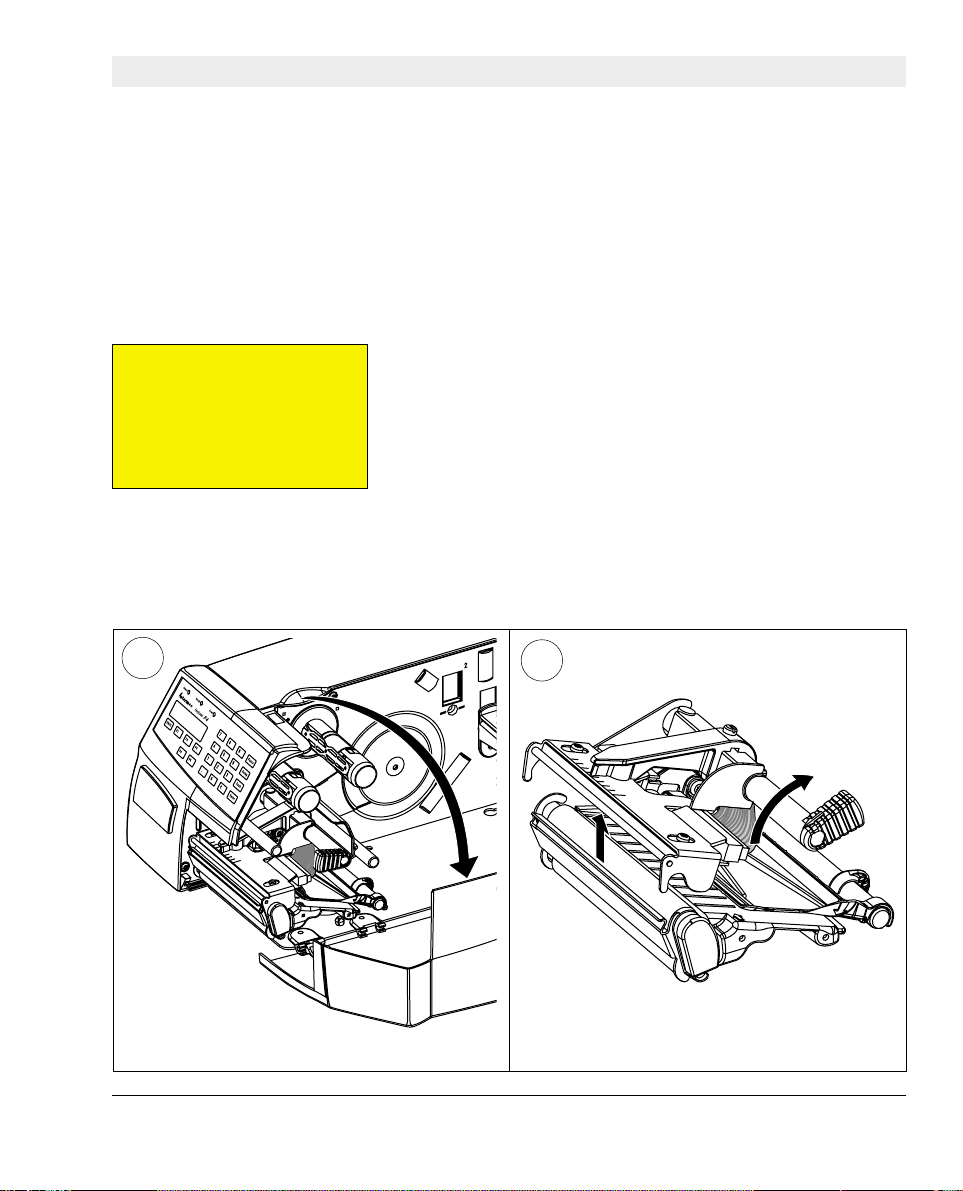

Important!

Sa ve the l abe l ind ica ting t he

sensitivity num ber attached to

th e medi a roll . You will n eed

th is nu mber to se t the m edi a

sensitivity, see Appendix 2.

1

The EasyCoder F4 can print on labels, tickets, tags, and continuous

stock using either direct ther mal pri nting on specia l heat-sensitive

paper or thermal transfer printing using a special ink -coated ribbon.

For ther mal tra nsfer print ing, the pr inter is fi tted with a transfer

rib b o n m e c h anism .

Therma l tra nsfer printi ng makes it possible to use a wide range of

receiving face materials. Make sure to select a type of ribbon that

matches the type of receiving face material (see Appendix 2, “Media

Specifi cat ion”) and to set up the pr inter accordingly (see Chapter

6. “Setting Up the Printer.”)

The Easy Coder F4 can use t ransfer ribbon rolls wound wit h the

ink-coated side facing either outward or inward. Illustrations in this

manual show the ink-coated side facing inward.

Most transfer ribbons do not smear at room temperature.

2

Open the side door.

Turn the printhead lift lever clockwise to raise

the printhead

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 330

Page 32

Ribbon Load, cont.

3 4

Chapter 5 Ribbon Load

In case of ribbon reload, remove any used

ribbon and empty ribbon core.

Unpack a roll of original Intermec thermal

transfer ribbon.

5 6

Slide the ribbon roll onto the supply hub so the

ink-coated side faces down when the ribbon is

routed through the print mechanism.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 31

Route the ribbon through the print mechanism

and pull out approximately 20 cm (8 inches)

of ribbon.

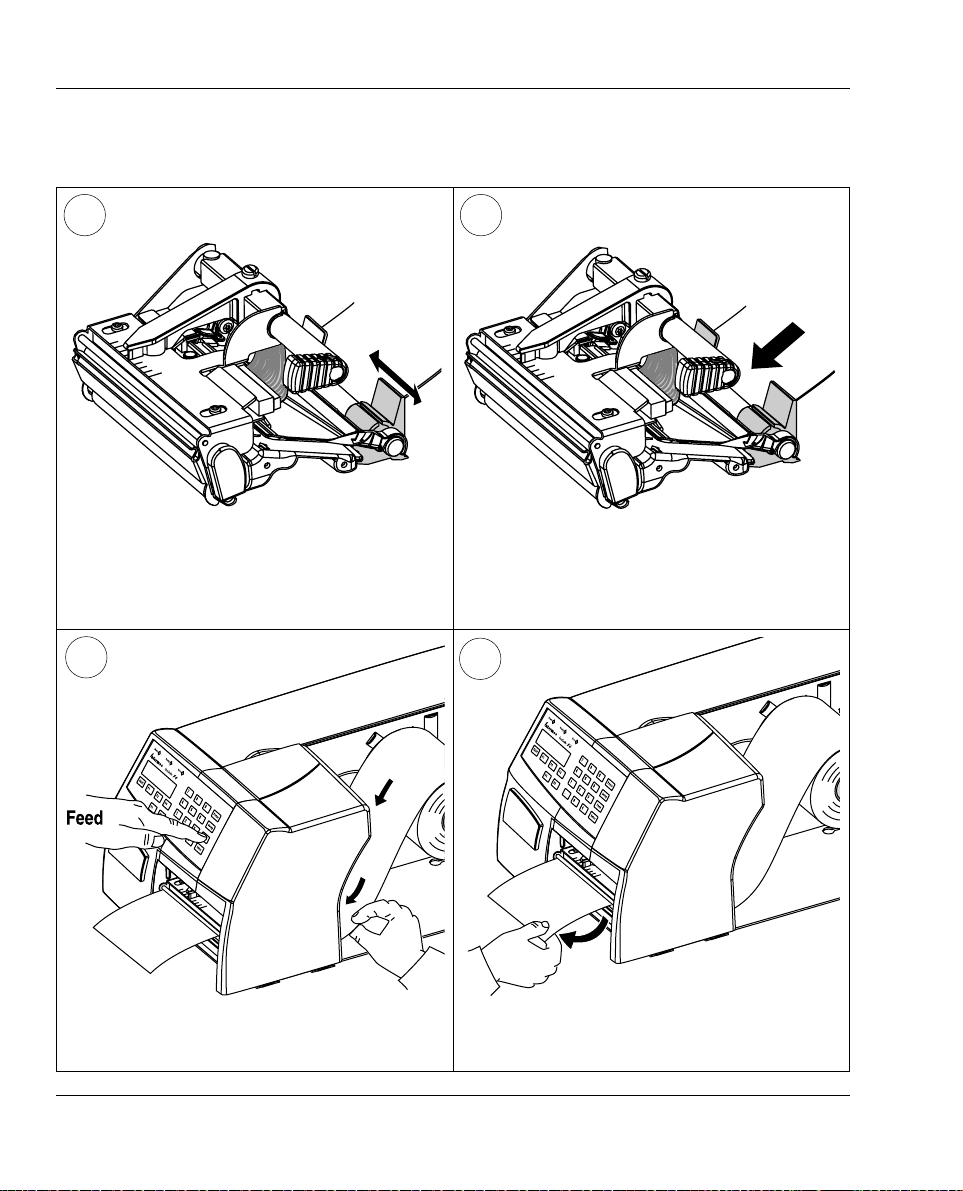

Page 33

Chapter 6 Setting Up the Printer

Ribbon Load, cont.

7 8

Without releasing the ribbon, turn the print-

head lift lever counterclockwise to engage the

printhead and lock the ribbon.

ribbon rewind hub so the ribbon is wound up

9 10

Turn the printhead lift lever clockwise to raise

the printhead and release the ribbon.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 332

Slide the empty cardboard core onto the

when the hub rotates counterclockwise.

Manually advance the ribbon until all of the

transparent leader has passed the printhead

and the ribbon becomes tight.

Page 34

Ribbon Load, cont.

11 12

Turn the printhead lift knob counterclockwise

to engage the printhead.

Chapter 5 Ribbon Load

Close the side door.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 33

Page 35

Chapter 6

Setting Up the Printer

Description

Default Setup

The setup controls the pr inter in regard of serial commun ication,

test and service operations, and specifi es which types of media and

ribbon are loaded in the printer.

Check the list below to see if the printer’s default setup matches your

requirements. If not, you will hav e to c hange the setup. To enter the

Setup Mode, press the <Setup> key on the printer’s built-in ke yboard

and follow the instructions in Chapter 7, “Setup Mode.”

The printer is, by def ault, set up according to the list below:

Communication

Baud rate: 9600 bps

Character length: 8 bits

Parity: None

Stop bits: 1 bit

Protocol: XON/XOFF

Test/Service

Testprint: n.a.

Data dump: No

Memory reset: n.a.

Label rest dots: 0

Form adj dots X: 0

Form adj dots Y: 0

Media

Media type: Gap

Paper type: DT

Label length: 1200 dots

Sensitivity: 420

Darkness: 0%

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 334

Page 36

Setup Parameters

Chapter 6 Setting Up the Printer

Serial Communication

• Baud Rate

• Data Bits

• Parity

• Stop Bits

• Protocol

The serial com munication paramet ers control the communication

between the printer and the connected computer or other devices on

the serial port. The serial communication parameters hav e no effect

on parallel communication.

Make sure the printer’s communication parameters match the setup

of the connected device or vice versa. If not, the response from the

printer to the host will be garbled.

Baud Rate

The baud rate is the t ransmission spe ed in bits per second. There

are 8 options:

• 1200

• 2400

• 4800

• 9600 (default)

• 1 9200

• 38400

• 57 600

• 115200

Data Bits

Th is pa rame ter spe cifie s the nu mber of b its th at wil l define a

character.

• 7 Characters ASCII 000 to 127 decimal

• 8 Characters ASCII 000 to 255 decimal (default)

Parity

The par ity decides how the fi rmware will check for transmission

errors. There are four options:

• None (default )

• Even

• Odd

• Space

Stop Bits

The number of stop bits specifi es how many bits will defi ne the end

of a character. There are two options:

• 1 (default)

• 2

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 35

Page 37

Chapter 6 Setting Up the Printer

Setup Parameters, cont.

Serial Communication,

cont.

Protocol

• XON/XOFF (default)

In the XON/XOFF protocol, data fl ow cont rol is achie ved by

using XON (DC 1) and XOFF (DC3) characters. Message blocks

are not required to be bracketed by the Sta rt of Text (STX) and

End of T ext (ETX) characters. Howe ver, at power up or after a reset

all characters except ENQ or VT will be ignored until an STX is

detected. The message length in this protocol is unrestricted. That

is, the printer processes information as it is being downloaded and

stops when there is no more information.

XON/XOFF protocol conforms to generally accepted i ndustry

standards. No end-of-message response is sent to the host other

than XOFF. An X O N will be sent on power u p .

Since DC1 and DC3 are used for data fl ow control, the printer status

characters are different than those of the Standard Protocol. If the

host ignores the printer’s X OFF , the printer will resend an XOFF

after receiving every 15 characters from the host.

Condition Character

Buffer already full GS

Printhead raised US

Ribbon fault US

No label stock EM

Buffer now full DC4

Printhead hot SI

Label at strip pin FS

Label skipping DC2

Printing DC2

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 336

Page 38

Setup Parameters, cont.

Chapter 6 Setting Up the Printer

Serial Communication,

cont.

Protocol, cont.

• Intermec Standard Protocol

The Intermec Printer Standard Protocol is a half-duple x protocol.

All data t ransmissions to the printer consist of status inquiry

(ENQ), status dump (VT), or message blocks. Each message

block starts with the Start of Te xt (STX) character and ends with

the End of Text (ETX) char acter. Each message block must be

255 characters or less, including the STX a nd ETX charact ers.

The printer responds to each status inqui ry or message block

with the printer status. The host should check the printer

status before downloading a message block to the printer.

ENQ causes the printer to t ransmit its highest priority status,

while VT instr ucts t he pri nter to tra nsmit al l status t hat applies

in the order of their priority. The possible printer status in

descending priorities are

Condition Character

Buffer already full GS

Printhead raised US

Ribbon fault US

No label stock EM

Buffer now full DC3

Printhead hot SI

Label at strip pin FS

Label skipping DC1

Ready DC 1

Printing DC1

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 37

Page 39

Chapter 6 Setting Up the Printer

Setup Parameters, cont.

Test/Service

•

Testprint

•

Data Dump

•

Memory Reset

•

Label Rest Dots

•

Form Adj Dots X

•

Form Adj Dots Y

Testprint

This pa rt of the Setup Mode al lows you to print various ty pes of

test labels. Go to the desired option and select whether you want to

print al l informat ion or just a single format, page, udc, font. Press

<Enter> and the pr inter wil l sta rt pr int ing the test label or labels.

Pre ss the < Pause> butto n to hold the p rint ing temp orar ily. To

resume printing, press <Pause> again. To term inate the pr inting,

press <C>. The follo wing options are available:

• Confi gurat i on

Select between software (SW) and hardware (HW).

The Software Confi guration Label contains:

- Current confi guration parameters stored in the printer’s

memory

- Defi ned pages

- Defi ned formats

- Defi ned graphics

- Defi ned fonts

- Any installed printer options

The Hardware Confi guration Label contains:

- Printer memory information

- Printer mileage

- Printhead settings

- Firmware checksum, program, and version number

• Format

The Format Lab el contains a single format that you can use to

evaluate the print qua lity of a pa rt icula r format. Select between

pri nting a sing le specifi ed format or labels for all the format s

stored in the printer’s memory .

• Page

The Page Label tests the ability of the printer to receive and print

single or multiple pages of label data that is sent from the host.

Select between printi ng a single specifi ed page or labels for all

the pages stored in the printer’s memory .

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 338

Page 40

Setup Parameters, cont.

Chapter 6 Setting Up the Printer

T est/Service, cont.

Testprint, cont.

• UDC

The UDC Label tests the ability of the printer to receive and print

single or mu ltiple user-defi ned characters (bitmap gr aphics) that

are sent from the host. Select bet ween pr i nt i ng a single U DC or

labels for all the UDCs stored in the printer’s memory.

• Font

The Font Label contains all the characters in a single font. Select

between printi ng a single font or labels for all the fonts stored

in the printer’s memor y. The latter uses a lot of media so it is

recommended to test one font at a time.

Data Dump

If data dump is enabled by selecting the “Yes” option, the printer

prints al l data and protocol chara cters received on the serial por t.

An ASC II and h exadeci mal rep resent ation of ea ch chara cter is

printed.

Memory Reset

There are two options. The memory will be reset to factory default as

soon as an op ti o n has bee n selected and <Enter> is pressed. Select

betwee n “All ”, which resets the entire memory and “Confi guration”

which just resets the confi guration part of the memory .

Label Rest Dots

Specifi es where labe ls stop fo r remov al. Use this f or peel-o ff (self -strip)

applications. Allowed range is -30 (furt hest back) to 30 (furthest

forward). Default is 0. Also available as an IPL command (<SI>fn).

Form Adj Dots X

Specifi es where the X-position of the origin should be placed on the

label. Allowed range is - 30 (cl osest to the leading edge) to 30 (furthest

from the leading edge). Default is 0.

Form Adj Dots Y

Specifi es where the Y-position of the origin should be placed on the

label. Allo wed range is - 30 (c losest to the cen ter section) to 30 ( furthest

from the center section). Default is 0 .

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 39

Page 41

Chapter 6 Setting Up the Printer

Setup Parameters, cont.

Media

• Media Type

• Paper Type

• Label Length

• Sensitivity

• Darkness

The media pa rameters tell t he fi rmware the character istics of the

media that will b e used, so the printout will be po siti oned correctly

and get the best quality possible.

Media Type

The Media Type parameters control how the label stop sensor (LSS)

and the media feed work. There are three media type options:

• Gap is used for adhesive labels mounted on liner (backing paper)

or continuous paper stock with detection slots. Default.

• Mark is used for labels, tic kets, or strip provided wi th black marks

at the back.

• Continuous is used for continuous stock without any detection

slots or black marks.

Paper T ype

The Pa per Typ e pa ram ete rs co ntr ol how t he t ran sfer r ibb on

mechanism a nd the r ibbon sensor work. There are t wo paper type

options:

• DT (Direct Thermal) is used for heat-sensi tive media without any

need for a thermal transfer ribbon. Default.

• TTR (Thermal Transfer) is used for non heat-sensitive receiving

face materials in combination with a thermal transfer ribbon.

Label Length

The Label Lengt h setup specifi es the length in dots of each copy

along t he media fe ed dir ection (X-c oordin ate). T his is use d for

“label-out” detection.

Sensitivity (Media Sensitivity Number)

This setup parameter specifi es the characteristics of the direct thermal

media or combination of receiving face material and thermal transfer

ribbon, so the pr inter’s fi rmware can opti mize the heati ng of the

printhead and the print speed. Standard supplies from Intermec are

labeled with a 3-digit media sensitivity number (see Appendix 2)

which is used to sp ecify the me dia grade. T he media sensitivity

number can also be changed using PrintSet, third-party software, or

an IPL command (<SI>gn[,m]). Default is 420 for direct thermal

printing and 567 for thermal transfer printing.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 340

Page 42

Setup Parameters, cont.

Chapter 6 Setting Up the Printer

Media, cont.

Darkness

Use this para meter to ma ke m inor adjustments of the blackness i n

the printout, for example to adapt the printer to variations in quality

between different batches of the same media quality. The value can

be setwithin the range -10 to 1 0% where -10 is the lightest and 10 is

the darkest. Default value is 0%.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 41

Page 43

Chapter 7

Setup Mode

Entering

Setup Mode

at Installation

Navigating in Setup Mode

To enter the Setup Mode, press the < Setup> key on the printer’s

built-in keyboard. T he following message in th e display window

indicates that you have entered the Setup Mode:

SETUP:

COMMUNICATION

While going th rough the set up procedu re, you are guided by texts

in the printer’s displ ay. Yo u can step bet ween setup pa rameter s,

acknowledge displayed values, select or type new values etc. using

some of the keys on the printer’s keyboard.

Move o ne men u to th e left o n the sam e

level1.

Move one menu t o the rig ht on the sa me

level1.

Move up one level or scroll back in a stack

of options1.

Move down one level or scroll forward in a

stack of options1.

-

Enter numeric values.

Specify negative values (leading position).

Clear erroneously entered values.

Acknowledge and move to next menu.

Print test labels in the T estprint menus.

Exit the Setup Mode.

(Can be used anywhere in the Setup Mode.)

1

/. Lef t, right , up, an d down refer to the o verviews l ater in thi s

chapter.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 342

Page 44

Setup Mode Overview, Part 1

Chapter 7 Setup Mode

SETUP:

COMMUNICATION

Continued on next page

COMMUNICATION:

BAUDRATE

COMMUNICATION:

DATA BITS

COMMUNICATION:

PARITY

COMMUNICATION:

STOP BITS

COMMUNICATION:

PROTOCOL

BAUDRATE:

9600

19200

38400

57600

115200

1200

2400

4800

DATA BITS:

8

7

PARITY:

NONE

EVEN

ODD

SPACE

STOP BITS:

1

2

PROTOCOL:

XON/XOFF

STANDARD

LEGEND:

Boxes with thick lines indicate default settings.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 43

Page 45

Chapter 7 Setup Mode

Setup Mode Overview, Part 2

Continued from previous page

SETUP:

TEST/SERVICE

SETUP:

MEDIA

TEST/SERVICE:

TESTPRINT

TEST/SERVICE:

DATA DUMP

TEST/SERVICE:

MEMORY RESET

TEST/SERVICE:

LABEL REST DOTS

TEST/SERVICE:

FORM ADJ DOTS X

TEST/SERVICE:

FORM ADJ DOTS Y

MEDIA:

MEDIA TYPE

MEDIA:

PAPER TYPE

MEDIA:

LABEL LENGTH

MEDIA:

SENSITIVITY

MEDIA:

DARKNESS

TESTPRINT:

CONFIG

TESTPRINT:

FORMAT

TESTPRINT:

PAGE

TESTPRINT:

UDC

TESTPRINT:

FONT

DATA DUMP:

NO

YES

MEMORY RESET:

ALL

CONFIGURATION

LABEL REST DOTS:

[0]:

FORM ADJ DOTS X:

[0]:

FORM ADJ DOTS Y:

[0]:

MEDIA TYPE:

GAP

MARK

CONTINUOUS

PAPER TYPE:

DT

TTR

LABEL LENGTH:

[1200]:

SENSITIVITY:

[420]:

DARKNESS:

[0]:

CONFIG:

SW

HW

FORMAT:

ALL

SELECT

PAGE:

ALL

SELECT

UDC:

ALL

SELECT

FONT:

ALL

SELECT

SELECT:

[0]:

SELECT:

[0]:

SELECT:

[0]:

SELECT:

[0]:

Continued on the next page if an EasyLAN 100i interface board is installed.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 344

Page 46

Setup Mode Overview, Part 3

Continued from the previous page If an optional an EasyLAN 100i interface board

is installed in the printer

Chapter 7 Setup Mode

SETUP:

NETWORK

• Press <Setup> to exit the Setup Mode.

NETWORK:

IP SELECTION

Read

IP SELECTION:

MANUAL

Read

Set

NETWORK:

IP ADDRESS

NETWORK:

NETMASK

NETWORK:

DEFAULT ROUTER

DHCP

BOOTP

RARP

IP ADDRESS:

192.168.1.79

NETMASK:

255.255.255.0

DEFAULT ROUTER:

192.168.1.1

Use <.> and <0> - <9>

to set IP address.

Use <C> to erase.

Use <.> and <0> - <9>

to set netmask.

Use <C> to erase

Use <.> and <0> - <9>

to set default router.

Use <C> to erase.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 45

Page 47

Chapter 8

Options

Introduction

The EasyCoder F4 is designed to provide a high degree of fl exib ilit y

because it has a mo dular design. By add ing options to the basic

printer, the EasyCoder F4 can be adapted for a variety of applications.

Most options can easily be installed by the operator, how e ver, a fe w

should be instal led by a n author i ze d ser v ice te ch n ician or are only

available as factory-installed options.

Covers

(used when a transfer ribbon

mechanism or liner takeup is

not fi tted)

1.5-inch Rotating

Supply Hub

Supply Roll

Post

Label Taken

Sensor

Short Side Door

Long Side Door

Transfer Ribbon

Mechanism

Long Side Door

with 8-inch Megatop

3-inch Adapter

Liner Takeup

and Guide

Shaft

Narrow Quick-Load Guides

Wide Quick-Load Guides

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 346

Page 48

Chapter 8 Options

DTP Model

Side Doors and Megatop

Integral Liner Takeup Unit

Media Supply Hub

In the dedicate d di rect t her ma l pr inti ng (DT P) model, the ther ma l

transfer ribbon mechanism is omitted.

The EasyCoder F4 comes with either a short side door, which only

covers the print mechanism or with one of two types of long side

doors, which encloses the entire media compartment. The standard

long side do or has a fl at top and a slot for externa l media supply.

The 8-inch Megatop version has a hinged transpa rent canopy that

encloses a media roll with a diameter up to 213 mm (8.38 inches).

The stand ard long side door is generally illustrated th roughout t his

manual, but pictures of the short side door can be found in Chapter

4, “Media Load/T ear-off wi th Quick-Load.”

The integral liner takeup unit is an optional device for peel-off

(self-strip) operation, which means that the labels are separated from

a liner (backing paper) after printing and the liner is wound up on an

internal hub. The unit also includes a guide shaft. Peel-off cannot be

combined with Quick-Load guides, see below.

The rotati ng media supply hub is designed to fi t media roll cores

with an internal diameter of 38-40 mm (1.5 inch). The hub can be

fi tted in the same positions as the supply roll post (see Chapter 2,

“Instal lati on.”) Being factory installed, the position of the hub is not

intended to be changed by the operator.

3-inch Adapter

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 47

The 3 -inch /76 mm adap ter is with a ro tating m edia supply hub

and makes it possible to use media rolls with 3 inch/ 76 mm inner

diameter cores. The ad apter is pressed onto the med ia supply hub

and secured by a screw.

The 3-inch adapter is not used with a media roll supply post.

Page 49

Chapter 8 Options

Quick-Load Guides

Label Taken Sensor

Interface Boards

For Quick-Load operation (see Chapter 4, “Media Loa d”), a set of

wide or narrow Quick-Load guides is installed at the rear of the print

mechanism instea d of the stand ard edge g uide. The outer gu ide is

adjustable for different media widths. T wo sets of Quick -Load guides

are i ncluded a s stand ard in t he deliver y (either fa ctory-fi tted or

loose). They can easily be installed by the operator:

1. Open the upper media guide (see illustration in Chapter 10,

“Maintenance/Cleaning the Media Guides”).

2. Pull out the standard edge guide from the shaft.

3. Fit the appropriate set of Quick-Load guides onto the shaft as

illustra ted o n th e fi rst page of this chapter.

The L abel Taken Sensor ( LTS) is a phot oelectr ic sensor, which

enables the printer’s fi rmware to detect i f the latest printed label,

ticket, tag etc. has been removed before printing another copy.

A number of different interface boards are available for use with the

EasyCoder F4. The interface boards are either factor y fi tted or can

easily be fi tted b y an a uth orized se rvice techni ci an.

The EasyCoder F4 can accommodate one interface board.

The IPL version of the EasyCoder F4 only support s two of these

interface boards:

• IEEE 1284 Parallel Interface Board

• EasyLAN 100i Interface Board

Refer to Appendix 3, “Interfaces” f or more information.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 348

Page 50

Chapter 9

Troubleshooting

Symptom Possible Cause Remedy Refer to

Overall weak printout Wrong media grade Change parameter Appendix 2, Chapter 6

Contrast value too low Change parameter Chapter 6

Printhead pressure too low Adjust Chapter 11

Worn printhead Replace printhead Chapter 10

Wrong printhead voltage Replace CPU board ☎ Call Service

Printout weaker on one side Uneven printhead pressure Adjust arm alignment Chapter 11

Weak spots Foreign particles on media Clean or replace Chapters 4 & 5

Media/ribbon don’t match Change to matching media Appendix 4

Poor media or ribbon quality Use Intermec media/ribbon Appendix 2

Worn printhead Replace printhead Chapter 10

Worn platen roller Check/replace ☎ Call Service

Overall dark printout Wrong media grade Change parameter Appendix 2, Chapter 6

Contrast value too high Change parameter Chapter 6

Printhead pressure too high Adjust Chapter 11

Wrong printhead voltage Replace CPU board ☎ Call Service

Excessive bleeding Wrong media grade Change parameter Appendix 2, Chapter 6

Contrast setup value too high Change parameter Chapter 6

Printhead pressure too high Adjust Chapter 11

Faulty energy control Replace CPU board ☎ Call Service

Dark lines along media path Foreign objects on printhead Clean printhead Chapter 10

White lines along media path Printhead dirty Clean printhead Chapter 10

Missing dots on printhead Replace printhead Chapter 10

Large part of dot line missing Failing printhead Replace printhead Chapter 10

Failing strobe signal Check CPU-board ☎ Call Service

Printout missing along inner edge Bad media alignment Adjust Chapter 4

Small core & supply post in upper pos. Move post to lower pos. Chapter 2

Transfer ribbon breaks Ribbon not fi tted correctly Reload ribbon Chapter 5

Wrong media grade (too much energy) Change parameter, Appendix 2, Chapter 6

then clean printhead Chapter 11

Bad energy control Adjust ☎ Call Service

Transfer ribbon wrinkles Faulty ribbon break shaft adjustment Adjust Chapter 11

Incorrect edge guide adjustment Adjust Chapter 4

Too strong printhead pressure Adjust Chapter 11

No thermal transfer printout Ink-coated side does not face media Reload ribbon Chapter 5

Media feed not working properly Changed media characteristics Press Feed Chapter 4

Wrong label rest dots parameter Check/change Chapter 6

Wrong sensor position Check/change Chapter 11

Dirty or blocked sensors Clean media guides Chapter 10

Faulty sensors Replace ☎ Call Service

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 49

Page 51

Chapter 10

Maintenance

Printhead Cleaning

Cleaning the pr inthead on a regu lar basis is impor tant for the li fe

of the p rint head a nd for the p rinto ut qual ity. You should cle an

the pr inthead each t ime you replace the r ibbon and media . This

section describes how to clean the print head using cleaning cards.

If additional cleaning is required, for example removing adhesive

residue from the platen roller or tear bar, use a cotton sw ab moistened

with isopropyl alcohol.

Isopropyl alco hol [(CH 3)2CHO H; CA S 67- 63- 0] is a h ighly

fl ammable, moderately toxic, and mildly irritating substance.

1 2

Warning!

Open the side door.

Turn the printhead lift lever clockwise to raise

the printhead.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 350

Page 52

Printhead Cleaning, cont.

Chapter 10 Maintenance

3

Remove any media and transfer ribbon.

5

4

Open the cleaning card envelope and pull out

the cleaning card. Read the warning text.

6

Insert most of the cleaning card under the

printhead (1). Engage the printhead (2).

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 51

Pull out the cleaning card (1) and raise the

printhead (2).

Page 53

Chapter 10 Maintenance

Printhead Cleaning, cont.

87

Wait for approx. 30 seconds to allow the

cleaning fl uid to dissolve the residue.

9

Pull out the cleaning card. If necessary, repeat

the process with a fresh cleaning card.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 352

Insert most of the cleaning card under the

printhead (1). Engage the printhead (2).

10

Allow the cleaned parts to dry before loading

any media and ribbon.

Page 54

External Cleaning

Chapter 10 Maintenance

1

Always remove the power cord

before cleaning!

3

2

Wipe e xternal surfaces with a soft cloth slightly

moistened with water or a mild detergent.

4

Never spray the printer. Protect it from water

when cleaning the premises.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 53

Never use any sharp tools for removing stuck

labels. The printhead and rollers are delicate.

Page 55

Chapter 10 Maintenance

Cleaning the Media Guides

Both part s of the label stop sensor, which controls the paper feed,

are covered by transparent plastic guides. The g uides have areas,

th rough which th e light betwee n the two par ts of the la bel stop

sensor is transm itted. T hese ar eas (indicate d by a shade of gray in

illustration # 2 below) must be kept clean from dust, stuck labels,

and adhesive residue.

If the printer starts to feed out labels in an unexpected way , raise the

upper guide–as described below–and check for any ob ject that may

block the beam of light (dust, stuck labels, adhesive residue, etc.).

If necessa ry, clean the guides using a cleaning card or a soft cloth

soaked with isopropyl alcohol. Do not use any other chemicals. Be

careful not to scratch the guides.

Isopropyl alco hol [(CH

fl ammable, moderately toxic, and mildly irritating substance.

1 2

Warning!

CHO H; CA S 67- 63- 0] is a h ighly

3)2

Lift the inner part of the upper guide and

pull it outwards,disengaging it from the lower

guide. Take care not to damage the cable.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 354

Tilt the upper guide upwards and clean the

areas marked with grey. After cleaning, reas-

semble in reverse order.

Page 56

Chapter 10 Maintenance

Printhead Replacement

The pr inthea d is subject to wear bot h from the t herma l transfer

ribbon or the di rect t her ma l med ia a nd from t he rapid heati ng and

cooling process dur ing printi ng. Thus, the printhead wi ll require

periodic rep lace men t.

Time between printhead replacements depends on the print images,

the type of di re ct ther ma l med ia or ther ma l t ra nsfer ribbon in use,

the amount of energy to the printhead, the print speed, the ambient

temperature, and several other factors.

While replacing the printhead, the power should be off.

1 2

Caution!

Turn the printhead lift lever clockwise to raise

Open the side door.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 55

the printhead.

Page 57

Chapter 10 Maintenance

Printhead Replacement, cont.

3

Remove any media and transfer ribbon.

5

4

Pull the printhead bracket away from the

magnet in the pressure arm.

6

Snap-lock

Disconnect the printhead bracket from the print

mechanism as indicated by the arrows and pull

out the printhead as far as the cables allow .

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 356

Disconnect the cables from the printhead. Note

the snap-lock on the inner connector. Pull at the

connectors–not the cables!

Page 58

Printhead Replacement, cont.

Chapter 10 Maintenance

87

Connect the two cables to the replacement

printhead.

9

Turn the printhead lift lever counterclockwise

so the magnet engages the printhead bracket.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 57

Put back the printhead in reverse order and

check that the printhead cables run freely.

10

Load a new supply of media and ribbon, as

described earlier in this manual.

Page 59

Chapter 11

Adjustments

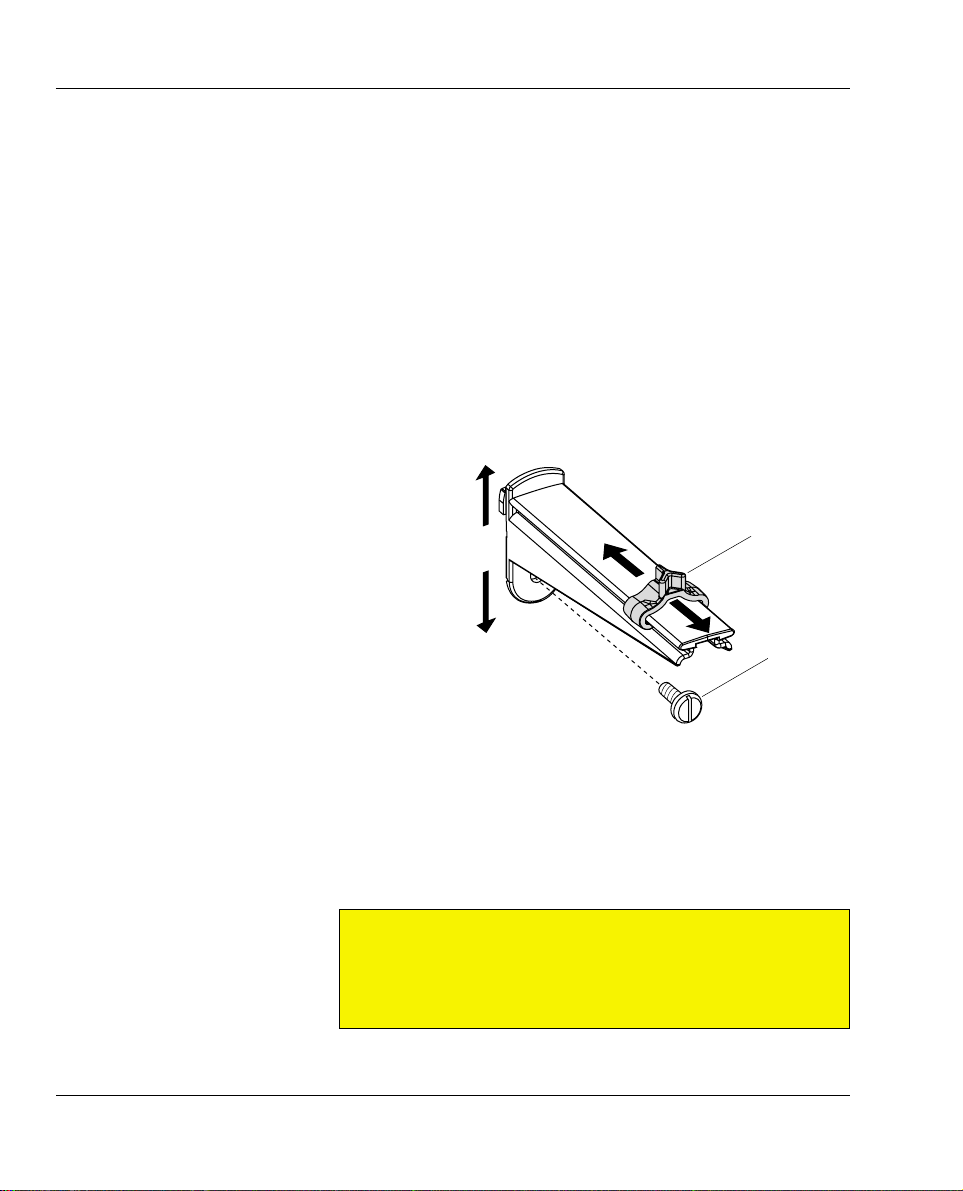

Narrow Media

Adjustment

Screw

Pressure Arm

Center of Media

The printer is factory-adjusted for full-size media width. When using

media less than full width, it is recommended that you adjust the

position of the p re s sure arm so it beco mes ce n t e re d with the m edia.

Thereby, an ev en press ure across the media is obtained.

A poorly adjusted pressure arm may be detected by a w eaker printout

on either s i d e o f the m edi a p ath .

T o ad just the pressure arm, proceed as follo w s:

• Loosen the straight-sl ot scre w that holds the pressure arm. Move

the arm inwards or outwards until the arrow on the tip of the arm

becomes centered with the media.

While moving the arm, push at the part where the screw

is situated, not at the tip. If the arm is hard to move, lift

the printhead and pull the printhead bracket free from the

magnet in the arm.

• After having centred the arm, lock it by tightening the screw.

Note!

In order to provide a better view,

the i llust raton d epicts a d edicated direct thermal printer.

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 358

Page 60

Chapter 11 Adjustments

Label Stop Sensor Position

One Sensor

The label stop /black mark sensor (LSS) is a photoelect ric sensor

that controls the printer’s media feed by dete cting gaps between

labels or slots or black marks in continuous stock, depending on the

printer’s setup in regard of media type (see Chapter 6 “Setting Up the

Printer”). An obvious prerequisite is that the LSS must be aligned

with t he gaps, slots, or bla ck marks. I f using ir regula rly-shaped

labels, align the LSS with the front tips of the labels

The LSS can be moved laterally between 5 fi xed positions. There is

one part of the sensor on top of t h e upp er media guide and another

part underneath the lower guide. These must be adjusted individually

to the same position. Using a small screwdriver, push them inwards

as far as they go and then pull them out–one at the time–while

counting the clicks fr om the snap-locks. A hole in the bottom plate

gives access to the lower sensor part.

The various detect ion points of the sensor in relation to the inner

edge of the media are as follo w s:

One click out 3 mm .1 18 inches

Two clicks out 8 mm .315 inches

Three clicks out 12 mm .472 inches

Four clicks out 16 mm .63 9 inches

Five c licks out 20 mm .787 inches

Upper part of LSS

One Diode + One Sensor

Lower part of LSS

(printhead and headlift shaft omitted for

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 59

Print Mechanism

improved visibility)

Page 61

Chapter 11 Adjustments

Printhead Pressure

The pressure of the thermal printhead against the ribbon or media is

factory-adjusted. However, the use of thicker or th inner media than

normal could require the printhead pressure to be readjusted.

Using a straight -slot scre wdriver , turn the adj ustment screw cl ockwise

for more pressure (+ ) or countercl ockwise for less pressure (-). Print

a few labels and check the printout. Increa sed pressure generally

gives a da rker pri ntout and v ice versa. Repe at until t he desir ed

result is obtained.

T o return to the factory setting, tighten the screw (+) as f ar as it goes

and then loosen it (-) six full turns.

Caution!

Do not use a higher printhead pressure than necessary because it

may increase the wear of the printhead and shorten its life.

Adjustment Screw

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 360

Page 62

Chapter 11 Adjustments

Ribbon Break Shaft

Adjustment Screw

If ribbon wrinkling is occurring, you may need to adjust the

alignment of the front ribbon break shaft so that it runs parallel to the

printhead and the ribbon supply and rewind hubs. The adjustment is

done using a straight-slot screw that is located immed iately behi nd

the front ribbon break shaft.

• If the r ibbon tends to slide outwards, turn t he screw carefully

clockwise (fw) to move the outer end of the break shaft

forward.

• If the ribbon tends to slide inwards, turn the screw carefully

counterclockwise (bw) to move the outer end of the break

shaft backward.

Important!

Before readju sting the bre ak shaf t, mak e sure that th ere is no

ot her ca use fo r the wr ink ling of t he ri bbo n (See C hap ter 9,

“Troubleshooting.”)

Ribbon Break Shaft

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 3 61

Page 63

Appendix 1

Technical Data

Printing

Print T echnique Thermal Transfer and/or Direct Thermal

Printhead Resolution 8 dots/mm (203.2 dpi)

Print Speed (variable) 100 to 200 mm/sec. (≈ 4 to 8 inches/sec.)

Print Width (max) 104 mm (4.095 inches) = 832 dots

Print Length (max) 32767 dots = 409.5 cm(16 1 .25 inches)1

Media Width (min/max) 25 to 1 1 4.3 mm ( 1 to 4.5 inches) Standard edge guide

Media Width (min/max) 40/80 to 1 1 4.3 mm ( 1 .57/3. 1 5 to 4.5 inches) Quick-Load guides

Media Roll Diameter (max) 21 3 mm (8.38 inches) Short door/no takeup

Media Roll Core Diameter 38 to 40 mm (1.5 inches) or 76 mm (3 inches)

Ribbon Width (max) 11 0 mm (4 .33 inches)

Ribbon Roll Diameter (outer) 62 mm (2.44 inches) ≈ 200 m (655 ft) ribbon

Ribbon Roll Core Diameter (inner) 25.4 mm ( 1 .00 inches)

Print Directions 4

Modes of Operation

T ear-Off (Straight-through) Yes

Peel-Off (Self-strip) Optional With liner takeup unit

Firmware

Operating System Intermec IPL 3

Built-in fonts (std) 3 scaleable + 21 simulated bitmap fonts

Built-in bar code symbologies (std) 25

Physical Measures

Dimensions (W x L x H) 244 x 397 x 178 mm (9.61 x 1 5.63 x 7.00 inches) With long side door

Weight (excluding media) ≈ 7 kg (1 5.5 pounds) Depending on model

Ambient Operating Temperature +5°C to +40°C (+41 °F to +1 04°F)

Humidity 20 to 80% non-condensing

Electronics

Microprocessor 32 bit RISC

On-board Flash SIMMs 2 sockets for 2 or 4MB each Std. 1 x 2MB

On-board DRAM SIMM 1 Std. 4MB

Power Supply

Mains Voltage >90 to <264 VAC, 45 to 65Hz

PFC Regulation IEC 61000-3-2

Maximum Power Consumption Continuous 1 40W; Peek 300W

Intermec EasyCoder F4 – Installation & Operation IPL Version, Ed. 362

Page 64

Technical Data, cont.

Sensors

Label Gap/Black Mark/Out of Media Y es 5 fi xed positions

Printhead Lifted Yes

Ribbon End Yes

Controls

Control Lamps 3

Display 2 x 16 character LCD w. background light

Keyboard 22 keys membrane-switch type

Print button (1) Does not work with IPL

Beeper Yes

Data Interfaces

Serial 1 x RS-232

Connection for Optional Interface Boards 1

Memory Card Adapter 1 Firmware update only

Accessories and Options