Page 1

Service Manual

EasyCoder PC4

Bar Code Label

Printer

Page 2

Intermec Technologies Corporation

Corporate Headquarters

6001 36th Ave. W.

Everett, WA 98203

U.S.A.

www.intermec.com

e information contained herein is proprietary and is provided solely for the purpose of allowing

customers to operate and/or service Intermec manufactured equipment and is not to be released,

reproduced, or used for any other purpose without written permission of Intermec.

Information and specifications in this manual are subject to change without notice.

© 2005 by Intermec Technologies Corporation. All Rights Reserved

EasyCoder, EasyLAN, Fingerprint, and LabelShop are registered trademarks of Intermec Tech

nologies Corp. e word Intermec, the Intermec logo, InterDriver, and PrintSet are trademarks of

Intermec Technologies Corp.

e name Centronics is wholly owned by GENICOM Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a trademark of Microsoft Corporation.

roughout this manual, trademarked names may be used. Rather than put a trademark (™) symbol

in every occurrence of a trademarked name, we state that we are using the names only in an editorial

fashion, and to the benefit of the trademark owner, with no intention of infringement.

Page 3

Intermec EasyCoder PC4—Service Manual iii

Preface

Contents

About is Manual ...............................................................................................................v

Notices and Approvals ..........................................................................................................

vi

1

Models and Options 1

1.1 Models............................................................................................................................ 2

1.2 Options ...........................................................................................................................

3

1.3 EasyCoder PC4 Specifications ........................................................................................

4

1.4 EasyCoder PC4 Measures ...............................................................................................

6

2

Main Parts 9

2.1 Taking the Printer Apart ................................................................................................10

2.2 Reassembling the Printer ...............................................................................................

10

2.3 Exploded View ..............................................................................................................

11

3

Top Cover 13

3.1 Description................................................................................................................... 14

3.2 Tear-Off Plate ................................................................................................................

15

4

Print Frame 17

4.1 Description.......................................................... .........................................................18

4.2 LED and Feed Switch ...................................................................................................

19

4.3 Top Cover Locks ...........................................................................................................

21

4.4 Base Lock Spring Hooks ...............................................................................................

21

4.5 Printhead ......................................................................................................................

22

4.6 Ribbon End Sensor .......................................................................................................

25

4.7 Label Gap Sensor (Emitter) ...........................................................................................

27

4.8 Ribbon Feed Mechanism ..............................................................................................

28

5

Base Frame 33

5.1 Main Parts..................................................................................................................... 34

5.2 Main Board ...................................................................................................................

35

5.3 Platen Roller .................................................................................................................

36

5.4 Peel-Off Mechanism ......................................................................................................

37

5.5 Motor assy ....................................................................................................................

39

5.6 Media Guides ................................................................................................................

40

5.7 Base Locks ....................................................................................................................

41

5.8 Label Gap/Black Mark Sensors ......................................................................................

43

5.9 Media Spindle ...............................................................................................................

45

6

Bottom Cover 47

6.1 Bottom Cover ...............................................................................................................48

Page 4

iv Intermec EasyCoder PC4—Service Manual

Preface

7

Main Board 49

7.1 Description................................................................................................................... 50

7.2 Accessing the Main Board .............................................................................................

51

7.3 Connections ..................................................................................................................51

7.4 Test Points .....................................................................................................................

52

7.5 Block Diagram ..............................................................................................................

54

7.6 Internal Memory ...........................................................................................................

55

7.7 Schematics ....................................................................................................................56

8

Power Supply 61

8.1 Description.................................................................................................................... 62

9

Memory Cartridge (option) 63

9.1 Description................................................................................................................... 64

9.2 Memory Sizes ................................................................................................................

65

9.3 Schematics ....................................................................................................................66

10

Starting Up 67

10.1 Normal Mode .............................................................................................................68

10.2 Test Mode ...................................................................................................................

69

10.3 Dump Mode ...............................................................................................................

70

11

Firmware Upgrading 71

11.1 Requirements ..............................................................................................................72

11.2 Step-by Step Instructions ............................................................................................

73

12

Troubleshooting 75

12.1 Checklist..................................................................................................................... 76

Page 5

Intermec EasyCoder PC4—Service Manual v

Preface

About This Manual

is Service Manual is intended to facilitate installation, troubleshooting

and repair of the Intermec EasyCoder PC4 in the version delivered at the

date of publishing. us, all information on the ESim firmware is based on

version 6.xx. e on-going product improvement can be followed in the

Technical Bulletins published at the Intermec Knowledge Center.

is Service Manual is supplemented by the following publications, which

the service technician also should keep easily available in their latest ver

-

sions:

• Intermec EasyCoder PC4, Quick Start Guide (multilingual)

• Intermec EasyCoder PC4, User’s Guide

• Intermec EasyCoder PC4, Spare Parts Catalog

• ESim v6.xx, Programmer’s Reference Manual

Please note that the operations described in this manual only should be car

ried out by skilled and authorized personnel with proper training and full

understanding of written English. Moving parts may cause harm, if incor

-

rectly manipulated.

It is assumed that the reader possesses adequate skills in mechanics and

electronics and is familiar with the ESim protocol and its related standard

application programs. It is also assumed that the reader has access to the

standard tools of an electronics workshop.

Page 6

vi Intermec EasyCoder PC4—Service Manual

Preface

FCC Notice (United States of America)

WARNING

is equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instructions manual,

may interfere with radio communications. It has been tested and found to

comply with the limits for a Class A computing device pursuant to Sub

part J of Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial envi

ronment. Operation of this equipment in a residential area is likely to cause

interference in which case the user, at his own expense, will be required to

take the appropriate measures needed to correct the problem.

DOC Notice (Canada)

Canadian Dept. of Communication

REGULATIONS COMPLIANCE

(DOC-A)

is digital apparatus does not exceed the class A limits for radio noise

emissions from a digital apparatus as set out in the radio interference regu

-

lations of the Canadian Department of Communication.

Ministère des Communications du Canada

CONFORMITE DE REGLEMENTS

(DOC-A)

Le présent appareil numérique n’émet pas de bruits radio-électriques dépassant les limites applicables aux appareils numériques de classe A prescrites

dans le règlement sur brouillage radioélectrique édicté par le Ministère des

Communications du Canada.

EU Standard EN 55022 (The European Union)

WARNING

is is a Class A ITE product. In a domestic environment this product

may cause radio interference in which case the user may be required to take

adequate measures.

Notices and Approvals

Page 7

Intermec EasyCoder PC4—Service Manual 1

1

Models and Options

is chapter provides information on the various models of the EasyCoder

PC4 and contains specifications and physical measures.

Page 8

2 Intermec EasyCoder PC4—Service Manual

Chapter 1—Models and Options

1.1 Models

ere are two main models of the EasyCoder PC4; one dedicated direct

thermal (DT) model and one dual-capable direct thermal/thermal transfer

(TTR) model. Both models are based on a common double clam-shell

mechanical platform and have the same type of electronics, so except from

the fact that the direct thermal model has no transfer ribbon mechanism,

there are very few differences.

Both models are available with two different printheads; one with a density

of 203.2 dots per inch (8 dots per mm) and a maximum print width of 4.1

inches (104 mm), and another with a density of 300 dots per inch (11.81

dots per mm) and a maximum print width of 4.02 inches (102.2 mm).

Since there is no need to open the top cover in the DT model, the top

cover locks are cut off in flush with the bottom of the print frame.

e machine label, which provides information on model, part number,

serial number, etc. is attached to the bottom of the base frame.

e EasyCoder PC4 has a separate power supply unit that delivers 24

VDC to the printer's main board, where it is transformed to the various

voltages required by the printhead, motor, and logics (see Chapter 8.1).

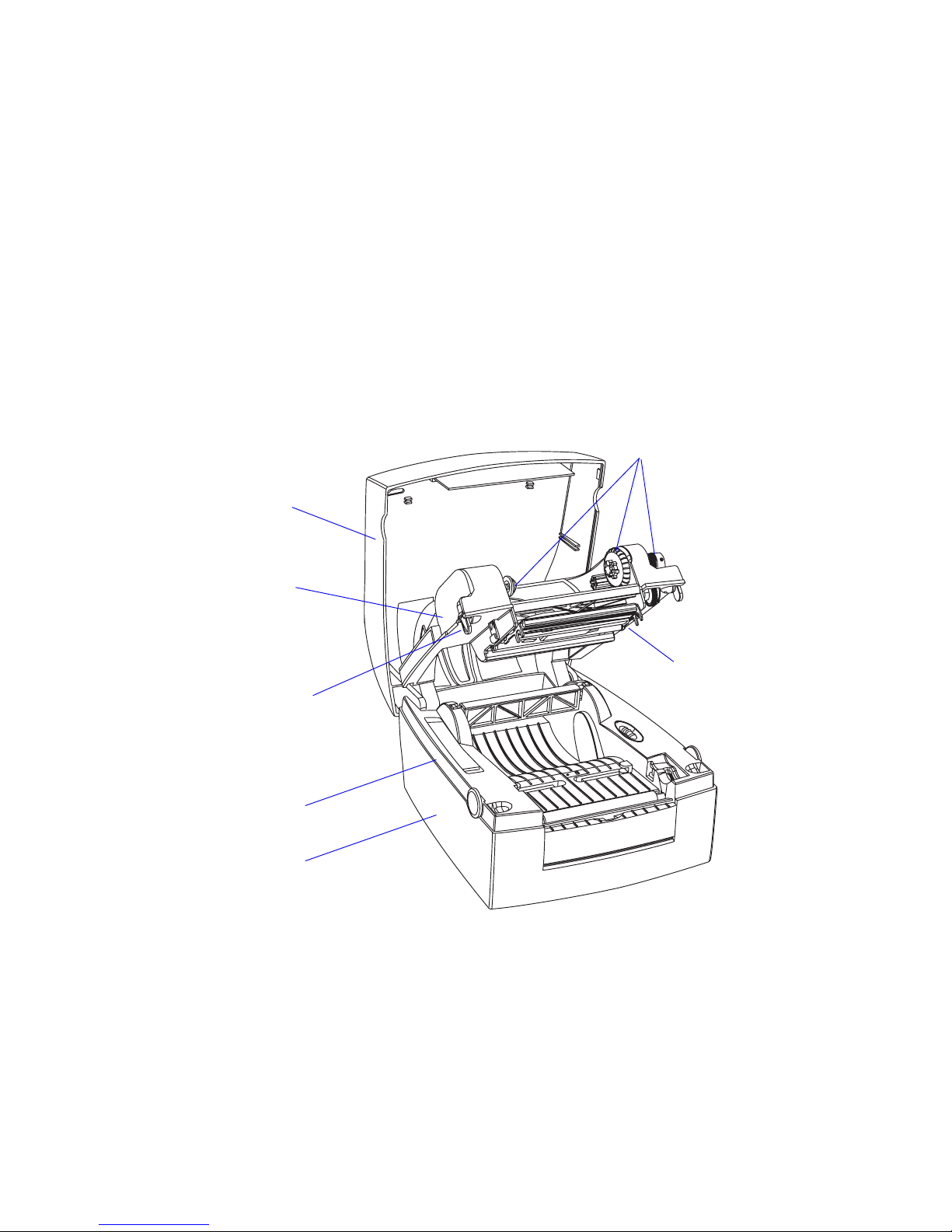

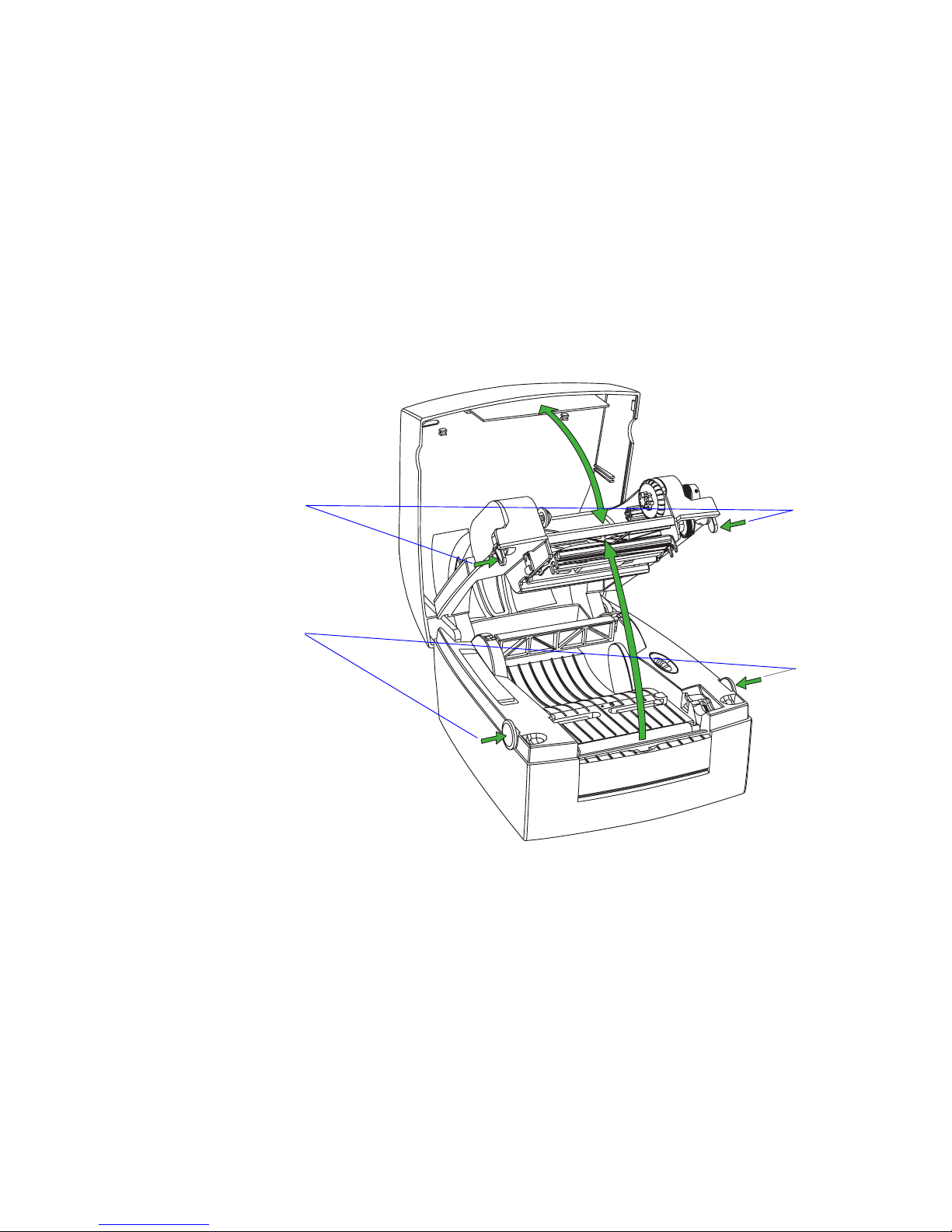

Thermal transfer

mechanism

(omitted in DT model)

Printhead

Top cover locks

(differ in DT and

TTR models)

Print frame

Top cover

Base Frame

Bottom Cover

Page 9

Intermec EasyCoder PC4—Service Manual 3

Chapter 1—Models and Options

e power supply unit (PSU) accepts 100 to 240 VAC/50 to 60 Hz. e

power supply has a standard 2-pin input voltage socket, so various types of

power cords can be used according to local voltages and standards.

e power supply has a fixed 1.5 m (4.9 ft) long cable that is connected to

the printer’s rear plate.

1.2 Options

e available options for the EasyCoder PC4 are memory cartridges, USB,

serial and parallel interface cables, a keyboard/display unit, a paper cutter,

a battery unit and an assortment of power cords. Refer to the EasyCoder

PC4, Spare Parts Catalog

or Spare Parts List for updated information.

Page 10

4 Intermec EasyCoder PC4—Service Manual

Chapter 1—Models and Options

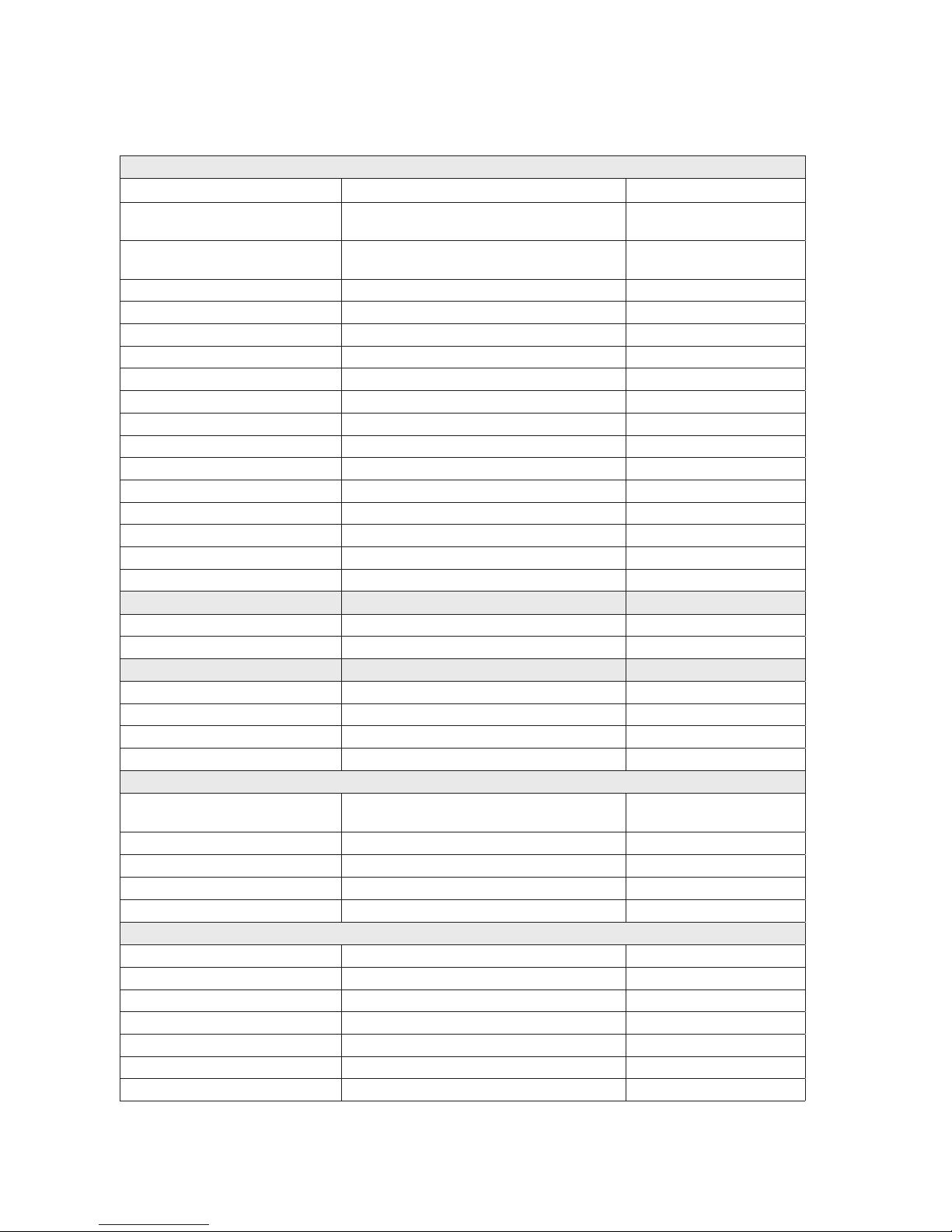

1.3 EasyCoder PC4 Specifications

Printing

Print Technique ermal Transfer and/or Direct ermal

Printhead Resolution

203.2 dpi (8 dots/mm) or

300 dpi (11.81 dots/mm)

Print Speed (selectable) 30, 40, 50, 75 or 100 mm/sec.

(1.2,1.6, 2, 3 or 4 in/sec.)

Print Width (max) at 203.2 dpi 104 mm (4.1 inches) = 832 dots

Print Width (max) at 300 dpi

102.2 mm (4.02 inches) = 1208 dots

Print Length (min/max) at 203.2 dpi 6.35/472.5 mm (0.25/18.6 inches) Standard (no cartridge)

Print Length (min/max) at 300 dpi 6.35/220.0 mm (0.25/8.66 inches) Standard (no cartridge)

Media Width (min/max) 25.4 to 118 mm (1.00 to 4.65 inches)

Media ickness (min) 0.06 mm (0.003 inches)

Media ickness, rolls (max) 0.15 mm (0.006 inches)

Media ickness, fan-folds (max) 0.17 mm (0.006 inches)

Media Roll Diameter (max) 127 mm (5.0 inches)

Media Roll Core Diameter 25.4 or 38.1 mm (1.0 or 1.5 inches)

Ribbon Width (min/max) 33 to 110 mm (1.33 to 4.33 inches)

Ribbon Roll Diameter, Outer (max) 41 mm (1.6 inches)

Ribbor Roll Core Diameter, Inner 13 mm (0.5 inches)

Print Directions 4

Modes of operation

Tear Off (Straight-through) Yes

Peel Off (Self-strip) Yes

Firmware

Operating System Intermec ESim v6.xx

Fonts 5 resident

Font Magnification Horizontal max 8 times, vertical max 9 times

Built-in Bar Code Symbologies

33

Physical Measures

Dimensions (W × L × H) 230 × 257 × 167 mm

(9.06 × 10.11 × 6.58 inches)

Weight (excluding PSU and media) Approx. 2.3 kg (5 pounds) Depending on model

Ambient Operating Temperature +5°C to +40°C (+41°F to +104°F)

Ambient Storage Temperature

-20°C to +50°C (-4°F to +122°F)

Humidity

10 to 90% non-condensing

Electronics

Microprocessor 16-bit 20 MHz (16M of address space)

On-board Flash memory 1024K (774K firmware, 250K available to user)

On-board RAM memory 2048K (576K firmware, 1050K print buffer)

Power Supply Unit Separate unit

Input Voltage 100 to 240 VAC, 50 to 60Hz, 1.9A

Output Voltage 24 VDC, 3.0A

Input Voltage (mobile applications) 23.5 VDC ± 0.5V, 6A peak No PSU connected

Page 11

Intermec EasyCoder PC4—Service Manual 5

Chapter 1—Models and Options

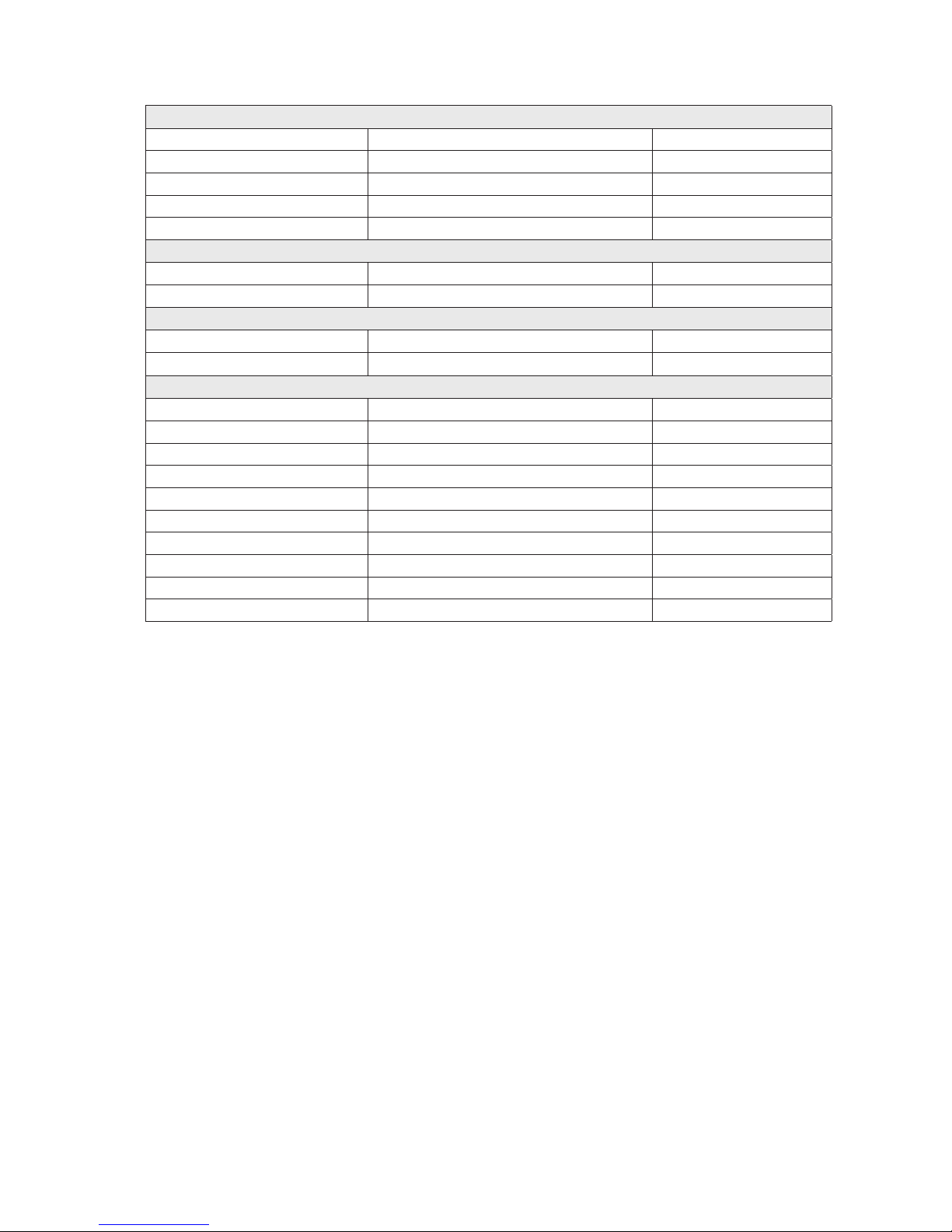

Sensors

Label Gap/Black Mark/Out of Paper Yes

Label Taken Yes Not with cutter

Print Frame Open/Closed Yes

Ribbon End Yes TTR model only

Head up (DOOR L & R) Yes

Controls

Control Lamps

1 Tri-colored LED

Feed Button 1

Data Interfaces

Serial

1 × RS-232 + 1 × USB(v1.1)

Parallel

1 × Centronics

Accessories and Options

Parallel Interface Cable Standard

RS-232 Cable Option

Memory Cartridge Option 1MB flash

Keyboard/Display Unit Option

Paper Cutter Option

V-spring for stiff/thick media Option

>150µm/5.9 mils

Mobile Battery Unit Option

Battery Pack Option

Battery Charger Option

USB cable Option

Page 12

6 Intermec EasyCoder PC4—Service Manual

Chapter 1—Models and Options

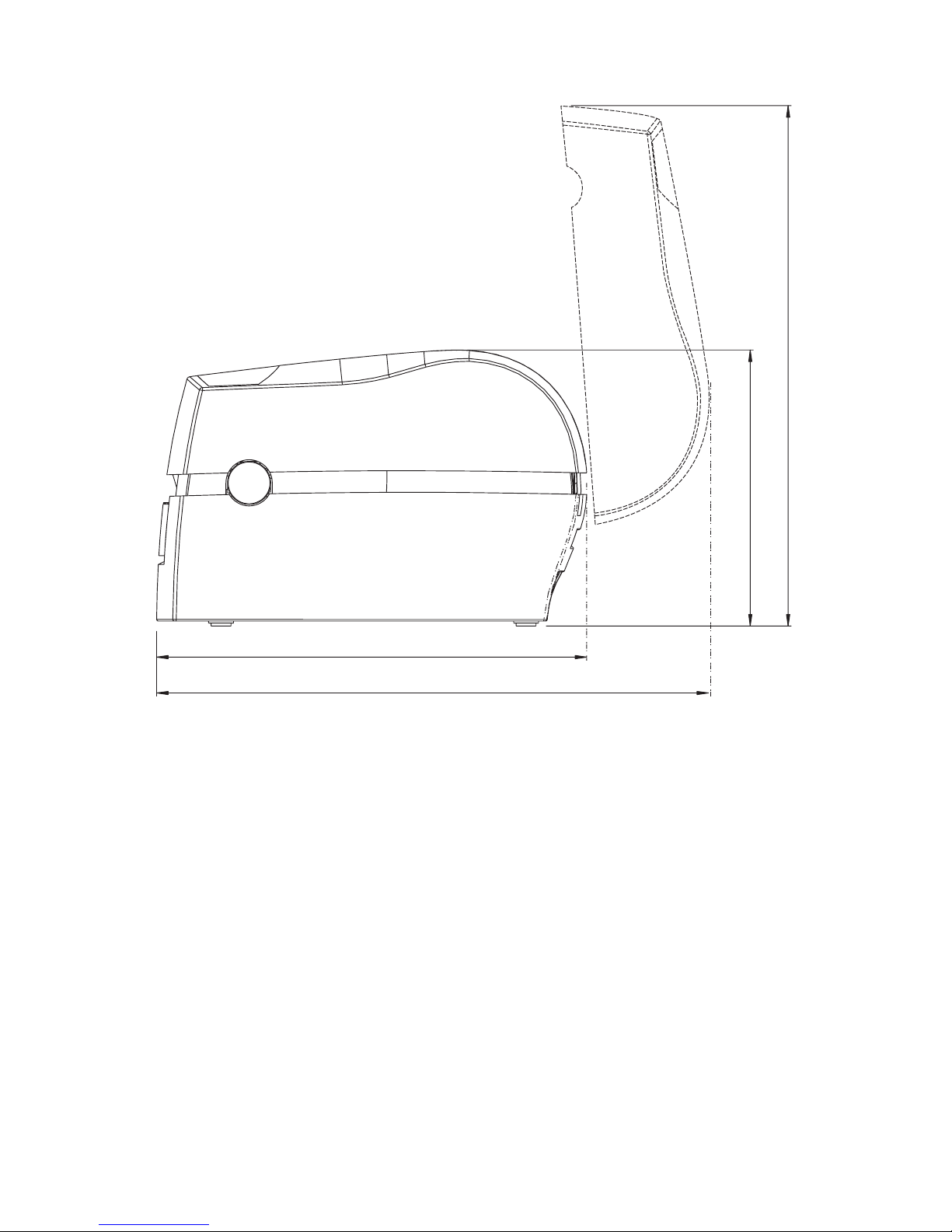

259 mm (10.20 in)

166 mm (6.54 in)

314 mm (12.36 in)

333 mm (13.11 in)

1.4 EasyCoder PC4 Measures

Side View

Page 13

Intermec EasyCoder PC4—Service Manual 7

Chapter 1—Models and Options

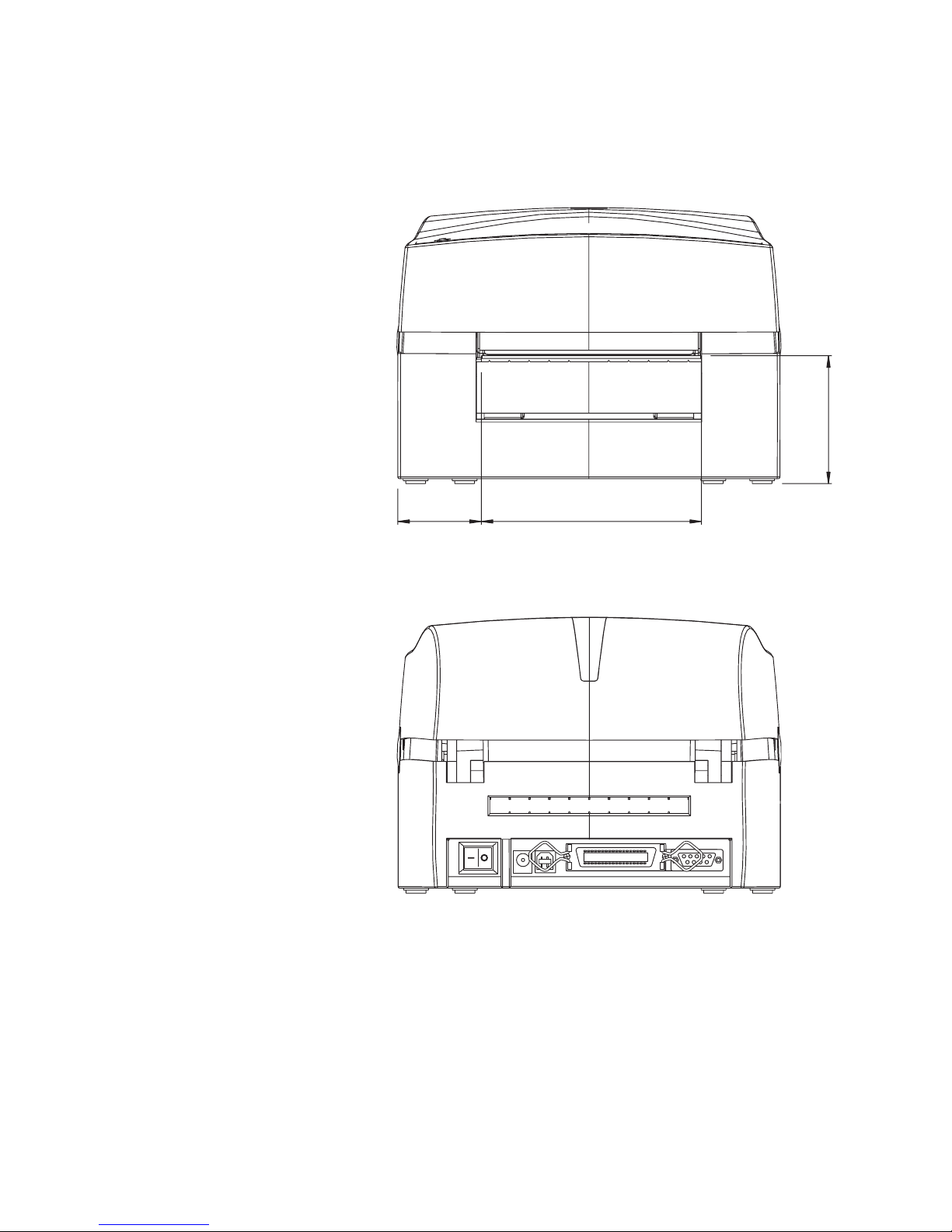

50 mm (1.97 in) 133 mm (5.24 in)

77 mm (3.03 in)

Front View

Rear View

Page 14

8 Intermec EasyCoder PC4—Service Manual

Chapter 1—Models and Options

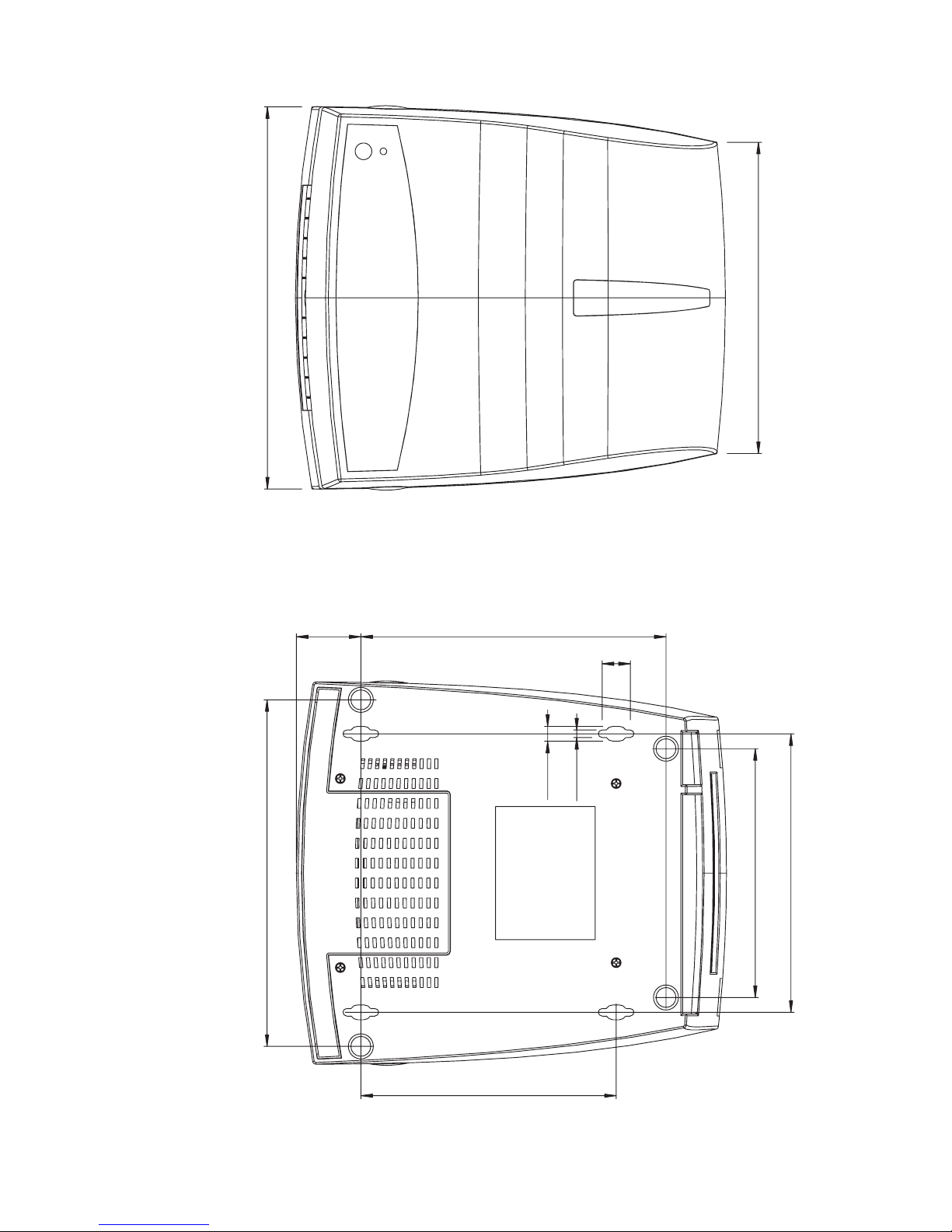

230 mm (9.06 in)

188 mm (7.40 in

)

39 mm (1.54 in)

17 mm (0.67 in)

9 mm (0.35 in)

168 mm (6.61 in)

209 mm (8.83 in)

150 mm (5.91 in)

4.6 mm (0.18 in

)

184 mm (7.24 in)

154 mm (6.06 in

)

Top View

Bottom View

Page 15

Intermec EasyCoder PC4—Service Manual 9

2

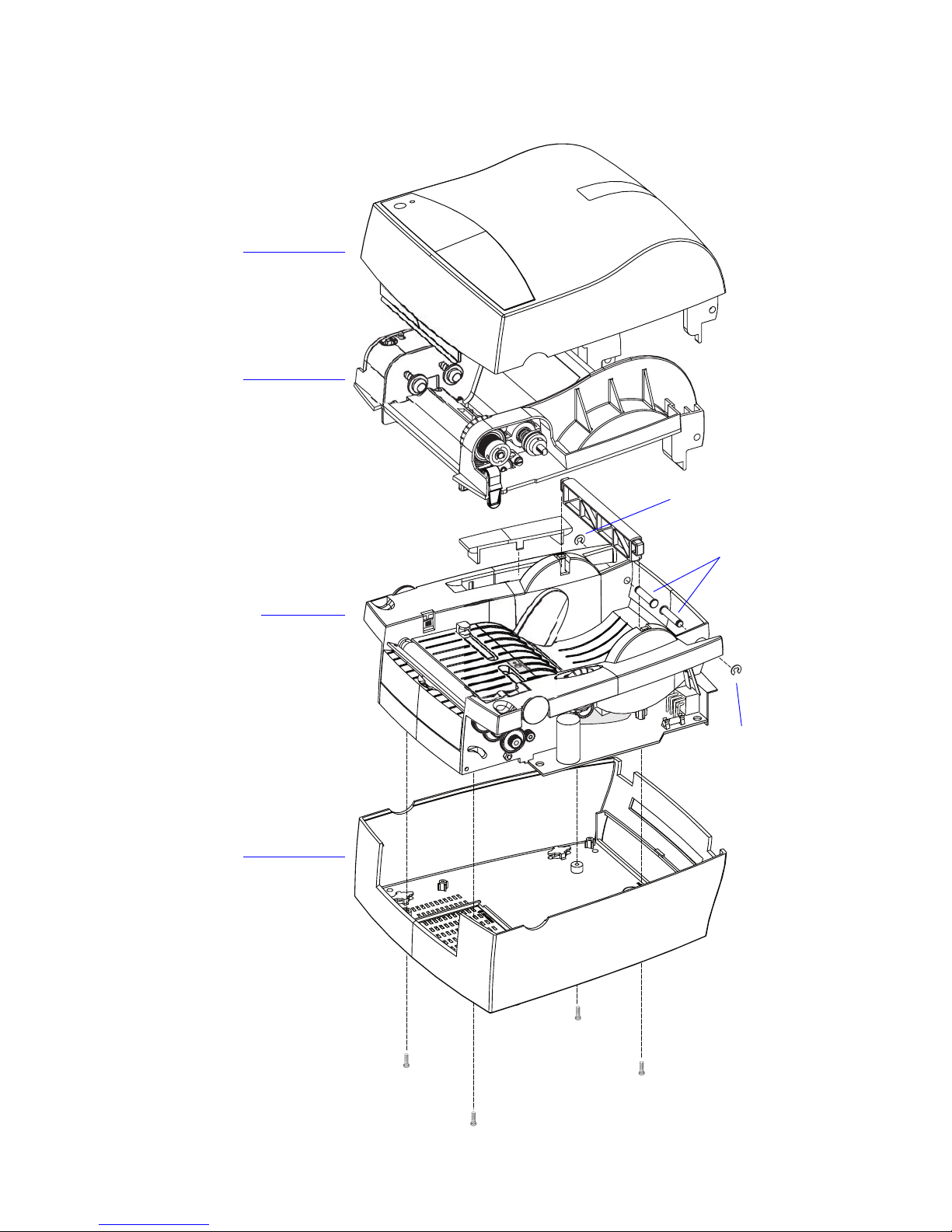

Main Parts

is chapter shows the printer’s main parts and explains how the printer is

taken apart and reassembled. Each of the main parts is described in more

detail in the chapters that follow.

Page 16

10 Intermec EasyCoder PC4—Service Manual

Chapter 2—Main Parts

2.1 Taking the Printer Apart

e EasyCoder PC4 is a so called double clam-shell design, where the print

frame and the top cover are hinged to a base frame.

e bottom part of the base frame is enclosed by the bottom cover, which

is held by four Phillips screws. Once the bottom cover has been removed,

the two pairs of bolts and E-rings that hold the base frame, the print frame,

and the top cover become accessible. You will also need to disconnect a

number of cables from the main board.

In most cases, you do not need to dismantle the base frame, print frame,

and top cover.

In the illustration in Chapter 2.3, all cables have been omitted. Detailed

descriptions of the main parts and their sub-assemblies can be found in

Chapters 3 to 7.

All screws are Phillips-type of various sizes.

2.2 Reassembling the Printer

Reassemble the printer in reverse order. Refer to Chapter 7.3 for a connection diagram, which helps you put all the cables back correctly. When put

ting the printer back into the bottom cover, tilt it a little so the rear plate is

inserted first, then carefully manipulate the front part in place. Secure the

assembly with the four Phillips screws.

Page 17

Intermec EasyCoder PC4—Service Manual 11

Chapter 2—Main Parts

2.3 Exploded View

Top Cover

Print Frame

Base Frame

Bottom Cover

Bolts

E-ring

E-ring

Page 18

12 Intermec EasyCoder PC4—Service Manual

Chapter 2—Main Parts

Page 19

Intermec EasyCoder PC4—Service Manual 13

3

Top Cover

is chapter describes the parts of the top cover and explains how to

replace the tear-off plate.

Page 20

14 Intermec EasyCoder PC4—Service Manual

Chapter 3—Top Cover

3.1 Description

e top cover encloses the print frame. It is attached to the base frame

using the same pair of bolts and E-rings as the print frame. e top cover

and the print frame opens together when the base locks on either side of

the printer are pressed. en the top cover can be released from the print

frame by pressing the two green locks at either side of the print frame, as

shown below. Note that in case of a PC4 DT printer, the locks are cut off

and you will need to insert a flat screwdriver or similar to release the locks.

Base locks

Top cover locks

Page 21

Intermec EasyCoder PC4—Service Manual 15

Chapter 3—Top Cover

e top cover is made up of the following parts:

• Top cover plastic moulding

• Clear plastic window (permanently glued to the moulding)

• Two media load instruction labels

• Tear-off plate (snap-locked to the moulding)

• Name plate (glued to the moulding)

3.2 Tear-Off Plate

e only part that can be replaced easily is the tear-off plate. It is provided

with two snap-lock tabs that engage bars at the inside of the top cover. Two

L-shaped rails hold the plate. If you need to remove the tear-off plate with

-

out discarding it, be careful not to break the tabs, which are quite delicate.

Top cover moulding

Clear window

Tear-off plate

Name plate

Page 22

16 Intermec EasyCoder PC4—Service Manual

Chapter 3—Top Cover

Page 23

Intermec EasyCoder PC4—Service Manual 17

4

Print Frame

is chapter describes the print frame which contains the thermal printhead, the transfer ribbon supply, the LED control lamp, the Feed key, and

the emitter of the label gap sensor. It also provides instructions for how to

replace the various parts.

Page 24

18 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

4.1 Description

e print frame comes in two versions; one for the DT model and another

for the TTR model. Both are based on the same plastic moulding. ey

both have either a 203.2 dpi (8 dots/mm) printhead or a 300 dpi (11.81

dots/mm) printhead.

Direct Thermal (DT) Model

Thermal Transfer (TTR) Model

Print frame moulding

LED control lamp

Feed switch

(No ribbon load label)

(No transfer

ribbon mechanism)

(No ribbon end sensor)

Short top cover locks

Print frame moulding

LED control lamp

Feed switch

Ribbon load label

Transfer

ribbon mechanism

Ribbon end sensor

Long top cover locks

Printhead

Printhead

Label gap sensor

(Emitter)

Label gap sensor

(Emitter)

Page 25

Intermec EasyCoder PC4—Service Manual 19

Chapter 4 —Print Fram

4.2 LED and Feed Switch

Description

e LED control lamp and Feed switch are fitted on the same Feed Switch

PCB inside a housing on the left side of the print frame. e board is con

nected to JP9 on the main board via a four cables that run inside the left

side hinge of the print frame. e control lamp shines through a transpar

ent window and the Feed switch is activated via a dome, both in the name

plate on the top cover.

Replacement

e Feed Switch PCB can be accessed for replacement by removing the

cable cover, which is held in place by a Phillips screw and a snap lock. e

Feed Switch PCB is inserted between two rails in the moulding and is cov

-

ered by an isolation sheet.

Green (solid) Media loaded

Ribbon loaded (TTR only)

Green (flashing) Receiving data

(T

est Mode only)

Red (solid) Out of media

Out of ribbon (TTR only)

Printer reset

Red (short flashes) Upgrading firmware

Ov

ertemperature

Red (long flashes) Media jam in cutter

Ov

erheated printhead or

stepper moto

r

Orange

Error condition detecte

d

Dark

Po

wer off

Color Meaning

Feed switch PCB

Cable cover

Screw

Snap lock

Print frame

Isolation sheet

Page 26

20 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

Schematics

JP1

1

2

3

4

LED1

RED

SW1

LED1

YELLO

W

R1

R2

Page 27

Intermec EasyCoder PC4—Service Manual 21

Chapter 4 —Print Fram

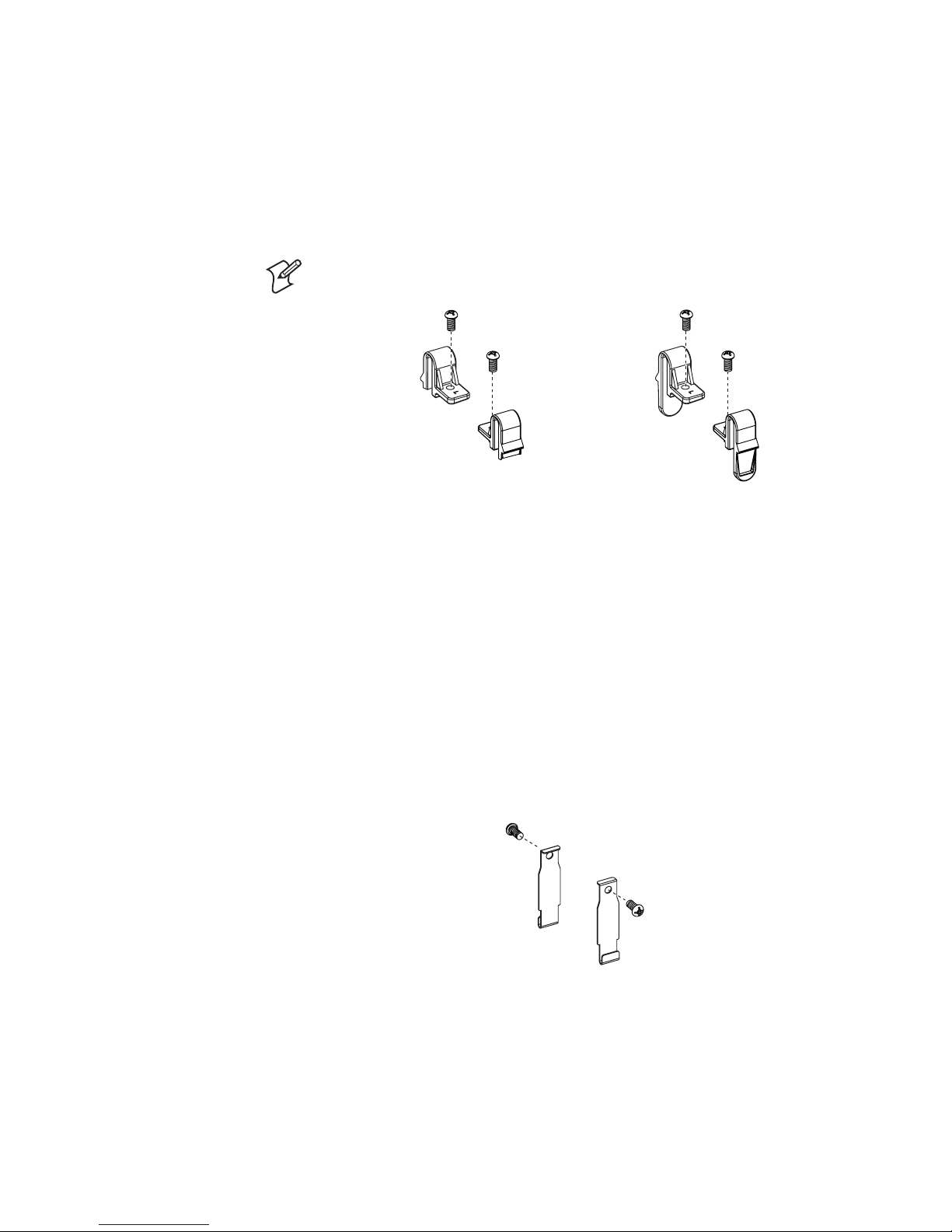

4.3 Top Cover Locks

Description

e top cover locks are shorter in the DT model than in the TTR model,

because there is normally no need to separate top cover and the print

frame, when there is no need for ribbon reload.

Note: Parts are marked with “L” or “R” indicating left or right side (frontal

view).

DT Model TTR Model

Replacement

e locks are attached to the print frame moulding with Phillips screws. To

access the left side lock, you will need to remove the cable cover as shown

in the instructions for replacing the Feed Switch PCB earlier in this chap

-

ter.

4.4 Base Lock Spring Hooks

Description

Two spring hooks that are engaged by the base lock (see Chapter 5.7) are

fitted to the print frame moulding using Phillips screws. e spring hooks

are identical for the DT and TTR models.

Replacement

e left-side spring hook is fitted inside the same housing as the Feed

switch PCB. To access it, you will need to remove the cable cover as shown

in the instructions for replacing the Feed Switch PCB earlier in this chap

-

ter.

e right-side spring hook is easily accessible in the DT model whereas in

the TTR model, you will need to dismantle the ribbon takeup mechanism

(see Chapter 4.8).

Page 28

22 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

4.5 Printhead

Description

ere are two types of thermal printheads; one with a density of 203.2 dpi

(8 dots/mm), and another with a density of 300 dpi (11.81 dots/mm).

ese printheads fits both the DT model and the TTR models. Printheads

need to be replaced at intervals depending on type of printing, print speed,

ambient temperature and other environmental conditions, type of media

and ribbon, etc.

Some simple measures can be taken by the user to prevent premature wearout:

• Clean the printhead regularly, as described in the EasyCoder PC4 User’s

Guide. Not only will a dirty printhead result in an inferior printout, but

any residue on the dots will prevent heat to dissipate through the ribbon

and media.

• Follow the recommendations regarding density setup, see the

D com-

mand in the ESim v6.xx, Programmer’s Reference Manual. Too much

energy to the printhead will wear it out rapidly.

• Do not use higher Print Speed setting than necessary, see the

S com-

mand in the ESim v6.xx, Programmer’s Reference Manual.

• Low ambient temperature requires more energy to the printhead dots

than room temperatures and will therefore cause more wear to the print

head. High print speed accelerates the wear. us, at low temperatures,

select as low a print speed as is acceptable.

• Never print outside the media path. Dots that are not in contact with

the media will not be cooled properly.

• When using preprinted labels or labels with some type of varnish or

non-standard top coating for direct thermal printing, use original

Intermec labels or inks recommended by leading manufacturers of direct

thermal media. e labels must not contain any aggressive substances

such as chloride or grinding substances such as titanium dioxide.

• Only use original Intermec transfer ribbon or ribbons recommended by

Intermec.

Note: ere are two different types of V-springs; a standard type for media

fulfilling the specifications in the EasyCoder PC4 User’s Guide, and a stron

-

ger type for thick and stiff media (>150µm/5.9 mils). e latter is recog

-

nized by its yellow paint coating.

Page 29

Intermec EasyCoder PC4—Service Manual 23

Chapter 4 —Print Fram

Replacement

e thermal printhead can be replaced without tools.

To reduce the risk of electrostatic discharges, use ESD protection bracelets or similar equipment.

• Open the print frame and remove any transfer ribbon.

• Press the printhead and print frame firmly together so you overcome the

pressure of the V-shaped spring. Be careful not to touch the line of dots

at the front of the printhead, but press against the metal bracket or white

plastic cover.

• While keeping up the pressure, slide the printhead forward so the tabs at

both sides of the printhead bracket become disengaged from the pockets

at the inner sides of the cavity in the print frame.

• Continue to press forward so the U-shaped slots in the sides of the print

head bracket also become disengaged from the studs at the inner sides of

the cavity in the print frame.

Printhead assy

Tab

Pocket

Stud

Slot

V-Spring

Do not touch dot line!

Page 30

24 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

• Now the printhead assy is free but still connected by three sets of cables.

Disconnect the grounding cable.

• Carefully disengage the snap-locks that hold the printhead cover to the

printhead bracket and remove the cover.

• Disconnect the two remaining cables.

• Remove the V-spring.

• Now you can install the printhead assy in reverse order. e printhead

kit comes as a complete unit including printhead, bracket, cover plate,

ground terminal, screws, and V-spring.

Be careful not to touch the dots on the printhead and make sure that the

tip of the V-spring runs between the two guiding ridges on the printhead

bracket.

• Test that the printhead can move slightly up against the pressure force

of the V-spring. Finally, check that the printhead is working properly by

printing a test label as described in Chapter 10.2.

Printhead bracket

Cable to CNB

on Main Board

Printhead cover

V-Spring guides

Snap-lock

Snap-lock

Cable to CNA

on Main Board

Ground cable teminal

Page 31

Intermec EasyCoder PC4—Service Manual 25

Chapter 4 —Print Fram

4.6 Ribbon End Sensor

Description

e ribbon end sensor is a photoelectric sensor that detects when the

printer runs out of ribbon. It is only fitted in the TTR model of EasyCoder

PC4. A beam of light is transmitted from an LED (light emitting diode)

and reflected back to a receiver by the silvery foil trailer of the ribbon. e

sensor triggers at 4V.

Note: e Ribbon End Sensor only works if the ribbon has a silver-colored

trailer that can reflect the light.

A DT printer can be set to detect ribbon end, and a TTR printer can be

set to ignore ribbon end, without any error being reported (see ESim v6.xx,

Programmer’s Reference Manual

, OD command).

Both the emitter and the receiver are fitted on a small printed circuit board,

which is installed in a pocket on the print frame moulding. A cable runs

inside the left-side hinge of the print frame and down to the main board,

where it is connected to JP7. e same circuit board is also used for the

label taken sensor.

Refer to Chapter 5.2 for an description of how to access the main board.

Replacement

Do not remove the sensor unless you intend to discard it, since you may

damage some of the components when you pull it up.

• Disconnect the cable from JP7 on the main board.

• Remove the cable cover.

• Carefully pry the sensor PCB loose (it may be fitted with a drop of glue)

and pull it straight up using a small pair of pliers while carefully manip

ulating the cable and connecter through the hinge and out through the

wall of the ribbon supply cavity.

• Install a replacement sensor in reverse order.

Ribbon end sensor

Page 32

26 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

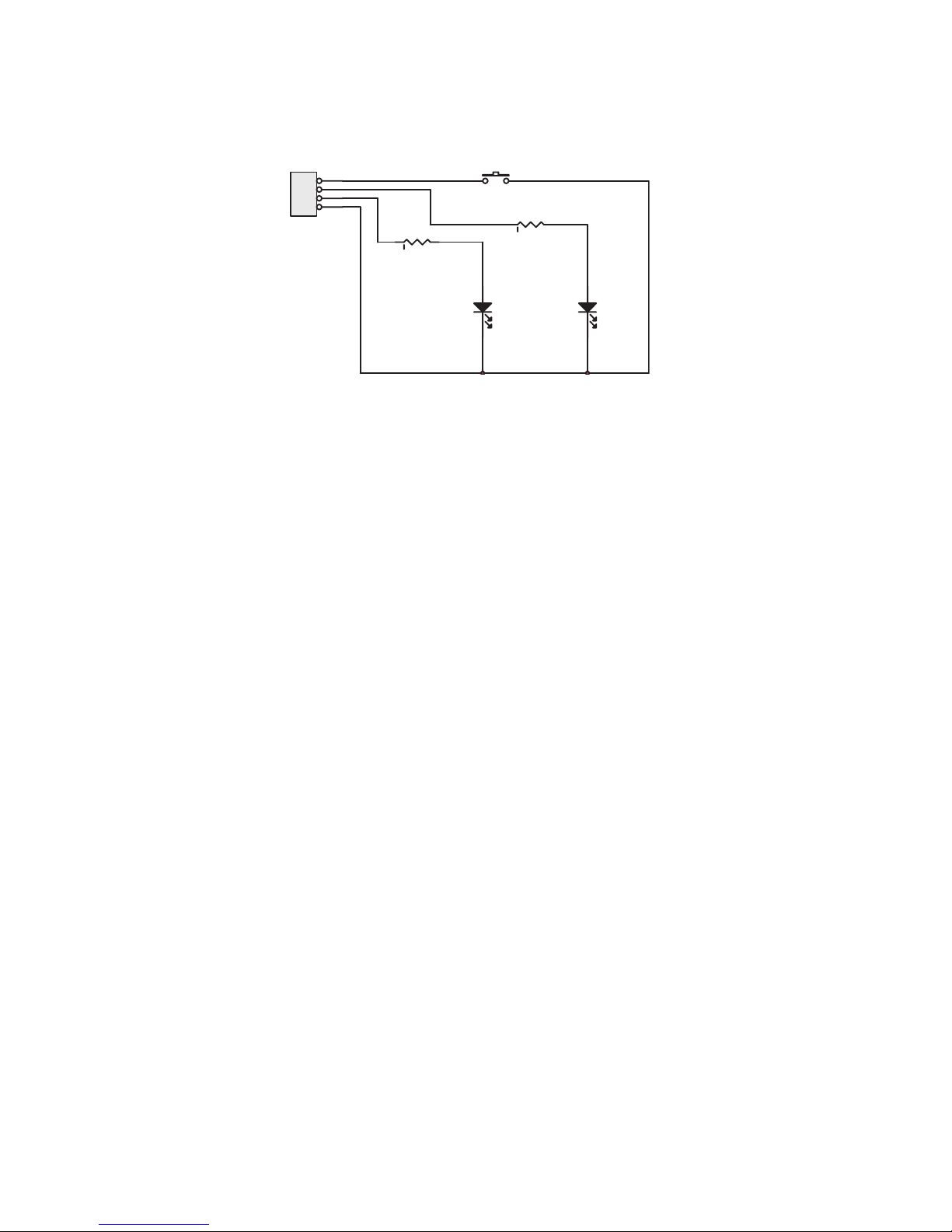

Schematics

RIBBON

S01 S02 R2 R3

YES 150 100K

YES 300STRIPPER

SW1

ON: ENABLE

OFF: DISABLE

ON

OFF

S02

12

3

4

5

R2

S01

1

2

3

4

C1

JP1

1

2

3

R3

SW1

Page 33

Intermec EasyCoder PC4—Service Manual 27

Chapter 4 —Print Fram

4.7 Label Gap Sensor (Emitter)

Description

e label gap sensor consists of two parts, a light emitter fitted in the print

frame and a receiver part fitted in the base frame (see Chapter 5.8). ey

work together with the black mark sensor to determine where a form (that

is, a label, ticket, or tag) starts so the media feed motor can be controlled

by the firmware. e label gap sensor also detects out-of-media conditions.

e label gap sensor emitter consists of a light emitting diode (LED) fitted

on a printed circuit board, which is fitted with a screw and washer in a

pocket on the upper side of the print frame, immediately to the rear of

the ribbon slot. (In the TTR model, the board is hidden under the ribbon

load label.) e LED shines downward through a hole in the print frame

moulding. Before replacing the sensor, check that the hole is not blocked

by dust or similar. e label gap sensor is connected to JP10 on the main

board via a cable running inside the left hand hinge of the print frame.

Replacement

• Disconnect the cable from JP10 on the main board.

• Remove the cable cover.

• Remove the screw that holds the circuit board and pull it straight up

while carefully manipulating the cable and connector through the hinge

and out through the wall of the ribbon supply cavity.

• Install a replacement circuit board in reverse order.

Schematics

Label gap sensor

JP1

1

2

S01

Page 34

28 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

4.8 Ribbon Feed Mechanism

Description

ough the ribbon feed mechanism is not available as spare parts, it is still

appropriate to descibe how it works. Since it is factory-adjusted, please

refrain from dismantling it on your own.

e ribbon mechanism consists of four different elements, all of which are

attached to the print frame moulding:

• Ribbon supply

• Ribbon core holders

• Ribbon takeup

• Ribbon takeup drive train

In the illustrations that follow, all other parts have been omitted to give a

clearer view.

Ribbon Supply

e ribbon supply mechanism breaks the rotation of the ribbon supply

spool in order to keep the ribbon tight using a spring-loaded friction cou

pling. Another spring dampens sudden jerks. e friction is affected by the

position of the fixed holder along the ribbon supply shaft.

If you need to dismantle this assembly, make sure that the ends of the short

spring fit into the holes in the ribbon return cap and friction plate and

rotate the ribbon return cap so the hook that holds the long spring passes

the 12 o‘clock position (see the arrow). When fitting back the fixed holder,

make sure that the screws hit the indents in the ribbon supply shaft, that

was made when the printer was assembled at the factory.

Ribbon supply shaft

Spring

StarLoc washer

Ribbon return cap

Spring

Friction plate

Wool fiber disc

Fixed holder

Screws (2)

Page 35

Intermec EasyCoder PC4—Service Manual 29

Chapter 4 —Print Fram

Ribbon Core Holders

e ribbon core holders are spring-loaded and hold the ends of the ribbon

cores opposite to the ribbon feed mechanism. A green plastic disc is pressfitted on a metal shaft, that goes through the left-side wall of the print

frame moulding. e shaft is held by an E-ring inside the Feed button

cavity. A spring on the shaft makes it possible to snap the core in place. No

adjustments are facilitated.

E-ring

Washer

Spring

Ribbon core holder

Page 36

30 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

Ribbon Takeup

e ribbon takeup is driven by the stepper motor via a train of gears and

rotates the ribbon takeup core so the transfer ribbon is pulled forward

along with the media. ere is a spring-loaded friction coupling similar

to the ribbon supply. A large green wheel which engages a one-way clutch

makes it easier to wind up the ribbon leader at ribbon load.

If you need to replace the right-side base lock spring hook, just remove the

E-ring and lift out the entire rewind assembly without dismantling it any

further. is way, you will keep the factory adjustments.

Ribbon rewind shaft

Fixed holder

Screws (2)

E-ring

Spring

Gear

Wool fiber disc

One-way clutch holder

Friction plate

Page 37

Intermec EasyCoder PC4—Service Manual 31

Chapter 4 —Print Fram

Ribbon Takeup Drive Train

e ribbon takeup assembly is driven by the stepper motor via a train of

gears. ere is a spring-loaded arm with two connected gears under the

ribbon takeup. e rear gear engages the gear wheel of the ribbon takeup,

whereas the other gear engages the gear train in the base frame when the

print frame is in closed and locked position. is implies that the ribbon

takeup can be rotated freely in both directions when the print frame is in

open position, but only in one direction when it is closed.

ere are no facilities for adjustments.

Spring

Arm

Gears (2)

E-rings (2)

Bolt

Page 38

32 Intermec EasyCoder PC4—Service Manual

Chapter 4—Print Frame

Page 39

Intermec EasyCoder PC4—Service Manual 33

5

Base Frame

is chapter describes the main parts of the base frame and provides

replacement instructions.

Page 40

34 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

Platen roller

Peel-off mechanism

(or Paper cutter)

Main board

Memory cartridge blind plate

Peel-off bar

Motor assy

Media guide assy

Base lock assy

5.1 Main Parts

e base frame consists of a plastic moulding to which a number of assemblies are fitted. e same base frame is used for both the DT and the TTR

models of the EasyCoder PC4.

Note that the 203.2 dpi (8 dots/mm) and the 300 dpi (11.81 dots/mm)

printers not only have different firmware versions and printheads, but also

different types of stepper motors. us, modifications of printing density

are not intended.

e optional paper cutter is normally factory-fitted, but could be fieldinstalled by an authorized service technician (see EasyCoder PC4 Cutter,

Installation Instructions). It replaces the standard peel-off mechanism.

Media spindle

Black mark/

Label gap sensor

Label taken sensor

Base frame moulding

Dust protection

sheet

Page 41

Intermec EasyCoder PC4—Service Manual 35

Chapter 5—Base Frame

5.2 Main Board

Description

e main board processes all data and is the connection node for all sensors, the motor, the input voltage, and the computer interfaces. It also has

an On/Off switch and provisions for fitting an optional memory expansion

cartridge. e main board is described in detail in Chapter 7 along with

schematics and a connection diagram.

Replacement

• Make a backup on the host of all files you want to move to the flash

memory of the new board.

• Take precautions to eliminate any electrostatic discharges.

• Make sure the main board is disconnected from any power source.

• Remove the single Phillips screw almost at the center of bottom side of

the board.

• Disconnect all cables to the main board.

• Remove the nut at the top of the rear plate and disconnect the ground

-

ing cable

• Install a new board in reverse order. Refer to Chapter 7.3 for a connec

-

tion diagram.

• Download the saved files from the host to the flash memory of the new

board.

Page 42

36 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

5.3 Platen Roller

Description

e platen roller feeds the media and provides counter-pressure for the

printhead. It is coated with silicon rubber and driven by the stepper motor

via a train of gears. e media feed is measured in dots, just like the print

width (1 dots = 0,125 mm/4.9 mils).

e platen roller is subject to wear and may need to be replaced.

Replacement

• From above, insert a flat-tipped screwdriver between the gear and the

platen cover and disengage the snap-lock of the platen cover. Pry up the

platen cover.

• Push the right-side bushing to the right to disengage it. en, using

a moderate amount of force, pry the bushing, gear, and platen roller

upwards.

• Lift out the platen roller and the left-side bushing.

• Replace with a new set of platen roller, bushings, and gear in reverse

order. Make sure that the D-plane of the left side bushing fits into the

D-shaped hole, and that the tab on the right-side bushing fits into the

corresponding slot in the base frame moulding before locking the assem

-

bly with the platen cover.

Plastic bushing

with brass insert

Right-side bushing

Tab

Platen roller

Platen cover

Snap-lock

Gear

Page 43

Intermec EasyCoder PC4—Service Manual 37

Chapter 5—Base Frame

5.4 Peel-Off Mechanism

Description

e peel-off mechanism is hinged to the base frame moulding. It has a

spring-loaded idle roller that is pressed against the platen roller, when the

peel-off (self-strip) mechanism is closed so the liner is pulled down over the

peel-off bar, which causes the labels to be separated from the liner.

e peel-off mechanism is fitted with a label taken sensor, which is used to

halt the printing until a printed label has been removed. e label taken

sensor is disabled by the

ON command, see ESim v6.xx, Programmer’s

Reference Manual

.

e label taken sensor consists of an LED and a photoelectric sensor with

an on/off switch. e light from the LED is reflected back to the sensor by

the back side of any label or similar that remains to be removed from the

outfeed area. e sensor triggers at 4V, which must drop to 1V before the

sensor changes it state. e same circuit board is also used as for ribbon

detection.

Replacement

e peel-off mechanism comes as a complete unit including the label taken

sensor.

• Disconnect the label taken sensor cable from JP8 on the main board.

• Disengage the hinges from the inner walls of the base frame moulding

and pull out the peel-off mechanism.

• Install a replacement unit in reverse order.

Hinges

Label Taken Sensor

Roller

To JP8

on main board

Page 44

38 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

ON/OFF Switch

e On/Off switch makes it possible for the operator to enable/disable the

label taken sensor without having to issue an ESim command.

Schematics

OFF

ON

RIBBON

S01 S02 R2 R3

YES 150 100K

YES 300STRIPPER

SW1

ON: ENABLE

OFF: DISABLE

ON

OFF

S02

1

2

3

4

5

R2

S01

12

3

4

C1

JP1

1

2

3

R3

SW1

Page 45

Intermec EasyCoder PC4—Service Manual 39

Chapter 5—Base Frame

5.5 Motor assy

Description

e motor assembly consists of a stepper motor and a thermistor mounted

on a bracket, which is attached to the inner, right side of the base frame

moulding. e motor pulley and two shafts protrude through holes in the

base frame moulding. Outside the moulding two gears are fitted on the

shafts. e gears form a train from the motor pulley to the gear of the platen

roller. e platen roller gear engages the ribbon takeup gear, when the print

frame is closed.

Note: e stepper motor differs between the 202.3 dpi (8 dots/mm) and

the 300 dpi (11.81 dots/mm) models.

e termistor protects the stepper motor from overheating by stopping the

printing at approx. +80°C (+176°F). is is indicated by the LED flashing

red. When the temperature gets down to approx. +60°C (+140°F), which

usually takes 4.5 to 5 minutes, the LED switches back to green and any

interrupted print job is automatically resumed. Overtemperature is caused

by excessive load on the stepper motor (high print speed, continuous print

ing of too many labels, etc.) possibly in combination with a high ambient

temperature.

e stepper motor is connected to JP1 and the thermistor to JP2 on the

main board.

Replacement

e motor assy mechanism comes as a complete unit including stepper

motor, bracket, thermistor, gears, washer, E-rings, and nuts.

• Disconnect the cables from JP1 and JP2 on the main board.

• Remove the E-rings, washer, and gears

• Remove the two M3 self-locking nuts.

• Pull out the motor and bracket.

• Install a replacement unit in reverse order.

Washer

E-ring

E-ring

To JP1 on main board

To JP2 on main board

Motor, thermistor, and bracket

M3 nut

M3 nut

Pulley

Gear

Gear

Page 46

40 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

5.6 Media Guides

Description

e EasyCoder PC4 is designed to have the media centered in relation to

the printhead. It has two stoppers that keep the media roll centered on the

media spindle and two guides that align the media before it is fed under

the printhead. e stoppers and guides can be simultaneously adjusted for

various media widths using a single adjustment knob, that activates a worm

rod via a gear.

Note: Parts are marked with “L” or “R” indicating left or right side.

e allowed media width is 25 mm (1 inch) to 116 mm (4.57 inches).

Replacement

e media guide assy mechanism comes as a kit as illustrated below.

• Rotate the adjust knob to minimum media width.

• Remove the screws that hold the label stoppers to the label guides and

pull out the stoppers.

• Remove the screw that holds the knob holder and take out the knob and

holder.

• Pull the gear away from the worm bushing.

• Pull out the worn rod and the label guides from the slots in the base

frame moulding while manipulating the guides out through the enlarged

slots in the base frame moulding starting at the left side.

• Pull out the worm rod from the worm bushing at the right side.

• Reassemble in reverse order.

Label stoppers

Label guides

Washer

Screw

Knob holder

Adjustment knob

Gear

Worm bushing

Worm rod

Screw

Screw

Page 47

Intermec EasyCoder PC4—Service Manual 41

Chapter 5—Base Frame

5.7 Base Locks

Description

e top cover and the print frame are connected by the top cover locks and

can be tilted up from the base frame as a single unit. e top and bottom

parts of the printer are held together by the base locks, one at each side of

the base frame. e base locks engage the base lock spring hooks fitted at the

print frame (see Chapter 4.4).

Note: Parts are marked with “L” or “R” indicating left or right side.

When the print frame is closed, the V-spring ensures that the printhead

is pressed against the platen roller with a sufficient force to provide a clear

printout and to drive the media.

e base locks are each provided with a microswitch that is activated by the

base lock spring hook in order to detct whether the print frame is in locked

position or not. Closed and locked position is assumed when both micro

-

switches are activated.

e right-side base lock is connected to JP12 and the left-side base lock is

connected to JP11 on the main board.

Page 48

42 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

Replacement

e base locks come as a kit with two complete assembled units, one for

each side.

• Disconnect the cables from JP12 and JP11 on the main board.

• Remove the screws that hold the locks.

• Install new base locks in reverse order.

In the illustration below, the right-side base lock is exploded to better show

the principles of design.

Push button

Microswitch

Holder

Spring

Base frame

Screws (2)

Screw

Page 49

Intermec EasyCoder PC4—Service Manual 43

Chapter 5—Base Frame

5.8 Label Gap/Black Mark Sensors

Description

e receiver part of the label gap sensor and the black mark sensor are

fitted on the same circuit board. e purpose of the label gap/black mark

sensors is to control the printer’s stepper motor to feed the media properly

in relation to the gaps between labels, detection slots, or black marks at the

back of the media. It also detects out-of-media conditions. e label gap/

black mark sensor PCB is fitted below a window in the floor of the media

cavity using two screws. It is connected to JP13 on the main board.

To allow the use of parallel labels fitted on the same liner, the sensors are

placed slightly to the right of the center-line (as seen from the front) as fol

-

lows:

- Label Gap Sensor 4.5 mm 0.177 inches

- Black Mark Sensor 10 mm 0.394 inches

e board has one LED emitter and two receivers. e black mark sensor

emitter shines upwards. e black mark sensor receiver detects light

reflected by the back side of the media. No light received is interpreted as a

black mark.

e label gap sensor receiver detects light from the emitter board in the

print frame (see Chapter 4.7) that passes through gaps in the media or

through the liner between labels. No light received is interpreted as a label

(or similar) and light received is interpreted as a gap. is function can be

reversed using the

OS command, see ESim v6.xx, Programmer’s Reference

Manual

.

e sensitivity of the label gap sensor is adjusted automatically when enter

ing the Test Mode (see Chapter 10.2). At the same time, the label length is

determined.

Replacement

• Remove the main board from the base frame moulding.

• Disconnect the cable from JP13 on the main board.

• Adjust med media guides for maximum media width.

• Remove the screws that hold the sensor board.

• Install new board in reverse order.

Page 50

44 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

Schematics

C1

S02

1

2

3

4

JP1

1

2

3

4

5

SO1

R2

R3

Page 51

Intermec EasyCoder PC4—Service Manual 45

Chapter 5—Base Frame

1 inch

25.4 mm

!

5.9 Media Spindle

Description

e media spindle holds the media roll during printing. It is snap-locked

between the two crescent-shaped extensions on the base frame moulding

on either side of the media supply cavity.

e media spindle can be rotated to fit media cores with an inner diam

eter of either 25.4 mm (1 inch) or 38.1 mm (1.5 inches). Text and arrows

moulded into the spindle indicate core size in millimeters on one side and

inches on the other.

As an alternative to using a media supply roll on the spindle, fan-folds or

similar can be routed from an external supply behind the printer and into

the media cavity through a slot in above the printer's rear plate.

1.5 inch

38.1 mm

!

Page 52

46 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

Page 53

Intermec EasyCoder PC4—Service Manual 47

is chapter describes the bottom cover and explains how to remove the

accessory cover.

6

Bottom Cover

Page 54

48 Intermec EasyCoder PC4—Service Manual

Chapter 6—Bottom Cover

6.1 Bottom Cover

Description

e bottom cover assembly is fitted to the base frame using four Phillips

screws. An accessory cover, which facilitates installation of an optional

paper cutter, is snapped-locked to the bottom cover. Four rubber feet are

glued to the bottom plate, which also has four screw pockets that allow the

printer to be permanently attached to a table or similar.

Screw pockets

Bottom cover

Accessory cover

Screw (4)

Rubber foot (4)

Page 55

Intermec EasyCoder PC4—Service Manual 49

7

Main Board

is chapter describes the main board including test points, connections,

memory organization, and schematics.

Page 56

50 Intermec EasyCoder PC4—Service Manual

Chapter 7—Main Board

7.1 Description

e main board contains the electronics and firmware that translates

incoming data on the RS-232, USB, and parallel interfaces and processes

them into a bitmap pattern, that controls the heating of the dots on the

printhead, which in turn creates the printout. It also controls the media

feed and detects various error conditions using the connected sensors and

switches. e main board has a memory where the user can store graphics

and forms. e memory can be expanded by fitting an optional memory

cartridge directly to a connector on the main board.

PRODUCT/REV. NO.

Page 57

Intermec EasyCoder PC4—Service Manual 51

Chapter 7—Main Board

7.2 Accessing the Main Board

e main board is fitted with a single screw to the bottom of the base

frame (see Chapter 5.2). Remove the screw and disconnect the cables as

required. When the printer is assembled, the main board is supported by

mouldings extending both from the base frame and from the bottom cover.

Always disconnect the power supply and take precautions against elec

-

trostatic discharges before touching the main board.

7.3 Connections

is simplified illustration shows where the various cables are connected to

the main board.

SW1 On/Off Switch

JP6 USB

CN2 Printhead

CN1 Printhead

JP3 Centronics

JP4 RS 232

Printhead GND

J1 Power Supply

JP10 Upper Label Gap Sensor

JP13 Lower Label Gap

Sensor/Black Mark Sensor

JP7 Ribbon End Sensor

JP9 Feed Switch/LED

JP15 Memory Cartridge

JP11 Headlift (left)

JP1 Motor

JP8 LT

S

JP14 Cutter

JP2 Thermistor

JP12 Headlift (right)

PRODUCT/REV. NO.

Page 58

52 Intermec EasyCoder PC4—Service Manual

Chapter 7—Main Board

7.4 Test Points

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP12

TP13

TP14

TP16

TP17

TP15

TP18

TP19

TP20

TP21

TP22

TP27

TP28

TP29

TP30

TP31

TP32

TP33

TP35

TP36

TP37

TP38

TP34

RODUCT/REV. NO.

Page 59

Intermec EasyCoder PC4—Service Manual 53

Chapter 7—Main Board

TP1 POWER Power in detection to CPU

TP2 VDD 24V

TP3 VCC 5V

TP4 3.3V

TP5 RESET System reset

TP6 Stepper motor over temperature signal

TP7 PHSTB1 TPH control

TP8 Gate Voltage on TPH power switch

TP9 TPH Dot resistance measuring point

TP10 TPH_CTL TPH control

TP11 TPH_TM N/A

TP12 Future use

TP13 Future use

TP14 TXD0 RS232 TTL

TP15 RTS0 RS232 TTL

TP16 RXD0 RS232 TTL

TP17 CTS0 RS232 TTL

TP18 PBUSY Parallell port Busy signal

TP19 PACK Parallell port Ack signal

TP20 PINT Parallell port Interrupt

TP21 PP1 Parallell port Data strobe signal

TP22 USB Crystal 6MHz

TP23 USBRXF N/A

TP24 USBTXE N/A

TP25 USBCS_W N/A

TP26 USBCS_R N/A

TP27 RIBBON Ribbon present signal

TP28 STRIP Label taken signal(LTS)

TP29 DOOR Head lift signal

TP30 POT_MID Digital potentiometer control

TP31 POT_CLK Digital potentiometer control

TP32 POT_DI Digital potentiometer control

TP33 POT_CS Digital potentiometer control

TP34 CPU crystal 20MHz

TP35 WRCASL DRAM Control

TP36 WRCASH DRAM Control

TP37 RD# Read enable

TP38 RAS DRAM Control

Page 60

54 Intermec EasyCoder PC4—Service Manual

Chapter 7—Main Board

7.5 Block Diagram

RAM:

2048K

(U4)

Fl

ash:

1024K

(U2, U3)

MEMORY

POWER BLOCK

24 VDC input

DC to DC Converte

r

(J1)

CPU

16 bit, 20 MHz

incl. UART & IO

(U1)

CONNECTORS

JP9: Feed switch & LED

JP5:

Future options

JP10: Upper label gap sensor

JP11, JP12: Headlift switches (l & r)

JP13:

Lower label gap & black mark sensor

JP8: Label taken sensor

JP7: Ribbon end sensor

JP14:

Cutter interface

PARALLEL PORT

Centronics 36pin female

(JP3)

RS-232 PORT

DB-9pin female

(JP 4)

MOTOR BLOCK

Polar stepper motor

(JP1)

External thermistor sensor

(JP2)

MEMORY CARTRIDGE

1MB Flash

(JP15)

PRINTHEAD

8 or 11.81 dots/mm

(CN1, CN2)

MEMORY DECODER (PAL)

(U7)

USB PORT

Class B female

(JP6)

5V24V

Page 61

Intermec EasyCoder PC4—Service Manual 55

Chapter 7—Main Board

7.6 Internal Memory

e EasyCoder PC4 has, as a standard, a flash memory of 1024K and an

RAM memory of 2048K fitted on the main board.

e memory is organized as follows:

Flash Memory

Firmware and 5 std. bitmap fonts 774K

User available (forms, graphics, soft fonts) 250K

Sum 1024K

RAM Memory

Firmware

576K

Print buffer

1050K

Reserved RAM 422K

Sum 2048K

e internal memory can be expanded using an optional flash memory

cartridge, see Chapter 9.

Page 62

56 Intermec EasyCoder PC4—Service Manual

Chapter 7—Main Board

7.7 Schematics

CPU, Memory, and Reset

Y

ROM

EM

LAN

ETXE

TOLS

DR

AC

M

A

RDS 61x

M8

MARDS 61xM4

23

2_

S

R

t

e

nr

eh

tE

.ETO

N

) EVRESER (

) EVRESER (

MAR

OD

E 61

X M1MOR H

S

A

L

F

2

X 8

X

K

2

1

5

M

ARDS

6

1 X

M4

M

ARDS

6

1 X

M

8

RO

) EVRESER (

) EVRESER (

) EVR

E

S

E

R (

)

EVRESE

R

(

) E

V

RESER

(

) EV

RE

S

ER

(

TESER

7AM

E

K

C

M

MA9

01DM

41DM

8DM

6DM

MQDL

MA1

MWE#

7DM

MCS#

MA

8

K

L

CM

51

D

M

1DM

MA10

21DM

1DM

0DM

7DM

4AM

6DM

6

A

M

3DM

5AM

8DM

5DM

0ABM

1

A

M

#

S

AR

M

31DM

MBA1

MCAS

#

4

1

D

M

MQDU

MA7

5DM

MBA0

9AM

01DM

4DM

3

1

D

M

4DM

11DM

2DM

#SACM

MRAS#

3DM

21

A

M

MA6

MQDU

8AM

MA5

0AM

3AM

MA0

1A

B

M

21DM

9DM

MA4

MA

2

KLC

M

5

1

D

M

2DM

0DM

9DM

MQDL

11DM

#S

C

M

2AM

MA3

E

KC

M

01AM

#E

W

M

A10

5A

11A51A51A

1

D

4

1D

9

A

A17

4A

2

1

A

6D

11D

41

D

9A

D15

2A

7

1A

21

D

D13

31A

01D

4D

01A

8D

6

D

9

D

71A

6

1A

7

D

7

D

8D

8

D

1

A

7A

A12

6

D

8A

21

D

0

1D

61A

0D

4D

01A

5A

5

D

9

D

6A

A16

1A

7A

51A

11D

D5

D2

4D

7D

9A

5

1D

51D

3A

3

A

3D

31

A

31A

D1

9A

51D

2A

3

A

9D

3

D

31D

41A

7A

8A

1D

51D

5

D

9

D

4A

41A

2

D

D7

01A

D8

1A

5A

1

1A

5

1

A

D11

6A

6A

71

A

D3

3

D

2

1

D

31A

A13

01D

A14

2D

4D

11A

21A

1

D

2A

2

A

3A

9

D

3D

D12

31A

2

D

0

D

0

1A

0

1A

11

A

21A

2

1A

4

1

D

1

D

6A

31D

2

D

61A

0D

D4

A1

1

1

1A

51A

7

1A

4

A

4

1A

8D

1A

6D

8A

8A

41A

61A

0D

21A

1

1

D

41D

5

D

21D

3

1

D

31D

61A

A15

11

D

D14

01D4

1

A

D0

7D

5A

7A

D6

5D

71A

4A

01

D

21AM

11

AM

MA11

12A

9

1A

9

1A

81A

A21

A1

8

9

1A

9

1

A

A22

91A

A19

32A

81

A

02A91A

8

1A

A20

A2

0

A2

2

81A

A23

A2

1

81A

22A

81

A

DNG

CCV

C

CV

CC

V

CCV

CCV

CC

V

CC

V

V3

.

3 V3.3

V3

.

3

V3

.3

V3

.

3

CCV

UPC_D

N

G

UPC_DN

G

UPC_DNG

UPC_

DN

G

UPC_DNG

CCV

CCV

CCV

CCV

CC

V

T40015M

2

U

1

234

567

8

9

0111213141

51

819102122232425262728292

03

1

3

2

3

61

71

C

N

61A

51A

2

1

A

7A6A5A4A

3A2A1A0A

0

D

1D

4D2D

5

D

6D

7D

E

C

01A

E

O

11A

9

A

8A

31A

4

1A

C

N

EW

CC

V

3

D

DNG

A8U

D

MS_41

S

L47

1 2

4

U

J54-A16161811M

112141

51

617181

0

1

98765

4

42

3

20

2

2

2

2

9

1

52

1

2

6217238292031323334363735383931424

04

31

CN

CN

-S

A

RCN

C

N

0A

1A

7O/I6O/I5O/I4O/

I

ccV

3

O

/

I

2

O/

I

5A

4A

3A

ss

V

0O/

I

2

A

6

A

c

cV

7A

ccV

8

A

1O/I

9

A

-E

O

H

S

AC

-L

SA

C

CN

8O/I9O/I

1

1O/I

ss

V

01

O/I

2

1

O/I

3

1O/I

51O/I

ssV

4

1O/I

-EW

K0136R

73PT

1U

PGS2

0

803

M

123456789

01

11

213141

51

61

718191

021222324

2

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

374757

677787970

8

40

39

38

37

63

5343

33

23

13

039282

72

62

52

1

8

2

8

384858687888980919

29

39

49

596979

89

99

001

144

143

142

141

140

139

138

101

201

301

401

501

601

701

801

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

4DxRS/4DS/4DxT/1XENA/69P

4KLC/0XENA/59P

4SS/4STR/4STC/ni4BT/1AD/49P

3SS/3STR/3STC/ni3BT/0AD/39P

3D

xR

S

/3

A

DS

/3D

xT/ni2BT/29P

3

D

xTS/3LCS/3DxR/

n

i1B

/

19P

3KLC/ni0

B

T/09P

641P

541P

441P

341P

241P

141P

041P

ETYB

ssVNC

nicX/78P

tuocX/68P

-TESER

tuoX

ssV

niX

ccV

-IMN/58P

Vss

P65/CLK1

P64/CTS1-/RTS1-/CTS0-/CLKS

1

P63/TxD0

P62/RxD

0

P61/CLK0

P60/CTS0-/RTS0-

P137

P136

P135

P134

P57/RDY-

P56/ALE/RAS-

P55/HOLD-

P54/HLDA-/AL

E

P133

Vs

s

P132

Vc

c

P131

P130

P53/BCLK/ALE/CLKout

P52/RD-/DW-

P51/WRH-/BHE-/CASH-

P50/WRL-/WR-/CASL

-

P127

P126

P125

P147/CS0-/A23

P46/CS1-/A22

P45/CS2-/A21

P44/CS3-/A20(M12)

)1

1

AM

(/

9

1

A

/3

4P

ccV

)0

1AM

(81

A/24P

ssV

)9AM(/71A/14P

)8AM(/61A/04P

)51D()7AM(51A/73P

)41D()6AM(41A/63P

P66/RxD1

Vc

c

P67/TxD1

P70/TxD2/SDA2/TA0out

ni

5BT

/n

i0

AT/

2

LC

S/

2

D

xR

/17

P

V/tu

o1

AT

/2

K

L

C/2

7

P

-V/ni1

AT

/

2S

TR

-2STC/37P

W/

t

u

o

2AT/4

7P

-W/ni2AT/57P

tuo3AT/67P

ni3AT/77P

U/tuo4AT/08P

-U/

n

i4

A

T/18P

-0TNI/28P

-1TNI/38P

-2TNI

/

4

8

P

)

3

1

D(

)5AM

(

31

A

/53P

)

2

1

D(

)4AM

(

21

A

/43P

)

1

1D

()3AM

(

11

A

/33P

)

01D(

)

2

AM

(

01

A

/2

3

P

)9D

()1

AM

(

9A

/

13P

42

1

P

32

1

P

221P

12

1

P

02

1

P

ccV

)8D()0AM(8A/0

3

P

ssV

)7D(7A/72P

)6D(6A/62P

)5D(5

A

/52P

)4D(4

A

/42P

)3D/(3A/32P

)2D/(2A/22P

)1D/(1A/12P

P97/ADtrg-/RxD4/SCL4/STxD4

AVc

c

Vref

P100/AN0

AVs

s

P101/AN1

P102/AN2

)0D/(0A/02P

-5

T

NI/51D/71P

-4TNI/41D/61P

-3TNI/31D/51P

21

D

/4

1

P

11

D

/

3

1

P

01

D

/21

P

9D/11

P

P10/D8

P07/D7

P06/D6

P05/D5

P04/D4

P114

P113

P112

P111

P110

P03/D

3

P02/D

2

P01/D1

P00/D0

P157

P156

P155

P154

P153

P152

P151

Vs

s

P150

Vc

c

P107/AN7/KI

3

P106/AN6/KI

2

P105/AN5/KI

1

P104/AN4/KI

0

P103/AN3

24C

F

u1.

0

6U

A

61

82134T

1

2

345

6

7

8

9

01

112131

41

51

61

718191

02

12

22

324

2

52

6

2

7

2 8

2

92

0

3

13

2333

4353

63

73

83

930414

24

34

44

54

6

4

7

4

849

4

05152

5

3

5

4

5

DD

V

0QD

Q

DDV

1QD

2QD

Q

SSV

3QD

4QD

QDDV

5QD

6QD

QSSV

7Q

DDDV

MQDL

EW/

SAC/SA

R

/

SC/

0AB

1AB

PA/01A

0A1A2A

3

A

SSV

D

DV

4

A

5A6A7A

8A

9A

11A

C

.N

EKC

K

L

C

MQDU

UFR/C.N

SSV

8QD

QDDV

9QD

01QD

QSS

V

11QD

2

1

QD

Q

D

D

V

31QD

41Q

D

QS

S

V

5

1

QD

SS

V

83PT

34C

Fu

1

.0

22U

)V3(64C39

1

2

3

4

876

5

SC

KS

N

I

D

TUOD

CCV

CN

CN

DNG

2

1

C

Fu

1.0

43PT

75

R

0

01

8

5

R

K01

04C

Fu1.0

11U

CA5

4L

V5E

R

CA5

4

LV5ER

1

3

2

TUO

GND

NIV

1Y

zHM02

93C

F

u

1

.

0

7R

K001

2X

C

F

p0

1

83

C

Fu1.

0

95R

M1

5

3PT

11C

F

u1.

0

1XC

Fp01

5

PT

11NR

K01_8NR

18

27

36

45

56R

033

7U

CP5

1

-B01V

2

2FTA

02\PID

1234567

8

9

516171

81910212223242

011

121 31

41

0I/KLC

1I

2I

3I

DP/4I

5I6I7I

8I

1O/I

2O/I

3O/I

4O/I

5O/I

6O/I

7O/I

8O/I9O/I

CCV

9I

01I

11I

DNG

0O/I

C82

1

T57-V821

4

CL

5U

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

821

721

621

521

421

321

221

121

021

911

811

711

611

511

411

311

211

111

011

901

8

0

1

7

0

1

601501

4

0

1

3

0120

1

101

001

99

8979

33

435363

73839

3

04

14

243444

546474

849

4

05152

53545

55

65758

595

06

16

263

646

GND

TD

I

VC

C

CASL#

CASH

#

OE

#

A1

2

A1

1

A1

0

GND

A9

A8

A7

A6

A5

A4

VC

C

A3

A2

A1

A0

RAS#

WE

#

GND

D1

5

D1

4

D1

3

D1

2

D1

1

VC

C

TC

K

VC

C

VC

C

TD

O

VC

C

A1

1

A9

A8

A7

A6

GND

A5

A4

A3

A2

A1

A0

VC

C

A1

0

BA

1

BA

0

CS

#

RAS#

CAS#

GND

WE

#

F4

F3

F2

F1

F0

VC

C

TM

S

GND

51QD41QD31Q

D

2

1

QD

1

1Q

D

DN

G

CCV

0

1

QD

9QD

8QD

7QD

6Q

D

0EO

G

/0A

C

C

V

I/0KLC

D

N

G

I/3KLC

1E

O

G/0H

5QD

4QD

3QD

2QD

1QD

CCV

D

N

G

0QD

HMQD

L

MQ

D

KLC

EKC

2

1

A

DNG

D

NG

01D

9D8D7D6D5D

DNG

CCV

4D3D2D1D0D

0H

NIKC

DNG

I/2KLC

CCV

0G

1G2G3G4G5G

CCV

DN

G6G

7G8G9G

01G

3U

T40015

M

1

2

3

456

7

8

9

0111213141

51

819102122232425262728292031

3

2

3

61

71

C

N

6

1A

51A21

A

7A6A5A4A

3A2A1A0A

0

D

1D

4D2D

5D6D

7D

E

C

0

1A

EO

11A

9A

8

A

31A

4

1A

C

N

EW

CC

V

3

D

DNG

16R

K01

00126R

06

R

K01

0

3346R

4

4

C

Fu1

.

0

5

1P

J

A05REDAEH

1

3

5

7

9

11

31517

1

9

112

32527

2

921

3

33537

3

931

4

345474

94

2

4

6

8

01

214

1

6

181

0

2

2242

6

2

82

032343

63

83

04

24

44

64

84

05

6

3PT

14C

Fu1.0

TESER2

APM2

BPM2

A

0

IM2

A

1

IM2

2S

C

_

T

OP

B

0

IM2

B

1

IM2

H

S

AC

R

W

SAR

L

S

A

C

RW

1DXT2

#

DR

0

DXR

2

1

DXR

2

0STC20ST

R2

0

DXT

2

HSACRW

#

DR

2F

3F

#RW

2MAR

1MAR

#RW

#RW

0F

SA

R

1F

LSA

CRW

#

DR

0F

#

D

R

#

D

R