Page 1

http://waterheatertimer.org/Digital-control-centers-and-manuals.html#PE953

Pool & Spa Control System

158--01540

Installation Guide

For Software Version 3.4

Page 2

Intermatic

7777 Winn Road

Spring Grove, IL 60081

(815) 675-2321

Need Technical help?

Phone: 815-675-2321

Fax: 815-675-7001

(8:00 am through 4:30 pm CT, Monday through Friday)

Connect with us

Intermatic.com

©2014 Intermatic Incorporated 158--01540

Page 3

Two-Year Limited Warranty

If within the warranty period specied on the package, this product fails due to a defect in material or

workmanship, Intermatic Incorporated will repair or replace it, at its sole option, free of charge. This warranty

is extended to the original purchaser only and is not transferable. This warranty does not apply to: (a) damage

to units caused by accident, dropping or abuse in handling, acts of God or any negligent use; (b) units which

have been subject to unauthorized repair, opened, taken apart, or otherwise modied; (c) units not used in

accordance with instructions; (d) damages exceeding the cost of the product; (e) sealed lamps and/or lamp

bulbs, LEDs and batteries; (f) the nish on any portion of the product, such as surface and/or weathering,

as this is considered normal wear and tear; (g) transit damage, initial installation costs, removal costs, or reinstallation costs.

INTERMATIC INCORPORATED WILL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION

OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES.

ALL IMPLIED WARRANTIES, INCLUDING THE WARRANTY OF MERCHANTABILITY AND THE WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE HEREBY MODIFIED TO EXIST ONLY AS CONTAINED IN THIS LIMITED WARRANTY, AND SHALL BE

OF THE SAME DURATION AS THE WARRANTY PERIOD STATED ABOVE. SOME STATES DO NOT ALLOW LIMITATIONS ON THE

DURATION OF AN IMPLIED WARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

This warranty service is available by either (a) returning the product to the dealer from whom the unit was

purchased or (b) completing a warranty claim on-line at www.intermatic.com.

This warranty is made by: Intermatic Incorporated, Customer Service 7777 Winn Rd., Spring Grove, Illinois

60081-9698. For warranty service go to: http://www.Intermatic.com or call 815-675-7000.

3Warranty

Because of our commitment to continuing research and improvements, Intermatic Incorporated reserves the

right to make changes, without notice, in the specications and material contained herein, and shall not be

responsible for any damages, direct or consequential, caused by reliance on the material presented.

(CUT ALONG DASHED LINE)

WARRANTY REGISTRATION

Owner’s Name___________________________________ Signature_____________________________________________

Street Address__________________________________________ Date of Purchase ______________________________

City__________________________________ State_____ Zip ______________ Phone _________________________

Authorized Dealer ________________________________________ Sales Rep ___________________________________

City__________________________________ State_____ Zip ______________ Phone _________________________

How did you hear about our product? (Please check all that apply.)

___Pool Store Employee ___Pool Builder ___Pool Service ___Direct Mail Ad ___In-Store Display

___Friend/Relative ___Magazine ___Newspaper ___Radio ___TV ___Catalog ___Other: ___________

To activate your warranty, please return this portion to:

Intermatic, Inc.

7777 Winn Road

Spring Grove, IL 60081

or by FAX: 815-675-7055

Page 4

4

Garantie limitée deux ans

Si, durant la période de garantie indiquée sur l’emballage, ce produit présente un défaut de matériau ou de fabrication,

Intermatic Incorporated s’engage à le réparer ou à le remplacer, à sa seule discrétion, sans frais. Cette garantie s’applique

uniquement à l’acheteur original et elle est incessible. Cette garantie ne s’applique pas : (a) aux dommages au dispositif

causés par un accident, une chute ou une mauvaise manipulation, une catastrophe naturelle ou une utilisation négligente; (b)

aux dispositifs soumis à des réparations non autorisées, qui ont été ouverts, démontés ou modiés de quelconque manière;

(c) aux dispositifs qui n’ont pas été utilisés conformément aux instructions; (d) aux dommages dépassant le coût du produit;

(e) aux lampes scellées et/ou aux ampoules, aux LED et aux piles; (f) à la nition de l’une des parties du dispositif, telle que

la surface ou les caractéristiques de résistance aux intempéries, ce qui est considéré comme de l’usure normale; (g) aux

dommages causés par le transport, aux coûts d’installation initiale, aux coûts de démontage ou de remontage.

INTERMATIC INCORPORATED NE POURRA ÊTRE TENUE RESPONSABLE DE DOMMAGES INDIRECTS OU CONSÉCUTIFS. CERTAINES JURIDICTIONS

N’AUTORISENT PAS L’EXCLUSION OU LA LIMITATION DES DOMMAGES INDIRECTS OU CONSÉCUTIFS. DANS CE CAS, LES LIMITES CI-DESSUS NE

S’APPLIQUENT PAS. LA PRÉSENTE GARANTIE REMPLACE TOUTES LES AUTRES GARANTIES EXPRESSES OU IMPLICITES. TOUTES LES GARANTIES

IMPLICITES, NOTAMMENT GARANTIE DE QUALITÉ MARCHANDE ET GARANTIE D’ADAPTATION À UNE FIN PARTICULIÈRE, SONT MODIFIÉES AUX

PRÉSENTES POUR EXISTER UNIQUEMENT TELLES QUE COMPRISES DANS LA GARANTIE LIMITÉE, ET AURONT LA MÊME DURÉE QUE LA PÉRIODE

DE GARANTIE INDIQUÉE CI-DESSUS. CERTAINES JURIDICTIONS N’AUTORISENT PAS LES LIMITES DE DURÉE D’UNE GARANTIE IMPLICITE. DANS

CE CAS, LES LIMITES CI-DESSUS NE S’APPLIQUENT PAS.

Le recours à la présente garantie se fait soit (a) par renvoi du produit au vendeur auprès duquel il a été acheté, soit (b) en

remplissant le formulaire de réclamation en ligne à www.intermatic.com.

La présente garantie est offerte par : Intermatic Incorporated, Customer Service 7777 Winn Rd., Spring Grove, Illinois 60081-

9698. Pour recourir à la garantie, aller à: http://www.intermatic.com ou composer le 815-675-7000.

En raison de son attachement constant à la recherche et à l’amélioration de ses produits, Intermatic, Inc. se réserve le droit

de modier, sans préavis, les caractéristiques et le contenu de la présente documentation et décline toute responsabilité pour

d’éventuels dommages, directs ou consécutifs, liés au contenu présenté.

(DÉCOUPER SUIVANT LA LIGNE POINTILLÉE)

ENREGISTREMENT DE LA GARANTIE

Nom du propriétaire________________________________ Signature___________________________________________

Adresse de domicile__________________________________________ Date d’achat______________________________

Ville___________________________ Province_____ Code postal_____________ Téléphone___________________

Revendeur autorisé______________________________________ Repr. commercial______________________________

Ville___________________________ Province_____ Code postal_____________ Téléphone___________________

Comment avez-vous entendu parler de ce produit? (Cochez toutes les options pertinentes.)

___ Personnel de magasin ___Piscinier ___Service d’entretien ___Publipostage ___Présentoir

de piscines de piscine en magasin

___Ami/parent ___Magazine ___Journal ___Radio ___TV ___Catalogue ___Autre: ___________

Pour activer la garantie, veuillez renvoyer cette portion à:

Intermatic, Inc.

7777 Winn Road

Spring Grove, IL 60081

ou par télécopie: 815-675-7055

Page 5

Contents

Two-Year Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Garantie limitée deux ans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Safety and Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Informations importantes sur la sécurité et l’entretien . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1:

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MultiWave Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

(PE953) Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

(PE653) Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

(P5043ME) Expansion Module (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

(PA122) Water Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

(178PA28A) Freeze (Air Temperature) Sensor . . . . . . . . . . . . . . . . . . . . . . . . 11

(PA122) Solar (Air Temperature) Sensor (Optional) . . . . . . . . . . . . . . . . . . . . . 11

(PE24VA) 24-Volt Valve Actuator (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . 12

(PE30000) Load Center (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5Contents

Chapter 2:

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting the PE653RC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting the PE30000 Load Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting the PE653 Receiver on the Load Center . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3:

Installing — Ratings, 120V/240V Wiring, Power In/Out . . . . . . . . . . . . . . . . . 16

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

120V Wiring Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

240V Wiring Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Power to/from PE653RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting a P5043ME Expansion Module Communication Cable to Receiver . . . . 20

Power to/from PE653RC with P5043ME . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4:

Filter Pump Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Single Speed Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-Speed Pump Terminal/Circuit Connections for PE653RC . . . . . . . . . . . . . . . . 22

1-Speed Pump Terminal/Circuit Connections for PE653RC with P5043ME . . . . . . . 24

2-Speed Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-Speed Pump Terminal/Circuit Connections for PE653RC . . . . . . . . . . . . . . . . 26

2-Speed Pump Terminal/Circuit Connections for PE653RC with P5043ME . . . . . . . 28

Variable Speed Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting a Pentair Variable Speed Pump Communication Cable to Receiver . . . . 30

External Variable Speed Pump Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 6

MultiWave Control System Installation Guide

6

Chapter 5:

Basic Wiring — 240V Cleaner/Lights/Actuators

Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pool/Spa Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . 34

Chapter 6:

Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1 Heater on PE653 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1 or 2 Heaters on P5043ME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Heater Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connection for Jandy® Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connection for Raypak® Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connection for Hayward® Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Connection for Pentair® Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connection for Sta-Rite/Pentair® Heater with DDTC . . . . . . . . . . . . . . . . . . . . 43

Chapter 7:

Blower/Chlorinator/Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

PE653RC with Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

PE653RC with Cleaner Pump or Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

PE653RC and P5043ME with Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chlorinator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting AutoPilot Salt Chlorine Generator Control Cable to Receiver . . . . . . . . 47

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Installing the Water Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Installing the Freeze (Air Temperature) Sensor . . . . . . . . . . . . . . . . . . . . . . . 48

Installing the Solar (Air Temperature) Sensor . . . . . . . . . . . . . . . . . . . . . . . . 48

NOTE: All trademarks are the property of their respective owners.

www.intermatic.com

Page 7

Important Safety and Service Information

7Safety

WARNING

Risk of Fire or Electric Shock

• IMPORTANT SAFETY INSTRUCTIONS, READ

AND FOLLOW ALL INSTRUCTIONS, SAVE THESE

INSTRUCTIONS

• Disconnect power at the circuit breaker(s) or disconnect switch(es) before installing or servicing.

• This control must be installed according to the National Electrical Code (NEC) and local code requirements. For

Canadian installations, section 10 & 68 of the CEC. IMPORTANT: This installation is subject to the approval by

the local inspection authority.

• The control panel to be a minimum of 3m (in Canada) or 5ft (in USA) from the inside wall of the pool, spa, or

pond, unless separated from the body of water by a fence, wall or other permanent barrier that will make the

unit inaccessible to persons in the water.

• Use up to #8 AWG wires, rated at least 90°C - COPPER Conductors ONLY.

• The control is not provided with integral GFCI protection for the lighting circuit. When this control is used to

power or switch an underwater luminaire, suitable GFCI protection shall be provided in the eld.

• This control should not be connected to any equipment which would cause bodily injury or property damage

should it be activated unexpectedly.

• For outdoor locations, raintight, or wet locations, conduit hubs that comply with requirements of the UL514B

(standard for tting for conduit and outlet boxes) are to be used.

• Bonding between conduit connections is not automatic and must be provided as part of the installation.

• If the power disconnect point is out of sight, lock it in the “OFF” position and tag it to prevent unexpected

application of power.

• This unit is not a safety disconnect. A proper sized fused disconnect or breaker of no more than 125A capacity

must be provided in the power supply circuit. Proper gauge wire should be based on local code requirements

of amperage and wire length.

• Do NOT exceed the maximum current carrying capacity of this control.

• Receiver must be mounted in a vertical (upright) position on top of the enclosure.

• KEEP DOOR CLOSED AT ALL TIMES when not servicing and secure with lock or tie-wrap.

NOTICE

• Do NOT touch circuit board components; contact can create a static discharge, which can damage the

microprocessor.

Page 8

MultiWave Control System Installation Guide

8

Informations importantes sur la sécurité et l’entretien

AVERTISSEMENT

Risque d’incendie ou de

choc électrique

• INSTRUCTIONS DE SÉCURITÉ IMPORTANTES,

LIRE ET RESPECTER TOUTES LES INSTRUCTIONS,

CONSERVER CES INSTRUCTIONS

• Débrancher l’alimentation au niveau des disjoncteurs ou des sectionneurs avant de procéder à l’installation ou à

l’entretien.

• Ce panneau de commande doit être installé conformément aux codes de l’électricité en vigueur. Pour les

installations au Canada, voir les sections 10 et 68 du CCE. IMPORTANT : Cette installation est soumise au

contrôle et à l’acceptation par les autorités compétentes locales.

• Le panneau de commande doit être à un minimum de 3 m (au Canada) ou de 5 pi (aux États-Unis) de la paroi

intérieure de la piscine, du spa ou du bassin, sauf s’il est séparé de l’eau par une clôture, un mur ou autre

barrière permanente qui rend l’appareil inaccessible aux personnes se trouvant dans l’eau.

• Utiliser des ls jusqu’au n° 8 AWG, classés 90 °C minimum - Conducteurs en CUIVRE UNIQUEMENT.

• La commande n’est pas équipée d’un disjoncteur différentiel (GFCI) intégré pour la protection du circuit

d’éclairage. Si la commande est utilisée pour alimenter ou commuter un luminaire immergé, une protection

adaptée par GFCI devra être prévue dans l’installation.

• Cette commande ne doit être raccordée à aucun autre matériel susceptible de provoquer des blessures

corporelles ou des dommages matériels en cas d’activation inattendue.

• Pour les installations extérieures, utiliser des embouts de raccordement de conduit anti-intempéries ou pour

zone humide conformes aux exigences d’UL514B (norme sur les raccords de conduit et les boîtiers de prises).

• La liaison entre les raccordements de conduits n’est pas automatique et doit être prévue dans le cadre de

l’installation.

• Si le point de coupure n’est pas visible, le condamner en position ARRÊT et l’étiqueter pour éviter tout remise

sous tension imprévue.

• Cet appareil n’est pas un sectionneur de sûreté. Prévoir un sectionneur avec fusible ou un disjoncteur de calibre

adapté d’une capacité de 125 A au maximum dans le circuit d’alimentation électrique. Le calibre de l utilisé

doit être conforme aux normes en vigueur concernant l’intensité de courant et la longueur de l.

• Ne PAS dépasser la capacité maximale d’intensité de courant de cette commande.

• Le récepteur doit être montée en position verticale (debout) sur le dessus du boîtier.

• GARDER LA PORTE FERMÉE EN PERMANENCE en-dehors des opérations d’entretien et sécuriser avec un

cadenas ou une attache autobloquante.

AVIS

• Ne pas toucher les composants du circuit imprimé ; le contact peut provoquer une décharge d’électricité

statique susceptible d’endommager le microprocesseur.

www.intermatic.com

Page 9

Chapter 1:

Overview

IMPORTANT: The installer must fill out the MultiWave Pool & Spa Control System

Worksheet for Programming at the back of this guide so that the controller can be

programmed.

The MultiWave Control System brings wireless control to a new level of simplicity. It features

push button control and a clear, easy-to-read backlit display panel. This manual provides

guidelines and instructions for installing the MultiWave Control System.

(PE653) Receiver

Overview

9

(2T2485GA)

Enclosure

PE953 Controller

Water Temperature

Sensor (PA122)

Figure 1-1. PE653RC MultiWave Control System.

Page 10

MultiWave Control System Installation Guide

10

MultiWave Components

(PE953) Controller

The hand-held controller transmits user commands to the PE653 Receiving Device,

PE650 Receiving Device, or Z-Wave home control devices, and displays the status of the

installed equipment.

The unit, which features a backlit display, is water resistant and shock resistant. It requires

three (3) AA batteries with an expected battery life of one year.

When the components of a specic system are linked to a network, unique network ID

codes supplied by the receiver prevent unauthorized use of the system by neighboring

systems.

(PE653) Receiver

The PE653 receiver is the central hub of the MultiWave. It receives commands from the

PE953 controller to activate circuits. The receiver controls the ON/OFF operation of up to

ve circuits. It can also communicate with variable speed pumps. The receiver features

an internal supercapacitor to maintain data up to 8 hours in case of power loss.

(P5043ME) Expansion Module (Optional)

The P5043ME controls up to four 24 VAC water valve actuators. There are two dedicated

actuators for the pool and spa, one for a water feature (i.e. waterfall, fountain, slide) and

one for the solar heating/cooling feature.

In addition to the actuators, the P5043ME can control up to two heaters (1 heater dedicated

to the pool and 1 dedicated to the spa), can control other variable speed pumps (limited

to Jandy, Hayward, Century, Marathon or Speck), and can be controlled by a dry contact

switch. The USB port allows for MultiWave system updates.

The P5043ME is ideal for those pool and spa combination applications with the additional

possibility of a water feature, solar feature, variable speed pump, 1 or 2 heaters and/or a

dry contact switch. The dry contact switch can be triggered by any switching device you may provide —

light switch, spring wound AUTO/OFF, wireless switch, relay and more.

www.intermatic.com

Page 11

(PA122) Water Temperature Sensor

The Intermatic Water Sensor (PA122) monitors both pool and spa water

temperature, depending on the position of the diverter valves. Installation is

necessary for the thermostatic control to work.

(178PA28A) Freeze (Air Temperature) Sensor

The freeze/air temperature sensor measures air temperature. When the air

temperature drops below a user-congured setpoint, the freeze sensor turns pumps

ON to circulate water through the pipes to ensure they do not freeze or burst.

(PA122) Solar (Air Temperature) Sensor (Optional)

11 Overview

The solar/air temperature sensor measures air temperature near the solar

collector. It can be congured for either heating or cooling solar applications.

Page 12

MultiWave Control System Installation Guide

12

(PE24VA) 24-Volt Valve Actuator (Optional)

Designed with quality in mind, Intermatic’s 24-volt valve actuators provide

reliable control of 2-way and 3-way diverter valves for pool/spa combinations

and water features. The water ow can be altered for specic applications

through the adjustable cam, which rotates diverter valves to multiple degree

settings. The cam settings can be easily adjusted by simply removing the lid.

These valve actuators are compatible with all pool/spa valves currently offered in

the industry and will retrot into all pool/spa control systems.

• 24 VAC Input Voltage

• Automates compatible diverter valves for pool/

spa combos

• Adjustable cam rotates diverter valves to

• Designed to operate most 2-way and 3-way

diverter valves

• Shipping Weight - 3 lbs. (1.4 kg)

• Agency Approval - CSA/C-US

multiple degree settings

(PE30000) Load Center (Optional)

The PE30000 load center provides a safe and efcient environment for the control

components of MultiWave Pool/Spa Series Kits which include expansion module

and/or relay modules.

The PE30000 Series panel includes an eight-position 80 Amp breaker base, two

mechanism slots, and four décor knockouts for GFCIs and switches.

The panel provides a low voltage raceway for low voltage control lines (i.e. actuators,

sensors, etc…) and a convenient side knockout for an outdoor receptacle.

The panel is rated for indoor/outdoor use and is suitable for pool equipment control and for direct

connection to a wet-niche or no-niche luminaire.

www.intermatic.com

Page 13

Chapter 2:

Mounting

Mounting the PE653RC System

Follow this procedure to mount the MultiWave enclosure and PE653 receiver.

1. Select a location to mount the receiver that is near the pool/spa equipment; at least 3m

(in Canada) or 5 ft (in USA) from the inside wall of the pool, spa, or pond, unless separated

from the body of water by a fence, wall, or other permanent barrier that will make the unit

inaccessible to persons in the water. NOTE: The receiver must be mounted in a vertical

(upright) position on top of the enclosure.

2. Select the knockouts to be used and insert a athead screwdriver into the slot and carefully

punch the 1/2" knockout loose and remove the slug.

NOTE: If a 3/4" knockout is required, remove the outer ring with pliers after removing the

1/2" knockout. Smooth the edge with a le if required.

NOTE: If a low voltage circuit or a heater control circuit is to be used, remove the low

voltage knockout from the PE653 enclosure.

13 Mounting

3. Install conduit hub to knockout rated for outdoor locations, raintight, or wet locations that

complies with the requirements in UL 514B (standard for tting for conduit and outlet box).

4. Place the metal enclosure in the desired mounting location and mark the three mounting

holes. Install the top screw rst and then hang the enclosure by the keyhole. Then install the

bottom screws, tightening all screws for a secure mounting.

5. Install conduit as needed to comply with national and local electrical and safety codes.

6. Bond the enclosure in accordance with your state and local codes. Where required, connect a

No. 8 AWG solid copper wire to the enclosure with a Bonding Lug (part number 156T11047A).

Connect the bonding wire to an approved earth ground.

7. Identify and install all wires necessary to complete the installation. Allow a length of

approximately 18" (46 cm) of each wire at the metal enclosure for required connections of

junctions.

8. Connect wiring for circuits as required. Refer to the diagrams in Chapter 3 and Chapter 4 for

wiring suggestions for specic equipment combinations. All splices and wire nut connections

should be in the metal enclosure, not in the PE653 enclosure.

9. Check and tighten all connections and circuits.

10. Apply power.

Page 14

MultiWave Control System Installation Guide

14

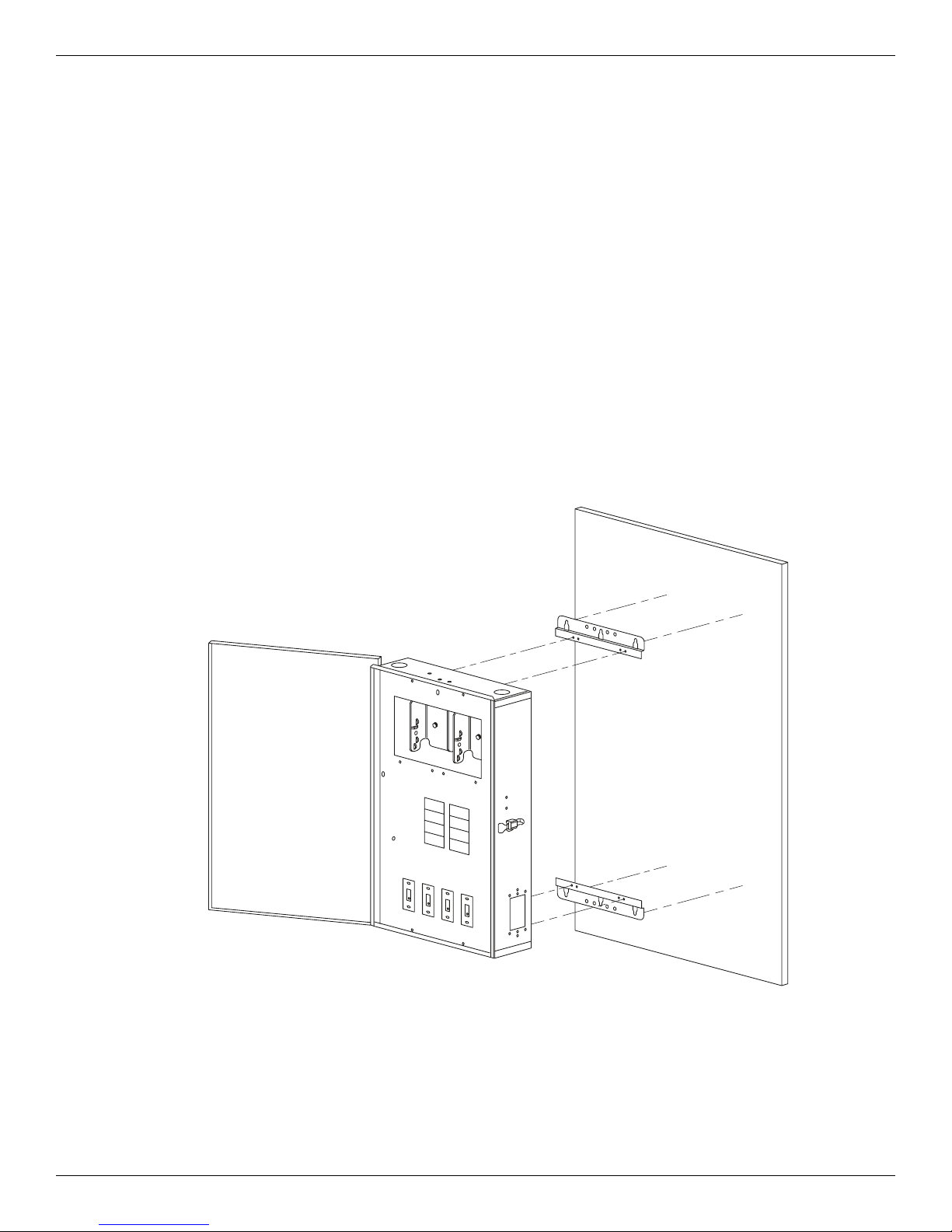

Mounting the PE30000 Load Center

Follow this procedure to mount the PE30000 load center.

1. Select a location to mount the load center that is near the pool/spa equipment; at least 3m

(in Canada) or 5 ft (in USA) from the inside wall of the pool, spa, or pond, unless separated

from the body of water by a fence, wall, or other permanent barrier that will make the unit

inaccessible to persons in the water. NOTE: Choose a at vertical surface or structure

capable of supporting the load center and allow space above the load center so that the

receiver can be mounted in a vertical (upright) position on top of the load center.

2. Remove the empty PE30000 enclosure from the kit.

3. Remove the #10 hex head screws from the outside back of the enclosure and attach the

mounting brackets.

4. Using the mounting brackets and hardware capable of supporting the load center, mount the

enclosure to the vertical surface or structure.

Figure 2-1. Mounting the load center.

www.intermatic.com

Page 15

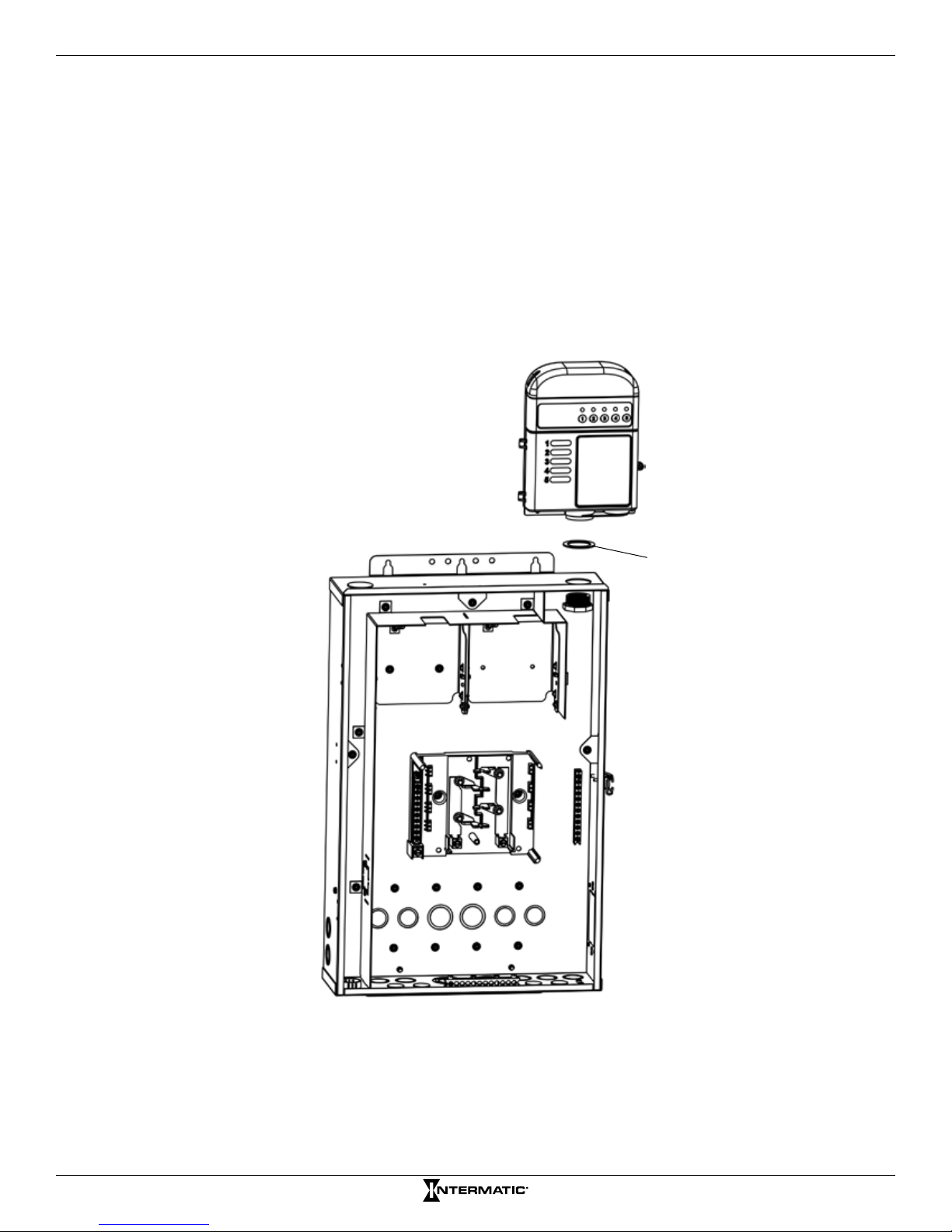

Mounting the PE653 Receiver on the Load Center

Follow this procedure to mount the PE653 Receiver on the load center.

1. Looking at the load center mounted on the supporting structure/surface, remove the

knockout located on the top right side. If no knockout is present, there should be a dimple

to use as a guide for drilling a 1-3/8" hole with a hole saw or punch. NOTE: DO NOT remove

the left-side knockout, as this is used to gain access to the low voltage raceway.

2. Remove the PE653 Receiver from the top of its small beige steel standard enclosure by

removing the plastic hub nut. Discard the standard enclosure and retain the plastic hub nut.

3. Use the plastic hub nut to mount the receiver to the top right of the load center. NOTE:

Gasket is required for rain tight connection for outdoor enclosures.

15 Mounting

Gasket

Figure 2-2. Mounting PE653 on load center.

Page 16

MultiWave Control System Installation Guide

16

Chapter 3:

Installing — Ratings, 120V/240V Wiring, Power In/Out

IMPORTANT: The installer must fill out the MultiWave Pool & Spa Control System Worksheet

for Programming at the back of this guide so that the controller can be programmed.

Ratings

Controller Power In:

•

120/240 VAC, 50/60 Hz, 5 W max.

Contact Ratings:

Load 1

•

120/240 VAC

•

20 A Resistive

•

17 Full Load A, 80 Lock Rotor A

•

5A Tungsten

Loads 2-5

•

120/240 VAC

•

15 A Resistive

•

10 Full Load A, 60 Lock Rotor A

•

5A Tungsten

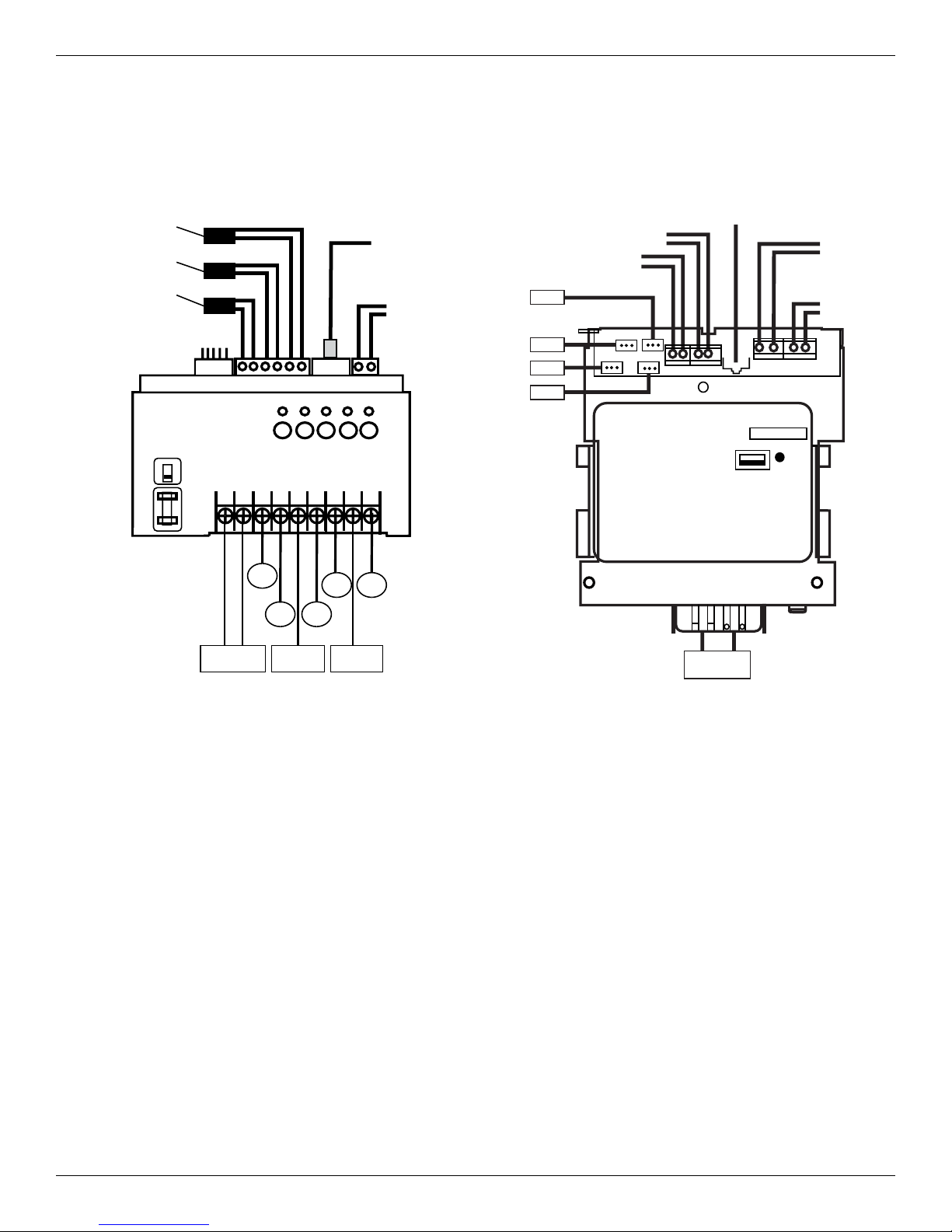

Antenna Section

120/240 VAC Selector

Switch

Fuse (250 VAC - 0.1 A)

Wiring Terminals

Threaded Conduit

Connection Bushing and Hub

Load ON Indicator

(Green LEDs)

Circuit ON/OFF Switches

Include/Exclude Switch

AC Power & Status

Indicator (Red)

Low Voltage Divider

(can be removed)

Low Voltage Knockout

Figure 3-1. PE653 Receiver.

www.intermatic.com

Page 17

120V Wiring Applications

This Installation Guide covers most typical applications. If you need more instructions for 120V or

specic applications (i.e. water feature, auxiliary devices), please go to http://www.intermatic.com

to access the MultiWave Congurator for more wiring diagrams or call technical support for

assistance.

Select breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

17 Installing — Ratings, 120V/240V Wiring, Power In/Out

Make sure that voltage selector switch is in 120V position

before applying power to terminals 1 & 2

NEUTRAL BUS

Single Pole

120 VAC

1-Speed Pump

(Circuit 1)

Figure 3-2. Wiring for 120V 1-Speed Pump

Breaker

RECEIVER

POWER

SUPPLY

120V

240V

1234 56

HOT (Circuit 1)

NEUTRAL

1 2

3

78

5

4

9

Page 18

MultiWave Control System Installation Guide

18

Select breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

Make sure that voltage selector switch is in 120V position

before applying power to terminals 1 & 2

1-Pole

Breakers

15 A. Max.

1-Pole Breaker

NEUTRAL BUS

120 VAC

1-Speed Pump

(Circuit 1)

120 VAC

NOTE: The combined load on terminals 6 & 7

must NOT exceed 15 amps resistive

RECEIVER

12 34 5

POWER

SUPPLY

120V

240V

123456789

HOT (Circuit 1)

NEUTRAL

Aux.

(Circuit 2)

Aux.

(Circuit 3)

120 VAC

Aux.

(Circuit 4)

120 VAC

Aux.

(Circuit 5)

120 VAC

Figure 3-3. Wiring for 120V 1-Speed Pump + Any 4 120V Auxiliary Components

www.intermatic.com

Page 19

240V Wiring Applications

This Installation Guide covers most typical applications. If you need more instructions for 240V or

specic applications (i.e. water feature, auxiliary devices), please go to http://www.intermatic.com

to access the MultiWave Congurator for more wiring diagrams or call technical support for

assistance.

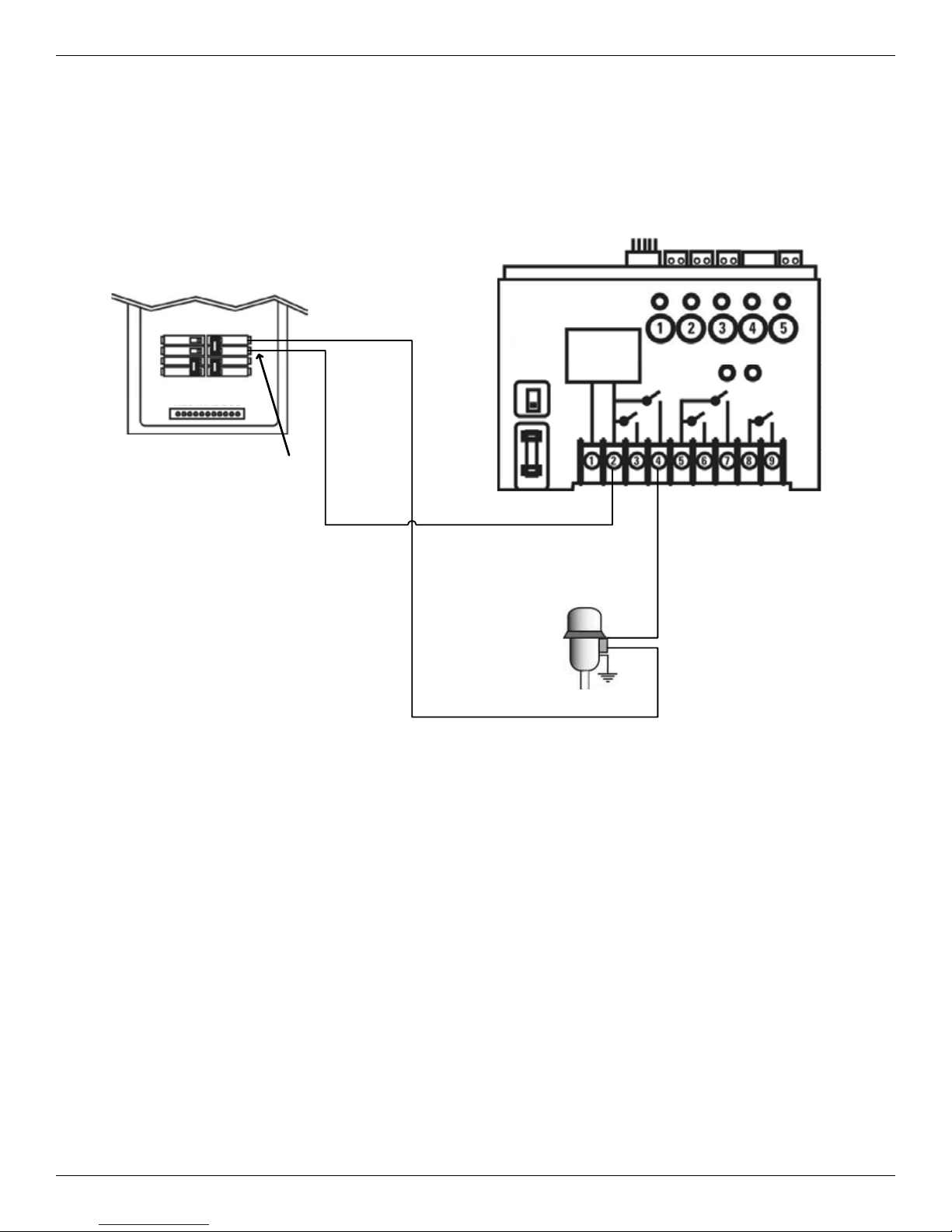

Power to/from PE653RC

NOTE: Contact Tech Support at Intermatic for additional diagrams.

2-Pole Breaker

NEUTRAL BUS

19 Installing — Ratings, 120V/240V Wiring, Power In/Out

RECEIVER

POWER

SUPPLY

120V

240V

Hot Line #1

Hot Line #2

Figure 3-4. Wiring 240V incoming power to PE653RC.

Hot Line #1

Page 20

MultiWave Control System Installation Guide

20

Connecting a P5043ME Expansion Module Communication Cable to

Receiver

Follow this procedure to connect the P5043ME Expansion Module communication cable to the

receiver.

NOTE: The expansion module connects to the same terminals as the AutoPilot Salt Chlorine

Generator. Both can be installed in the terminals.

1. Make sure the power is off at the receiver.

2. Connect the communication cable to the proper terminals on the expansion module. See

Figure 3-5.

3. Connect the green wire from the unattached end of the communication cable to the connector

terminal next to the Cat 5 cable. See Figure 3-5.

NOTE: Be sure to observe polarity when connecting the expansion module wires.

4. Connect the yellow wire from the cable to the connector terminal next to the green wire.

Observe Polarity

Power

Supply

1 2 3 4 5

120V

240V

1 2 3 4 5 6 7 8 9

Figure 3-5. PE653 Receiver to P5043ME wiring connections.

Communication

Lines

PE30000

Series

High Voltage

Compartment

Low Voltage

Compartment

Figure 3-6. High and low voltage wire

routing from PE653 Receiver to PE30000

Series Load Center.

www.intermatic.com

Page 21

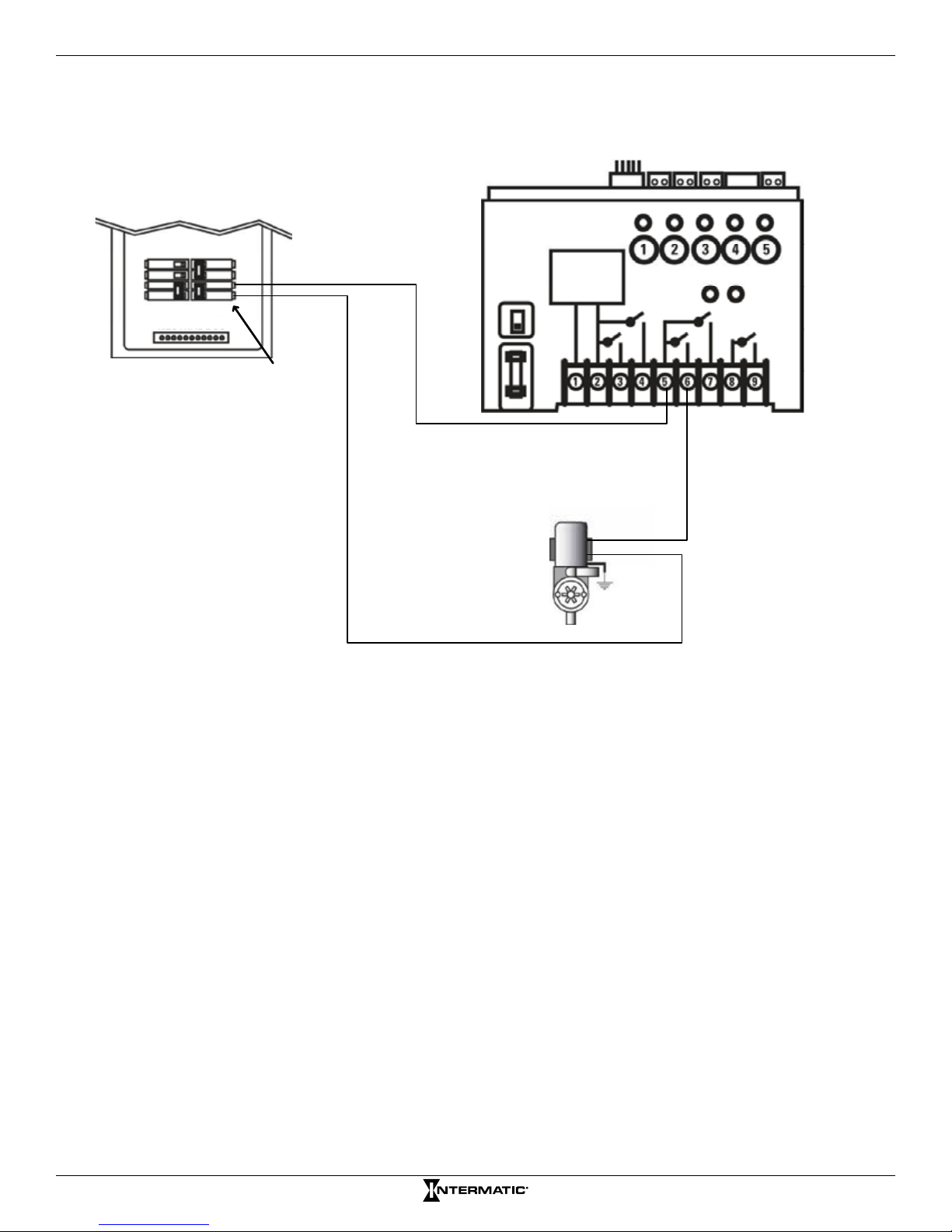

Power to/from PE653RC with P5043ME

NOTE: Contact Tech Support at Intermatic for additional diagrams.

21 Installing — Ratings, 120V/240V Wiring, Power In/Out

NEUTRAL BUS

Hot Line #1 Red

Hot Line #2 Black

Hot Line #1

Hot Line #2

Hot Line #1

2-Pole Breaker

P5043ME

Figure 3-7. Wiring 240V incoming power to PE653RC and P5043ME.

RECEIVER

POWER

SUPPLY

120V

240V

Hot Line #1

Page 22

MultiWave Control System Installation Guide

22

Chapter 4:

Filter Pump Installations

This chapter includes diagrams for systems with 1-speed, 2-speed and variable speed pumps.

Single Speed Pumps

1-Speed Pump Terminal/Circuit Connections for PE653RC

Manual Circuit

1 2 3 4 5

120V

240V

123 4 5 6 7 8 9

OperationButtons

(Controls corresponding

numbered circuits below)

Circuit

1

Circuit 2Circuit

Power In

120or240 VAC

Figure 4-1. PE653 Receiver power terminal identification.

L1 120

VACWire

Circuit 4Circuit

5

3

L2

Terminals 1, 2 and 5 – Power In

Terminal 3, Circuit 1 – 120/240 VAC 1-Speed Pump*

Terminal 4, Circuit 2 – 120/240 VAC Blower

Terminal 6, Circuit 3 – 120/240 VAC Booster (Cleaner) Pump*

Terminal 7, Circuit 4 – 120 VAC Light with GFCI*

Terminal 8/9, Circuit 5 – Heater**

* To break both lines, use relay kit PE21RLY. Request document 158--01559.

** See Chapter 6.

www.intermatic.com

Page 23

Receiver

Power

Supply

23Filter Pump Installations

Neutral Bus

120V

240V

2-Pole Breaker

Hot Line #2

Hot Line #1

240 VAC

1-Speed

Pump

Figure 4-2. Wiring Circuit #1 to a 240 VAC 1-Speed Pump for PE653RC.

Hot Line

#2

Page 24

MultiWave Control System Installation Guide

24

1-Speed Pump Terminal/Circuit Connections for PE653RC with

P5043ME

Solar/Air

Temperature

Sensor

Water

Temperature

Sensor

Freeze/Air

Temperature

Sensor

1 2 3 4 5

120V

240V

123 4 5 6 7 8 9

Circuit

1

Circuit 2Circuit

Antenna

Extender

(CAT5)

Pentair VSP and/or SCG

AND Expansion Module

Circuit 4Circuit

5

3

Other VSP

(CAT5)

Heater #1

Comm Cable

to Receiver

Act 2

Act 1

Act 3

Act 4

Heater #2

Remote

Switch

Power In

120or240 VAC

L1 120

VACWire

L2

Figure 4-3. PE653 Receiver Connections.

PE653 Receiver

Terminals 1, 2, 5 and 8 – Power In

Terminal 3, Circuit 1 – 120/240 VAC 1-Speed Pump*

Terminal 4, Circuit 2 – 120/240 VAC Auxiliary

Terminal 6, Circuit 3 – 120/240 VAC Booster

(Cleaner) Pump*

Terminal 7, Circuit 4 – 120/240 VAC Blower*

Terminal 9, Circuit 5 – 120 VAC Light with GFCI

* To break both lines, use relay kit PE21RLY.

Request document 158--01559.

Power In

240 VAC

Figure 4-4. P5043ME Expansion Module Hookups.

P5043ME Expansion Module

Power In

NOTE: Expansion module hookups are shown on

page 21, page 37 and page 39.

www.intermatic.com

Page 25

Neutral Bus

25Filter Pump Installations

Receiver

Power

Supply

120V

240V

2-Pole Breaker

Hot Line #2

Hot Line #1

240 VAC

1-Speed

Pump

Hot Line

#2

Figure 4-5. Wiring Circuit #1 to a 240 VAC 1-Speed Pump for PE653RC and P5043ME.

Page 26

MultiWave Control System Installation Guide

26

2-Speed Pumps

2-Speed Pump Terminal/Circuit Connections for PE653RC

Manual Circuit

1 2 3 4 5

120V

240V

123 4 5 6 7 8 9

OperationButtons

(Controls corresponding

numbered circuits below)

Circuit

1

Circuit 2Circuit

Power In

120or240 VAC

Figure 4-6. PE653 Receiver power terminal identification

L1 120

VACWire

Circuit 4Circuit

5

3

L2

Terminals 1, 2 and 5 – Power In

Terminals 3 and 4, Circuits 1 and 2 – 240 VAC 2-Speed Pump*

Terminal 6, Circuit 3 – 240 VAC Blower*

Terminal 7, Circuit 4 – 120 VAC Light with GFCI*

Terminal 8/9, Circuit 5 – Heater**

* To break both lines, use relay kit PE21RLY. Request document 158--01559.

** See Chapter 6.

www.intermatic.com

Page 27

Neutral Bus

2-Pole Breaker

Hot Line #2

Receiver

Power

Supply

120V

240V

High Speed #1

27Filter Pump Installations

Hot Line #1

Common

Low Speed #2

Figure 4-7. Wiring Circuits #1 & #2 to a 240 VAC 2-Speed Pump for PE653RC.

Page 28

MultiWave Control System Installation Guide

28

2-Speed Pump Terminal/Circuit Connections for PE653RC with

P5043ME

Solar/Air

Temperature

Sensor

Water

Temperature

Sensor

Freeze/Air

Temperature

Sensor

1 2 3 4 5

120V

240V

123 4 5 6 7 8 9

Circuit

1

Circuit 2Circuit

Antenna

Extender

(CAT5)

Pentair VSP and/or SCG

AND Expansion Module

Circuit 4Circuit

5

3

Other VSP

(CAT5)

Heater #1

Comm Cable

to Receiver

Act 2

Act 1

Act 3

Act 4

Heater #2

Remote

Switch

Power In

120or240 VAC

L1 120

VACWire

L2

Figure 4-8. PE653 Receiver Connections. Figure 4-9. P5043ME Expansion Module Hookups.

PE653 Receiver

Terminals 1, 2, 5 and 8 – Power In

Terminals 3 and 4, Circuits 1 and 2 – 240 VAC

2-Speed Pump*

Terminal 6, Circuit 3 – 240 VAC Booster (Cleaner)

Pump*

Terminal 7, Circuit 4 – 240 VAC Blower*

Terminal 9, Circuit 5 – 120 VAC Light with GFCI

* To break both lines, use relay kit PE21RLY.

Request document 158--01559.

Power In

240 VAC

P5043ME Expansion Module

Power In

NOTE: Expansion module hookups are shown on

page 21, page 37 and page 39.

www.intermatic.com

Page 29

Neutral Bus

29Filter Pump Installations

Receiver

Power

Supply

120V

240V

2-Pole Breaker

Hot Line #2

High Speed #1

Hot Line #1

Common

Low Speed #2

Figure 4-10. Wiring Circuits #1 & #2 to a 240 VAC 2-Speed Pump for PE653RC and P5043ME.

Page 30

MultiWave Control System Installation Guide

30

Variable Speed Pumps

Connecting a Pentair Variable Speed Pump Communication Cable

to Receiver

If you have a Pentair Variable Speed Pump, follow this procedure to connect the variable speed

pump communication cable to the receiver. This enables the pump to communicate with the

receiver.

1. Make sure power is off at the receiver and variable speed pump.

2. Connect the twist-lock connector end of the communication cable to the variable speed

pump.

3. Connect the green wire from the unattached end of the communication cable to the

connector terminal next to the Cat 5 cable. See Figure 4-11.

NOTE: Be sure to observe polarity when connecting the variable speed pump cable wires.

4. Connect the yellow wire from the cable to the connector terminal next to the green wire. See

Figure 4-11.

Cat 5

Cable

Cable

Connection

Green

Yellow

3

2

1

4 5

120V

240V

1 2 3 4 5 6

Polarity

Pump Communication Cable

Green

7

4 5

8 9

1 2 3

Yellow

Wire to panel – see

Pump Instructions

Jacketed Cable with Twist-Lock

Connector supplied by pump

manufacturer.

Figure 4-11. Connecting variable speed pump wiring.

www.intermatic.com

Page 31

External Variable Speed Pump Hookup

Other variable speed pumps compatible with the MultiWave receiver include Jandy®, Hayward®,

Marathon®, Century® and Speck®.

NOTE: A CAT5-568B network cable is required to route between the P5043ME Expansion

Module and the variable speed pump.

1. Insert the network cable into the Motor Control Input as shown in Figure 5-4.

2. Cut off the second RJ45 connector from the other end of the cable and strip each connector

wire.

3. Refer to the applicable gure for the variable speed pump manufacturer (Figure 4-12 to

Figure 4-15) to connect the wires to the expansion module.

31Filter Pump Installations

Page 32

MultiWave Control System Installation Guide

32

Set Number 1

Dip Switch to

On Position

ON

1 2 3

4 5

RS485

+12V A B

COM

Step 1

Step 2

Step 3

CAT5-568B Cable

Blue

Green

Orange

Motor

Control

Input

White/Green, White/Orange, White/Blue, White/Brown

Figure 4-12. Connecting the Century® Variable Speed Pump to the P5043ME.

Hayward EcoStar

®

Variable Speed Pump Connector

A B C D E F

G

H

PWR OUT

OVRD

Brown

ICOM

Figure 4-13. Connecting the Hayward EcoStar® Variable Speed Pump to the P5043ME.

CAT5-568B Cable

Motor

Control

Input

www.intermatic.com

INPUTS

NP1 NP2 NP3 NP4 12/24 VAC

Blue

Orange

Green

Brown

OUTPUTS

White/Green, White/Orange, White/Blue, White/Brown

Page 33

Motor

Control

Input

BLACK

YELLOW

GREEN

4 3 2 1

RS485

RED

5 4 3

Brown

COMMON

INPUT 4

INPUT 3

INPUT 2

INPUT 1

2 1

Blue

Green

Orange

33Filter Pump Installations

Remote

Control

Back of Pump

Controller

CAT5-568B Cable

Figure 4-14. Connecting the Jandy

CAT5-568B Cable

Motor

Control

Input

White/Green, White/Orange, White/Blue, White/Brown

®

Variable Speed Pump to the P5043ME.

Orange

Blue

Green

White/

Brown

Brown

White/Green

White/Blue

White/Orange

Green

Blue

White

Brown

Black

Red

Marathon/Speck

6-Conductor Cable

Low Voltage Remote Cable

Figure 4-15. Connecting the Marathon® or Speck® Variable Speed Pump to the P5043ME.

Page 34

MultiWave Control System Installation Guide

34

Chapter 5:

Basic Wiring — 240V Cleaner/Lights/Actuators

Cleaner

Receiver

Power

Supply

Neutral Bus

2-Pole Breaker

120V

240V

Hot Line #1

240 VAC

Cleaner Pump

Hot Line #2

Figure 5-1. Wiring Circuit #3 to a 240 VAC Cleaner Pump for PE653RC.

Hot Line #1

www.intermatic.com

Page 35

Lights

Neutral Bus

Neutral

Hot Line #1

120V

240V

Receiver

Power

Supply

Neutral

35 Basic Wiring — 240V Cleaner/Lights/Actuators

Hot Line #1

120 VAC GFCI

or

12 VAC Safety Transformer

Lights

Load Side of GFCI

or

Safety Transformer

Figure 5-2. Wiring Circuit #4 to a 120 VAC Light with GFCI for PE653RC.

Page 36

MultiWave Control System Installation Guide

36

Neutral Bus

Neutral

Hot Line #1

Receiver

Power

Supply

120V

240V

Neutral

Lights

Load Side of GFCI

or

Safety Transformer

Hot Line #1

Figure 5-3. Wiring Circuit #5 to a 120 VAC Light with GFCI for PE653RC and P5043ME.

120 VAC GFCI

or

12 VAC Safety Transformer

www.intermatic.com

Page 37

Pool/Spa Actuators

Power

Supply

120V

240V

1 2 3 4 5 6 7 8 9

1 2 3 4 5

Actuator for

pool/spa combo #1

ACT 1 ACT 2

ACT 3 ACT 4

Heater

#1

HEATER 1

Motor

Control

Input

HEATER 2 REMOTE SW

Heater

#2

37 Basic Wiring — 240V Cleaner/Lights/Actuators

OFF

Turn

12

Past

2

8

6

HOURS

Actuator for

pool/spa combo #2

Actuator for

Water Feature

Actuator for

Solar Feature

240 VAC

50/60 Hz

LINE 1 BLACK

LINE 2 RED

Figure 5-4. Connecting Equipment to P5043ME.

Page 38

MultiWave Control System Installation Guide

38

Chapter 6:

Heaters

1 Heater on PE653

Neutral Bus

2-Pole Breakers

120V

240V

Receiver

Power

Supply

Hot Line #1

Hot Line #2

Figure 6-1. Wiring Circuit #5 to a 240 VAC Heater for PE653RC.

240 VAC

HEATER

Low Voltage External Thermostat

or

Fireman’s Switch Connection

NOTE: Low Voltage Divider

provided must be installed for

Heater circuit.

www.intermatic.com

Page 39

1 or 2 Heaters on P5043ME

Power

Supply

120V

240V

1 2 3 4 5 6 7 8 9

1 2 3 4 5

Actuator for

pool/spa combo #1

ACT 1 ACT 2

ACT 3 ACT 4

Heater

#1

HEATER 1

Motor

Control

Input

HEATER 2 REMOTE SW

Heater

#2

39 Heaters

OFF

Turn

12

Past

2

8

6

HOURS

Actuator for

pool/spa combo #2

Actuator for

Water Feature

Actuator for

Solar Feature

240 VAC

50/60 Hz

LINE 1 BLACK

LINE 2 RED

Figure 6-2. Connecting Heaters to P5043ME.

Page 40

MultiWave Control System Installation Guide

40

Heater Connection

The Multiwave is designed as an external 2-wire heater controller for most heaters or heat

pumps. Locate the applicable instructions for connecting the heater to external control for your

heater pump manufacturer on the following pages. If you do not nd information regarding your

specic brand, refer to the heater manufacturer’s instructions.

Connection for Jandy® Heaters

1. Remove power.

2. Connect two #14 gauge wires minimum, with an insulation rating of 105°C, to terminals 8

and 9 on the PE653 (or to the Heater #1 or Heater #2 hookup when using P5043ME) and

route them through the low voltage knockout.

3. Make sure that the low voltage divider is

securely installed.

4. Locate the Fireman’s Switch terminal in the

control section of the heater.

5. Remove the factory-installed jumper wire.

6. Connect the other ends of the #14 gauge

To Limit

Switches

FactoryInstalled

Wire

To Limit

Switches

Low Voltage

Leads to PE653

(or P5043ME)

wires from Step 1 to the Fireman’s Switch

terminal bar in place of the factory-installed

wire loop.

7. Do not disconnect heater’s high limit or

Fusible Link Fusible Link

Heater Wiring

Before Modification

Heater Wiring

Modified for PE653

(or P5043ME)

pressure switches.

8. Turn heater thermostat(s) to maximum

Figure 6-3. Typical wiring connections for Jandy Heaters.

setting.

9. Turn the heater switch to the ON position. Refer to the heater manufacturer instructions for

programming the heater to be operated by an external control.

10. Re-apply power.

NOTE: For dual thermostat heaters, turn switch to Spa position.

www.intermatic.com

Page 41

Connection for Raypak® Heaters

1. Remove power.

2. Connect two #14 gauge wires minimum, with an

insulation rating of 105°C, to terminals 8 and 9

on the PE653 (or to the Heater #1 or Heater #2

hookup when using P5043ME).

3. Route the wires through the low voltage knockout

in the PE653 (or P5043ME) enclosure.

41 Heaters

Wires from PE653

(or P5043ME)

4. Make sure that the Low Voltage Divider is in

place.

5. Connect the orange/black wire and the black/

orange wire to the wire from terminal 8 on the

PE653 (or from the hookup on the P5043ME).

6. Connect the yellow/black wire to the wire from

terminal 9 on the PE653 (or from the hookup on

the P5043ME). See Figure 6-4.

7. Re-apply power.

Connection for Hayward® Heaters

1. Remove power.

2. Connect two #14 gauge wires minimum, with

an insulation rating of 105°C, to

9 on the PE653 (or to the Heater #1 or Heater #2

hookup when using P5043ME).

3. Route the wires through the low voltage

knockout in the PE653 (or P5043ME) enclosure.

4. Make sure that the Low Voltage Divider is in

place.

terminals 8 and

P7

Terminal

Figure 6-4. Typical wiring connections for Raypak Heaters.

Limit Switch Limit Switch

BL

OFF ON

FactoryInstalled

Wire Nut

Pressure Switch

Limit Switch Limit Switch

5. Remove the heater service door.

6. Remove factory-installed wire nut between two

red wires labeled “CONNECTION FOR FIELD

INSTALLED CONTROL SWITCH.”

7. Wire nut the two heater wires from receiver (or

expansion module) to the two red wires of the

heater. See Figure 6-5.

8. Do not disconnect heater’s high limit or pressure

switches.

9. Set the thermostat selector switch to ON, HIGH, or SPA.

10. Set the heater thermostat(s) to maximum.

11. Replace service door.

12. Re-apply power.

PE653

Wires to

(or P5043ME)

Pressure Switch

Figure 6-5. Typical wiring connections for

Hayward

®

Heaters.

OFF ON

Page 42

MultiWave Control System Installation Guide

42

Connection for Pentair® Heaters

1. Remove power.

2. Connect two #14 gauge wires minimum, with an insulation rating of 105°C, to terminals 8

and 9 on the PE653 (or to the Heater #1 or

Heater #2 hookup when using P5043ME).

3. Route the wires through the low voltage

knockout in the PE653 enclosure.

4. Make sure that the Low Voltage Divider is in

place.

5. Remove the heater service door.

6. Separate the black wires (common) from

each other.

7. Connect the wires from receiver (or

expansion module) to the two black wires on

the heater. See Figure 6-6.

8. Do not disconnect heater’s high limit or

pressure switches.

9. Turn the heater toggle switch on, and the

heater thermostat(s) to max.

10. When connecting an Intermatic Control

System to a Pentair Heater, Pentair requires

that you install the low voltage thermostat

wires in a conduit separate from ANY line

voltage wires.

VIO

BLK

BLK

RED

VIO

BLK

Wires from PE653

BLK

RED

Figure 6-6. Typical wiring connections for Pentair Heaters.

(or P5043ME)

11. Replace service door.

12. Re-apply power.

www.intermatic.com

Page 43

Connection for Sta-Rite/Pentair® Heater with DDTC

1. Remove power.

2. Connect two #14 gauge wires minimum, with an

insulation rating of 105°C, to

terminals 8 and 9

the PE653 (or to the Heater #1 or Heater #2 hookup

when using P5043ME).

3. Route the wires through the low voltage knockout

in the PE653 (or P5043ME) enclosure.

4. Make sure that the Low Voltage Divider is in place.

5. Remove the heater service door.

6. Locate the DDTC circuit board. Refer to the

manufacturer’s instructions for location.

7. Connect the wire lead from PE653 terminal 8 (or

P5043ME hookup) to the “COM” terminal on the

DDTC board.

8. Connect the wire lead from PE653 terminal 9 (or

P5043ME hookup) to the “POOL” terminal on the

DDTC board.

9. Replace service door.

on

Figure 6-7. DDTC Control Board.

43 Heaters

Wires from

Receiver (or

Expansion

Module)

10. Re-apply power.

11. With the “POWER” and “PRESSURE” lights lit on the front panel, depress the remote button

on the front display panel of the DDTC. The “REMOTE” light will come on and the remote

system now has control.

Page 44

MultiWave Control System Installation Guide

44

Chapter 7:

Blower/Chlorinator/Sensors

PE653RC with Blower

Neutral Bus

2-Pole Breaker

120V

240V

Receiver

Power

Supply

Hot Line #2

Hot Line

240 VAC

Blower

Hot Line #1

Figure 7-1. Wiring Circuit #2 to a 240 VAC Blower for PE653RC.

#2

www.intermatic.com

Page 45

PE653RC with Cleaner Pump or Blower

120V

Neutral Bus

2-Pole Breaker

Hot Line #2

Hot Line #1

240V

45Blower/Chlorinator/Sensors

Receiver

Power

Supply

240 VAC

Cleaner Pump

or Blower

(if 2-SPD is

wired)

Hot Line #1

Figure 7-2. Wiring Circuit #3 to a 240 VAC Cleaner Pump or Blower for PE653RC.

Page 46

MultiWave Control System Installation Guide

46

PE653RC and P5043ME with Blower

Neutral Bus

2-Pole Breaker

Hot Line #1

Receiver

Power

Supply

120V

240V

240 VAC

Blower

Hot Line #2

Hot Line #1

Figure 7-3. Wiring Circuit #4 to a 240 VAC Blower for PE653RC and P5043ME.

www.intermatic.com

Page 47

Chlorinator

Connecting AutoPilot Salt Chlorine Generator Control Cable to

Receiver

Contact your local AutoPilot dealer to verify your chlorine generator has been updated for this

feature. Follow this procedure to connect the generator control cable to the receiver. This enables

the generator to communicate with the receiver.

NOTE: The chlorine generator connects to the same terminals as the Pentair Variable Speed Pump

(or P5043ME Expansion Module communication cable). All three elements can be installed in the

terminals.

1. Make sure power is off at the receiver and salt chlorine generator.

2. Connect the twist lock connector end of the communication cable to the proper terminals on

the salt chlorine generator.

3. Connect the green wire from the unattached end of the communication cable to the

connector terminal next to the Cat 5 cable. See Figure 7-4.

NOTE: Be sure to observe polarity when connecting the salt chlorine generator wires.

4. Connect the yellow wire from the cable to the connector terminal next to the green wire. See

Figure 7-4.

47Blower/Chlorinator/Sensors

Cat 5 Cable

Green

Yellow

3

2

1

4 5

120V

240V

1 2 3 4 5 6

Cable Connection Polarity

Pump or Expansion Module

Communication Cable

Green

7

4 5

8 9

1 2 3

Yellow

Salt Chlorine Generator

Figure 7-4. Connecting AutoPilot Salt Chlorine Generator wiring.

Jacketed Cable with

Twist-Lock Connector

supplied by pump

manufacturer.

Page 48

MultiWave Control System Installation Guide

48

Sensors

Installing the Water Temperature Sensor

1. Make sure power is disconnected to the receiver.

2. Find a location to install the water temperature

sensor. The sensor must be installed after the lter

and before the input for the heater.

3. Drill a 3/8 inch hole in the pipe between the

lter pump and the lter.

4. Install the water temperature sensor probe into the

hole in the pipe and secure with a hose clamp. Make

sure the probe o-ring is in place.

5. Run the sensor wires to the receiver and insert both

wires into the middle terminals on the 6-pin terminal

block at the top of the receiver.

See Figure 7-5.

Installing the Freeze (Air Temperature)

Sensor

1. Make sure power is disconnected to the receiver.

2. Install the sensor onto a piece of conduit.

NOTE: Be sure to mount the sensor in a location that

enables it to accurately measure the air temperature.

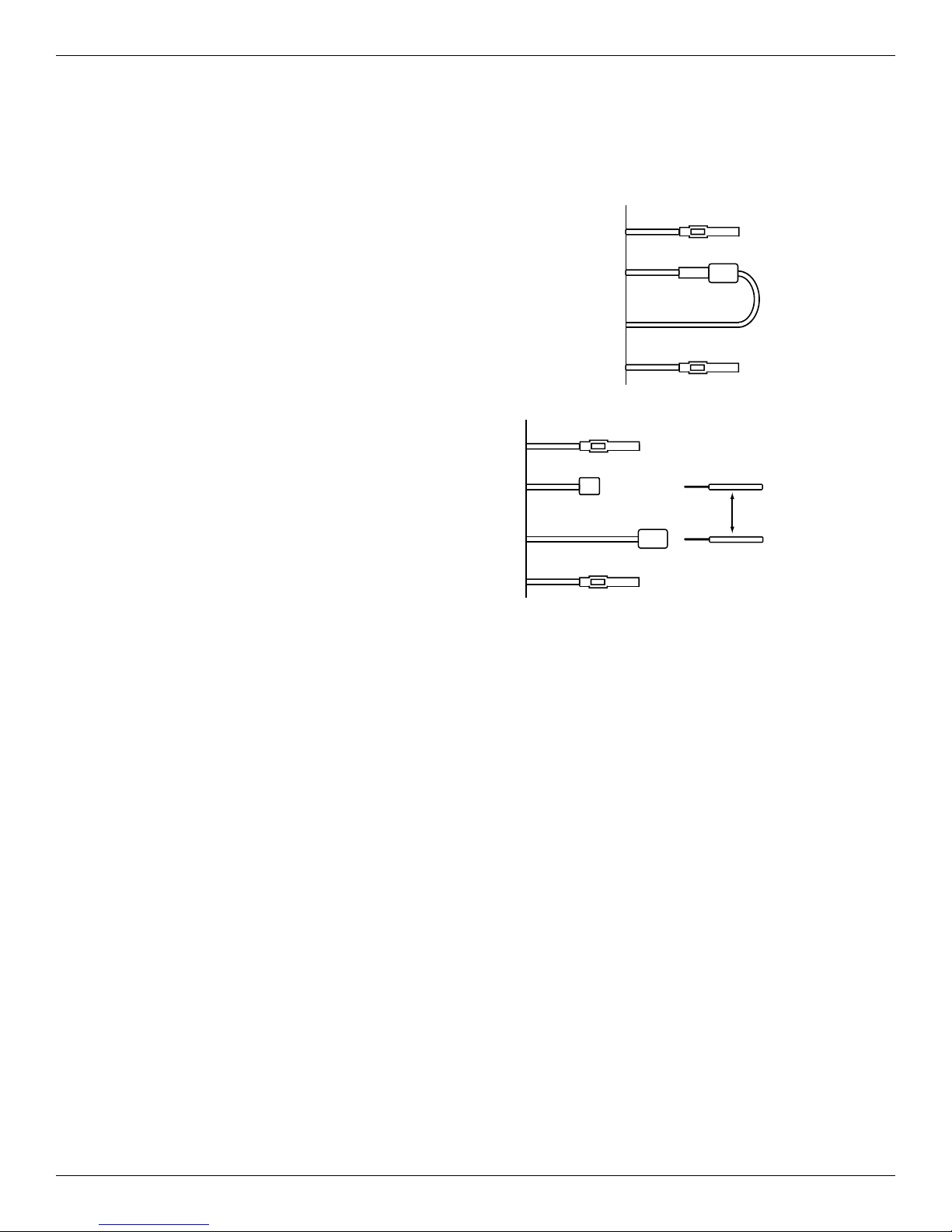

Middle

Terminals on

6-pin Terminal

block

Figure 7-5. Connecting water temperature

Freeze

(AirTemperature)

Sensor Cable

Water

Temperature

Sensor Cable

1 2 3 4 5

sensor cable wiring.

Water

Temperature

Sensor Cable

3. Run the sensor cable to the receiver.

4. Cut the connector off the cable with a wire cutter.

5. Strip the ends of the exposed cable wires and then

insert the wires into the terminals to the

left of the water temperature sensor wires.

See Figure 7-6.

NOTE: You do not have to observe polarity when

connecting the cable wires.

Installing the Solar (Air Temperature) Sensor

1. Make sure power is disconnected to the receiver.

2. Install the sensor onto a piece of conduit.

NOTE: Be sure to mount the sensor in a location that

enables it to accurately measure the air temperature

near the solar collector.

3. Run the sensor cable to the receiver.

4. Cut the connector off the cable with a wire cutter.

5. Strip the ends of the exposed cable wires and then

insert the wires into the terminals to the

right of the water temperature sensor wires.

See Figure 7-7.

NOTE: You do not have to observe polarity when

connecting the cable wires.

1 2 3 4 5

Figure 7-6. Connecting freeze (air temperature)

Water

Temperature

Sensor Cable

Figure 7-7. Connecting solar (air temperature)

sensor cable wiring.

Solar

(AirTemperature)

Sensor Cable

1 2 3 4 5

sensor cable wiring.

www.intermatic.com

Page 49

MultiWave Pool & Spa Control System

Worksheet for Programming

Solar/Air

Temperature

Sensor

Water

Temperature

Sensor

Freeze/Air

Temperature

Sensor

1 2 3 4 5

120V

240V

123 4 5 6 7 8 9

Circuit

1

Circuit 2Circuit

Antenna

Extender

(CAT5)

Pentair VSP and/or SCG

OR Expansion Module

Circuit 4Circuit

3

5

Act 2

Act 1

Act 3

Act 4

Heater #1

Other VSP

(CAT5)

Heater #2

Remote

Switch

Power In

120or240 VAC

L1 120

VACWire

L2

PE653 Receiver P5043ME Expansion Module

NOTE: For circuit options, see Chapters 4 through 6.

Put a dash in the circuits that are not used.

Circuit 1 _______________________________________

Circuit 2 _______________________________________

Circuit 3 _______________________________________

Circuit 4 _______________________________________

Circuit 5 _______________________________________

SYSTEM COMPONENTS:

¸ Freeze (Air Temperature) Sensor

¸ Water Temperature Sensor

¸ Solar (Air Temperature) Sensor

¸ Antenna Extender

¸ Pentair Variable Speed Pump (VSP)

¸ AutoPilot Salt Chlorine Generator (SCG)

Power In

240 VAC

NOTE: If this system does not include P5043ME,

draw an “X” through the entire second column.

¸ P5043ME Expansion Module

¸ Water Feature (Act 3)

¸ Heater #1

¸ Heater #2

¸ Solar Temperature System (Act 4)

¸ Remote Switch

¸ Other Variable Speed Pump (VSP)

¸ FREEZE OPTION IS DESIRED.

¸ OTHER Z-WAVE DEVICES ARE USED.

Page 50

Loading...

Loading...