Page 1

26 I-Wave Installation Guide

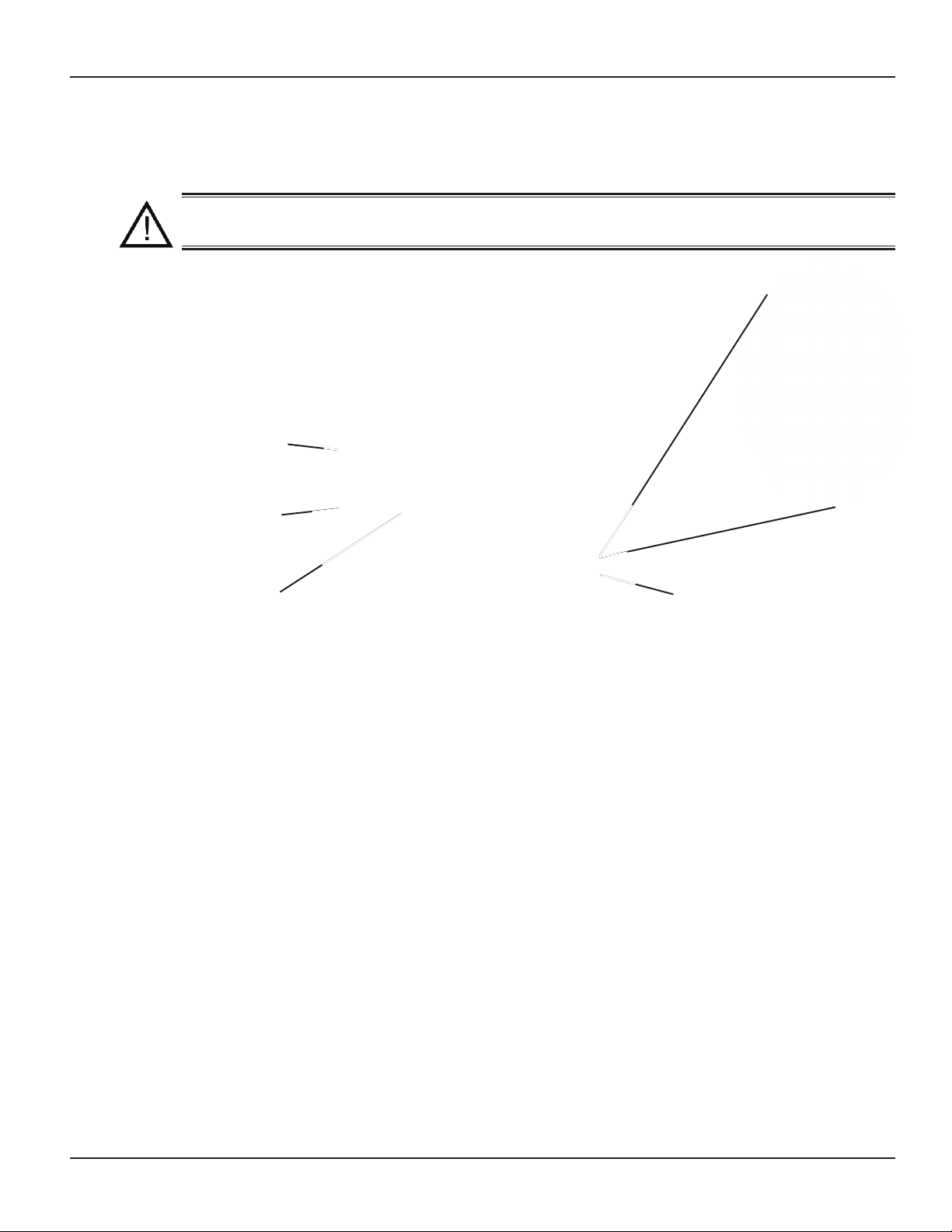

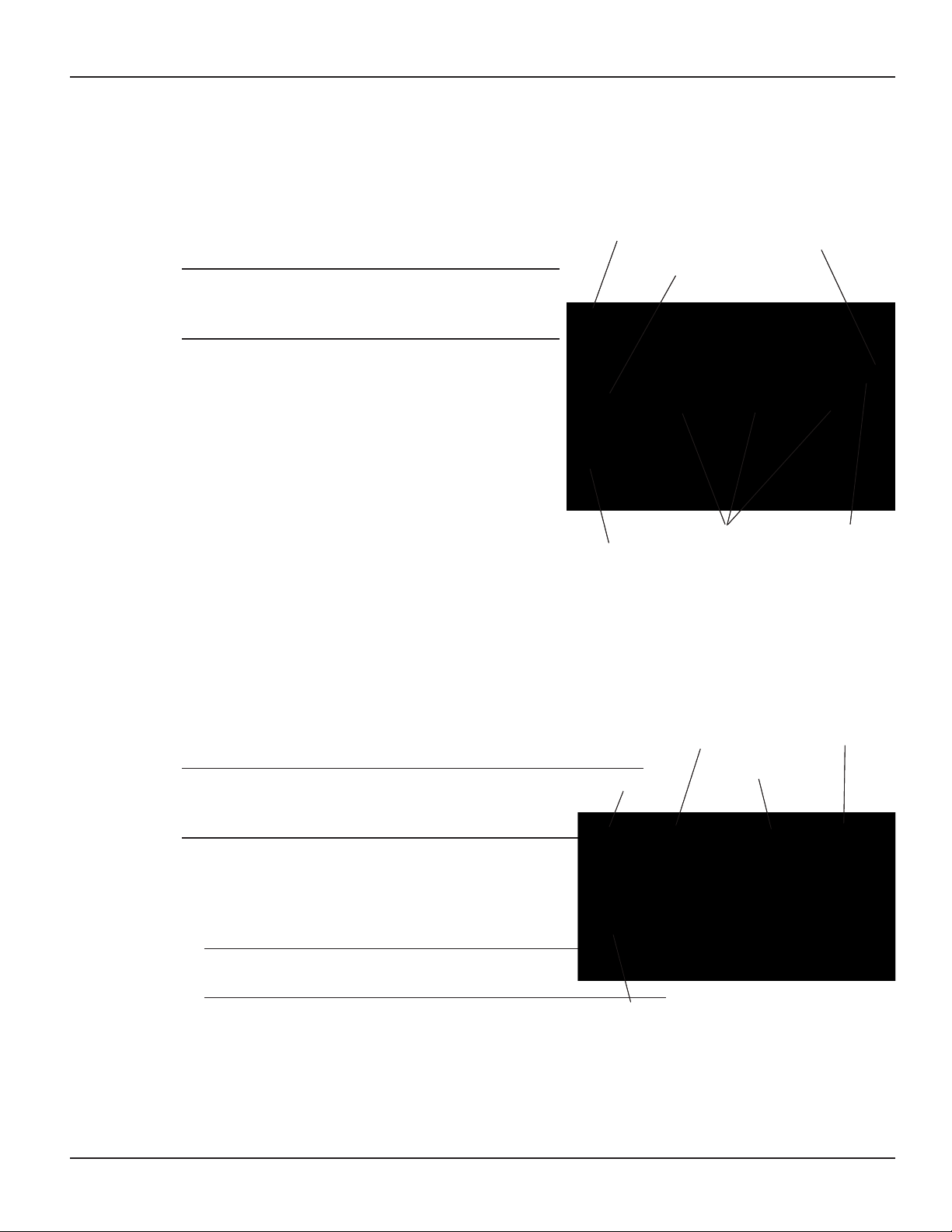

Identifying Connections and Selecting Proper Input Voltage

Figure 4-2 below shows the reverse side of the Three-Circuit Clock Control Panel. Detailed

connection information is provided below the diagram.

CAUTION: If the Source Voltage Selector Jumper is in the wrong position, the F1

fuse will blow and you may damage the circuit board, voiding the warranty.

Before making any connections: Set the Source Voltage Selector Jumper.

1.

The factory default position for this jumper is the 240 Volt position.

If the input voltage for the clock is 120 Volts, change this jumper to the

2.

120 Volt position.

Heater Fireman Switch

Connection

Freeze Probe

Connection

Wired or Wireless

Remote Control

Connection

Figure 4-2

Source Voltage

Selection Jumper

Connection Detail

Freeze Probe Connection — For the Intermatic Freeze Sensor (178PA0001A), which is

•

necessary for the freeze protection circuit and programming to work. Disconnect power when

connecting the freeze sensor. Only an Intermatic sensor can be used. Refer to page 34 for

programming information.

Heater Firemen Switch Connection — For the remen switch wires that connect to the Pool/

•

Spa heater. If installing with a Wireless Remote Control, use the two brown wires coming

from the panel-mounted antenna to create the circuit between this switch and the heater.

Connectors should be ¼” female spade connectors crimped to insulated-type wire. This

connection is a simple SPST contact, and switches the supplied heater voltage. It does not

supply voltage to the heater thermostat. In non-wireless installations, clip the “loop” supplied,

then connect with wire nut connectors. Refer to page 33 for programming information.

Remote Control Connection — For the Intermatic Remote Control (133PE1484A), which

•

allows you to remotely turn On or Off all three available circuits. It also has status lights that

indicate when a load is On, Off or delayed. If using the Three-Button Wired Remote Control

(133PE1484A), it connects here as well.

Copyright © 2006 Intermatic, Inc.

Page 2

Circuit Ratings

CLOCK SOURCE VOLTAGE — 120/240VAC, 50/60 Hz.

POWER CONSUMPTION — 6.0 Watts Max.

CIRCUIT CONTACT CONFIGURATION — SPST

CIRCUIT SWITCH RATINGS ALL MODES:

20A Resistive, 120/240 VAC., 50/60 Hz

•

20A FLA@120 VAC, 96A LRA@120 VAC, 50/60 Hz

•

17A FLA@240 VAC, 80A LRA@240 VAC, 50/60 Hz

•

5 Amps Tungsten, 120/240 VAC, 50/60 Hz

•

5 Amps Ballast, 120/240 VAC, 50/60 Hz

•

EVENTS PER CIRCUIT — 3 On/Off Events Per Circuit

INTERNAL BATTERY POWER

40 Year retention for all programmed settings

•

Up to 24-hours

•

Four: Programming the Three-Circult Clock Mechanism 27

Mode Selection/Definition

IMPORTANT NOTE—There are ve modes to choose from, depending on your

pool or spa equipment pad conguration. Each mode has specic programming,

timing, and lockout features that are designed to work with specic types of pool

or spa equipment. Mode setting is generally done only once and usually during the

initial installation. It is purposely difcult to enter the mode-changing program

and should only be done by a Qualied Installer. Be sure you fully understand each

mode denitions and installation, prior to selecting the proper mode.

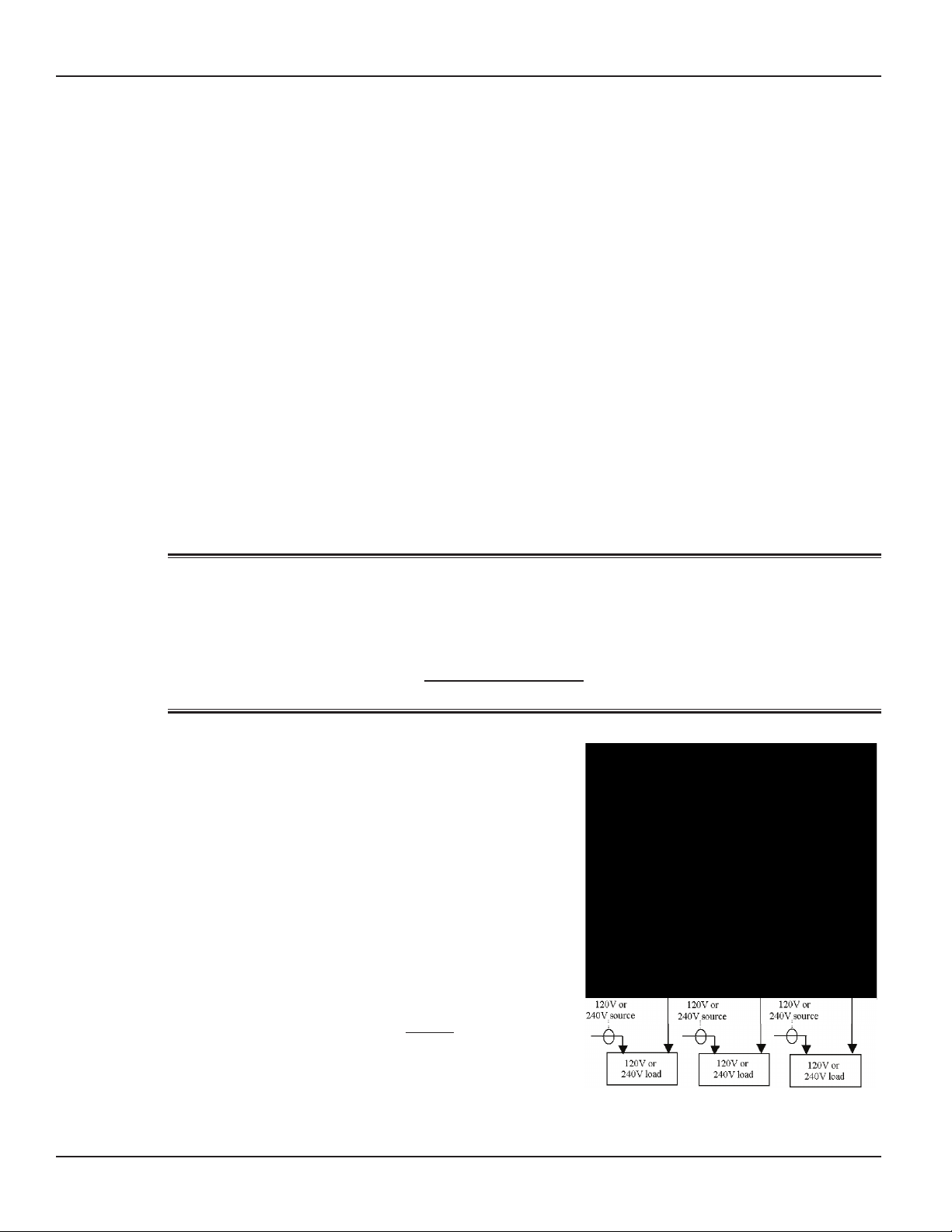

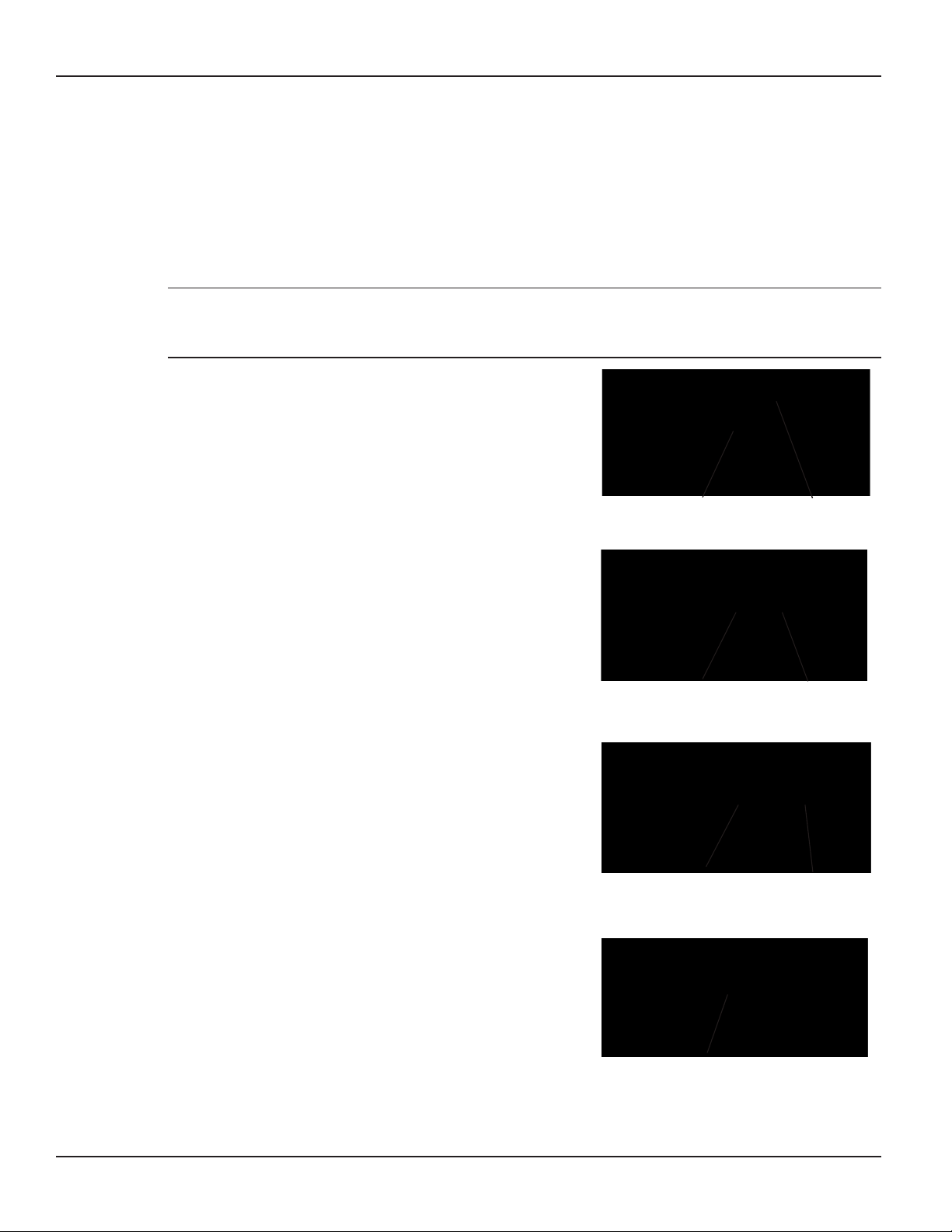

Mode 1 — (Aux1, Aux2, Aux3)

Each of the three single pole circuits are dened

generically, and can control any load within each

of its individual circuit ratings. All three circuits act

independent of each other.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Providing a brighter solution.™

Figure 4-3Figure 4-3

Page 3

28 I-Wave Installation Guide

Mode 2 — (Pump High, Pump Low, Aux3)

Circuit one and two are dedicated single pole

outputs for a two-speed pump load. Circuits one and

two will never be ON at the same time, consistent

with a two-speed pump application. Circuit

three is single pole circuit for a generic load, and

independent of circuits one and two..

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

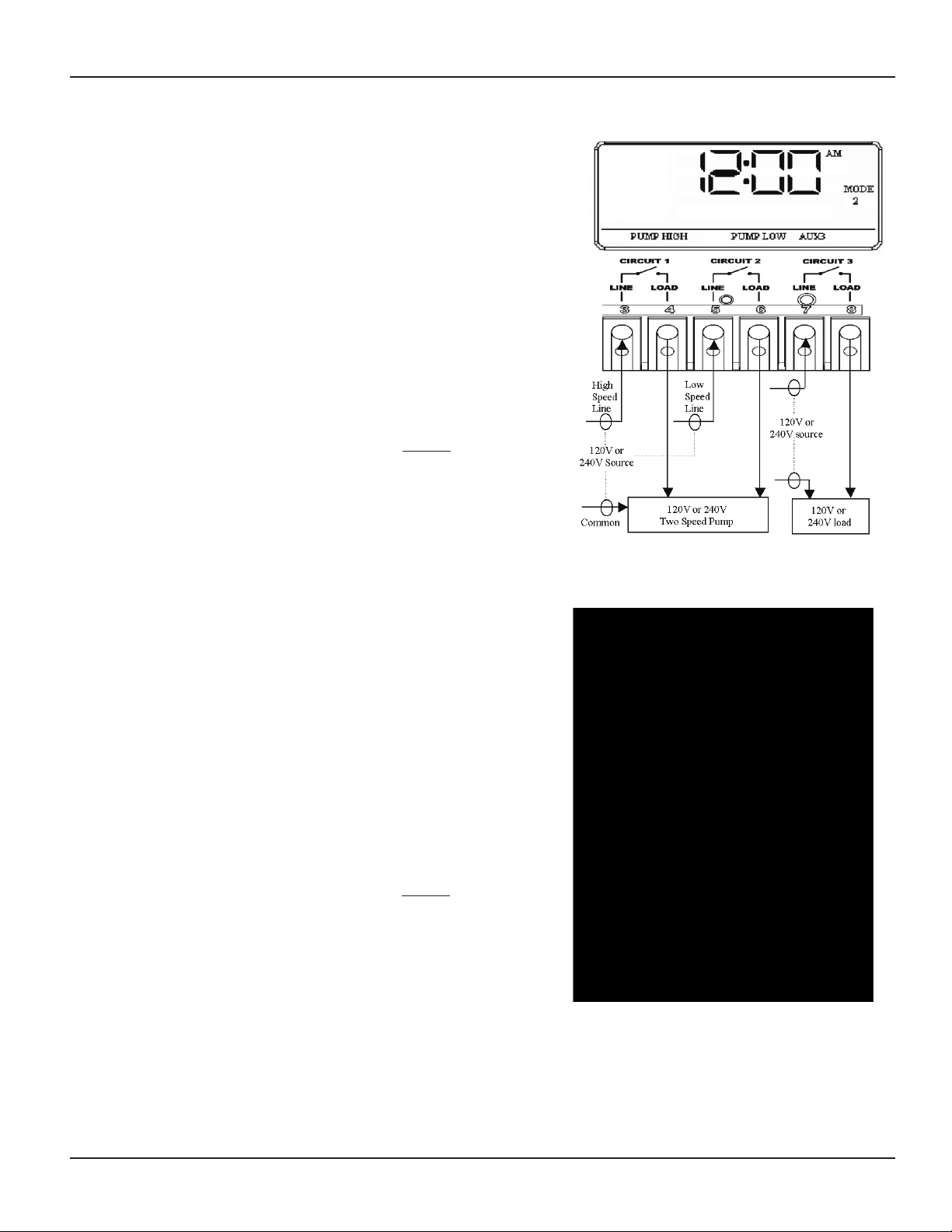

Mode 3 — (Pump, Aux2, Cleaner Pump)

Circuit one and three are dedicated single pole

outputs for a single speed pump working with a

pressure side cleaner pump. Circuit three will never

come on unless circuit one is on for at least one

minute, consistent with a pressure side cleaner

pump. Circuit two is a single pole circuit for a

generic load, independent of circuits one and three..

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Figure 4-4Figure 4-4

Copyright © 2006 Intermatic, Inc.

Figure 4-5Figure 4-5

Page 4

Four: Programming the Three-Circult Clock Mechanism 29

Mode 4 — (Pump High, Pump Low, Cleaner Pump)

Circuit one and two are dedicated single pole

outputs for a two-speed pump load. Circuits one and

two will never be ON at the same time, consistent

with a two-speed pump application. Circuit three

is also a dedicated single pole output for a pressure

side cleaner pump. Circuit three will never come

on unless circuit one is on for at least one minute,

consistent with a pressure side cleaner pump.

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Figure 4-6Figure 4-6

Mode 5 — (Pump, Pump, Aux3)

Circuit one and two are now coupled together

making up one circuit capable of switching the

power source to one pump. The On/Off button for

circuit one now controls both circuit one and two

simultaneously. The On/Off button for circuit two is

disabled. Circuit three remains a single pole circuit

for a generic load, and is independent of circuits one

and two..

NOTE: This drawing illustrates

NOTE: This drawing illustrates

that only one leg is broken, with

that only one leg is broken, with

the other leg going directly to

the other leg going directly to

load, whether 120V or 240V.

load, whether 120V or 240V.

Providing a brighter solution.™

Figure 4-7Figure 4-7

Page 5

30 I-Wave Installation Guide

<Mode> button

<ENTER> button

“SET MODE”

<Arrow>

buttons

Circuit outputs will

be defined

Mode

Number

blinks

<Mode> button

<ENTER> button

“SET MODE”

<Arrow>

buttons

Circuit outputs will

be defined

Mode

Number

blinks

<PROGRAM>

button

Program Menu

Displayed Time

<Arrow>

buttons

AM/PM Indicator

<PROGRAM>

button

Program Menu

Displayed Time

<Arrow>

buttons

AM/PM Indicator

Setting Mode

Overview

Determine the mode that would be best for your installation, then select it using the instructions

provided below.

Procedure

NOTE: If you don’t press a button within 60 seconds

while setting Mode, the control will save current

settings and return to normal operating mode.

With a small pointed tool (i.e., pen, pencil,

1.

screwdriver, etc.,), press and hold the <MODE>

button for about 5 seconds until the display

shows SET MODE and the Mode Number

blinks.

Use the <Arrow> buttons to cycle through all

2.

ve available modes. Each circuit output will

be dened on the display as you cycle through

the available modes.

Setting Time of Day

Once the desired mode number is displayed,

3.

press and release the <ENTER> button. This

saves the mode number to memory and exits SET MODE programming.

Overview

This procedure makes sure that timer-controlled actions will occur at the right time.

Procedure

NOTE: If you don’t press a button within 60 seconds

while setting Time of Day, the control will save

current settings and return to normal operating mode.

Press and release the <PROGRAM> button. The

1.

displayed time will start to blink, and the program

menu will display Set Clock.

Use the <Arrow> buttons to change the time.

2.

NOTE: Check the AM and PM indicator to make

sure your setting is correct.

When the time is set, you have two choices:

3.

•

•

Press and release the <ENTER> button to save and exit programming.

Press and release the <PROGRAM> button to save and go on to the next programming

feature.

Copyright © 2006 Intermatic, Inc.

Page 6

Four: Programming the Three-Circult Clock Mechanism 31

NO EVENT 1 Not definedNO EVENT 1 Not defined

First Event

(EVENT1)

Start Time

First Event

(EVENT1)

Start Time

Stop Time

First Event

(EVENT1)

Stop Time

First Event

(EVENT1)

NO EVENT 2NO EVENT 2

Setting the On/Off Times for Each Circuit

Overview

You can set up to three separate ON/OFF times per load or circuit, and you can set specic times

for them to turn on and off, i.e., you want the lter pump to run from noon till 4:00 P.M., or you

want lights on from 7:00 P.M., off at 11:00 P.M., then on again at 6:00 A.M. and off at 8:00 A.M.

Procedure

PROGRAMMING TIP: You can use the <ENTER> button to review all the events for each circuit.

You can use the <PROGRAM> button to advance through each circuit and on to the next

programming feature.

If you pressed and released the program key from the

1.

previous procedure, the screen display should look

like the illustration at the right. [If not, press and

release the <PROGRAM> button twice.]

Note that the display indicates that the rst event of

circuit one has not been dened (NO EVENT1).

Use the <Arrow> buttons to dene the Start time for

2.

the rst event (EVENT1) for circuit one. The screen

displays:

Once you are satised with the start time, press and

3.

release the <ENTER> button, saving the start time. The

display will prompt for the Stop time for the rst event

(EVENT1) for circuit one. The screen displays:

Use the <Arrow> buttons to dene the Stop time

4.

for the rst event (EVENT1) for circuit one. Press

and release the <ENTER> button when complete.

The program will now advance to the second event

(EVENT2) for circuit one, as shown below. Note that

the display indicates that the second event of circuit

one has not been dened (NO EVENT2).

Repeat Steps 2 thru 4 to set a second event for circuit

5.

#1, and for subsequent events you wish to set up.

Providing a brighter solution.™

Page 7

32 I-Wave Installation Guide

Notes on Setting On/Off Times for Each Mode

General Note

The ON/OFF buttons were provided for service operations, and for circumstances where

•

instantaneous response is required. If the intent is to turn equipment on and off everyday at

the same time, programming individual events will make sure these functions take place.

All circuits will respond to a programmed off time. Therefore, when a circuit is turned on with

•

the ON/OFF button, it automatically turns itself off at the end of the next programmed event.

If there are no events programmed, the circuit stays on until the ON/OFF button is pressed

•

again.

If the ON/OFF button is pressed while the corresponding circuit is on, it turns the circuit

•

off and supersedes any program in progress. The priority is always given to the last manual

operation.

Mode 1 — (Aux1, Aux2, Aux3)

All three of the available circuits act independently, and up to three individual on/off times can

be set for each circuit independently.

Mode 2 — (Pump High, Pump Low, Aux 3)

In this mode circuits 1 & 2 are connect to a two speed pump, and Aux 3 is connected

independent of circuits 1 & 2. In the event that you program high and low speed to be on at the

same time or if their independent ON times overlap, high speed will always take precedence.

Example: Low speed is programmed to come ON at noon and run until 6 PM. High speed is

programmed to come on at 2 PM and turn off at 4 PM. In this case the pump will come ON

at noon in low speed, go to high speed at 2 PM, and back to low speed at 4 PM, and shut off

at 6 PM.

All manual ON operations for circuits 1 & 2 override all programmed ON times. Therefore, any

desired low and high-speed run combinations need to be programmed as separate events and

cannot controlled by combining the manual ON/OFF button with a scheduled event. The last

speed started manually has priority over all prior automatic and manual operations.

Example: You would like to run the pump in high speed for 6 hours and low speed for the

remainder of the time. Program a 6-hour event for high speed, and an 18-hour event for low

speed. Do not turn the low speed on manually, and program a 6-hour event for high speed.

The high speed will not occur.

Mode 3 — (Filter Pump, Aux2, Cleaner Pump)

The cleaner pump cannot turn on unless the lter pump has been on for at least 30 seconds.

Therefore, for any ON/OFF time programmed for the cleaner pump, the lter pump will come on

rst, followed 30 seconds later by the cleaner pump. Both the cleaner and lter pump will turn

off according to the programmed off time. When programming an event for the cleaner pump, it

is not necessary to program a separate event for the lter pump, as it will automatically turn on

when the cleaner pump turns on at its next scheduled on time.

Copyright © 2006 Intermatic, Inc.

Page 8

Four: Programming the Three-Circult Clock Mechanism 33

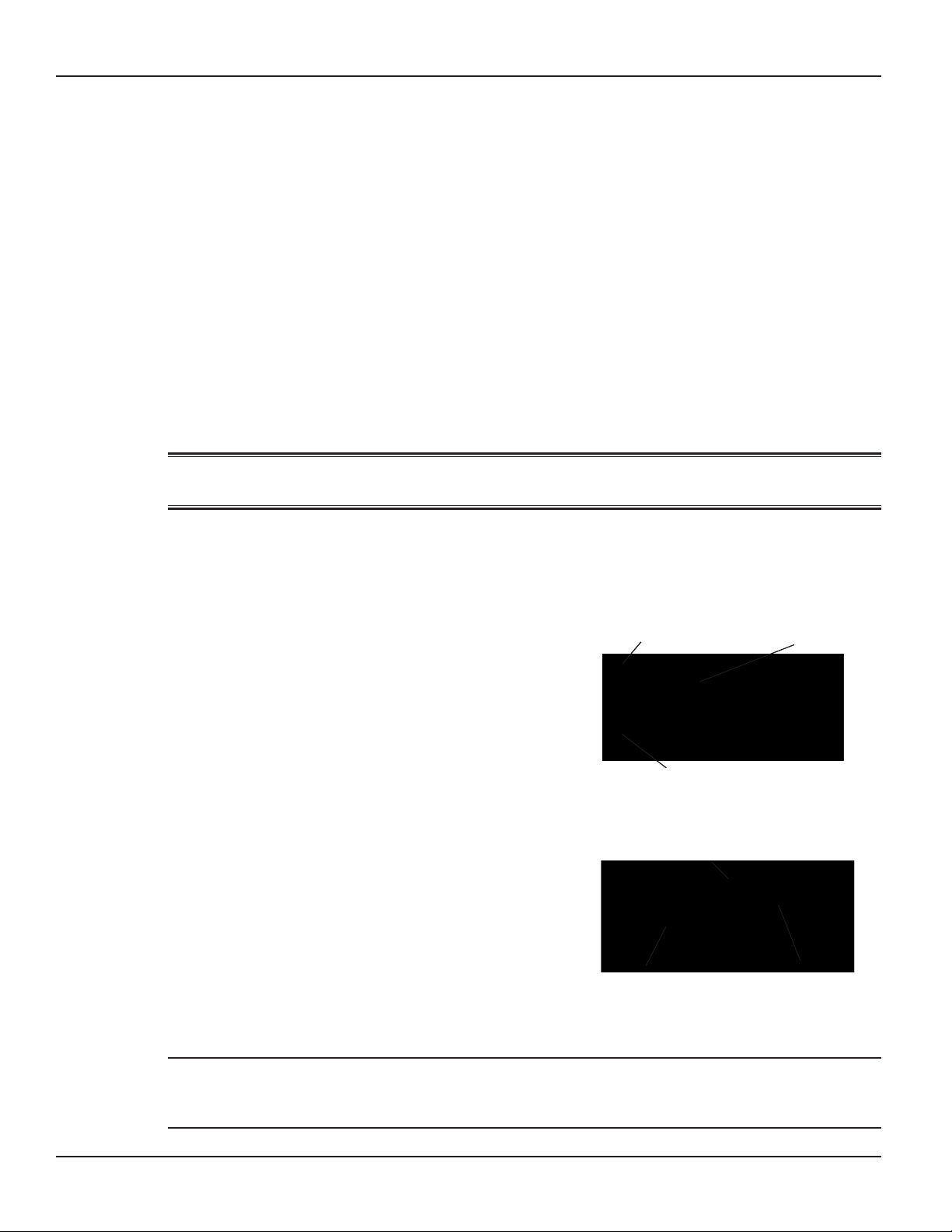

COOL DOWN

<PROGRAM> button

<ARROW> buttons

COOL DOWN

<PROGRAM> button

<ARROW> buttons

Counting Down

Minutes and Seconds

AUX1 Indicator

Blinking

Counting Down

Minutes and Seconds

AUX1 Indicator

Blinking

Mode 4 – (Pump High, Pump Low, Cleaner Pump)

Mode 4 is a combination of Modes 2 and 3, so refer above to Modes 2 and 3 for programming

specics. Note that if the cleaner pump is programmed to come ON, the control will turn ON

the lter pump to high speed 30 seconds prior to turning the cleaner pump ON, even if the lter

pump is currently on in low speed.

Mode 5 – (Aux1, Aux3)

Both of the available circuits act independently, similar to Mode 1. Therefore you can set up to

three individual ON/OFF times for each circuit and they will act independently.

Setting the Heater’s Cool Down Time (optional)

Overview

The heater’s cool down time is a time dened by the programmer. This time is dened as the

additional time the pump will run, over and beyond the desired pump OFF time, to make sure

the heater is cooled down before shutting off.

If the heater were to stay on after the pump had shut off, the water in the pipe

could boil, damaging the system. Refer to heater manufacturer for specic time.

If a cool down time is programmed, the cool down cycle will occur in all cases, even if the user

turns off the pump. To override the cool down time, press and release the ON/OFF key a second

time during the cool down cycle. The cool down feature only applies to Circuit #1, in all modes.

Procedure

Use the <PROGRAM> button to advance to the COOL

1.

DOWN setting, as shown. The default cool down time

is zero.

Use the <ARROW> buttons to modify the cool down

2.

time. The programming range is from zero to fteen

minutes and no seconds.

When you’ve set the cool down time, press the

3.

<ENTER> button to save and exit, or the <PROGRAM>

button to save and advance to the next programming feature.

The display will look like the example shown at the right

when the Heater’s Cool Down Time feature is activated. In

this example, the cool down time was set for 5 minutes,

and is in the process of counting down to zero, showing

minutes and seconds.

The AUX1 indicator is blinking, indicating that the Cool

Down feature is activated for Circuit #1. The Cool Down

feature only affects Circuit #1. When the countdown

display reaches zero, Circuit #1 will open and the time

display will change back to the time of day.

NOTE: You can override the Cool Down feature during countdown by pressing and releasing the

ON/OFF button associated with Circuit #1. This will end the cool down cycle and immediately

power off Circuit #1.

Providing a brighter solution.™

Page 9

34 I-Wave Installation Guide

32°F

Freeze Temp

1st Circuit

32°F

Freeze Temp

1st Circuit

Aux #1 and #3

Freeze

Aux #1 and #3

Freeze

Setting Freeze Temperature (optional)

Overview

Freeze temperature programming will not appear unless the optional Intermatic Freeze Sensor

(178PA28A) has been installed. This is the only freeze sensor that will work with the P1353ME

Controller.

Power must be disconnected when connecting the 178PA28A sensor.

If Intermatic Freeze Sensor (178PA28A) has been installed, use the following procedure to

program freeze temperature.

Procedure

Use the <PROGRAM> button to advance to the

1.

Freeze Temp setting, as shown. The 1st Circuit and

32°F are the factory default settings.

Use the <ARROW> buttons to modify the desired

2.

freeze temperature trip point. The programming range

is 32° through 44° F.

After you have set the desired trip temperature, push

3.

and release the desired ON/OFF button to indicate

which circuits should come ON when the trip temperature is reached.

When programming is complete, , press the <ENTER> button to save and exit, or the

4.

<PROGRAM> button to save and advance to the next programming feature.

The display will look like the example shown at the

right when the Freeze Control feature is activated. In

this example, the freeze sensor was connected, enabling

the Freeze Control feature. Circuits #1 and #3 were

programmed to come on during a Freeze condition.

AUX1 and AUX3 will blink, indicating that the control

has activated these two circuits due to a freeze condition.

NOTE: You can override the circuits during a freeze condition by pressing and releasing the

corresponding ON/OFF buttons. This will turn the devices OFF. The override will only last one

hour, so if the freeze condition still exists after one hour, Circuits #1 and #3 will come back on.

NOTE: Freeze protection stays enabled until the outside air temperature exceeds the

programmed freeze temperature for more than one minute.

Copyright © 2006 Intermatic, Inc.

Page 10

Five: Programming the Valve/Pump Switch Mechanism 35

Section 5:

Programming the Valve/Pump Switch

Mechanism

Overview of the Valve/Pump Switch Control Panel

Front View

HEATER THERMOSTAT CONNECTOR — supports the three

ACTUATOR CONNECTION —

The Pump/Valve Switch

mechanism supports up to

three 24V valve actuators.

SERVICE BUTTONS —

allow you to operate the

mechanism at the panel.

wires from the heaters thermostat. The wires should be

marked Pool, Common, and Spa. The mechanism will

switch the thermostat when the actuators change.

WIRED OR WIRELESS

CONNECTOR will support

either the wired spa side

remote or the panel-mounted

wireless transceiver.

POOL/SPA

THERMOSTAT SWITCH

— allows you to switch

between the pool and

spa thermostat or just

the spa only. In the spa

only mode, the pool

thermostat is disabled.

DUAL-VOLTAGE TRANSFORMER

— is capable of being powered

with either 120V or 240V.

CIRCUITS 1 & 2 — The pool to spa mechanism

supports up to two auxiliary 3HP circuit loads. You

can have different source voltages for each circuit,

depending on your equipment requirements.

JUMPER BLOCK

CONFIGURATION — used

when a simple single-pole

single through switch

is going to be used in

conjunction with the Sensor

Line to control the Pool to

Spa Mech. This is the most

inexpensive way to achieve

total pool/spa automation.

SENSOR LINE — allows the

mechanism to be controlled by

a single pole sing throw switch

(i.e. toggle switch, relay, wall

switch, etc.). See page xxx for

details.

Providing a brighter solution.™

Page 11

36 I-Wave Installation Guide

24VAC POWER-IN FOR PC

BOARD — The circuit board

for the Pump/Valve Switch

requires 24VAC power

from the transformer.

OMRON CONNECTIONS

— Each of the two Omron

relays connects to the PC

board at these points.

SENSOR LINE PLUG IN — The pool to spa mechanism

supports up to two auxiliary 3HP circuit loads. You

can have different source voltages for each circuit,

depending on your equipment requirements. The sensor line

allows the mechanism to be controlled by a single-pole

single throw switch. (i.e., a toggle switch, relay, wall switch, etc.)

POOL/SPA SWITCH CONNECTION — located on the face of the Pump/

Valve Switch mechanism connects to the PC board at this point, and

allows you to switch between the pool and spa thermostat or just the

spa only. In the spa only mode, the pool thermostat is disabled.

EXTERNAL TIMER PLUG IN —

into the PC board at this point

to control relay #1. Please see

page xx for instructions on

using an external timer.

OMRON RELAY #2 — This

relay can switch either

120V or 240V loads.

Can be ordered separately

(145T145A)

CONTROL FACE PLUG IN — a

control pad for service. The

control pad connects to the

PC board at this point.

OMRON RELAY #1 — This

relay can switch either

120V or 240V loads. Can

be ordered separately (145T145A)

24VAC POWER-IN FOR PC

BOARD — The circuit board

for the Pump/Valve Switch

requires 24VAC power

from the transformer.

OMRON CONNECTIONS

— Each of the two Omron

relays connects to the PC

board at these points.

SENSOR LINE PLUG IN — The pool to spa mechanism

supports up to two auxiliary 3HP circuit loads. You

can have different source voltages for each circuit,

depending on your equipment requirements. The sensor line

allows the mechanism to be controlled by a single-pole

single throw switch. (i.e., a toggle switch, relay, wall switch, etc.)

POOL/SPA SWITCH CONNECTION — located on the face of the Pump/

Valve Switch mechanism connects to the PC board at this point, and

allows you to switch between the pool and spa thermostat or just the

spa only. In the spa only mode, the pool thermostat is disabled.

EXTERNAL TIMER PLUG IN —

into the PC board at this point

to control relay #1. Please see

page xx for instructions on

using an external timer.

OMRON RELAY #2 — This

relay can switch either

120V or 240V loads.

Can be ordered separately

(145T145A)

CONTROL FACE PLUG IN — a

control pad for service. The

control pad connects to the

PC board at this point.

OMRON RELAY #1 — This

relay can switch either

120V or 240V loads. Can

be ordered separately (145T145A)

Rear View

Copyright © 2006 Intermatic, Inc.

Page 12

Five: Programming the Valve/Pump Switch Mechanism 37

Installing the Three-Button Wired Remote Control

The Three-Button Wired Remote Control (133PE1484A) can be installed to

plug into either the Three-Circuit Clock (PE1353ME) or Valve/Pump Switch

(PE4243ME).

When plugged into one of these mechanisms, it replaces the wireless method

of controlling the three circuits within the mechanism. For example, if you plug

the Three-Button Wired Remote Control into the Valve/Pump Switch, the two

relays and the pool/spa control will no longer be controllable using the HandHeld Wireless Remote. The Three-Button Wired Remote Control must be installed where a third

mechanism is needed in the enclosure box, since the Wireless Hand-Held Remote. can only

control two mechanisms.

See illustrations below for connection detail.

Connection to

Connection to

Valve/Pump Switch

Valve/Pump Switch

(PE4243ME)

(PE4243ME)

Three-Button Wired

Three-Button Wired

Remoe Control

Remoe Control

(133PE1484A)

(133PE1484A)

Connection to

Connection to

Three-Circuit Clock

Three-Circuit Clock

(PE1353ME)

(PE1353ME)

Installing Other Wired Remote Connections (Master Switch)

You can install any ON/OFF switch to the sensor line to provide wired control of the two relays

and the Pool/Spa actuators in the Valve/Pump Switch (PE4243ME), giving you dual control

(master switch and wireless) control of these circuits.

In use, a wired remote switch toggles all circuits to their opposite state. This means that if

Relays 1 and 2 are ON, and the actuator valve is in SPA, the wired remote switch will turn

Relays 1 and 2 OFF, while switching the actuator valve to POOL. It does this by toggling

Relays 1 and 2 and the actuator valve back and forth from their default state in order to return

the system to its default setting after the owner has made temporary changes to the settings.

For example, if using the phone while sitting in the spa, the owner may turn off the jets to

reduce noise. The next time the Master Switch is used, the jets will revert to being ON when

the system is in spa mode.

INSTALLATION ISSUE: If you want to change the default state for your installation and you

manually press the switches on the Valve/Pump Switch control panel, your changes will be

temporary with the wired remote switch (master switch) because it will return the circuits to their

factory default setting when it is activated, eliminating your custom settings.

Therefore, if you want to make permanent changes to the factory

defaults, you must use the jumper, as shown at the right. Then the

wired remote switch’s return to defaults will not delete your changes.

Putting the jumper on pins 1 and 2 sets the system default state

•

to OPEN = OFF. This is the factory default state.

Putting the jumper on pins 2 and 3 sets the system default state

•

to CLOSED = ON.

Providing a brighter solution.™

Page 13

38 I-Wave Installation Guide

Connecting the Heater Switch to Control Temperatures

Overview

The primary means of controlling the heater is using the Hand-Held Controller. If there is no

Hand-Held Controller in the system, the heater switch provides an alternate method.

This Switch can be also used in conjunction with the Hand-Held Controller to provide maximum

temperature limits for the pool and spa. Control by this Switch is primary over the Hand-Held.

Procedure

Wire the heater thermostats to the blue connectors visible

1.

on the front of the Valve/Pump Switch, as shown.

Set limits on the heaters themselves, so that when

2.

the Switch powers the heaters, they will reach the

temperatures you have set.

Make temperature adjustments at the heaters themselves.

3.

If Connecting an External Timer:

Overview

You can add an external timer to a circuit, converting it from

“on-demand” control to timer control. External timers are

available from Intermatic but are not included with the IWave system. When connected to the system, the external

timer powers Relay 1 on and off according to its time

settings.

Procedure

Connect your timer to Relay 1 on the back of the Valve/

Pump Switch Mechanism, as shown in the circled area of

the illustration at the right.

Copyright © 2006 Intermatic, Inc.

Page 14

Six: Programming the Hand-Held Transmitter 39

Actuator

Button

(Pool/Spa)

(not currently

functional)

Display Screen

ON/OFF

Function

Buttons

Up/Down

Arrow Buttons

Actuator

Button

(Pool/Spa)

(not currently

functional)

Display Screen

ON/OFF

Function

Buttons

Up/Down

Arrow Buttons

1 2 3 4 5

STAT

OK

POOL SPA

73

ºF SET

P 73

S 85

When you see

these numbers, it means

that circuit is ON

“POOL” or “SPA”

tells which mode

the system is in

“OK” means

Hand-Held

is communicating

with panel-mounted

transceiver

Current Temp

of the Pool or Spa,

depending on

whichever mode

the system is in

Temp settings

for pool (P)

or spa (S)

1 2 3 4 5

STAT

OK

POOL SPA

73

ºF SET

P 73

S 85

When you see

these numbers, it means

that circuit is ON

“POOL” or “SPA”

tells which mode

the system is in

“OK” means

Hand-Held

is communicating

with panel-mounted

transceiver

Current Temp

of the Pool or Spa,

depending on

whichever mode

the system is in

Temp settings

for pool (P)

or spa (S)

STAT

POOL

OO

ºF SET

P OO

S OO

STAT

POOL

OO

ºF SET

P OO

S OO

Section 6:

Programming the Hand-Held Remote

Transceiver

Overview

The Hand-Held Remote Tranceiver (PE950) is the focal point of user convenience. It’s waterresistant, shock-resistant, and is easy to program for handy remote control of the functions at a

specic pool-spa installation. An assortment of self-stick labels are provided to identify the

functions you program into the ve control buttons. We suggest that you program the device rst,

then apply the appropriate label from the assortment supplied.

Synchronizing the Hand-Held with the Receiver

When you’ve nished physical installation and wiring and have enabled power to the control

center, you need to synchronize the Hand-Held with the Panel-Mounted Transceiver. This is a

two step process: rst, delete any programming that might exist in the Hand-Held Remote and

Receiver, then synchronize the two devices with each other.

Deleting Any Existing Programming

This procedure deletes any existing programming from the Remote and Receiver units so they are

ready to be programmed into the network of this installation.

NOTE: If the word FAILURE instead of SUCCESS appears at the bottom of the screen during any of

the following steps, repeat the programming procedure, then try replacing the batteries in the

Hand-Held. If the problem persists, contact Intermatic Customer Service.

1.

Press any button on the Hand-Held Remote to wake it from sleep.

(The unit goes to sleep to conserve battery life when it has been idle

for 30 seconds.) The screen display on the Hand-Held looks like the

example on the right.

Detail on Hand-Held Remote Display ScreenDetail on Hand-Held Remote Display Screen

Providing a brighter solution.™

Page 15

40 I-Wave Installation Guide

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

4 RESET CONTROLLER

LEARN VER x

4 RESET CONTROLLER

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

3 RESET NODE

LEARN VER x

3 RESET NODE

STAT

POOL

OO

ºF SET

P OO

S OO

STAT

POOL

OO

ºF SET

P OO

S OO

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

LEARN VER x

1 INCLUDE NODE

Press and hold the <P/S> and <CHLR> buttons at the same time for

2.

about 5 seconds. This will put the device in programming mode, as

shown at the right.

Press the <4> function button to select

3.

RESET CONTROLLER. The screen

refreshes and displays only the line 4

RESET CONTROLLER, then returns to the

full screen with the word SUCCESS at the

bottom, as shown..

Now press the <3> function button on the Hand-Held Remote to

4.

select RESET NODE. The screen refreshes and displays only the line

3 RESET NODE.

Press the black button on the base of the Panel-Mounted Transceiver.

5.

The display returns to the full screen with the word SUCCESS at the

bottom, as shown.

The two devices are now “clean” and are ready to be linked together

within the network you have installed.

Linking the Hand-Held Remote to the Receiver

If necessary, press any button on the Hand-Held Remote to wake it

1.

from sleep. (The unit goes to sleep to conserve battery life when it

has been idle for 30 seconds.) The screen display on the Hand-Held

looks like the example on the right.

Press and hold the <P/S> and <CHLR> buttons at the same time for

2.

about 5 seconds. This will put the device in programming mode, as

shown at the right.

Press the <1> function button to select INCLUDE NODE. The screen

3.

refreshes and displays only the line 1 INCLUDE NODE, as shown.

Copyright © 2006 Intermatic, Inc.

Page 16

Six: Programming the Hand-Held Transmitter 41

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

2 ADD TO GROUP

LEARN VER x

2 ADD TO GROUP

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

STAT

OK

POOL

OO

ºF SET

P OO

S OO

STAT

OK

POOL

OO

ºF SET

P OO

S OO

Push the black button on the base of the Panel-Mounted Transceiver.

4.

The screen returns to the full screen with the word SUCCESS at the

bottom, as shown.

Press the <2> function button to select ADD TO GROUP. The screen

5.

refreshes and displays only the line 2 ADD TO GROUP.

Push the black button on the base of the Panel-Mounted Transceiver.

6.

The screen returns to the full screen with the word SUCCESS at the

bottom, as shown.

Press the <CHLR> button on the Hand-Held Remote to exit

7.

programming mode. On the left side of the screen, you will see the

words STAT OK.

The two devices are now linked together within the network you have

installed.

NOTE: If the two devices have not successfully reset or linked together — and you are seeing only

the word STAT on the left side of the screen — it’s likely that old programming still exists in either

device. Carefully repeat the two procedures above. If the problem persists, contact Intermatic

Customer Service.

Testing I-Wave Reception

At the heart of the I-Wave system is Z-wave™ wireless technology, which makes it easy to add

makes use of Transceiver Repeater Modules (HA04C) to ensure that no

problems in reception occur. Signal reception between Hand-Held

Controllers and the Control Center is affected by distance (about 100 feet,

direct line of sight) and by physical obstacles (like brick walls or

structures). However, by plugging in repeaters where necessary, it’s no

problem to span distances or overcome obstacles.

Test reception by walking around the yard with the Hand-Held Remote

and look on he screen to see if there are any areas where STAT OK

changes to STAT (which means the Hand-Held and the Control Center

are no longer communicating). If you identify any location where you are

out of range, you need to install and congure a repeater between the

location and the Control Center.

Transceiver Repeater Module

Transceiver Repeater Module

(HA04C)

(HA04C)

Providing a brighter solution.™

Page 17

42 I-Wave Installation Guide

STAT

OK

POOL

72

ºF SET

P 72

S 85

STAT

OK

POOL

72

ºF SET

P 72

S 85

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

LEARN VER x

1 INCLUDE NODE

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

2 ADD TO GROUP

LEARN VER x

2 ADD TO GROUP

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

Installing and Configuring Repeaters When Necessary

Plug a Transceiver Repeater Module (HA04C) into any electrical outlet that is located where

1.

you have determined a reception problem can be solved.

If necessary, press any button on the Hand-Held Remote to wake it

2.

from sleep. Because you are at a location in between the control

center and the problem area, the screen display on the Hand-Held

will look like the example on the right.

Press and hold the <P/S> and <CHLR> buttons at the same time for

3.

about 5 seconds. This will put the device in programming mode, as

shown at the right.

Press the <1> function button to select INCLUDE NODE. The screen

4.

refreshes and displays only the line 1 INCLUDE NODE, as shown.

Push the black button on the Repeater. The word SUCCESS appears

5.

at the bottom of the Hand-Held’s screen as shown.

Press the <2> function button on the Hand-Held to select ADD TO

6.

GROUP. The screen refreshes and displays only the line 2 ADD TO

GROUP.

Push the black button on the base of the Panel-Mounted Transceiver.

7.

The screen returns to the full screen with the word SUCCESS at the

bottom, as shown.

Press the <CHLR> button on the Hand-Held Remote to exit

8.

programming mode. When you now carry the Hand-Held Remote in

the problem area, you will now see the words STAT OK on the left

side of the screen.

The repeater is now part of the network. You can add more repeaters as necessary.

Copyright © 2006 Intermatic, Inc.

Page 18

Six: Programming the Hand-Held Transmitter 43

STAT

OK

POOL

72

ºF SET

P 72

S 85

STAT

OK

POOL

72

ºF SET

P 72

S 85

STAT

OK

SPA

85

ºF SET

P 72

S 85

STAT

OK

SPA

85

ºF SET

P 72

S 85

Everyday Use of the Hand-Held Controller

The complete everyday functionality of the pool/spa system you have installed can be

conveniently controlled using the Hand-Held Remote.

Changing between Pool and Spa

The Valve Actuator (PE24VA) that you have installed in the system directs water either to the

pool or the spa. To use the hand-Held Controller to control this valve:

Press any button on the Hand-Held Remote to wake it from sleep.

1.

(The unit goes to sleep to conserve battery life when it has been idle

for 30 seconds.) The screen display on the Hand-Held looks like the

example on the right.

Note on the Hand-Held Remote Screen the current mode for the

2.

system:

POOL on the left side of the screen indicates the pool temperature setting (shown in the

•

example).

SPA on the right side of the screen indicates the spa temperature setting.

•

Press the <P/S> button. The system will change to the opposite mode from its current setting.

:

3.

Note the change on the Hand-Held Remote Screen. In the example

4.

at the right, the mode is now changed to Spa, and the temperature

shown is the water temperature of the Spa.

NOTE: The large temperature display shown on the Hand-Held Remote

Screen reects the current water temperature of the Pool or Spa,

depending on which mode is active.

Setting Pool and Spa Temperatures

If connected and linked, the Hand-Held Remote controls the independent water temperatures of

both the pool and spa.

View the current temperature on the right side of the Hand-Held Remote Screen under the

1.

word SET.

P = current pool water set temperature

•

S = current spa water set temperature

•

Press the <P/S> button if necessary to change the system to Pool or Spa mode.

2.

Press the <UP> or <DOWN> arrow buttons to raise or lower the setting to the desired

3.

temperature. You can hold the button down and the value will automatically change.

Release the arrow button when the setting reaches the temperature you want. After a few

4.

seconds, the display returns to the current temperature of the pool or spa, depending on

which mode you select.

Providing a brighter solution.™

Page 19

44 I-Wave Installation Guide

STAT

OK

POOL

72

ºF SET

P 72

S 85

STAT

OK

POOL

72

ºF SET

P 72

S 85

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

Operating Programmed Functions

Depending on how you have wired the system, the ve function buttons on the Hand-Held

Remote control the ve circuits in the Control Center. You should apply the appropriate label to

the ve buttons — describing the appropriate equipment according to your installation — from

the assortment of labels supplied.

Buttons <1>, <2>, and <3> control circuits 1, 2, and 3 on the Three-Circuit Clock

•

Mechanism (P1353ME) that is installed on the left side of the Control Center.

Buttons <4> and <5> control Relay 1 and Relay 2 on the Valve/Pump Switch Control

•

(P4243ME) that is installed on the right side of the Control Center.

When you press any of these buttons, the appropriate circuit toggles ON or OFF. In addition,

when the circuit is ON, the Hand-Held Controller’s display shows the circuit number along the

top of the screen.

Advanced Features

Configuring Two or More Hand-Held Remote Controllers

Many installations will nd it convenient to use two Hand-Held Remote Controllers. Once you

have linked one Hand-Held to the Control Center, it’s easy to add a second controller to the

network.

Make sure the Hand-Held you are adding to the network has been reset, with any previous

1.

programming deleted.

Press any button on the Hand-Held Remote to wake it from sleep.

a.

(The unit goes to sleep to conserve battery life when it has been

idle for 30 seconds.)

Press and hold the <P/S> and <CHLR> buttons at the same time

b.

for about 5 seconds. This will put the device in programming

mode, as shown at the right.

Press the <4> function button to select RESET CONTROLLER. The

c.

device resets and the word SUCCESS appears at the bottom of the

screen.

On both Hand-Held units, press and hold the <P/S> and <CHLR>

2.

buttons at the same time for about 5 seconds to put them into

programming mode, as shown at the right.

Copyright © 2006 Intermatic, Inc.

Page 20

Six: Programming the Hand-Held Transmitter 45

LEARN VER x

1 MODE 3/4

2 READY FOR ADD

5 PREVIOUS OPTIONS

C EXIT

LEARN VER x

1 MODE 3/4

2 READY FOR ADD

5 PREVIOUS OPTIONS

C EXIT

LEARN VER x

2 READY FOR ADD

LEARN VER x

2 READY FOR ADD

LEARN VER x

1 MODE 3/4

2 READY FOR ADD

5 PREVIOUS OPTIONS

C EXIT

SUCCESS

LEARN VER x

1 MODE 3/4

2 READY FOR ADD

5 PREVIOUS OPTIONS

C EXIT

SUCCESS

STAT

OK

POOL

72

ºF SET

P 72

S 85

STAT

OK

POOL

72

ºF SET

P 72

S 85

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

LEARN VER x

1 INCLUDE NODE

2 ADD TO GROUP

3 RESET NODE

4 RESET CONTROLLER

5 MORE OPTIONS

C EXIT

On the Hand-Held you are adding to the network:

3.

Press the <5> button to select MORE OPTIONS. A new screen

a.

will appear, as shown at the right.

Press the <2> button on the new screen to select READY TO

b.

ADD. The screen refreshes and displays only the line 2 READY TO

ADD.

Promptly, on the Hand-Held that is already part of the network, press

4.

the <1> button to select INCLUDE NODE. After a few seconds, the

word SUCCESS should appear on the screens of both units.

Press the <CHLR> button on both Hand-Held Controllers to exit

5.

programming mode. The left side of the screen of both Controllers

will say STAT OK, indicating that the procedure has been successful.

NOTE: The rst Hand-Held you link to the Control Center is considered the PRIMARY controller

and all other units are SECONDARY. The PRIMARY controller must be used to “introduce” or

link any additional Hand-Held units to the Control Center.

Programming to Protect a Pool Cleaner Pump

When you installed and wired the system, you may have included a cleaner pump along with a

spa (Mode 3) or with a two-speed lter pump (Mode 4).

You will want to make sure this pump is never powered on when the system is in spa mode.

The system can accommodate these two scenarios.

Press any button on the Hand-Held Remote to wake it from sleep.

1.

(The unit goes to sleep to conserve battery life when it has been idle

for 30 seconds.)

Press and hold the <P/S> and <CHLR> buttons at the same time for

2.

about 5 seconds. This will put the device in programming mode, as

shown at the right.

Providing a brighter solution.™

Page 21

46 I-Wave Installation Guide

LEARN VER x

1 MODE 3/4

2 READY FOR ADD

5 PREVIOUS OPTIONS

C EXIT

LEARN VER x

1 MODE 3/4

2 READY FOR ADD

5 PREVIOUS OPTIONS

C EXIT

Press the <5> button to select MORE OPTIONS. A new screen will

3.

appear, as shown at the right.

Press the <1> button on the new screen to select MODE 3/4 ON.

4.

NOTE: This button toggles between ON and OFF.

That’s all there is to it. When Mode 3/4 is set to ON:

The system will automatically turn the cleaner pump OFF any time the spa mode is

•

activated, protecting the cleaner pump.

If the owner switches to pool mode or to the high-speed pump mode, the system waits

•

30 seconds before powering ON the cleaner pump, making sure there is adequate water in

the system.

Using Two Hand-Held Controllers to Operate the System

When two or more Hand-Held Controllers are being used to operate a system, each will

synchronize itself to the other according to whatever function the other controller has activated.

For example, if you press the <1> button on one controller, the following will happen:

Circuit 1 at the control center will toggle on or off, depending on its current state.

•

The number 1 will appear along the top of the Hand-Held Controller’s screen.

•

Then, a few seconds later, the number 1 will also appear along the top of the second

•

Hand-Held Controller’s screen.

The owner can add up to 5 Hand-Held Controllers to a system.

Manually Turning Equipment On and Off

At the Control Center

For service purposes, the ve circuits and the pool/spa actuators can be operated manually at the

Control Center.

Simply press any of the circuit buttons on either the Three-Circuit Clock or the Valve/Pump

Switch mechanisms to toggle between ON and OFF.

Any manual OFF/ON controlling will be reected on the screen of the Hand-Held Controller.

Copyright © 2006 Intermatic, Inc.

Page 22

Section 7:

Checking Out the System /

Troubleshooting

After you have completed installation and programming, make sure the system is working OK

by completing the checklist below. Later on, if problems develop in using the system, this same

checklist will help you troubleshoot the problem.

When you nish checking each item, place a check mark in the box at the right.

Seven: Checking Out System / Troubleshooting 47

What to check How to run the check

Time of Day Setting Verify that display on Three-Circuit Clock

Mechanism (P1353ME) is showing correct

time of day.

Press the rst ON/OFF button on the face of

Check circuits on the ThreeCircuit Clock Mechanism

(P1353ME)

Check circuits on the Valve/

Pump Switch Mechanism

(P4243ME)

Check that the Actuator

valves correct switch

between pool and spa.

Check that the actuator

valves are synchronized.

Verify that the Hand-Held

Remote is controlling pool

and spa temperature.

1.

the mechanism.

Verify that the Hand-Held Receiver shows

2.

that the circuit has powered on.

Verify that the wired function activates

3.

properly (e.g., a pump comes on).

Turn the circuit off using the appropriate

4.

button on the Hand-Held Remote.

Repeat with ON/OFF buttons two and three.

5.

Press the RELAY 1 button on the face of the

1.

mechanism.

Verify that the Hand-Held Receiver shows

2.

that the circuit has powered on.

Verify that the wired function activates (e.g.,

3.

a pump comes on).

Turn the circuit off using the appropriate

4.

button on the Hand-Held Remote.

Repeat with the RELAY 2 button.

5.

Press the VALVES button on the Valve/Pump

1.

Switch Mechanism (P4243ME).

Verify that the Hand-Held Receiver shows

2.

that the actuator valves have changed

position.

Verify that the actuator valves have correctly

3.

switched position.

Switch the valves back using the P/S button

4.

on the Hand-Held Remote.

As you watch them move back and forth, verify

that the valves are oriented the same way: to

pool, then to spa

TROUBLESHOOTING —

What to do if it doesn’t work

Follow instructions for setting the

1.

correct time on page 30 of this

manual.

Recheck that the set time is correct.

2.

If any of the circuits don’t work:

Check your wiring for the circuit.

1.

Make sure you have set the correct

2.

Mode for the installation. See page

27 of this manual.

If the Hand-Held Remote fails

3.

to turn off the circuit, check its

programming. See page 39 of this

manual.

If any of the circuits don’t work:

Check your wiring for the circuit.

1.

Make sure you have set the correct

2.

Mode for the installation. See page

27 of this manual.

If the Hand-Held Remote fails

3.

to turn off the circuit, check its

programming. See page 39 of this

manual.

If any of the valves don’t switch:

Check your wiring for the circuit.

1.

If the Hand-Held Remote fails

2.

to turn off the circuit, check its

programming. See page 39 of this

manual.

Re-synchronize the valves. See page 21

of this manual.

✔

Providing a brighter solution.™

Page 23

48 I-Wave Installation Guide

What to check How to run the check

Check that protection

for pool cleaner pump is

working.

Check wireless reception all

around the yard.

Check that the Fireman’s

Switch is working (if

installed).

Check that the Freeze Sensor

is working (if installed).

Check that the Three-Button

Wired Remote Control is

working (if installed)

Check that the External Timer

is working (if installed)

Mode 3 and 4

Press the ON/OFF button on the Three-

1.

Circuit Clock Mechanism (P1353ME) to

power OFF the pump.

Watch for the time display to count down

2.

the interval you have programmed.

Place the freeze sensor in a cup of ice.

1.

Wait for the temperature of the sensor to

2.

approaches that of the ice.

Verify that the heater has come on.

3.

Press each of the three buttons on the Wired

1.

Remote Control.

Verify that the functions controlled by those

2.

circuits activate properly.

TROUBLESHOOTING —

What to do if it doesn’t work

If any dead spots are located, install

Repeaters. See page 41 of this manual.

Re-program the Fireman’s Switch

timing. See page 33 of this manual.

Re-program the Freeze Sensor. See

page 34 of this manual.

If any of the circuits don’t work, check

your wiring for that circuit.

✔

Copyright © 2006 Intermatic, Inc.

Page 24

Section 7:

NEED ACTUAL ARTWORK — THIS IS JANDYNEED ACTUAL ARTWORK — THIS IS JANDY

Enclosure Specifications

Eight: Enclosure Specifications 49

Suitable listed breakers (purchase locally)

Suitable listed breakers (purchase locally)

CIRCULT BREAKER FILLER

CIRCULT BREAKER FILLER

MANUFACURER SINGLE DOUBLE TWIN QUAD GFCB

MANUFACURER SINGLE DOUBLE TWIN QUAD GFCB

Cutler-Hammer

Cutler-Hammer

Murray

Murray

Siemens

Siemens

Square-D

Square-D

Thomas & Betts

Thomas & Betts

BR

BR

MP-T

MP-T

QP

QP

HOM

HOM

TB

TB

BR

BR

MP-T

MP-T

QP

QP

HOM

HOM

TB

TB

Providing a brighter solution.™

BRD

BRD

MH-T

MH-T

QT

QT

HOMT

HOMT

TBBD

TBBD

BRD

BRD

MH-T

MH-T

QT

QT

HOMT

HOMT

TBBD

TBBD

BRD

BRD

MH-T

MH-T

QT

QT

HOMT

HOMT

TBBD

TBBD

PLATE

PLATE

BRFP

BRFP

LX100FP

LX100FP

QF3

QF3

HOMFP

HOMFP

FP-1C-TB

FP-1C-TB

Page 25

50 I-Wave Installation Guide

Section 9:

Warranty

ONE YEAR LIMITED WARRANTY

If, within one (1) year from the date of purchase, this product fails due to defect in material or workmanship, Intermatic Incorporated will repair

or replace it, as its sole option, free of charge. This warranty is extended to the original household purchaser only and is not transferable. This

warranty does not apply to: (a) damage to units caused by accident, dropping, or abuse in handling, acts of God, or any negligent use; (b) units

which have been subject to unauthorized repair, opened, taken apart, or otherwise modified; (c) units not used in accordance with instructions; (d)

damages exceeding the cost of the product; (e) sealed lamps and/or lamp bulbs, LEDs, and batteries; (f) the finish on any portion of the product,

such as surface and/or weatheriong, as this is considered normal wear and tear; (g) transit damage, initial installation costs, removal costs, or

reinstallation costs.

INTERMATIC INCORPORATED WILL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY

IS IN LIEU OF ALL OTHER EXPRESS OR IMPLIED WARRANTIES. ALL IMPLIED WARRANTIES, INCLUDING THE WARRANTY OF MERCHANTABILITY

AND THE WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY MODIFIED TO EXIST ONLY AS CONTAINED IN THIS LIMITED

WARRANTY, AMND SHALL BE OF THE SAME DURATION AS THE WARRANTY PERIOD STATE ABOVE. SOME STATES DO NOT ALLOW

LIMITATIONS ON THE DURATION OF AN IMPLIED WARRANTY, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

This warranty service is available by either (a) returning the product to the dealer from whom the unit was purchased, or (b) mailing the product,

along with proof of purchase, postage prepaid, to the authorized service center listed below. This warranty is made by: Intermatic Incorporated/

After Sales Service/7777 Winn Rd., Spring Grove, IL 60081-7000 <http://intermatic.com>. Please be sure to wrap the product securely to avoid

shipping damage.

Because of our commitment to continuing research and improvements, Intermatic Incorporated reserves the right to make changes, without notice,

in the specifications and material contained herein, and shall not be responsible for any damages, direct or consequential, caused by reliance on

the material presented.

WARRANTY REGISTRATION

Owner’s Name___________________________________ Signature_____________________________________________

Street Adddress_________________________________________ Date of Purchase ______________________________

City__________________________________ State ______ Zip ______________ Phone __________________________

Authorized Dealer _____________________________ Sales Rep ____________________________

City__________________________________ State _________ Zip ______________ Phone _______________________

How did you hear about our product? (Please check all that apply.)

___Pool Store Employee ___Pool Builder ___Pool Service ___Direct Mail Ad ___In-Store Display ___

Friend/Relative

___Magazine ___Newspaper ___Radio ___TV ___Catalog ___Other: _____________________________

To activate your warranty, please return this portion to:

Intermatic, Inc.

7777 Winn Road

Spring Grove, IL 60081

or by FAX: 815-675-7055

Copyright © 2006 Intermatic, Inc.

Page 26

Nine: Warranty 51

Installation Notes

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

Providing a brighter solution.™

Page 27

Intermatic, Inc.

7777 Winn Road

Spring Grove, Illinois 60081-9698

www.intermatic.com

Intermatic Customer Service: 815-675-7000

(8 a.m. through 4:30 p.m. CT, Monday through Friday)

©2006 Intermatic, Inc.

Printed in U.S.A. [code number]

Loading...

Loading...