ESL Supervised Wireless

g

1

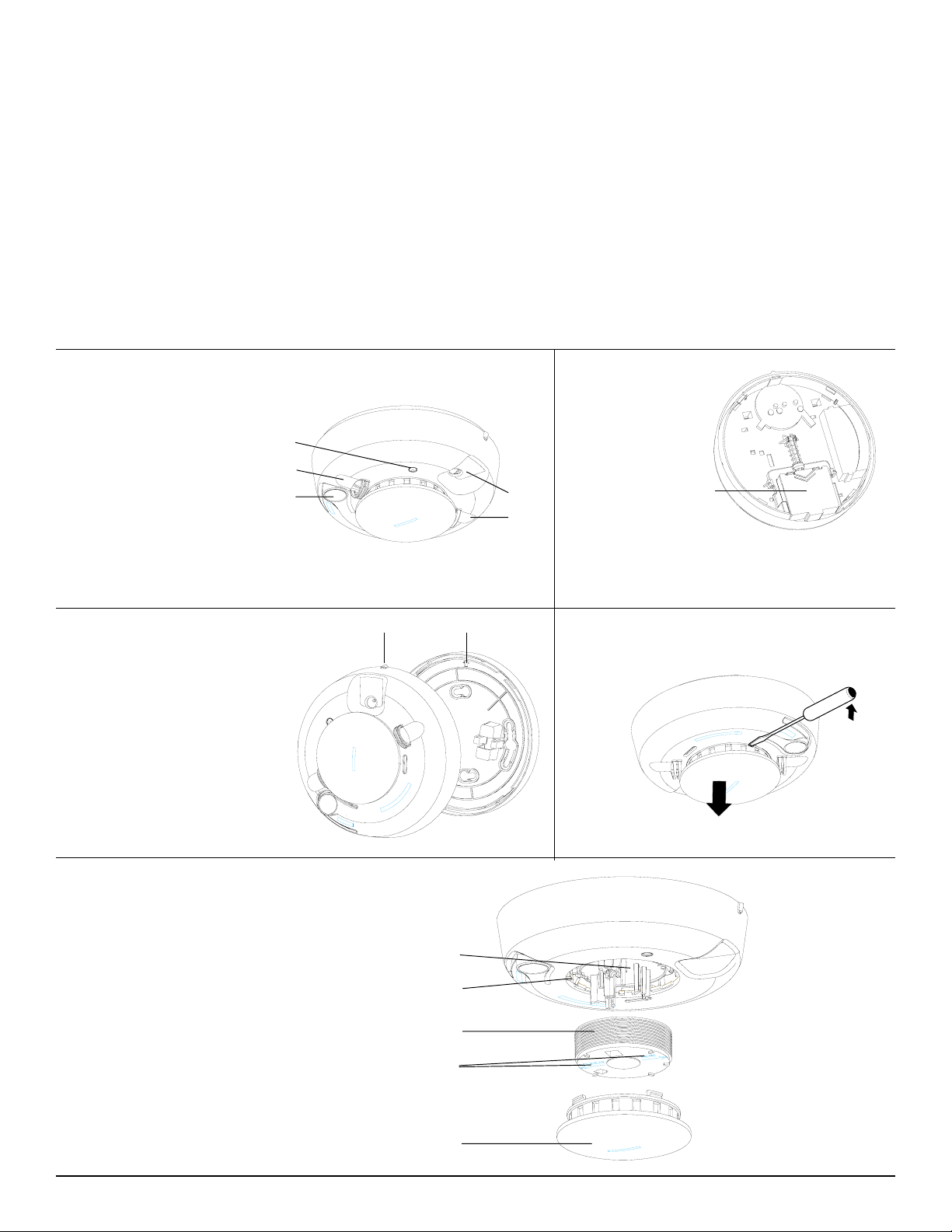

1 LED

2 Temperature sensor

3 Test/Silence button

4 Sounder vent

1 VOYANT DEL

2 Capteur de température

3 Bouton de Test/Arrêt

4 Évent du résonateur

1

2

3

Smoke Alarms

Manual TX-6010-01-1

Détecteurs de fumée sans fil

contrôlé ESL

Manuel TX-6010-01-1

2

4

2

1 Battery compartment

1 Compartiment de la pile

1

3

1 Alignment tab

2 Alignment arrow

1 Touche d’alignement

2 Flèche d’alignement

5

1 Optical base

2 Optical chamber latch

3 Optical chamber

4 Alignment arrows

5 Alarm cap

1 Support optique

2 Verrou de la chambre optique

3 Chambre optique

4 Flèches d’alignement

5 Couvercle de l’alarme

12

1

2

3

4

5

4

TX-6010-01-1

1

6

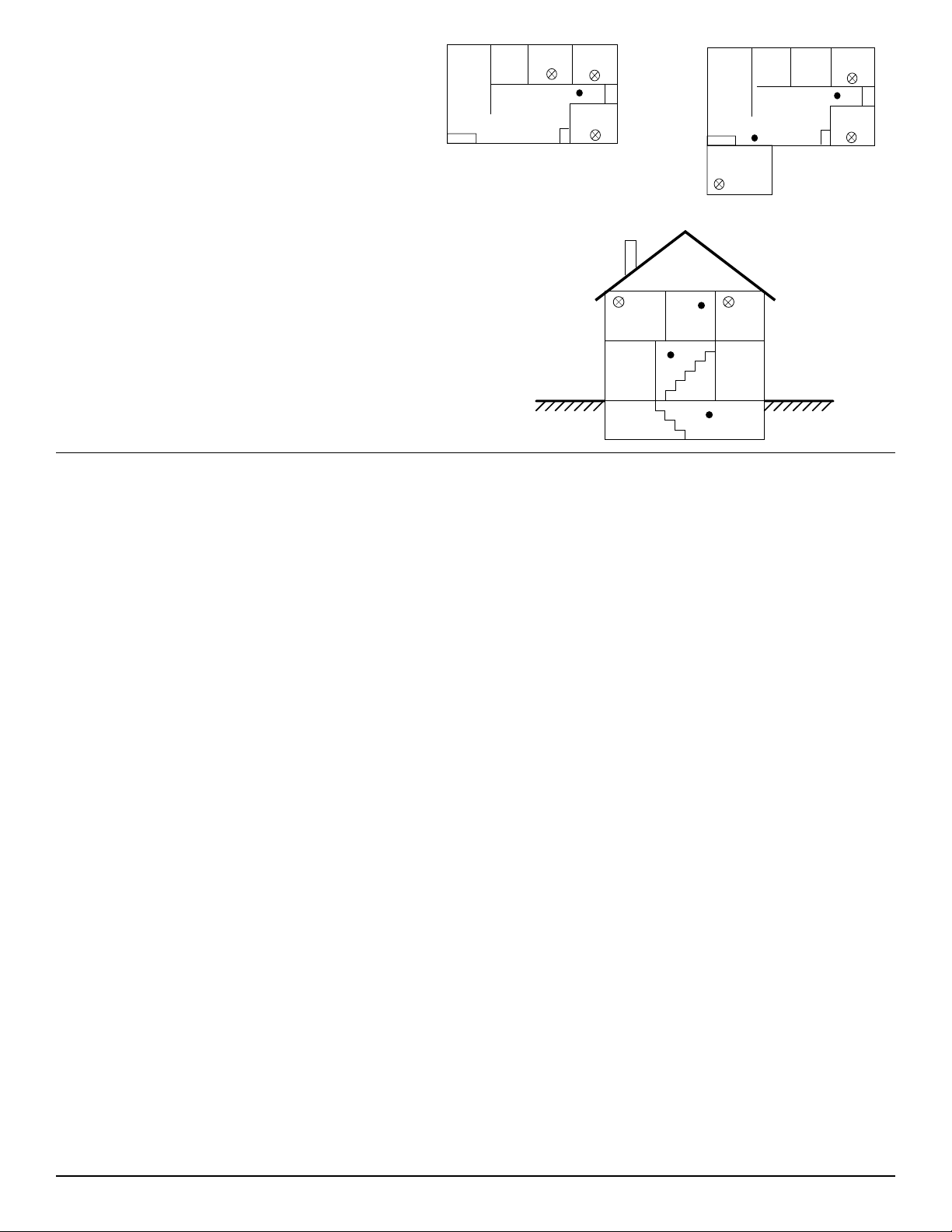

Required smoke alarms

Additional alarms required for new construction

1 Dining Room

2 Kitchen

Wireless

3 Living Room

4 Bedroom

5 TV Room

6 Basement

Détecteurs de fumée requis

Détecteurs supplémentaires nécessaires

dans les nouvelles pièces

1 Salle à manger

2 Cuisine

3 Salle de séjour

4 Chambre à coucher

5 Salle de télévision

6 Sous-sol

A

12344

4

C

B

51234

4300 Series

Wireless Smoke Detector

4

4

44

13

6

Description

The ESL supervised smoke alarms are self-diagnostic Learn Mode

wireless sensors with 319.5 MHz transmitters that use photoelectric

technology with a self contained sounder, a low battery annunciator,

status LED, and integrated fixed temperature and rate-of-rise heat

sensor. Each unit has a base tamper switch, is part of a residential

security/fire alarm system, and communicates with the system control

panel.

Transmitted Signal Output s

•Alarm •Tamper •Test

•Low battery •Trouble •Supervisory

Programming

This section describes the basic steps for programming (learning) the

unit into panel memory. For complete programming instructions, refer

to the specific panel installation instructions.

1. Separate the unit from the mounting base by turning the unit

counter clockwise about 15 degrees.

2. Slide the battery cover away from the unit to unsnap it and lift it

off. See Figure 2.

3. Observing polarity, insert the 2 lithium batteries (included) into the

battery compartment and replace the battery cover.

4. Attach the unit to the mounting base by lining up the alignment tab

(see Figure 3) on the unit with the alignment arrow on the mounting

base, then put the unit on the base and turn it clockwise about 15

degrees. The unit should snap into place.

5. Put the panel into installer programming mode (refer to your panel

installation instructions) and proceed to learning/enrolling sensors.

6. When prompted by the panel to learn/enroll the sensor, trip the

tamper by separating the unit from the mounting base. See Step 1.

7. Attach the unit to the mounting base. See Step 4.

8. Exit from installer programming mode.

Verify Programming and Unit-to-Panel

RF Communication

Before mounting, verify that the desired unit location provides good RF

communication to the panel.

1. Put the panel into Dealer Sensor Test mode (refer to the specific

panel installation instructions).

2. Take the unit to the desired mounting location.

3. Press and hold the unit Test/Silence button for 4 seconds. The unit

transmits a test signal.

2

4. Listen for the appropriate response from system sirens to determine

signal integrity from the unit to the panel (refer to the specific panel

installation instructions).

5. Exit from Dealer Sensor Test mode.

Mounting

Mounting hardware is included (screws and anchors), however you may

need different hardware depending on the installation.

1. Separate the unit from the mounting base. See Programming Step 1.

2. Place the mounting base on the mounting surface at the desired

location and mark the mounting holes using a pencil.

3. Secure the mounting base to the surface.

4. Attach the unit to the mounting base. See Programming Step 4.

Sensor Test

The system and sensor test verifies good communication between the unit

and receiver/panel. The sensor test should be performed weekly.

1. Put the panel into Sensor Test mode (refer to the specific panel

installation instructions).

2. Press and hold the Test/Silence button for 4 seconds. The unit

transmits a test signal.*

*Holding the Test/Silence button for 20 seconds will cause the unit to

send a signal through to a central station.

3. Listen for the appropriate response from system sirens (refer to the

specific panel installation instructions).

4. After testing all units, exit from Sensor Test mode.

Smoke Test

The smoke test verifies that the unit activates when detecting smoke, that

the transmitted signal is received by the receiver/panel, and that the panel

reports the alarm to the central monitoring station. The smoke test

should be performed annually.

1. Contact the central monitoring station to alert them you are testing

the system and they should not dispatch authorities.

2. Activate the unit using one of the following two methods:

Method 1 Hold a smoldering punk or cotton wick close to the unit and

direct the smoke into the smoke entry openings for about 20 seconds.

Method 2 Use Smoke! in a can® and follow the directions on the can.

Once activated, the transmitter LED turns on, the built-in sounder

emits a temporal 3 pattern, and the unit transmits an alarm signal. The

panel then processes the alarm signal and reports the alarm condition

to the central station.

TX-6010-01-1

3. Press the Test/Silence button to quiet the sounder. The unit automatically resets when smoke is no longer present and the LED should turn

off and return to normal operation (one flash every 9 seconds).

4. Contact the central monitoring to verify they received the alarm

report.

5. Alert the central monitoring station when you are finished testing.

Sensitivity T est

1. Press and hold the test/silence button for two seconds, then release it.

The unit transmits a test signal, then performs a self-test that causes

the LED to flash 1 to 9 times.

2. Count the number of LED flashes, then use the following table to

determine if any action is necessary.

Flashes

0- 1 Indication: Unservicable hardware fault.

Action: Reset and rerun sensitivity test. If the error

persists, replace unit.

2- 3 Indication: Unit is becoming insensitive.

Action: Clean and reset the unit. Rerun sensitivity test.

If the error persists, replace the unit.

4- 7 Indication: Unit is within normal sensitivity range.

Action: N/A

8- 9 Indication: Unit is becoming too sensitive.

Action: Verify the optical chamber is snapped down

securely. Clean the unit and replace the optical

chamber.

After the LED flashes, if the sensitivity is within limits and all other tests

pass, the unit goes into alarm and resets after 7 seconds. If the sensitivity

is not within limits, or an unserviceable hardware fault has been detected,

the unit LED extinguishes until the unit is serviced.

Troubleshooting

The following describes how the unit indicates a fault condition. Correct

fault conditions as soon as possible.

• The LED stops working (no flashing or turning on), see Sensitivity Test.

• The unit stops transmitting supervisory signals if the unit has an

unserviceable hardware fault or is not sensitive enough, causing the

panel to indicate the detector is in a supervisory condition. However,

the unit can still transmit alarm signals.

• The unit transmits a trouble (CleanMe) signal, see Maintaining the

Units.

Cleaning

Clean the cover with a dry or damp (water) cloth as needed to keep it free

from dust and dirt.

When necessary, clean the interior and replace the optical chamber (part

#211) as follows:

1. Disconnect the alarm notification appliances.

2. Remove the unit from the mounting base. See Programming Step 1.

3. Remove the batteries. See Replacing the Batteries.

4 . Slide a flat-blade screwdriver in the slot on the alarm cap and gently

push the handle down to pry the alarm cap up and off. See Figure 4.

5 . Squeeze the optical chamber where indicated and pull it up and away

from the optical base and discard. See Figure 5.

6 . Blow out or use a soft-bristled brush to remove all dust and dirt from

the optical base.

7. Line the new optical chamber up with the optical base and snap into

place both sides of the optical chamber.

8. Replace the alarm cap as follows:

-Line the alarm cap up with the unit.

-Insert the alarm cap into the unit and turn clockwise approximately

15 degrees. It should snap firmly into place.

9. Observing the proper polarity, replace the batteries and the battery

compartment cover.

10 .Reattach the unit to the mounting base. See Programming Step 4.

11. Test the sensitivity and reconnect all alarm notification appliances.

See Sensitivity Test.

Important !

The control panel alarm and all auxiliary functions

should be verified for a complete test of the system.

Maintenance

The units are designed for easy field service and maintenance. When

installed and used properly, they require minimal maintenance.

The units should be tested weekly.

When a unit requires maintenance, it extinguishes its LED and sends a

signal to the control panel as described in the following table.

Signal Action Required

Trouble Signal Sensitivity range is too high and the unit needs

cleaning. See Cleaning. Panels supporting this

feature identify the trouble as “Partial Obscurity”

on system touchpad displays.

Low Battery Batteries in the unit are low. Replace the batteries.

When to Replace the Batteries

When the battery voltage gets low, the unit transmits a low battery signal

for the panel to receive. The panel activates trouble beeps through system

sirens and identifies the unit with the low battery on system touchpad

displays. If the batteries are not replaced within seven days, the unit’s

built-in sounder emits a short beep or chirp every 45 seconds. Unit chirps

can be silenced for 24 hours by pressing the Test/Silence button. Batteries

should be replaced as soon as possible.

Replacing the Batteries

Use only 3V lithium batteries listed in Specifications.

1. Remove the unit from the mounting base. See Programming Step 1.

2. Slide the battery compartment cover away from the alarm to unsnap it

and lift it off. See Figure 2.

3. Remove the batteries and dispose of them properly.

4. Observing correct polarity, insert two new 3V lithium batteries into the

battery compartment and replace the cover.

5. Reattach the unit to the mounting base. See Programming Step 4.

6. Test the system.

TX-6010-01-1

Specifications

Voltage 3VDC

Typical average standby current 35µA

Typical test current 2m A

Typical alarm current 70mA

Battery type 3V lithium, Duracell® 123,Panasonic

CR123A, Sanyo® CR123A

Low battery threshold 2.70V causes low battery signal

Sounder 85dBa at 10' temporal pattern

Low battery beep rate 1 every 45 sec.

Sensitivity 2.2% ± 1.3% / ft.

Operating temperature 40°-100°F (4.4°-37.8°C)

Operating humidity range 0-95% non-condensing

Color white

Alarm dimensions 5.6" x 2.4" (14.2cm x 6.1cm)

Base dimensions 5.4" x 0.46" (13.7cm x 1.17cm)

Drift compensation adjustment 0.5% / ft. max.

Heat detector specifications:

Rate-of-rise 15°F/min>105°F (8.3°C/min>40.6°C)

Fixed 135°F ± 5°F (57.2°C ± 2.8°C)

RFI Immunity 20V/m minimum; 0-1000MHz

RF frequency 319.5 MHz

Transmitter ID Pre-programmed, 1 Million codes

Modulation type AM

Signal format P WM

Signal output types alarm, tamper, test, low battery,

trouble, supervisory

Listings UL217, C-UL US, CSFM, FCC

3

®