Interlogix ATS1500A-SM, ATS1500A-LP, ATS1500A-MM, ATS3500A-MM, ATS1500A-IP-LP Installation And Programming Manual

...

Advisor Advanced

ATSx500A(-IP) Installation

and Programming Manual

P/N 466-2576 (EN) • REV B • ISS 16SEP16

Copyright

© 16SEP16 UTC Fire & Security Americas Corporation, Inc. All

rights reserved.

Trademarks and

patents

Interlogix, Advisor Advanced ATSx500A(-IP) name and logo are

trademarks of UTC Fire & Security.

Other trade names used in this document may be trademarks or

registered trademarks of the manufacturers or vendors of the

respective products.

Manufacturer

UTC Fire & Security Americas Corporation, Inc.

3211 Progress Drive, Lincolnton, NC, 28092, USA

Authorized EU manufacturing representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, Netherlands

Version

This document applies to the following Advisor Advanced firmware

versions:

ATSx500A(-IP): MR_3.0

Certification

EN 50131-1 System requirements

EN 50131-3 Control and indicating equipment

EN 50131-6 Power Supplies

EN 50136-1-1 Alarm systems -Alarm Transmission systems

ATS1500A(-IP): Security Grade 2, Environmental class II

ATS3500A(-IP): Security Grade 3, Environmental class II

ATS4500A-IP: Security Grade 3, Environmental class II

Note: ATS1500A(-IP) is upgradable to Security Grade 3 using the

ATS-MM-TK (MM enclosure) or the ATS-SM-TK (SM enclosure)

tamper kit.

Tested and certified by VdS Schadenverhütung GmbH

Important: To comply with the above standards, it is required to

configure the system according to settings listed in Chapter 8

“Regulations” on page 301 onwards.

This product has not been designed to comply with EN 50134 and

EN 54 norms.

European Union

directives

UTC Fire & Security hereby declares that this device is in

compliance with the applicable requirements and provisions of one

or more of the Directives 2014/30/EU and 2014/35/EU. For more

information see www.utcfireandsecurity.com or www.interlogix.com.

2002/96/EC (WEEE directive): Products marked with this symbol

cannot be disposed of as unsorted municipal waste in the European

Union. For proper recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or dispose of it at

designated collection points. For more information see:

www.utcfssecurityproducts.eu/recycle/

Contact information

www.utcfireandsecurity.com or www.interlogix.com

Customer support

www.utcfssecurityproducts.eu

Content

Important information iii

Chapter 1 Quick installation and programming 1

Quick installation 2

Quick programming 4

Chapter 2 Installation 7

General installation information 8

Maintenance 16

Mounting 18

Earthing 20

Shielding 21

Cabling 22

Configuration 30

Specifications 35

Chapter 3 System functions 41

Function list 43

Zones 45

Areas 50

Set and unset 51

Inhibit and isolate 53

Keys 54

Bus devices 58

Users 60

User groups 62

PIN 66

Outputs 67

Access control 68

Condition filters 74

Triggers 76

Calendar 77

Events 79

Tests and diagnostics 80

Alarm reporting 84

User programmable functions 88

Autoset 91

Wireless device programming 92

Using cameras 98

Engineer reset 102

Timed unset / ATM 103

Chapter 4 Programming 105

The Advisor Advanced menu 106

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual i

How to program the options 108

Remote access 113

Initial start-up 114

Chapter 5 Menu reference 117

1 Service menu 120

2 Device menu 142

3 User menu 162

4 Zones and areas 171

5 Door menu 196

6 Outputs and filters 217

7 Calendar 225

8 System option menu 232

9 Dialler menu 258

Chapter 6 Software 287

Programming Advisor Advanced via configuration software 288

Upgrading Advisor Advanced firmware 290

Chapter 7 Troubleshooting 295

Recovery procedure 296

Device troubleshooting 297

Chapter 8 Regulations 301

Options affected by EN 50131 regulations 302

Options affected by other regulations 308

Appendix A Advisor Advanced events 311

Appendix B Advisor Advanced reporting codes 327

Glossary 337

Index 343

Programming map 351

ii Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Model

Enclosure

Dimensions (mm)

Weight (kg)

ATS1500A-MM

Metal

MM, 315 x 388 x 85

5.2

ATS1500A-IP-MM

Metal

MM, 315 x 388 x 85

5.2

ATS1500A-SM

Metal

SM, 250 x 250 x 86

2.8

ATS1500A-IP-SM

Metal

SM, 250 x 250 x 86

2.8

ATS1500A-LP

Plastic

LP, 257 x 400 x 112

2.6

ATS1500A-IP-LP

Plastic

LP, 257 x 400 x 112

2.6

ATS3500A-MM

Metal

MM, 315 x 388 x 85

5.2

ATS3500A-IP-MM

Metal

MM, 315 x 388 x 85

5.2

ATS3500A-LP

Plastic

LP, 257 x 400 x 112

2.6

ATS3500A-IP-LP

Plastic

LP, 257 x 400 x 112

2.6

ATS4500A-IP-MM

Metal

MM+, 315 x 445 x 88

5.4

ATS4500A-IP-LM

Metal

LM, 475 x 460 x 160

10.9

Important information

This document includes an overview of the product and detailed instructions

explaining how to install your Advisor Advanced system and program it.

To use this document effectively, you should have the following minimum

qualifications:

• Basic knowledge of alarm systems and components

• Basic knowledge of electrical wiring and low-voltage electrical connections

Read these instructions and all ancillary documentation entirely before installing

or operating this product.

Important note

This manual provides information for all Advisor Advanced and Advisor

Advanced-IP control panels in all variations. “Advisor Advanced control panel”

refers to any variant of the Advisor Advanced control panels, unless specifically

stated otherwise.

List of panel variants

Table 1: List of ATSx500A(-IP) panel variants

Notes

• Not all variants may be available.

• Weight does not include batteries.

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual iii

Safety sign identifies actions or practices that are required by

EN 60950 Safety Standard.

Limitation of liability

To the maximum extent permitted by applicable law, in no event will UTCFS be

liable for any lost profits or business opportunities, loss of use, business

interruption, loss of data, or any other indirect, special, incidental, or

consequential damages under any theory of liability, whether based in contract,

tort, negligence, product liability, or otherwise. Because some jurisdictions do not

allow the exclusion or limitation of liability for consequential or incidental

damages the preceding limitation may not apply to you. In any event the total

liability of UTCFS shall not exceed the purchase price of the product. The

foregoing limitation will apply to the maximum extent permitted by applicable law,

regardless of whether UTCFS has been advised of the possibility of such

damages and regardless of whether any remedy fails of its essential purpose.

Installation in accordance with this manual, applicable codes, and the instructions

of the authority having jurisdiction is mandatory.

While every precaution has been taken during the preparation of this manual to

ensure the accuracy of its contents, UTCFS assumes no responsibility for errors

or omissions.

Advisory messages

Advisory messages alert you to conditions or practices that can cause unwanted

results. The advisory messages used in this document are shown and described

below.

WARNING: Warning messages advise you of hazards that could result in injury

or loss of life. They tell you which actions to take or to avoid in order to prevent

the injury or loss of life.

Caution: Caution messages advise you of possible equipment damage. They tell

you which actions to take or to avoid in order to prevent the damage.

Note: Note messages advise you of the possible loss of time or effort. They

describe how to avoid the loss. Notes are also used to point out important

information that you should read.

iv Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 1

Quick installation and

programming

Summary

The chapter contains basic steps of connection and programming of the Advisor Advanced

control panel and auxiliary devices.

For more detailed description of the installation process, see Chapter 2 “Installation” on page 7.

For details on programming, see Chapter 4 “Programming” on page 105 and Chapter 5 “Menu

reference” on page 117.

Content

Quick installation 2

Quick programming 4

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 1

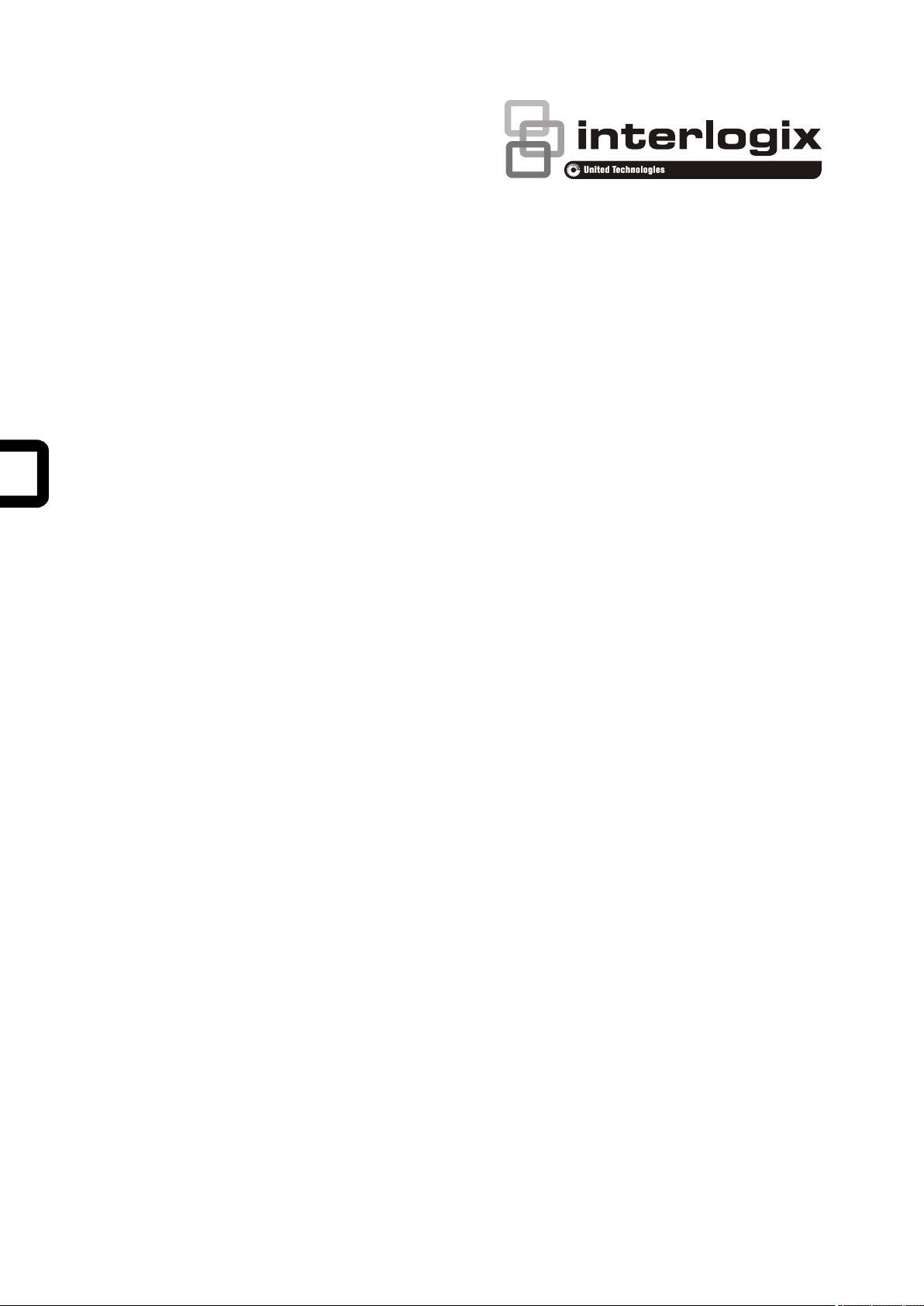

Chapter 1: Quick installation and programming

RxTx

S

Y

S

P

O

L

L

M

I

/

P

A

N

E

L

E

T

H

E

R

N

E

T

S

I

M

G

S

M

G

P

R

S

/

3

G

DGP Addr

1 2 3 4

S

I

M

U

S

B

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4

S5

+

+

S1

C

+

S2

C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~~+

-

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

EARTH

CTD-

D+

0V

+12V

COMMS

TAMPER

+

S3

C

CON16

NTC

ATS7700

ATS608ATS624

ATS626

1K

4K7

4K7

4K7

4K7

4K7

4K7

4K7

+12V

Zone

GND

4K74K7

Zone

GND

DC101

DD1012AM

+ -

TDA74xxNG

1K 1K

2

2

OffOnIsolated fault

contact

3 resistor single

zone

(Terminal 3-10)

=

=

J1

J1

JF JT JA

2 2K

3K

4 7K

1K

2 2K

4 7K

5 6K

1K

2 2K

4 7K

5 6K

1

2

3

4

1

2

1

2

1

2

3

4

5

6

121

2

SW1 - Generic settings

LED ON

Remote OFF

Auto Rem. Test ON

Positive Polarity

LED OFF

Remote ON

Negative Polarity

Range

SW2 - AM/Fault settings

Mask to alarm and

fault relay

Auto reset

Advanced AM sens.

AM Day mode only

Mask to fault relay

only

Authorized reset

Standard AM sens.

AM Day and Night

4

1 .m( 3 ft )

12

40 .m( ft )

9

30 .m( ft )

6

20 .m( ft )

Auto Rem. Test OFF

10K

Zone

J1

1

Alarm

GND

+12V

Fault

Alarm

Fault

1 3 4

5

2 6

7

8 9

Quick installation

2 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

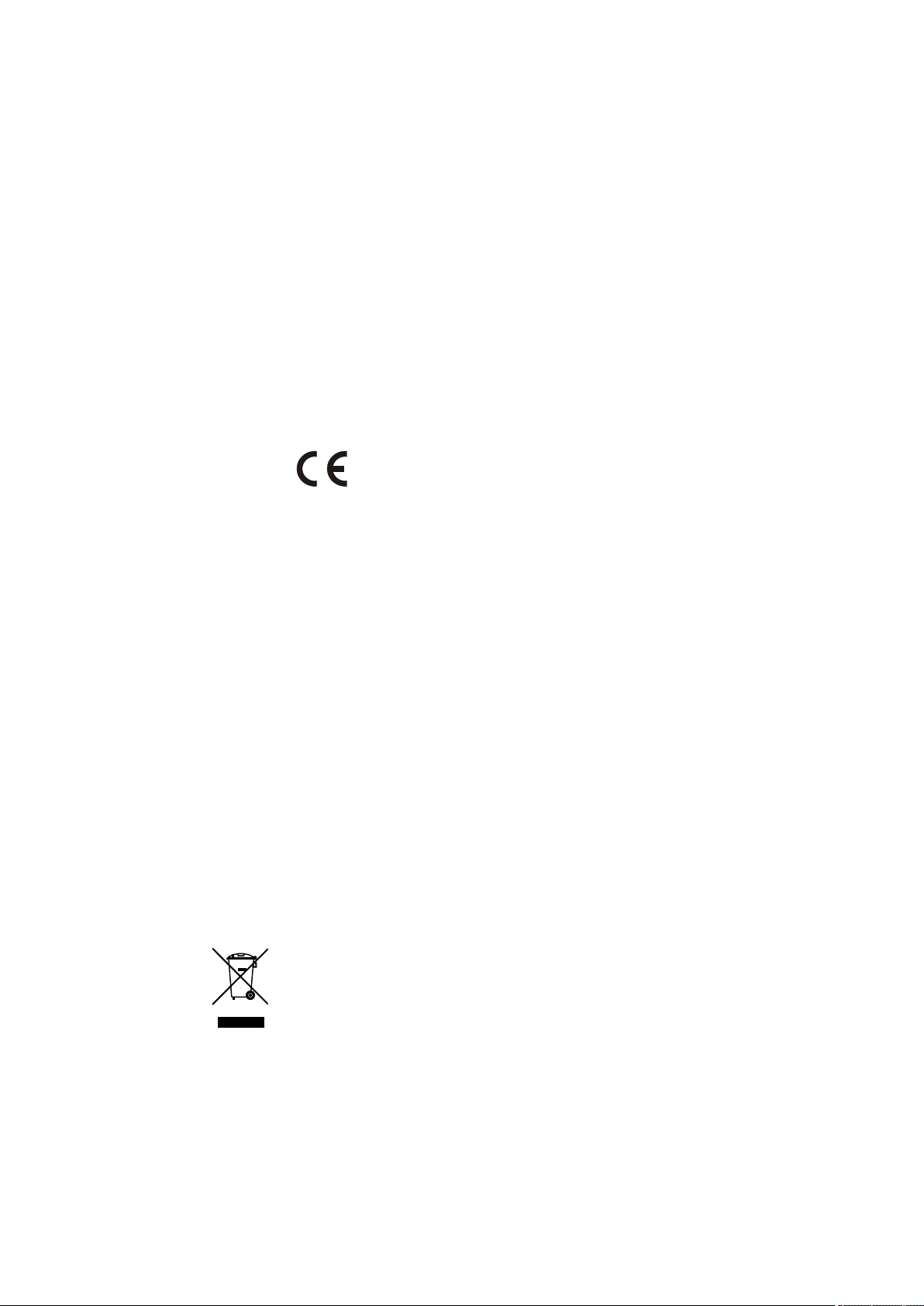

Chapter 1: Quick installation and programming

D+0V+12V D- IN OUT

Rx

Tx

EARTH

CTD-

D+

0V

+12V

COMMS

TAMPER

D+0V+12V D- IN OUT

0

12

3

4

5 6

7 8 9

12

abc

jkl

tuv

def

ghi

.,’?!

*

#

A B C

Address 1

RxTx

S

Y

S

P

O

L

L

M

I

/

P

A

N

E

L

E

T

H

E

R

N

E

T

S

I

M

G

S

M

G

P

R

S

/

3

G

DGP Addr

1 2 3 4

S

I

M

U

S

B

1

1

ATS1135 ATS1135

TDA74xxNG

0

12

3

4

5 6

7 8 9

12

abc

jkl

tuv

def

ghi

.,’?!

*

#

A B C

Address 2

2

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 3

Chapter 1: Quick installation and programming

Display

Instructions

INFO

Inst required

Press Enter to continue.

1>Panel language

Choose English.

2>Defaults

Choose EN 50131 Grade 3.

4>PIN length

Enter 6.

5>Time&date

Set current time and date.

6 Install

>Cancel<

Choose OK

Installer

PIN:127800

Press Enter to continue.

Supervisor

PIN:112200

Press Enter to continue.

Auto Config?

>Yes<

Press Enter to continue.

Rkp 1-16 BUS1

R-?-------------

Exp 1-15 BUS1

-?-------------

Wait until the panel

configures all bus devices

and zones.

Added

R:1 D:0 Z:8

Press Enter to continue.

UTC F&S

THU 05 Mar 12:21

Press 112200, Menu

1>Zone options

2 Isolate

Go to menu 8.8 Service in

8>Service in

Enable?

Enable Installer in time

UTC F&S

THU 05 Mar 12:21

Press 127800, Menu

Inh reports

>No<

Press Enter to continue.

Inh tampers

Unset areas

1>Service menu

2 Device menu

1>Change PIN

***********

Press Enter.

New PIN

>_

Enter the new installer PIN.

4>Zones&Areas

Press Enter.

1>Zone menu

Press Enter.

0>Add zone

1 Zone 1

Select a zone.

01 Zone name

>1 Zone 1 <

Quick programming

Initial start-up

Note: See “The Advisor Advanced menu”

on page 106 for menu explanation. For

more information on editing options, see

“How to program the options” on page 108.

Switch the panel on. The further messages

and menus are listed in the table below.

Press Cancel, Cancel to log off.

Programming menu entry

The panel restarts.

Auto configuration

The installer menu is displayed.

Changing installer PIN

Go to 3.1.n.2.1 Change PIN (see page 163).

Configuring zones

Go to 4.1 Zone menu (see page 171).

For each zone used in the system, enter

zone name in 4.1.n.1 Zone name (page

172).

Enabling service in

Next, set its zone type in 4.1.n.2 Zone type

4 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

(see page 172).

Chapter 1: Quick installation and programming

02 Zone type

>Entry/Exit 1<

0>Add user

1 Installer

Press Enter to add a user.

INFO

User added

01>User name

User 3

Press Enter.

01 User name

>User 3 <

Enter a new user name.

Lock user data?

>Cancel<

Choose OK and confirm.

1 Area name

>Area 1 <

Enter a new area name

1>PSTN

3 GSM/SMS/GPRS

0>Add CS

1 CS 1

Calling CS 1...

Ready

Adding users

Go to menu 3.1 Users (see page 162).

Configure other options of the user:

• 3.1.n.2 PIN (page 162)

• 3.1.n.3 User card (page 163)

• 3.1.n.6 User groups (page 164), etc.

Repeat for other users.

When leaving the user configuration,

confirm locking the user data.

Select the required path and configure it

depending on the hardware used.

Next, go to menu 9.1 Central station

(page 258).

Add a new CS, or choose an existing one.

Configure the following parameters:

• 9.1.n.1 CS name (page 258)

• 9.1.n.2 Transm path (page 259)

• 9.1.n.3 Protocol (page 259)

• 9.1.n.5 Accounts (page 259)

• Other options, depending on the

communication path used.

Test the communication using menu

1.2.6.n.6 Man. test call (page 131), where

<n> is the number of the configured Central

Station.

Configuring areas

Go to 4.2 Areas (see page 185).

Change the area name in 4.2.n.1 Area

name (see page 185).

Configure other options of the area:

• 4.2.n.2 Exit time (see page 186)

• 4.2.n.3 Entry time (see page 186), etc.

Caution: Before enabling 4.2.n.5.4 Dual

unset (see page 189), make sure to add

users that can assist the unset. See “Adding

users” above.

Configuring Central Station

Regulations

If necessary, follow the instructions given in

Chapter 8 “Regulations” on page 301 to

configure other options, required by the

appropriate standards and norms.

Configure the communication path in 9.3

Path options (page 267).

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 5

Chapter 1: Quick installation and programming

6 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2

Installation

Summary

This chapter includes an overview of the product and detailed instructions

explaining how to install the components of your Advisor Advanced system.

Note: A qualified installer, complying with all applicable codes, should perform

whatever hardware installation is required.

Content

General installation information 8

Advisor Advanced housings 8

Advisor Advanced layout 12

Keypads and readers 13

Maintenance 16

Mains power connection 16

Battery replacement 16

Mounting 18

General installation guidelines 18

Earthing 20

Shielding 21

Cabling 22

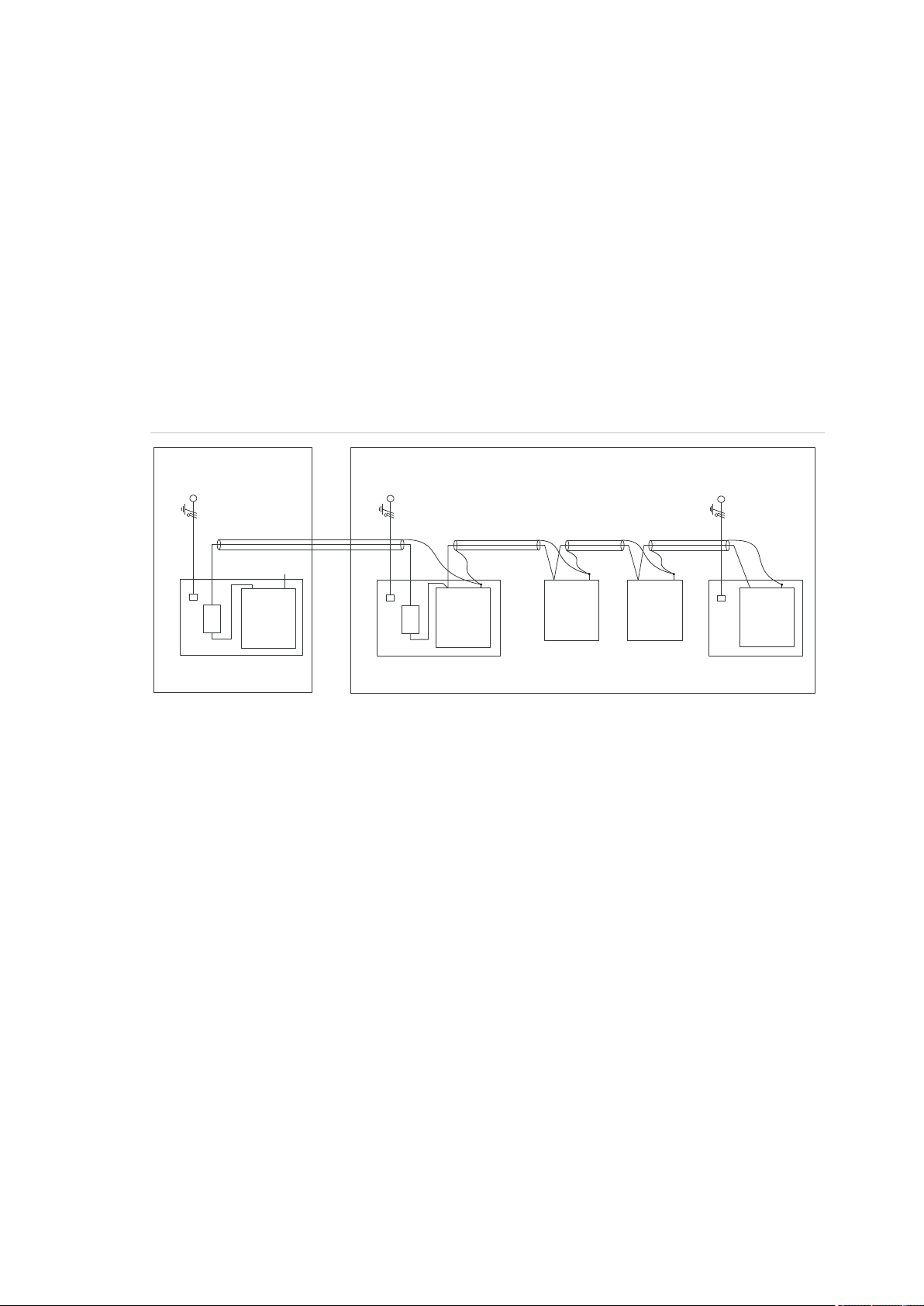

System databus preferred wiring 22

System databus connection 22

Zone connection 23

Values for end-of-line resistors 24

EOL connection types 27

Siren connection 28

Other connections 28

Configuration 30

Defaulting the panel 30

Zone configuration 30

Outputs 30

Zone and output addressing 31

Specifications 35

Auxiliary current and battery capacity 39

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 7

Chapter 2: Installation

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4

S5

+

+

S1

C

+

S2

C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~

~

+ -

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

CT

+

S3

C

CON16

NTC

COMMS

+12V0V D+ D-

250

250

9

30

61.5

28.2

37.2

125

9

61.5

126.4

118

Ø20

(2)

()1 ()1

()1

()1 ()1

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4

S5

+

+

S1 C

+

S2 C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~

~

+ -

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

CT

+

S3 C

CON16

NTC

COMMS

+12V0VD+ D-

315

40

385

55

(1)

(1)

(1)

(1)

(1)

(1)

15

104.9

102.5

60

(2)

60

15

24.1

51

35

40

General installation information

Advisor Advanced housings

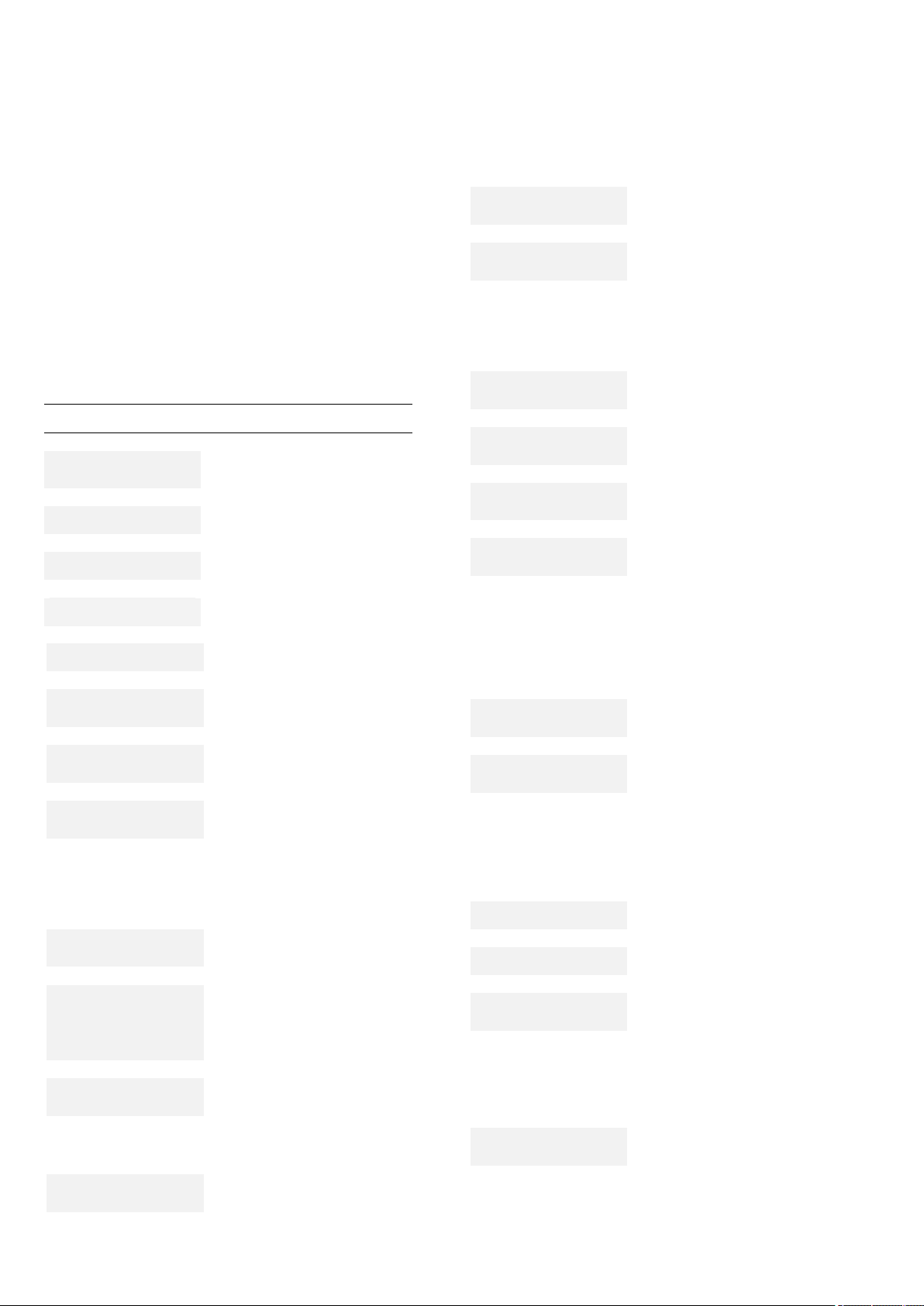

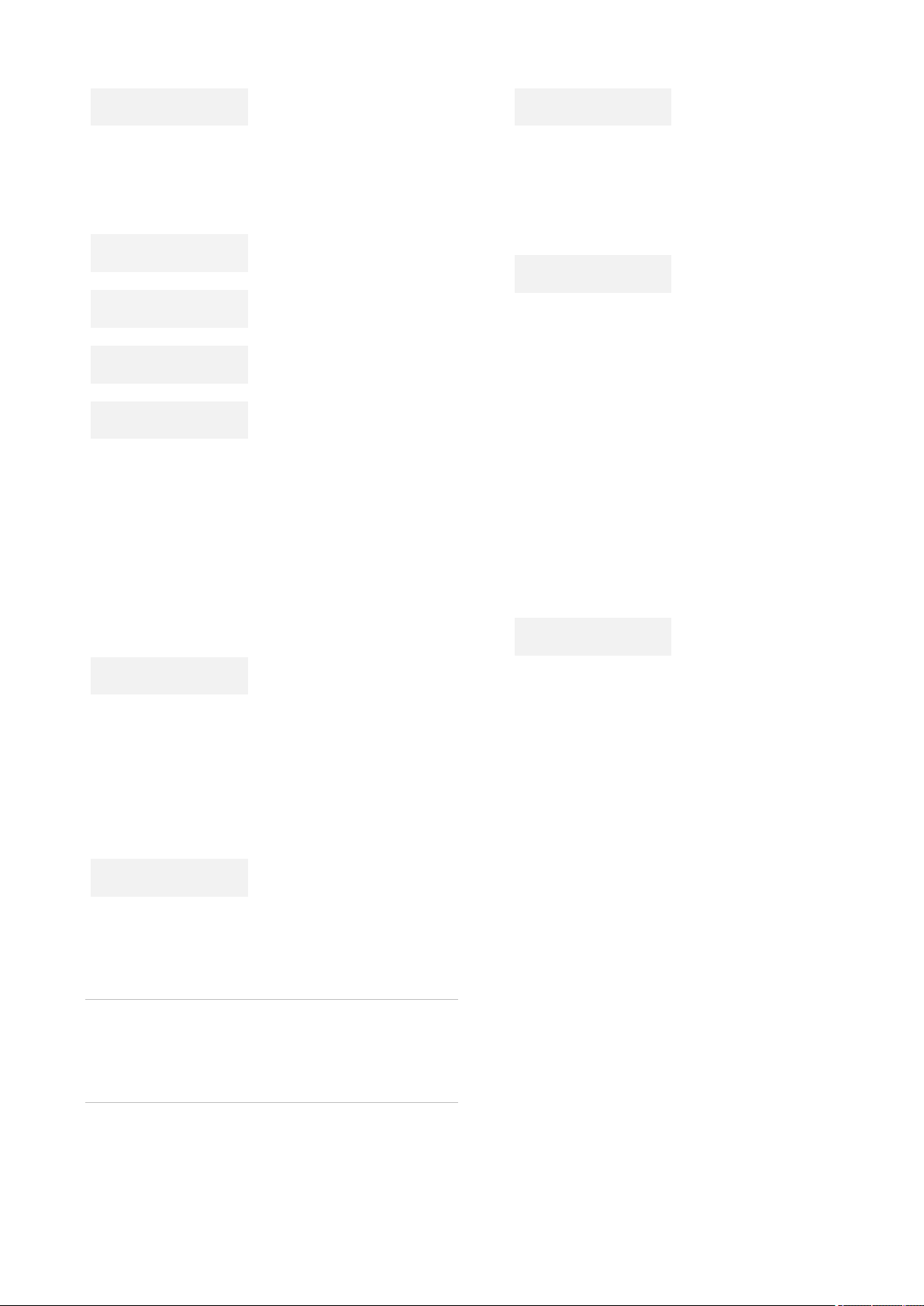

The housings with mounting holes (items 1) are shown in figures below.

Item 2 indicates the pry-off tamper wall stub location.

All dimensions are given in mm.

Figure 1: Small metal housing (-SM)

Figure 2: Medium metal housing (-MM)

8 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4

S5

+

+

S1

C

+

S2

C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~

~

+ -

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

CT

+

S3

C

CON16

NTC

COMMS

+12V0V D+ D-

259

129.5

73

403

54.5

45.5

73

395

50.5

70

126.5

41.5

70

253

()1

()1 ()1

()2

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4

S5

+

+

S1 C

+

S2 C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~

~

+ -

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

CT

+

S3 C

CON16

NTC

COMMS

+12V0VD+ D-

35

315

75

31

33

24

460

35

92.5

157.5157.5

()1 ()1 ()1

()1

()1

()2

Figure 3: Large polycarbonate housing (-LP)

Figure 4: Medium metal housing (-MM+)

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 9

Chapter 2: Installation

N

N

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4 S5

+

+

S1 C

+

S2 C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~

~

+ -

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

CT

+

S3 C

CON16

NTC

COMMS

+12V0VD+ D-

()1()1 ()1

()1

()1

()2

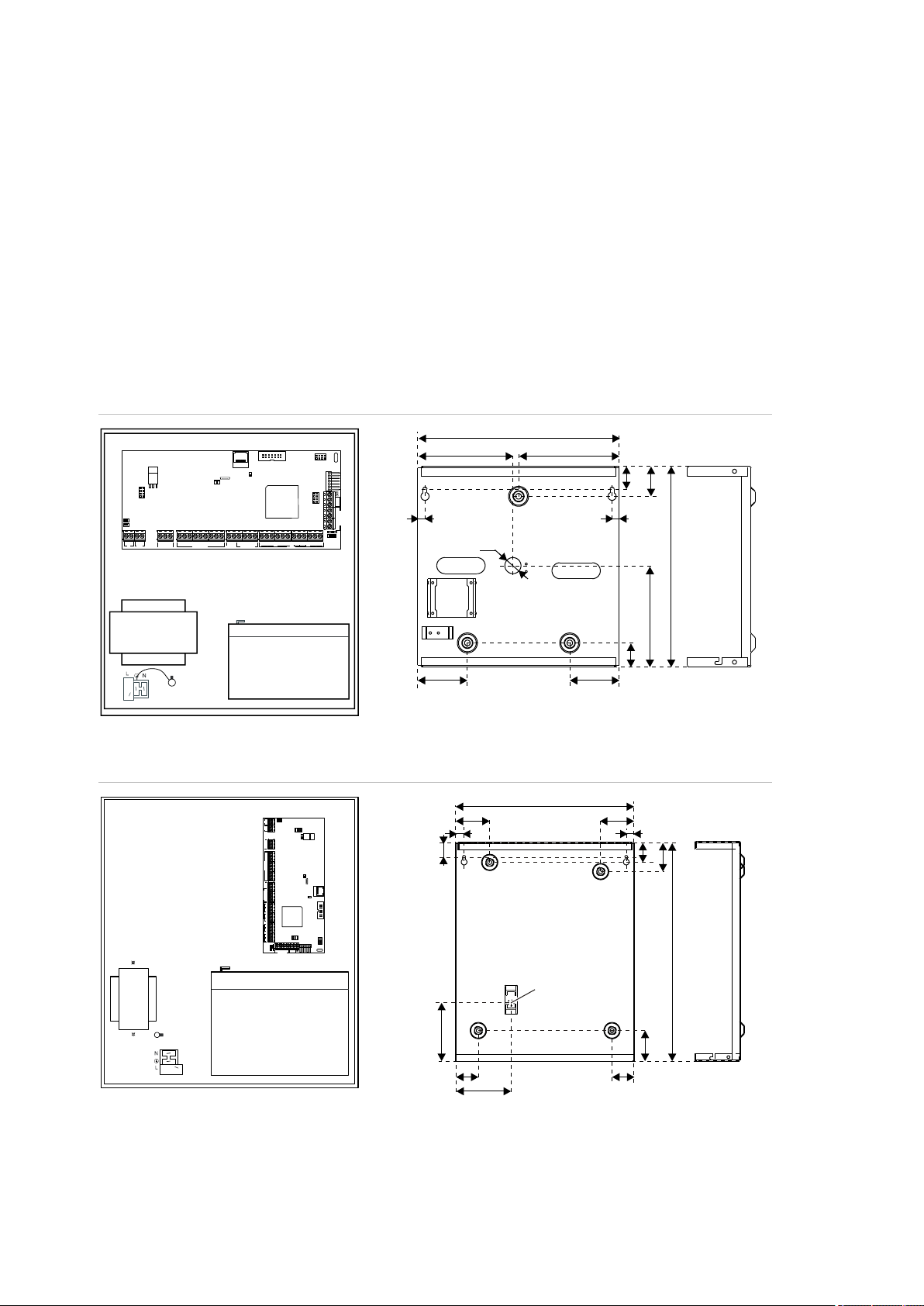

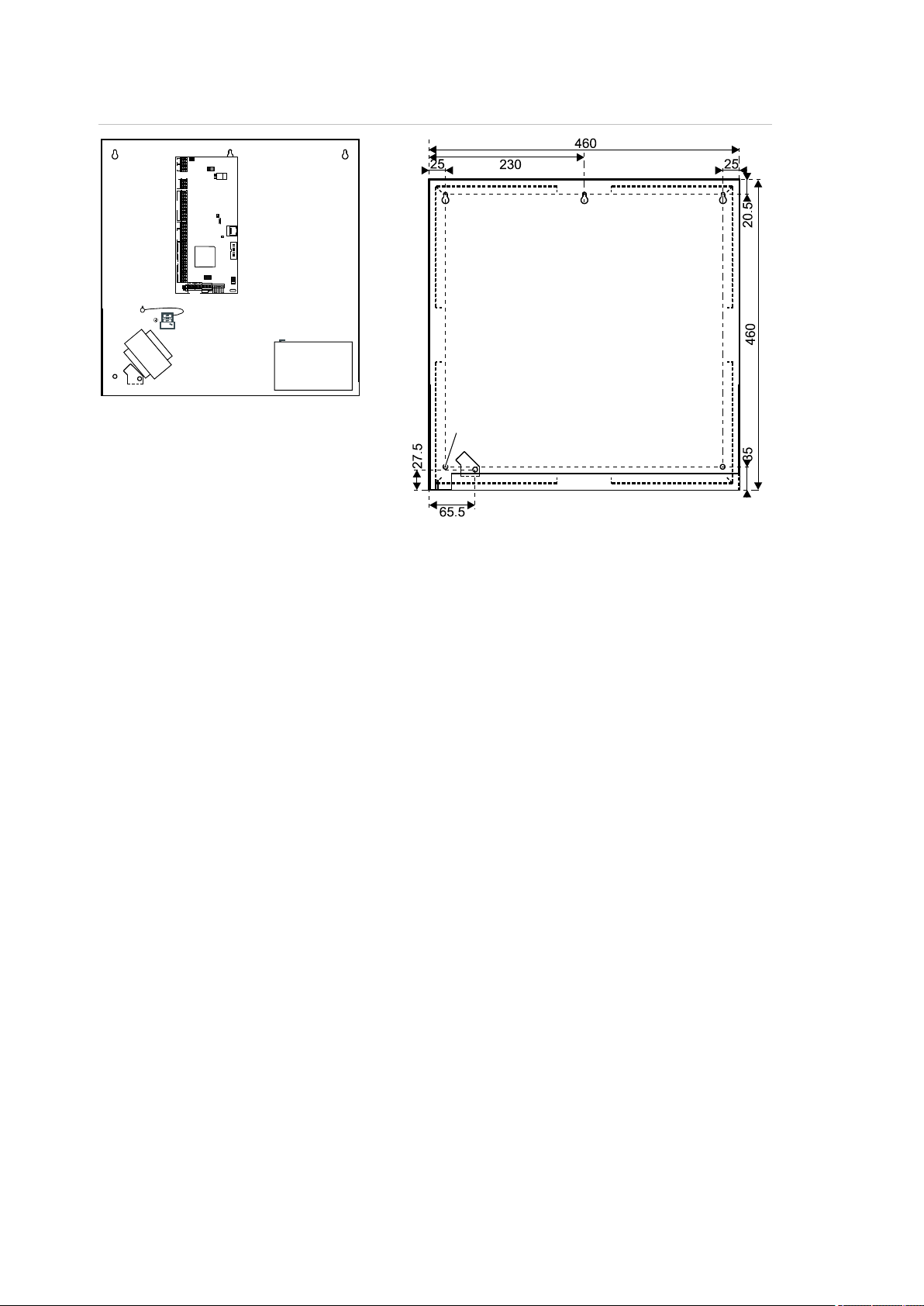

Figure 5: Large metal housing (-LM)

For more details on connections and connecting devices to the Advisor

Advanced, see “Cabling” on page 22.

For details on connecting pry-off tampers, see “Pry-off tamper mounting” below.

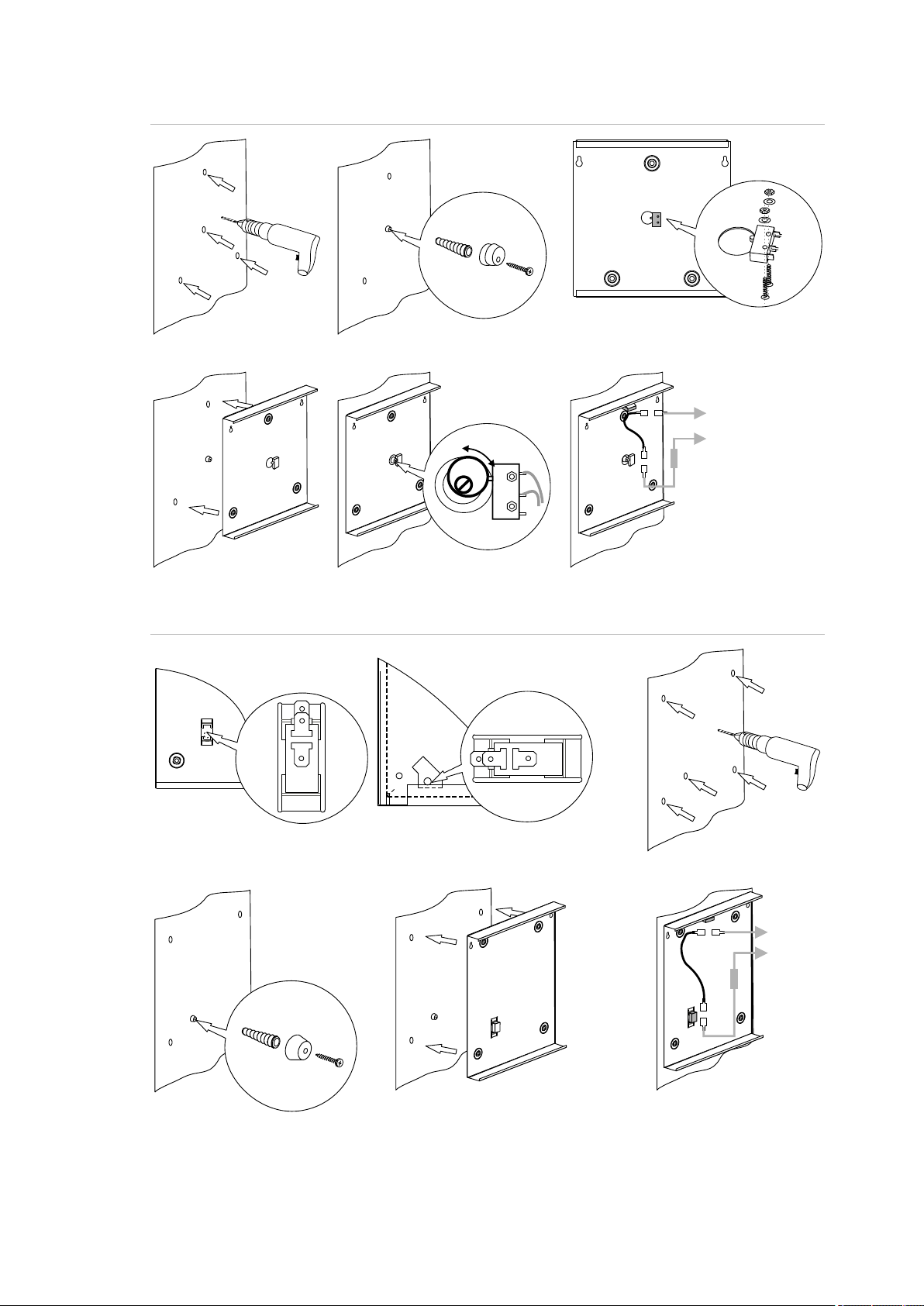

Pry-off tamper mounting

For small housing (SM), follow the steps in Figure 6 on page 11 to install pry-off

tamper. For medium (MM and MM+), and large housings (LM), follow the steps in

Figure 7 on page 11. For large plastic housing (LP), follow the steps in Figure 8

on page 12.

10 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

COM

NO

COM

NO

C

T

TAMPER

A B C

D E F

COM NO

COM

NO

C

T

TAMPER

B

C

D E

A

MM, MM+ LM

Figure 6: Small housing (SM) pry-off tamper mount

Figure 7: Medium (MM and MM+) and large housing (LM) pry-off tamper mount

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 11

Chapter 2: Installation

(1) Interface to output expander

(2) USB fault LED

(3) USB power LED

(4) USB connector (micro-A/B type)

(5) Ethernet RJ-45 connector (ATS-IP only)

(6) IP communication LED (ATS-IP only)

(7) Heartbeat LED

(8) MI-bus connector for MI devices

(9) Interface to input expander

(10) Interface to PSTN module

(11) Optional: enclosure ambient temperature

sensor

(12) ATS670 databus expander connector

(13) Panel earth terminal

(14) External tamper switch

(15) RS-485 system databus connections

(16) T2: Device firmware upgrade mode

(DFU)

(17) RS-485 system databus communication

LEDs

(18) T1: Restores installer default PIN

(19) System databus termination jumper

(20) AC power supply terminal

(21) Battery connection

(22) Low current (OC) outputs

(23) High current outputs

(24) Siren tamper switch

(25) 12 VDC auxiliary power output

(26) Zone inputs

B

A

()1 ()2 ()3 ()5 ()6 (10)(9)

(22)

(21)

(23)

(18)

(16)

(24) (25)

(19)

(17)

(15)

(14)

(26)

()4 (11)

(13)

RxTx

USB

MI

IP

CON12

CON13

T1

T2

S4

S5

+

+

S1

C

+

S2

C

T C

+

+

- -

1 C 2 3 C 4 5 C 6 7 C 8

~

~

+ -

AC

BATT

LC-OUTPUTS

HC-OUTPUTS

SIR TMP AUX POWER

INPUTS

CT

+

S3

C

CON16

NTC

COMMS

+12V 0VD+ D-

(12)

(20)

(8)

(7)

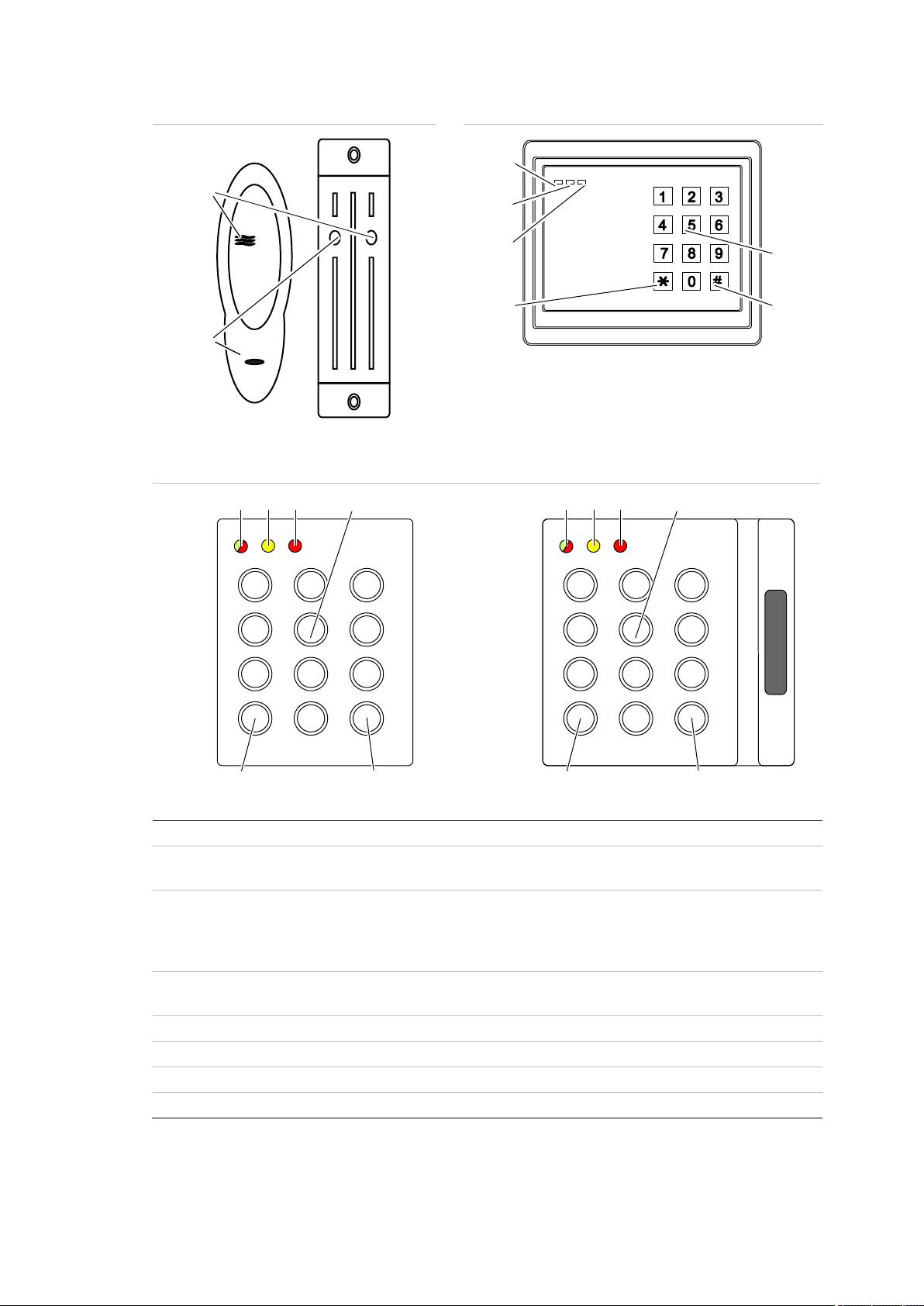

Figure 8: Large plastic housing (LP) pry-off tamper mount

Advisor Advanced layout

Figure 9: Advisor Advanced ATSx500A(-IP) PCB layout

12 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

Figure 10: ATS111xA keypad

Figure 11: ATS1135 keypad

(1)

AC mains LED

Green on: AC mains supply on

(2)

Access LED

Blue flashes: card read

(3)

Fault LED

Yellow on: system fault active

Yellow flashing: general alert (EN 50131)

(4)

Alarm LED

Red on: alarm condition active

(5)

LCD display

Displays messages

(6)

/ Up

Scroll up in the menus

Change value

Delete

(7)

? / Help

Show help

Scroll text (ATS113x only)

(8)

Partset

Part set an area

Scroll text (ATS111x only)

(9)

F / Function

Show active zones / faults

Function key modifier

Scroll text (ATS113x only)

(10)

On

Full set an area

(11)

/ Right

Enter the selected menu

Move cursor right

(12)

/ Left

Return to the previous menu

Move cursor left

(13)

X / Clear

Exit the current user function

Volume control modifier

(14)

Off

Unset an area

1

8

9

16

!!

3

21

4 6

5

7

98

0

*

Menu

#

Enter

(1) (2)

(3)

(4)

(5)

(7)

(8)

(9)

(10)

(20)

(19)

(18)

(17)

(16)

(15)

(14)

(13)

(12)

(11)

(6)

0

12

3

4

5

6

789

12

abc

jkl

tuv

def

ghi

.,’?!

*

#

A B C

(1) (3) (6) (4) (2)

(14)

(10)

(21)

(12)

(6)

(18)

(11)

(22)

(9)

(13)

(23) (16) (17)(15) (19) (7)

(25)

(24)

Keypads and readers

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 13

Chapter 2: Installation

(15)

/ Down

Scroll down in the menus

Change value

Backspace

(16)

Alphanumeric keys

Keys 1 to 9, alphanumerical data. See “Keypad layout” on page

112.

(17)

Menu

Request entry to the menus

(18)

Enter

Complete the step

Enter the selected menu entry

(19) 0 Key 0

Toggle selection

(20)

Area LEDs 1 to 16

On: area set

Off: area unset

Flashing: area alarm condition

(21)

Partset 1

Part set 1 of areas

(22)

Partset 2

Part set 2 of areas

(23)

A, B, C

Programmable function keys

(24)

LED1

Programmable LED 1

(25)

LED2

Programmable LED 2

14 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

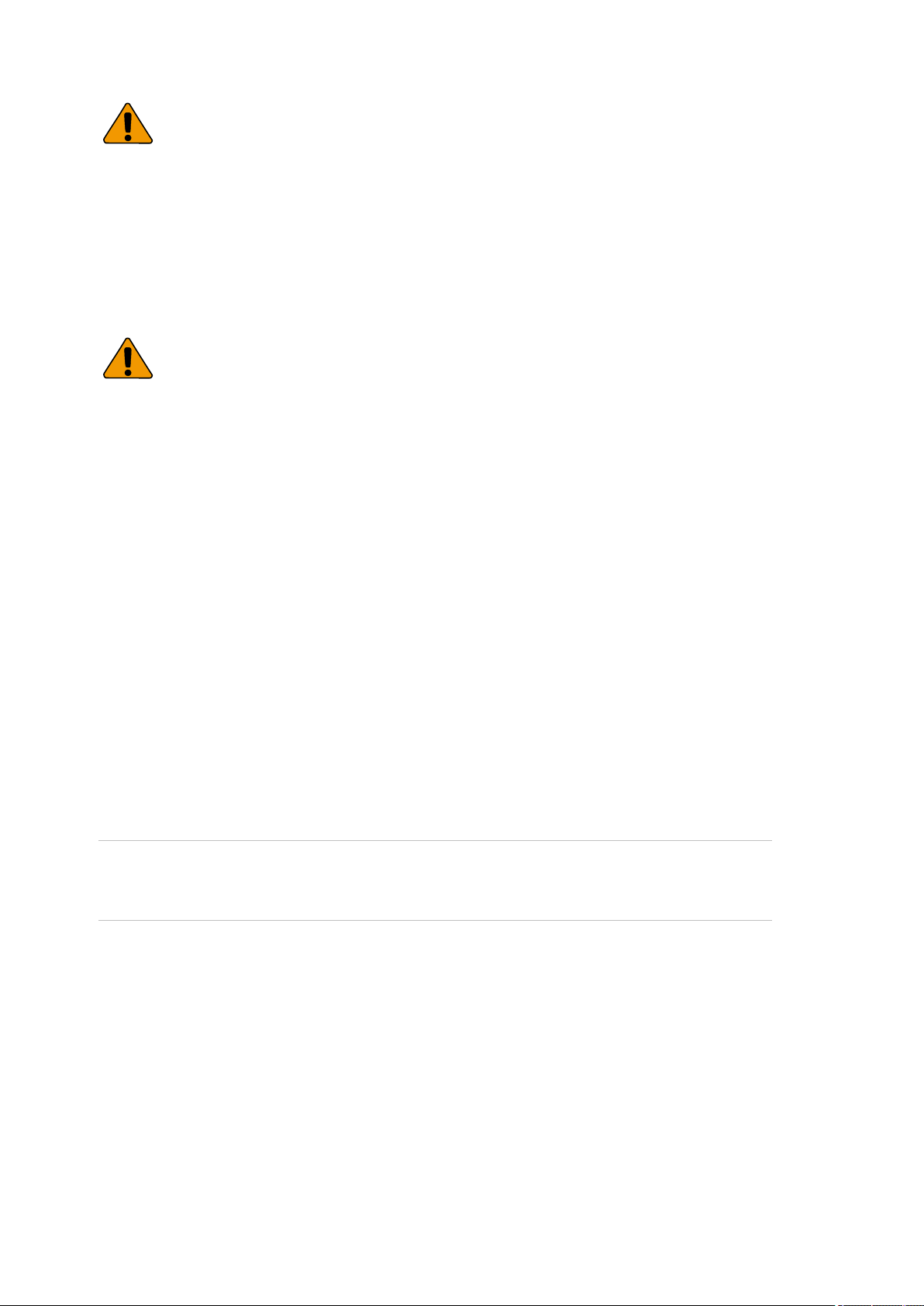

Figure 12: ATS1190/ATS1192 readers

Figure 13: ATS1197 reader with keypad

Figure 14: ATS1151/ATS1156 readers

(1)

Blue LED

Access granted

(2)

Red LED

On: area set

Flashing: general alert (EN 50131)

(3)

Dual LED

Green on: AC mains supply on

Green flashing: AC mains supply off, or unlocked while unset

Red on: all areas set

Red flashing: unlocked while set

(4)

Yellow LED

On: All zones are in normal state

Flashing: general alert (EN 50131)

(5)

Red LED

Flashing: alarm

(6)

Numeric keys

Keys 0 to 9, numerical data

(7)

Off

Unset an area

(8)

On

Full set an area

(1)

(2)

OFF ON

(3)

(4)

(5)

(6)

(7)

(8)

1 2 3

4 5 6

7 8 9

*

0 #

(4) (5) (6)

(7) (8)

(3)

1 2 3

4 5 6

7 8 9

*

0 #

(3) (4) (5) (6)

(7) (8)

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 15

Chapter 2: Installation

Maintenance

Mains power connection

The intrusion control panel is only allowed to be serviced by dedicated service

personal. The screw of the housing is intended to protect the product from

unintended use.

For metal housing, the screw is already installed out of the box. For plastic

housing, the screw, available inside housing, should be mounted before first time

use.

Use the mains connector terminal for connecting the AC mains supply. A fixed

cable or flexible mains lead to earthed mains outlet can be used. When fixed

wiring is used, insert a dedicated circuit breaker in the power distribution network.

In all cases the mains connection must comply with local regulations.

In case the panel is connected to the power grid using fixed wiring, it is

recommended that earth wire is longer than line and neutral.

Do connect incoming line and neutral to mains connection block according to the

label. This assures that the line will be protected by the mains fuse, and that

service can be done by service personnel.

Make sure that before connecting the mains power, the mains power supply is

disconnected.

When installing the mains power, use strain reliefs such as cable ties and

coupling PG16s to ensure proper wiring. If product entry hole breakouts are

used, it is required to also make use of UL-V2 (or better) approved PG16 cable

gland. Refer to PG16 specification to meet minimum and maximum cable

diameters.

In all cases local regulations must be observed.

WARNING: Electrocution hazard. To avoid personal injury or death from

electrocution, remove all sources of power and allow stored energy to discharge

before installing or removing equipment.

Battery replacement

This product may contain one (or more) sealed, rechargeable, BS-type lead-acid

battery. Because removing a battery may affect the product’s configuration

settings or trigger an alarm, only a qualified installer should remove the batteries.

To remove a battery:

1. Make sure that your product settings allow you to open the cover without

starting the tamper alarm.

2. Switch off the mains power, if necessary, and remove the cover.

16 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

3. Disconnect the battery. Note that depending on the battery model the connectors may be located differently.

4. Remove the battery from the holder.

In case a battery BS131 (12 V / 18 Ah) in an ATS1640 housing is used in

combination with ATS7700 PSTN expander board, it is required to have double

insulation in place. Use adequately insulated wires for PSTN cabling, and make

use of heat shrink.

Dispose of the battery as required by local ordinances or regulations.

See the specifications for your product or contact technical support for

information on replacement batteries.

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 17

Chapter 2: Installation

Mounting

The unit is mounted with screws or bolts through the mounting holes in the rear

section of the enclosure.

Important: When the product is mounted to the wall, assure that at least

3 times the weight of the product can be supported. The product weight is the

product itself plus battery and accessories.

Ensure that the unit is mounted on a flat, solid, vertical surface such that the

base will not flex or warp when the mounting screws and bolts are tightened.

Leave a 50 mm clearance between equipment enclosures mounted side by side

and 25 mm between the enclosure and the sidewall.

The rechargeable battery must not be fitted until the control panel is secured to

the fixing surface. Under no circumstances should the panel be transported with

a battery fitted.

Take care that wire terminals are isolated. The use of cable ties to neatly secure

cables is recommended.

General installation guidelines

The Advisor Advanced control panels have been designed, assembled, and

tested to meet the requirements of current relevant standards for safety,

emission, and immunity to environmental electrical and electromagnetic

interference.

If the following guidelines are followed, the system will give many years of

reliable service.

In addition to the following guidelines, during the installation of the Advisor

Advanced control panel, it is essential to follow any country-dependent local

standard requirements applicable to the installation. Only a qualified electrician or

other suitably trained and qualified person should attempt to wire this system to

the AC mains or to the public telephone network.

• Ensure that there is a good earth available for the alarm system.

• Maintain a separation between low voltage and mains supply cables. Use

separate points of cable entry to the control panel cabinet.

• If the upper and/or lower cabinet entry cable holes are used to route wiring

into the control panel, always use a proper pipe fitting system by means of an

appropriate conduit and junction box. For this purpose, use only materials of

suitable flammability class (HB or better).

18 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

• For mains power connection, use the mains connector terminal either through

a permanent wiring or a flexible mains cable to an earthed mains outlet.

Always use cable ties to fix the mains cable at the dedicated fixing point

provided near the mains terminal connector.

- When installing permanent, fixed wiring, insert an easily accessible,

dedicated bipolar circuit breaker in the power distribution network.

- Never attempt to solder mains connection wires at the ends where they will

be wired to the terminal connectors.

• Avoid loops of wire inside the control panel cabinet and route cables so that

they do not lie on top or underneath of the printed circuit board. The use of

cable ties is recommended and improves neatness of the wiring within the

box.

• The battery used with this unit, must be made of materials of suitable

flammability class (HB or better).

• Any circuit connected either directly to the onboard relay contacts or to the

external relay contacts through the onboard electronic output must be rated

as a SELV (safety extra-low voltage) operating circuit.

- A mains switching relay must not be fitted inside the control panel cabinet.

- Always place a suppression diode (e.g. a 1N4001) across the relay coil.

- Use only relays with good insulation between the contacts and the coil.

- Maximum cable length for open collector output connection may not exceed

30 m. For longer distances, use relay output expansion (for example, ATS624

four-relay expander).

• The minimum clearance between equipment closures is 50 mm (between

equipment vents).

• Only use these units in a clean environment and not in humid air.

Environmental requirements are given in “Specifications” on page 35.

• For the panel terminal connections, the recommended torque is 0,3 to

0,4 N·m. This torque setting is independent from the AWG (thickness) of the

wires used. A value of 0,4 N·m is also the maximum allowed torque for this

connector.

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 19

Chapter 2: Installation

Earthing

WARNING: The correct earthing procedures must be followed.

Earthing of one cabinet containing several devices

All devices designed for the system have earth connections via metal studs to

the metal housing. Make sure that these metal studs make good connection to

the housing (beware of paint). The earth connections of every piece of equipment

in the system can be used for connecting the screen of shielded cables.

If a device is placed in a plastic housing the earth lug of the device does not have

to be connected.

Earthing panels in a single building

In one building several cabinets or devices are earthed to a safety ground.

The safety ground for the building must be checked by a licensed contractor.

Earthing panels in more buildings

If the wiring extends to separate buildings, more than one common earth system

will be used. Use ATS1740 isolator/repeaters to isolate the system databus. In

this way the system is protected against variations in earth potential.

20 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

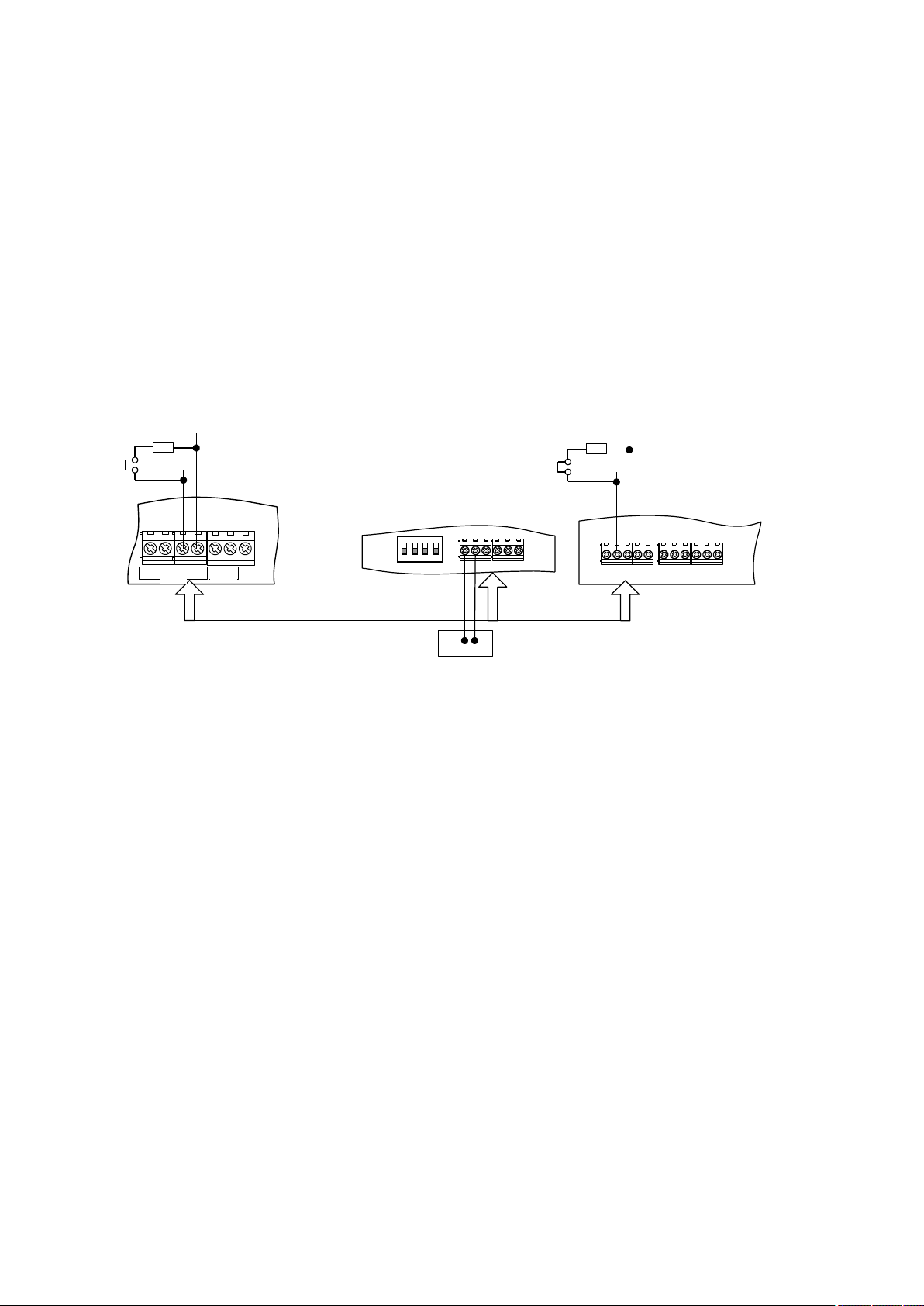

(1) Building 1

(2) Building 2

(3) Mains power with local earth

(4) Earth and shielding

(5) Mains power connector

(6) Advisor Advanced control panel

(7) System databus

(8) Device in plastic housing

(9) Device in metal housing

1740

ATS1201(E)

1740

Advisor

Advanced

ATS1210(E)

ATS1135

ATS1203(E)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(3)

(3)

(4)

(4)

(4)

(4)

(5)

(5)

(7)

(7)

(8)

(9)

(8)

(9)

(9)

Shielding

The shielding of all shielded cables used in the system should only be connected

at one side to one common earthing point in a building (see Figure 15 below). If a

shielded databus cable is routed via more than one plastic device the shielding

from incoming and outgoing cable must be connected.

In case the IP connection is used, take care that the Ethernet FTP cable remains

within a single building. Do make use of a proper router or switcher to isolate

Ethernet cables between various buildings.

Figure 15: System shielding

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 21

Chapter 2: Installation

(1) TERM link fitted (first device on local

databus).

(2) Advisor Advanced control panel

variants.

(3) Preferred data cable type is WCAT 52

(two twisted pairs).

(4) Advisor LCD keypad (TERM switch is

set to OFF).

(5) Separate 12 V power supply (required if

keypad is more than 100 m from the

nearest panel or expander. Connect the

negative terminal of the power supply to

the “−” wire of the databus.

(6) TERM link fitted (last device on local

databus).

(7) Any remote expander like ATS1201(E) or

ATS1210(E).

D+0V+12V D- IN OUT

CTD-D+

-

1 C 2 C 3 C

470 ohm

+ -

470 ohm

(1)

(2)

(3)

(5)

(4)

(6)

(7)

EARTH

CTD-

D+

0V

12V

COMMS

TAMPER

Cabling

System databus preferred wiring

The terminator jumper (also called TERM link), or DIP switch must be ON, or a

470 Ω resistor must be fitted at each of the devices at the extreme ends of the

daisy chained databus. In a star-wiring configuration, the TERM link is only fitted

on the devices at the ends of the two longest system databus cable runs.

Figure 16: System databus wiring

System databus connection

The system databus is used to connect remote expanders (to provide extra

zones) and keypads to the Advisor Advanced control panel. Remote devices can

be up to 1.5 km from an Advisor Advanced control panel.

Keypads and remote expanders must be connected via a shielded data cable

with two twisted-pairs from the system databus connection (WCAT 52 is

recommended).

We recommend that you use a separate power supply for a keypad when the

distance between that keypad and the nearest device is more than 100 meters.

If the keypad is powered with a separate power supply, do not connect “+” from

the system databus. Connect “+” of the local power supply to “+” on the keypad,

and connect 0 volts from the power supply and 0 volts from the system databus

22 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Chapter 2: Installation

C

(1)

T

()2

RA

Z2Z1

A A A

T T

RT

()2 ()2

C

(1)

A

T

()2

RA

Z2Z1

RT

()2 ()2

A

T

A

T

to the keypad terminal marked “−”. The maximum number of devices allowed on

the databus is given in “General features” on page 36.

Two system databuses

Particular panel variants allow you to connect more bus devices by using a

second system databus. To install another system databus, use ATS670 second

RS485 LAN extension module.

System addresses of devices connected to the additional bus (BUS2) are

determined by adding 16 to keypad physical addresses, and 15 to expander

addresses. So, BUS1 handles keypads 1 to 16 and expanders 1 to 15, while

BUS2 — keypads 17 to 32 and expanders 16 to 30.

Note: Door controllers can only be installed on BUS1.

Zone connection

The inputs are set up as standard EOL freely programmable zones. However, by

programming the zones as dual loop, all zone inputs can be programmed to give

a few states indication for the same zone.

Depending on the detector model, do the following to set up zones:

• Choose your EOL connection type. See “EOL connection types” on page 27.

• Program input mode. See “8.6.1 Input mode” on page 248 for the panel, or

“2.2.2.n.4.4 Input mode” on page 152 for expanders.

• Set end-of-line resistor values. See “8.6.2 EOL” on page 248 for the panel, or

“2.2.2.n.4.5 EOL” on page 152 for expanders.

• Configure anti-masking option. See “4.1.n.6.7 Anti mask” on page 175.

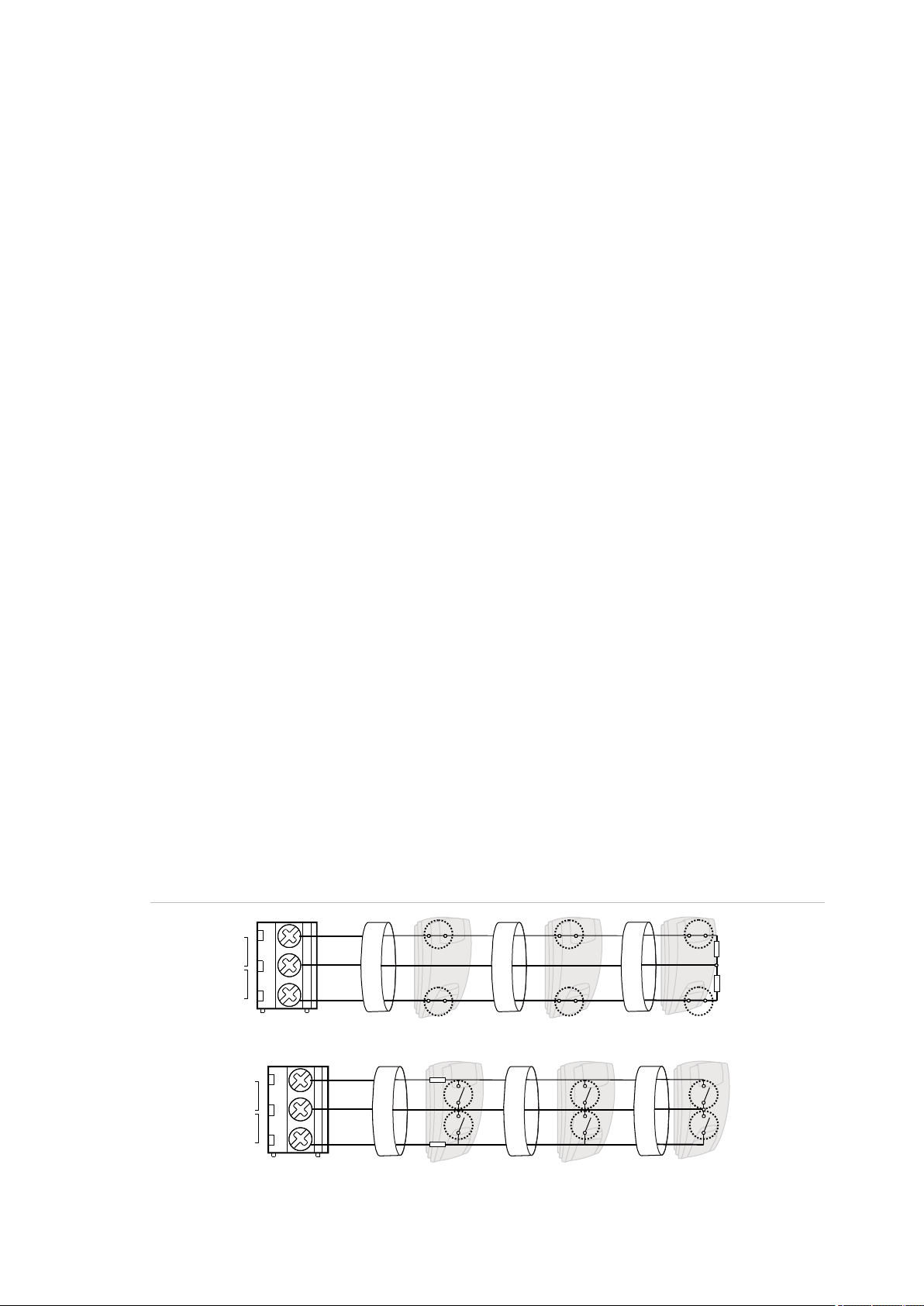

Single loop zone wiring

In single loop zone wiring, two zones are required, one zone for alarm and one

zone for tamper. The tamper contacts are wired in series with an EOL resistor.

Figure 17: Single loop examples

Advisor Advanced ATSx500A(-IP) Installation and Programming Manual 23

Chapter 2: Installation

(1) Zone terminal

C Common terminal

Z1 Zone 1 input

Z2 Zone 2 input

(2) Detector

A Alarm relay

T Tamper relay

(1) Zone terminal

C Common terminal

Z1 Zone 1 input

Z2 Zone 2 input

(2) Detector

A Alarm relay

T Tamper relay

C

Z2

(1)

RA

A

()2

RT

T

Z1

A A

T T

()2 ()2

Dual loop zone wiring

In dual loop wiring, one zone can detect a few detector states. At least two

resistors are used to define alarm and tamper states. Depending on the

programmed settings, there can be additional states defined as masking alarm or

sensor fault. These states can be the following:

• Short (tamper)

• Active (alarm)

• Normal

• Masking

• Sensor fault

• Open (tamper)

Figure 18: Dual loop example

Possible EOL connections are listed in “EOL connection types” on page 27.

Values for end-of-line resistors

The following list contains the values for end-of-line resistors and possible zone

states. Both the resistance and the voltage measured across the zone are

shown.

Depending on the input type and anti-masking option, the following EOL values

can be available.

24 Advisor Advanced ATSx500A(-IP) Installation and Programming Manual

Loading...

Loading...